Crayfish food as well as preparation method and production equipment thereof

A kind of production equipment and lobster technology, applied in the field of snack food, can solve the problems of lack of automatic production equipment, etc., achieve good market prospects, improve the effect of less products and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

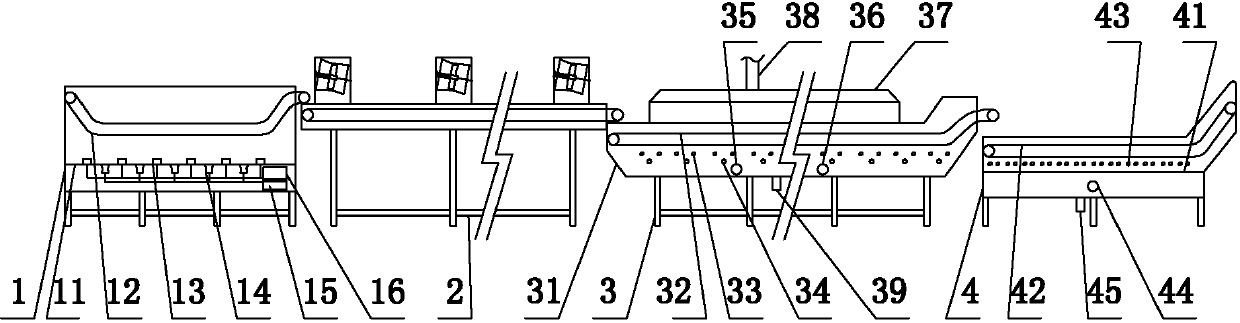

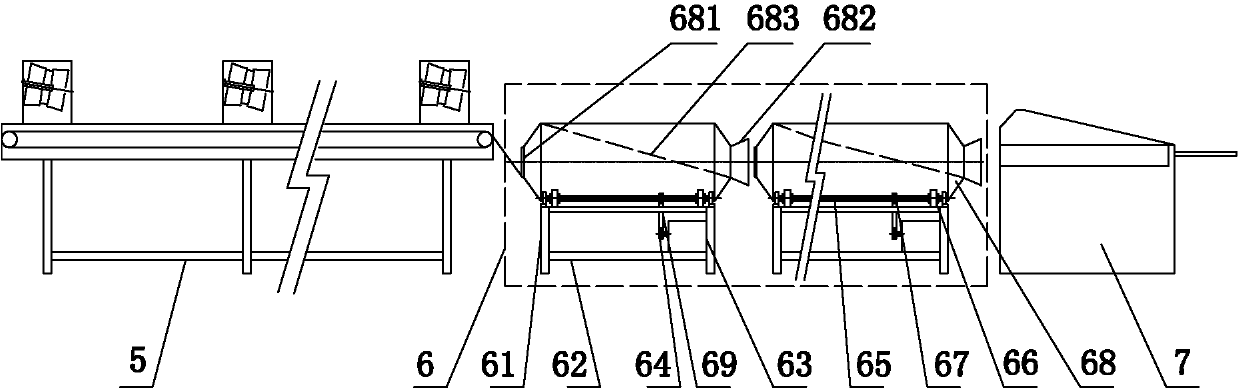

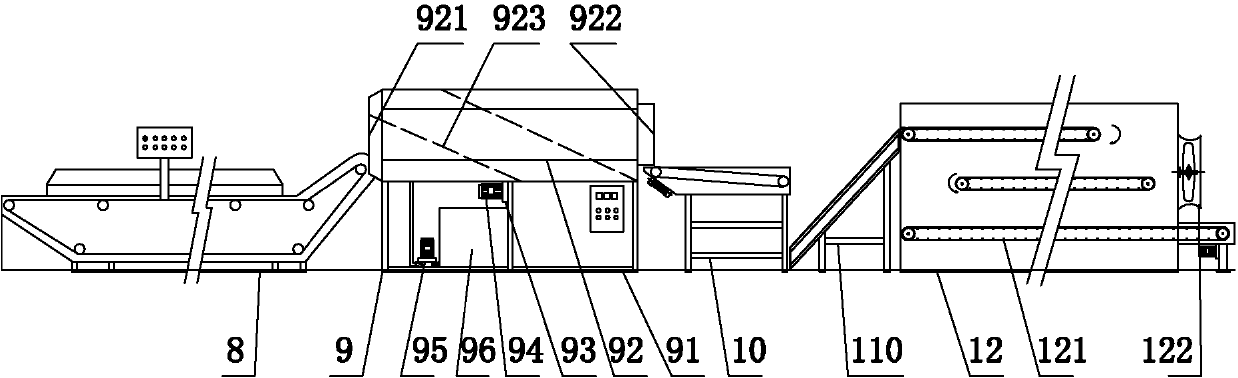

Image

Examples

Embodiment 1

[0040] Embodiment 1: choose 100 parts of shrimp balls through selection and deshelling, put them into an ultrasonic foaming cleaning machine and clean them for 3 minutes, after cleaning, carry out wind blowing and spreading to cool, and the shrimp shells are cleaned and drained to make chitosan Standby; then put the shrimp balls into the deep fryer with water and oil and fry them at 150°C for 5 minutes; put the fried shrimp balls into the marinating machine for stewing for 5 minutes Minutes, after stewing, let the wind blow and cool; send the stewed shrimp balls into a multi-stage mixer, add spices to the first-stage mixer, and add glutamyl aminotransferase, nisin, etc. to the follow-up mixer in turn Food additive, after fully mixing, let it stand at 30°C for 3 hours; send the evenly stirred shrimp balls into a vacuum packaging machine for vacuum packaging; send the packaged shrimp balls into a pasteurization machine for low-temperature sterilization , keep at 70°C for 20 minu...

Embodiment 2

[0044] Embodiment 2: Embodiment 1: choose 100 parts of shrimp balls through selection, shelling, put into the ultrasonic foam cleaning machine and clean for 4 minutes, after cleaning, carry out wind blowing and spread cool, and the shrimp shells are made into chitosan for subsequent use; Put the shrimp balls into the deep frying machine mixed with water and oil to fry, the oil temperature is 175°C, and the frying time is 4 minutes; After cooking, let the wind blow and cool; send the marinated shrimp balls into a multi-stage mixer, add spices into the first-stage mixer, and add food additives such as glutamyl transaminase and nisin in sequence in the follow-up mixer, After fully mixing, let it stand at 30°C for 3.5 hours; send the evenly stirred shrimp balls into a vacuum packaging machine for vacuum packaging; send the packed shrimp balls into a pasteurization machine for low-temperature sterilization, and keep 70 ℃ for 25 minutes; put the low-temperature sterilized shrimp bal...

Embodiment 3

[0047] Embodiment 3: Embodiment 1: choose 100 parts of shrimp balls through selection, shelling, put into the ultrasonic foaming cleaning machine and clean for 5 minutes, after cleaning, carry out wind blowing and cool, and the shrimp shells are made into chitosan for subsequent use; Put the shrimp balls into the deep frying machine mixed with water and oil for frying, the oil temperature is 200°C, and the frying time is 3 minutes; After cooking, let the wind blow and cool; send the marinated shrimp balls into a multi-stage mixer, add spices into the first-stage mixer, and add food additives such as glutamyl transaminase and nisin in sequence in the follow-up mixer, After fully mixing, let it stand at 30°C for 4 hours; send the evenly stirred shrimp balls into a vacuum packaging machine for vacuum packaging; send the packaged shrimp balls into a pasteurization machine for low-temperature sterilization, and keep 70 ℃ for 30 minutes; put the low-temperature sterilized shrimp bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com