Construction technology for prefabricating a corrugated steel web PC I beam into combined box girder bridge

A technology of corrugated steel webs and construction technology, which is applied to bridges, bridge materials, bridge construction, etc., can solve the problems of long construction period, immaturity, and high cost of manpower and material resources, and achieve low input costs, simple structure, and easy construction. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

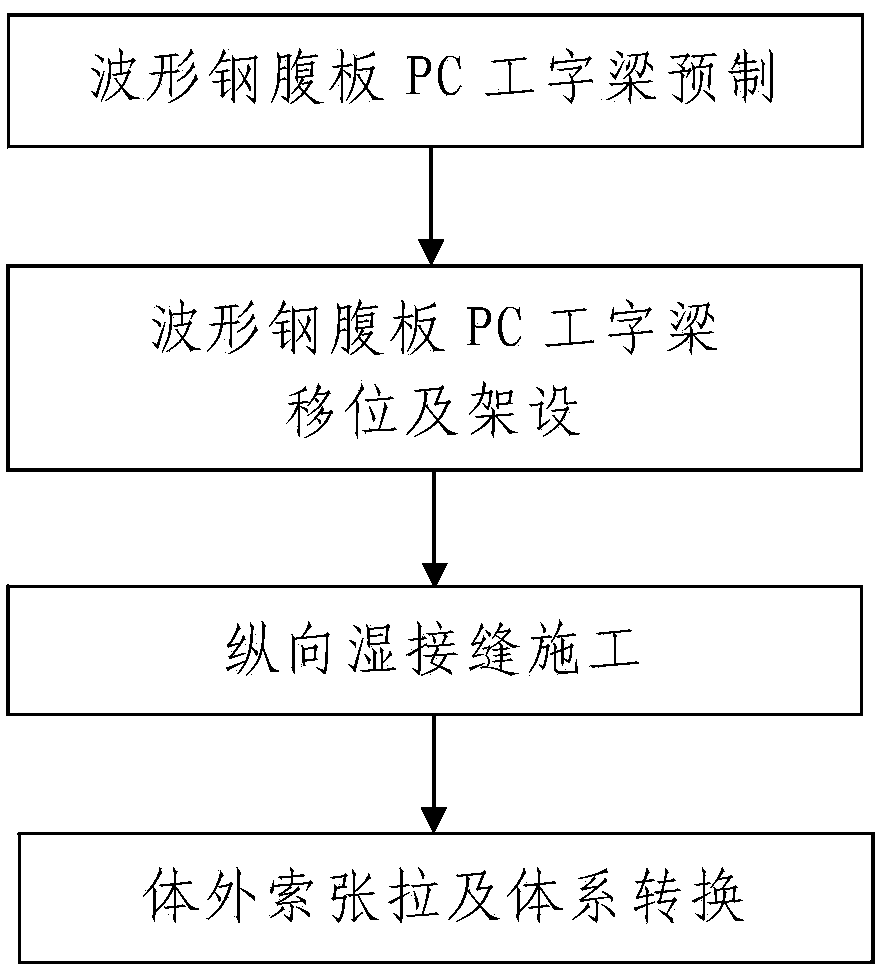

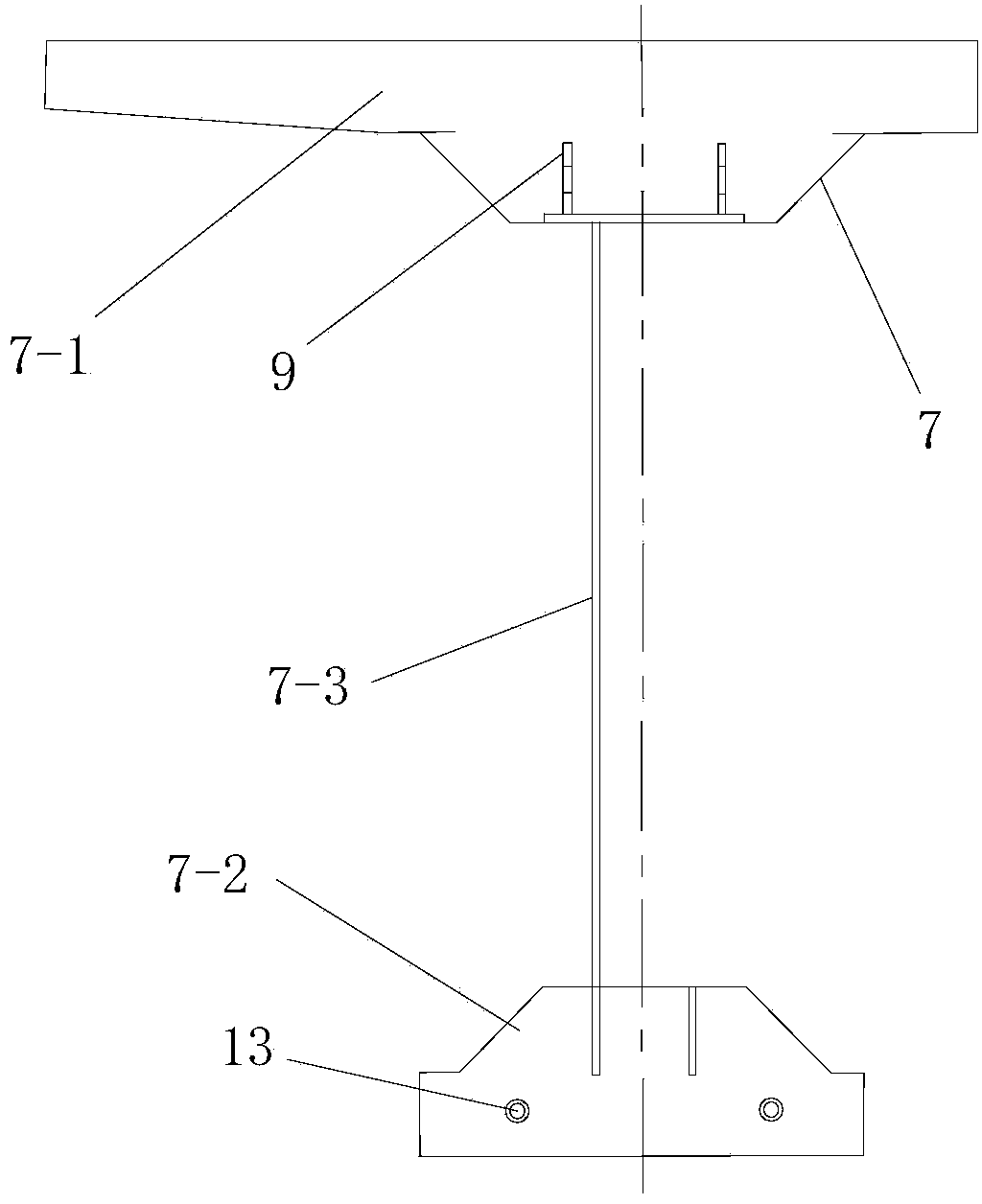

[0069] Such as figure 1 A construction process of prefabricated corrugated steel web PC I-beam to composite box girder bridge is shown. The composite box girder bridge constructed includes a composite box girder erected on the lower support system of the bridge. The direction is divided into a plurality of composite box girder segments, each of which is formed by connecting two PC I-beams 7 with corrugated steel webs arranged symmetrically. The process includes the following steps:

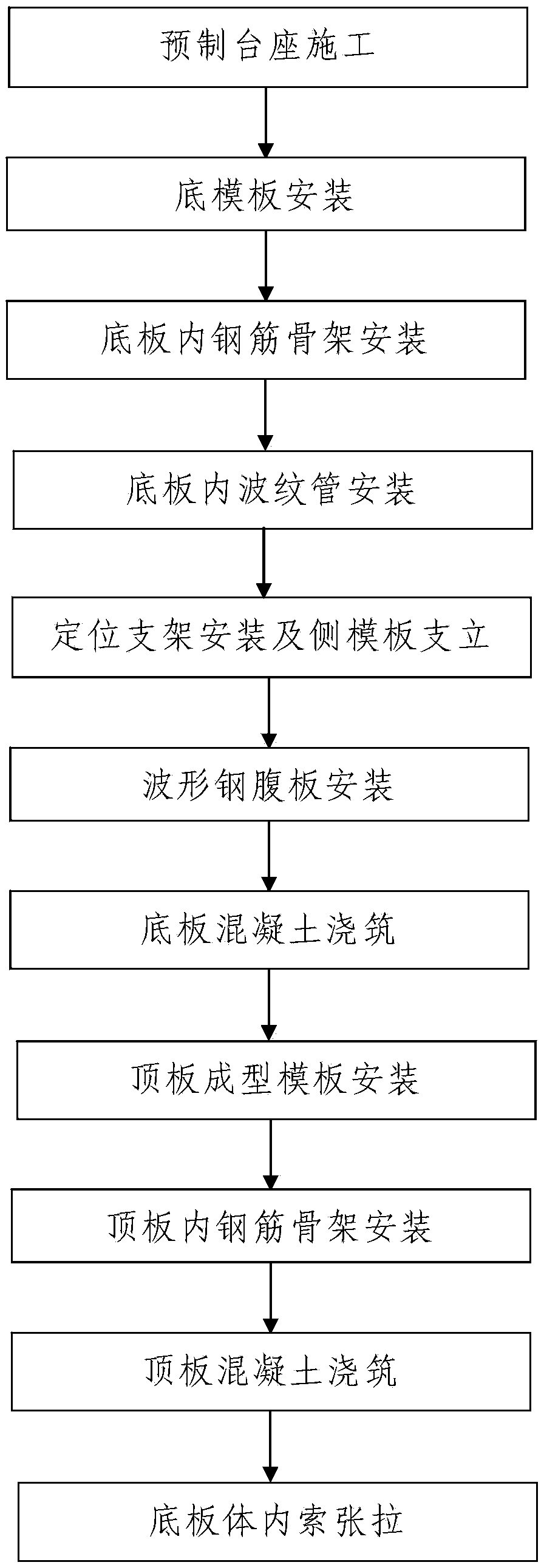

[0070] Step 1. Prefabrication of PC I-beams with corrugated steel webs: combination Picture 1-1 , the corrugated steel web PC I-beam 7 required for the construction of the composite box girder is prefabricated, and the process is as follows:

[0071] Step 101, construction of prefabricated pedestal: first lay a layer of concrete cushion 5 on the prefabricated site, and construct concrete pedestal 1 on the concrete cushion 5 as a prefabricated pedestal for corrugated steel web PC I-beam 7, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com