Preparation method of synthetic wig fiber

A wig and fiber technology, applied in the field of chemical fiber materials, can solve problems such as loss of edible value, and achieve low cost, good interface binding ability, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

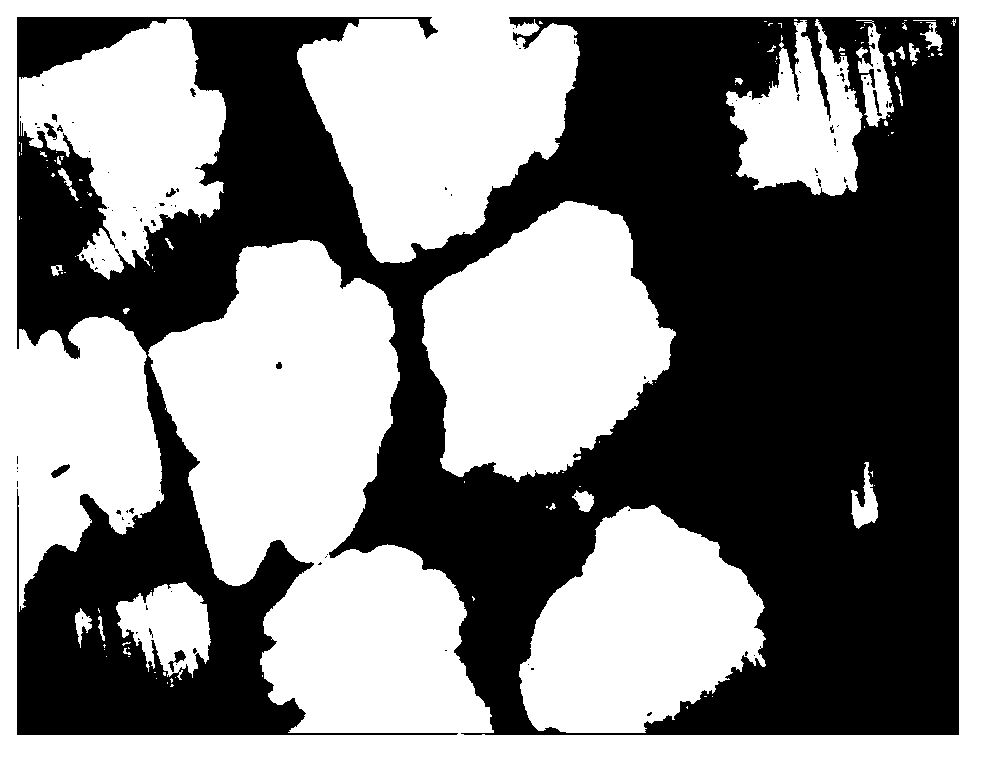

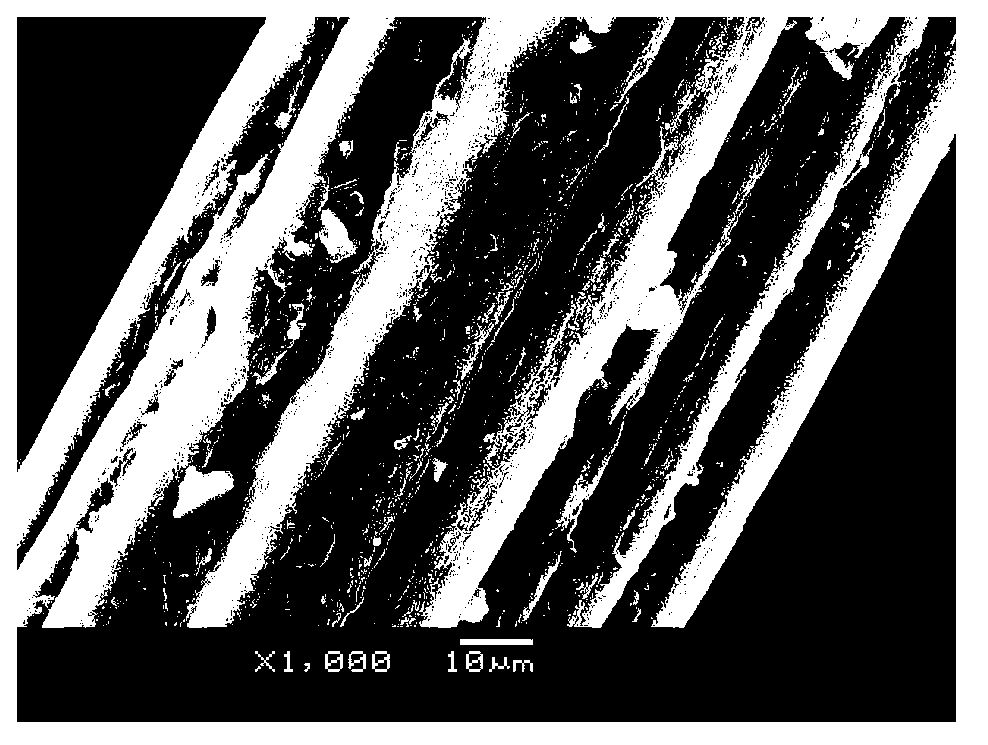

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of Antarctic krill shrimp meat protein solution:

[0031] Take 100ml of 2% sodium hydroxide solution and 10g of Antarctic krill shrimp powder, add them to a 250ml three-necked flask in turn, stir and dissolve at 70°C for 5 hours, cool naturally to 35-40°C, and then use a suction filter to extract filter, and collect the filtrate to obtain the Antarctic krill shrimp meat protein solution. The obtained protein solution was packaged with plastic wrap and stored in a dry place at 4°C for future use.

[0032] (2) Preparation of blended spinning solution:

[0033] ① Weigh 1.05g of sodium alginate powder, add a water-titanium dioxide mixed solution with a titanium dioxide content of 0.01%, and stir at room temperature for 20-30 minutes to completely dissolve the sodium alginate to obtain 3% seaweed Sodium acid solution 35g.

[0034] ②Mix 3.89g of the Antarctic krill shrimp meat protein solution prepared in step (1) with 35g of the sodium alginate solution ob...

Embodiment 2

[0038] (1) Preparation of Antarctic krill shrimp meat protein solution:

[0039] Take 100ml of 4% sodium hydroxide and 10g of Antarctic krill powder, add them to a 250ml three-neck flask in turn, stir and dissolve at 60°C for 6 hours, cool naturally to 35-40°C, and then filter with a suction filter and collect the filtrate to obtain the Antarctic krill shrimp meat protein solution. The obtained protein solution was packaged with plastic wrap and stored in a dry place at 4°C for future use.

[0040] (2) Preparation of blended spinning solution:

[0041] ① Weigh 1.05g of sodium alginate powder, add a water-titanium dioxide mixed solution with a titanium dioxide content of 0.01%, and stir at room temperature for 20-30 minutes to completely dissolve the sodium alginate to obtain alginic acid with a mass concentration of 3%. Sodium solution 35g.

[0042] ②Mix 8.75g of Antarctic krill shrimp meat protein solution prepared in step (1) with 35g of sodium alginate solution obtained ...

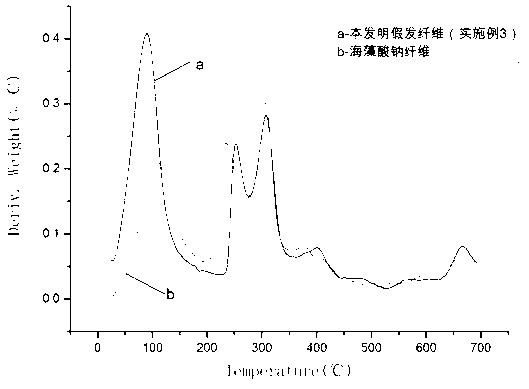

Embodiment 3

[0045] (1) Preparation of Antarctic krill shrimp meat protein solution:

[0046] Take 100ml of 3% sodium hydroxide and 10g of Antarctic krill shrimp powder, add them to a 250ml three-neck flask in turn, stir and dissolve at 80°C for 5 hours, cool naturally to 35-40°C, and then filter with a suction filter and collect the filtrate to obtain the Antarctic krill shrimp meat protein solution. The obtained protein solution was packaged with plastic wrap and stored in a dry place at 4°C for future use.

[0047] (2) Preparation of blended spinning solution:

[0048] ① Weigh 1.6g of sodium alginate powder, add a water-titanium dioxide mixed solution with a titanium dioxide content of 0.01%, and stir at room temperature for 20-30 minutes to completely dissolve the sodium alginate to obtain alginic acid with a mass concentration of 4%. Sodium solution 40g.

[0049] ②Mix 4.44g of the Antarctic krill shrimp meat protein solution prepared in step (1) with 40g of the sodium alginate solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com