Gradient temperature processing method for air-dried meat

A technology of gradient variable temperature and processing method, which is applied in the field of gradient variable temperature processing of air-dried beef and mutton, and gradient variable temperature processing of air-dried meat. It can solve the problems of long air-drying time, insufficient flavor substances, and high equipment requirements, so as to save production costs and improve production. Efficiency, the effect of simplifying the air-drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1. Verification of the effect of air-drying mutton with gradient variable temperature

[0056] Mutton myofibrillar protein was dissolved in 50mM phosphate buffer (pH6.0) containing 0.6M NaCl, and the protein concentration was adjusted to 30mg·mL -1 . Use 1M NaOH or HCl to adjust the system to the pH value required for the test, and heat it in a water bath after dispensing. -1 The temperature was raised linearly to 75°C and held for 20 minutes. During the heating process, the molecular force was studied for gels at 25°C, 35°C, 45°C, 55°C, 65°C, and 75°C. In addition, differential scanning calorimeter (DSC) was used to analyze the thermal stability of sheep myofibrillar protein under different pH systems. min -1 , use the Q20 empty aluminum box as a blank control, and use the software that comes with the instrument to analyze the thermal denaturation temperature (Tmax) of the protein.

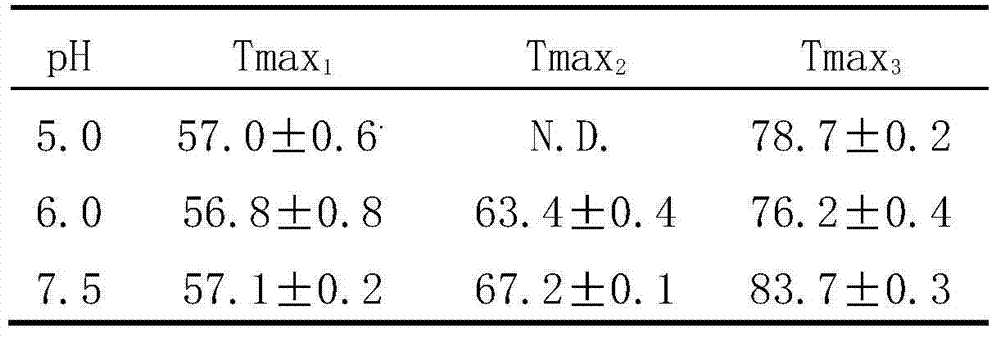

[0057] 1. Muscle thermal denaturation temperature verification

[0058] T...

Embodiment example 2

[0062] Implementation Case 2 Air-dried Beef and Mutton Gradient-variable Temperature Air-drying Method

[0063] 1. Process flow

[0064] Raw meat → thawing (not thawing), trimming → marinating → air-drying → cutting strips → frying → drying → packaging → sterilization → labeling and packing → inspection and storage

[0065] 2. Process points

[0066] 1. Raw meat is thawed (not thawed), trimmed

[0067] After the raw meat is thawed by the high-humidity gradient variable temperature thawing method, the visible fat and tendons are removed, and trimmed into meat strips of about 2cm×2cm for later use. The chilled fresh raw meat does not need to be thawed, and is directly trimmed into meat strips;

[0068] 2. Pickled

[0069] The obtained meat strips are put into a vacuum tumbler for pulse vacuum pickling, vacuum tumbled and marinated according to the quantitative marinade ratio, the added salt is 0.8-1.2% of the raw meat strips by weight, and the pickling temperature is 0-7°C, ...

Embodiment example 3

[0078] Implementation case 3 Verification of the effect of air-dried beef with gradient temperature change

[0079] Beef, the thigh part of an adult cow

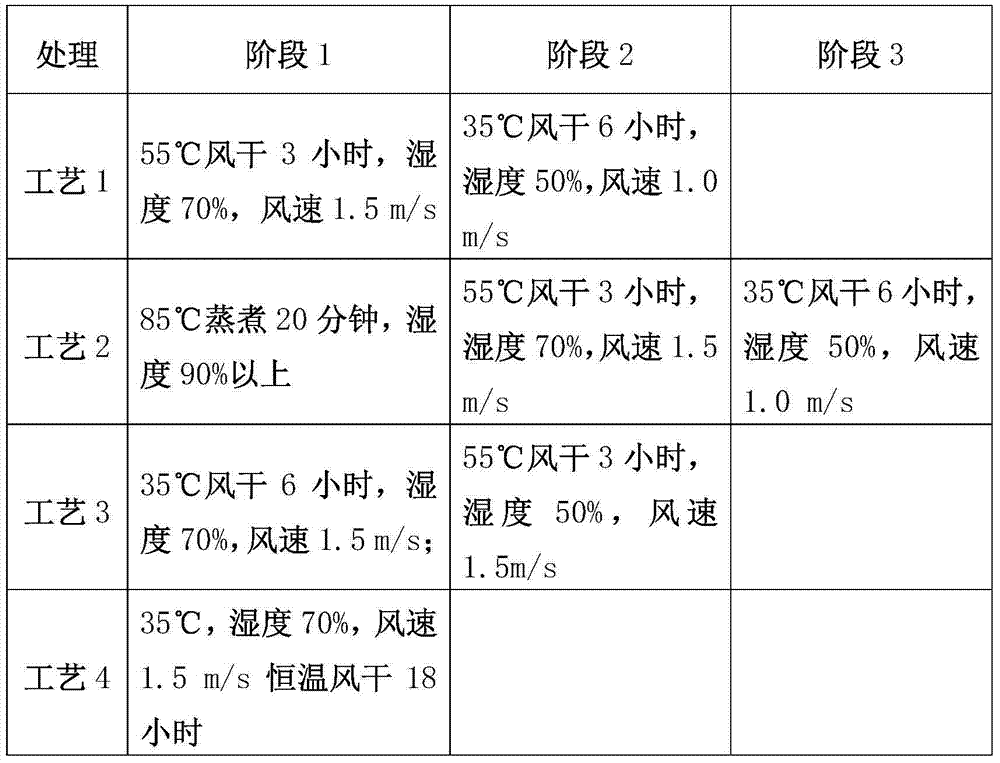

[0080] This embodiment divides experimental group (process 1) and control group (process 2,3,4), as shown in table 1, except air-drying process, experimental group and control group adopt the method described in implementation case 2 to carry out processing and production . Sensory evaluation of finished product and determination of moisture content after air drying and finished product.

[0081] Table 1 air-drying process table

[0082]

[0083] 2. Sensory evaluation verification

[0084] Table 2 Sensory evaluation form

[0085] deal with

taste and smell

Taste

color

total score

Craft 1

7.3±1.1

7.5±0.9

7.5±0.8

8.3±0.4

8.5±0.7

Craft 2

6.5±1.3

6.0±1.0

7.3±1.2

7.0±0.9

7.1±1.0

Craft 3

7.2±1.0

6.5±0.7

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com