Ready-to-eat fish meat protein power and preparation method thereof

A protein powder and fish meat technology, applied in the direction of fish protein composition, protein food composition, food science, etc., can solve the problem of not finding fish protein step-by-step enzymatic hydrolysis to prepare fish protein powder, unable to meet the nutritional needs of infant fish protein, Restrictions on nutrient absorption and utilization, and achieve the effect of good flavor, low production cost and energy consumption, and low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

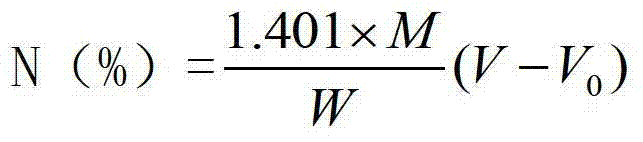

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Preparation of instant fish protein powder of the present invention

[0030] Proceed as follows:

[0031] (1) Choose thawed cod, wash the fish body with water, remove the fish head, tail and internal organs, and then wash the blood stains on the surface and cavity of the fish body with running water. , get fish.

[0032] (2) Take 100 grams of fish meat, add 100 grams of water to the fish meat, cook at high temperature and high pressure (2 atmospheres, 121°C) for 5 minutes, pour off the fat-containing solution in the upper layer; then add 80 grams of water to obtain fish meat paste I.

[0033] (3) Add 0.10 g of neutral protease (purchased from Beijing Donghua Qiangsheng Biotechnology Co., Ltd., the same below) to fish paste I, and carry out enzymatic hydrolysis at 50°C and pH 7.0 for 0.25h, then Then add 0.15 g of flavor protease (the flavor protease was purchased from Novozymes, Denmark, the same below), carry out the enzymolysis reaction at 45°C and pH ...

Embodiment 2

[0036] Embodiment 2 Preparation of instant fish protein powder of the present invention

[0037] (1) Choose thawed Spanish mackerel, wash the fish body with water, remove the fish head, tail and viscera, and then wash the blood stains on the surface and cavity of the fish body with running water. The temperature of the cleaning water does not exceed 25°C; Fish, get fish.

[0038] (2) Take 200 grams of fish meat, add 200 grams of water to the fish meat, cook under high pressure and high temperature (2 atmospheres, 121°C) for 8 minutes, pour off the fat-containing solution in the upper layer; then add 200 grams of water to obtain fish meat paste I.

[0039](3) Add 0.15 g of neutral protease to fish paste I, carry out enzymatic hydrolysis at 50°C and pH 6.8 for 0.5 h, then add 0.20 g of flavor protease, and carry out enzymatic hydrolysis at 45°C and pH 6.2 The hydrolysis reaction was carried out for 0.25h, then incubated at 95°C for 4min, and then centrifuged at room temperature...

Embodiment 3

[0042] Embodiment 3 Preparation of instant fish protein powder of the present invention

[0043] Proceed as follows:

[0044] (1) Choose thawed cod, wash the fish body with water, remove the fish head, tail and internal organs, and then wash the blood stains on the surface and cavity of the fish body with running water. , get fish.

[0045] (2) Take 1,000 grams of fish, add 500 grams of water to the fish, cook under high pressure and high temperature (2 atmospheres, 121°C) for 10 minutes, pour off the fat-containing solution in the upper layer, and then add 1,000 grams of water to obtain fish paste Ⅰ.

[0046] (3) Add 0.5 g of neutral protease to fish paste Ⅰ, carry out enzymatic hydrolysis at 50°C and pH 7.3 for 0.3 h, then add 1.0 g of flavor protease, and carry out at 50°C and pH 6.6 Enzymolysis reaction for 0.25h, and then incubated at 90°C for 5min; then centrifuged at room temperature and 3000g for 5min to obtain supernatant and 275g of precipitate; the obtained supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com