Injection-molded current transformer and preparation method thereof

A current transformer and injection molding technology, which is applied in the direction of current measurement only, voltage/current isolation, and current/voltage measurement, can solve problems such as bubbles in the insulating layer, poor appearance consistency, and reduced withstand voltage strength of the insulating shell. Good insulation and sealing, stable and reliable quality, and good appearance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

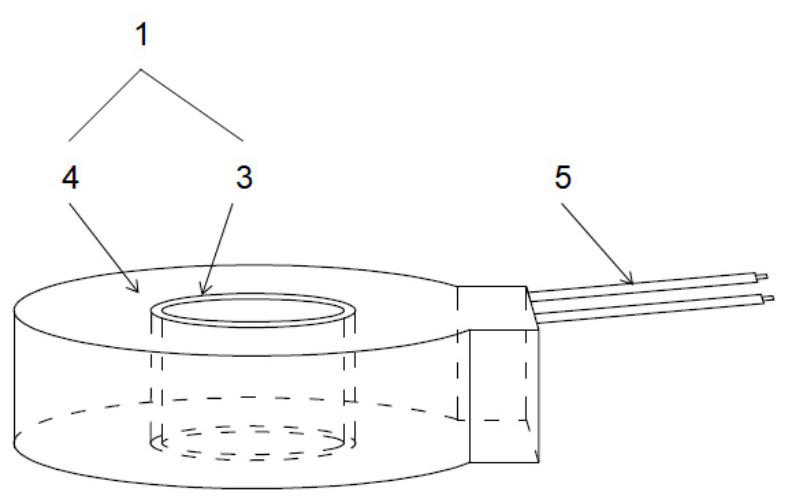

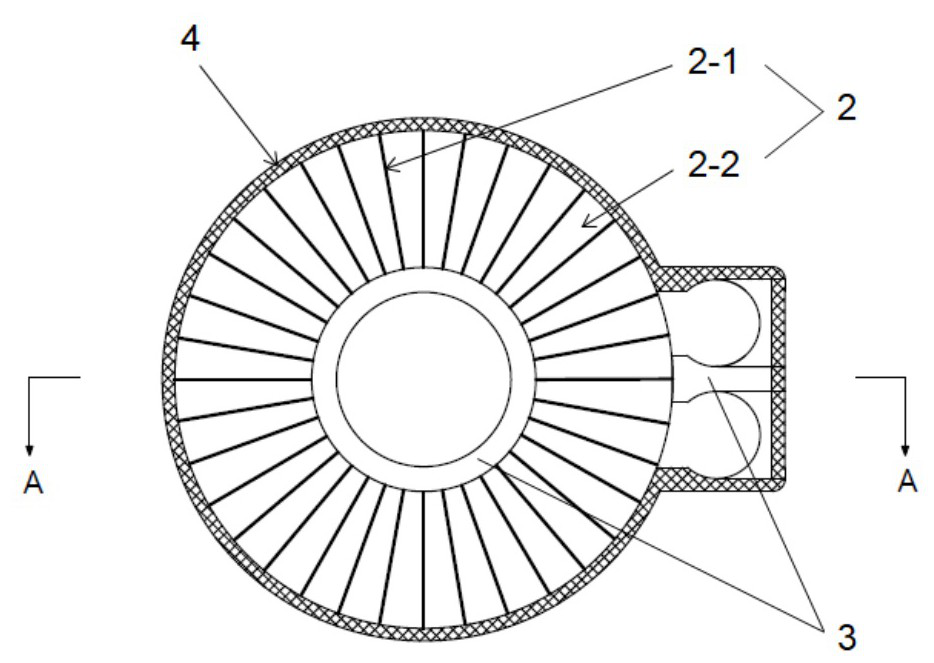

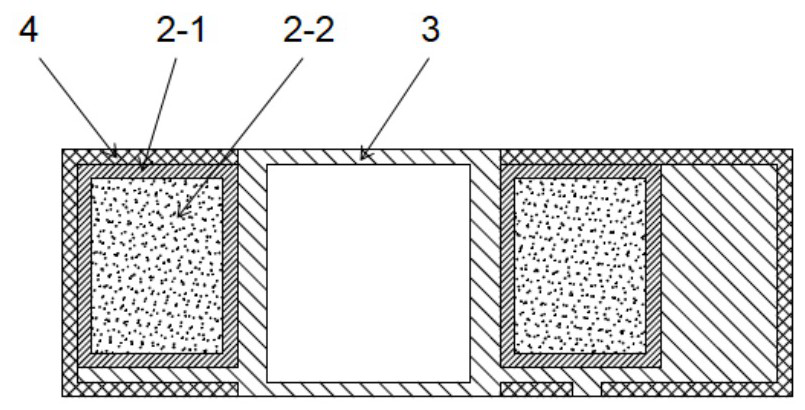

[0035] Such as Figure 1 to 3 In the present invention, the injection molded current transformer is prepared by the injection molding process, including the support body 3 equipped with the winding core 2, including the core 2-2, the enameled wire 2-1, lead 5 and The housing 1, the housing 1 includes a support body 3 and a plastic layer 4 surrounded outside the current transformer. The winding core 2 is wrapped from the lacquer line 2-1 as the secondary winding, and both ends of the enamel wires 2-1 are welded to interfaces of the two leads 5, and the lead 5 is embedded in the lead fixed slot 3-3. The extension of the housing 1 is extended to the housing 1 through the outlet hole 3-4. The material of the core 2-2 can be used in an amorphous soft magnetic alloy, a nanocrystalline mnemy alloy, a ferrite or a slope alloy; the material of the support body 3 can be used in polyethylene terephthalate ( At least one of PBT), polyethylene terephthalate (PET) and styrene-acrylonitrile (AS r...

Embodiment 2

[0044] Such as Figure 6 As shown in the present embodiment, the difference in the injection molded current transformer with the first embodiment is that the boss 3-1 is a cross-shaped convex structure, and four positioning structures are provided on the boss 3-1. The positioning structure is that the positioning the projection 3-1a, the inner hole shape of the winding core 2 matches the outer surface of the boss 3-1. The through hole 3-2 is cross-shaped, and can select the insertion direction of the insertion of the insertion of the bus bar according to the actual needs, and adapt to different application scenarios. Correspondingly, in the preparation method of the injection molded current transformer of the present embodiment, when the support is prepared, the boss 3-1 is the support body injection mold of the cross-shaped column convex structure.

Embodiment 3

[0046] Such as Figure 7 As shown in the present embodiment, the difference in the injection molded current transformer with the first embodiment is that the bosses 3-1 are circular and rectangular bostructures, and two positioning is provided on the boss 3-1. Structure, the positioning structure is a positioning protrusion 3-1B, and the inner hole shape of the winding core 2 matches the outer surface of the boss 3-1. The through holes 3-2 are rounded and rectangular combined structures, which can be used to install a winding wire busbar or pass through the wire directly. Correspondingly, in the preparation method of the injection molded current transformer of the present embodiment, when the support is prepared, the boss 3-1 is used as a support of the boss 3-1 as a circular and rectangular combination of convex structure. Sports injection mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com