Strong cooling heat dissipation method and device of high-power iron core reactor

A technology of heat dissipation device and reactor, applied in transformer/inductor cooling, transformer/inductor magnetic core and other directions, can solve the problems of short service life, difficult heat dissipation, temperature rise, etc., to improve service life, compact product structure, Craftsmanship effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

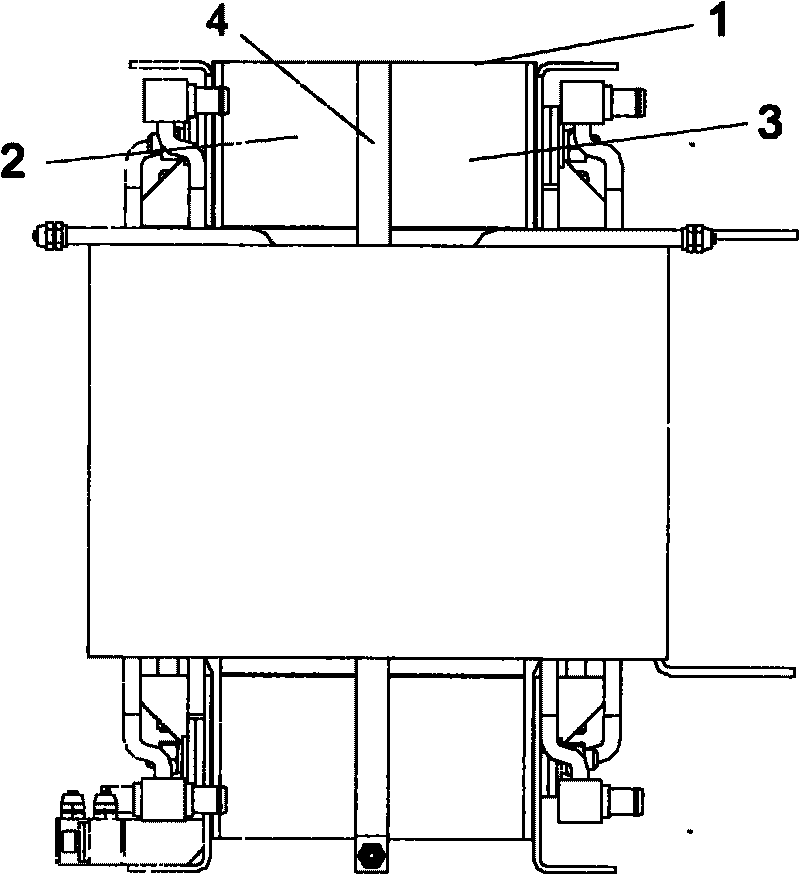

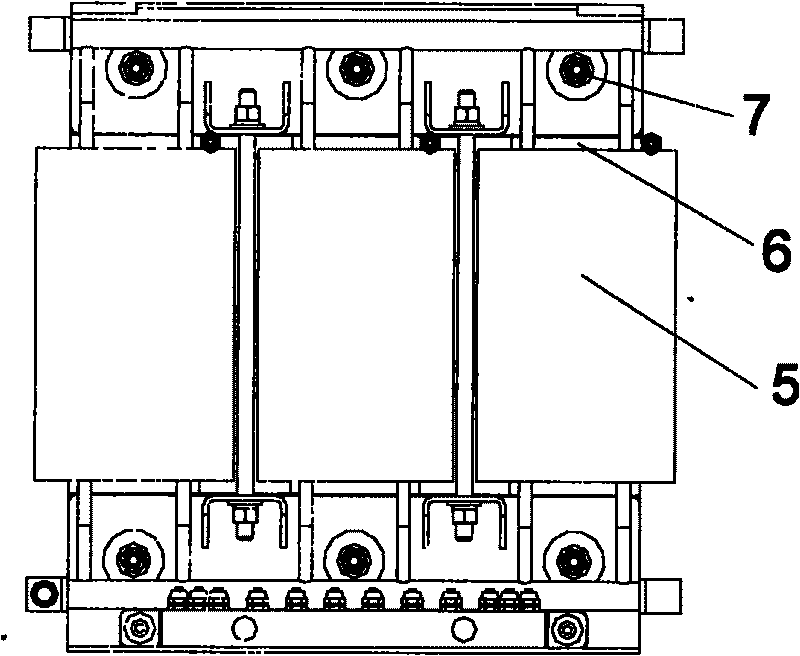

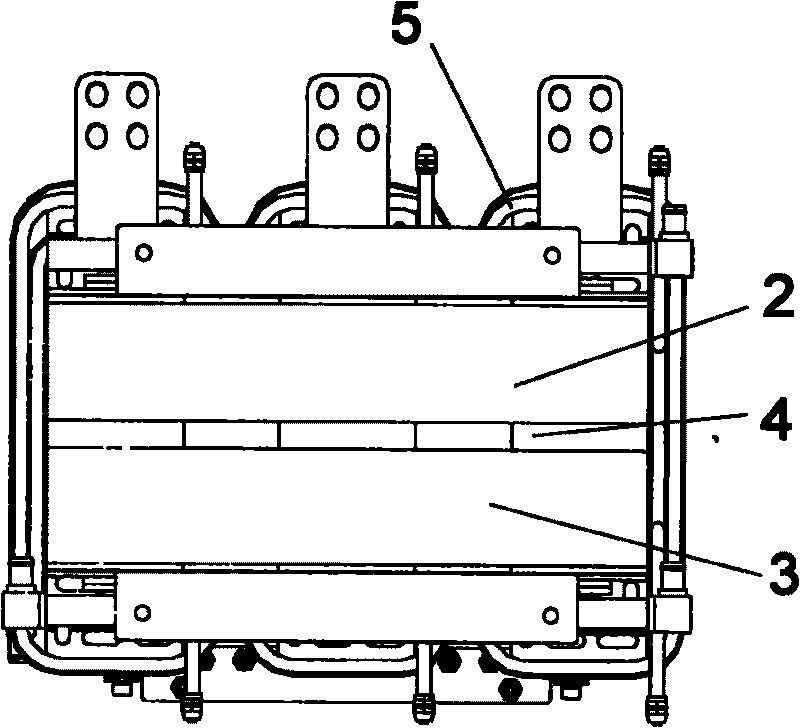

[0031] attached Figure 1-4 An embodiment of the present invention is given, and the present invention will be further described below in conjunction with the accompanying drawings.

[0032] It can be seen from the drawings that the present invention is a high-power iron-core reactor heat dissipation method, which is to disassemble the reactor iron core 1 along the longitudinal section of the iron core (that is, the direction in which the reactor coil and the coil are connected) Divided into two parts, namely the left iron core part 2 and the right iron core part 3, and a radiator (plate) 4 is added between the left iron core part 2 and the right iron core part 3. The two sides of the reactor (plate) 4 are closely attached to one side of the left iron core part 2 and the right iron core part 3 respectively, and the heat dissipation of the iron core part is passed through the radiator (plate) 4 in the middle of the reactor iron core of the two parts of the reactor. Go, cool th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com