Improved A2/O biological membrane reactor capable of synchronously removing carbon, nitrogen and phosphorus, and operation method thereof

An operation method and an improved technology, applied in the field of an improved A2/O biofilm synchronous decarbonization nitrogen and phosphorus removal reactor, can solve the problems of inhibited bacterial activity, insufficient function of the reaction zone, and conflicting sludge age. , to achieve efficient degradation and solve the effect of carbon source competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

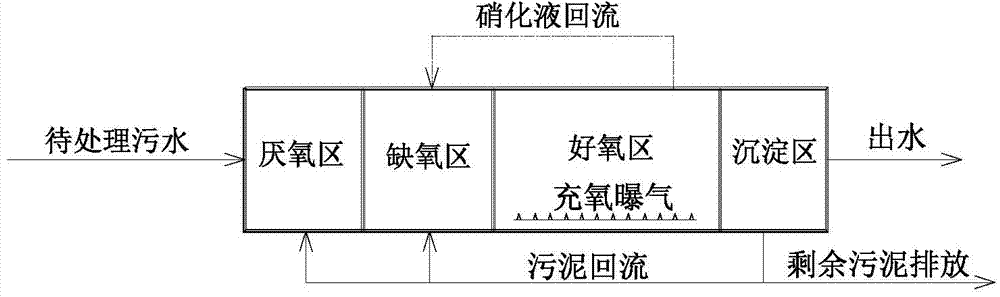

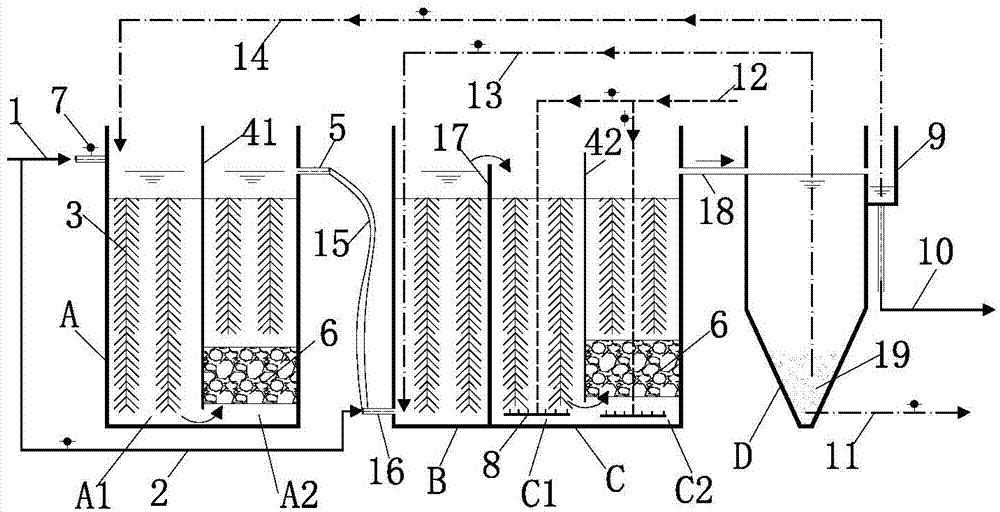

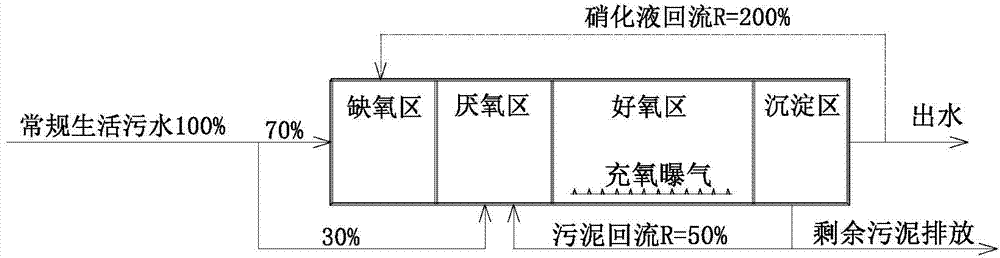

[0070] Embodiment 1: the treatment of conventional domestic sewage

[0071] see image 3 , The anoxic zone, the anaerobic zone, the aerobic zone and the sedimentation zone all adopt a cuboid structure, and the sedimentation zone adopts an advection sedimentation tank. The four pools use the same wall to save concrete materials. Raw water I first enters the anoxic zone, then enters the anaerobic zone and the subsequent aerobic zone, and finally exits from the sedimentation zone. The anoxic zone is divided into the first anoxic zone and the second anoxic zone by a partition, the first anoxic zone is filled with combined filler, and the volume of filler added is 70% of the total volume of the first anoxic zone; the second anoxic zone Add combined filler to the upper part of the zone, and add spherical suspended filler filled with volcanic rock particles to the lower part. The volume of the combined filler is 40% of the total volume of the second anoxic zone, and the volume of t...

Embodiment 2

[0075] Example 2: Treatment of low-carbon source domestic sewage

[0076] see Figure 4 , The connection mode and the operation process between each reaction zone of the reactor are the same as Example 1.

[0077] The control parameters are: the percentage of the water volume of the raw water I to the total water volume is 50%, and the percentage of the water volume of the raw water II to the total water volume is 50%. Nitrification liquid reflux ratio R=200%, sludge reflux ratio R=75%, dissolved oxygen DO is controlled at 0.3mg / L in anoxic zone, DO in anaerobic zone is controlled at 0.17mg / L, dissolved oxygen DO in aerobic zone Controlled at 1.8mg / L, dissolved oxygen DO in the refluxed nitrification solution was controlled at 0.6mg / L. The hydraulic retention time of sewage in the anoxic zone A is HRT=2.2h, the hydraulic retention time in the anaerobic zone B is HRT=8h, the hydraulic retention time in the aerobic zone C is HRT=12h, and the hydraulic retention time in the sed...

Embodiment 3

[0079] Embodiment 3: the treatment of textile printing and dyeing wastewater

[0080] see Figure 5 , Printing and dyeing wastewater first uses a lifting pump to lift the wastewater from the regulating tank to the coagulation tank. After adding chemicals to the coagulation tank, it enters the sedimentation tank for mud-water separation to remove part of the organic matter and suspended matter, while reducing the chroma of the raw water. The pretreated wastewater relies on gravity flow, enters the anoxic zone and anaerobic zone respectively according to the preset ratio of raw water I and raw water II, and then enters the subsequent aerobic zone in turn. After the biochemical reaction, the effluent enters the subsequent sedimentation area for mud-water separation, the sludge flows back to the anaerobic area, the nitrification solution flows back to the anoxic area from the effluent channel of the sedimentation area, and the remaining sludge is discharged for treatment. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com