Patents

Literature

305 results about "I-beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

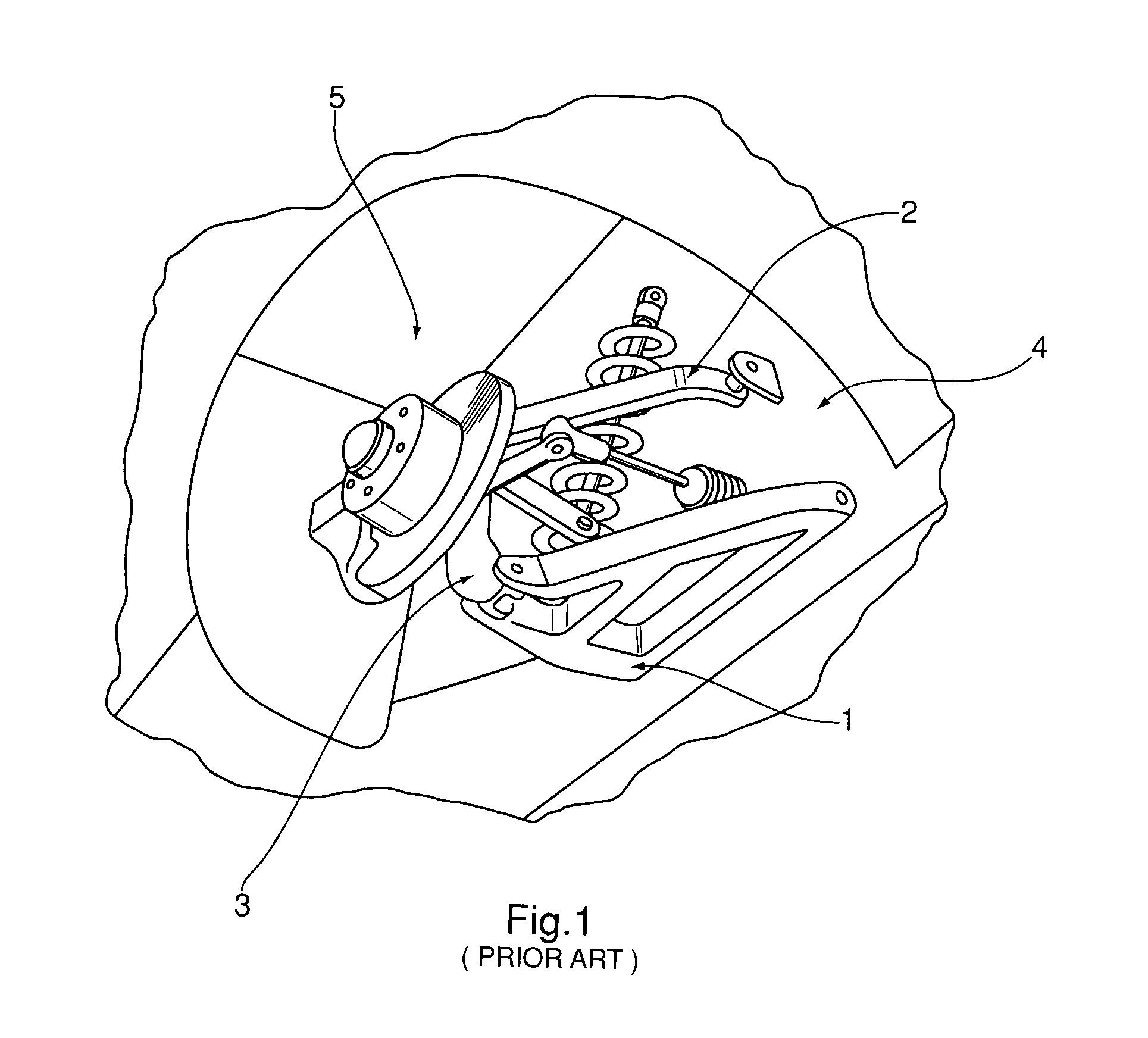

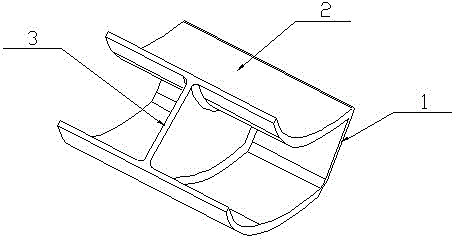

An I-beam, also known as H-beam (for universal column, UC), w-beam (for "wide flange"), universal beam (UB), rolled steel joist (RSJ), or double-T (especially in Polish, Bulgarian, Spanish, Italian and German), is a beam with an I or H-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". I-beams are usually made of structural steel and are used in construction and civil engineering.

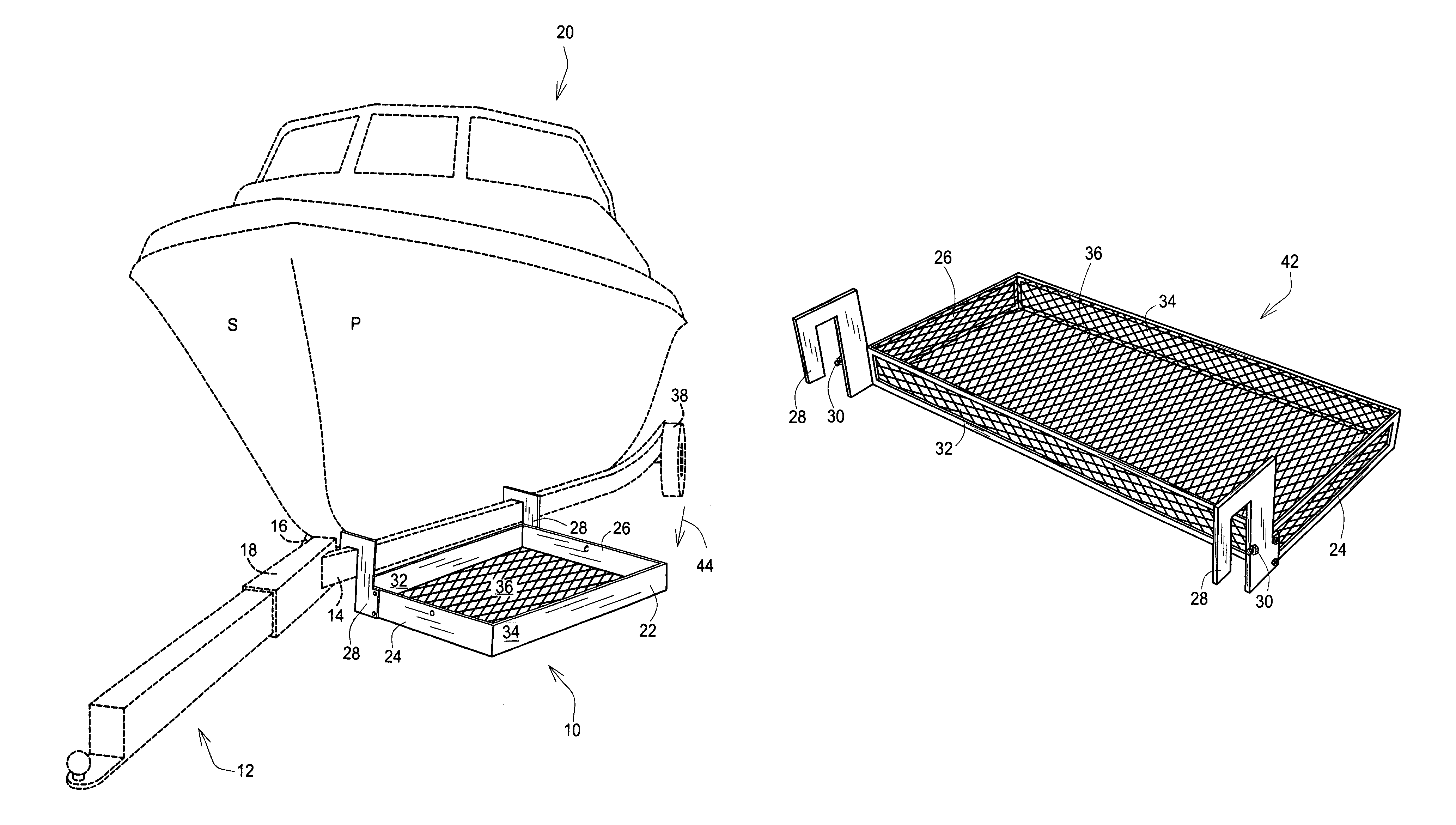

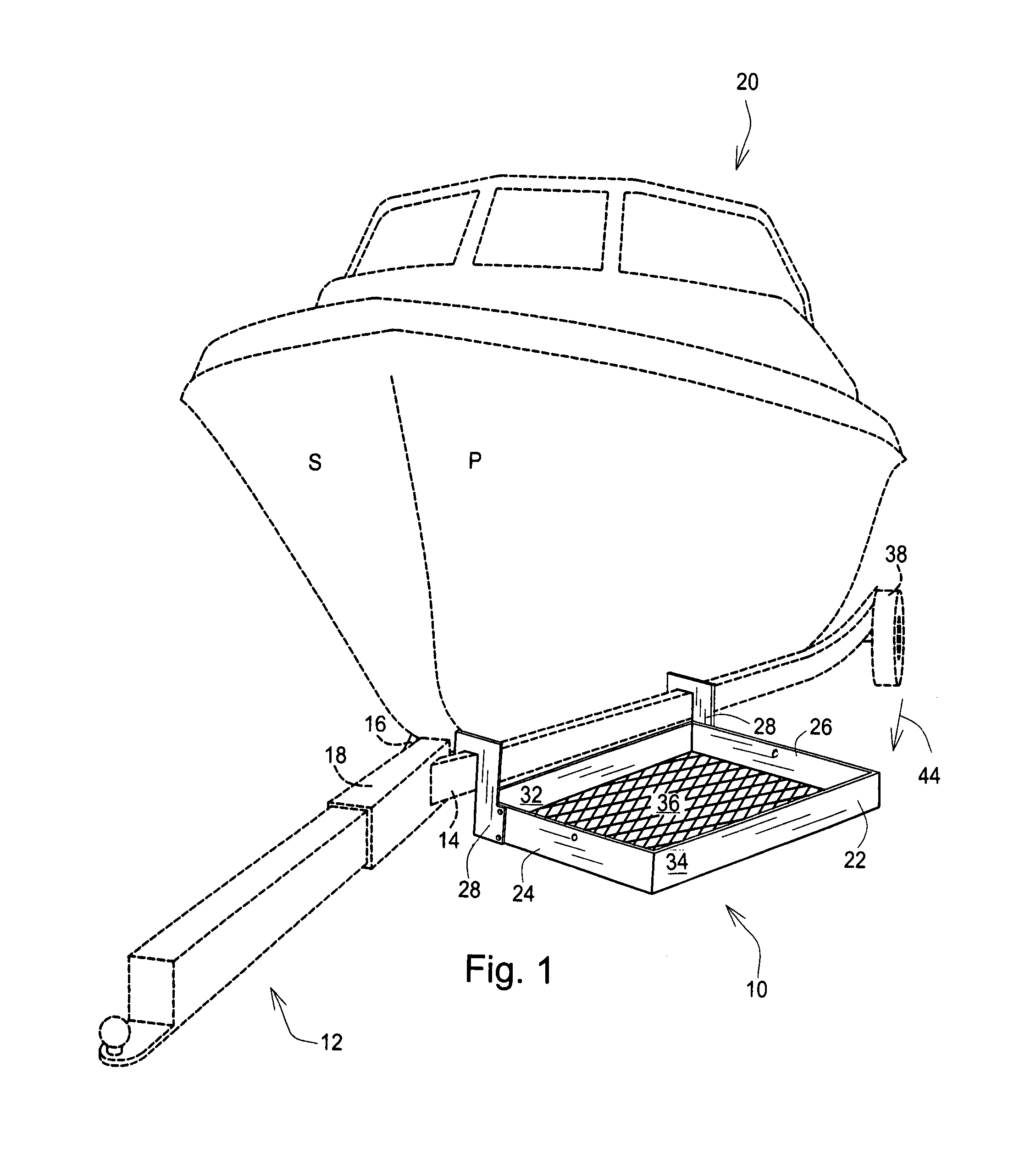

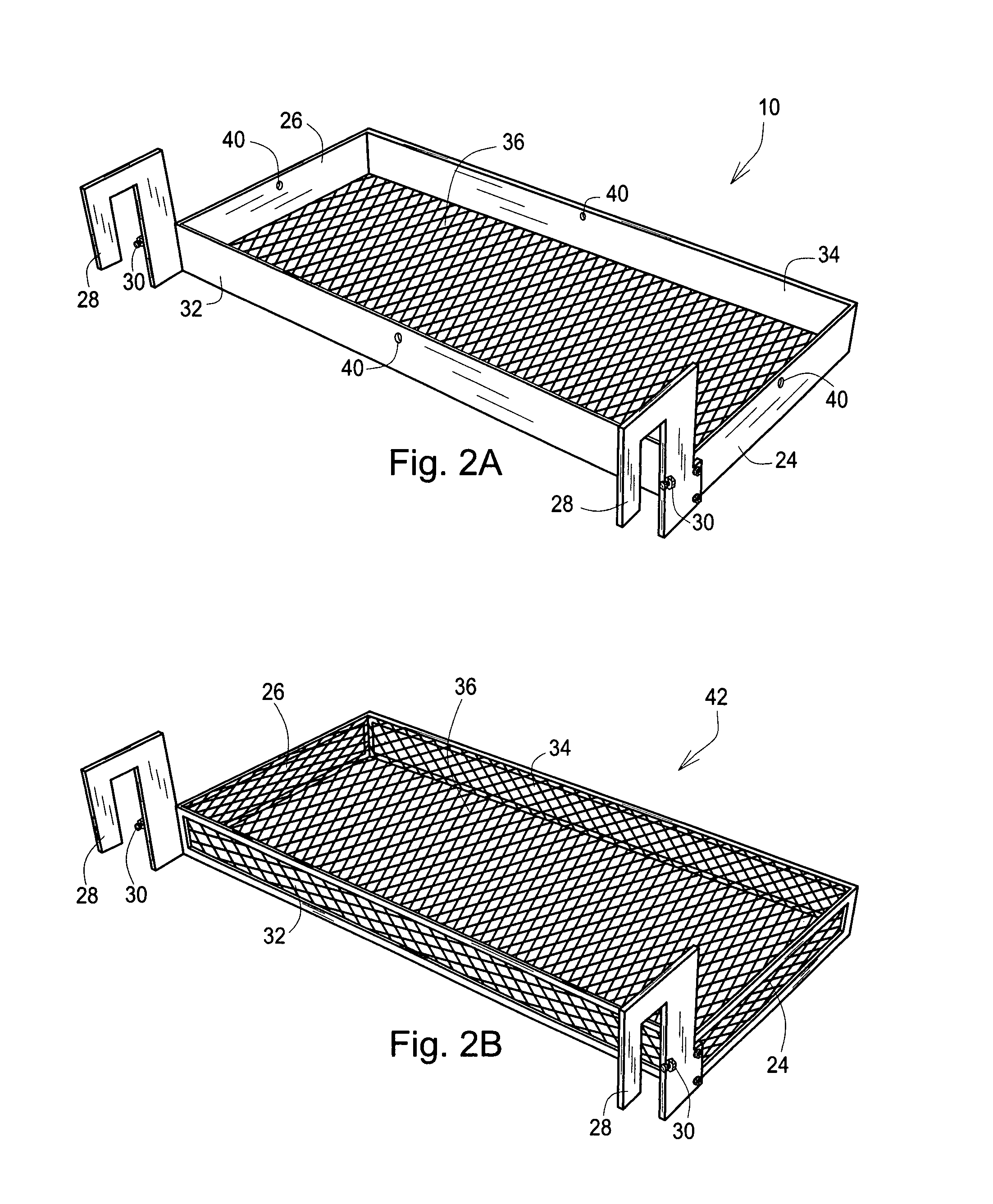

Universal hanger cargo carrier for a boat trailer

InactiveUS7802709B1Prevent theftSmall sizeSupplementary fittingsStowing appliancesLocking mechanismBungee cord

A universal, adaptable hanger mounted cargo carrier for removable mounting over and around a trailer frame without requiring modification of either I-beam or box beam trailer rails. The carrier comprises a generally rectangular box with steel mesh floor and opposed inverted corner J-hook mounts for slidable mounting of the carrier over the trailer frame rail extending deep enough below the bottom of the rail to enable a locking mechanism to at least partially close the opening of the inverted J-hook below the frame. Inverted “U” shaped spacers reduce the size of the J-hook opening, thereby adapting the carrier for flush mounting on a range of different sized rails. A steel mesh floor and holes in the walls of the carrier for insertion of hook ends of bungee cords allow for retention and transport of objects of varying size and shape.

Owner:LEWIS JEFFREY THOMAS +1

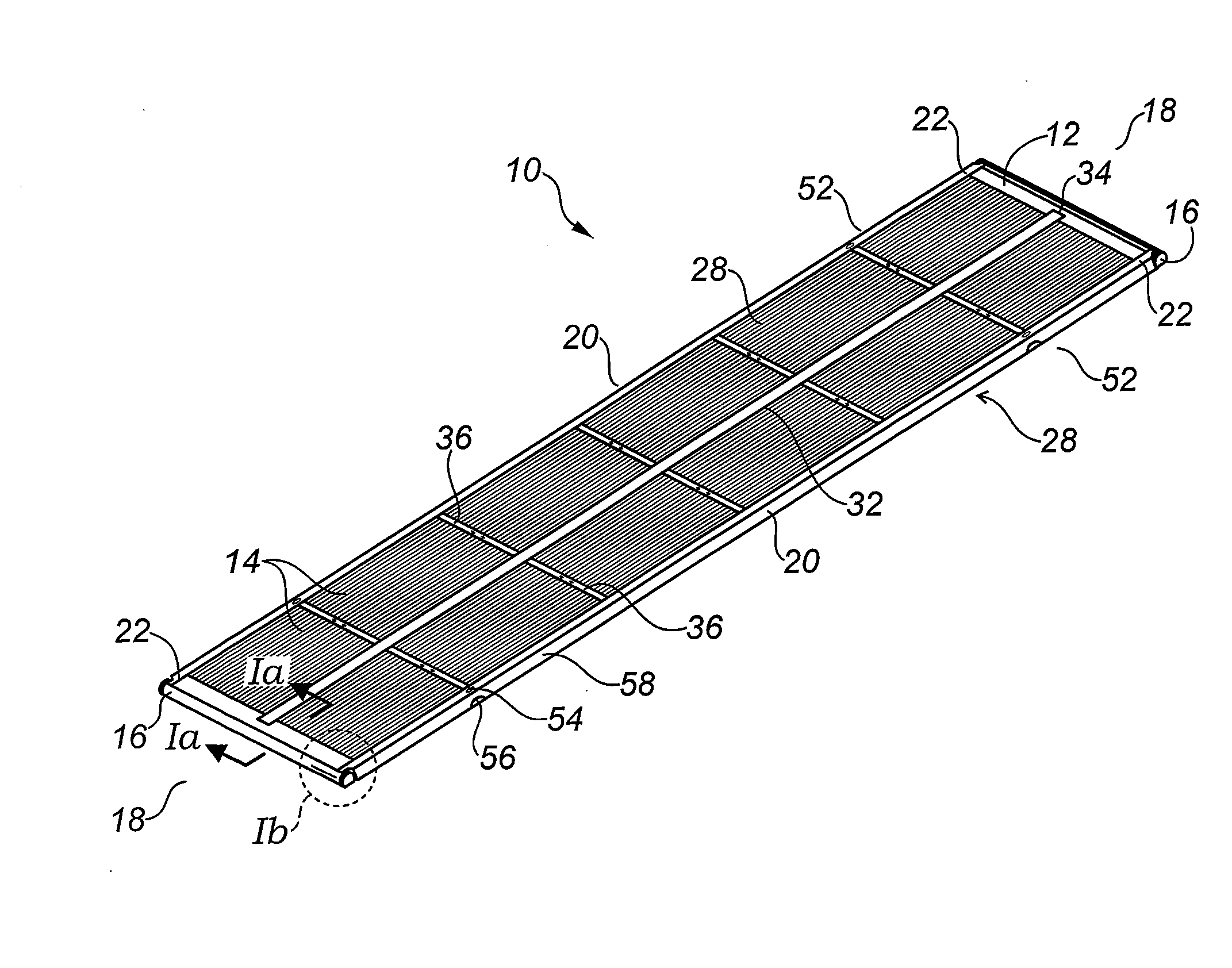

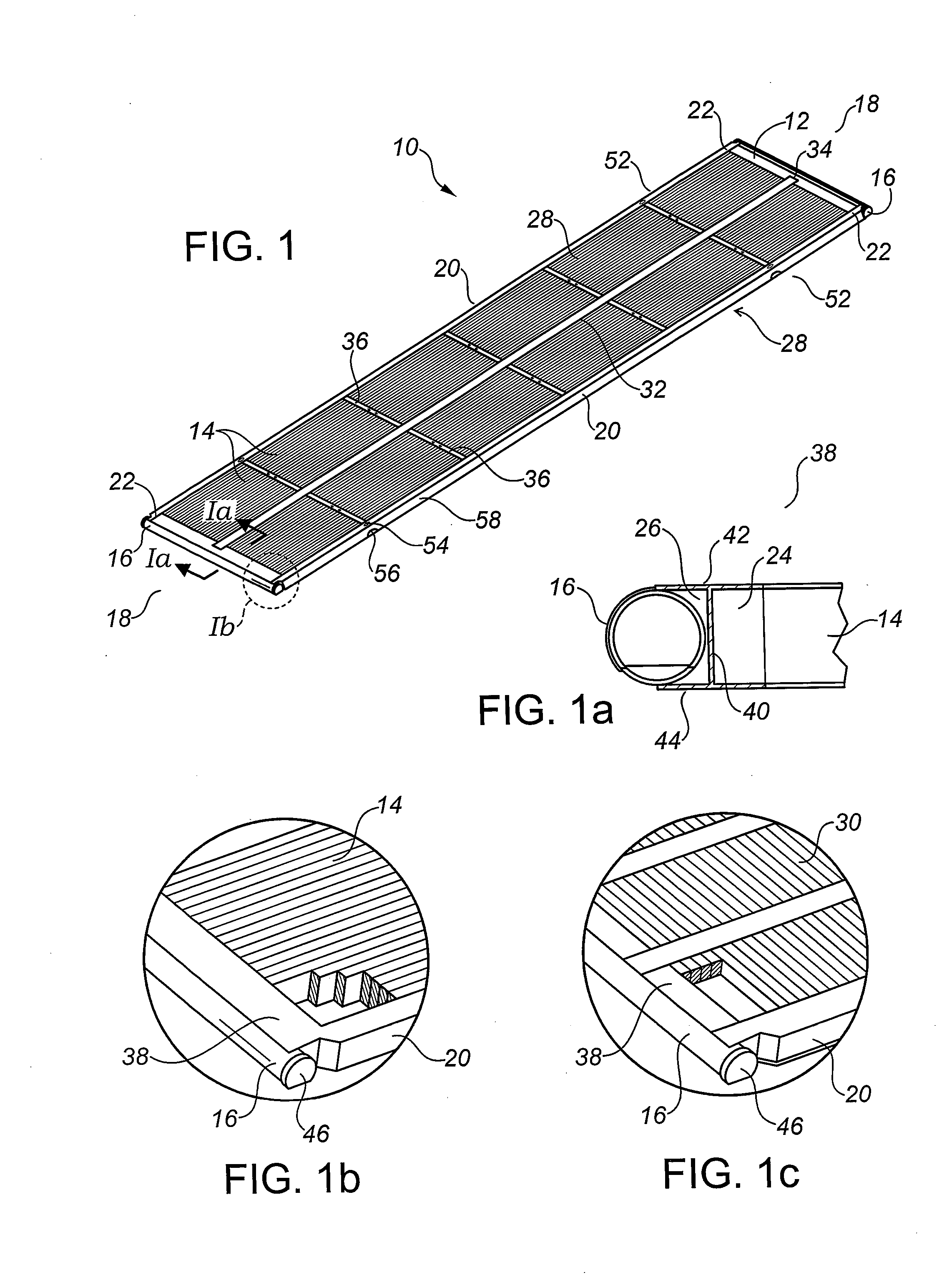

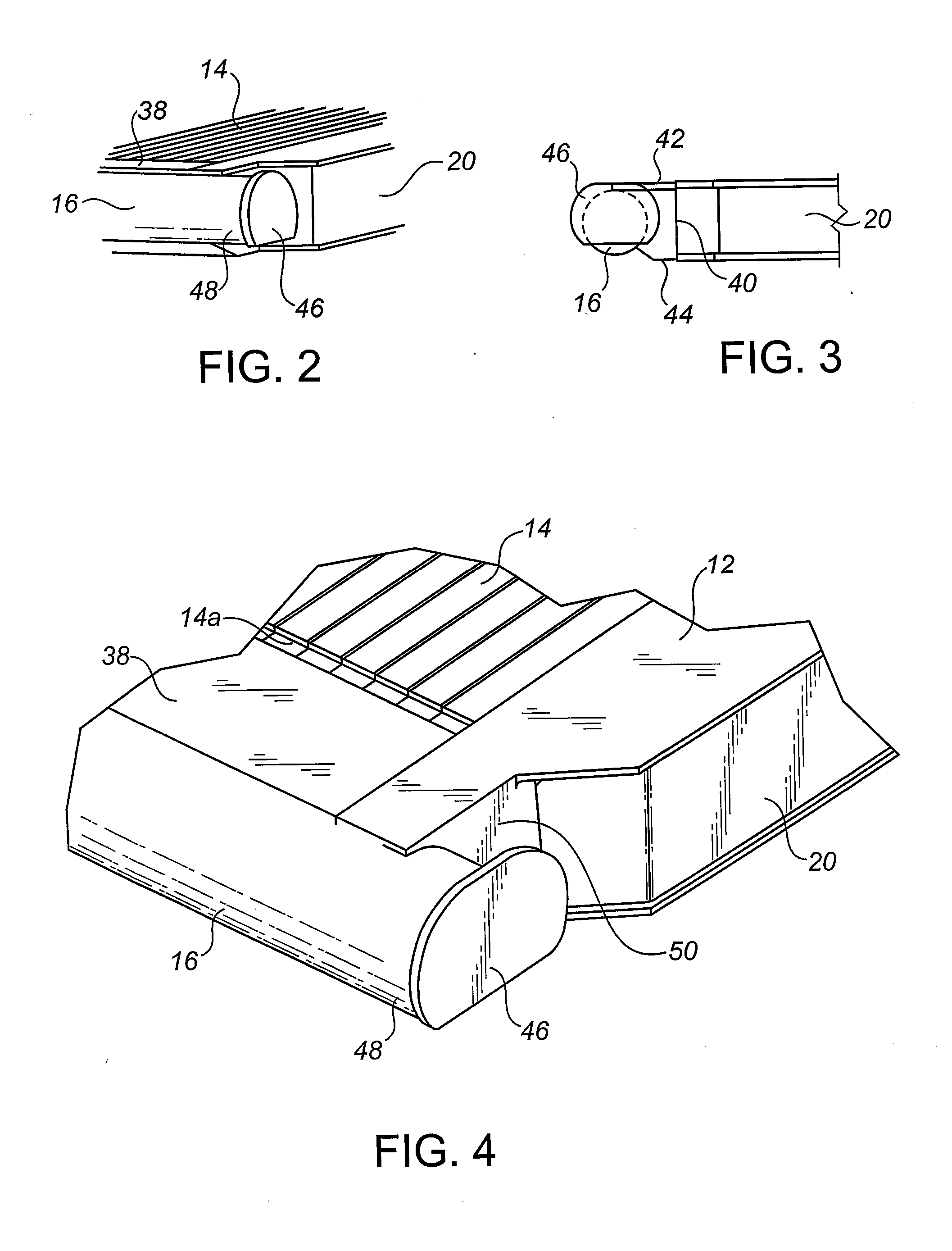

Reinforced ground cover mats

The invention is directed to reinforced ground cover mats which can be used to facilitate the passage of heavy equipment and vehicles on wet or disturbed ground. The ground cover mats are comprised of boards contained within a metal frame. A structural support in the form of an I-beam encases the boards and frame on one side, and a tubular member such as a pipe on the other side, thereby increasing the strength at the middle of the mat ends. Further, the tubular member can be modified at its ends to facilitate insertion of a sling and stacking of adjacent mats. The mat also comprises means for lifting, including passages through which chains or cable may be threaded, lifting shackle assemblies or pear link assemblies.

Owner:MAXXIMAT

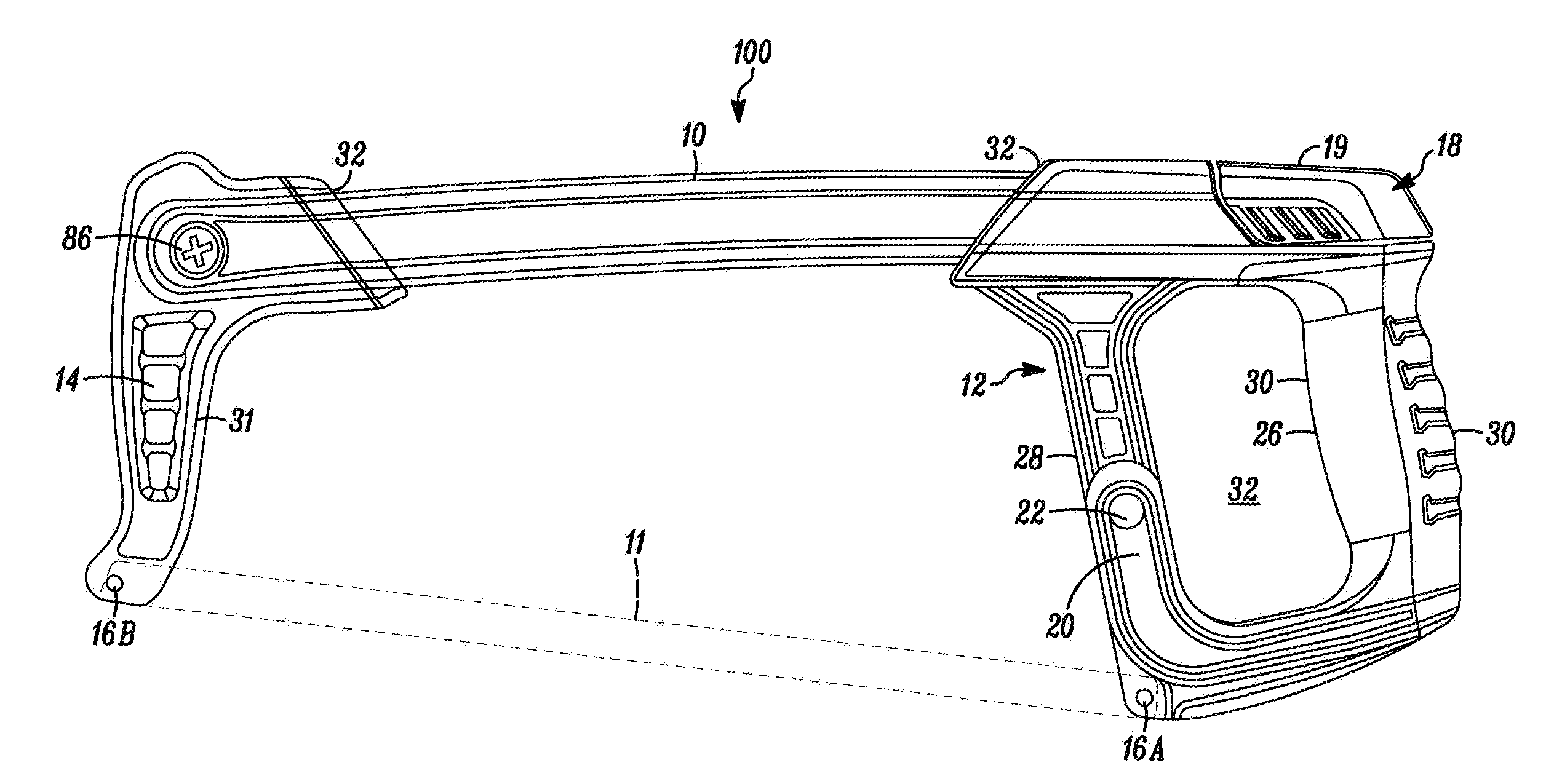

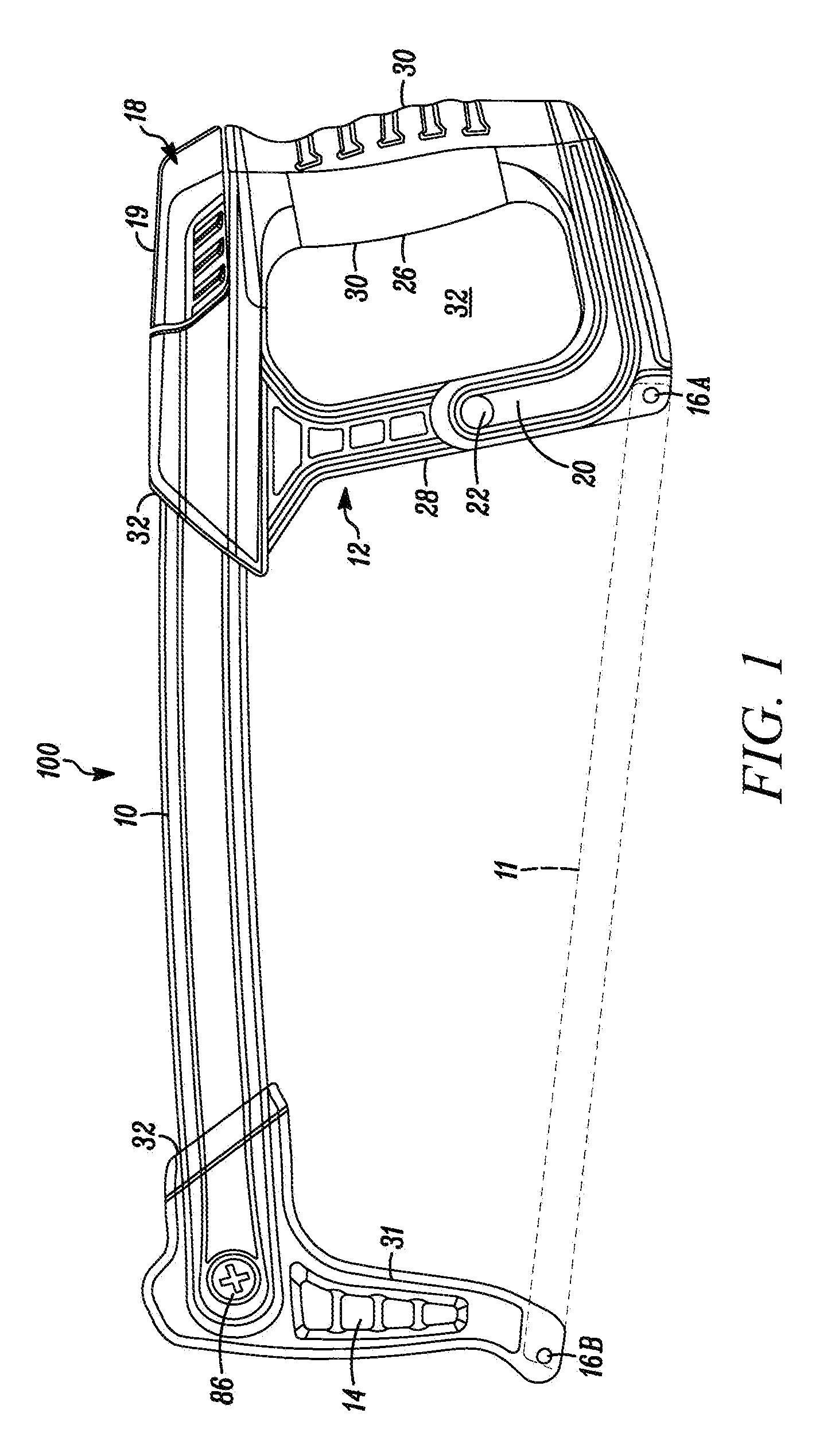

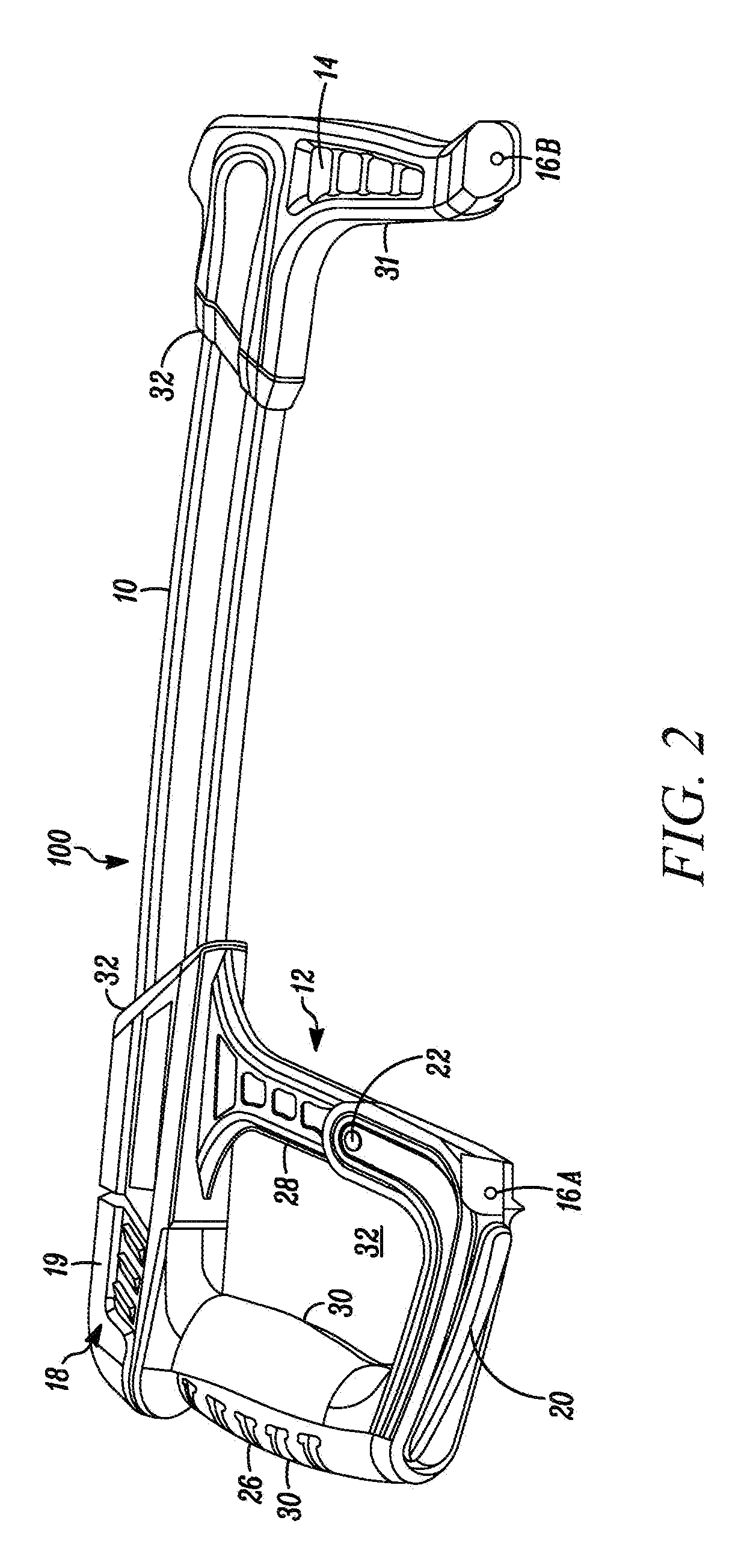

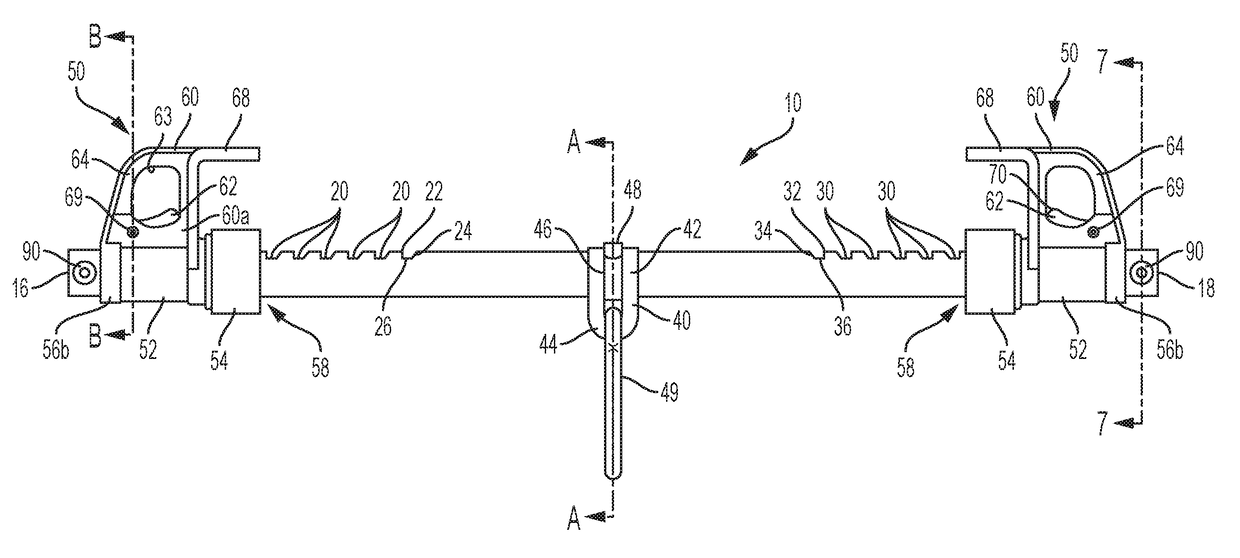

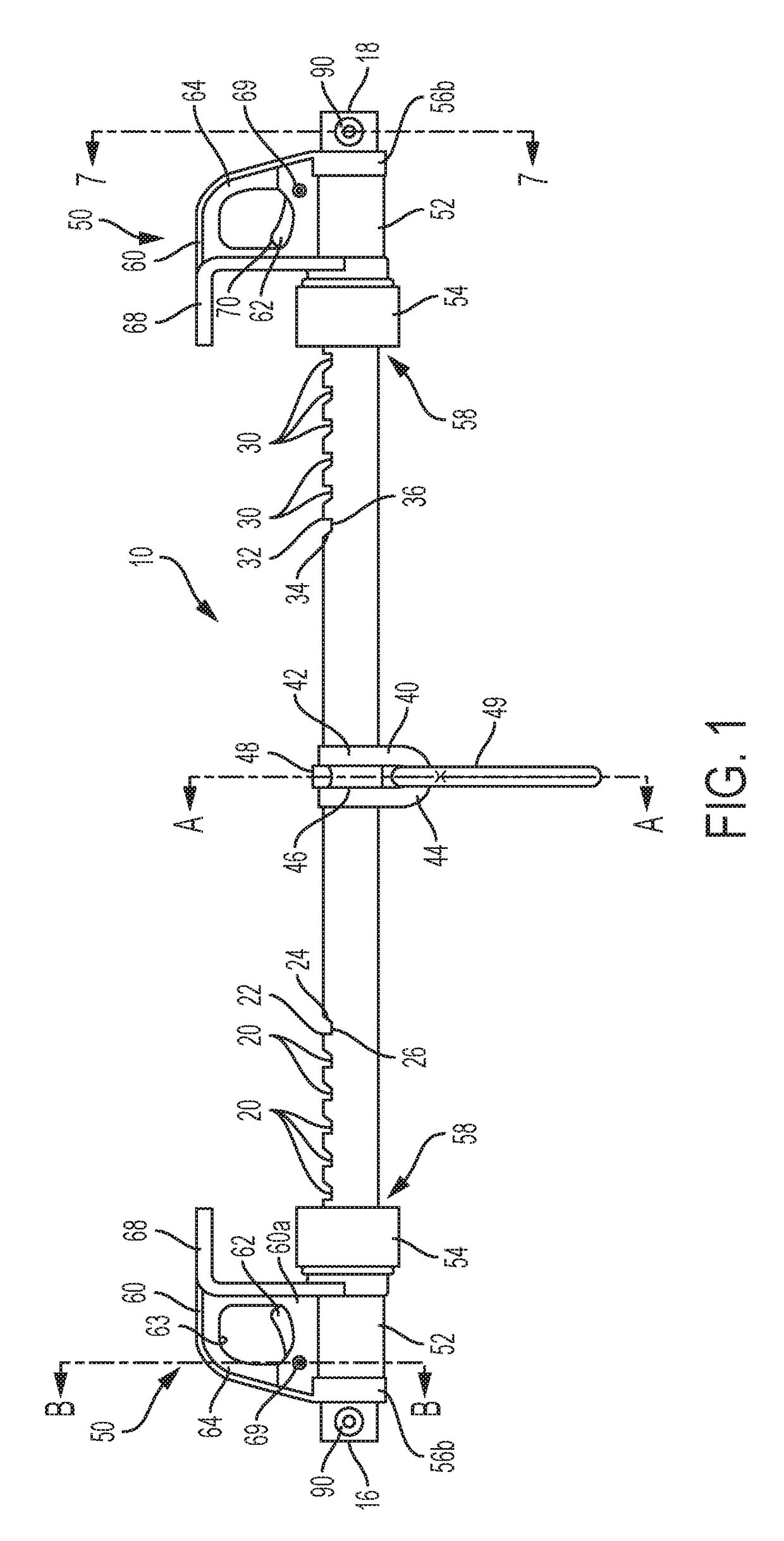

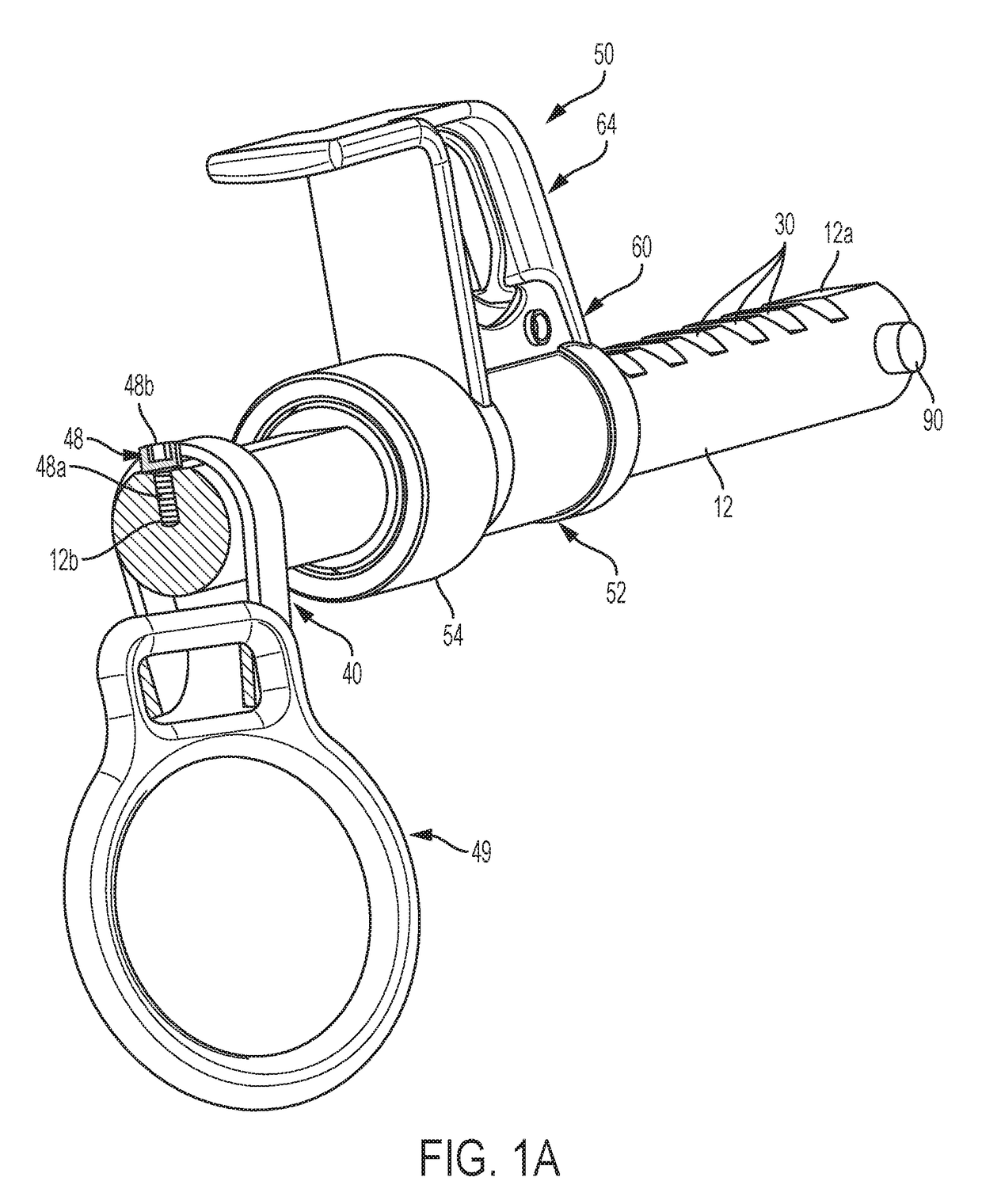

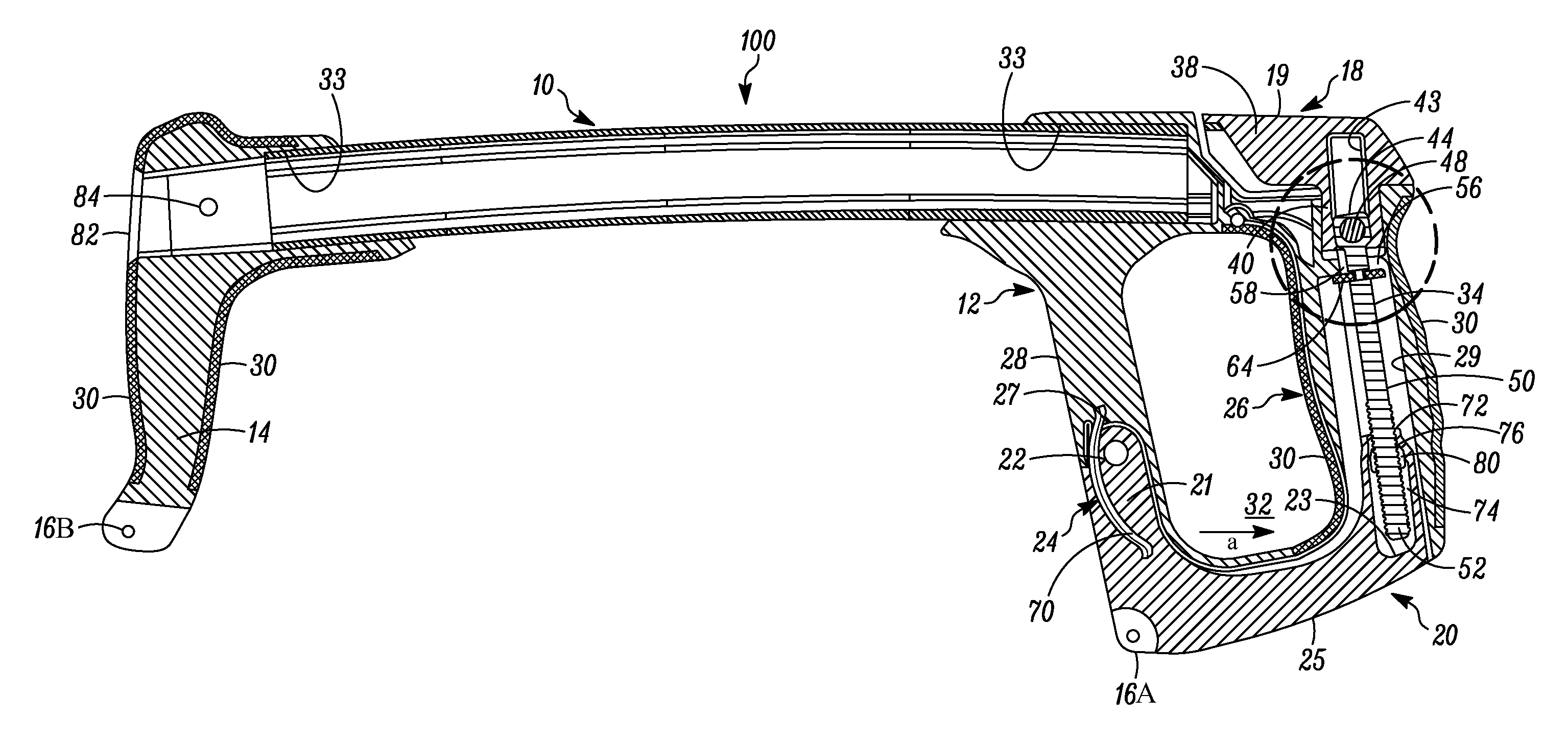

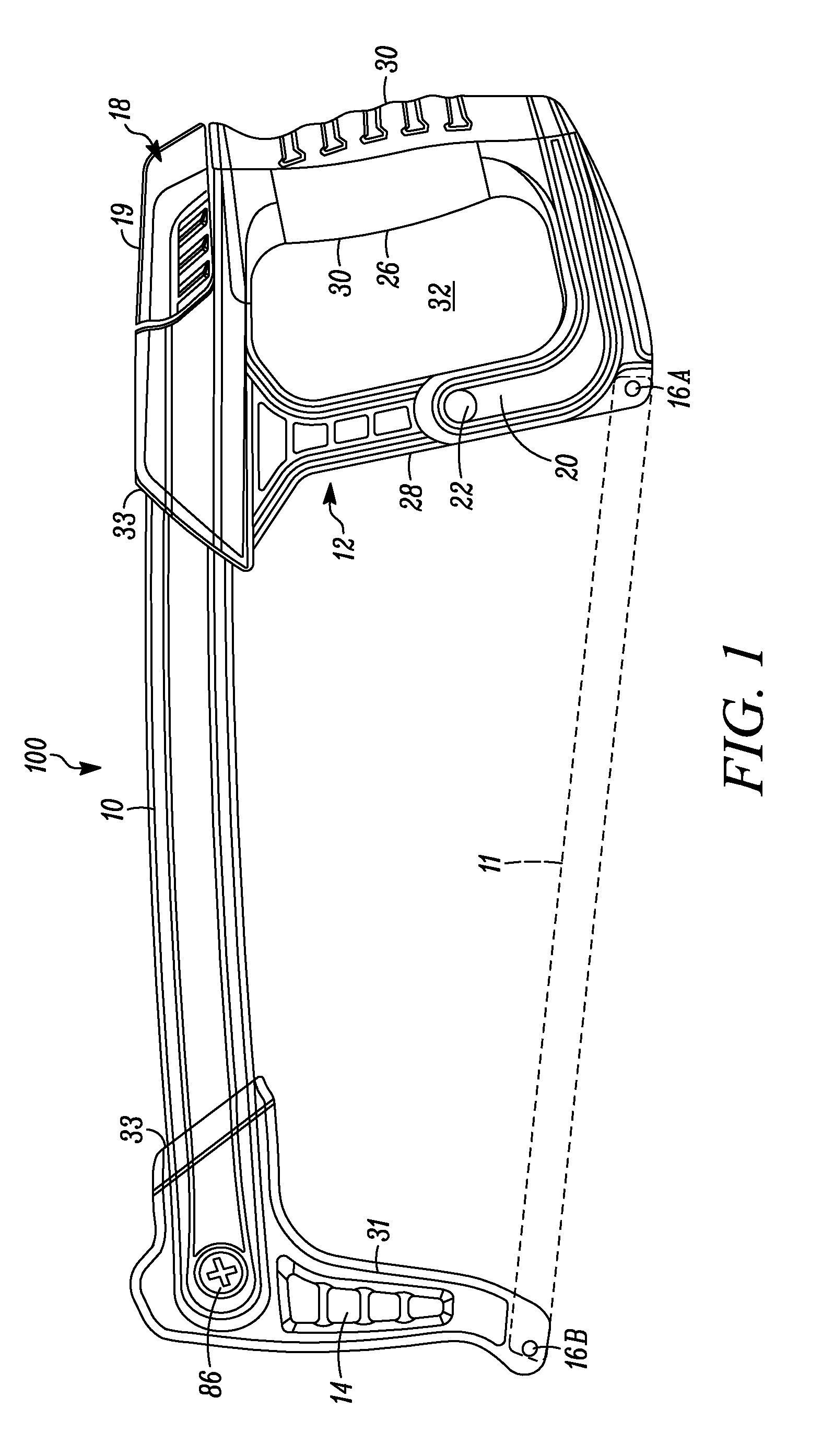

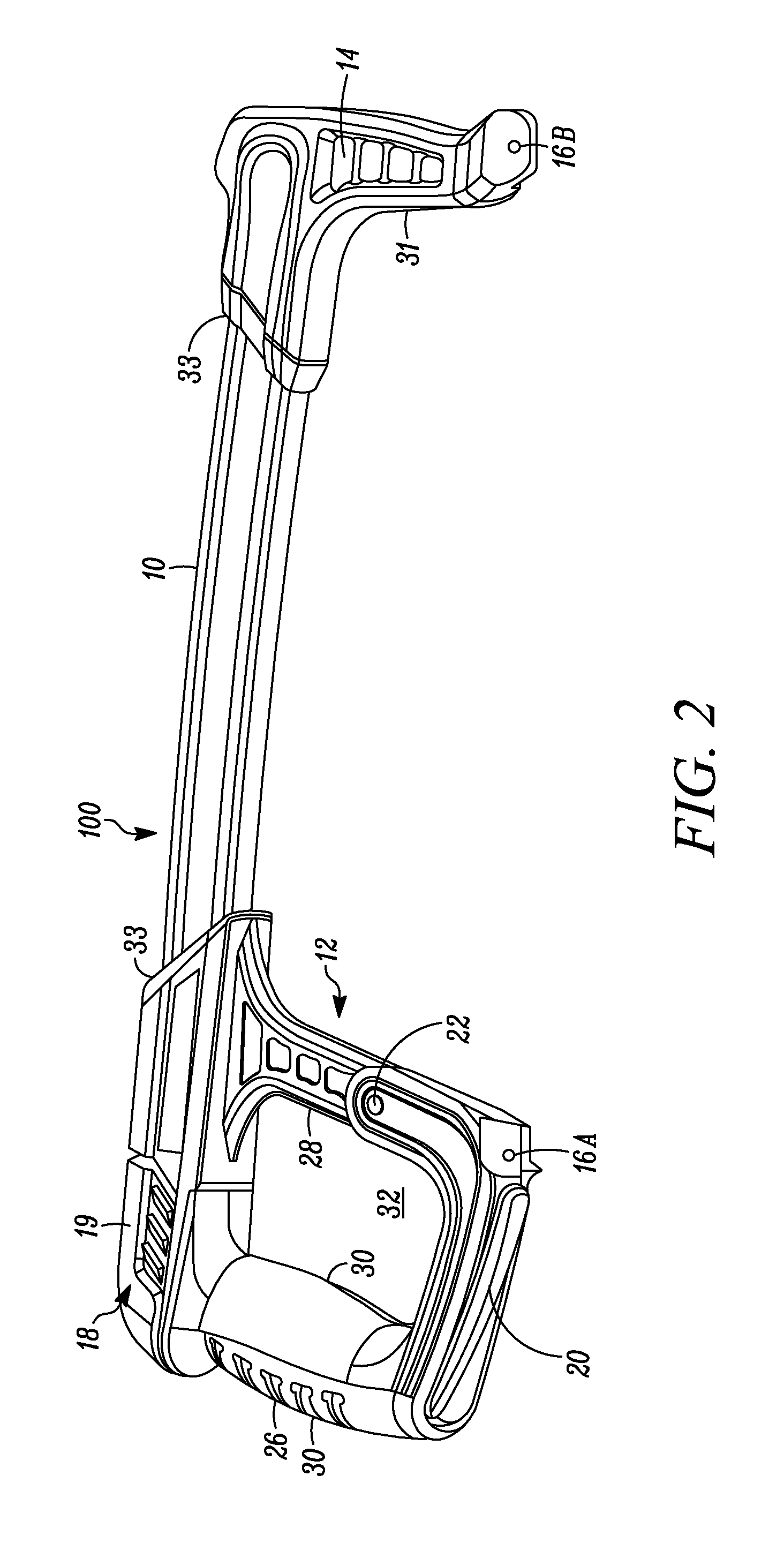

Hacksaw with Blade Tensioning Mechanism

ActiveUS20100132203A1Avoid vertical movementImprove the level ofMetal sawing devicesSawing apparatusEngineeringKnife blades

A hacksaw with an improved mechanism for applying and adjusting the tension on a blade mounted to a blade mount on a front arm and a blade mount on a rocker arm. The rocker arm is pivotally coupled to a handle and is spring biased to place an initial tension on a blade held by the rocker arm and the front arm. A rotatably mounted lever is positioned on the handle for vertically displacing a nut captured in the rocker arm to pivot the rocker arm and adjust the tension on the rocker arm-held blade. An elongate top frame bar of the hacksaw defines a hollow I-beam cross-section accessible from the face of the front handle and is capable of storing saw blades. A bale screw is positioned in the front member for securing the blades in a position extending past the front handle.

Owner:BLACK & DECKER INC

Wedge clamp

A wedge clamp providing for a positive attachment to structural angles, I-beams, H-beams, T-bars, plates, boards, conventional angles, bulb angles, channels, plates and other similar structural shapes comprises a clamp wedge and body that capture objects with two opposing surfaces securing the objects against each other using a fastener or other means to engage both parts of the clamp to pull the wedge through the body and causing the objects being attached together to be squeezed together. The wedge clamp is also used to support other members using a bolt or threaded rod attached to the wedge clamp which in this case normally attaches to a single flange of the structure.

Owner:MYERS MELVIN L

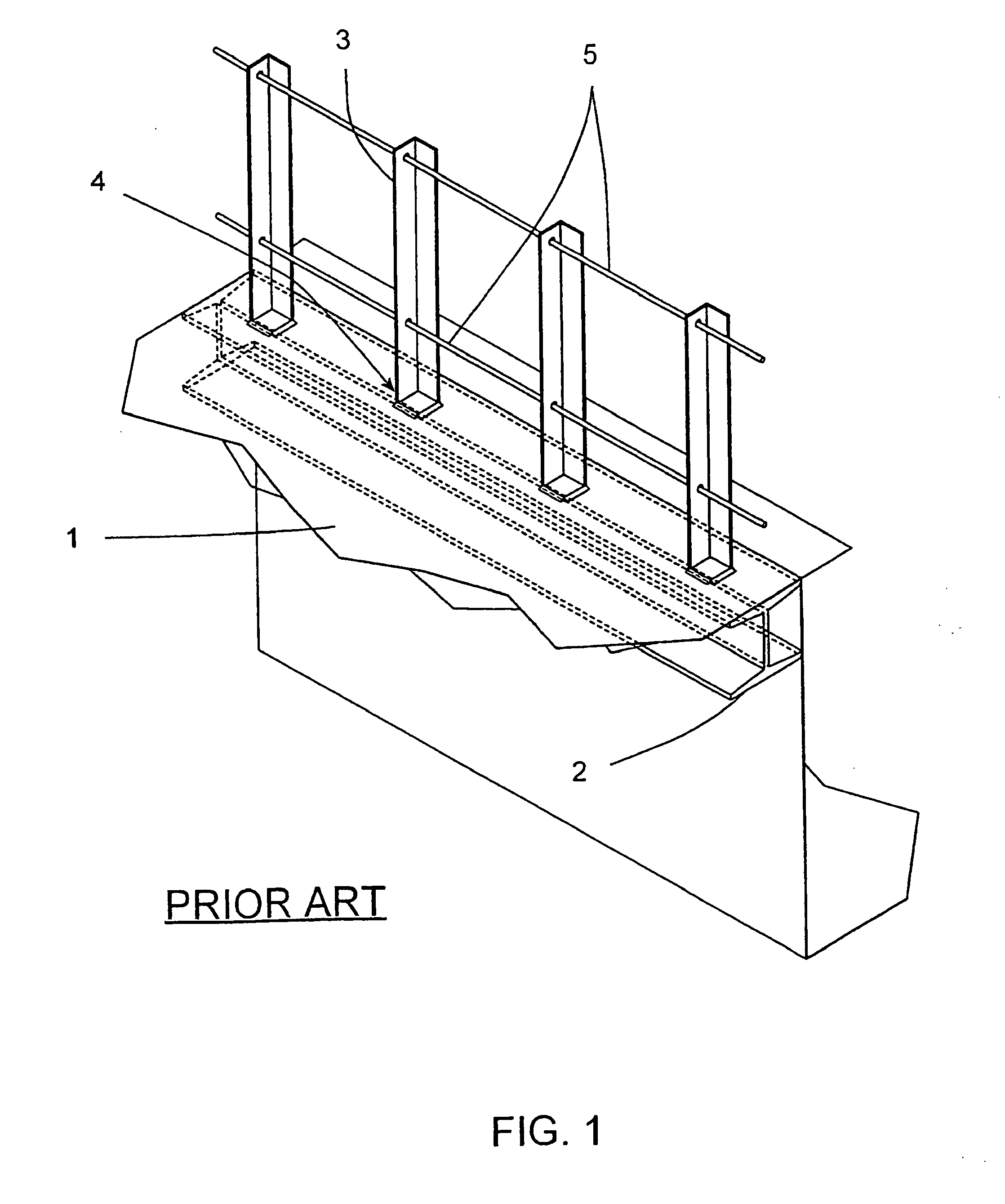

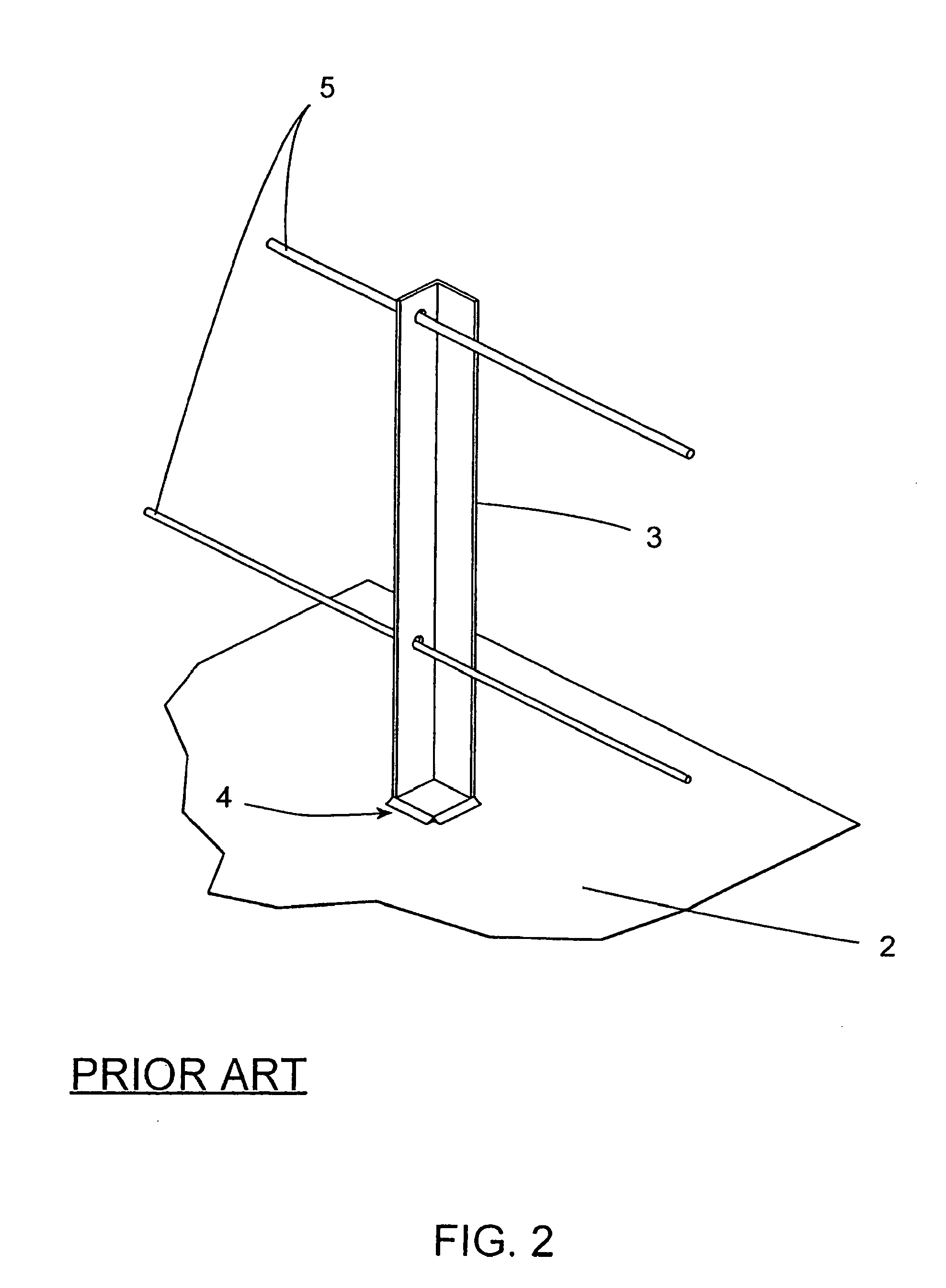

Reusable fall restrain supports and fall arrestor

A system for providing re-usable safety support fences and fall restraints for the construction industry. The system comprises a plurality of disposable bases which are welded to I-beams or otherwise permanently attached to a floor or roof, and a plurality of removable support posts that screw into the disposable bases. The support posts form the posts of a safety fence through which steel cables are threaded to form a fence. Also, a fall arrestor, comprising an eye hook onto which a construction or maintenance worker on the perimeter of a building may attach, can be screwed into the permanently mounted disposable base. Additional embodiments for use with concrete construction instead of steel I-beams are disclosed.

Owner:PERIMETER PROTECTION PROD LLC +1

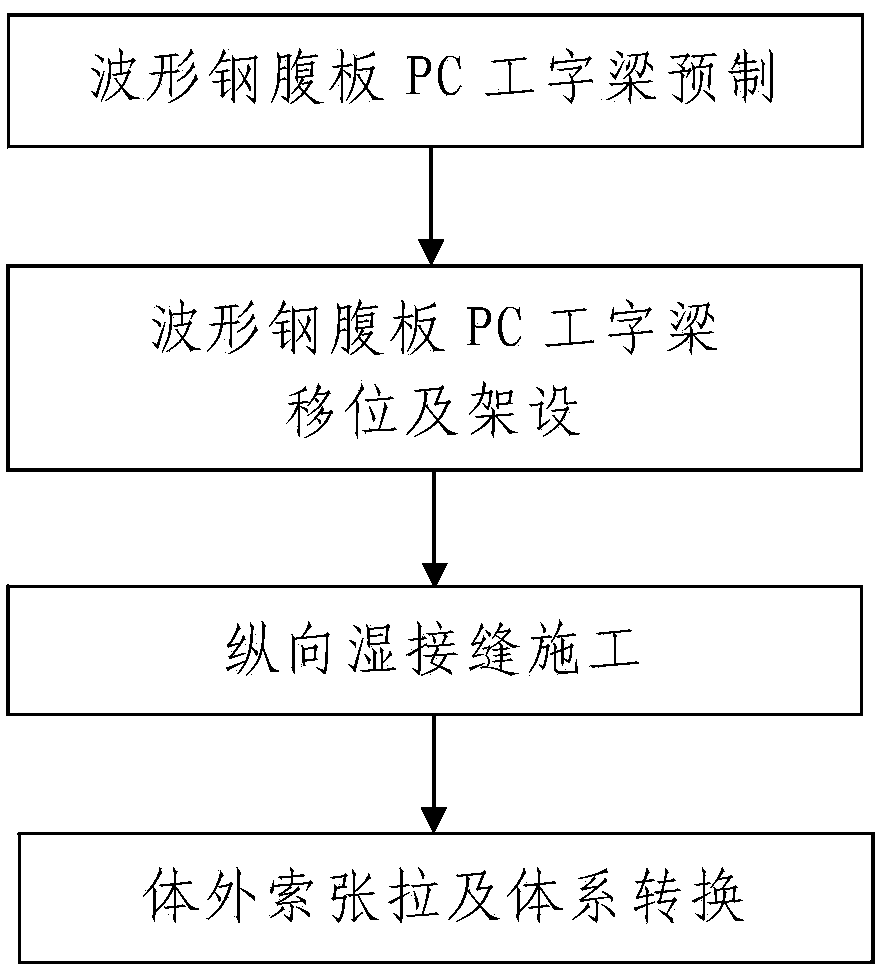

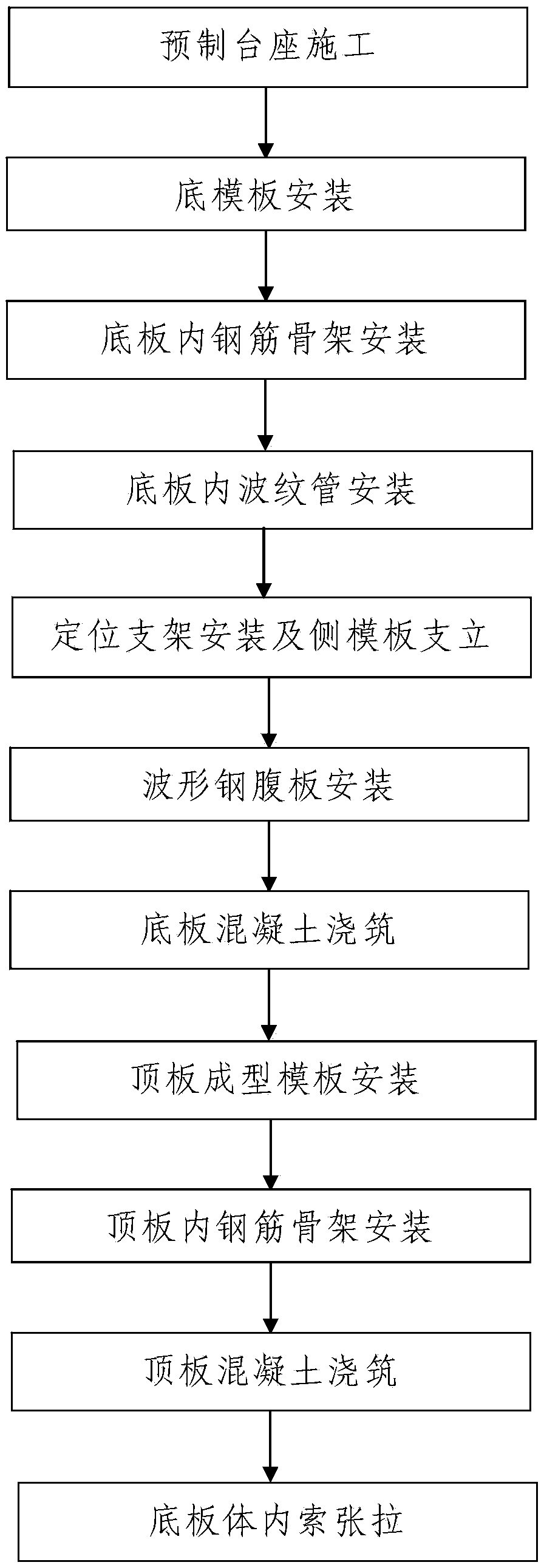

Construction technology for prefabricating a corrugated steel web PC I beam into combined box girder bridge

ActiveCN104195959ASimple structureEasy constructionBridge erection/assemblyBridge materialsEngineeringRebar

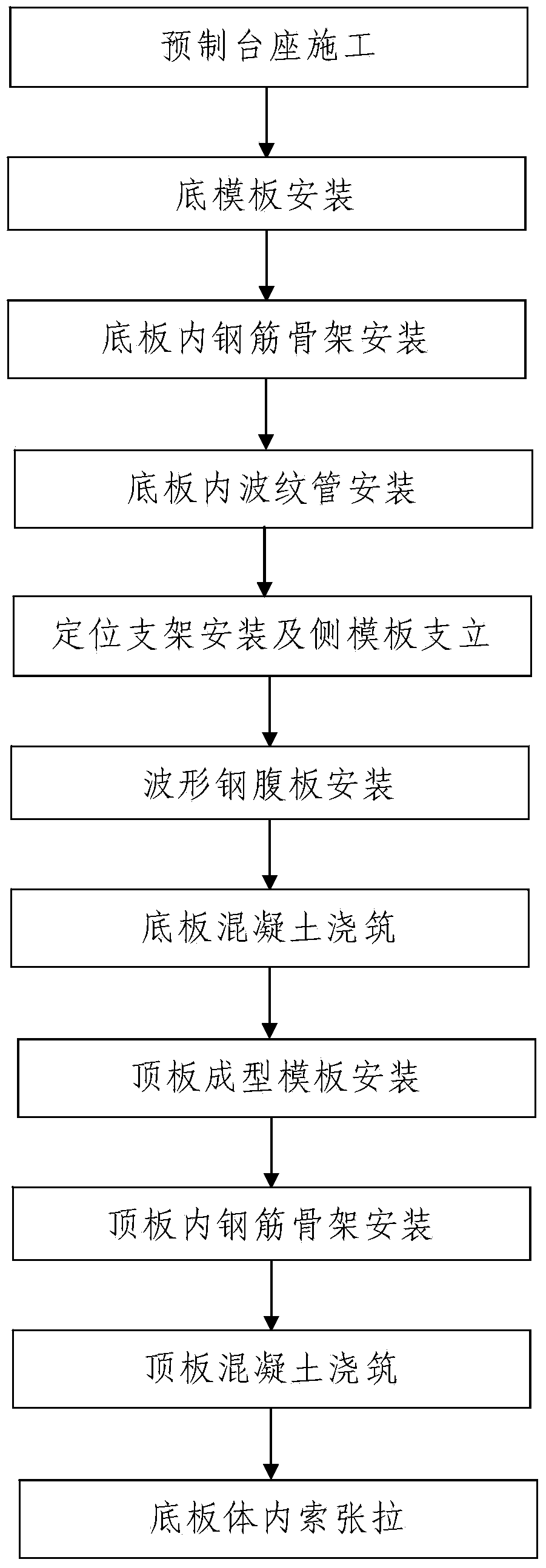

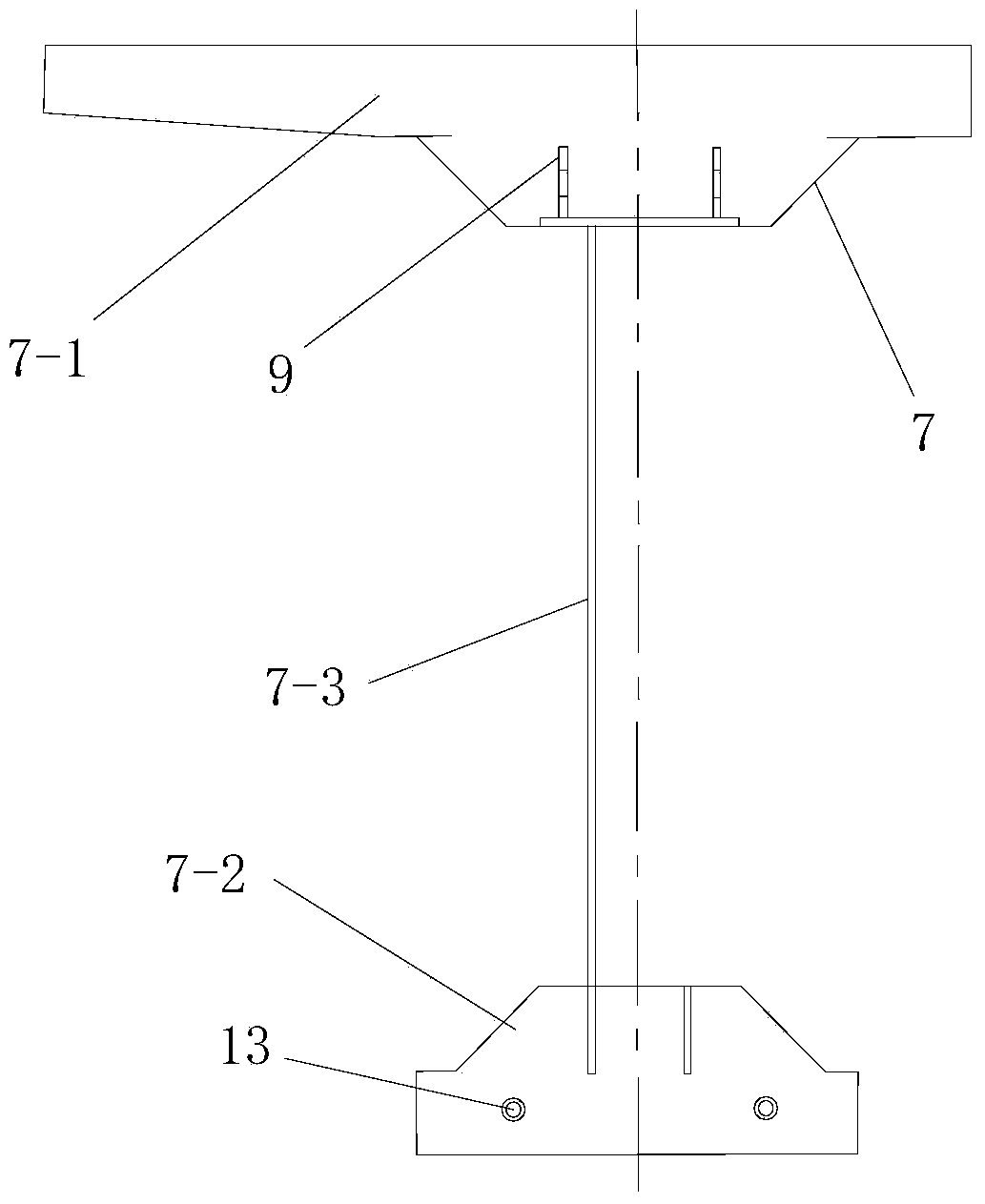

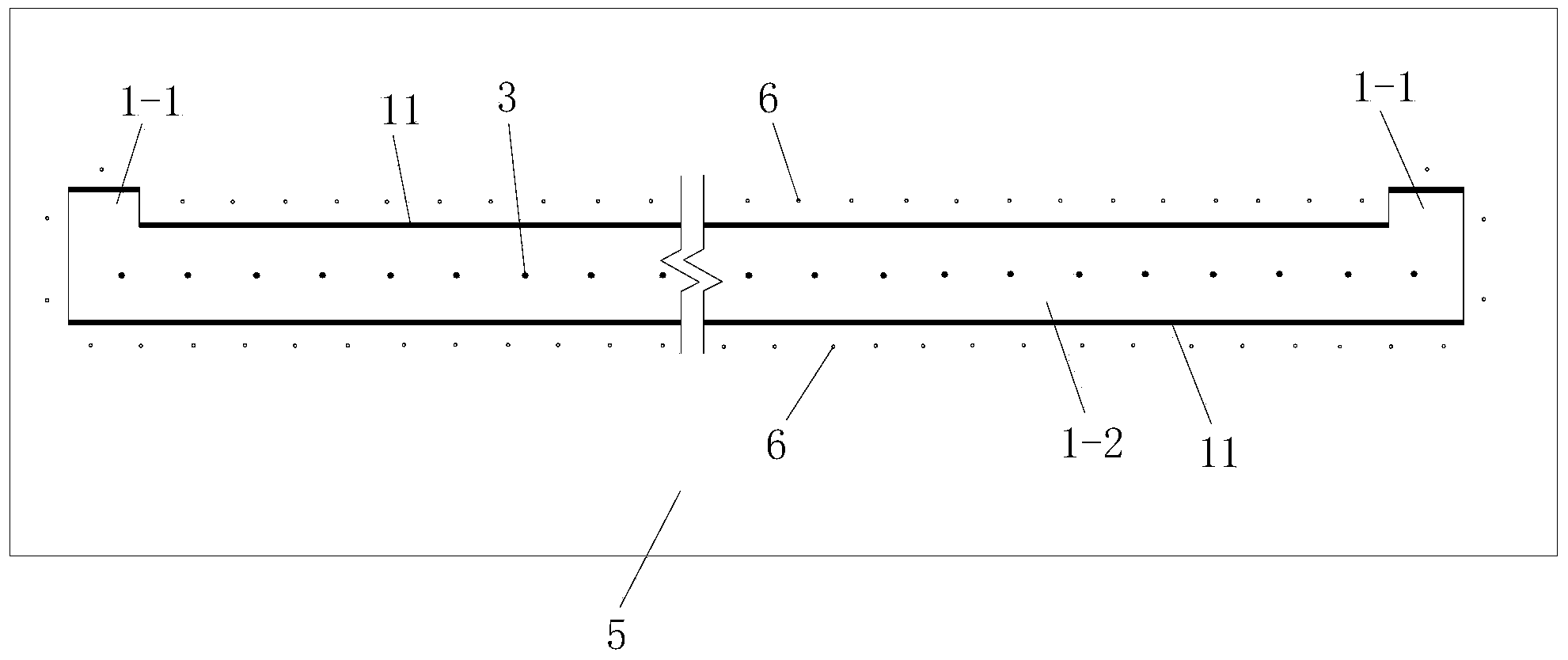

The invention discloses a construction technology for prefabricating a corrugated steel web PC I beam into a combined box girder bridge. Each combined box girder segment in a combined box girder of the combined box girder bridge is formed by connecting two corrugated steel web PC I beams. The construction technology comprises the following steps: Step I, prefabricating the corrugated steel web PC I beams: pedestal prefabricating construction, installation of a soffit formwork, installation of a reinforcement cage in a bottom plate, installation of a corrugated pipe in the bottom plate, installation of a positioning bracket and erection of a side formwork, installation of a corrugated steel web, pouring of concrete on the bottom plate, installation of a top plate molding template, installation of the reinforcement cage in a top plate, pouring of concrete on the top plate, and stretch-drawing of a cable in the bottom plate; Step II, displacement and erection of the corrugated steel web PC I beams; Step III, lengthways wet joint construction; Step IV, stretch-drawing of a cable out of the bottom plate and system conversion. According to the invention, the processing steps are simple, the design is reasonable, the implementation is convenient, the construction period is short, the construction quality is high, pedestal prefabricating and the positioning bracket are combined to complete bridge prefabrication, and the construction quality of the combined box girder bridge can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

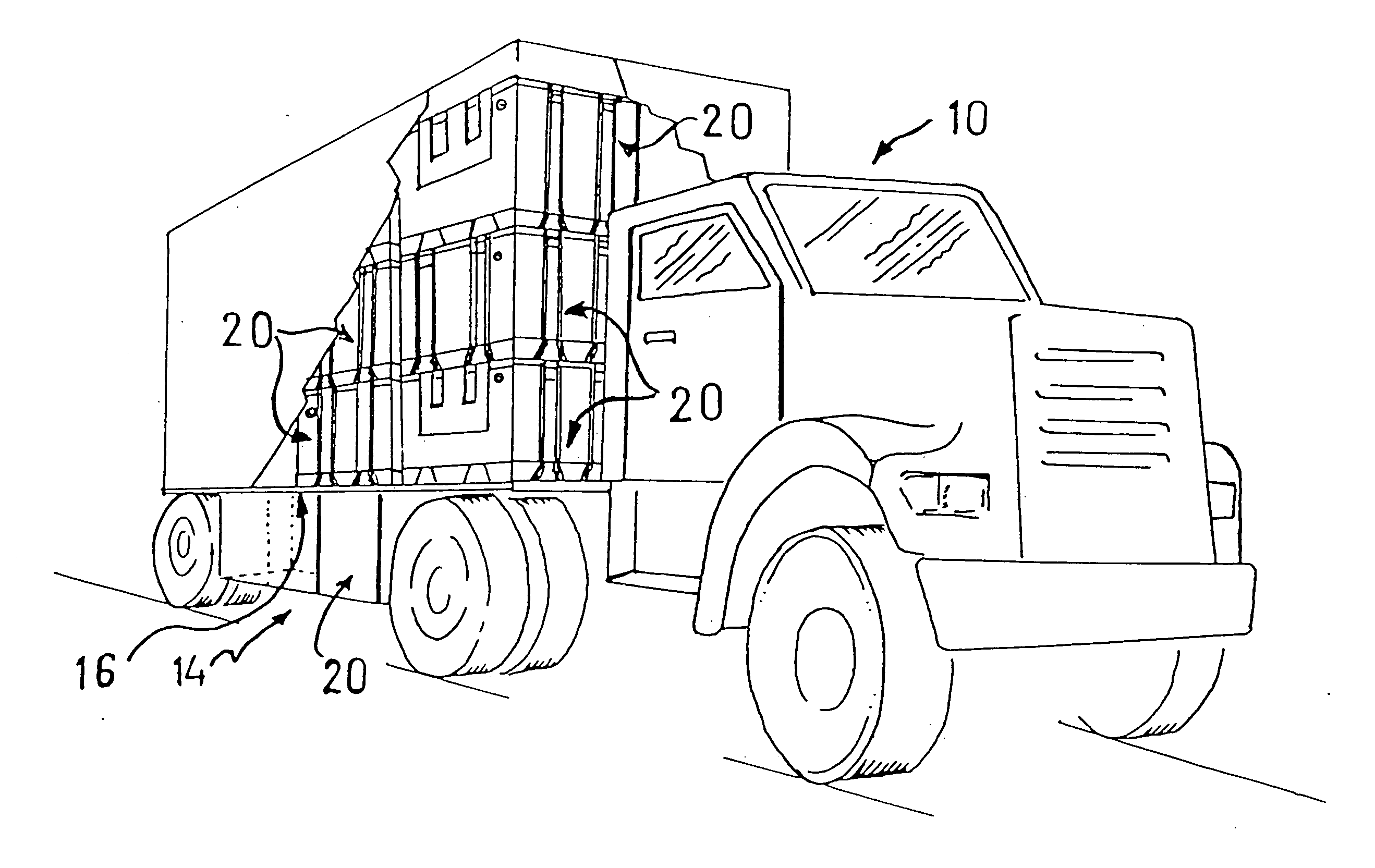

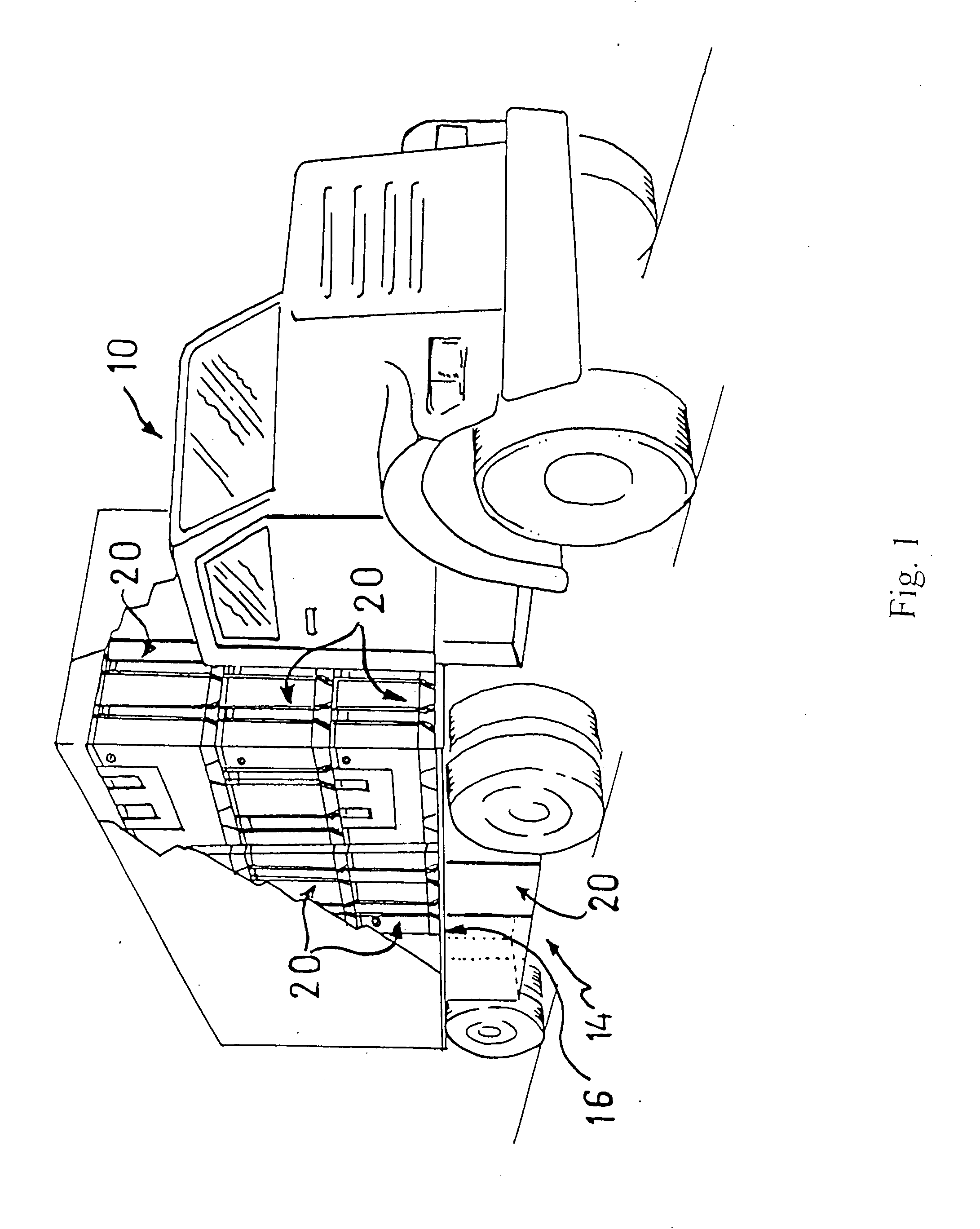

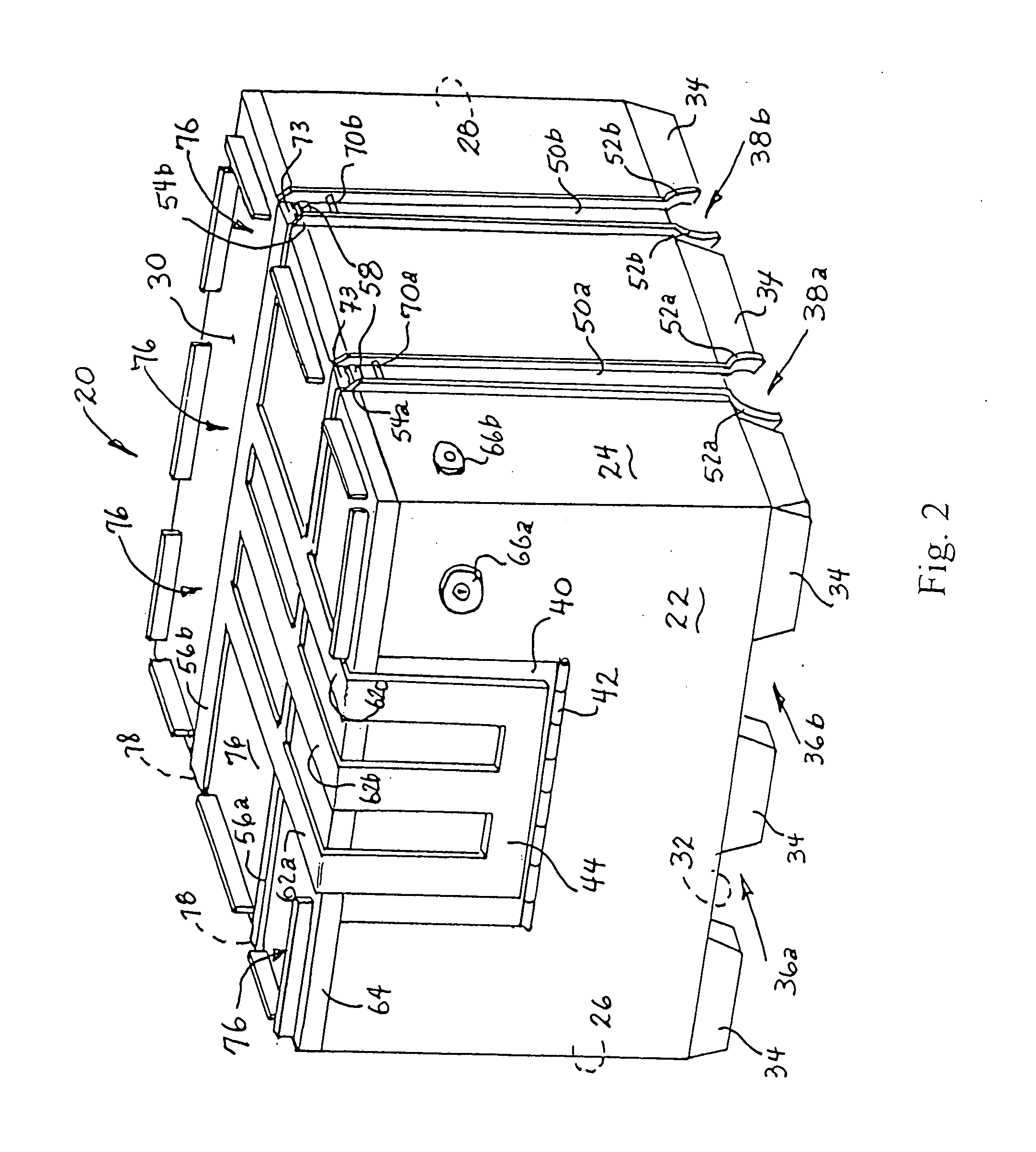

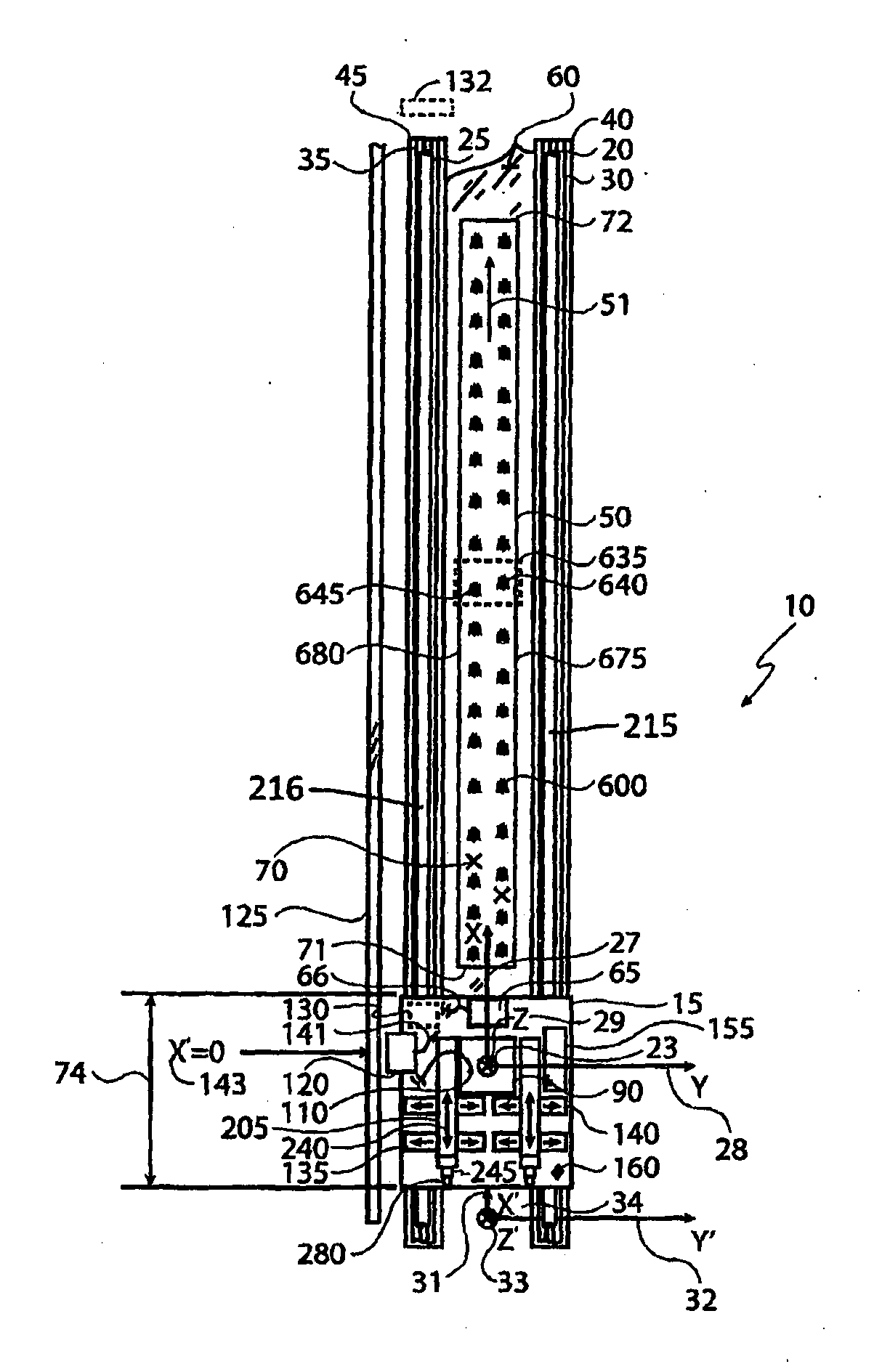

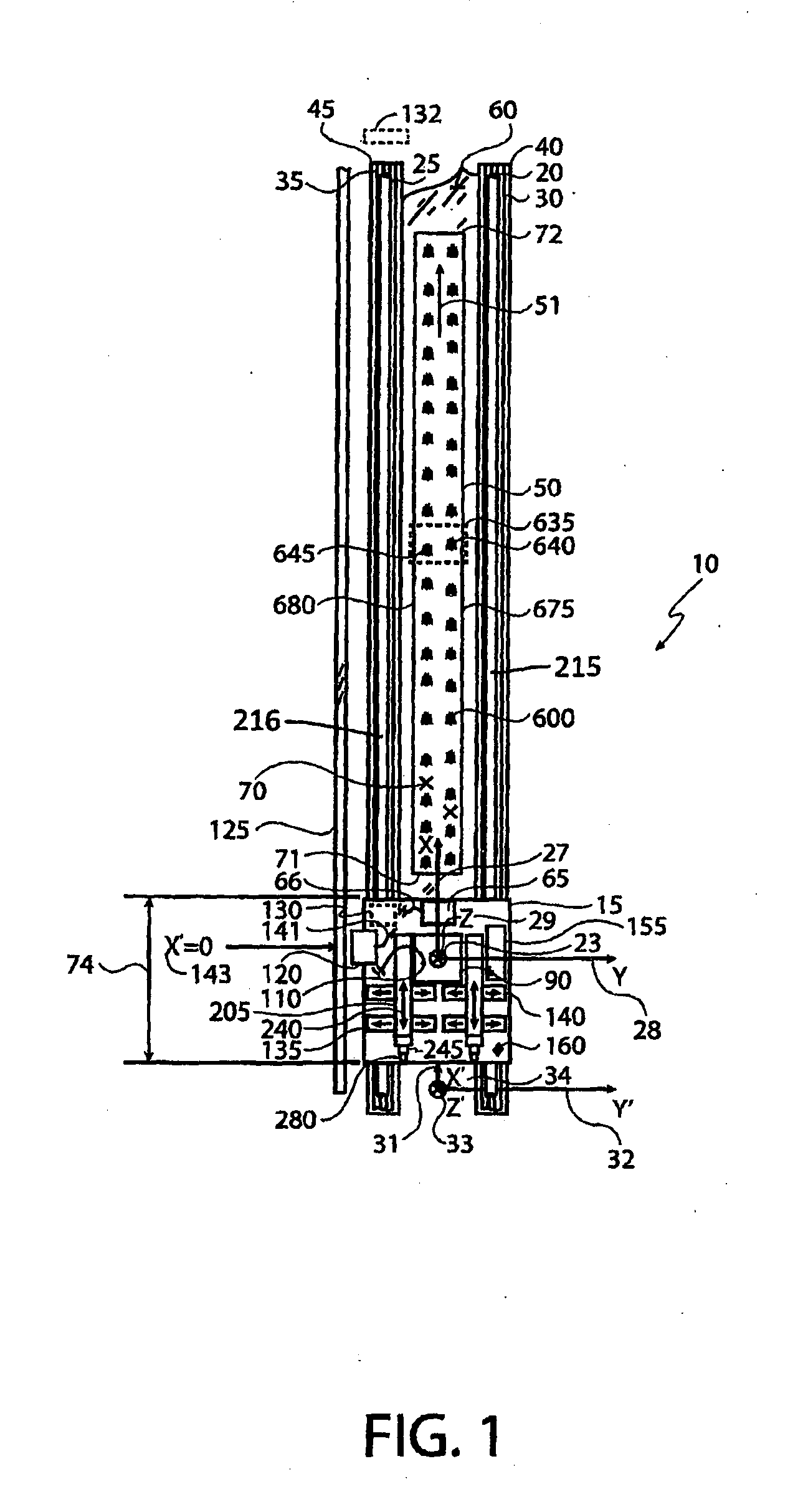

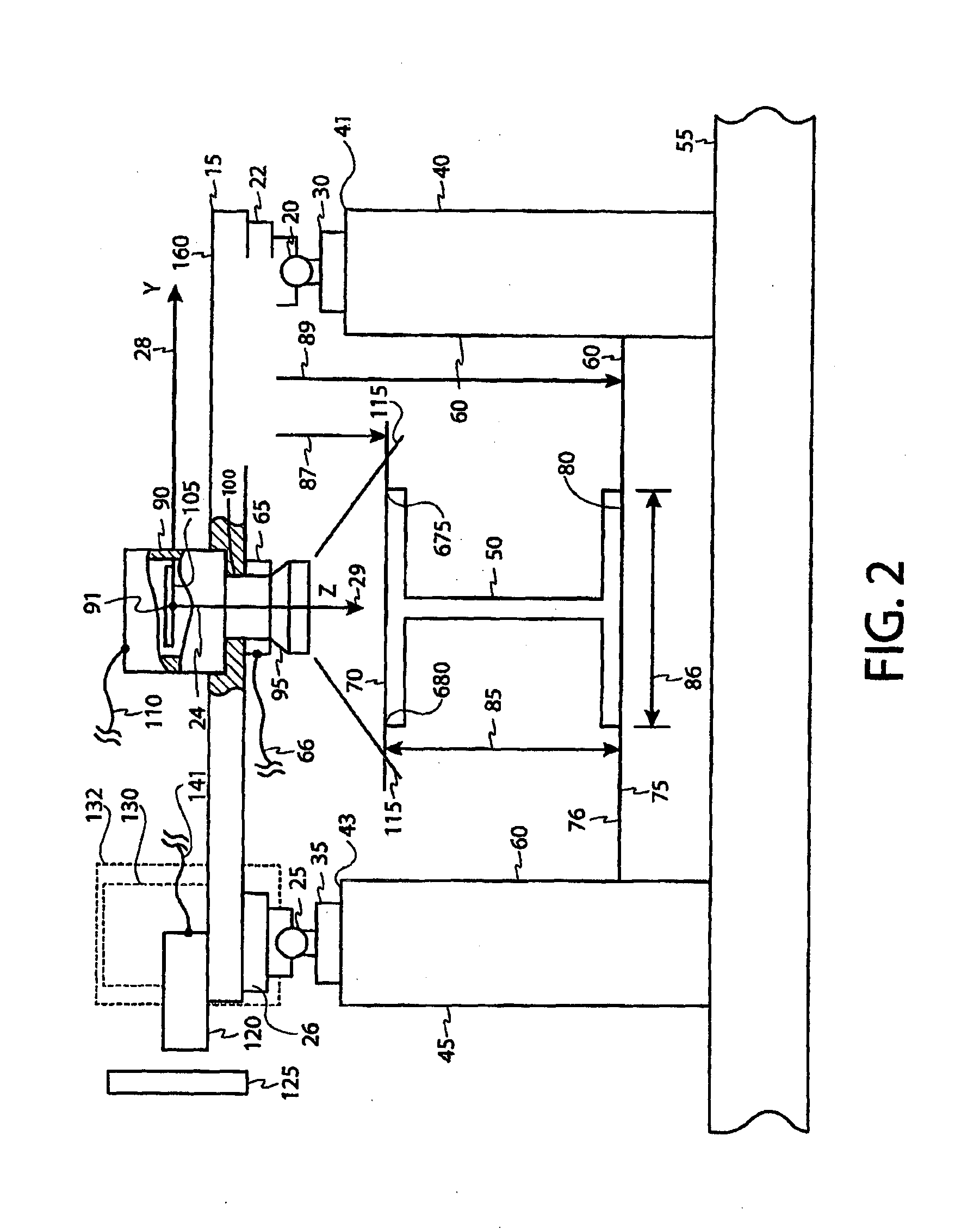

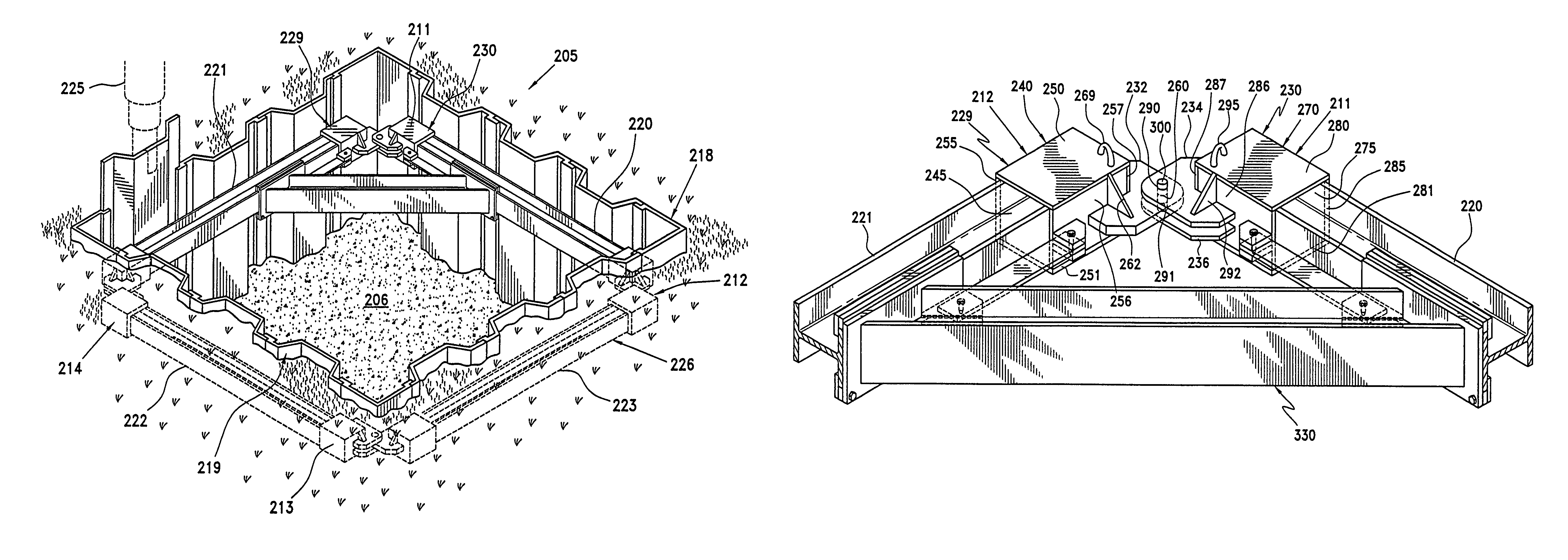

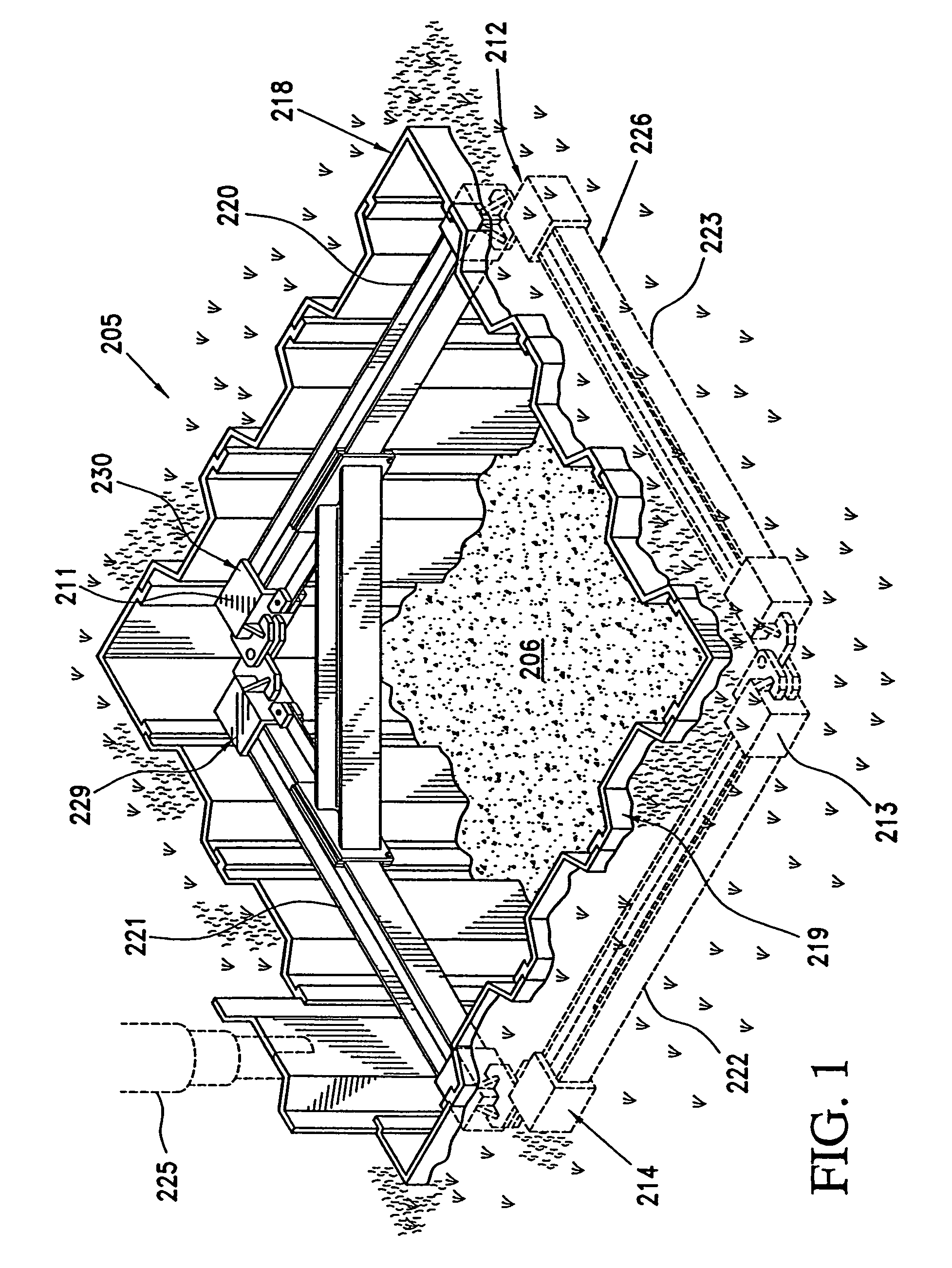

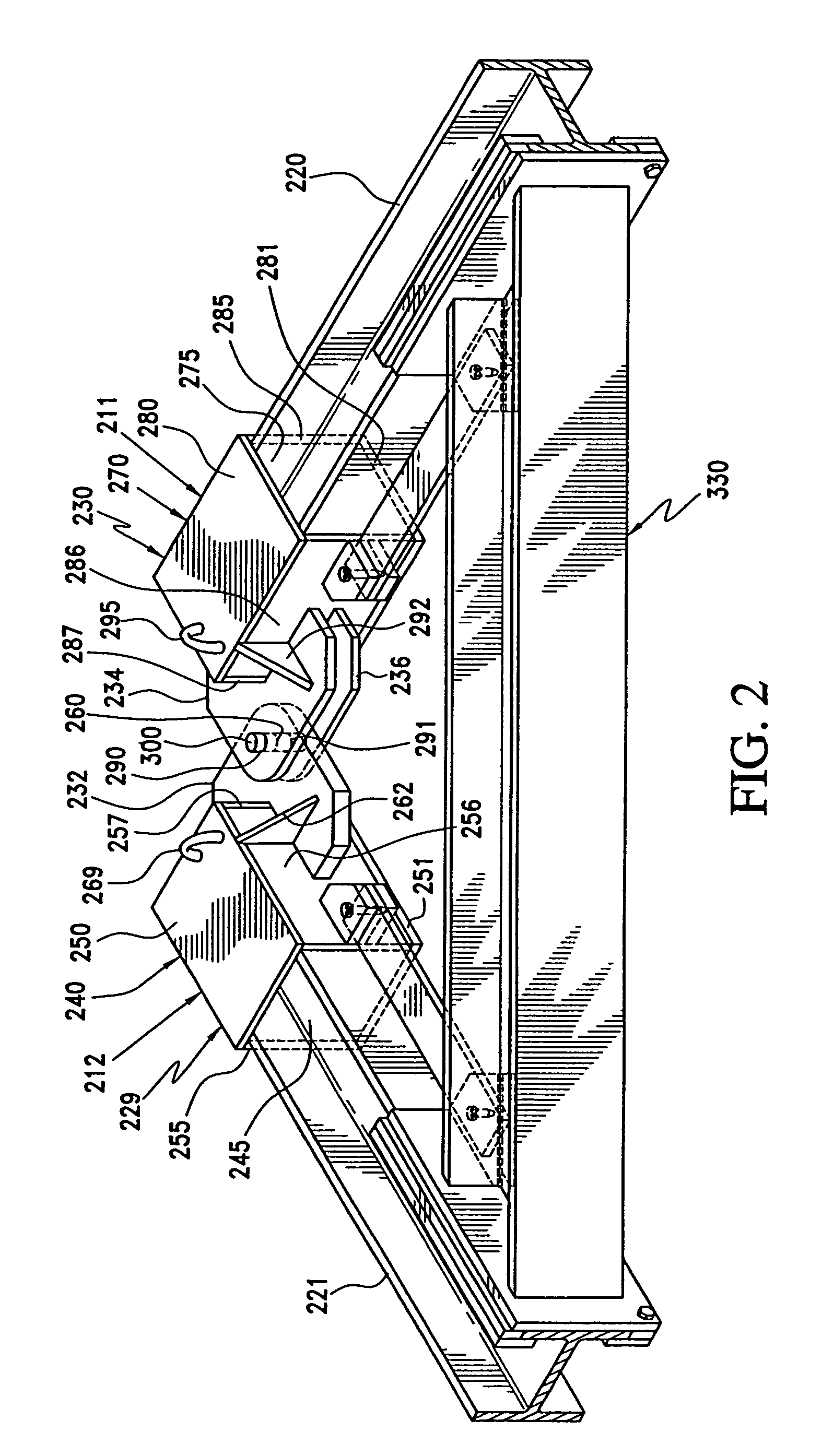

Private pallet-box cargo shipping system

A cargo transportation system comprising secure (fully closeable and lockable), sealable, stackable, trackable, universal, auto-latching “pallet boxes” that may be used in two main ways: 1) secured to the undercarriage transverse I-beams of over-the-road semi-trailers by means of loading alignment and hanger assemblies that provide positive locking-in-place; and 2) stackable, up to three or more high, inside the trailer bodies. The inventive pallet boxes are designed to be secured by auto-latching hanger assemblies that are retrofittable on individual types of semi-trailer undercarriages, both US and metric (European, Central and South American, and Asian) standard dimensions. The pallet boxes include vertical sidewall load-bearing channel members permitting stacking fully-loaded pallet boxes three or more high. The pallet boxes may be refrigerated, insulated, or atmospherically controlled, e.g., chargeable with preservative, security or disinfecting gases, during shipping.

Owner:VERDASEE SOLUTIONS +1

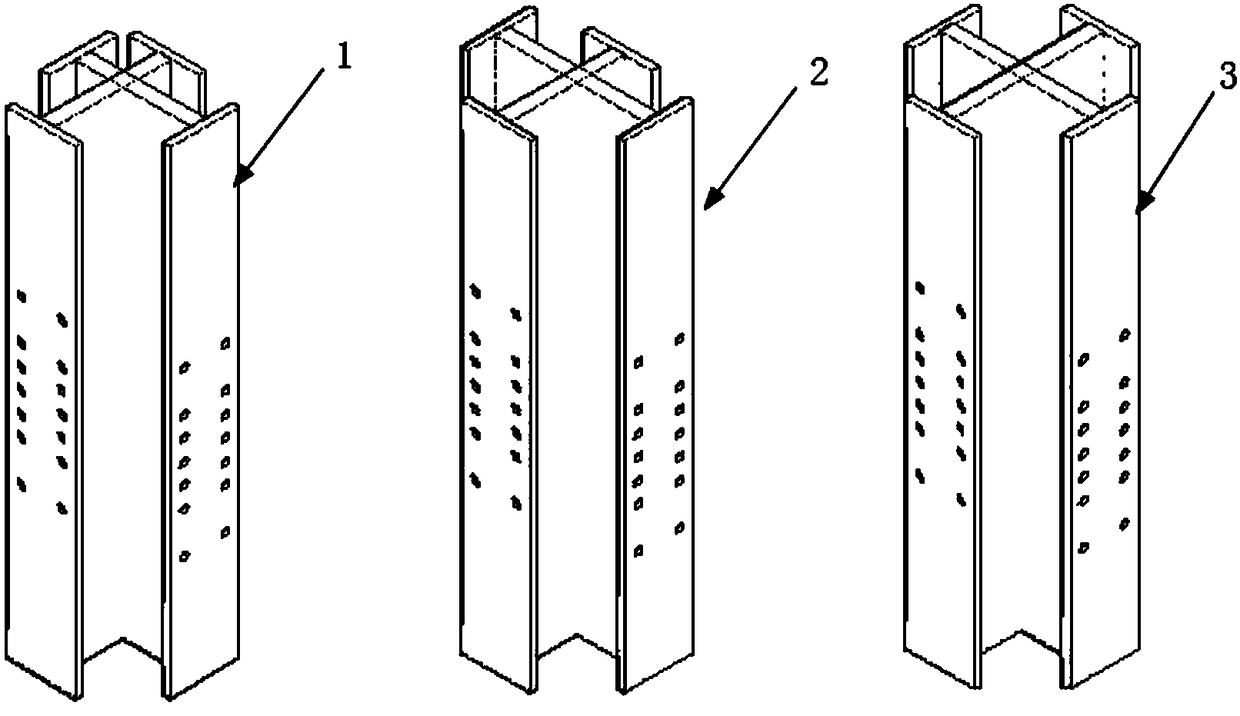

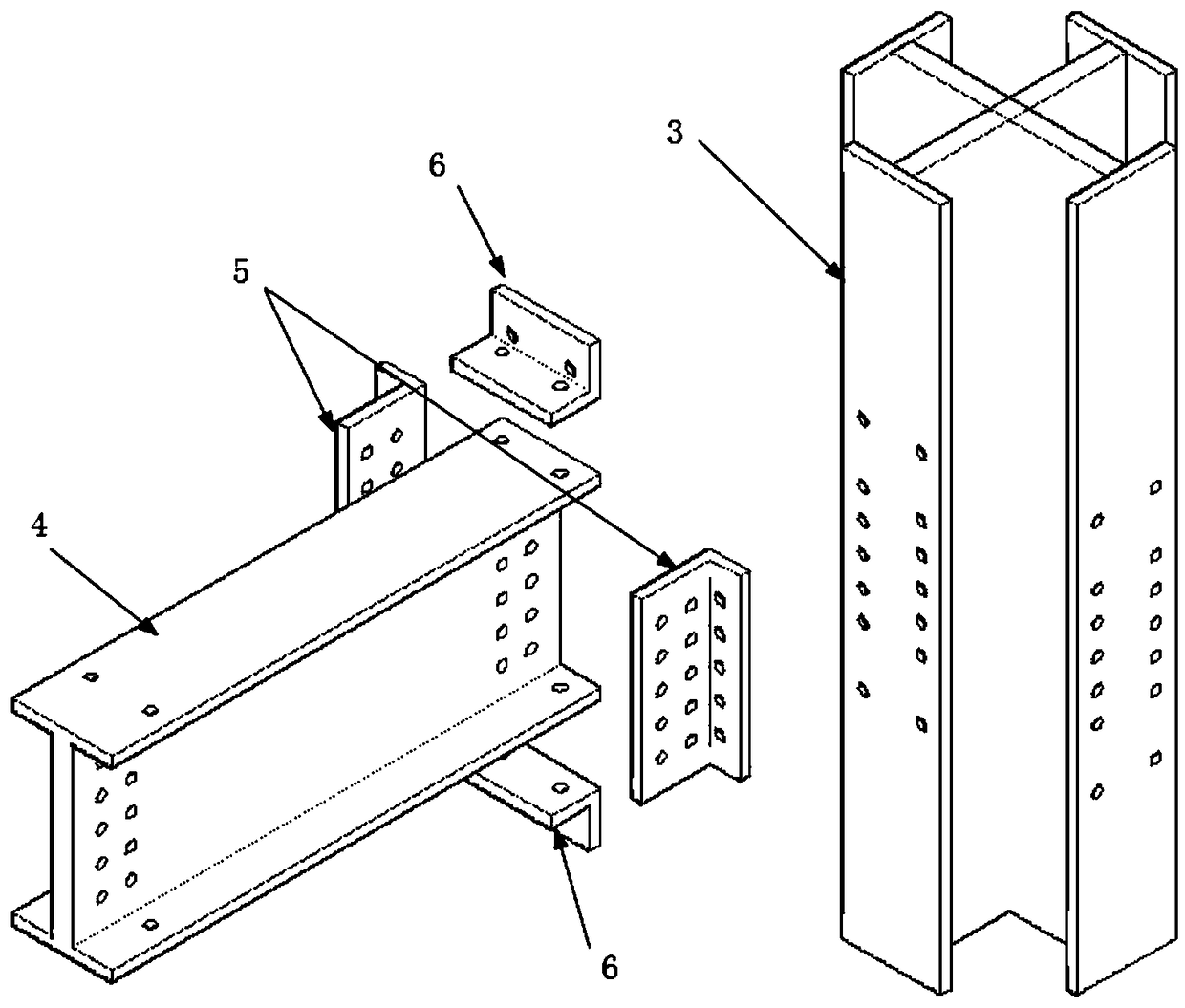

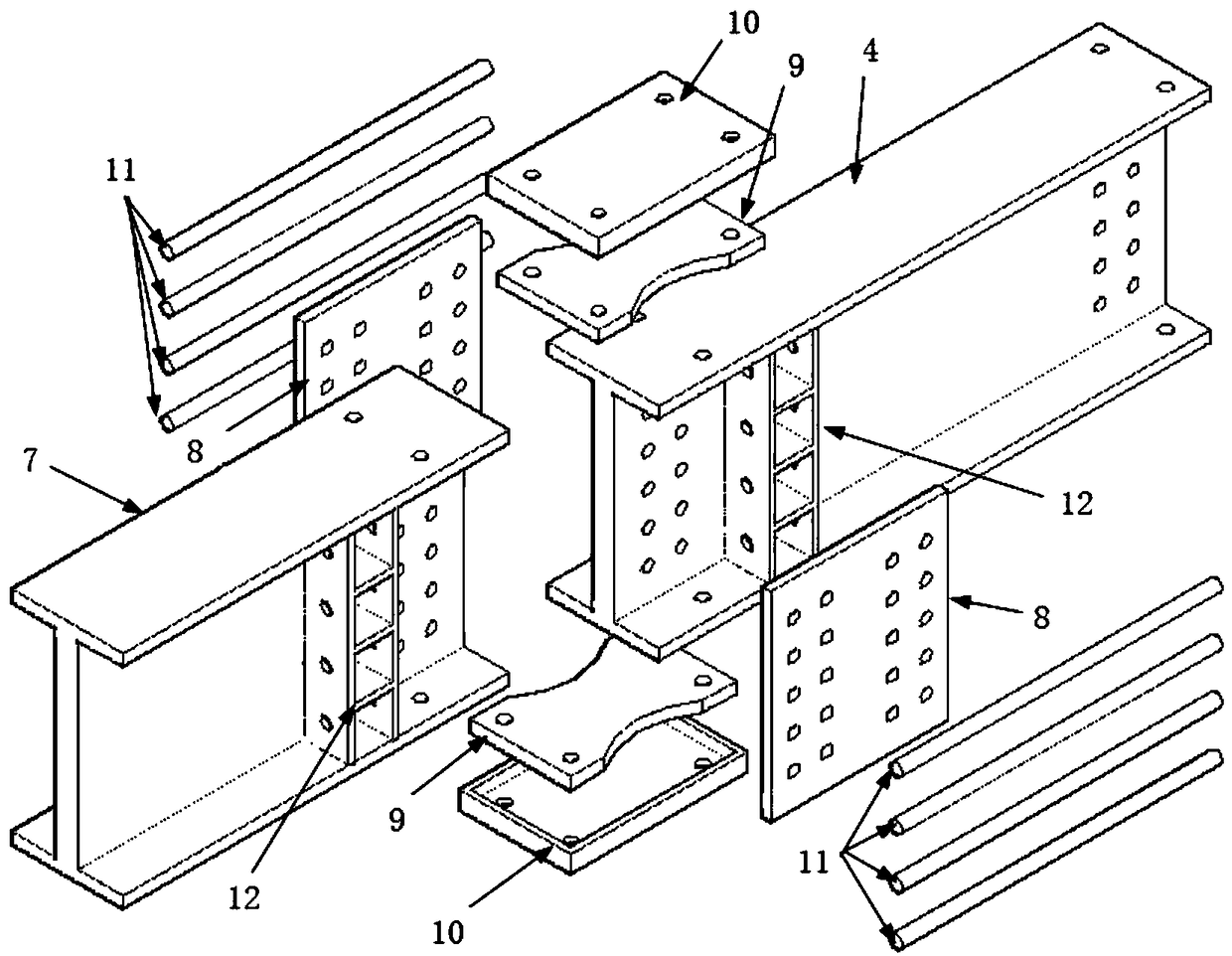

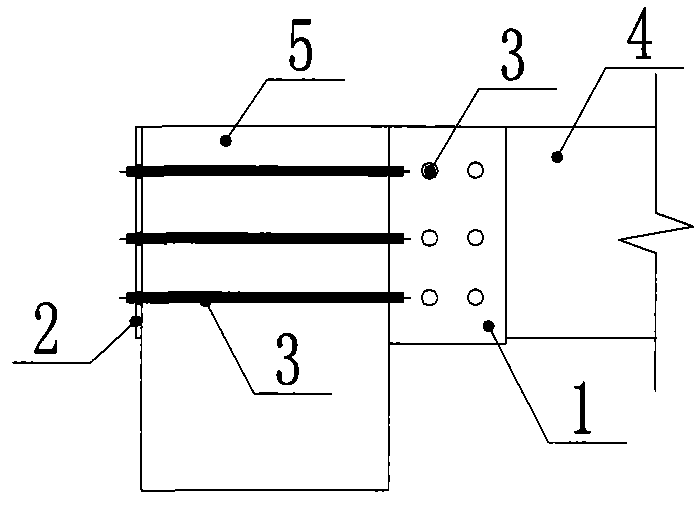

Assembling multi-section beam center support steel frame capable of self-centering after earthquake

The invention discloses an assembling multi-section beam center support steel frame capable of self-centering after earthquake. An I-beam is connected with special-shaped columns of different forms through a web angle steel and a flange angle steel to form a connecting form of full bolts without weld seams; a middle I-beam is connected with an end I-beam through a web connecting plate and a high-strength silicone rubber plate to form a connecting form of full bolts without weld seams with good ductility and high energy consumption; a prestressed steel cable is applied at the connecting part ofthe full bolts without the weld seams of the middle I-beam and the end I-beam to form self-centering nodes after the prestressed earthquake, and after the nodes are connected in sequence, a precast concrete-profiled steel plate composite slab or a poured concrete slab is assembled to form an assembling multi-section beam center support steel frame structure system capable of self-centering afterthe earthquake.

Owner:BEIJING UNIV OF TECH

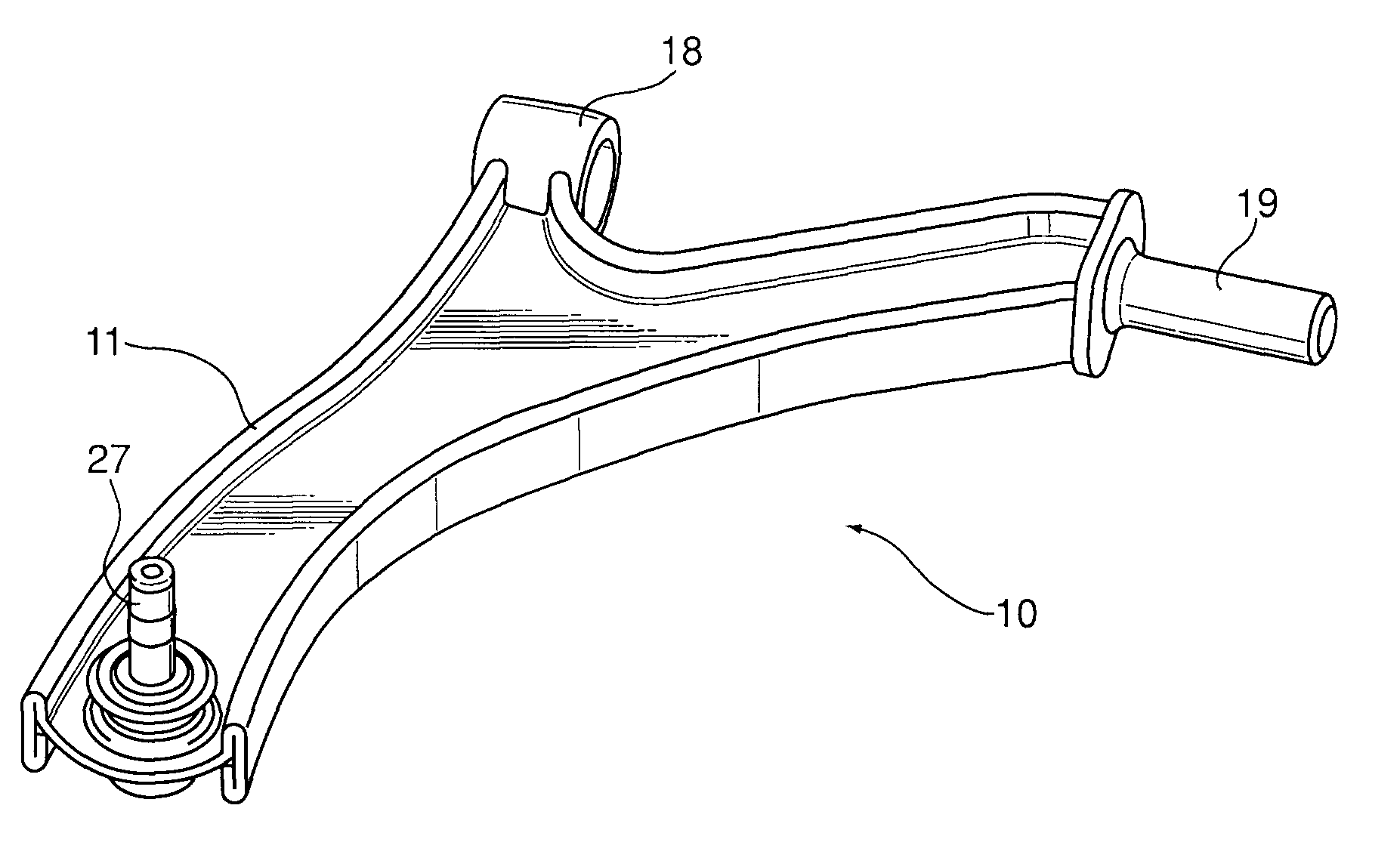

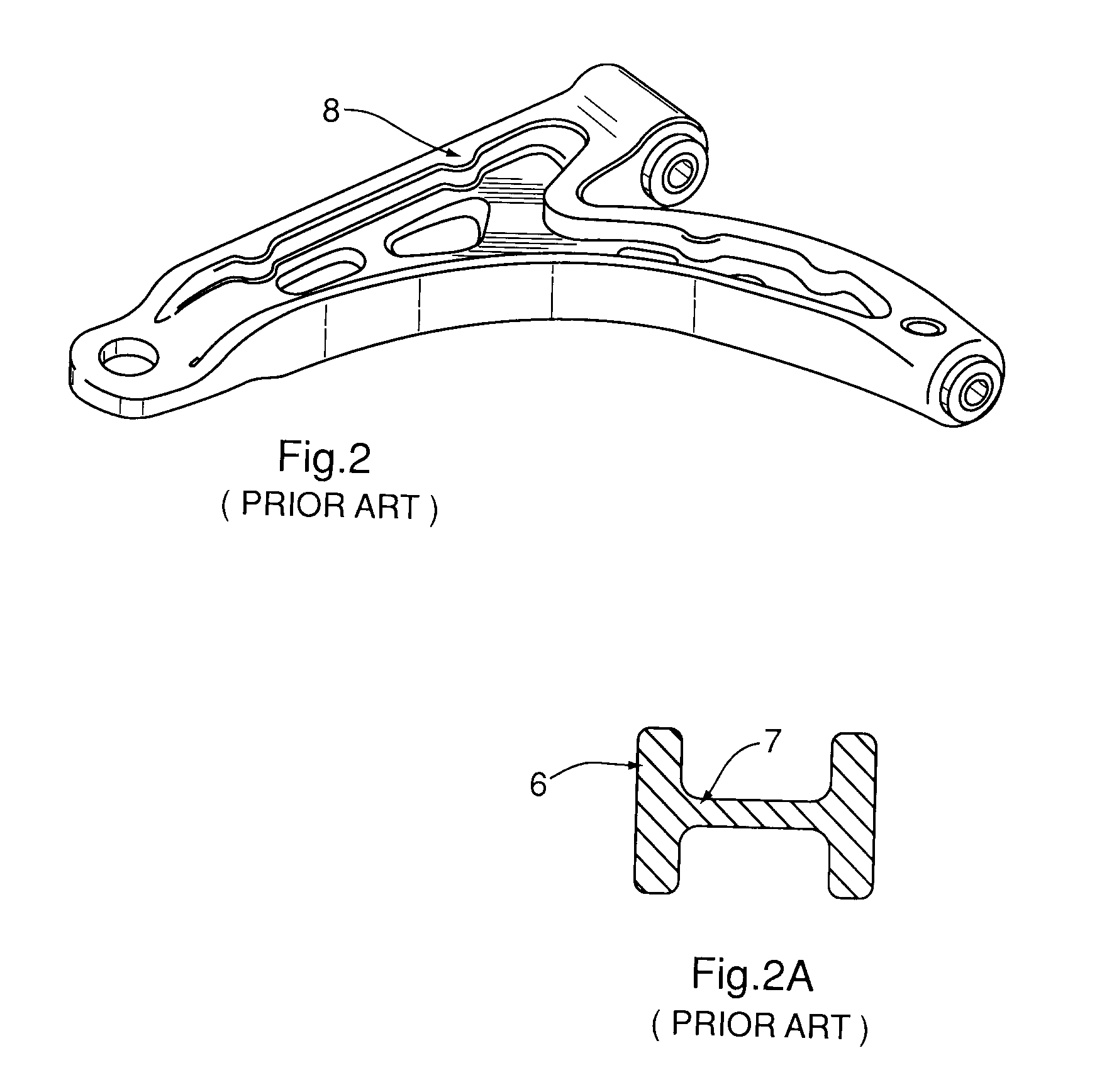

Structural i-beam automotive suspension arm

ActiveUS20100264615A1High inherent stiffness and strengthReduce quality problemsResilient suspensionsPivoted suspension armsControl armI-joist

A structural element comprising a vehicle suspension control arm is constructed from a complex, single piece, sheet metal stamped component formed from a material of uniform thickness. The stamping is configured with the correct plan view shape and formed into an I-beam cross-section comprising a central web portion and two flange portions. The central web portion is configured as a single material thickness and the flange portions comprise upstanding and downstanding closed sections with a continuous double returned segment. The open ends of the sheet metal terminate at or near the central web portion and are welded to the web portion, and in an alternative embodiment also to the continuous double returned segment, to create a favorable structural I-beam section with flange portions twice the thickness of the web portion.

Owner:MULTIMATIC INC

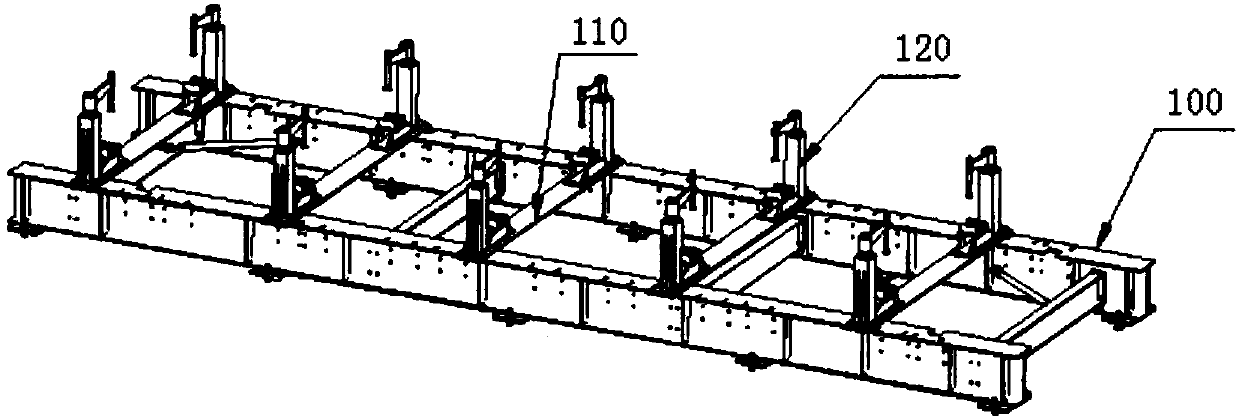

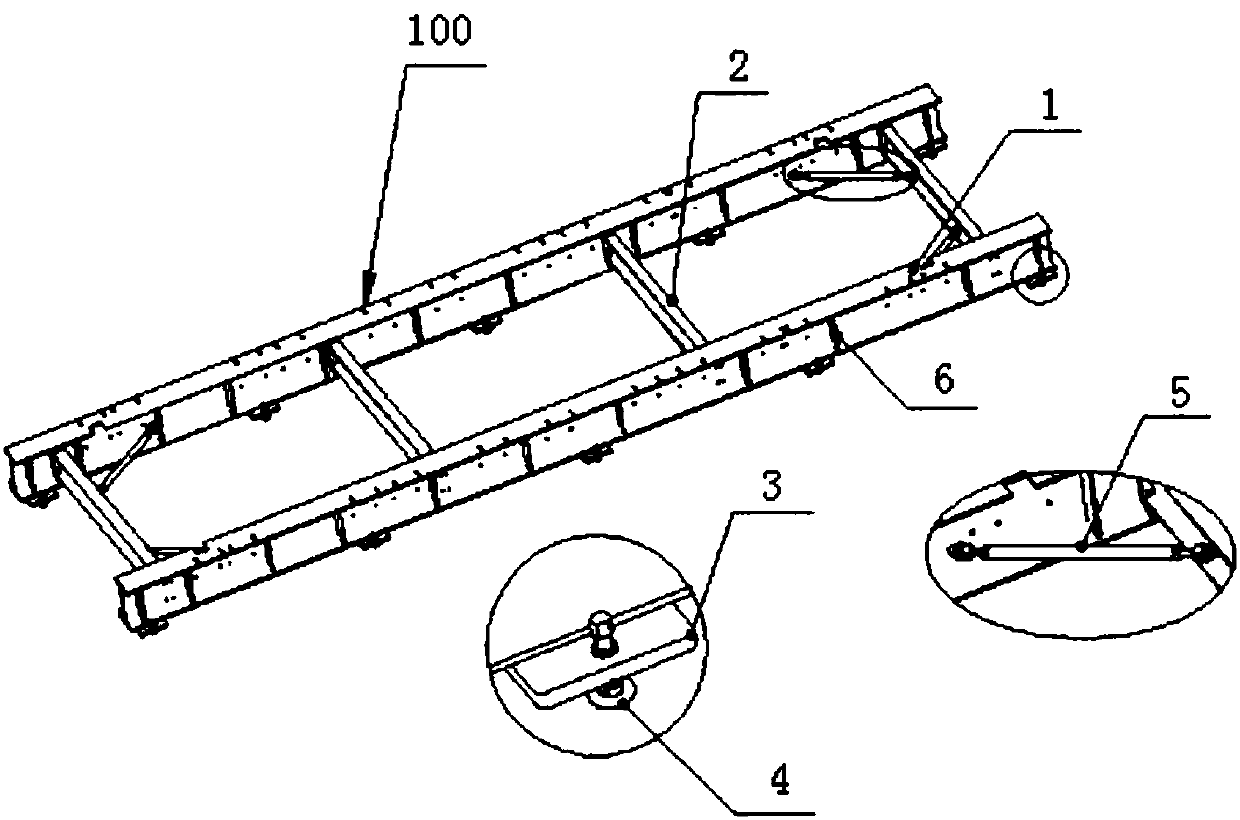

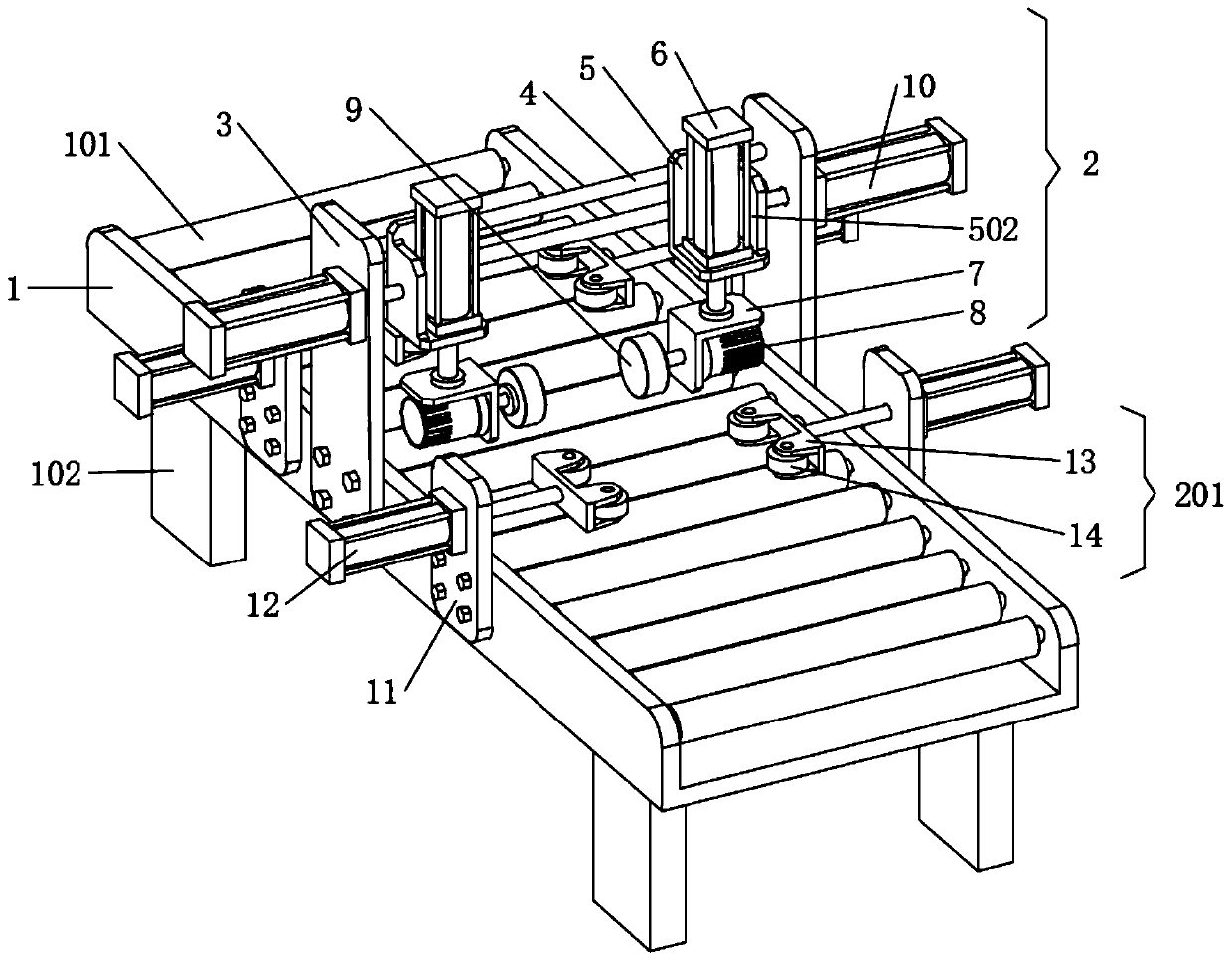

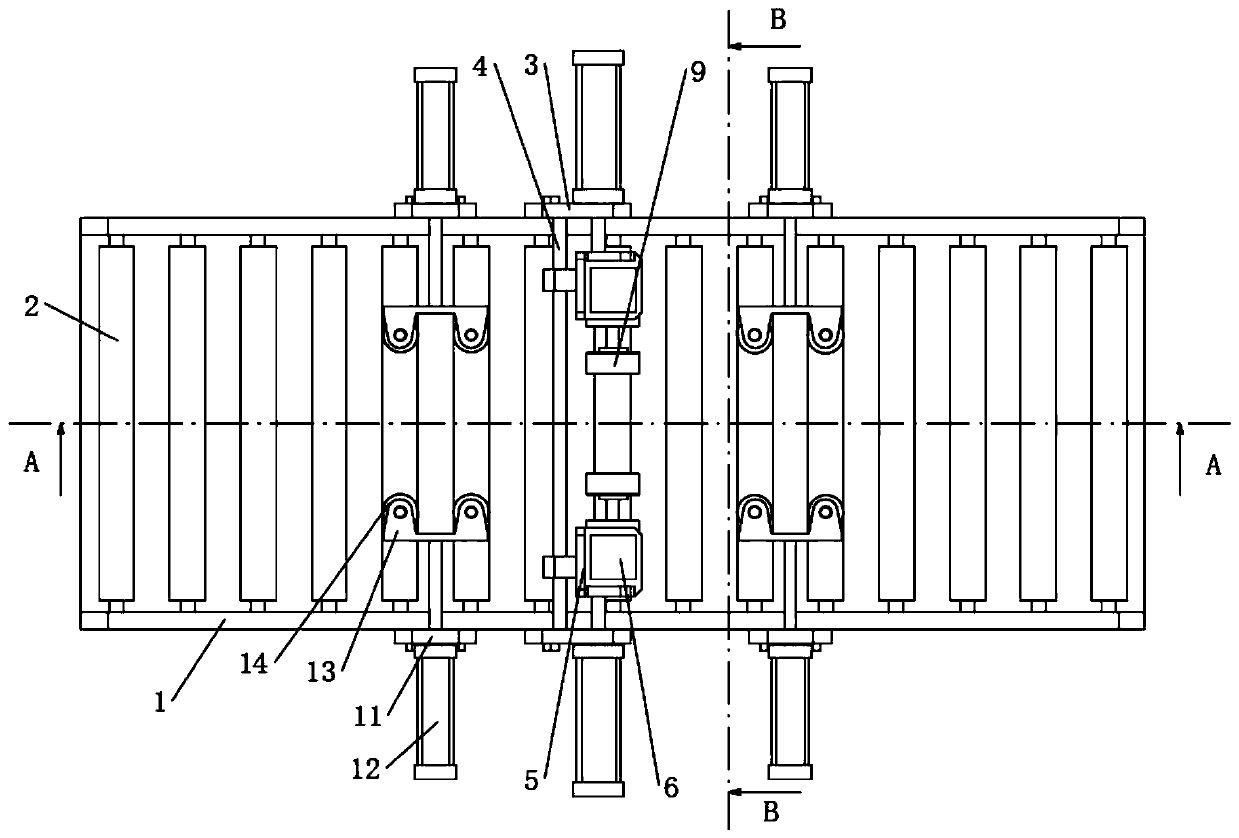

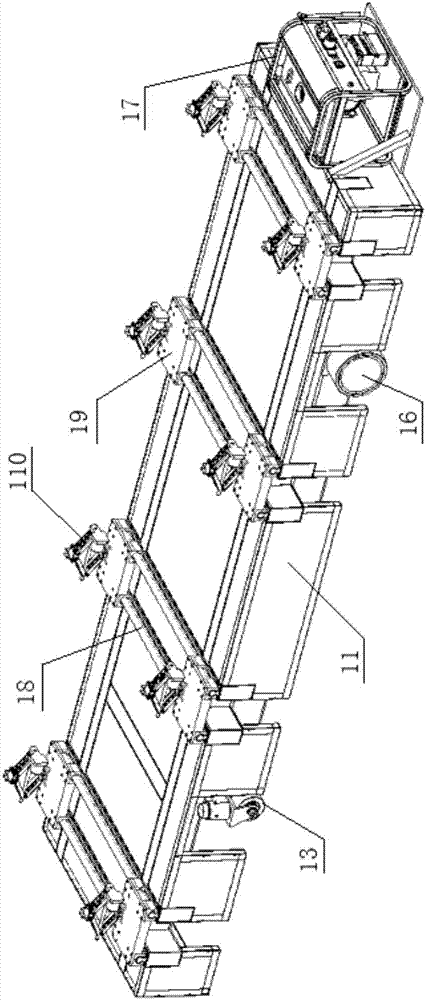

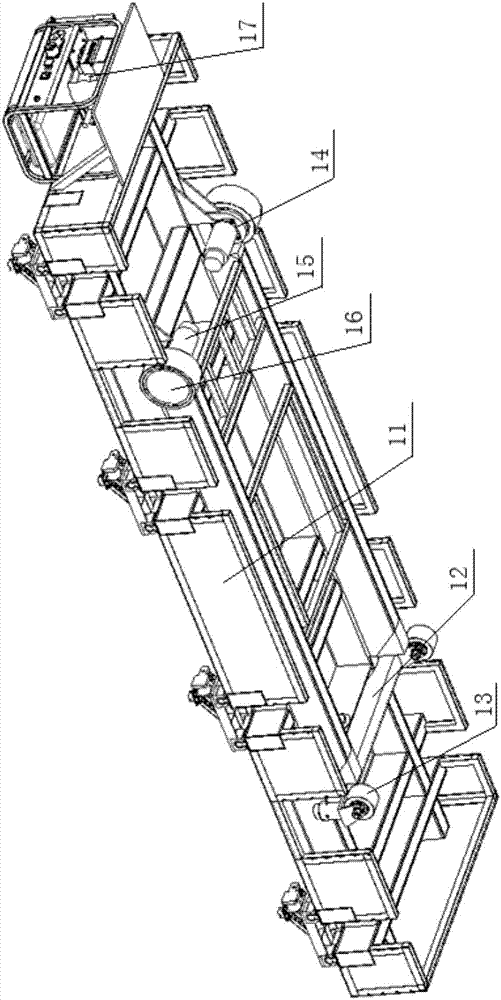

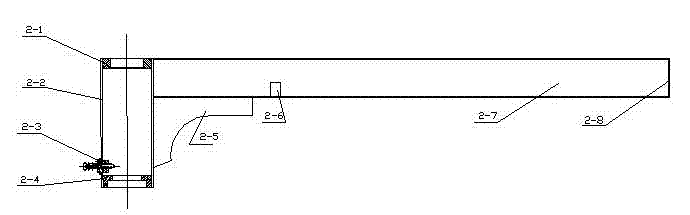

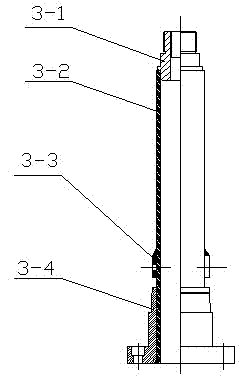

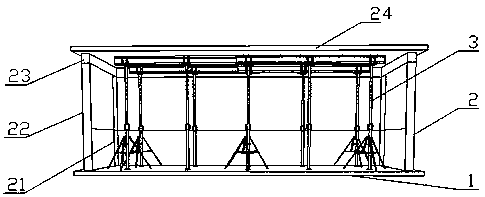

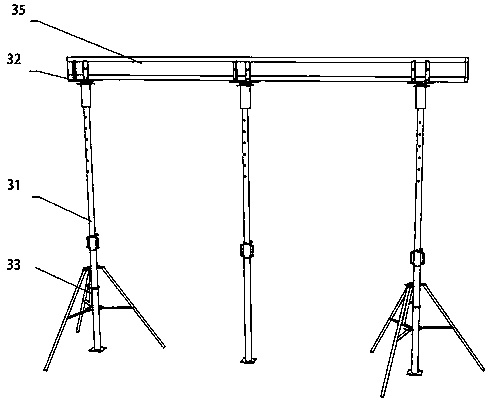

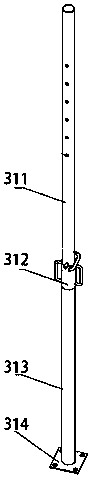

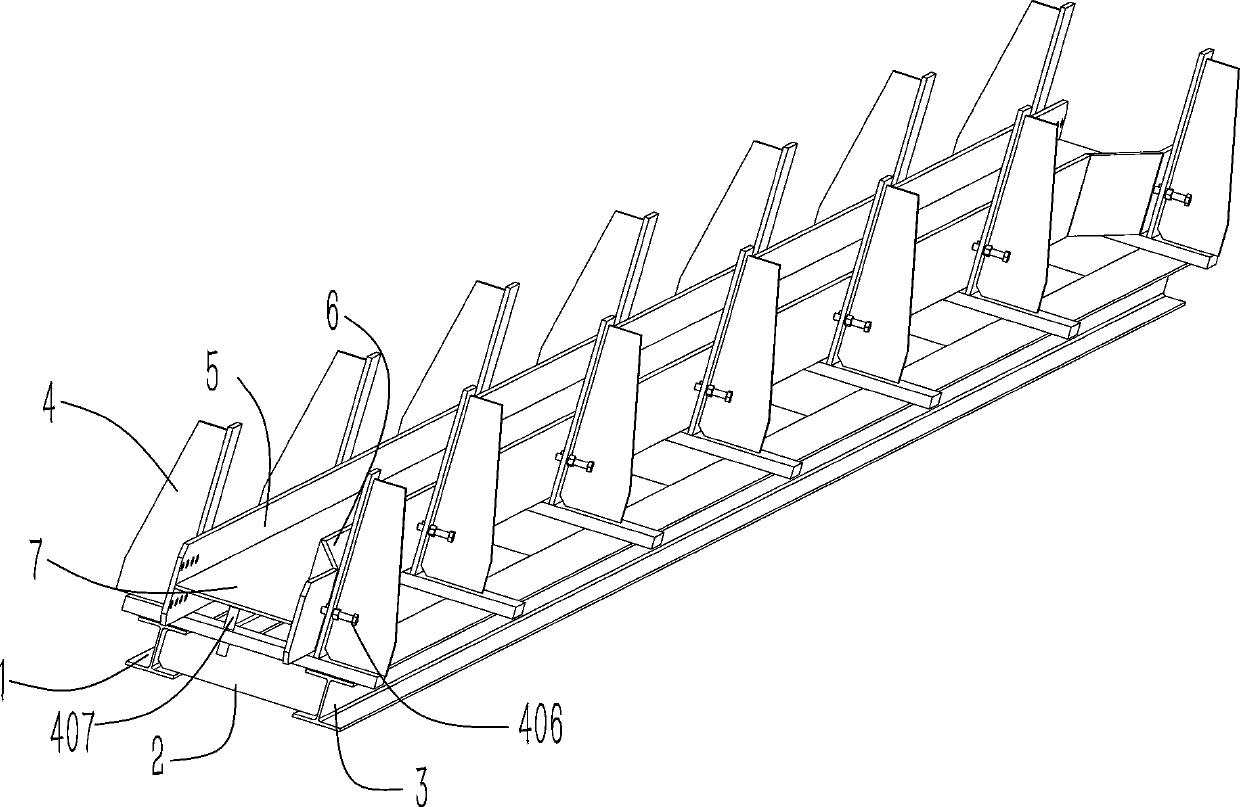

Sky train body welding fixture and welding method thereof

PendingCN107790949ASave tuning timeEasy to switchWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCantilever

The invention provides a sky train body welding fixture and a welding method thereof. The sky train body welding fixture comprises a foundation fixture, a cross beam, a boundary beam clamping device,a boundary beam type block and an assistant support rod for assembly of a train body. The cross beam is installed across the foundation fixture. The boundary beam clamping device is positioned at twoends of the cross beam. The boundary beam type block is connected with the boundary beam clamping device. The foundation fixture comprises a longitudinal I beam, a horizontal I beam, a bottom plate, an adjusting bolt, a support rod component and a longitudinal reinforcing rib. The boundary beam clamping device comprises a cantilever mechanism, an upright structure and a bottom base. The upright structure is vertically installed on the bottom base. The cantilever mechanism is connected with the upright structure. The provided welding fixture has the characteristics of simple structure, novel design, convenient operation, and strong universality and is capable of effectively controlling the welding deformation, realizing the double functions of positioning and welding deformation resistance,guaranteeing the quality, reducing the labor intensity and improving the production efficiency.

Owner:ZHUZHOU LINCE GRP

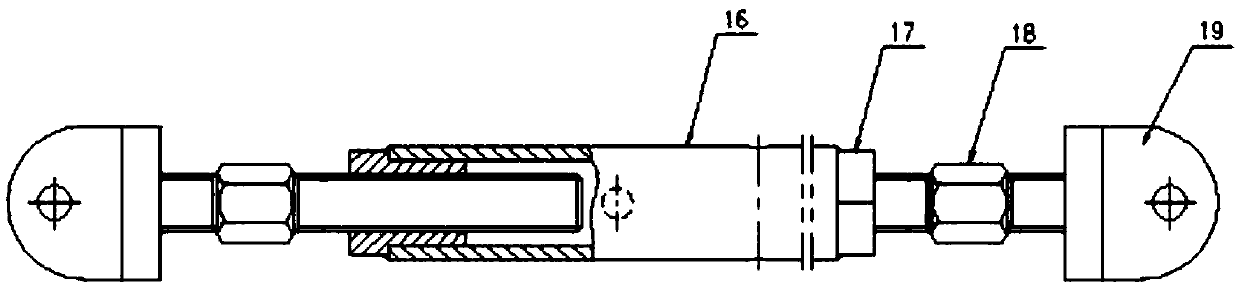

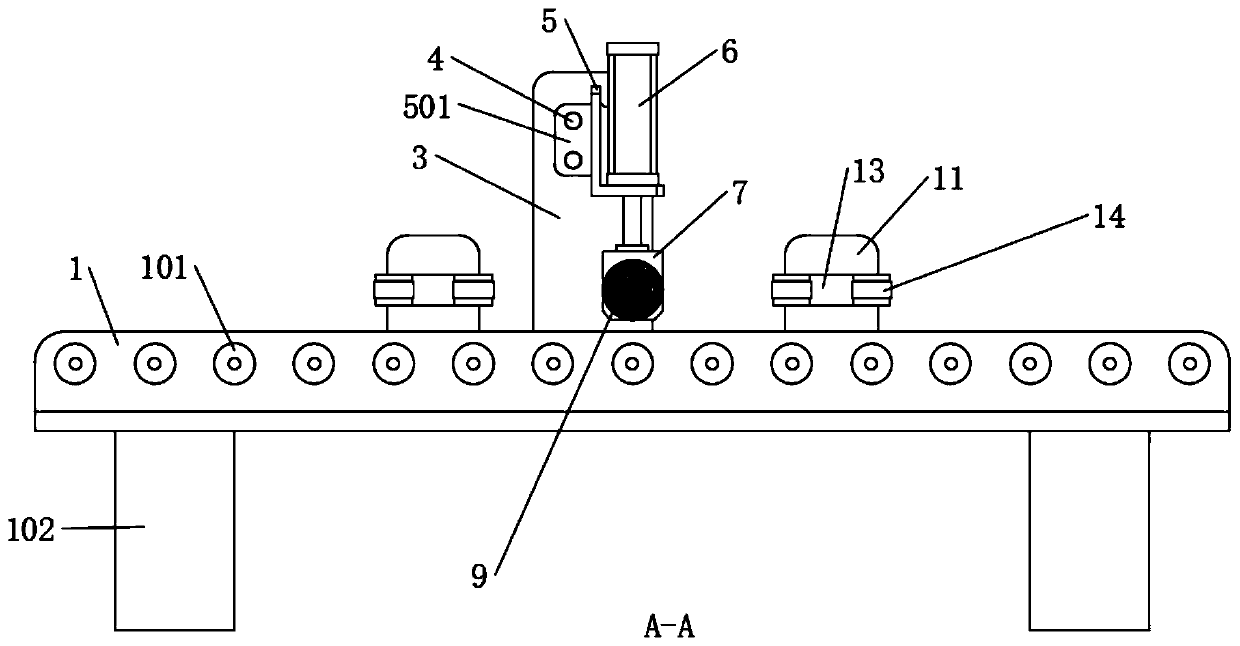

I beam burring device capable of being suitable for different specifications

InactiveCN111571356ARealize up and downSanding removal is comprehensive and effectiveEdge grinding machinesGrinding carriagesHydraulic cylinderPolishing

The invention discloses an I beam burring device capable of being suitable for different specifications and relates to the field of burring devices. The I beam burring device capable of being suitablefor different specifications comprises a machine table, a polishing device and guiding devices. A roller bed is arranged in the machine table, the polishing device is arranged on the machine table, and the guiding devices are arranged on two sides of the polishing device. By controlling a telescopic rod of a transverse shifting driven hydraulic cylinder to stretch, two lifting hydraulic cylinderblocks are adjusted to move in an axial direction of a sliding shaft till two millstones are in contact with the side wall of an I beam. By driving the millstones by a polishing motor, the side wall of the I beam is polished to burr. Meanwhile, by controlling the telescopic rod of a lifting hydraulic cylinder to stretch, the millstones lift up and down, so that it is convenient to polish and burrthe side wall of the I beam comprehensively and effectively.

Owner:陈烁

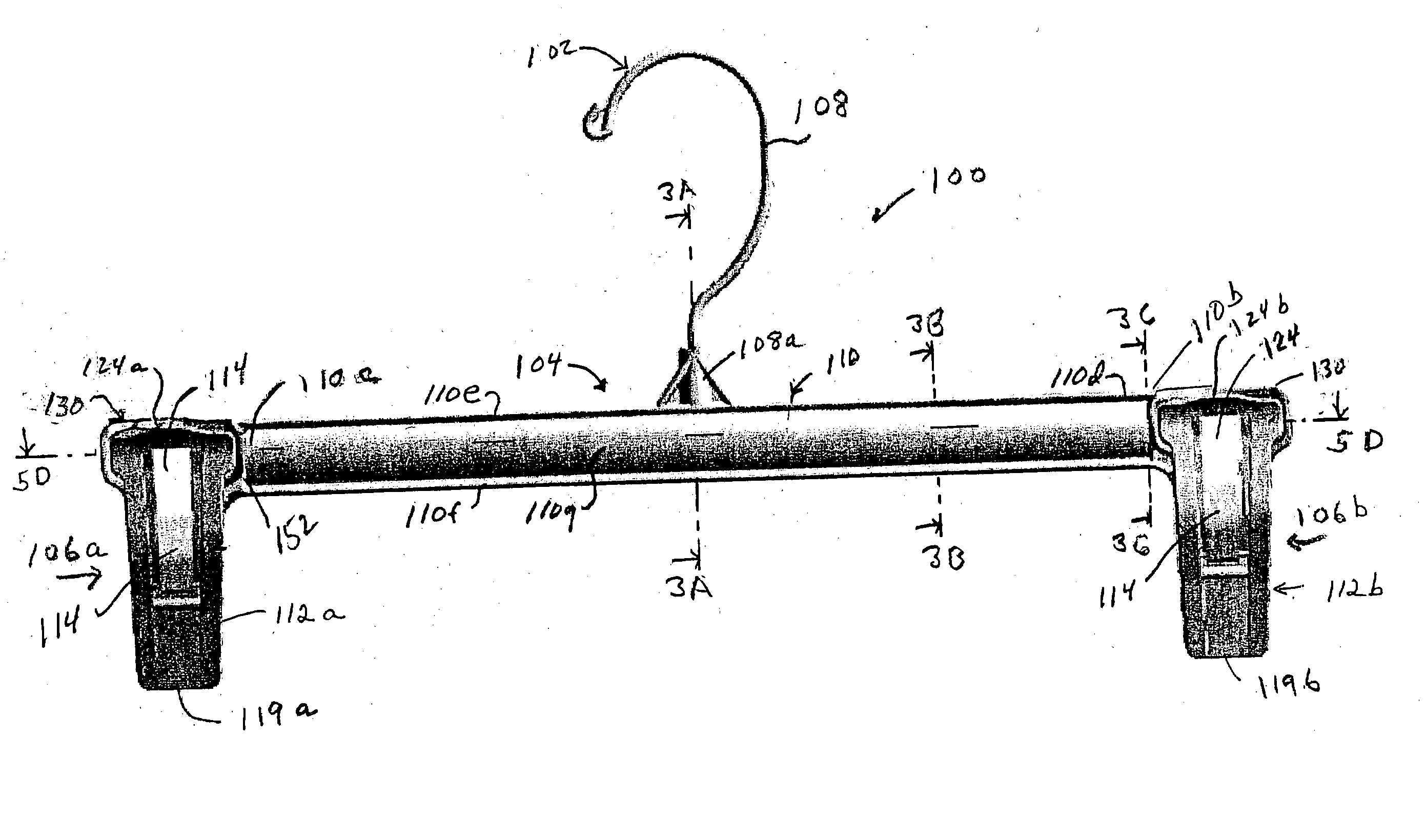

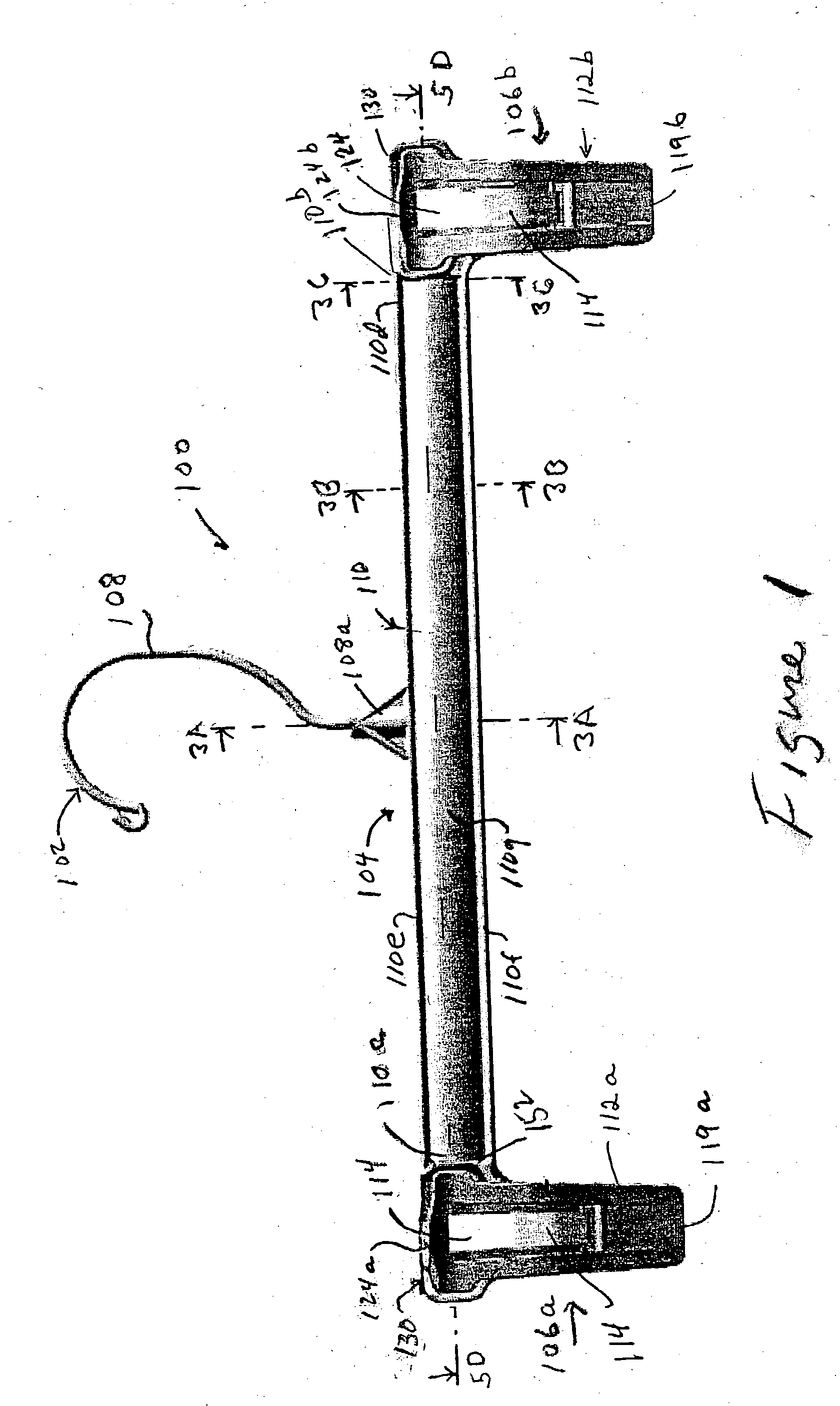

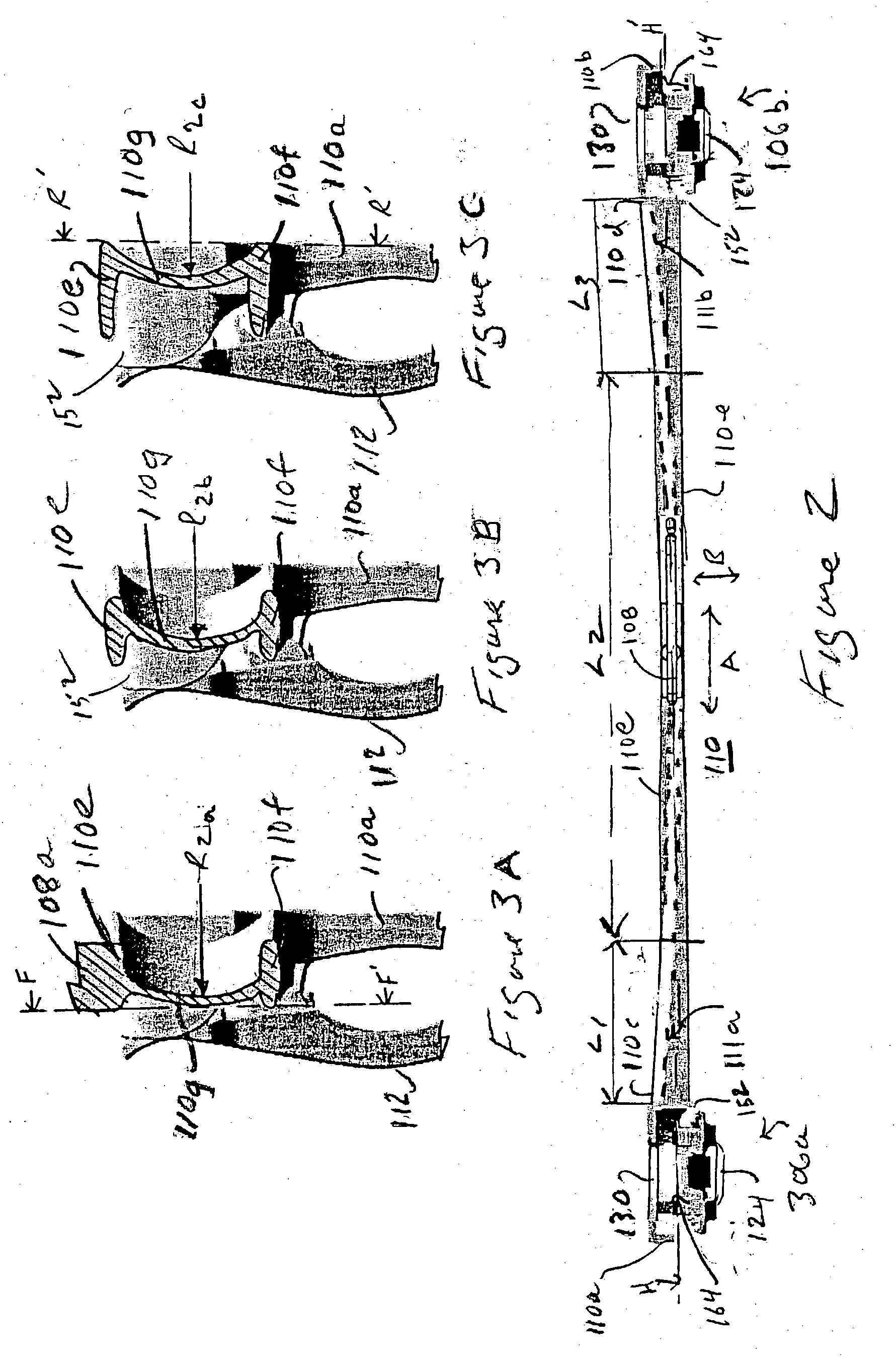

Hanger beam construction

Owner:PROSPERITY PROD HK LTD

Machine vision robotic stud welder

The present disclosure teaches systems and methods for robotic welding of studs onto the surface of I-beams. These systems and methods will find industrial applicability in, for example, the steel erection industry.

Owner:STRUCTURAL SERVICES

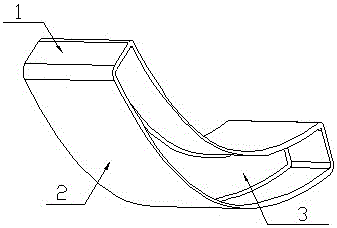

Preparation method of special-shaped carbon fiber composite I-beam and special-shaped I-beam prepared through method

The invention provides a preparation method of a special-shaped carbon fiber composite I-beam and the special-shaped I-beam prepared through the method. The preparation method of the special-shaped carbon fiber composite I-beam comprises the steps that a setting agent is scattered on carbon fiber fabric according to the mass of 3-8 g / m<2>, heat setting is conducted, the fabric is cut into the required shape through a cutting machine after setting of the carbon fiber fabric is completed, the fabric cut into the specific shape is laid on a mold prepared in advance in an attached mode, so that a prefabricated body is obtained, and the prefabricated body is placed in a vacuum bag to be stored in an airtight mode after laying is completed; composite liquor is formed, so that a crude special-shaped carbon fiber composite I-beam is obtained; and the finished special-shaped carbon fiber composite I-beam is obtained by treating the crude special-shaped carbon fiber composite I-beam. The special-shaped carbon fiber composite I-beam is high in bearing capacity, good in rigidity, low in self weight and high in surface smoothness, the porosity of a product is low, and the outer surface dimension and the resin content can be controlled accurately.

Owner:HENGSHEN

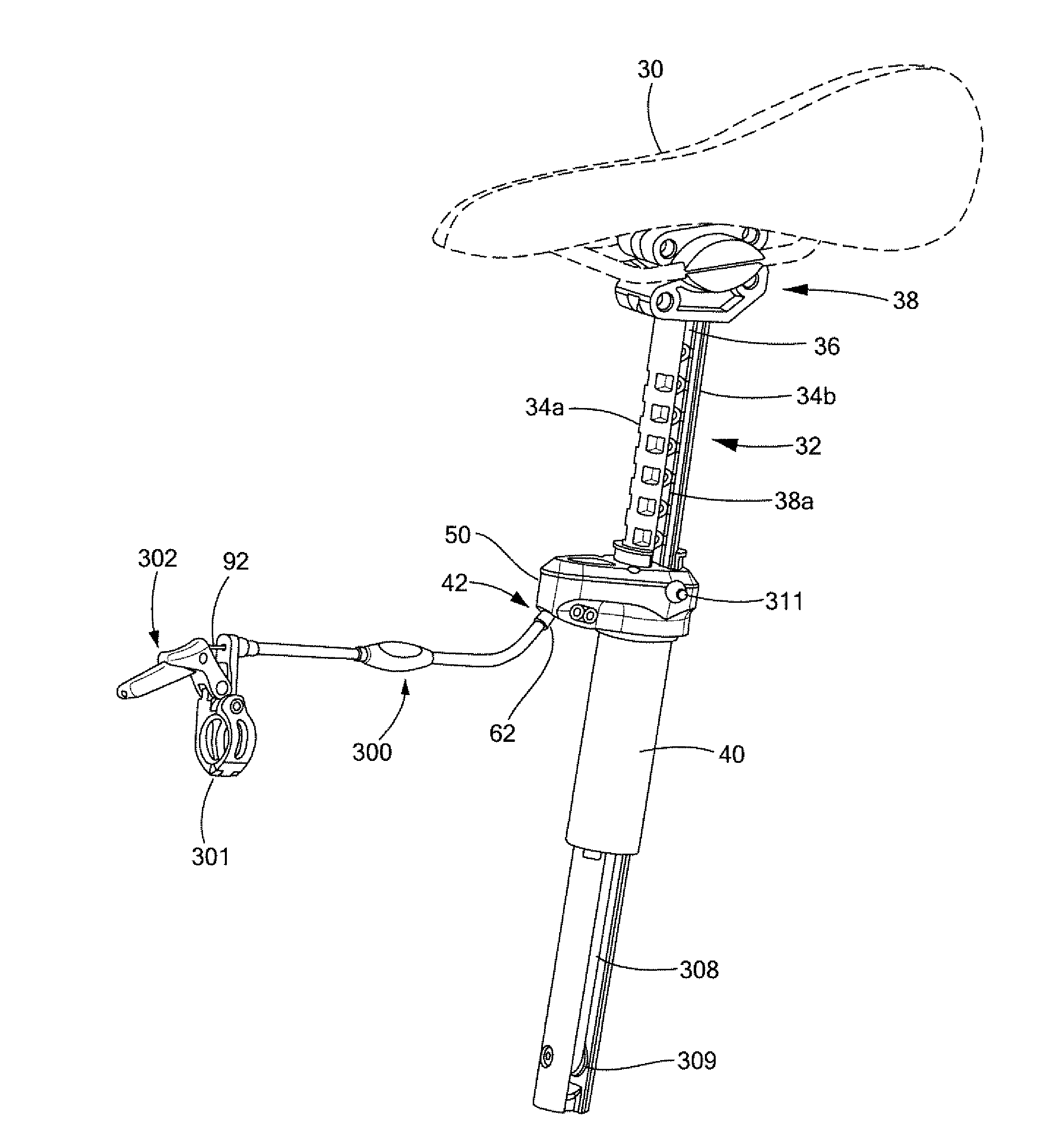

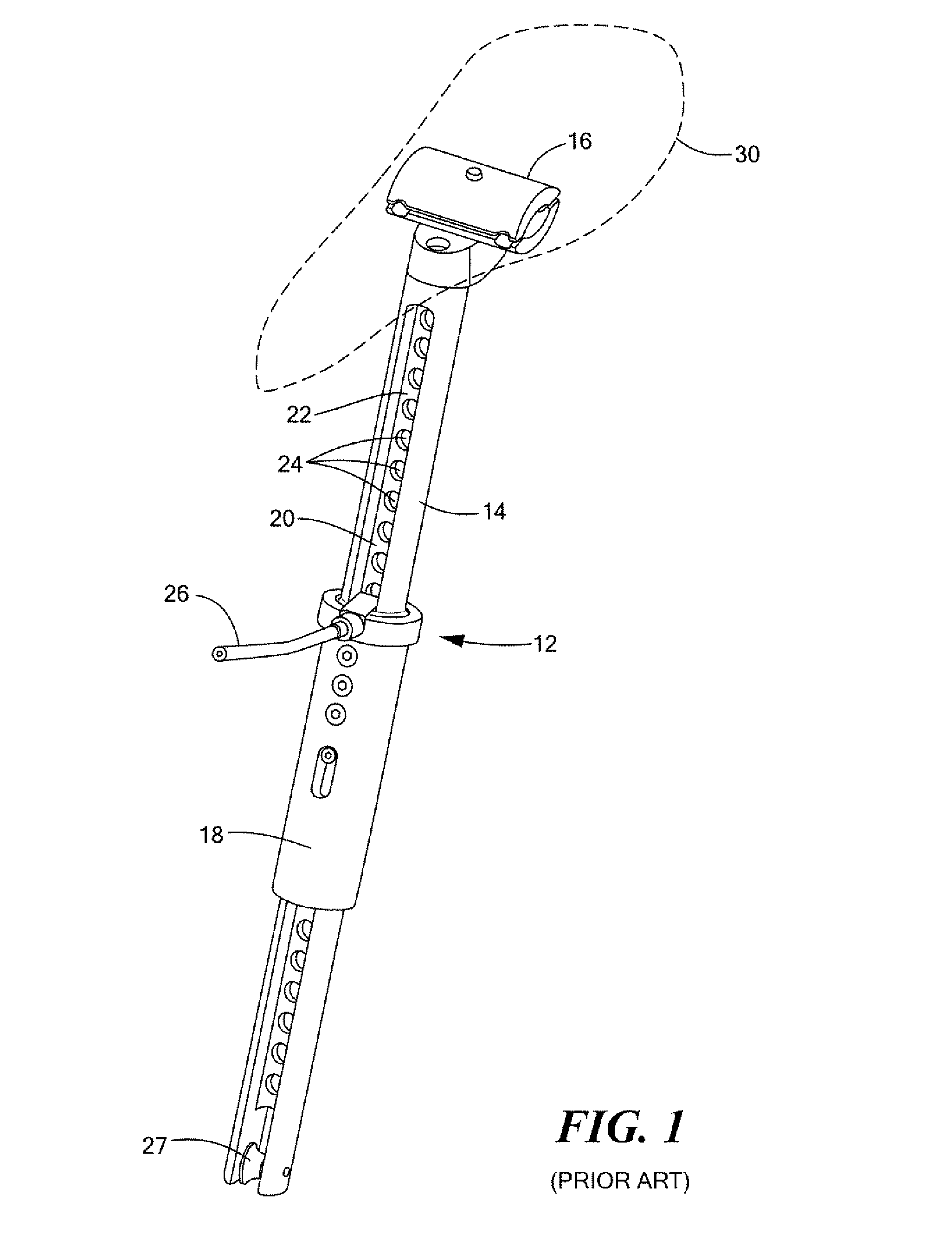

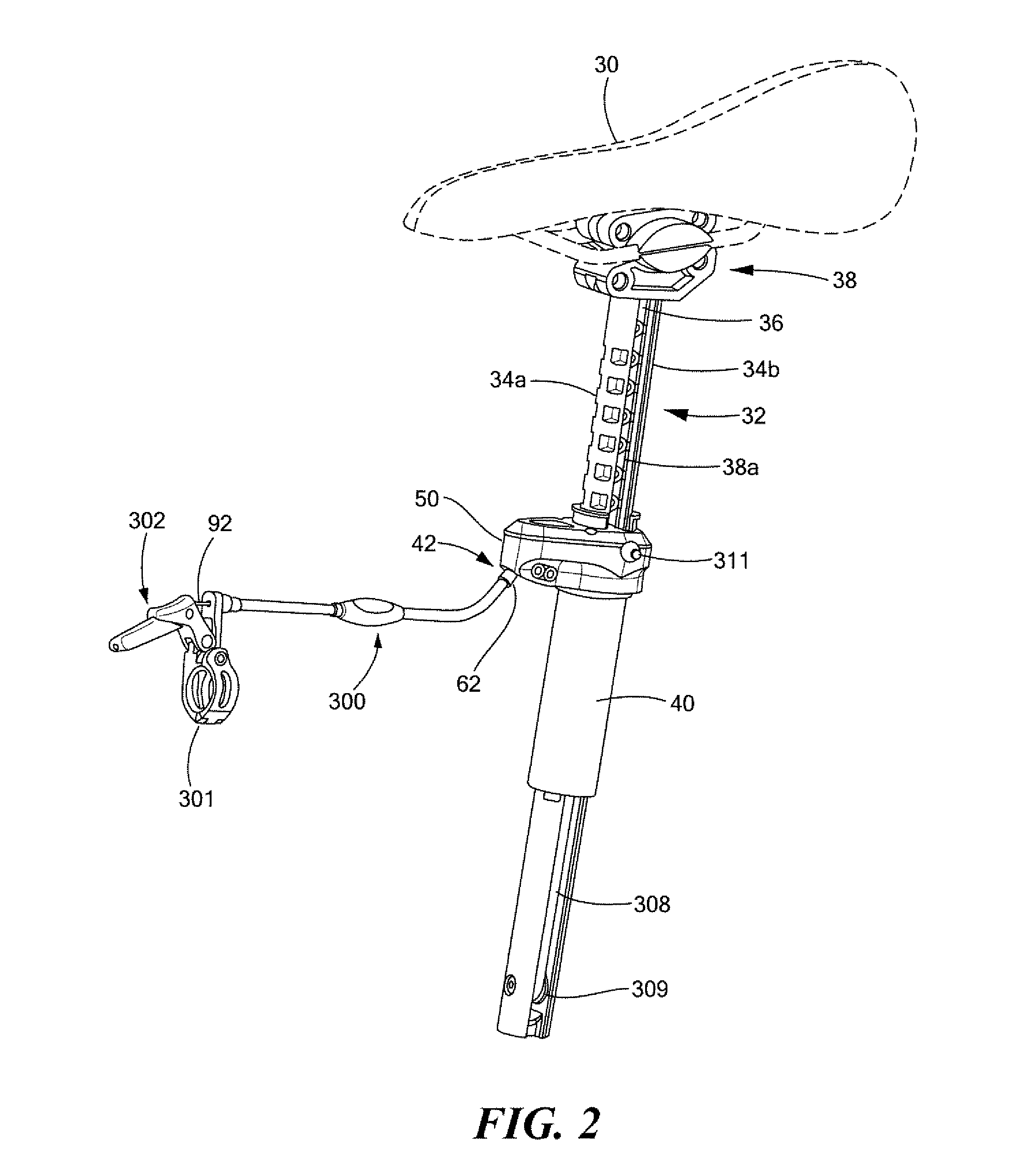

Adjustable cycle seat

An adjustable cycle seat includes a seat post configured as an I-beam with front and rear flanges and a web therebetween defining side channels. A sleeve about the post is attached to the cycle. At least one spring is interconnected between the post and the sleeve biasing the post upward. An actuatable locking mechanism releasable secures the post to the sleeve.

Owner:RASE COMPONENTS

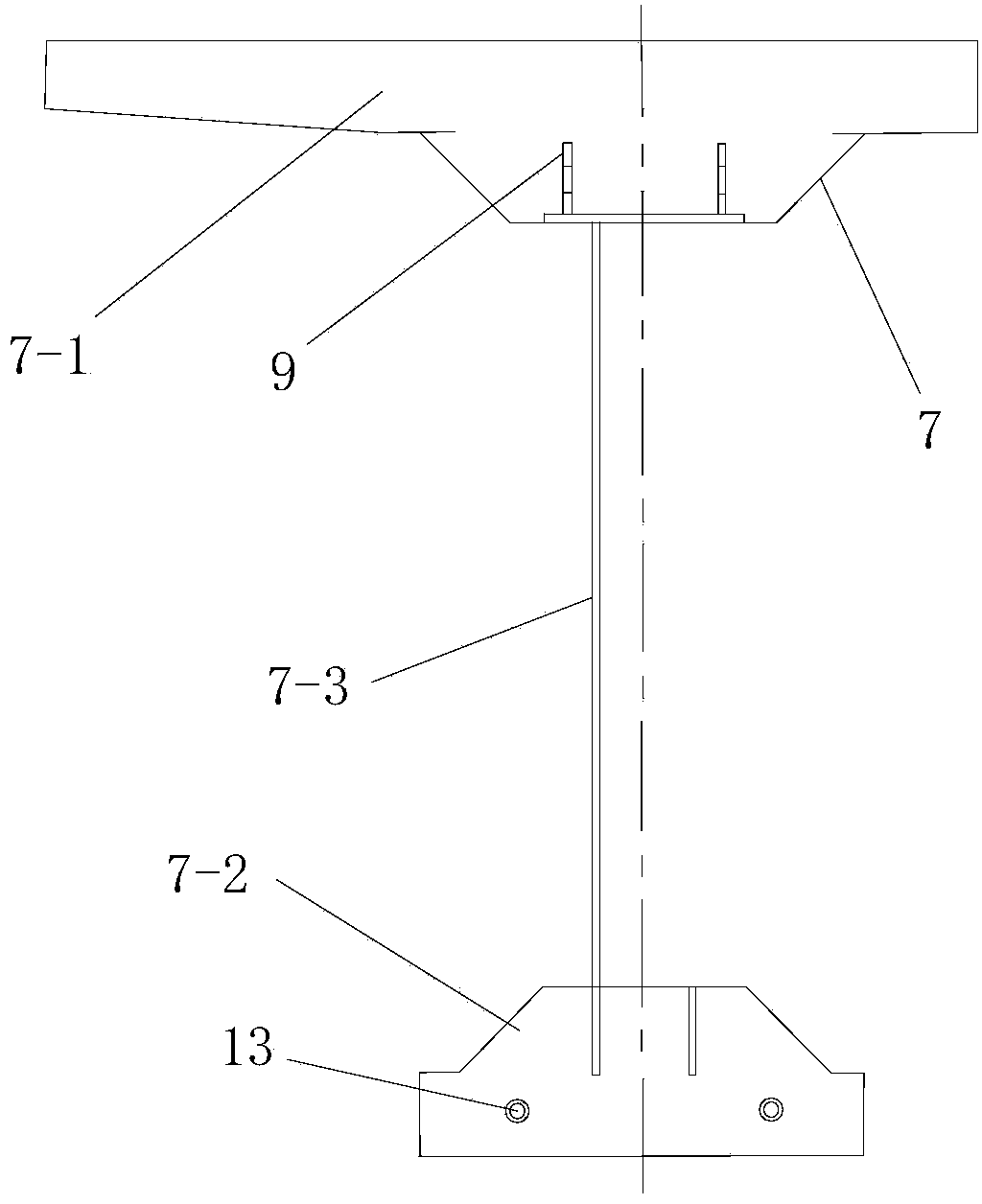

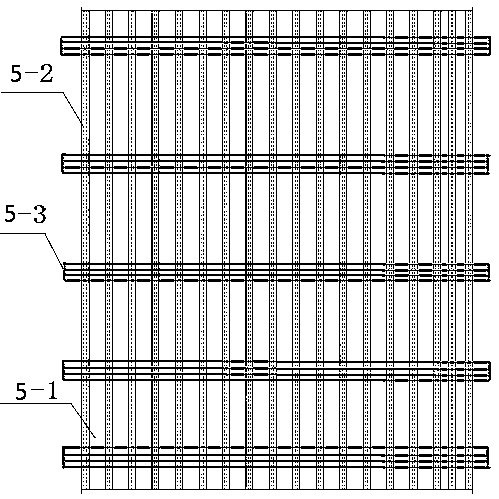

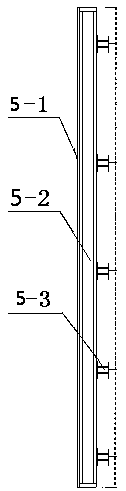

Prefabricating construction process for corrugated steel web prestressed concrete I-shaped beam

The invention discloses a prefabricating construction process for a corrugated steel web prestressed concrete I-shaped beam. The process comprises the following steps: 101, constructing a prefabricated pedestal; 102, mounting a bottom die plate; 103, mounting a reinforcement framework in a bottom plate; 104, mounting a corrugated pipe in the bottom plate; 105, mounting a positioning bracket and supporting a side die plate, wherein the positioning bracket comprises a supporting frame, and a plurality of positioning rods for positioning a corrugated steel web; 106, mounting the corrugated steel web, namely, mounting the corrugated steel web is mounted above the reinforcement framework in the bottom plate, and positioning through the positioning bracket; 107, pouring the concrete of the bottom plate; 108, mounting a top plate molding die plate; 109, mounting the reinforcement framework in a top plate; 110, pouring the concrete of the top plate; 111, stretching an inner cable in a bottom plate body. The prefabricating construction process is simple in steps, reasonable in design, convenient to implement, short in construction period, and high in construction quality; the prefabricated pedestal is matched with the positioning bracket to finish the prefabricating of a beam body, and the quality of a prefabricated beam body can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

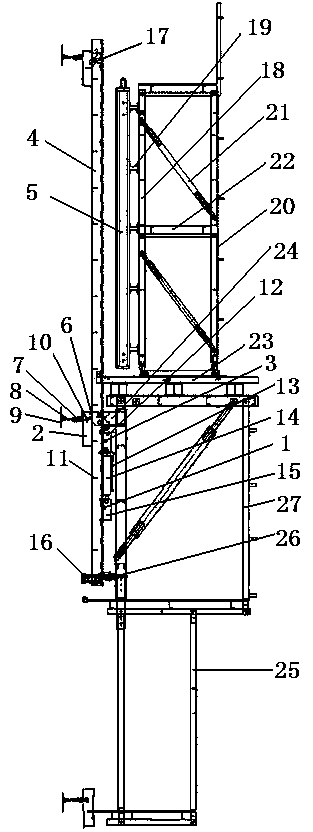

Coastal environment high pier hydraulic self-creeping formwork construction method

PendingCN111119060AEasy to operateImprove securityBridge structural detailsBridge erection/assemblyPurlinShaped beam

The invention discloses a coastal environment high pier hydraulic self-creeping formwork construction method. The method comprises the steps of tower column starting section construction, tower columnfirst section construction, hydraulic creeping formwork installation, tower column second section construction, tower column remaining section construction and creeping formwork removal, the hydraulic creeping formwork comprises an embedded part mechanism embedded in a high pier wall, and a frame body mechanism comprises a lower hanging bracket and a bearing frame; the formwork installation comprises a formwork consisting of a panel, a woodworking I-shaped beam and a steel enclosing purlin, a movable template bracket and a backward moving device; a hydraulic power mechanism comprises an upperreversing box, a lower reversing box, a hydraulic pump and a hydraulic oil cylinder which are connected with the guide rail in a sliding manner; the guide rail is composed of two steel channels and guide rail stair stops, and the upper reversing pawl of the upper reversing box and the lower reversing pawl of the lower reversing box are arranged between the guide rail stair stops. The constructionmethod is convenient to operate, high in safety and convenient to construct, working hours and construction sites are saved, and formwork bumping damage is reduced; and the formwork is recycled, theworkload of hoisting machinery is greatly reduced, and the construction process is stable, synchronous and safe.

Owner:YANJIAN GRP CO LTD +1

Releasable I-beam anchor

Owner:RELIANCE INDUSTRIES LIMITED

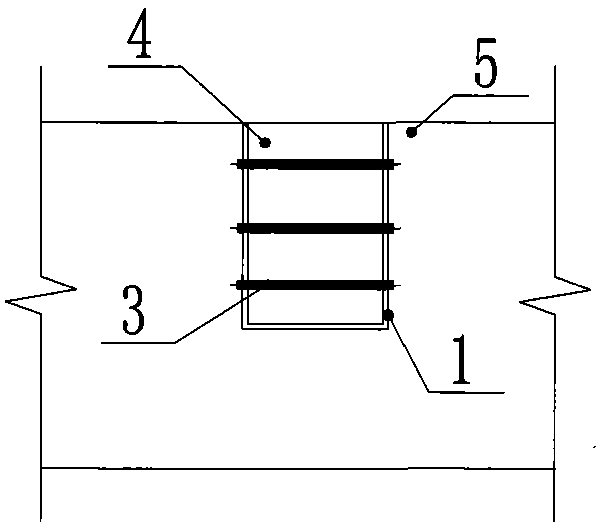

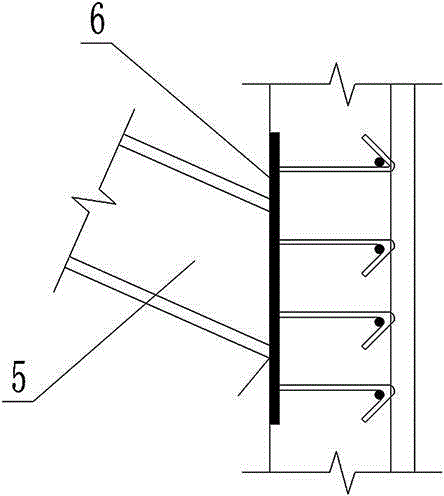

U-shaped-hoop joint connector of main beam and auxiliary beam of recombinant-bamboo frame

InactiveCN103615051AReliable power transmissionSafe and reliable connectionBuilding constructionsEngineeringBeam column

The invention provides a U-shaped-hoop joint connector of a main beam and an auxiliary beam of a recombinant-bamboo frame, aiming to solve the technical problem about connection of main beams and auxiliary beams of recombinant-bamboo frames in construction engineering. The U-shaped-hoop joint connector mainly comprises a U-shaped hoop, a joint plate, bolts, recombinant-bamboo frame beams and recombinant-bamboo frame columns. The U-shaped-hoop joint connector is characterized in that the recombinant-bamboo frame beams are prefabricated in a factory; the U-shaped hoop is disposed on the lateral side of the main beam of the recombinant-bamboo frame and at the end of the auxiliary beam of the recombinant-bamboo frame; at the joint of the main beam and the auxiliary beam, the joint plate and the U-shaped hoop are connected to the lateral side of the main beam of the recombinant-bamboo frame through the bolts; after the auxiliary beam of the recombinant-bamboo frame is hoisted, the main beam and the auxiliary beam, both mounted with the U-shaped hoop, of the recombinant-bamboo frame are integrated through the bolts. The U-shaped-hoop joint connector is safe and reliable in connection, capable of transferring force well, simple to construct and mount, practical and convenient.

Owner:YANGZHOU POLYTECHNIC INST

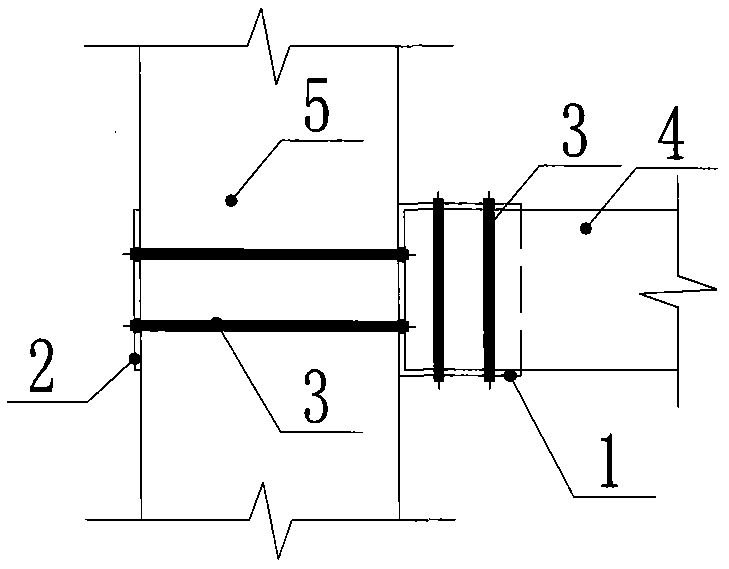

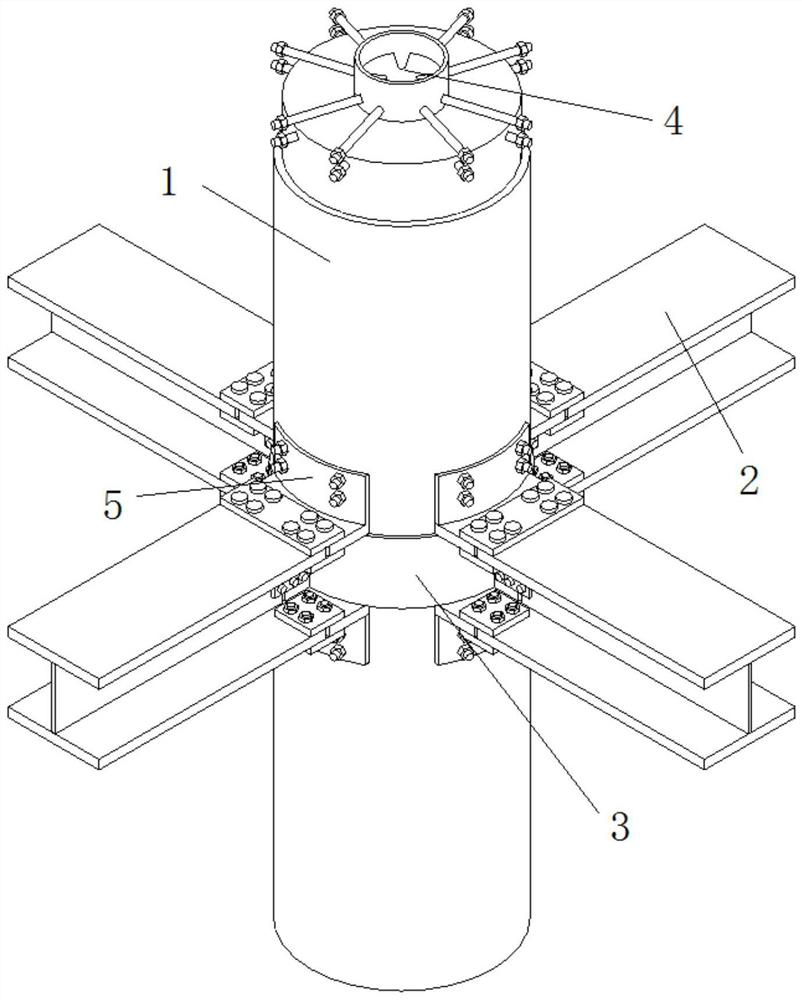

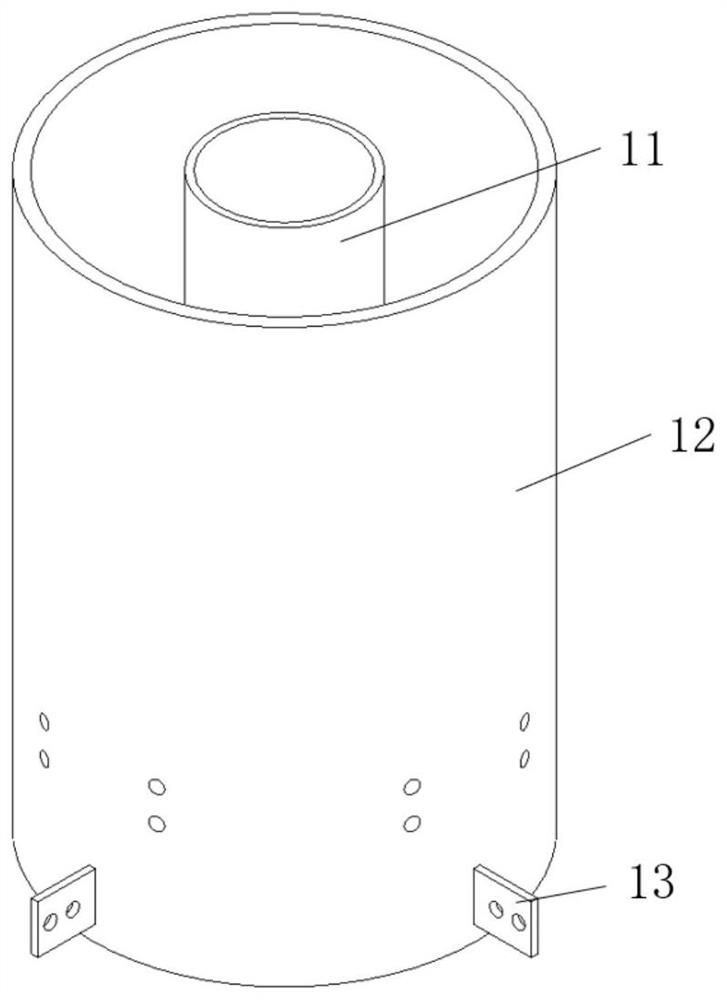

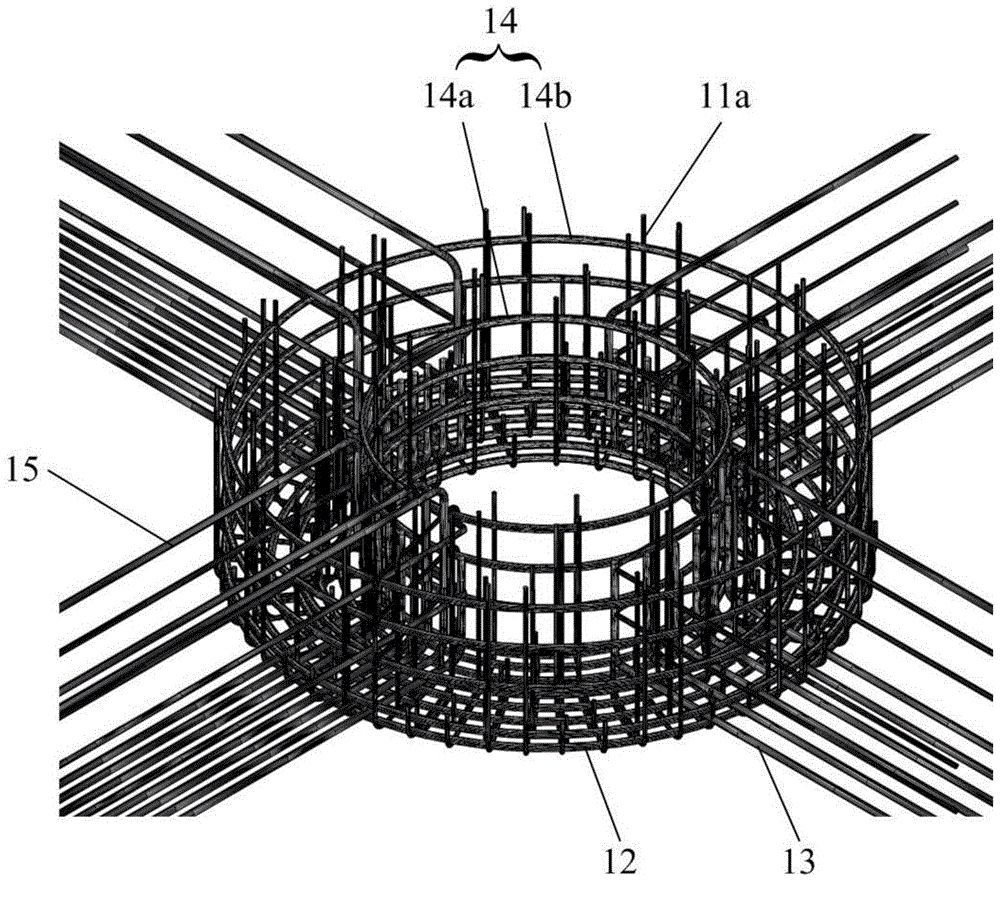

Double-steel-pipe concrete beam-column joint with built-in FRP rib connecting device and mounting method

ActiveCN111733986APrevent bucklingHigh strengthStrutsBuilding reinforcementsShaped beamConcrete beams

The invention relates to the field of building structures, in particular to a double-steel-pipe concrete beam-column joint with a built-in FRP rib connecting device. The double-steel-pipe concrete beam-column joint comprises double steel pipe columns, an I-shaped beam, a joint connecting piece, an inner supporting piece and an outer ring plate. The double steel pipe columns comprise inner steel pipes and outer steel pipes. The joint connecting piece comprises a connecting inner pipe and a connecting outer sleeve disc, and the connecting inner pipe and the connecting outer sleeve disc are bothround steel pipes. The inner supporting piece is of a columnar structure, and bolt holes are evenly distributed in the two ends of the inner supporting piece along the circumference. The outer ring plate comprises a horizontal part and an annular part which are perpendicular to each other. The upper-layer steel pipe column and the lower-layer steel pipe column are connected through the joint connecting piece and the inner supporting piece, the two ends of the inner supporting piece are inserted into the upper inner steel pipe and the lower inner steel pipe correspondingly, and FRP ribs sequentially penetrate through the annular part, the outer steel pipes, the connecting inner pipe and the inner steel pipes and then are fixed into the bolt holes of the inner supporting piece. According tothe double-steel-pipe concrete beam-column joint, the excellent tensile property and fatigue load resistance of the FRP ribs are utilized, the anti-seismic energy dissipation capacity of the joint iseffectively improved, and the safety and bearing capacity of the structure are enhanced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

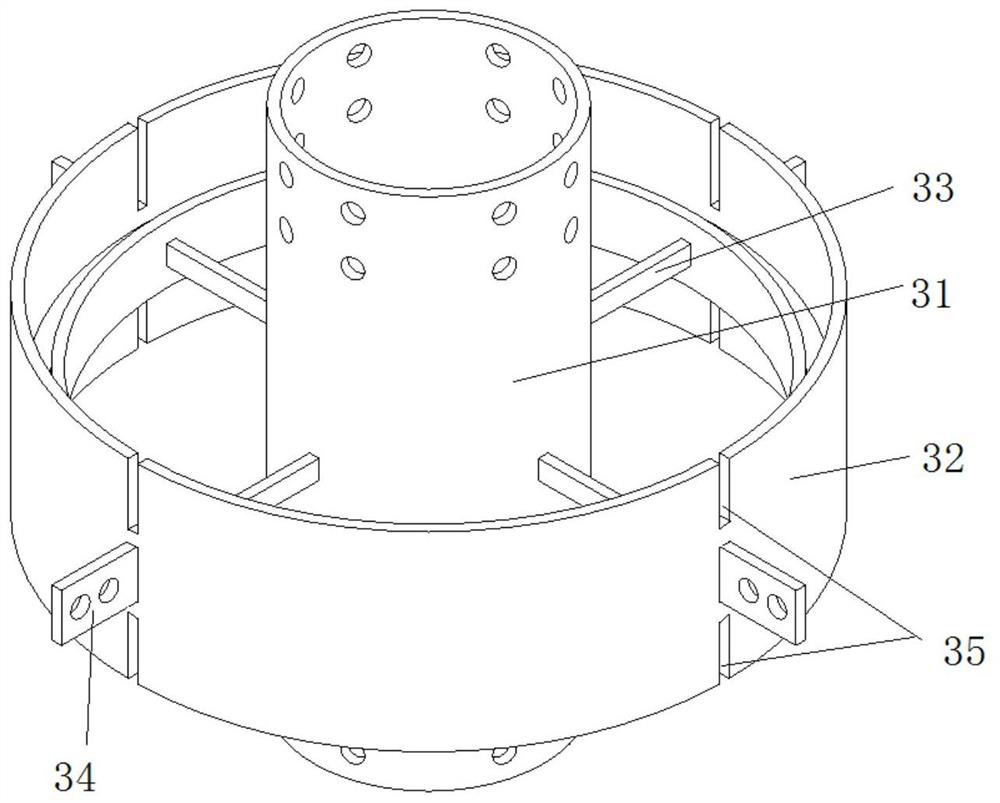

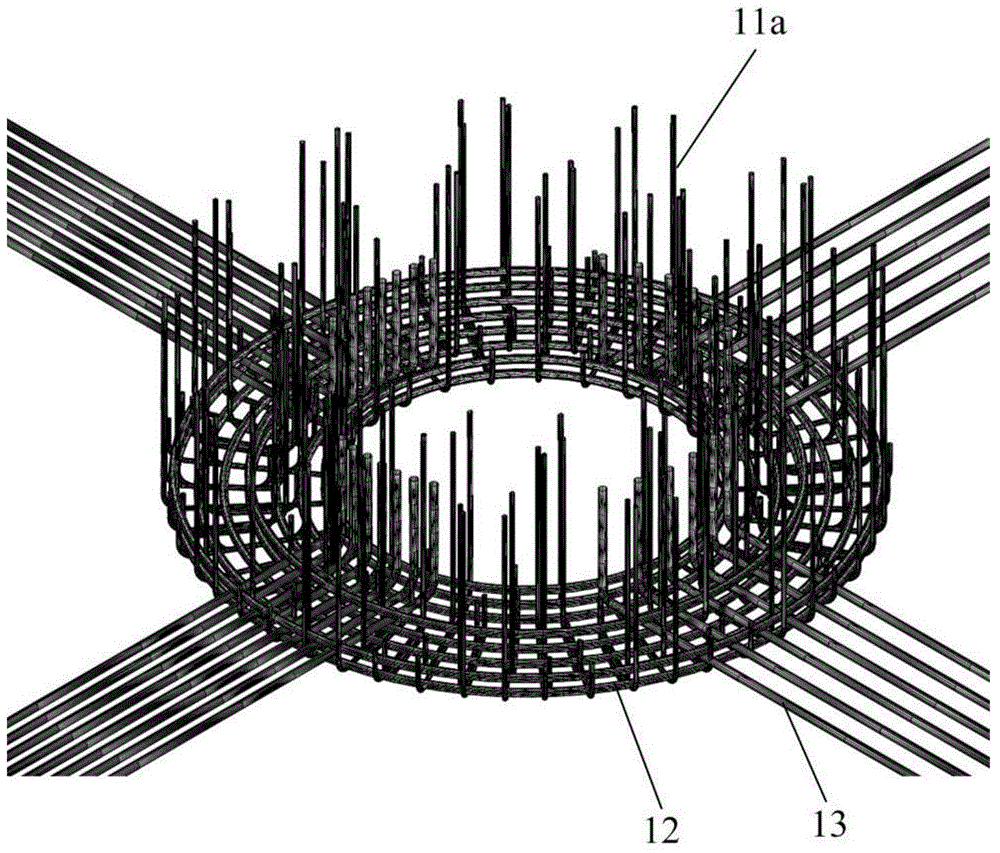

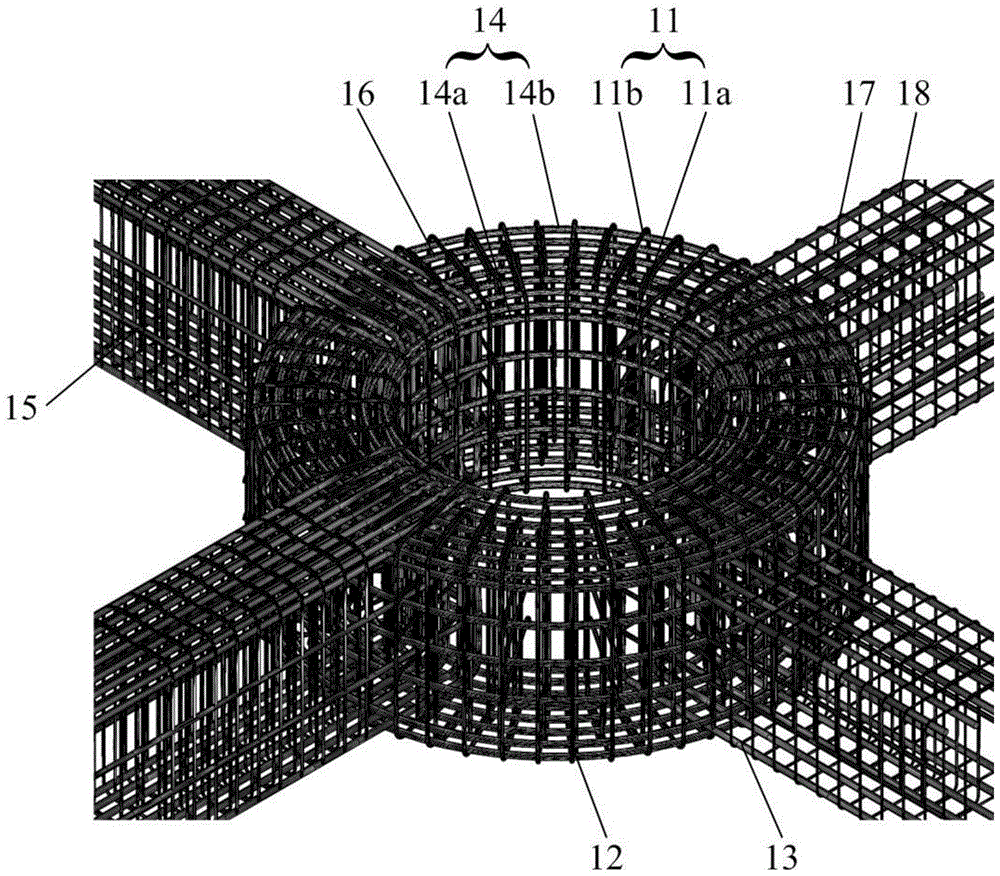

Construction method of constructing beam-column joint using ring beam

InactiveCN104947712AGuarantee the construction qualitySolve the problem of crossingArtificial islandsBuilding constructionsMultiple frameRebar

The invention discloses a construction method of constructing a beam-column joint using a ring beam, and relates to the technical filed of building construction. The construction method aims at solving the problems that the construction technology of rebar traversing in the position of the joint of the beam-column joint is complicated in an existing reverse building method, and harmful effect is caused to the joint structure when adjusting an original rebar structure on site. The construction method comprises the steps that 1 construction is conducted to form a concrete filled steel tubular column in the reverse building method, and a ring beam bottom cast is fixed to a bent surrounding the concrete filled steel tubular column; 2 multiple first U-shaped stirrups, ring beam bottom bars and lower rebars are erected in radial direction supported by the ring beam bottom cast; 3 multiple ring beam waist bars and multiple frame beam waist rebars are erected in the longitudinal direction of the axis of the concrete filled steel tubular column; 4 ring beam far bars and second U-shaped stirrups are erected, the first U-shaped stirrups and the second U-shaped stirrups can be put together and erected to form first annular stirrups, and the first annular stirrups are enclosed and fixed to the outer sides of the ring beam bottom bars, the ring beam waist bars and the ring beam face bars; fixing side formworks are installed, concreting is conducted, when a designed strength is reached, the formworks are removed, and construction of the beam-column joint is completed.

Owner:SHANGHAI NO 4 CONSTR

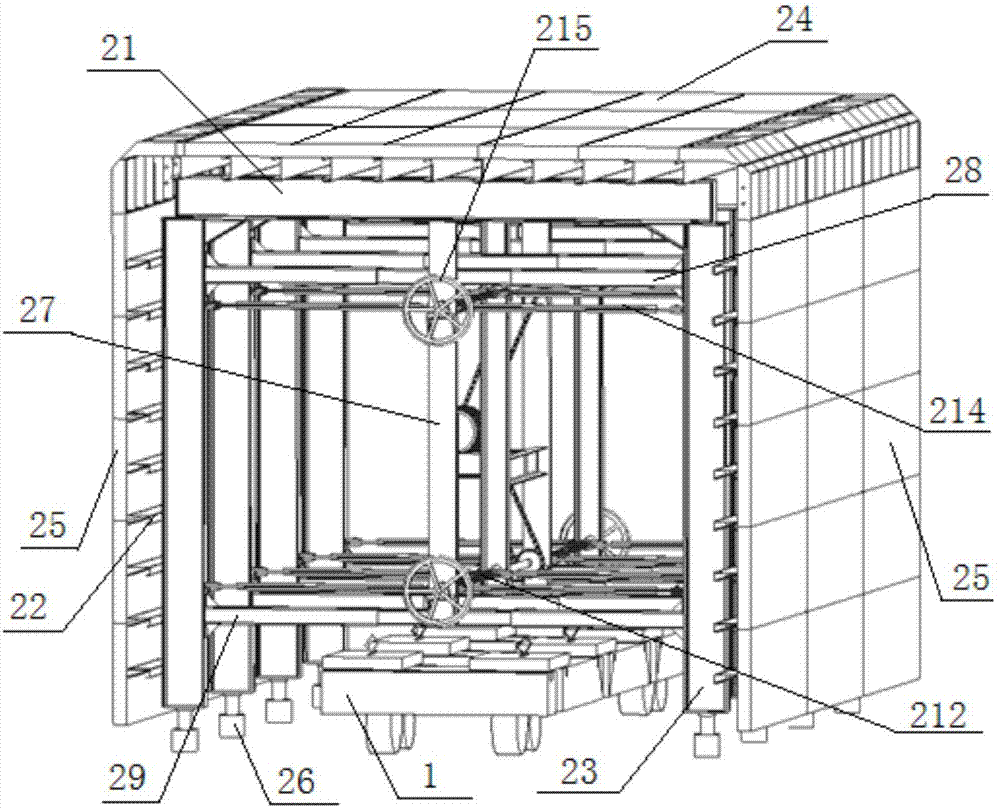

Automatic inner formwork equipment suitable for pipe gallery construction and construction method thereof

ActiveCN107956487AQuick and stable installationQuick supportUnderground chambersHydro energy generationControl systemArchitectural engineering

The invention discloses automatic inner formwork equipment suitable for pipe gallery construction and a construction method thereof. The automatic inner formwork equipment comprises an inner formwork,a moving trolley and a control system, and the control system controls walking of the moving trolley and telescoping reinforcement of telescopic I-beams of the inner formwork. The moving trolley of the equipment can carry the inner formwork to a specified construction site, and the action of placing and spreading the inner formwork can be automatically completed through an automatic loading and unloading mechanism of the moving trolley in cooperation with supporting jacks and the telescopic I-beams of the inner formwork. By adopting the control system for control, the problems that in the prior art, the labor intensity of workers is high, many potential safety hazards exist, the construction efficiency is low and the input cost is high are effectively relieved, and the function of automatic construction is achieved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

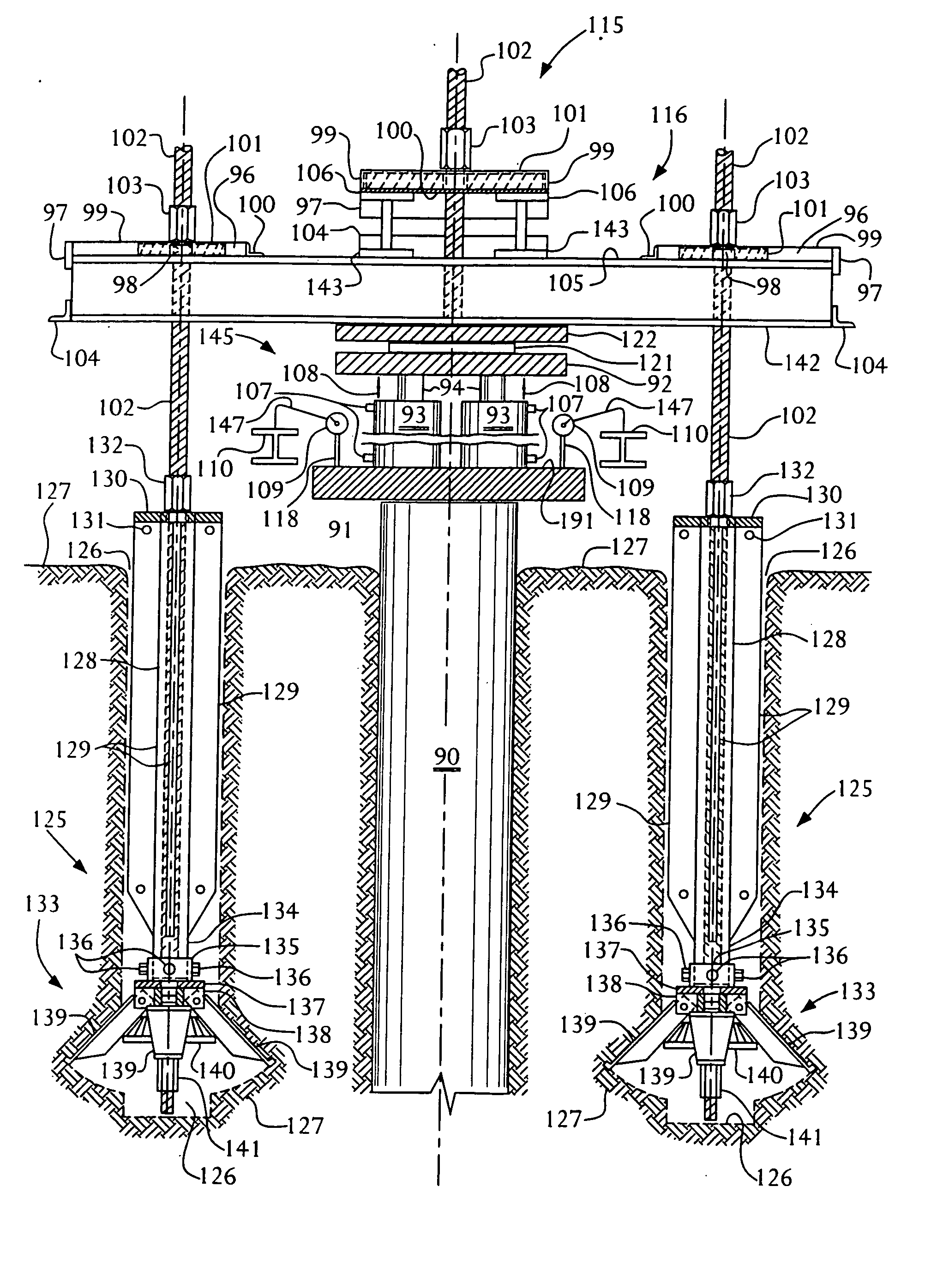

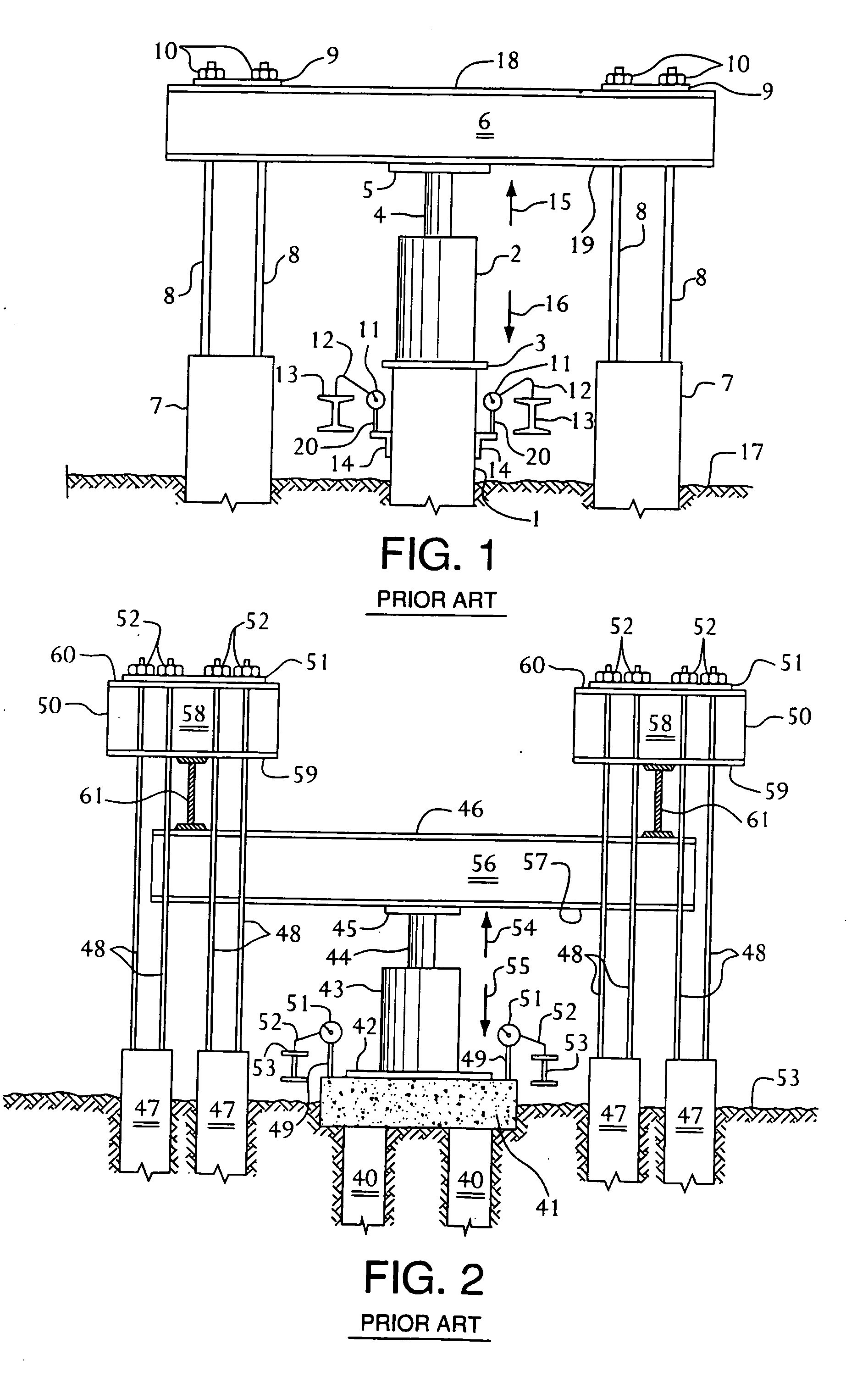

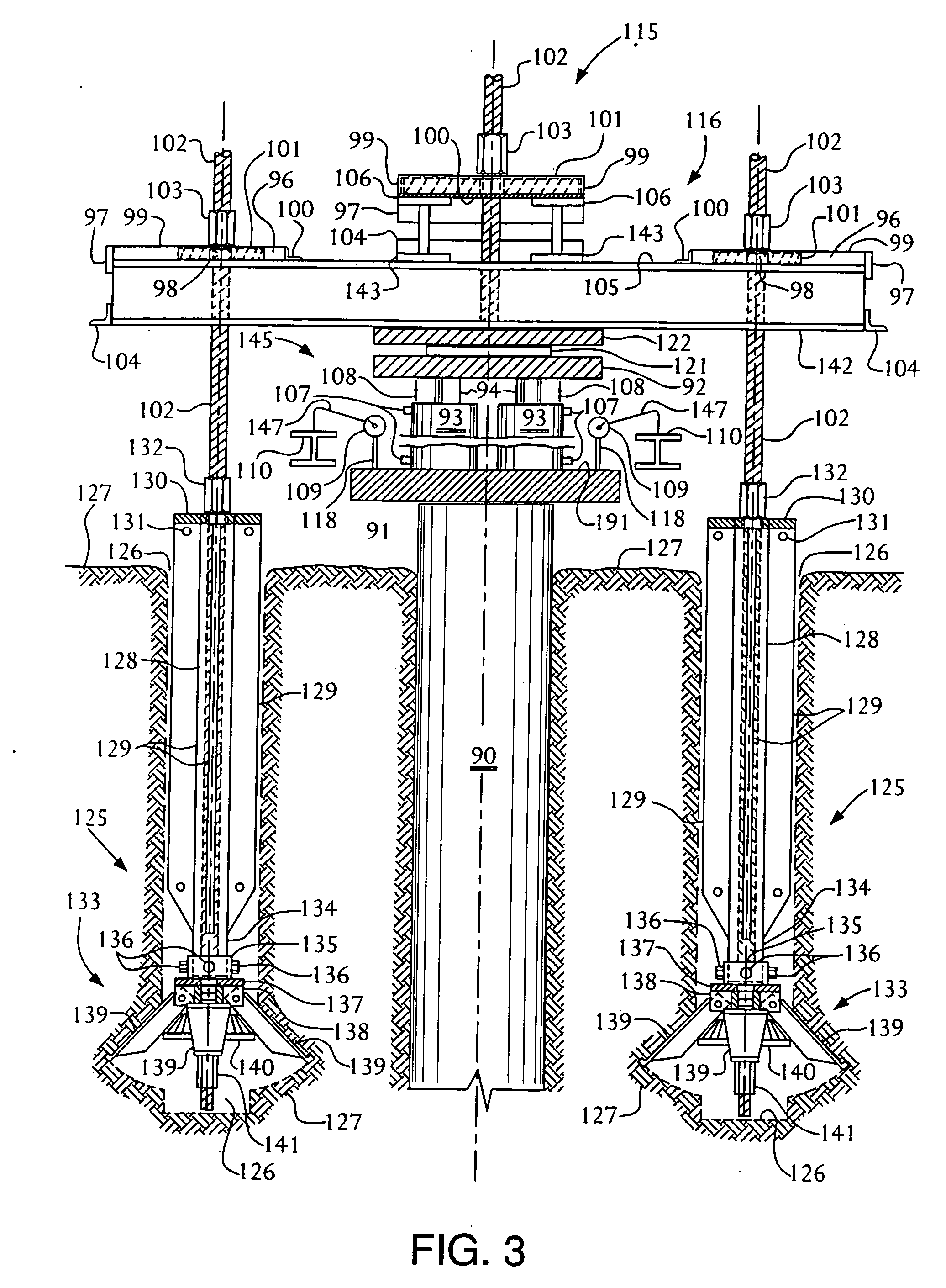

Pile testing reaction anchor apparatus and method

InactiveUS20060070454A1Foundation testingMaterial strength using tensile/compressive forcesLoad bearingArchitectural engineering

Pile testing apparatus and method apply static compressive forces on a pile to be tested for load bearing capacity. Retractable and reusable reaction anchor assemblies are installed into the ground for pile testing and then are retrieved from the ground after completion of the pile testing and are reused from one pile test site to another. The invention operates to receive an equal and opposite reaction force on an I-beam and provide at least two retractable and reusable reaction anchor assemblies installed into the ground at a depth significantly less than required with conventional pile testing methods. The I-beam is braced by the two retractable and reusable reaction anchor assemblies and held stationary in counter-action against the opposite reaction force on the I-beam. The pile testing apparatus and method of the present invention reduce costs considerably and can be used immediately as contrasted to conventional methods using concrete.

Owner:METAL FOUND ACQUISITION

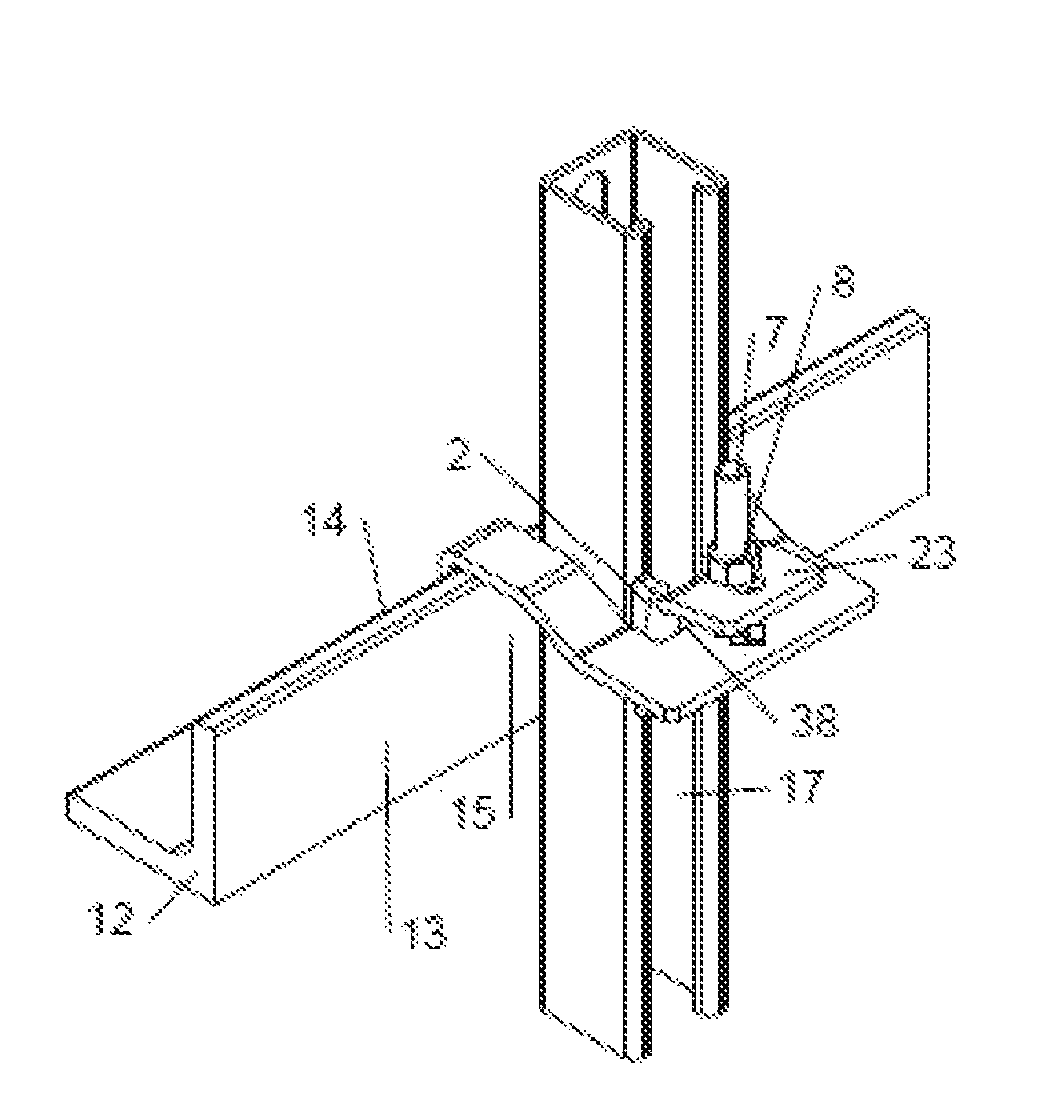

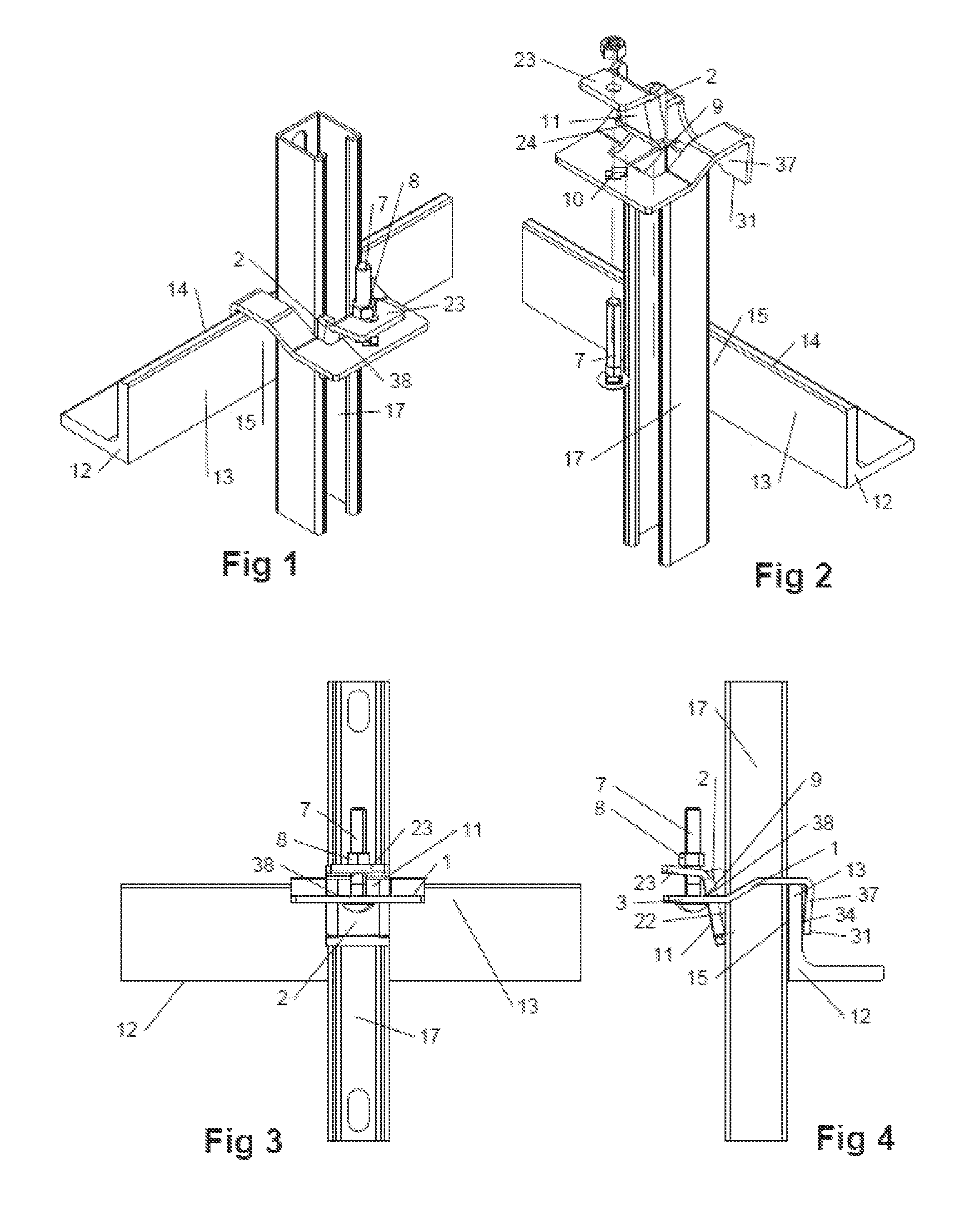

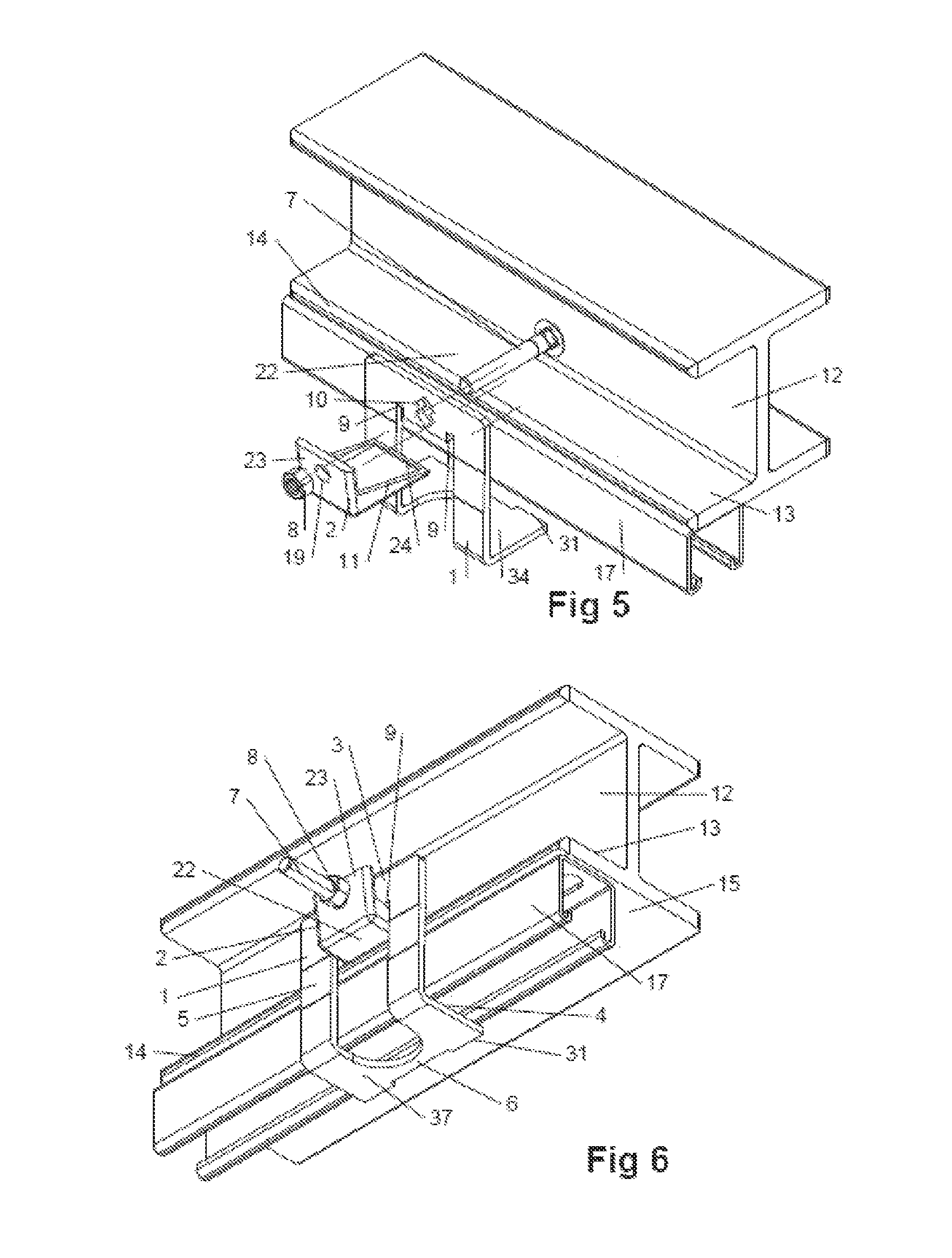

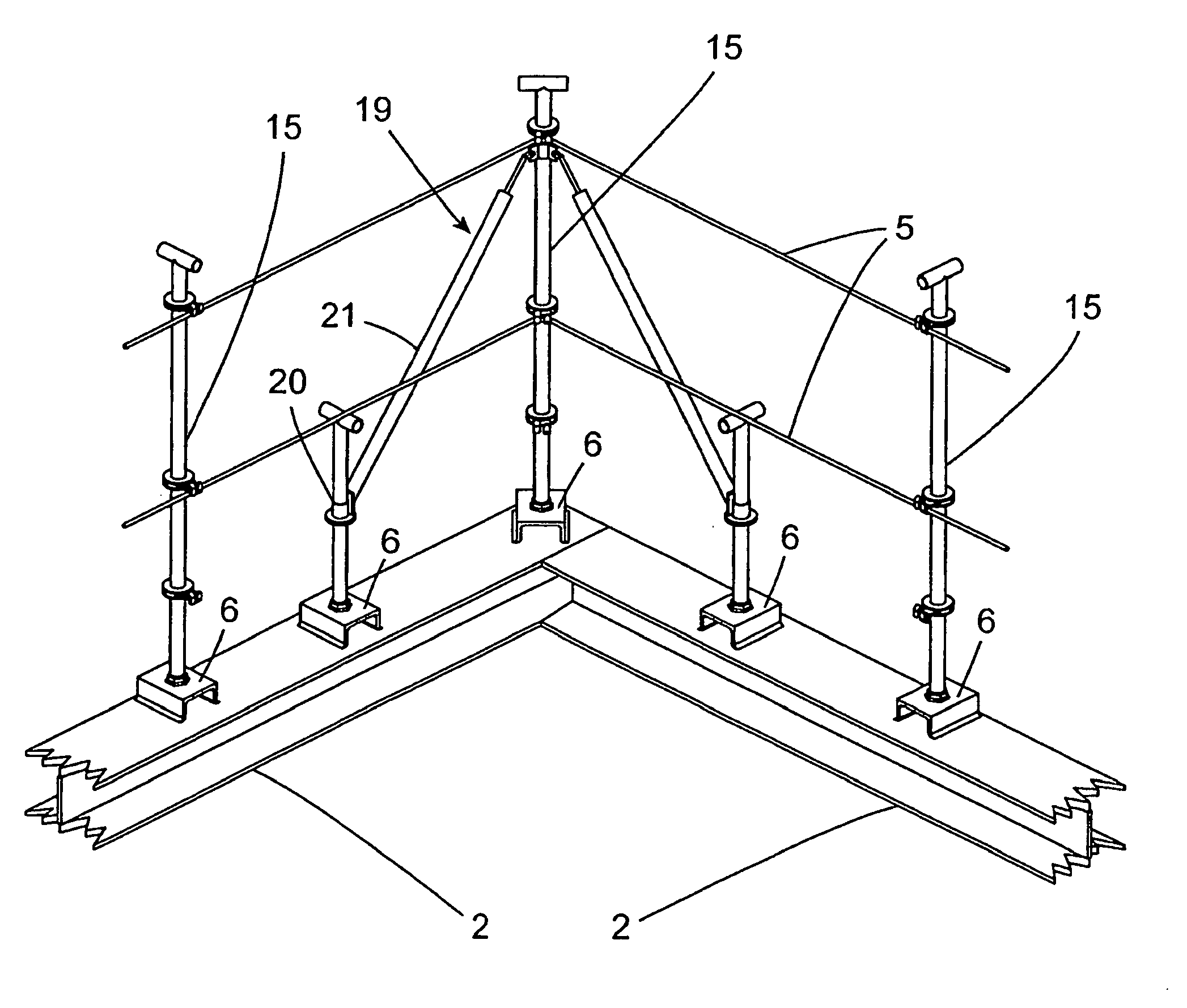

Corner connection for temporary shoring

A corner connection used to secure I-beams together at corners within the excavation site is provided with a reinforcing assembly that allows for greater loads. Typically, four I-beams are connected together to form a rectangular frame that is suspended within the excavation for bracing the shoring walls thereof; however, any polygonal shape may be used. The corner connection itself comprises mating socket or connecting members that are placed over the ends of I-beams to be fastened together. One of the connecting members includes an outwardly extended tab while the other includes a pair of outwardly extended tabs. The first outwardly extending tab fits between the two extending tabs of the corresponding connecting member. All of the tabs are provided with apertures that are placed in alignment when the connection is made so that a bolt or pin can be passed through the apertures to secure the two connectors together. An additional set of tabs is provided on the connecting members that is also provide with apertures. A reinforcing assembly is provided and includes a reinforcing bar with tabs. A first spacer bar is attached to the reinforcing bar and one connecting member and a second spacer bar is attached to the reinforcing bar and an adjacent connecting member. The spacer bars, the reinforcing bar and the connection members are all connected with tab / pin connections. Advantageously the reinforcing assembly can use the existing second set of tabs located on the prior art connectors. Such an arrangement provides much greater support for the sidewalls of the excavation site.

Owner:MEYER JOHN HENRY +1

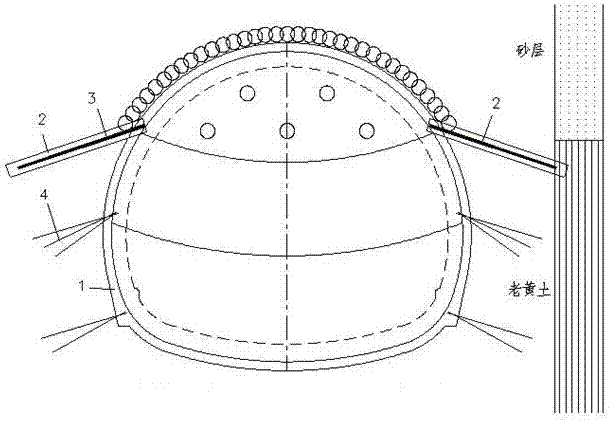

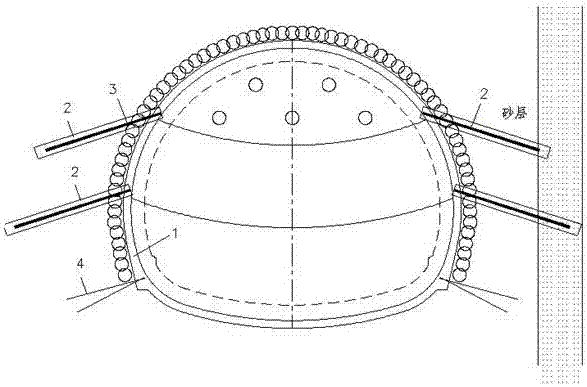

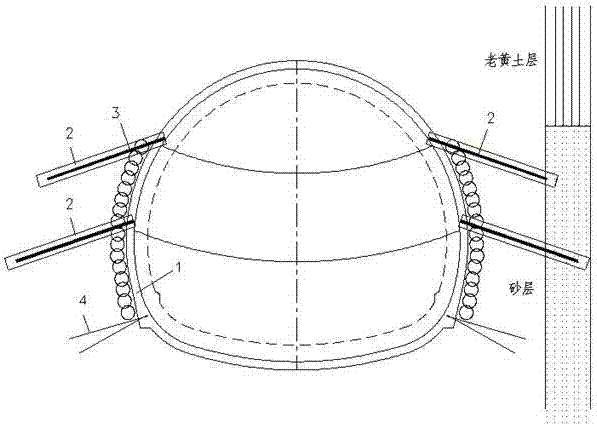

Lock foot pile support structure for controlling tunnel initial support settlement convergence

PendingCN106979027ASimple processLess impact from process changeoverUnderground chambersTunnel liningArchitectural engineeringSteel frame

The invention discloses a lock foot pile support structure for controlling tunnel initial support settlement convergence. The structure comprises an initial support in the tunnel grotto. A tilted lock foot pile is arranged at the outer wall of the initial support; the lock foot pile comprises a rotary jetting pile body, and the rotary jetting pile body is connected to an L-shaped steel core material. The other end of the L-shaped steel core material is connected with a connecting steel bar. The connecting steel bar is connected to an I beam steel frame of the initial support. The lock foot pile support structure for controlling the tunnel initial support settlement convergence has the advantages that the technical process is simple; the effected interference to the process conversion is less, the operation is convenient; the work efficiency is improved; the problems that the excavations of middle and lower steps cause the arch foot to be vacant, the side wall of the tunnel is unstable or the slippage and the grouting and anchorage effect of lock foot are poor are overcome; the stability of the palm surface, the deformation and settlement of the control cavern and the mechanized construction are achieved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Roof steel structure and construction method thereof

InactiveCN105040880AImprove stabilityOvercoming technical deficienciesBuilding roofsBuilding material handlingEngineeringI-beam

Owner:中国华西企业股份有限公司

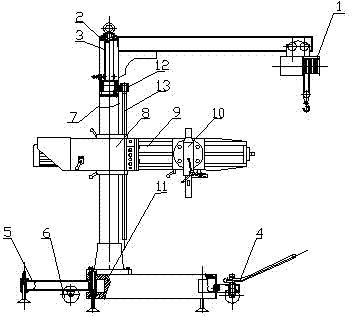

Movable type suspension crane rocker arm drilling machine

InactiveCN103111654AImprove product qualityLow costLarge fixed membersBoring/drilling machinesPolyesterClassical mechanics

The invention discloses a movable type suspension crane rocker arm drilling machine which is divided into a suspension crane and a radial drill. The movable type suspension crane rocker arm drilling machine comprises a base (11), a vertical column (7), a drilling machine gearbox (8), a horizontal arm (9) and a main shaft box (10), wherein a column body of the vertical column (7) is connected with the horizontal arm (9) in a sliding mode, the horizontal arm (9) is connected with the main shaft box (10) in a sliding mode, the drilling machine gearbox (8) is arranged on the horizontal arm (9) and the horizontal arm (9) is connected with a lifting lead screw (13) through variable gears. The bottom end of the vertical column (7) is connected with the base (11), and the top end of the vertical column (7) is connected with a vertical shaft (3). The vertical shaft (3) is connected with an I-beam rocker arm assembly (2). One end of the I-beam rocker arm assembly (2) is provided with a suspension crane electric block (1). According to the movable type suspension crane rocker arm drilling machine, two rocker arms do not interfere with each other and rotate independently. Polyester foaming is used to fill the vertical column space, so that the problem that the steel pipe vertical column is not good in shock absorption effect in the machining of a lathe is resolved, and the humming sound and the ringing sound occurring when the metal pipe is struck are avoided. The production quality of the vertical column is improved greatly and the cost of the vertical column of the lathe is reduced greatly.

Owner:JIANGXI PROVINCE ZHONGCHUN MACHINE TOOL BEARING MFG

Hacksaw with blade tensioning mechanism

ActiveUS8881411B2Improve the level ofLower Level RequirementsMetal sawing devicesSawing apparatusClassical mechanicsKnife blades

A hacksaw with an improved mechanism for applying and adjusting the tension on a blade mounted to a blade mount on a front arm and a blade mount on a rocker arm. The rocker arm is pivotally coupled to a handle and is spring biased to place an initial tension on a blade held by the rocker arm and the front arm. A rotatably mounted lever is positioned on the handle for vertically displacing a nut captured in the rocker arm to pivot the rocker arm and adjust the tension on the rocker arm-held blade. An elongate top frame bar of the hacksaw defines a hollow I-beam cross-section accessible from the face of the front handle and is capable of storing saw blades. A bale screw is positioned in the front member for securing the blades in a position extending past the front handle.

Owner:BLACK & DECKER INC

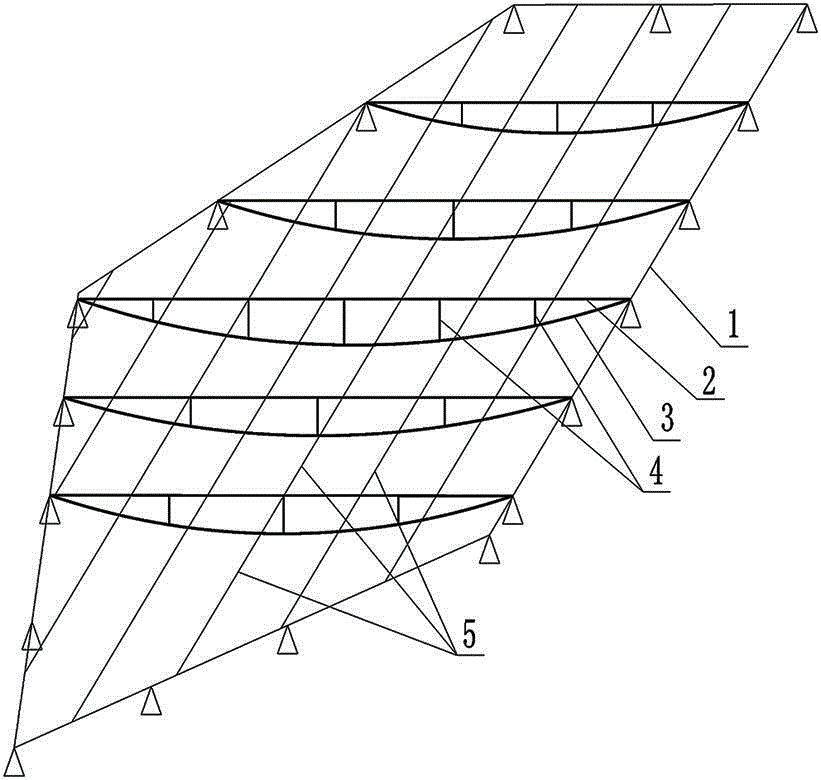

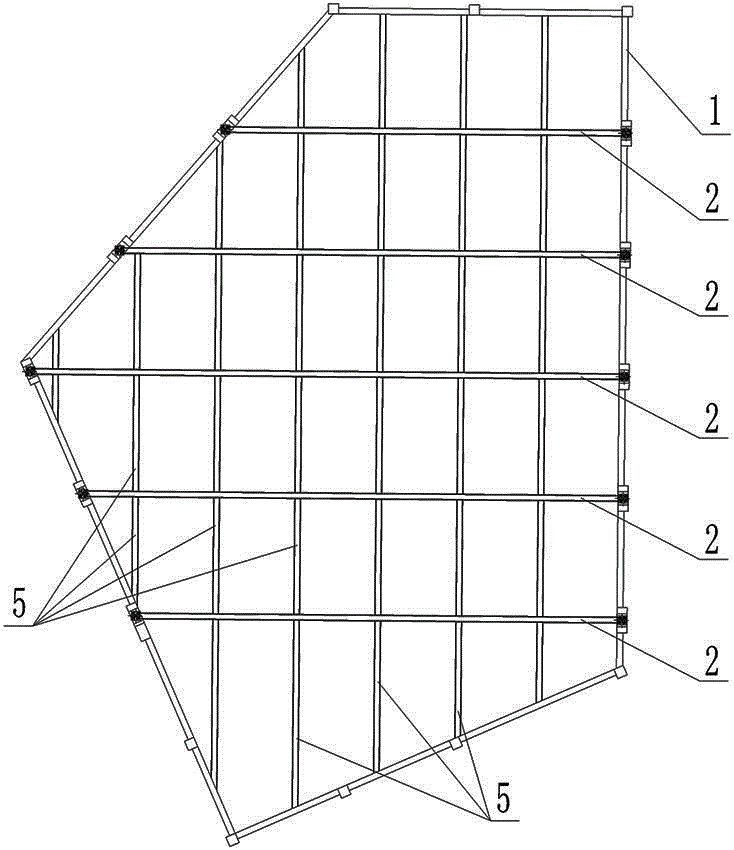

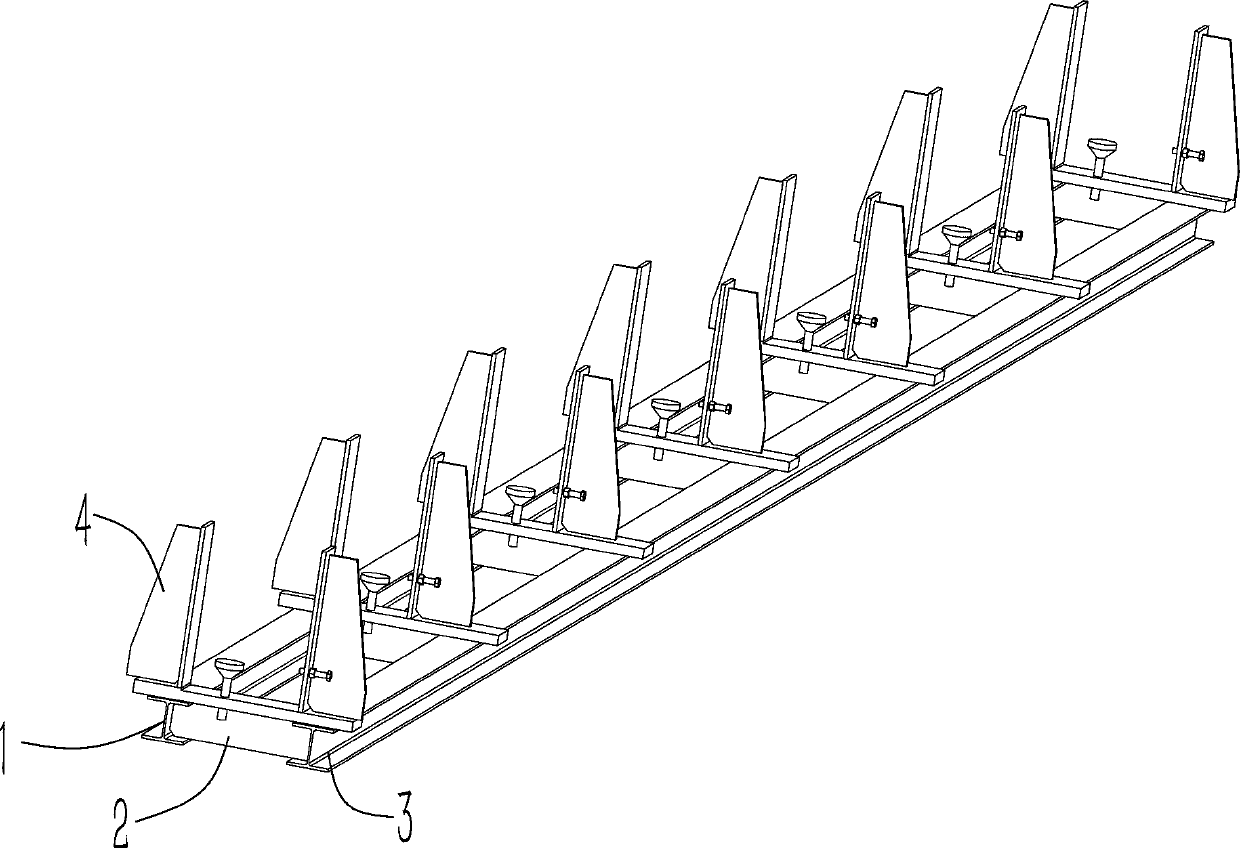

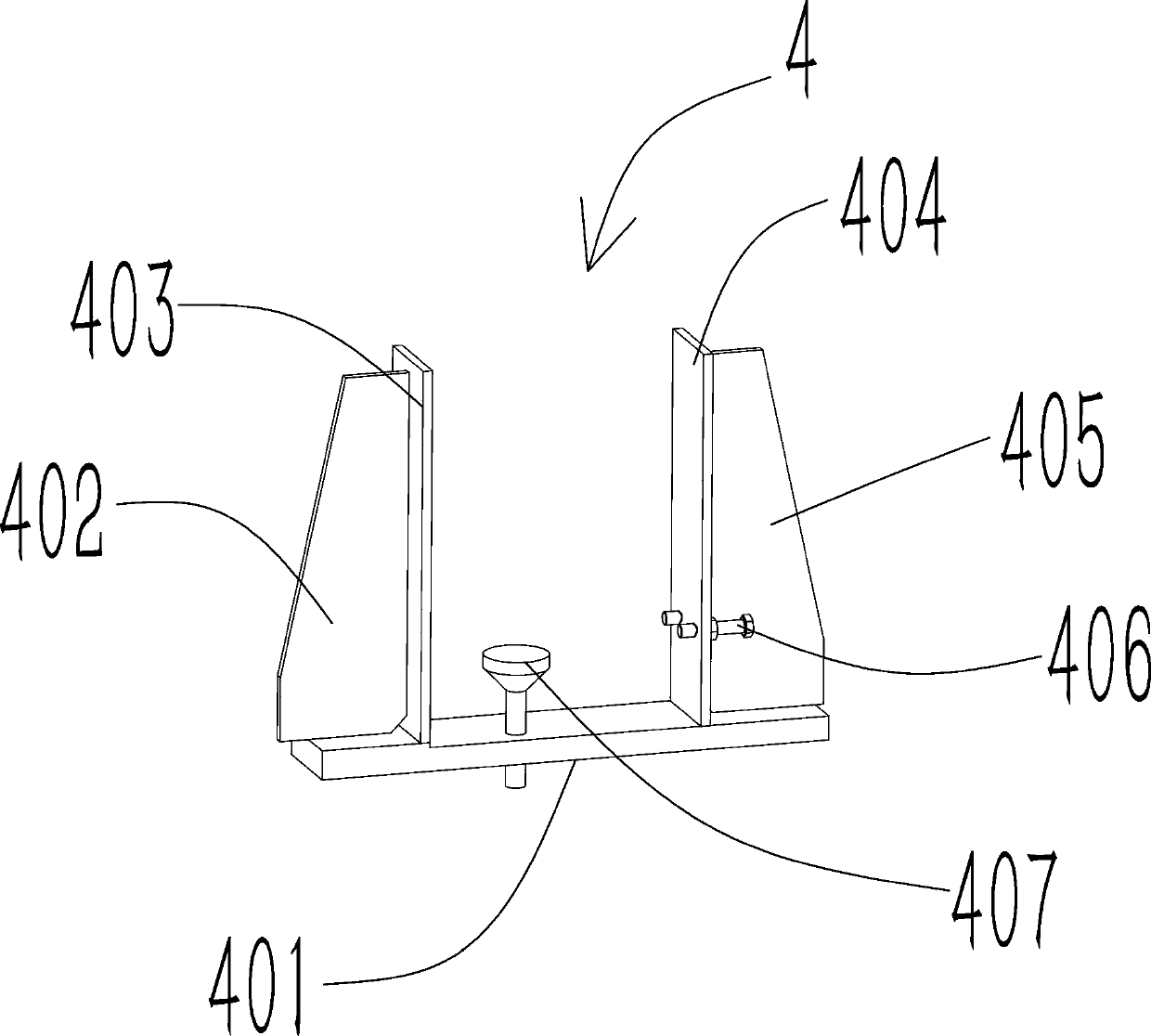

Supporting system and constructing technology for integrally pouring superimposed sheet and wallboard

PendingCN107663951ASimple structureHigh strengthBuilding material handlingSupporting systemFloor slab

The invention discloses a supporting system and a constructing technology for integrally pouring a composite floor slab and a wallboard. The supporting system comprises a bearing member, a member system and a supporting assembly, wherein the member system comprises the wallboard, a superposed beam, cast-in-place columns and the composite floor slab; the cast-in-place columns are arranged on the bearing member, the superposed beam and the wallboard are connected between the cast-in-place columns, the superposed beam is arranged above the wallboard, and the superposed beam comprises a precast beam and a cast-in-place beam arranged above the precast beam; the supporting assembly is arranged on the bearing member, a work space is arranged between the supporting assembly and the wallboard, andthe supporting assembly comprises a plurality of tripod type independent supports arranged on the bearing member and I beams arranged on the tripod type independent supports; the composite floor slabis arranged on the I beams, the lateral edge of the composite floor slab is attached to the superpose beam and / or the wallboard, and the composite floor slab comprises a prefabricated floor slab and acast-in-place floor slab arranged above the prefabricated floor slab. The supporting system has the advantages of simple structure, high whole strength, short construction time and ability in greatlyreducing total cost of the whole building construction.

Owner:浙江新邦远大绿色建筑产业有限公司 +1

Large I-shaped beam welding platform and welding method

PendingCN110900082AGuaranteed stabilityGuaranteed verticalityWelding/cutting auxillary devicesArc welding apparatusShaped beamStructural engineering

The invention provides a large I-shaped beam welding platform and a welding method. The large I-shaped beam welding platform comprises first I-shaped steel and second I-shaped steel which are placed in parallel; multiple connecting plates are arranged between the first I-shaped steel and the second I-shaped steel; the first I-shaped steel and the second I-shaped steel are connected through the multiple connecting plates; positioning devices are arranged on the connecting plates respectively; a large I-shaped beam profile is placed in the positioning devices, the end surface of the large I-shaped beam profile is supported by cushion blocks, and the side surfaces of the large I-shaped beam profile are locked and fixed by bolts; all the positioning devices are ensured to be in one horizontalplane, a first vertical plate and a second vertical plate in each positioning device are perpendicular to a transverse plate, and the bolt on the second vertical plate are used for locking the right side plate of the large I-shaped beam; and by placing the large I-shaped beam on the platform, the perpendicularity and the parallelism between two plates during welding can be ensured, locking and fixing are firm, the welding deformation quantity is small, tool positioning and clamping are achieved, and mounting and welding in size are achieved into place with one step.

Owner:YICHANG JIANGXIA MARINE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com