Preparation method of high-strength polyurethane-based composite film

A composite film and polyurethane technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of uneven mixing of two phases, limited force between layers, and inability to adjust the number of continuous deposition layers, etc., to achieve The effect of structural controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

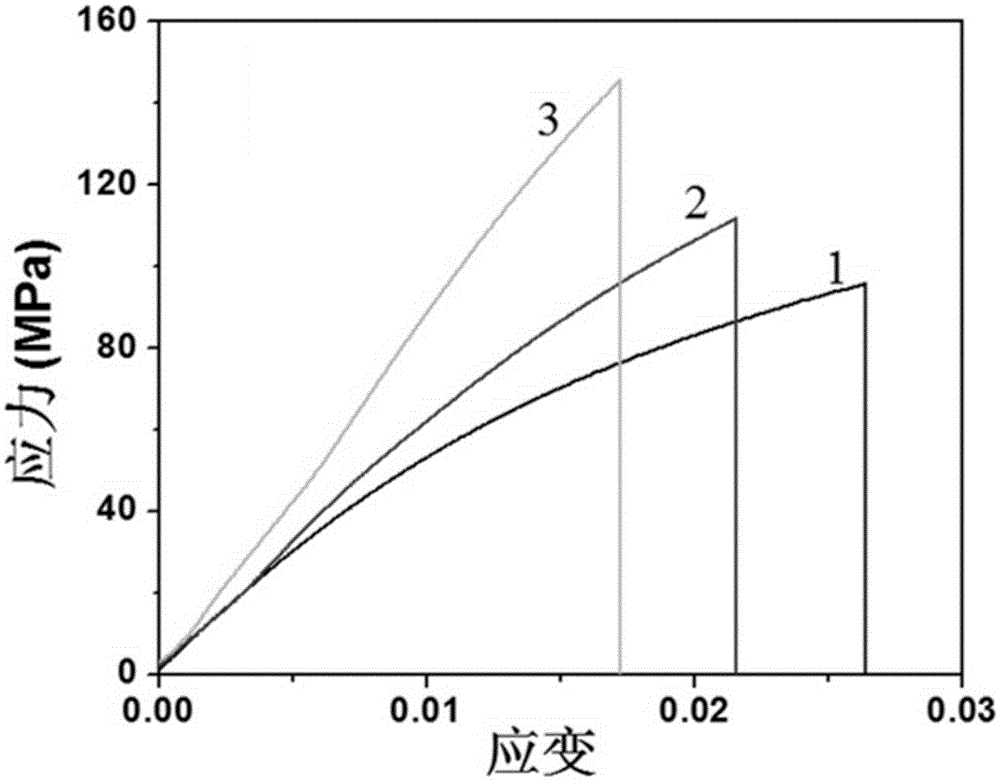

[0030] Embodiment 1: The preparation method of a high-strength polyurethane-based composite film described in this embodiment is specifically carried out according to the following steps:

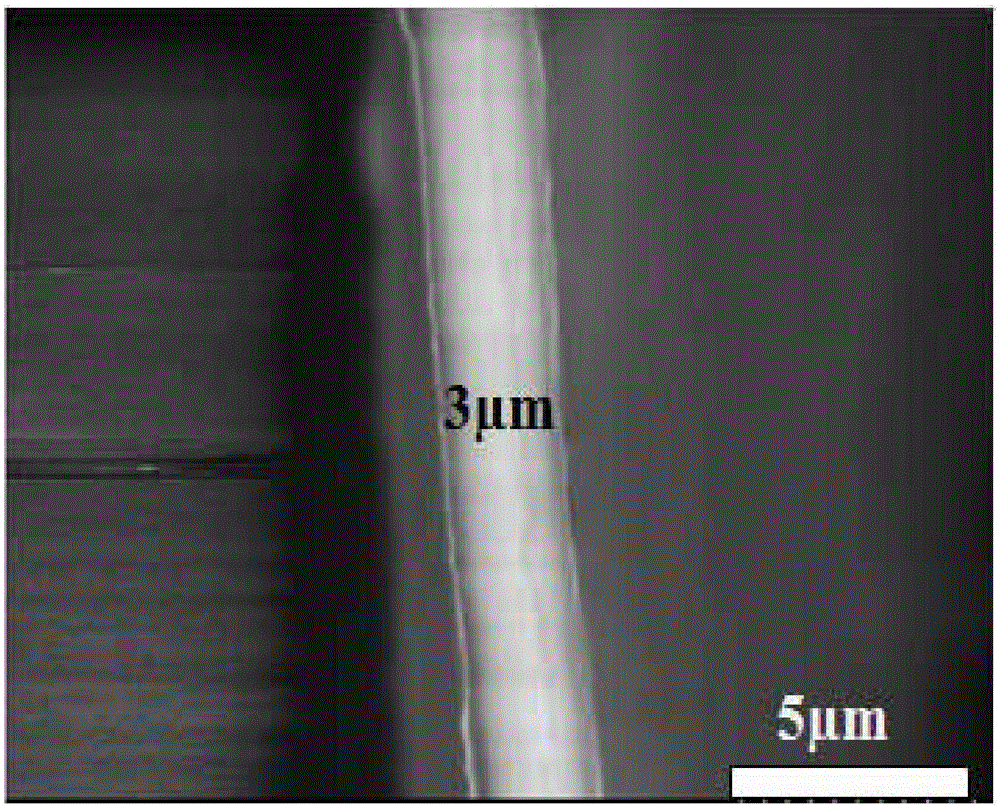

[0031] 1. Preparation of Kevlar nanofiber solution: Cut Kevlar fiber into pieces and dry to obtain Kevlar fiber with a length of 2cm to 5cm, add sodium hydroxide and Kevlar fiber with a length of 2cm to 5cm In an autoclave equipped with a dimethyl sulfoxide solution, and then place the autoclave at a temperature of 120°C to 150°C to react for 3 days to 5 days to obtain a Kevlar nanofiber solution;

[0032] The mass ratio of the Kevlar fiber to sodium hydroxide is 1:(1~3); the volume ratio of the quality of the Kevlar fiber to the dimethyl sulfoxide solution is 1g:(400~600) mL;

[0033] 2. Preparation of a mixed solution containing polyurethane: Dissolve polyurethane in ethyl acetate solution, then add 1-hydroxycyclohexyl phenyl ketone to obtain a mixed solution, stir the mixed solution mag...

specific Embodiment approach 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the negatively charged glass sheet described in step 3 is specifically prepared according to the following steps: the glass substrate is placed in ethanol and ultrasonicated for 20min to 30min to obtain The glass substrate after ultrasonic treatment, then immerse the glass substrate after ultrasonic treatment in the treatment liquid, treat for 2h to 3h, and rinse it with deionized water after treatment to obtain a negatively charged glass sheet; the treatment liquid is prepared by It is obtained by mixing concentrated sulfuric acid with a mass percentage of 98% and hydrogen peroxide with a mass percentage of 30%, and the mass ratio of the concentrated sulfuric acid to hydrogen peroxide is 3:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the mass ratio of Kevlar fiber to sodium hydroxide described in step 1 is 1:2. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com