Sky train body welding fixture and welding method thereof

A technology of aerial track and welding tooling, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor versatility, shrinkage and deformation quality of car body welding, unqualified, etc., to achieve convenient switching and solve key dimensions and contours Unsatisfactory degree, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

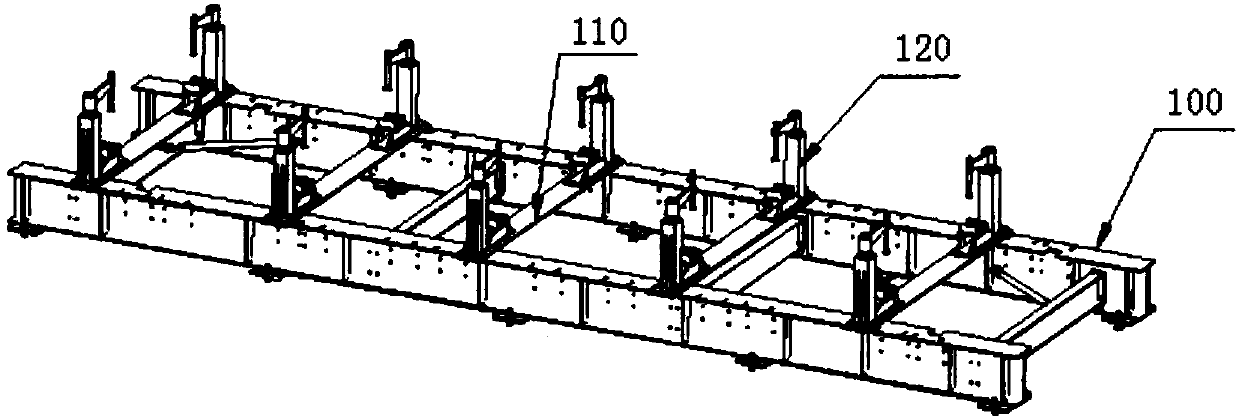

[0047] see figure 1 , a kind of aerial rail train car body welding tooling, including basic tooling 100, beam 110, side beam clamping device 120, side beam block and auxiliary strut for car body assembly, said beam 110 straddles the basic tooling 100 , the side beam clamping device 120 is located at both ends of the beam 110 , and the side beam block is connected with the side beam clamping device 120 .

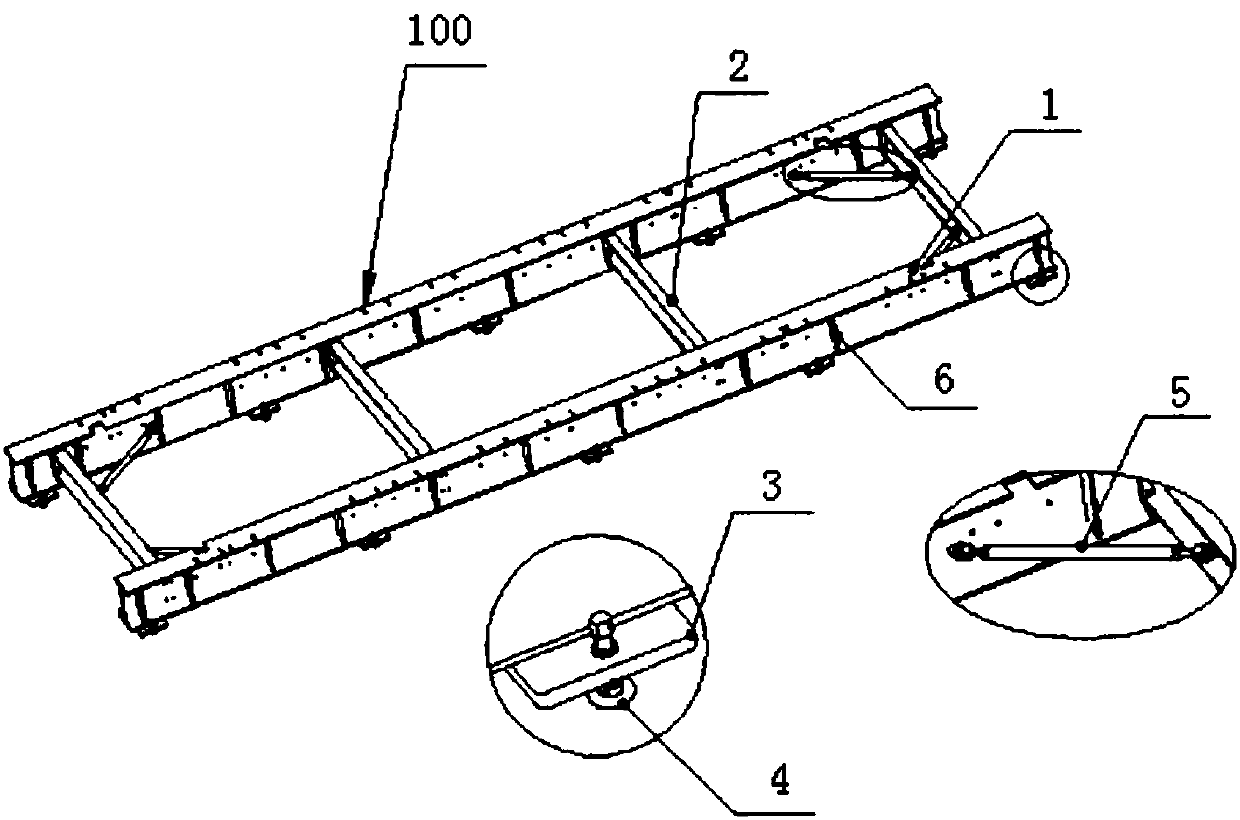

[0048] see figure 2 , image 3 , the basic tooling includes a longitudinal I-beam 1 , a transverse I-beam 2 , a bottom plate 3 , an adjusting bolt 4 , a strut assembly 5 and a longitudinal rib 6 . There are two longitudinal I-beams 1 parallel to each other, and several transverse I-beams 2 are parallel to each other. The transverse I-beams 2 span the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com