All composite material lightweight fuel tank shell for aircraft

A composite material and fuel tank technology, used in the field of aviation and aerospace vehicle components, can solve the problems of low stiffness, low performance, and heavy fuel tank weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

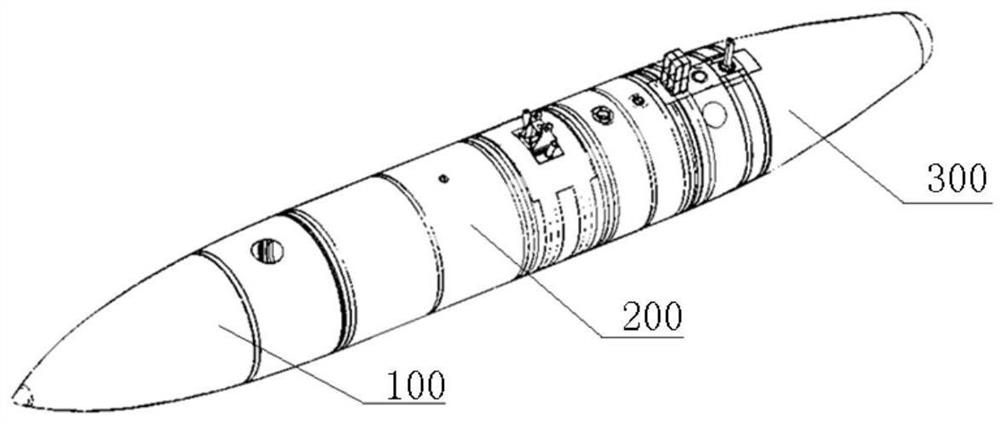

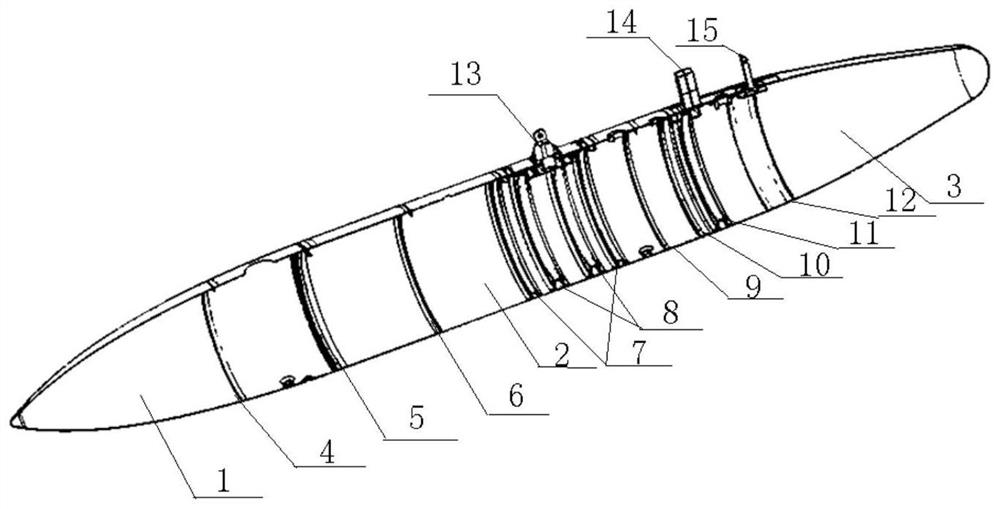

[0036] A high-rigidity composite fuel tank for aircraft, the main body is made of carbon fiber composite materials. Such as figure 1 , figure 2 , The overall structure is divided into three sections, including the front cone section 100, the middle column section 200, and the rear cone section 300. The specific structure includes cone section shell 1, column section shell 2, cone section shell 3, L-shaped Ring frame a4, L docking ring frame 5, L-shaped ring frame b6, small Ω-shaped ring frame 7, large Ω-shaped ring frame 8, L-shaped ring frame c9, L-joint ring frame b10, Ω-shaped ring frame 11, U-shaped Ring frame 12, main lifting point joint 13, stop block 14, rear hanging point joint 15, concentrated force decomposition structure 16, I-beam decomposition joint 17 and other detailed structures.

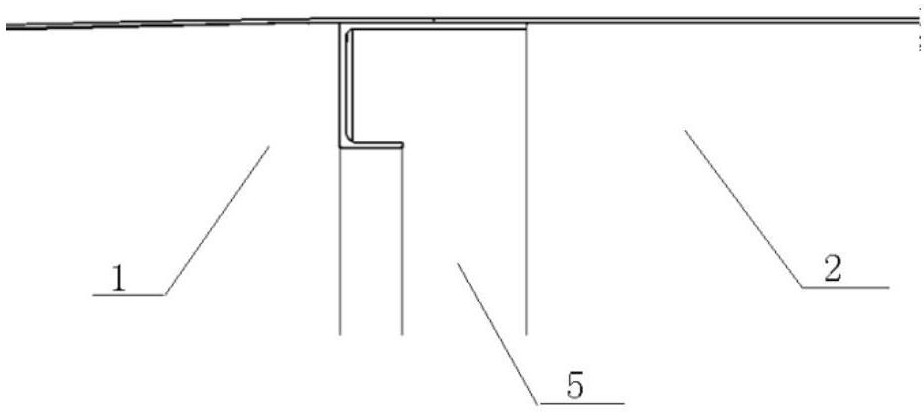

[0037] Such as image 3 , the front cone section 100 and the middle column section 200 are connected by plugging through the L docking ring frame a5. In specific use, after being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com