Patents

Literature

215 results about "Meat Proteins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Protein is made up of amino acids and is present in all animal sources, but meat contains more protein than other animal sources such as eggs and milk. Six ounces of steak contains about 42 g of protein, while one large egg contains only 6 g.

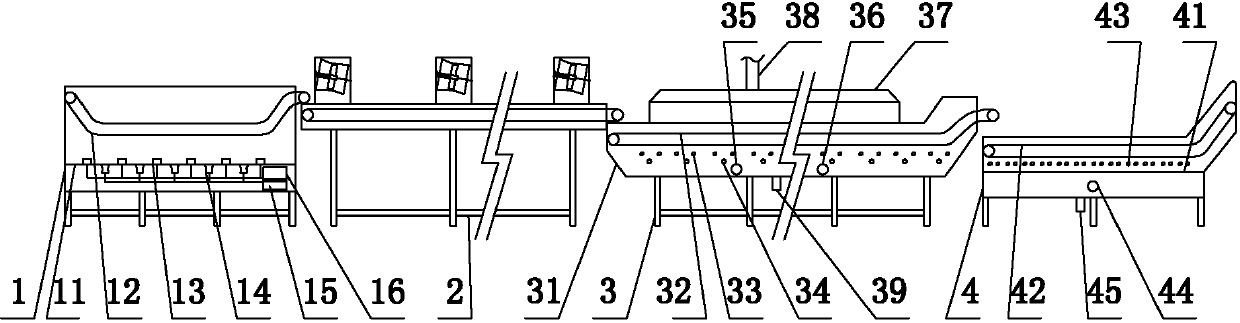

Crayfish food as well as preparation method and production equipment thereof

InactiveCN103960697AGood health effectSilky meatWater/sewage treatmentOil/fat bakingVegetable oilAdditive ingredient

Crayfish food comprises ingredients in parts by weight as follows: 100 parts of crayfish, 50 parts of vegetable oil, 10.6-15.2 parts of spice, 0.3-0.5 parts of transglutaminase, 0.3-0.5 parts of nisin, 0.2-0.5 parts of konjac glucomannan, 0.2-0.4 parts of chitosan, 0.4-0.5 parts of lecithin and 0.08-0.16 parts of delta-gluconolactone. According to the crayfish food, crayfish balls are used for preparing instant food, crayfish shells are used for preparing chitosan, and raw materials are sufficiently utilized; transglutaminase in the raw materials prompts crosslinking of crayfish meat protein crosslinking amino acid, tenderness of a product is improved, natural food antiseptics such as nisin and the like meet requirements of people for food health, and at the same time, the guarantee period of the crayfish food is prolonged to 12 months; and defects that crayfish products which can be stored at the normal temperature are less, the guarantee period is short and the like are overcome, and the crayfish food has good market prospect.

Owner:顾炎林

Technology for preparing broth powder by cooking and enzymatic hydrolysis

The invention discloses a technology for preparing broth powder by cooking and enzymatic hydrolysis, which comprises the steps of carrying out the working procedures of cooking, ultrafine smashing, enzymatic hydrolysis, Maillard reaction, micro-encapsulation, spray drying and the like on small pieces of bones and meat of plain chicken which removes the head, the paws and the internal organs and seasonings of vegetable oil, onion, ginger, garlic and the like, thereby preparing the broth powder. The cooking technology is applied for enhancing the flavor and the taste of the broth powder, thereby increasing the mellow, thick and fragrant base flavor of the broth powder; the superfine smashing is carried out on the materials, thereby increasing the enzymatic hydrolysis efficiency, increasing the content of small molecular peptides and calcium and leading the nutrition thereof to be more conductive to human body absorption; a composite enzyme preparation is added for carrying out the enzymatic hydrolysis, thereby effectively degrading meat proteins into the small molecular peptides and amino acids; and the microencapsulation is conductive to retaining the flavor of the broth powder for a long time, being easy to dissolve and extending the guarantee period. The broth powder prepared by the technology is characterized by meat flavor, mellow and thick base flavor and abundant amino acids, small molecular peptides and other nutrients, thereby being an essential cooking raw material for the hospitality industry and also an essential seasoning for home cooking.

Owner:河南省南街村(集团)有限公司

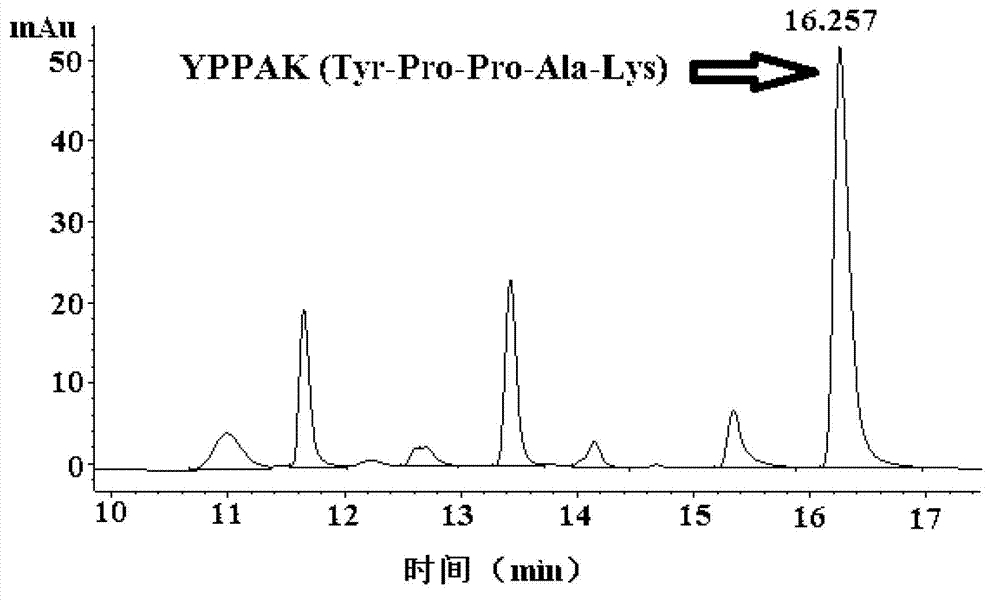

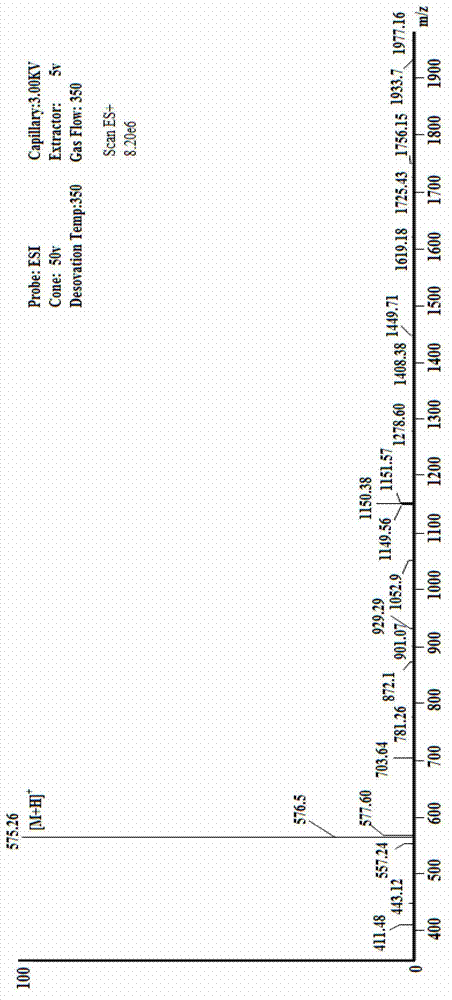

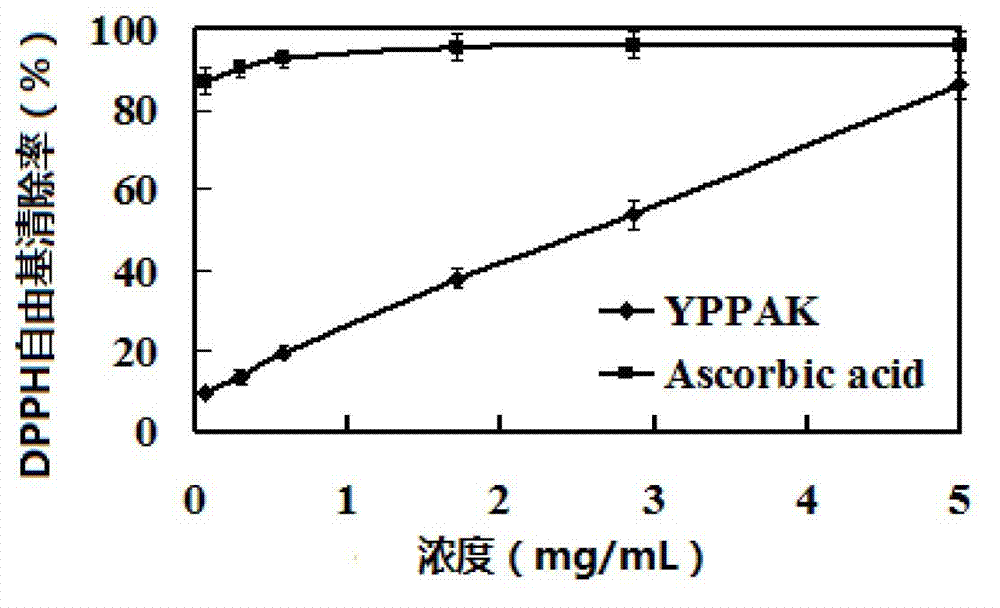

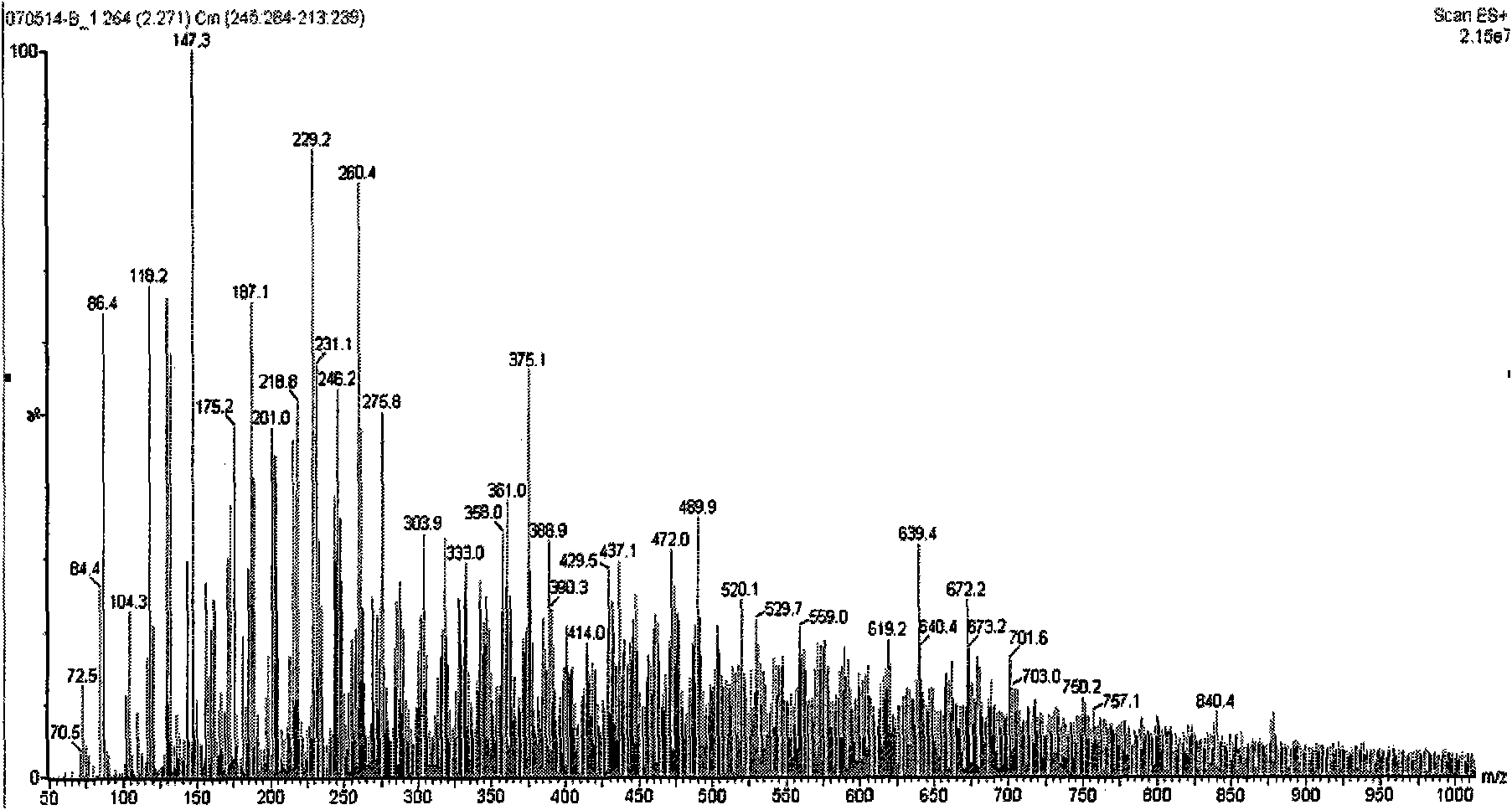

Mussel meat protein antioxidative peptide and preparation method thereof

InactiveCN103204906AThe preparation process is scientific and reasonableImprove cleanlinessPeptide preparation methodsFermentationFood additiveDPPH

The invention relates to a mussel meat protein antioxidative peptide and a preparation method thereof. The invention is characterized in that the antioxidative peptide is a pentapeptide compound with an amino acid sequence of YPPAK (Tyr-Pro-Pro-Ala-Lys), and according to ESI-MS detection, a molecular ion peak of m / z [M+H]<+> 575.26 is given out. The preparation method comprises the steps consisting of slurry homogenizing, degreasing, mixing, enzymatic hydrolysis, desalination, ultrafiltration, chromatography and the like. The prepared high-activity antioxidative peptide YPPAK (Tyr-Pro-Pro-Ala-Lys) has a good removal effect on DPPH free radicals, hydroxyl free radicals and superoxide anion free radicals; meanwhile, the YPPAK (Tyr-Pro-Pro-Ala-Lys) shows a good inhibitory effect on lipid peroxidation. The YPPAK (Tyr-Pro-Pro-Ala-Lys) has the advantages of safety, no toxic and side effects, good antioxidant activity, easy digestion and absorption, etc., and can be used as a medicine, a health food or foodstuff additive and the like.

Owner:ZHEJIANG OCEAN UNIV

Meat alternative

InactiveUS20050112271A1Texture can be alteredHigh in proteinProteins working-up by texturisingVegetable proteins working-upNutritive valuesSlurry

A meat alternative, having from about 65% to about 85% by weight of a hydrated plant protein source and from about 15% to about 35% by weight of a meat protein source, is formed by mechanically or chemically extracting collagen into a slurry of the meat and water, the collagen supporting the plant protein in the final product to create a pleasing texture and flavor. Dietary fiber is optionally added to retain moisture and increase nutritional value of the meat alternative. Additional gelling agents may be added to increase support for the plant protein, enhancing the product's texture. Optionally, additional plant or animal based flavorings are added to enhance the flavor and coloring agents may be added to enhance the visual aspects of the product. Nutraceuticals may be added to enhance the nutritional value.

Owner:PICKARSKI RON

Artificial micro-particle feedstuff for pseudosciaenacrocea larvae

InactiveCN1736241AImprove stabilityLow dissolution rateClimate change adaptationAnimal feeding stuffFish oilSoya bean

Disclosed is an artificial micro-particle feedstuff for pseudosciaenacrocea larvae, which comprises white fish meal, shrimp powder, mussel powder, calamari powder, yeast powder, hydrolyzed fish meat protein, fish oil, alpha-starch, sodium alginate, mineral salts mixture, vitamins mixture, feeding promoting agent, tomatine, ethoxy quinoline, beta-gluglucosan and soya bean lecithin by the weight ratio of 35-45, 10-20, 10-15, 8-12, 3-6, 5-10, 3-6, 6-12, 1-3, 1-3, 1-3, 0.1-0.2, 0.01-0.05, 0.05-0.08, 0.1-0.3 and 5-8.

Owner:OCEAN UNIV OF CHINA

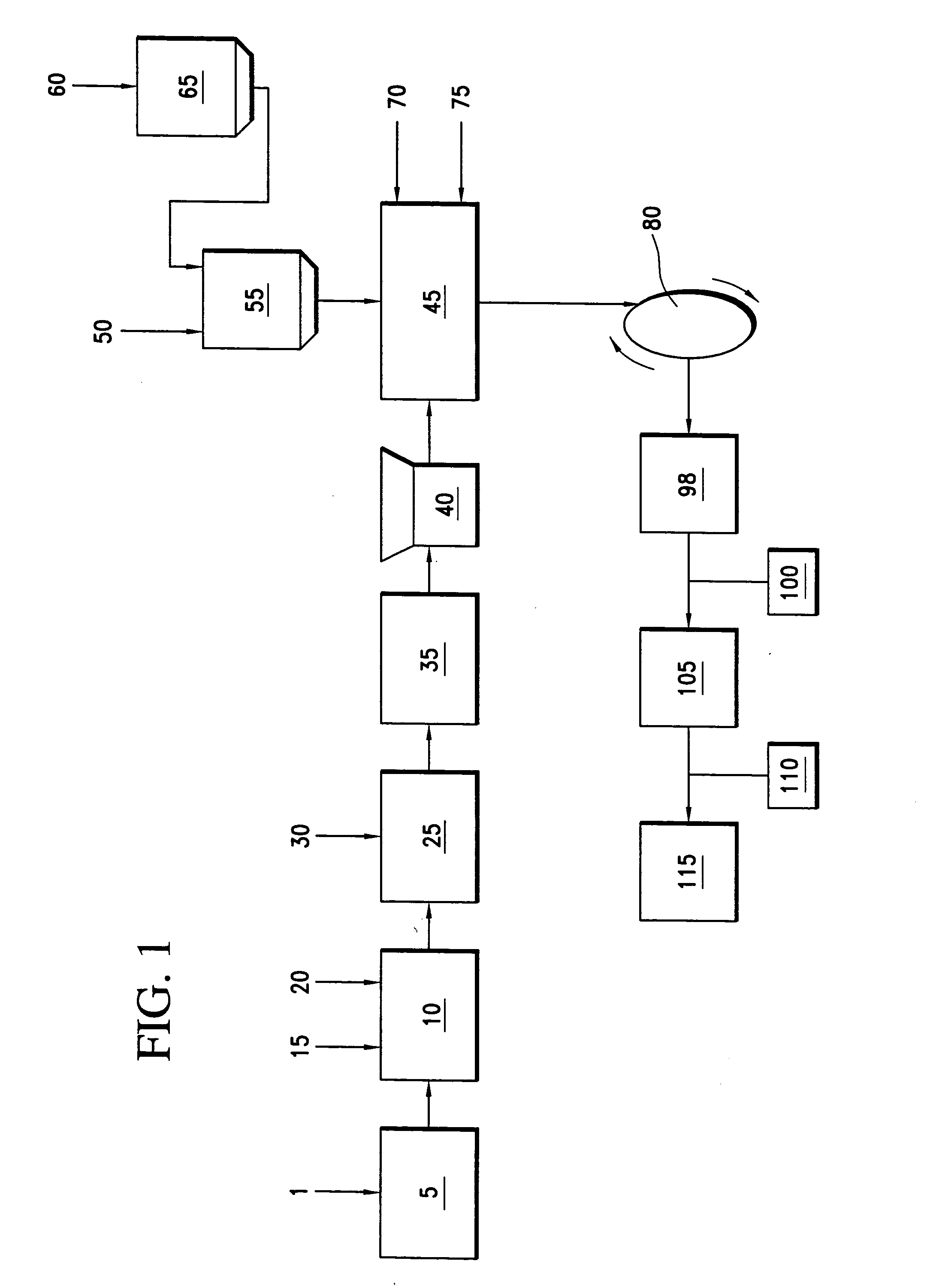

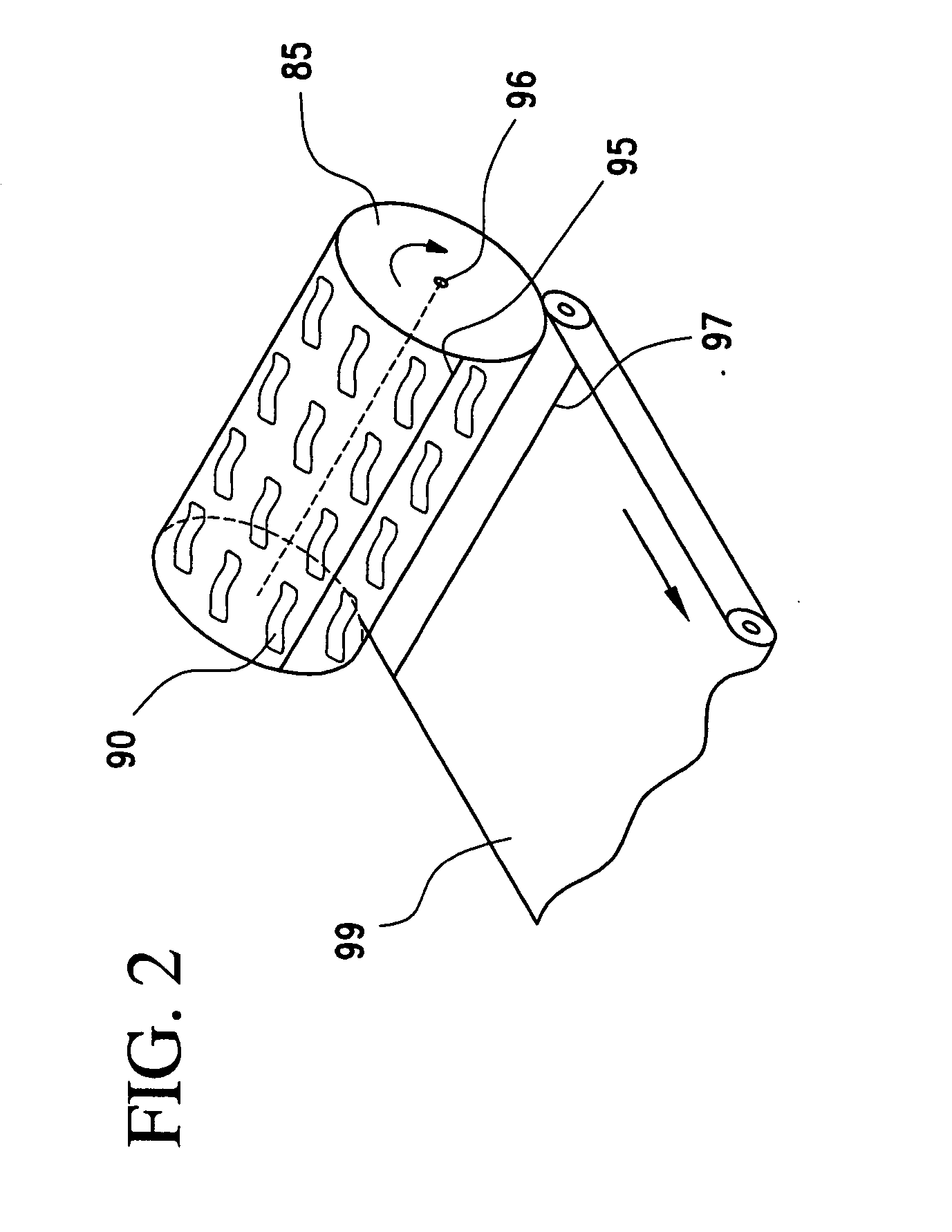

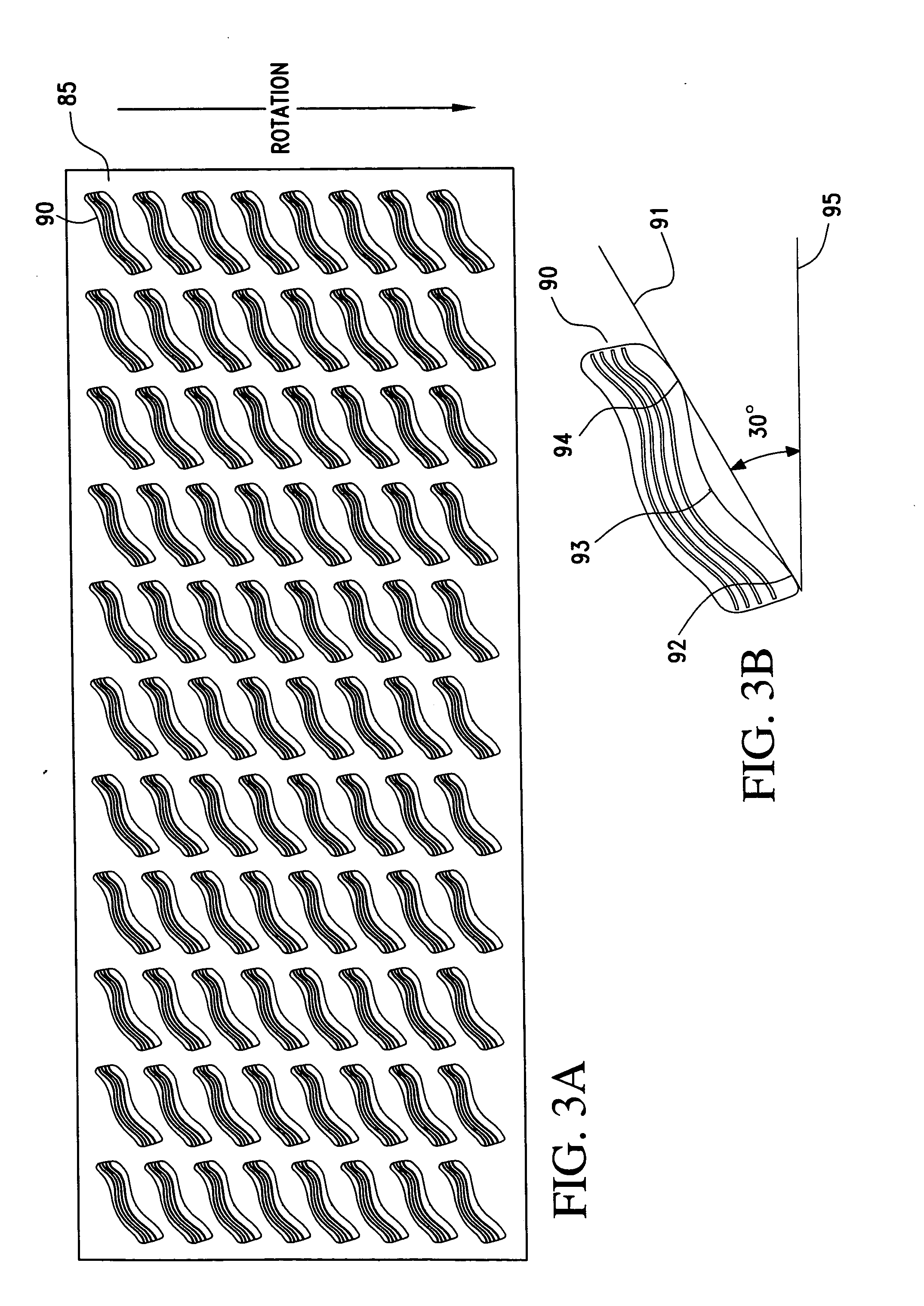

Meat-containing, strip-shaped food product and method of making same

ActiveUS20050048189A1High strengthImprove integrityMeat processingAnimal feeding stuffAdditive ingredientWater activity

A flexible, strip-shaped food product is made by comminuting substantially frozen meat and heating the comminuted meat to at least partially denature the meat proteins and cooling the cooked meat. About 4% by weight to about 45% by weight of wheat flour is admixed with the cooked meat, along with other ingredients, to form a dough. Use of the wheat flour unexpectedly increases tensile strength of the dough and products baked from the dough, and maintains flexibility of the strip-shaped food products over an extended period of time. Cooking of the meat in the presence of salt unexpectedly increases water activity of the pieces, resulting in a product that has a skin and a moist middle, while maintaining tensile strength. The dough is rotary-molded into strip-shaped pieces. The rotary mold may have angled die cups. The strip-shaped dough pieces are then baked and dried.

Owner:BIG HEART PET INC

Method for extracting antarctic krill grease and separating biological active substance

InactiveCN102676291ARealize comprehensive utilizationHigh extraction rateFatty oils/acids recovery from wasteFatty-oils/fats productionSolubilityOrganic solvent

The invention discloses a method for extracting antarctic krill grease and separating other biological active substances, and belongs to the technical field of deep processing of marine food products. Aiming at the characteristics that the water content of antarctic krill is high and the antarctic krill is easy to autolyze, the grease can be directly extracted from the frozen antarctic krill at low temperature by using hydrophobic and hydrophilic mixed solvents; a salt solution and a common organic solvent are added into residues and an organic solvent / salt multi-phase salting-out extracting system is formed by using salting-out extracting effect; the distributions of biological active substances with different polarities in the antarctic krill in each phase are different according to a solubility difference; and furthermore, the residual grease is extracted to obtain astaxanthin; and shrimp meat proteins are separated and the solvents in the residues are recycled. The method disclosed by the invention is simple in operation and easy to realize, and has low cost, short period and moderate extracting conditions, and the organic solvents are cheap and easy to recycle, so that the method is easy to industrialize.

Owner:DALIAN UNIV OF TECH +1

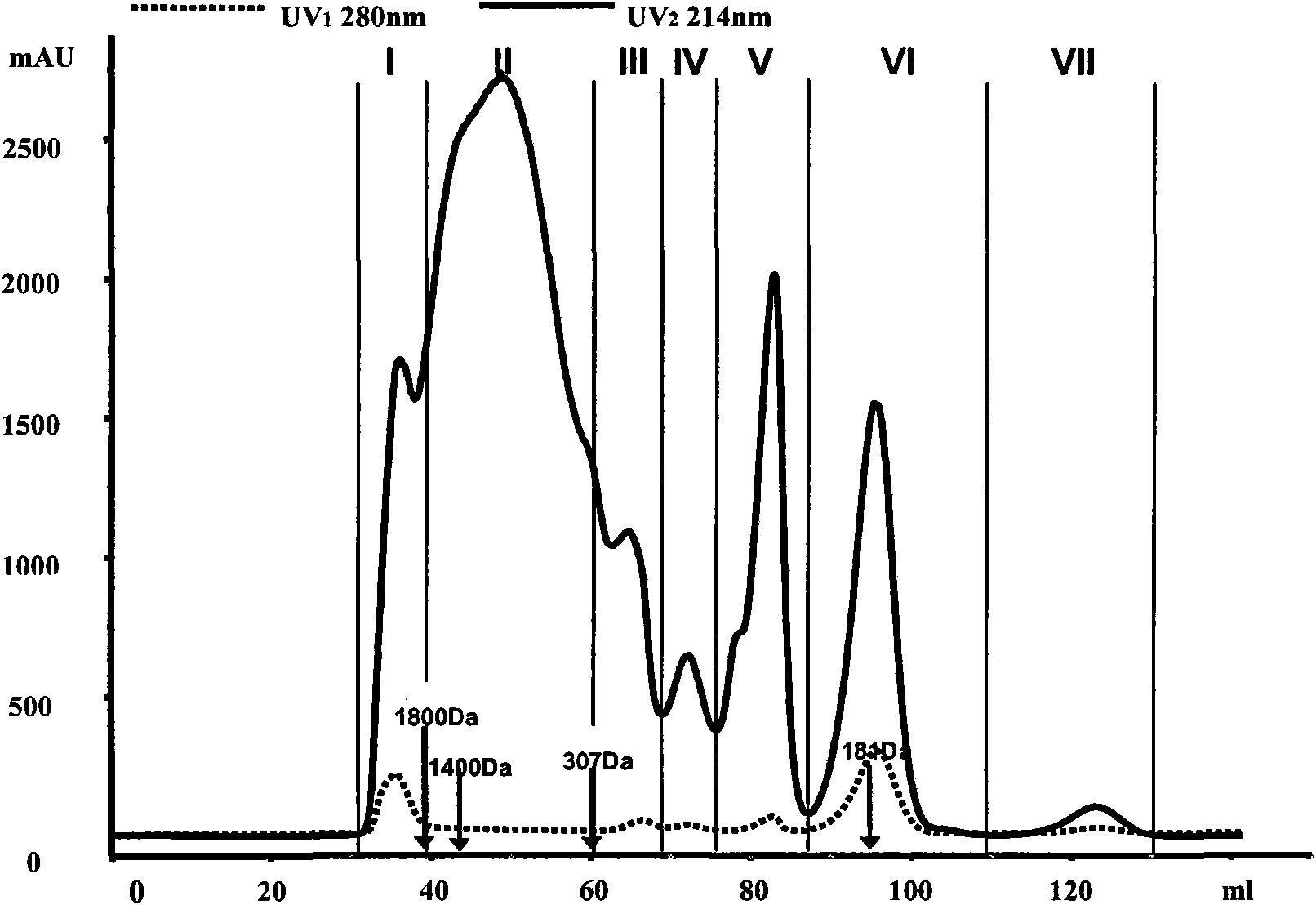

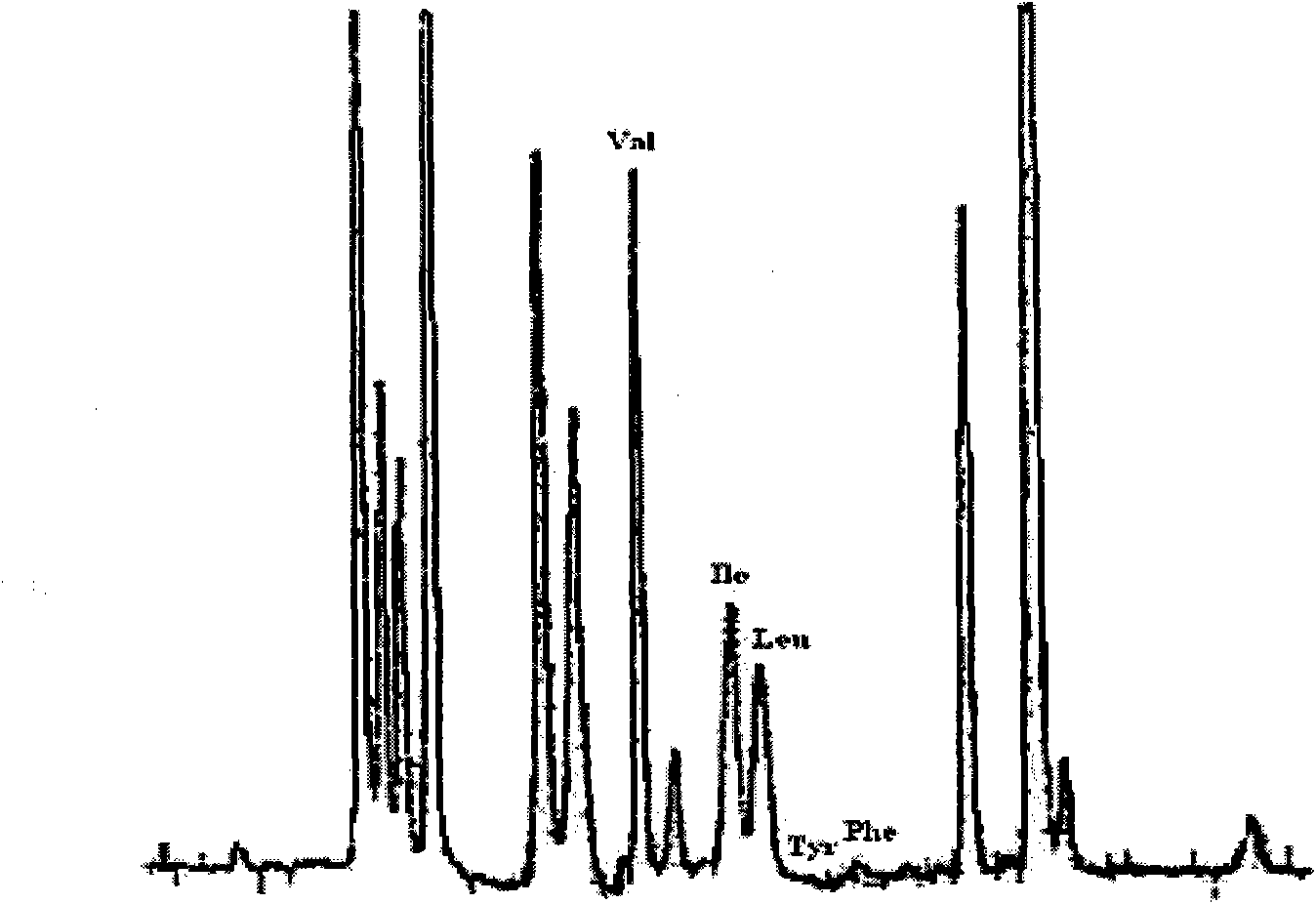

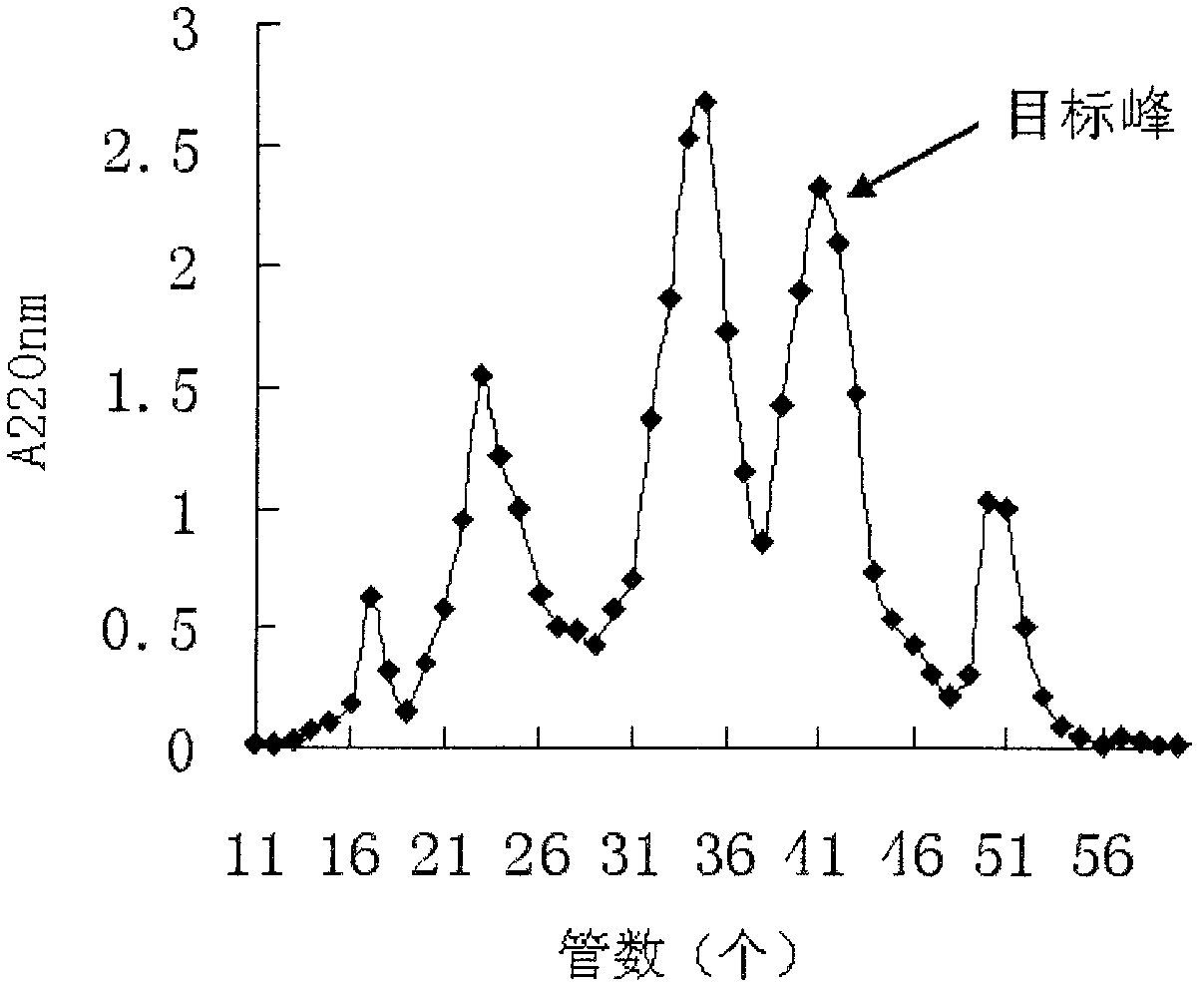

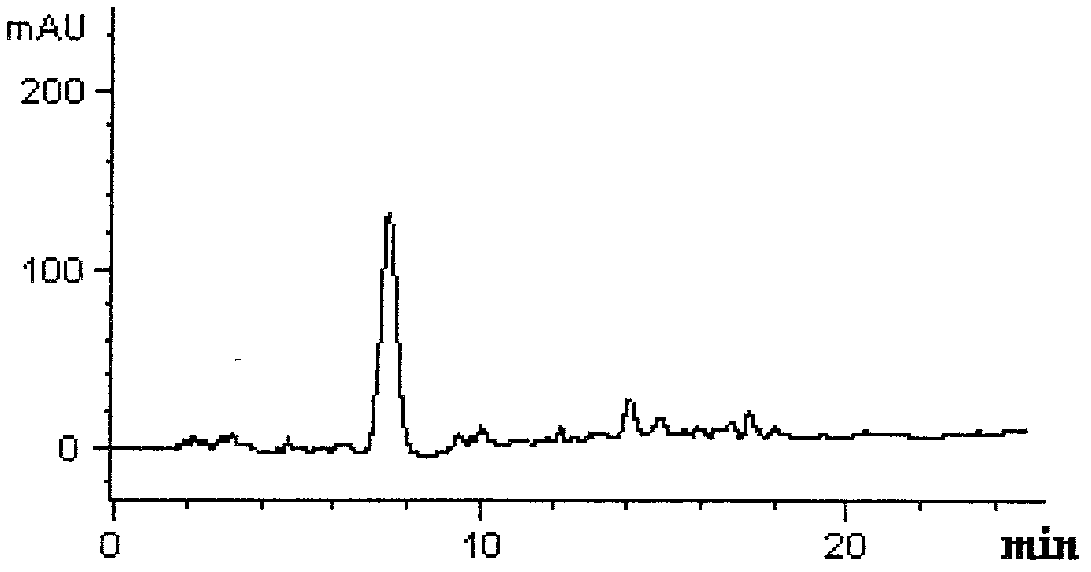

Method for preparing pinctada martensii high F value oligopeptide by enzymatic method

The invention discloses a method for preparing pinctada martensii high F value oligopeptide by an enzymatic method, relates to enzymatic hydrolysis of a pinctada martensii meat protein and desorption of an aromatic amino acid in a hydrolysate by adopting an effective separation means, and provides a method for preparing an oligopeptide mixture with the molecular weight of less than 2,000 Da and the F value (the molar ratio of a branched chain amino acid to the aromatic amino acid) of more than 20 by adopting the enzymatic hydrolysis of the pinctada martensii meat protein and an adsorbent adsorption and separation desorption effect. In the method, an aquatic animal protein is first taken as a raw material to prepare the high F value oligopeptide; the raw material is extracted by using hot water in a preparation process, the extract can be used for extracting taurine, and the precipitated protein is taken as an enzymatic substrate, so that the resource is utilized fully and effectively; a single enzyme, namely pancreatin is used as the preferred active enzyme; and the aromatic amino acid is desorbed by adopting a method of combining activated carbon static adsorption and gel filtration chromatography to prepare a high F value oligopeptide product.

Owner:GUANGDONG OCEAN UNIVERSITY

Protein product and process for preparing injectable protein product

InactiveUS20110244093A1Good moisturizing effectFunction increaseProtein composition from fishFood preparationMuscle tissueFood grade

Moisture is retained in cooked or thawed food by adding to the food an aqueous suspension of animal muscle protein obtained from animal muscle tissue. The aqueous suspension is obtained by mixing comminuted animal muscle tissue with a food grade base to form an aqueous basic solution of animal muscle protein. The basic solution is mixed with a food grade acid to precipitate the protein in an aqueous composition. The precipitated protein then is comminuted to form an aqueous suspension of comminuted animal muscle protein.

Owner:KEMIN PROTEINS LLC

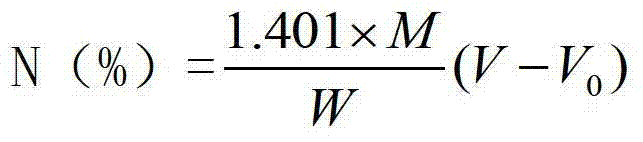

Method for preparing antihypertensive peptides through enzymolysis of ground meat proteins of tuna

InactiveCN102808010AIncrease added valueRich sourcesPeptide preparation methodsFermentationChemical synthesisAlkaline protease

The invention discloses a method for preparing antihypertensive peptides through enzymolysis of ground meat proteins of a tuna. The method comprises the steps of: (1) regarding the ground meat of the tuna as the raw material, mixing and homogenizing the raw material and a buffer solution according to a weight / volume ratio of 1 g: 3-5 ml, and then adjusting the pH value to 9.5-10 to obtain a mixed solution; (2) heating the mixed solution to 55-60 DEG C for pre-heating, and adding alcalase according to 1.0%-1.5% of the raw material for enzymolysis at an enzymolysis temperature of 55-60 DEG C for 4-6 h; and (3) performing enzyme deactivation on the obtained enzymolysis product to obtain an enzymolysis solution and then enabling the enzymolysis solution to sequentially suffer from ultrafiltration, desalination, freeze drying and chromatography to obtain the antihypertensive peptides. The method for preparing the antihypertensive peptides through the enzymolysis of the ground meat proteins of the tuna, disclosed by the invention, has the advantages of abundant source of the raw material, low price, simple preparation process, relatively strong activity of the prepared antihypertensive peptides; compared with a chemosynthetic ACE (Angiotensin Converting Enzyme) inhibitor, the ACEP (ACE Inhibitive Bioactive Peptide) prepared through enzymolysis of the ground meat of the tuna has the advantages of being safe and nontoxic, specific in antihypertensive efficacy, easy to digest and absorb and the like.

Owner:ZHEJIANG OCEAN UNIV

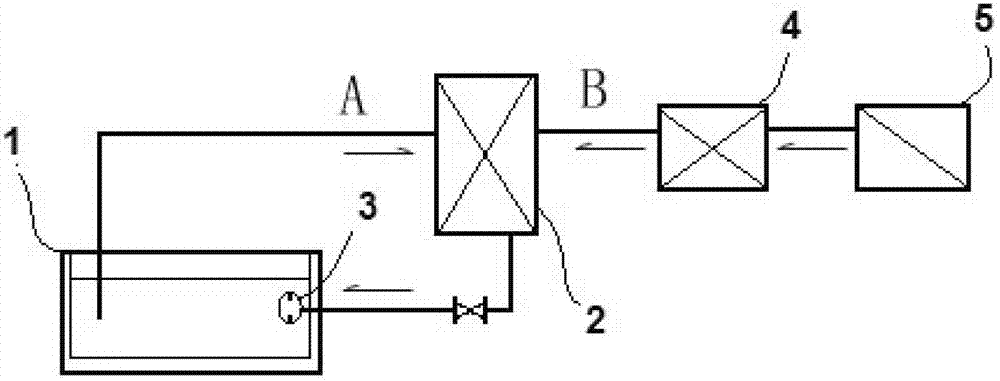

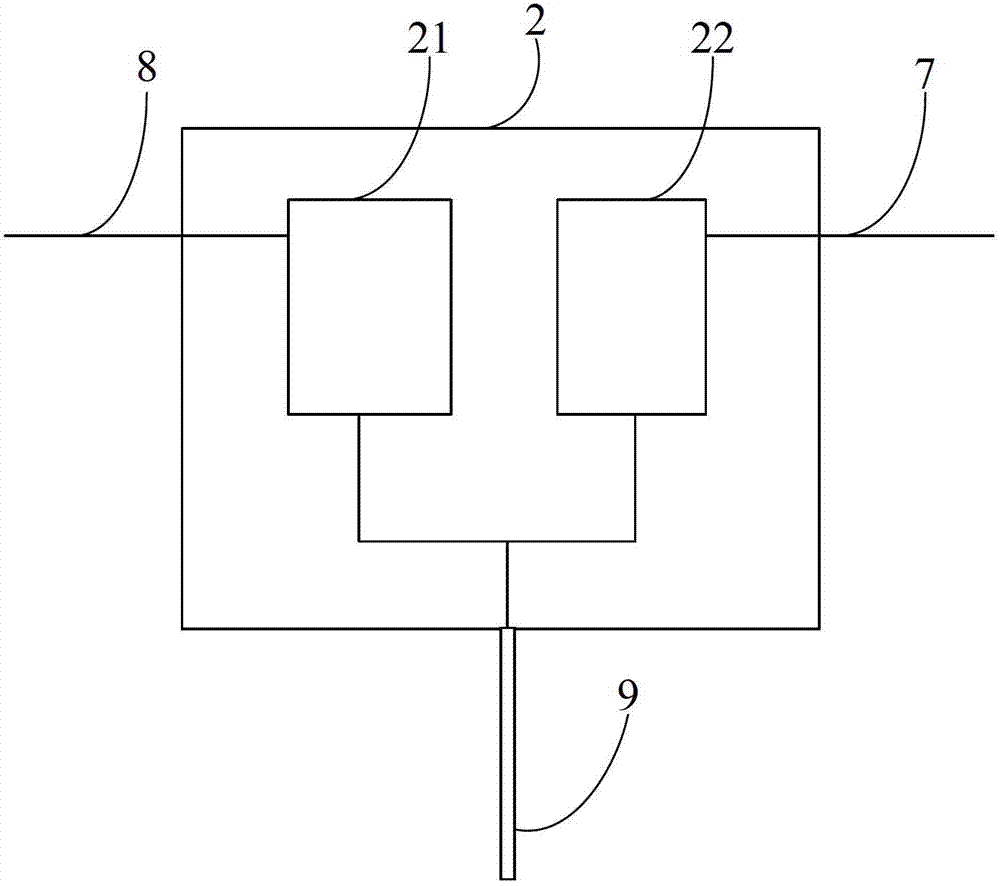

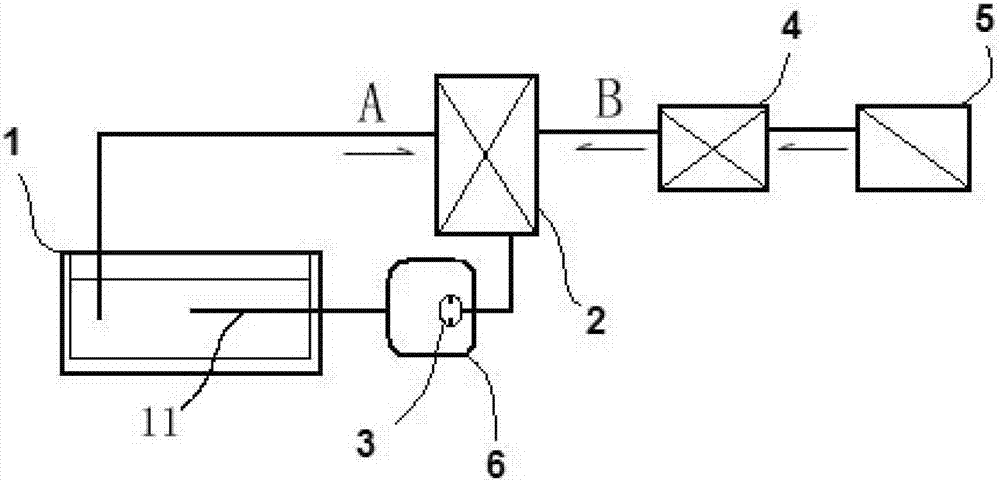

Sterilization and oxygenation equipment for aquaculture

ActiveCN102805051AImprove dissolution efficiencyImprove utilization efficiencyPisciculture and aquariaOzone generatorDisinfectant

The invention discloses sterilization and oxygenation equipment for aquaculture and belongs to the field of agricultural aquaculture. The equipment comprises a pure oxygen supplier, an ozone generator, a micro-nanometer bubble generating device and a micro-nanometer bubble generator, wherein the pure oxygen supplier is connected with the ozone generator; the micro-nanometer bubble generating device is provided with an oxygen inlet pipe, a water inlet pipe and a water outlet pipe; an oxygen outlet of the ozone generator is connected with the oxygen inlet pipe of the micro-nanometer bubble generating device; the water inlet pipe of the micro-nanometer bubble generating device is used for introducing processed culture water; the water outlet pipe is connected with the micro-nanometer bubble generator; and the micro-nanometer bubble generator is provided with a water outlet. The equipment has a simple structure, is convenient to move and can be directly connected with an original aquaculture system and a water circulation system. The connection is simple and convenient, and no reconstruction is needed. By the equipment, the output of aquatic products is improved by over 10 percent; and the aquatic products have abundant meat protein and amino acid, a good taste and no chlorine disinfectant residual.

Owner:BEIJING ZHONGNONG TIANLU MICRO NANO BUBBLE WATER S&T

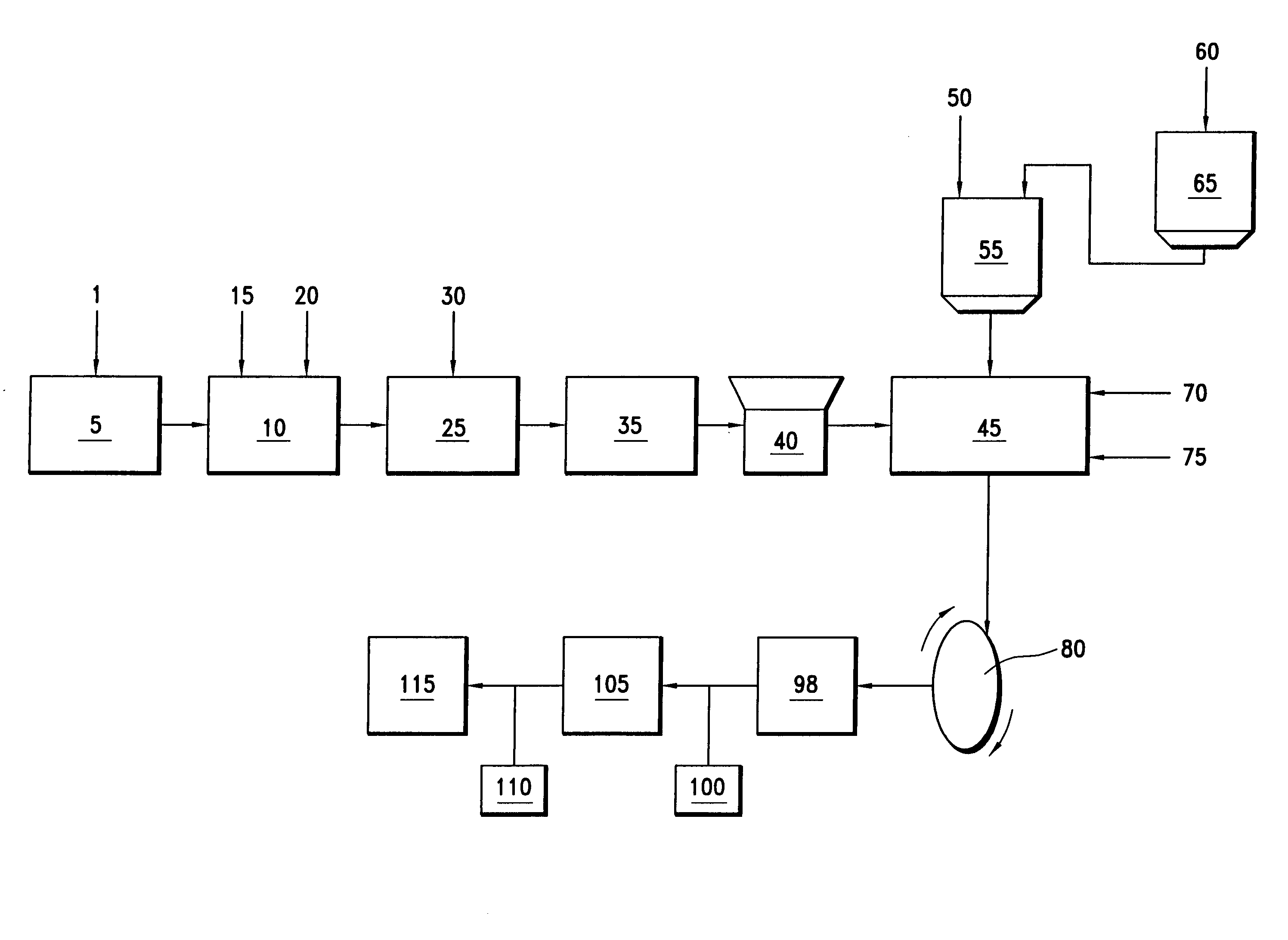

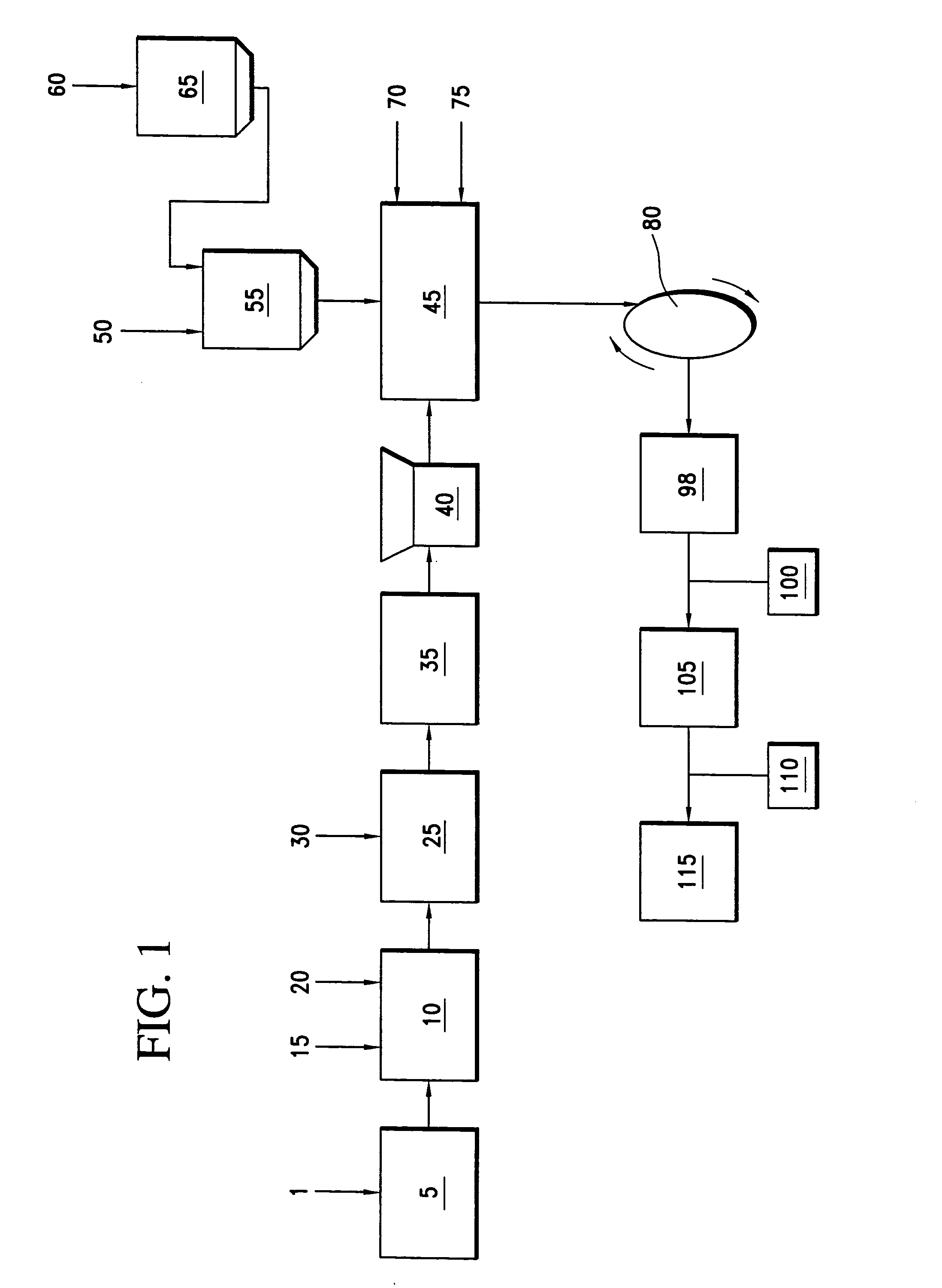

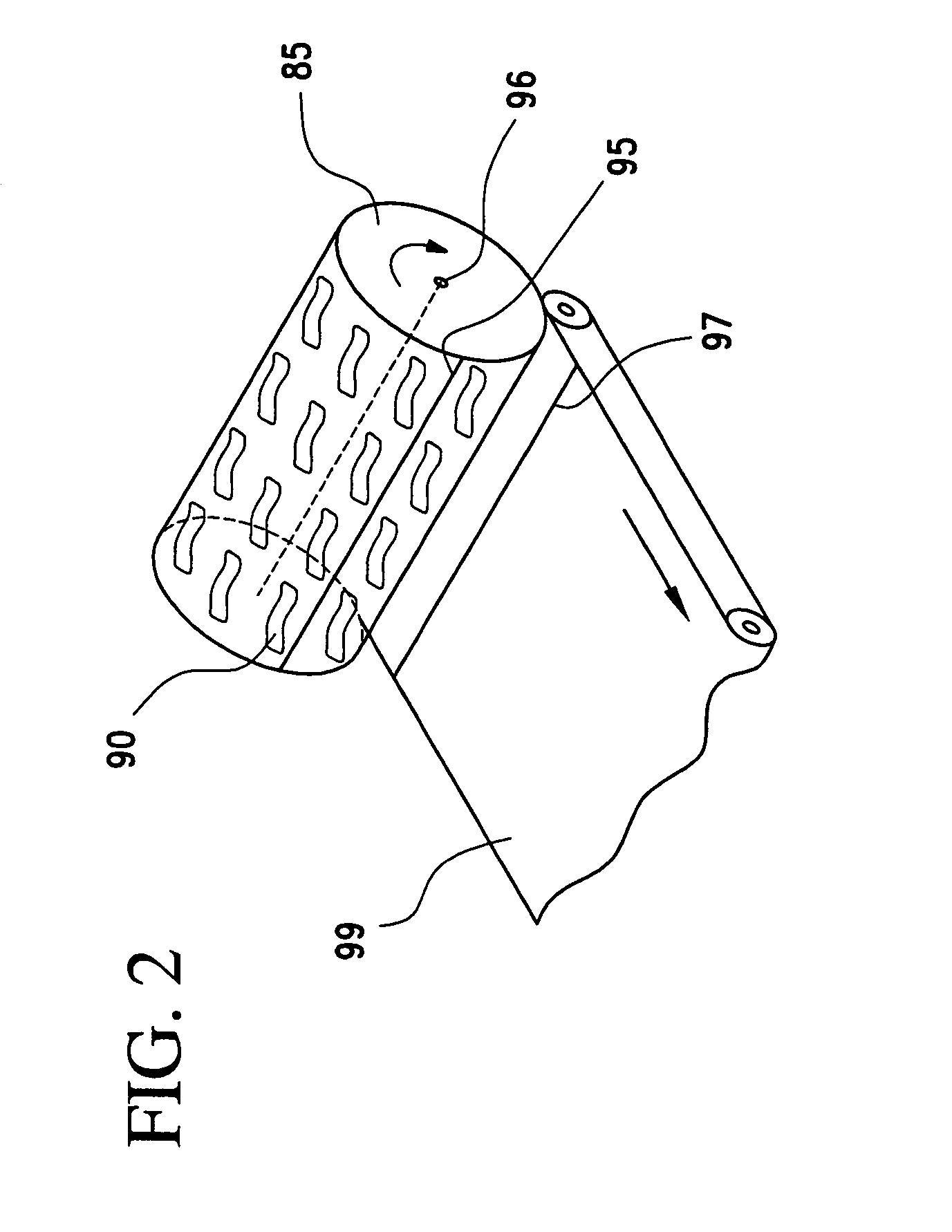

Jerky product and method of producing the same

InactiveUS6815000B2Shorten the timeEliminate needProteins working-up by texturisingVegetable proteins working-upFlavorMoisture

A jerky product resembling real meat jerky and methods of forming the same are provided. Generally, methods of forming jerky include providing an extruded dry material including a non-meat protein isolate and starch. The dry material is hydrated thereby forming a moist material which is then formed into an elongated body and dried to a moisture content of about 15-24% by weight. Smoke flavor may be added to the body by a smoking step or by the addition of an artificial smoke flavoring during the formulation thereof.

Owner:KESLER DAVID L

Meat-containing, strip-shaped food product and method of making same

ActiveUS7282235B2Good strength and integrityReduce breakageAnimal feeding stuffMeat processingWater activityAdditive ingredient

A flexible, strip-shaped food product is made by comminuting substantially frozen meat and heating the comminuted meat to at least partially denature the meat proteins and cooling the cooked meat. About 4% by weight to about 45% by weight of wheat flour is admixed with the cooked meat, along with other ingredients, to form a dough. Use of the wheat flour unexpectedly increases tensile strength of the dough and products baked from the dough, and maintains flexibility of the strip-shaped food products over an extended period of time. Cooking of the meat in the presence of salt unexpectedly increases water activity of the pieces, resulting in a product that has a skin and a moist middle, while maintaining tensile strength. The dough is rotary-molded into strip-shaped pieces. The rotary mold may have angled die cups. The strip-shaped dough pieces are then baked and dried.

Owner:BIG HEART PET INC

Processing method of freshwater crayfish pre-prepared products

The invention discloses a processing method of freshwater crayfish pre-prepared products. The method includes the steps of firstly, selecting and grading; secondly, cleaning; thirdly, frying; fourthly, vacuum cooling; fifthly, soaking with seasoning liquids; sixthly, nitrogen-filled packing; seventhly, quick-freezing; eighthly, performing cold storage. The method has the advantages that the crayfish is soaked with special cleaning fluids to allow the crayfish to spit out dirt in the intestine line, and complex manual intestine line removing is avoided; high-temperature fast frying and special soaking with special seasoning liquids are used, and the difficulties that crayfish meat protein deteriorates easily, flavor substances lose easily and flavor cannot enter the crayfish in subsequent processing are solved; the vacuumizing and nitrogen filling freshness keeping technology is used, and the crayfish is prevented from being oxidized by oil acid during storage.

Owner:洪湖市万农水产食品有限公司

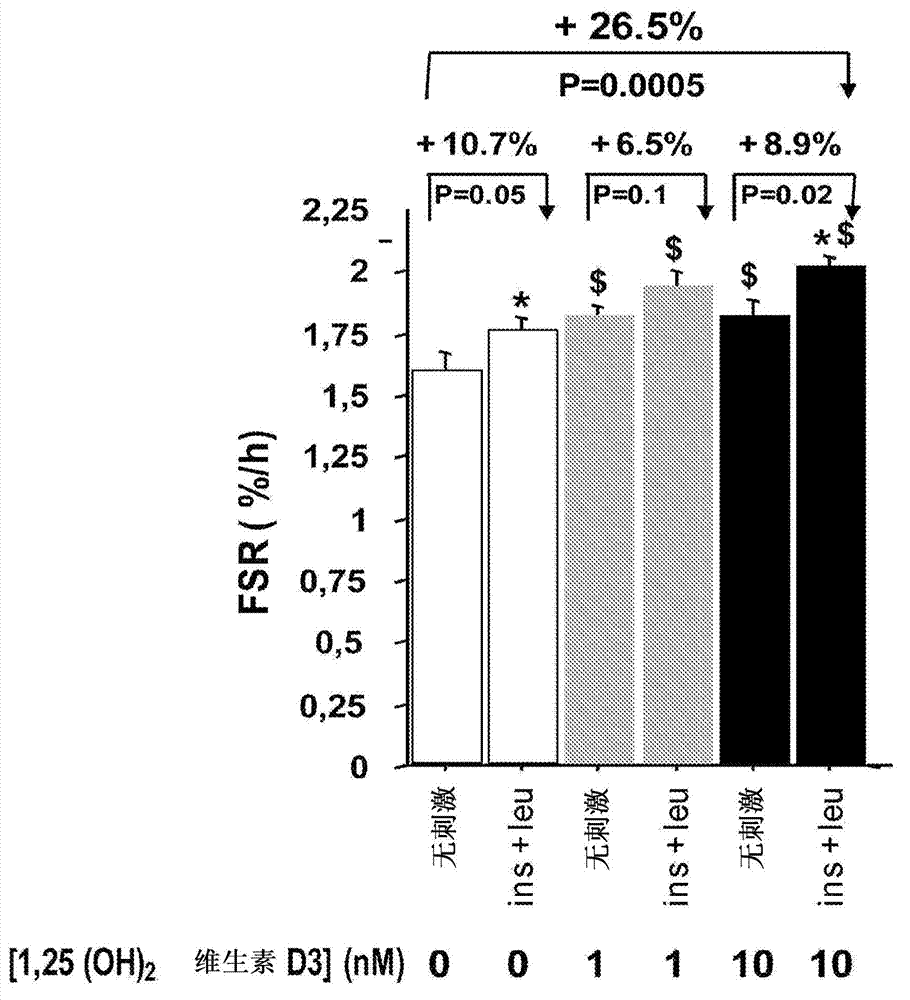

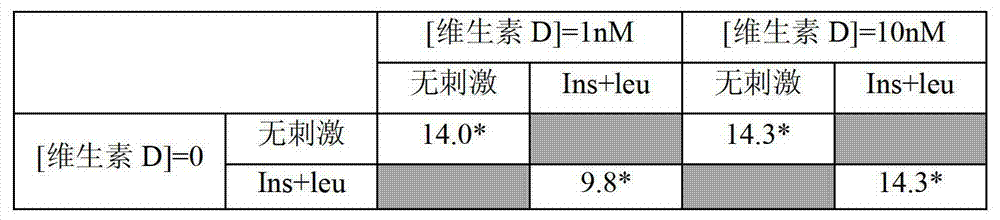

Nutritional composition for the stimulation of muscle protein synthesis

ActiveCN103079415AGood for healthImprove exercise effectOrganic active ingredientsVitamin food ingredientsMuscle strengthMammal

The invention relates to the use of an anabolic amino acid derivative stimulus acting in combination with vitamin D for the manufacture of a medicament or nutritional composition for the prevention and / or treatment of a loss of any one of muscle mass, muscle strength, muscle function, and physical function, or any combination thereof, in a mammal.

Owner:NUTRICIA

Bone and meat extract seasoning

The bone and meat extract seasoning is prepared with fresh animal bone, and through washing, soaking, squeezing to obtain meat, oil and blood water, steaming squeezed product at 100-110 deg.c for 4-6 hr, abandoning oil, cooling to 55-60 deg.c, adding meat protein hydrolase to react while stirring for 3-5 hr, milling in a colloid mill, homogenizing in a homogenizer to form fine homogeneous stable emulsion, adding preservative and concentrating to form paste, which may be further produced into different products in different shapes. The bone and meat extract seasoning as one green seasoning has high content of calcium, unique flavor and good taste, and may be used in cooking and as additive for preparing other seasoning.

Owner:杨天华

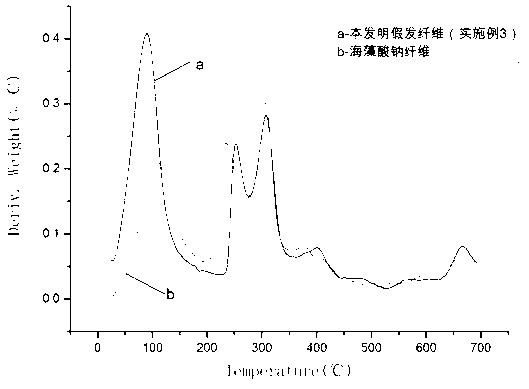

Preparation method of synthetic wig fiber

ActiveCN102926025AAbundant resourcesLow priceConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentFiberProtein solution

The invention discloses a preparation method of a synthetic wig fiber. The method is used for preparing the synthetic wig fiber with euphausia superba meat protein and sodium alginate served as raw materials by blended spinning. The preparation method comprises steps as follows: dissolving euphausia superba powder in an alkaline solution, separating, and purifying to obtain an euphausia superba meat protein solution; then mixing a protein solution and a sodium alginate solution based on a certain ratio, spinning, and solidifying to form; washing by water, and stretching; then dipping by a mixed aqueous solution of sodium dihydrogen phosphate and etherified silicone soil; and finally parching and sizing, so as to obtain the synthetic wig fiber based on the euphausia superba meat protein and the sodium alginate. The synthetic wig fiber prepared by the method disclosed by the invention is excellent in performance, has simulated and vivid effects, and can be widely applied to a wig-weaving field and a decorative art field.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Low cholesterol, functional, animal muscle protein composition and process

A low cholesterol protein composition derived from animal muscle tissue is provided. The low cholesterol protein composition is added to meat or fish prior to cooking to retain moisture during cooking in the fish or meat.

Owner:KEMIN PROTEINS LLC

Processing method for improving natural stability of plant protein milk, and application thereof

InactiveCN102405980AImprove physical and chemical propertiesImproves natural stabilityMilk substitutesBiotechnologyPre treatment

The present invention discloses a processing method for improving natural stability of plant protein milk, and an application thereof. The method comprises: A, carrying out pretreatment processes of sorting, washing, soaking and peeling for plant nutlet raw materials, then carrying out treatments of pulp grinding and filtering to obtain plant protein virgin pulp; B, heating the plant protein virgin pulp to a temperature of 60-80 DEG C, then conveying the heated plant protein virgin pulp to a primary homogenizer, carrying out primary homogenization under pressure of 60-100 MPa, then conveying to a secondary homogenizer to carry out secondary homogenization under pressure of 60-100 MPa; C, after carrying out the homogenization two times, carrying out conventional processes of degasification and sterilizing for the resulting plant protein pulp to obtain the plant protein milk, wherein the plant protein milk meets the standards of the beverage. The method is applicable for processing of peanut protein milk, walnut protein milk, macadamia nut protein milk, coconut meat protein milk, almond protein milk, cashew protein milk, bean protein milk and corn protein milk. According to the present invention, the hyperpressure homogenization method is adopted to carry out the two homogenization treatments for the plant protein milk, such that the particle size of the plant protein milk reaches or approaches the nanometer scale so as to improve physical and chemical properties of the protein milk, increase the natural stability, and the purpose of quality guarantee can be achieved without addition of more stabilizing agents.

Owner:YUNNAN MOER GARDEN BIOLOGICAL SCI & TECH DEV

Health care feedstuff additive for animals

The invention discloses a health care feedstuff additive for animals, capable of effectively improving the health of animals, degrading the harmful toxin inside the animal, improving the quality of meat protein, and promoting the animal growth and improving feedstuff utilization efficiency. The feedstuff additive contains 20g to 50g of lentinan and 1g to 3g of photosynthetic bacteria, wherein theviable count in per gram of the photosynthetic bacteria is from 20 billion to 30 billion.

Owner:程永发

Protein product and process for making injectable protein product

ActiveUS20110244092A1Good moisturizing effectFunction increaseProtein composition from fishFood preparationMuscle tissueFood grade

Moisture is retained in cooked or thawed food by adding to the food an aqueous suspension of animal muscle protein obtained from animal muscle tissue. The aqueous suspension is obtained by mixing comminuted animal muscle tissue with a food grade acid to form an aqueous acidic solution of animal muscle protein. The acidic solution is mixed with a food grade base to precipitate the protein in an aqueous composition. The precipitated protein then is comminuted to form an aqueous suspension of comminuted animal muscle protein.

Owner:KEMIN PROTEINS LLC

Instant health-care granules with high protein content and high dietary fiber content as well as preparation method thereof

InactiveCN106107529AAvoid the hassle of cookingConvenient for daily consumptionFood dryingFood ingredient functionsFiberAdditive ingredient

The invention discloses instant health-care granules with high protein content and high dietary fiber content as well as a preparation method thereof, and belongs to the technical field of health-care foods and health-care food processing. The instant health-care granules with high protein content and high dietary fiber content are mainly prepared from the following ingredients: 40-80 parts of quinoa, 30-50 parts of oat bran and 4-8 parts of seabuckthorn fruit peel powder. The preparation method adopts the following processing processes: respectively removing impurities, and carrying out curing and crushing on the quinoa and the oat bran; uniformly mixing the seabuckthorn fruit peel powder with the quinoa powder and the oat bran powder; carrying out microwave radiating; carrying out extruding so as to prepare granules; carrying out sterilizing; and carrying out packaging. The quinoa is rich in protein content and appropriate in essential amino acid ratios; moreover, the protein content and potency of the quinoa are both higher than rice and wheat flour, and are comparable to the meat proteins; thus, the quinoa is a rare-good source of protein for the vegetarians. The compatibility of the quinoa with the oat bran is rich in dietary fiber content, so that the granules are a very good protein source for the dieters who cannot eat meat. The quinoa and the oat bran are processed into the instant granules by the preparation method, so that the problems of rough taste of the oat bran as well as inconvenience for eating the quinoa are thereby overcome.

Owner:YANGZHOU RUNKANG BIOTECH CO LTD

Crab cream powder and preparation method thereof

The invention aims to provide a crab ovary and digestive glands powder made from the meat scraps and tailings of the fresh water crab ovary and digestive glands cutting process with more proper nutrition combination and product proportion and preparation method thereof, in order to increase the integral utility value of crab meat and the nutritive value of product, belonging to the fresh crab meat processing technology field. The crab ovary and digestive glands powder is made from the following raw materials in weight proportions of: wet crab ovary and digestive glands 30-50 parts, wet crab meat scraps 40-60 parts, edible vegetable oil 3-10 parts, ginger powder 1-5 parts, onion powder 1-5 parts and salt 1-4 parts. by the process of: cleaning and steaming or boiling crab, taking out the ovary, digestive glands and meat scraps in bully, frying by the edible vegetable oil while adding ginger powder, onion powder and salt. The invention fully utilizes the characteristic of high protein content of the meat scraps of the fresh water crab ovary and digestive glands cutting process, combines it with the crab ovary and digestive glands with high fat content properly, achieves the product with more reasonable composition proportion, and improves the utility value of meat scraps of the crab cutting process.

Owner:钱永言

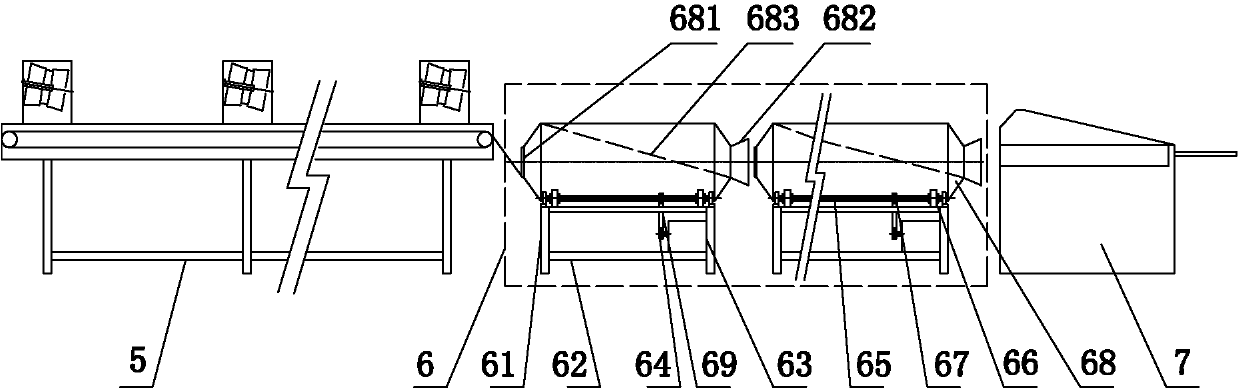

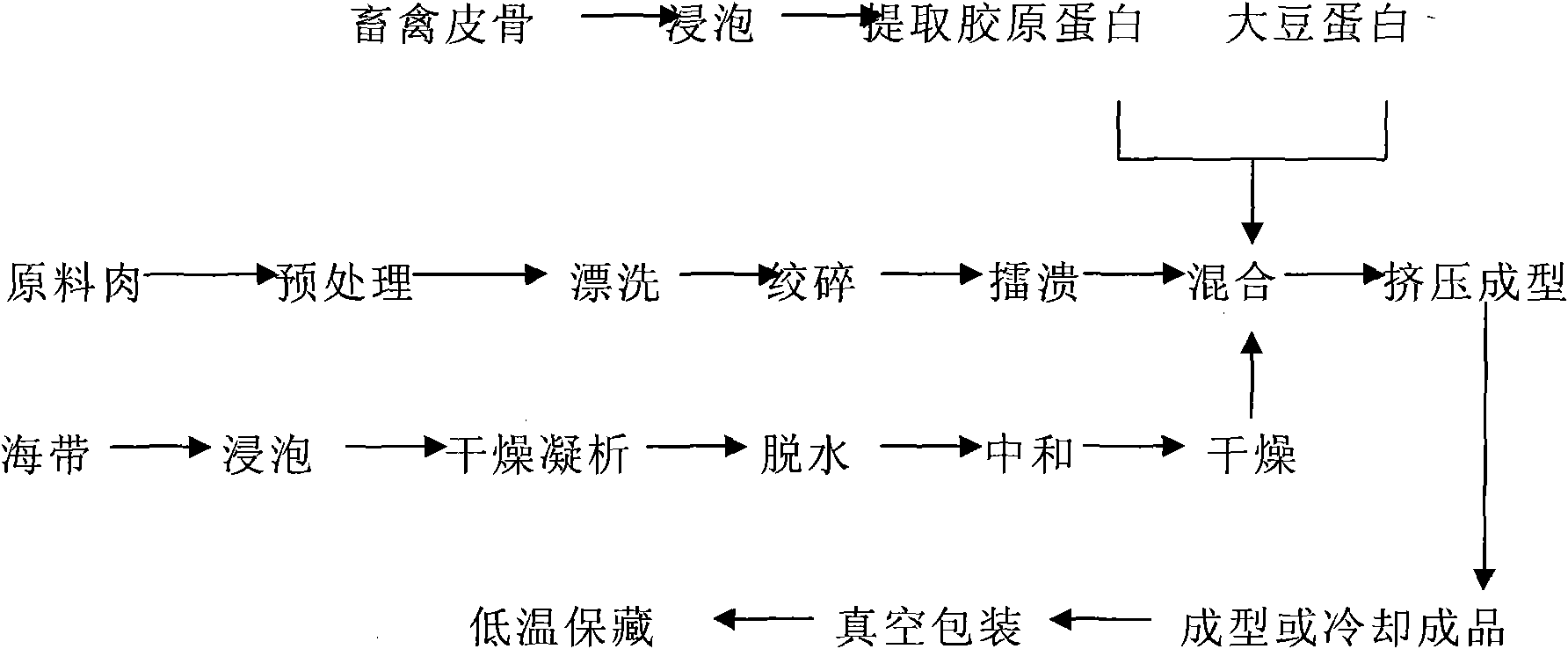

Extrusion production technique for meat simulated fibers

The invention relates to an extrusion production technique for meat simulated fibers, and belongs to the technical field of food science. A low-value meat raw material is used as a main raw material. The technique comprises the following steps of: adding auxiliary materials such as soy protein, animal dermal bone collagen, transglutaminase serving as meat protein coagulation additive, kelp glue serving as kelp extract and the like, performing recombination and cross-linking on multiple proteins and macromolecular polysaccharides by adopting double-screw extrusion technology (the rotational speed of screws is 280 to 450 revolutions per minute, the pressure of a micropore template is 1.7 to 6.0MPa at the temperature of between 150 and 200 DEG C, and the temperature of a cylinder is 170 DEG C), forming meat silk simulated fibers by extrusion, forming cross-linking reaction among meat protein molecules and in molecules, and reshaping micropore formed fibers to obtain recombinant meat food with good color, fragrance, taste and shape. The meat product produced by using the silk muscle simulated fibers produced by the technique is pure natural green food, does not contain chemical substances or preservatives, has the mouthfeel of real meat silks and the specific flavor of meat, has special fragrance and color at the same time, and can be absorbed more easily. Moreover, the added auxiliary materials such as collagen, kelp glue and the like form protein and polysaccharide polymers, so the nutritional components of the product are increased, the quality and structure properties of the product are greatly improved, the water holding property is improved, the problems such as gel cracking and the like are effectively avoided, the quality guarantee period of the product is prolonged, and the social benefit and the economic benefit of the product are increased.

Owner:TIANJIN UNIV OF SCI & TECH

Artificial micro-particle addictive for cynoglossus semilaevis young fry

InactiveCN1729833AImprove stabilityLow dissolution rateAnimal feeding stuffAccessory food factorsFish oilCynoglossus semilaevis

Disclosed is artificial micro-particle addictive for cynoglossus semilaevis young fry which comprises white fish meal, shrimp powder, mussel powder, calamari powder, yeast powder, hydrolyzed fish meat protein, fish oil, alpha-starch, gelatin, inorganic salts mixture, vitamins mixture, feeding promoting agent, coloring matter, anti-oxidant, micro ecological preparation and lecithin by the weight proportions of 35-40, 10-15, 10-15, 8-12, 3-6, 5-8, 3-6, 6-12, 1-3, 1-3, 1-3, 0.1-0.2, 0.01-0.03, 0.05-0.08, 0.1-0.3, 5-8.

Owner:OCEAN UNIV OF CHINA

Recombined meat adhesive and preparation method and application thereof

The invention discloses a recombined meat adhesive and a preparation method and application thereof, belonging to the field of food processing. The recombined meat adhesive comprises glutamine transaminase, non-meat protein and dietary fiber, has the advantages of low production cost, good adherence effect, great adherence strength to meat slices or meat blocks, little melting loss and boiling loss, great recombined meat tenderness and good flakiness, can effectively ensure the adherence effect, improves the demand of people for dietary fibers and increases the added value of products. The recombined meat prepared by the recombined meat adhesive has the adhesive property higher than or equal to 70g*cm<-2>, decreases the hardness by 62.8 percent and reduces the shearing force by 22.9 percent; the prepared raw and fresh recombined meat or cooked recombined meat has no obvious color difference (p is larger than 0.05) from one-piece meat and has no obvious taste difference (p is larger than 0.05) from the one-piece meat by sensory test.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Ready-to-eat fish meat protein power and preparation method thereof

ActiveCN103202383AHigh protein contentImprove solubilityProtein composition from fishReady to eatNeutral proteinase

The invention discloses ready-to-eat fish meat protein power, and belongs to the field of aquatic product processing. The ready-to-eat fish meat protein power is obtained by cooking fish meat of seawater fish at high temperature and high pressure, pouring a fat-containing solution on the upper layer, then adding water, performing enzymolysis on the fish meat respectively by using neutral proteinase and flavourzyme, performing centrifugating after the enzymolysis is finished, desalting supernate obtained by centrifugating to obtain desalted supernate, adding water into precipitates obtained by centrifugating, performing enzymolysis on the precipitates by using papain to obtain fish protein zymolyte, finally mixing the desalted supernate and the fish protein zymolyte, and homogenizing, concentrating, spraying and drying the mixture to obtain the ready-to-eat fish meat protein power. The invention also discloses a method for preparing the ready-to-eat fish meat protein power. The ready-to-eat fish meat protein power is high in protein content and high in polypeptide content and is high in dissolvability and convenient to eat; and furthermore, the preparation method is low in energy consumption and low in production cost.

Owner:BINZHOU WANJIA BIOTECH

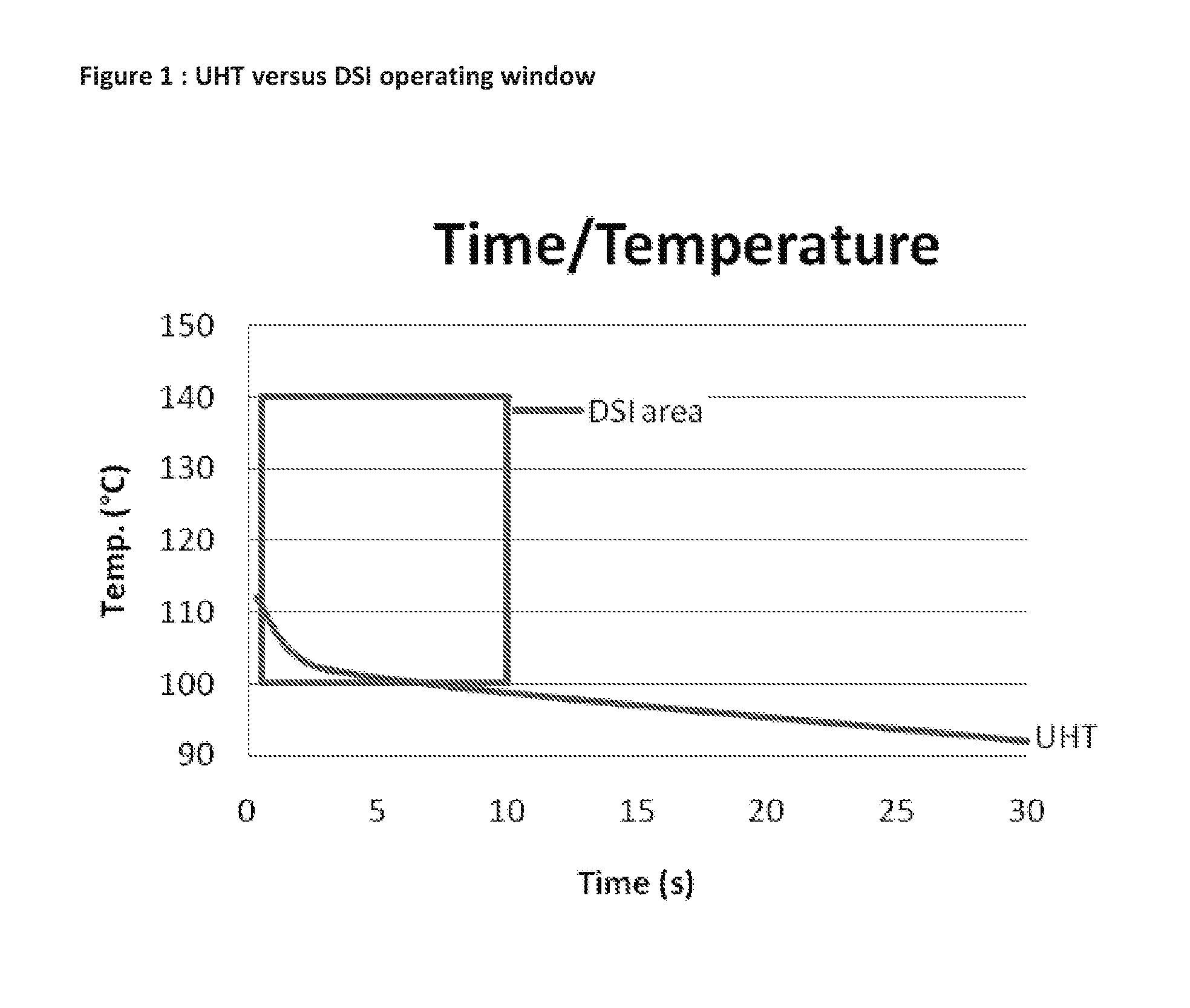

Whey Protein Composition with a Reduced Astringency

ActiveUS20140296162A1Low astringencyLow sandinessVitamin food ingredientsPeptide/protein ingredientsWhey proteinDivalent metal

The invention relates to a sterilized liquid or semi-solid acid enteral composition comprising per 100 ml 9 to 20 g of non-hydrolysed globular proteins, fat and at least 100 mg of divalent metal cations and having a pH ranging between 3 and 5. The invention further relates to a method for preparing a composition according to the invention, comprising a step wherein at least the non-hydrolysed globular proteins are subjected to a direct steam injection (DSI) at specific holding values, such as a holding temperature of 100 to 140° C. during a holding time of about 0.5 to 10 seconds, followed by a homogenization step and a sterilization step The composition according to the invention has a reduced astringency and can be used for medical purposes, such as for stimulating muscle protein synthesis in a mammal, in particular for treating sarcopenia, and for specific groups of people, such as elderly and sportsman.

Owner:NUTRICIA

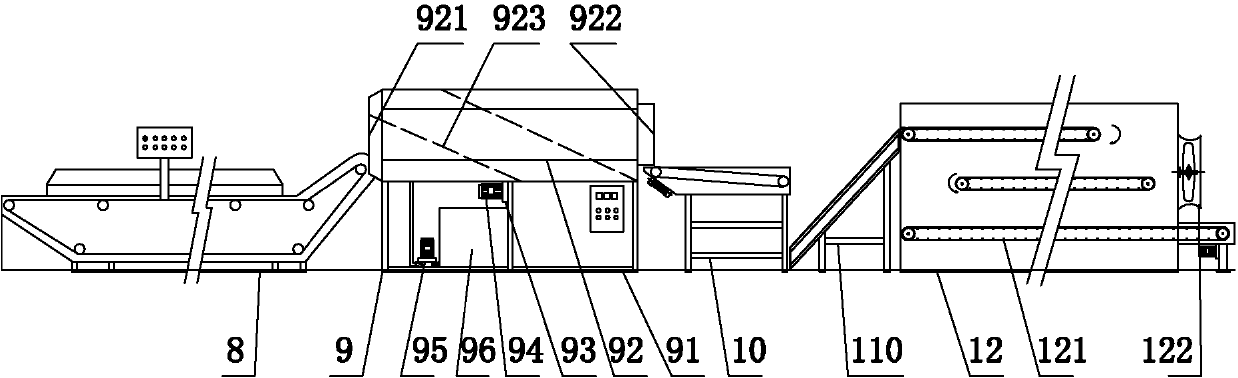

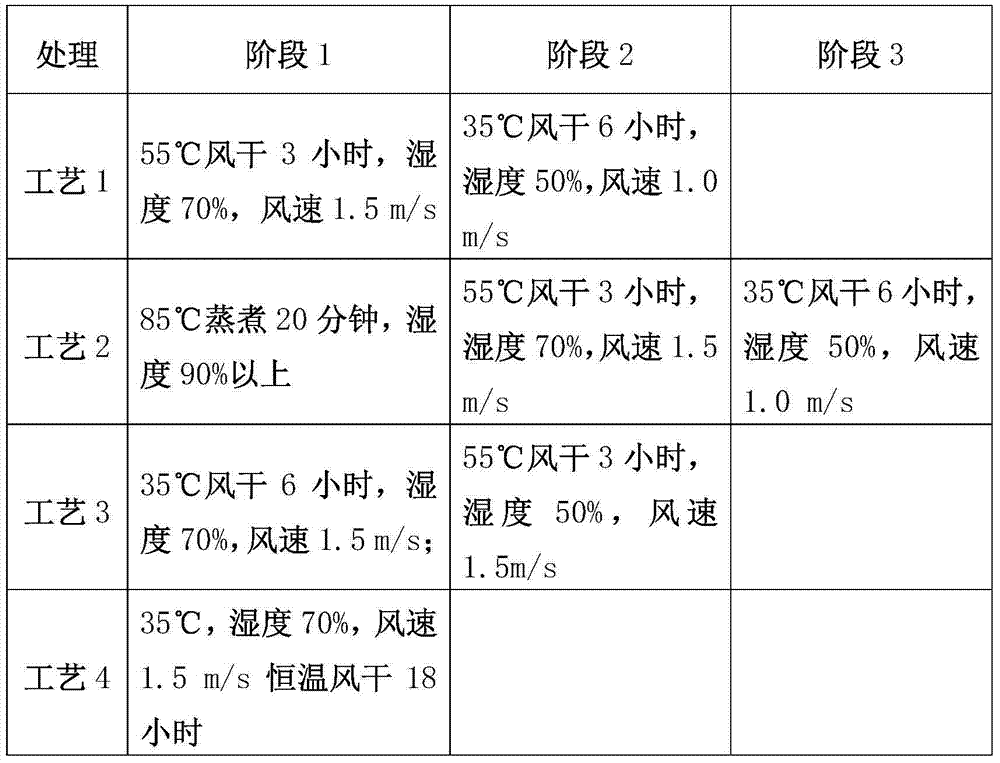

Gradient temperature processing method for air-dried meat

ActiveCN104489050AShorten drying timeIncrease productivityFood preparationMeat/fish preservation by dryingLean meatMoisture

The present invention relates to a gradient temperature processing method for air-dried meat, which is based on vacuum pickling and gradient temperature drying and mainly consists of the following steps: selecting of chunks of lean meat, thawing and trimming into meat strips, pulse vacuum or breathing rolling and pickling, high temperature air-drying, low temperature air-drying, trimming of the meat strips, frying at low temperatures, frying at high temperatures, spreading and drying in the air, packaging, testing and storing. The processing method uses the gradient temperature air-drying method according to the moisture removing law and gel force changes in the air-dried meat protein. The air-drying time is shortened to less than 10 hours, and thus the production efficiency is improved and the cost of production is saved; meanwhile, the uniformity of the air-dried meat products reaches more than 95%, and thus the product quality is improved, the air-drying process is simplified, and the processing method lays foundations for the development of air-dried meat products with various tastes and various appearances.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Moisturizing composition for protein materials

InactiveUS20080166464A1Good moisturizing effectProtein composition from fishDough treatmentBiotechnologyCellulose

A cooked or uncooked grain, vegetable or meat protein product comprising a) 0.05%-5% by total weight highly refined cellulose product defined by a fiber material that has a total dietary fiber (TDF) content greater than 30% as measured by AOAC 991.43 and a water holding capacity greater than five parts water per part fiber as measured by AACC 56-30 and comprises less than 90% soluble fiber and b) grain, vegetable or meat proteinaceous product

Owner:FIBERSTAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com