Patents

Literature

311results about How to "Control welding deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for welding specially-thick high-strength bridge steel plate

InactiveCN102744498AImprove welding efficiencyReduce manufacturing costArc welding apparatusWorkpiece edge portionsSteel platesSubmerged arc welding

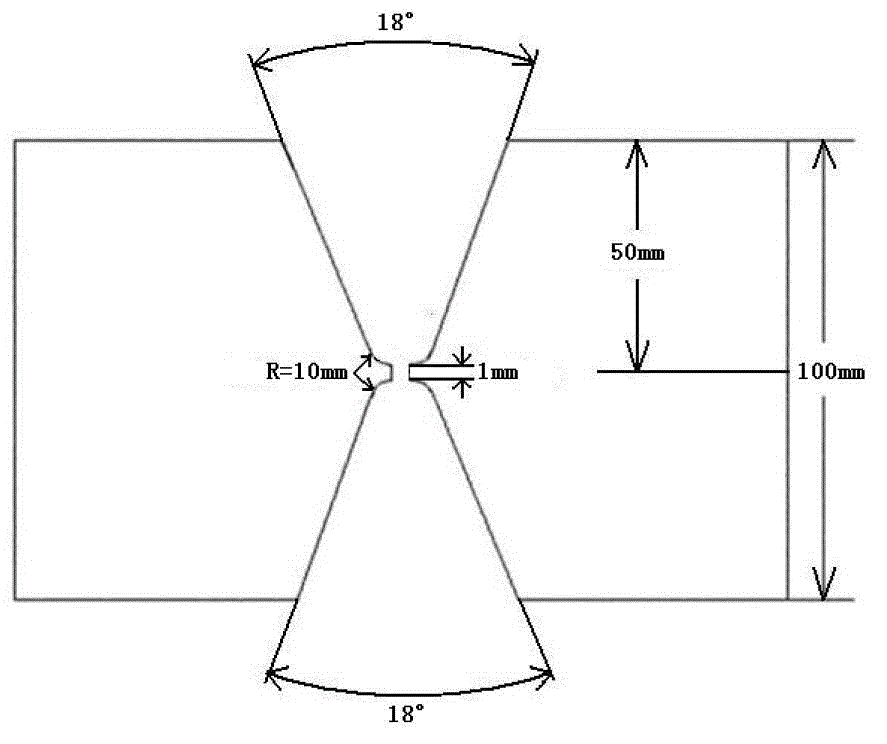

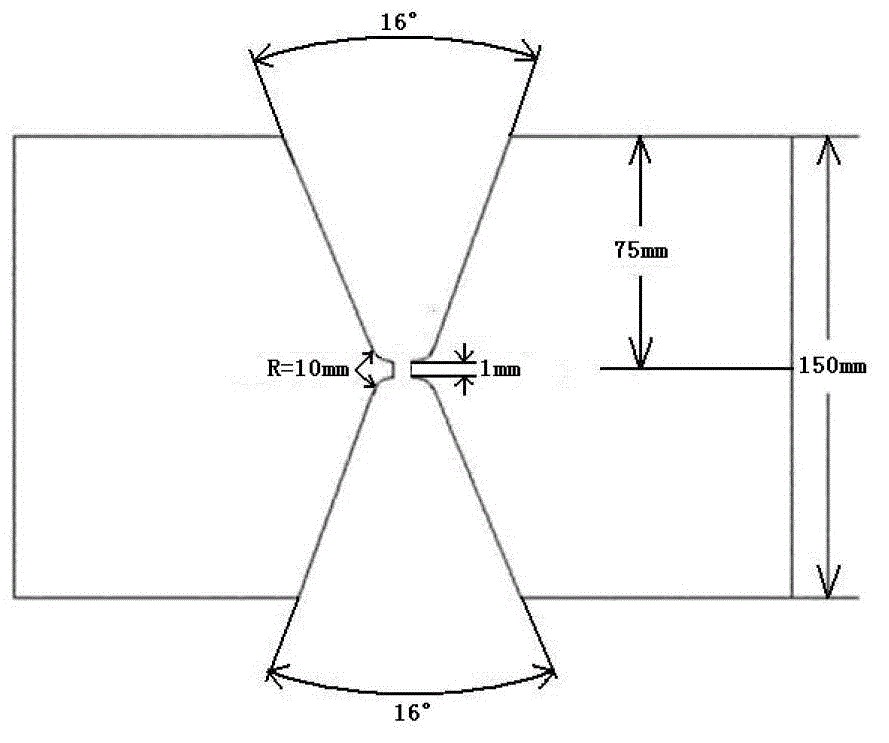

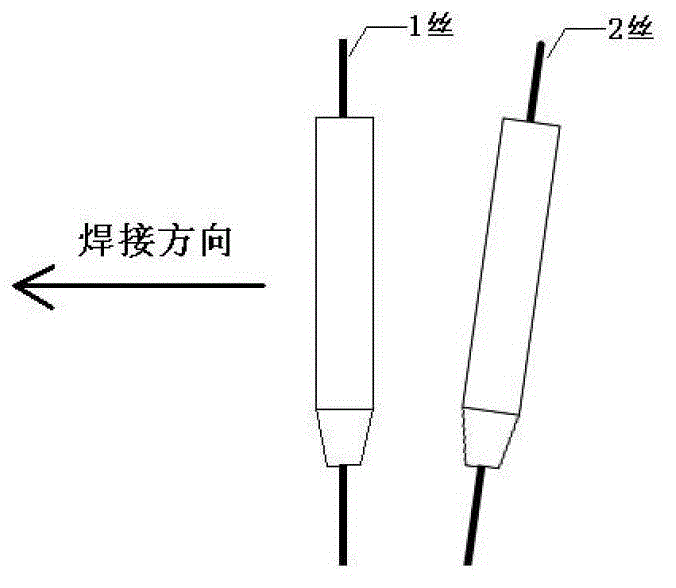

The invention provides a method for welding a specially-thick high-strength bridge steel plate and belongs to the technical field of specially-thick plate welding. The test plate of the method adopts a symmetric narrow gap U-shaped groove form, is combinedly welded by using two efficient welding methods, namely gas shielded welding for priming and bottom filling, and double-wire submerged arc welding for continuous filling and finishing, so as to achieve the purposes of reducing filling level and giving full play to the efficient double-wire submerged arc welding and high automation degree. The method has strong operability, greatly improves the welding efficiency of the specially-thick bridge steel plate, and significantly reduces manpower cost. Furthermore, by selecting a proper welding sequence, the method solves the problem that the welding deformation of the specially-thick steel plate is hard to control.

Owner:SHOUGANG CORPORATION

Cartridge receiver welding method and clamp applied to same

ActiveCN104162759AGuaranteed sizeGuaranteed contourWelding/cutting auxillary devicesArc welding apparatusPunchingButt joint

The invention provides a cartridge receiver welding method. The cartridge receiver welding method includes the following steps that during installation, it is guaranteed that an upper installation side and a lower installation side are higher than the wall of a cartridge receiver by 0-0.2 mm; manual argon arc welding positioning welding is conducted, and weld joint rolling and profile correction are conducted by a bench worker; through automatic argon arc welding and weld joint rolling and profile correction which are conducted by the bench worker, punching is conducted at the positions, to be welded and corresponding to twelve bosses, of the wall of the cartridge receiver through laser cutting; manual argon arc welding positioning welding is conducted on the twelve bosses, weld joints are leveled by the bench worker, and it is guaranteed that the bosses at the butt joint positions are higher than the wall of the cartridge receiver by 0-0.2 mm; manual argon arc welding is conducted on the twelve bosses; weld joints are leveled by the bench worker, the profile tolerance of a part is corrected, and it is guaranteed that gaps between the part and a model is not larger than 0.5 mm; welding of the cartridge receiver is completed. According to the cartridge receiver welding method, welding deformation can be well controlled, and therefore it is guaranteed that the size and the profile tolerance of the finished cartridge receiver meet requirements. The invention further provides a special clamp applied to the welding method.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

Submerged-arc welding process for T-type joint for extra thick steel plate

ActiveCN102240841AImprove welding qualityReduce the deterioration of mechanical propertiesArc welding apparatusCrazingThick plate

The invention discloses a submerged-arc welding process for a T-type joint for an extra thick steel plate and belongs to the technical field of welding of extra thick plates. The process comprises the following steps of: before welding, pre-heating the extra thick steel plate to 100 to 150 DEG C; removing pollutants of oxides, greasy dirt and the like on the surface of the groove of the extra thick steel plate; bottoming the extra thick steel plate by submerged-arc welding; forming systematical grooves and after the front face of the extra thick steel plate is bottomed, welding and filling; performing back gouging on the reverse side of the extra thick steel plate and welding and filling the reverse side; and filling welding wires on the front side of the extra thick steel plate and covering the side. The problems that manual bottoming efficiency is low, labor intensity is high, and heat cracking, undercutting, mechanical slag inclusion, large working amount of back gouging of the reverse side and the like are easily caused by submerged-arc welding bottoming when the T-type joint of the extra thick plate of which the thickness is 50 to 150mm is welded are solved; by the selection of an appropriate groove form, the welding sequence, and welding process parameters, and slow cooling measures, slag is easy to clean in a filling weld pass, the working amount of back gouging is reduced, the welding deformation is reduced, the welding residual stress is reduced and the quality of a weld joint is guaranteed; and the submerged-arc welding process is easy to operate and implement, and is convenient to popularize.

Owner:SHOUGANG CORPORATION

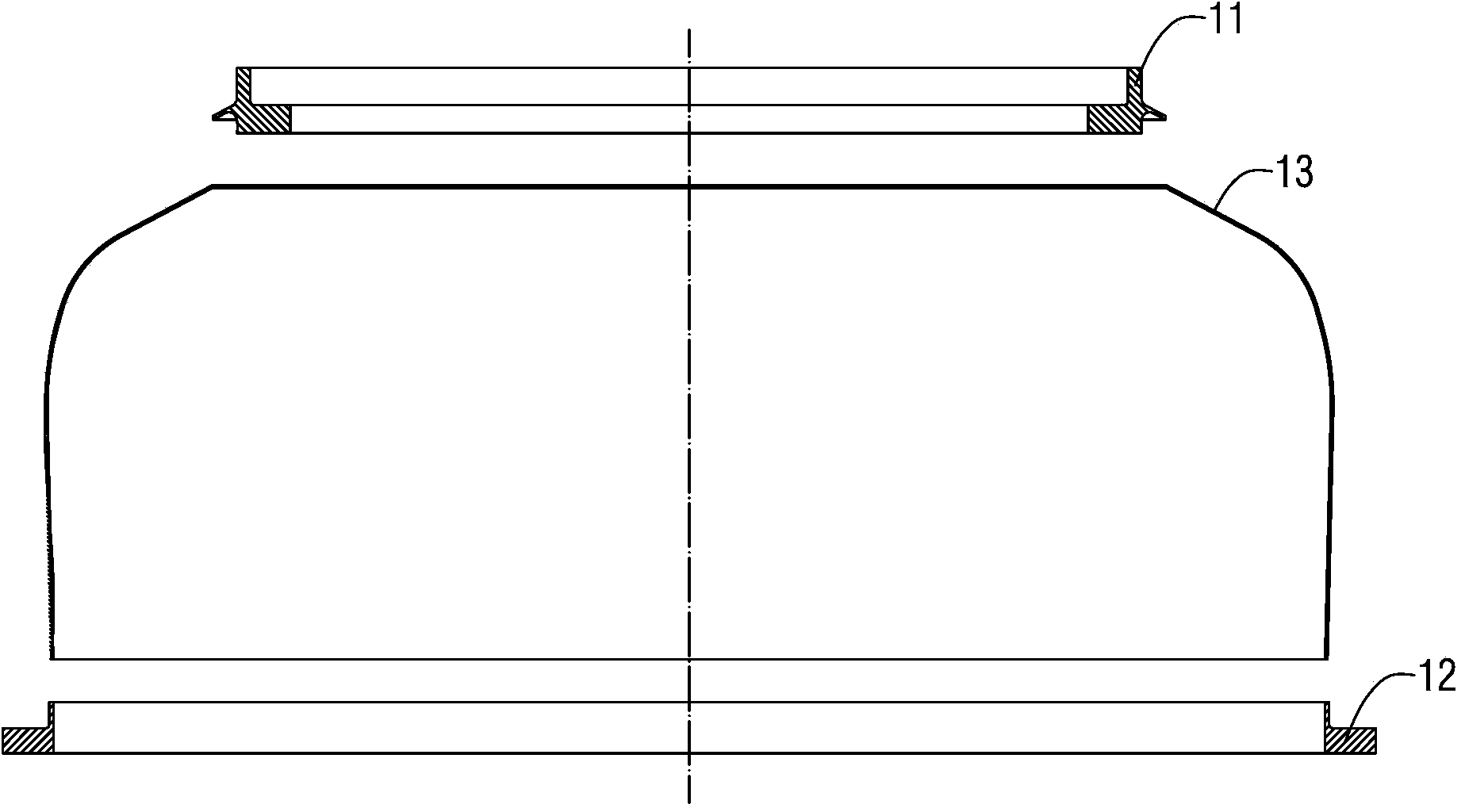

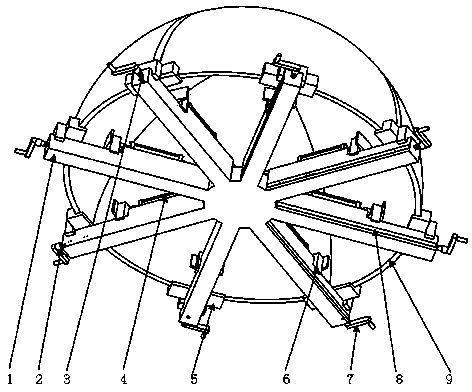

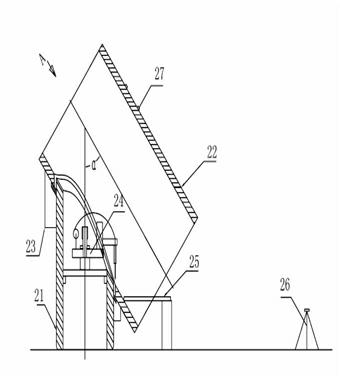

Assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers

ActiveCN103862215AGuaranteed sizeGuaranteed reliabilityWelding/cutting auxillary devicesFurnace typesStress relievingBall screw

The invention relates to an assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers. The assembly welding tool device comprises a supporting base plate, a ball screw, grouped rolling bearings, a movement air cylinder, external locating blocks, internal locating blocks, a manual rocker and a graduated scale, wherein the ball screw and an executive component drive most of the external locating blocks and most of the internal locating blocks to move along guide rails of the supporting base plate so as to carry out integrated locating clamping fixation on the curved surface end sockets. According to the assembly welding tool device and method commonly used for the large curved surface end sockets of the pressure containers, in the manufacturing process of the pressure containers, tool locating of the large end sockets can be achieved, welding deformation is prevented, the curved surface end sockets are placed on the assembly welding tool device to be clamped in an assembly locating mode, spot fixation is carried out on weld joints, and then welding operation is carried out on the internal weld joints and the external weld joints; after welding is accomplished, the curved surface end sockets are naturally cooled to have the normal temperature, postwelding is carried out on the curved surface end sockets, stress relieving is carried out on the curved surface end sockets, labor intensity of workers is reduced, the production and manufacturing cycle of products is shortened, and the production cost is reduced.

Owner:哈尔滨市黎明锅炉容器封头有限公司

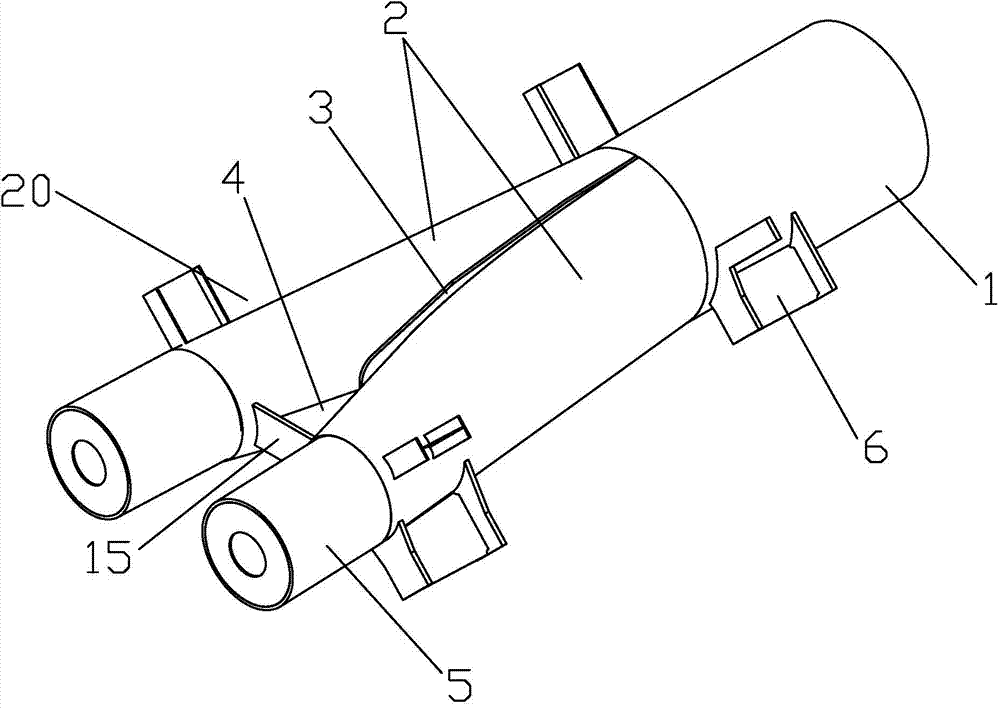

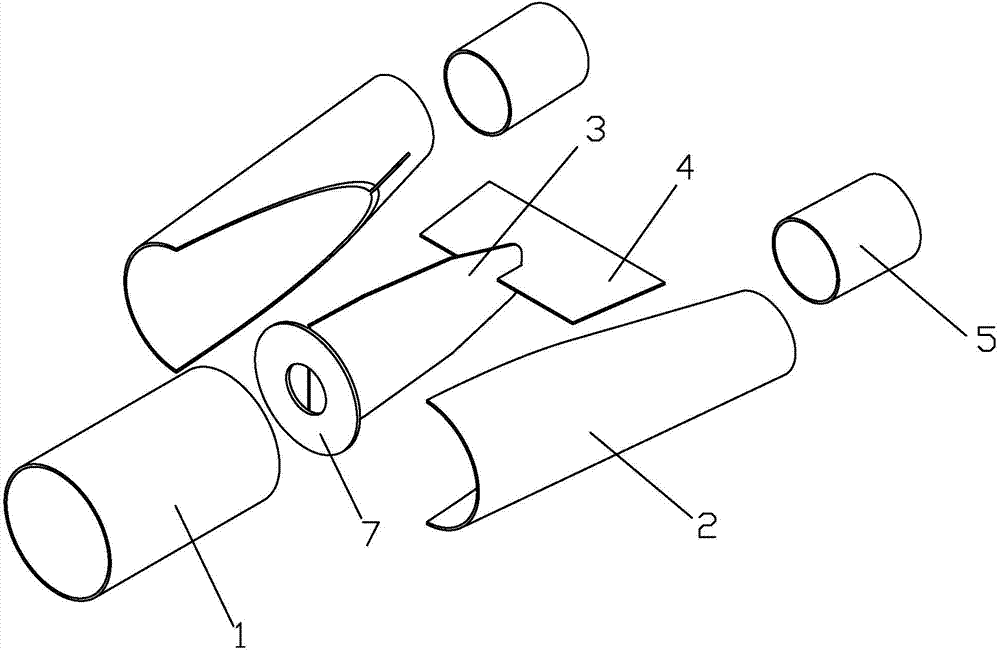

Vacuum electron beam welding method for thin-wall titanium alloy box structure with multiple cabin sections

ActiveCN104858542AControl welding deformationWeld Quality ControlElectron beam welding apparatusWelding/soldering/cutting articlesEngineeringTitanium alloy

The invention belongs to the field of welding technologies and particularly relates to a vacuum electron beam welding method for a thin-wall titanium alloy box structure with multiple cabin sections. All the cabin sections are welded by adopting the method of integral assembling and one-shot clamping, a reasonable welding sequence and reasonable welding parameters are selected, welding deformation and weld joint quality are controlled, and the technical difficulties that products are poor in integral rigidity and welding deformation is difficult to control are overcome. According to the scheme, a welded joint, achieving single face welding, double face forming and back face spatter avoiding, of a thin-wall titanium alloy box is achieved, and welding quality meets the requirements of the primary national military standard GJB1718A-2005 Electron Beam Welding. After the multiple sections of the box are spliced and welded, the appearance precision requirements that cylindricity is smaller than 1.0 mm-1.5 mm and coaxiality is smaller than 2 mm-3 mm, and meanwhile the hydraulic pressure strength and the airtight strength of the box meet product use requirements.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

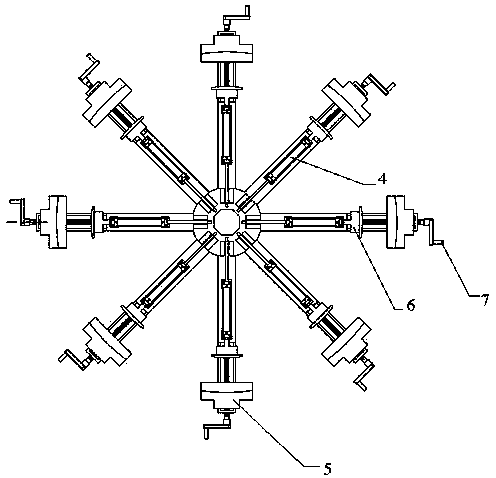

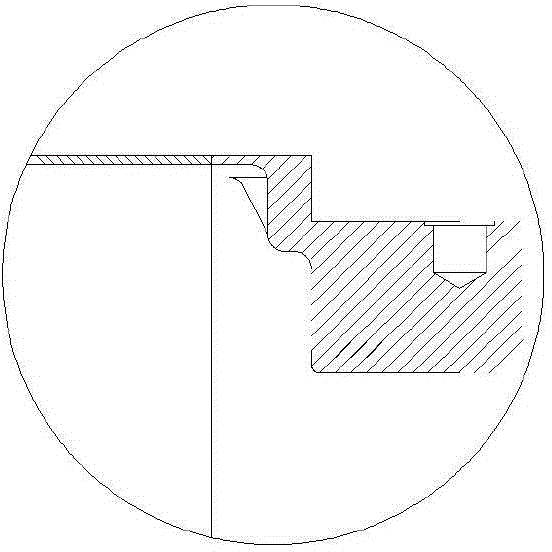

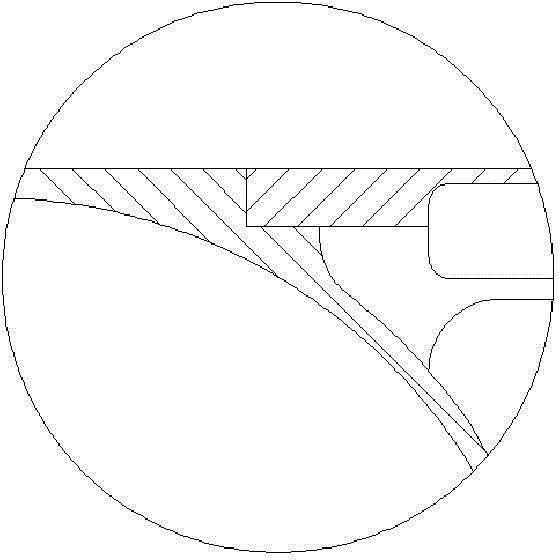

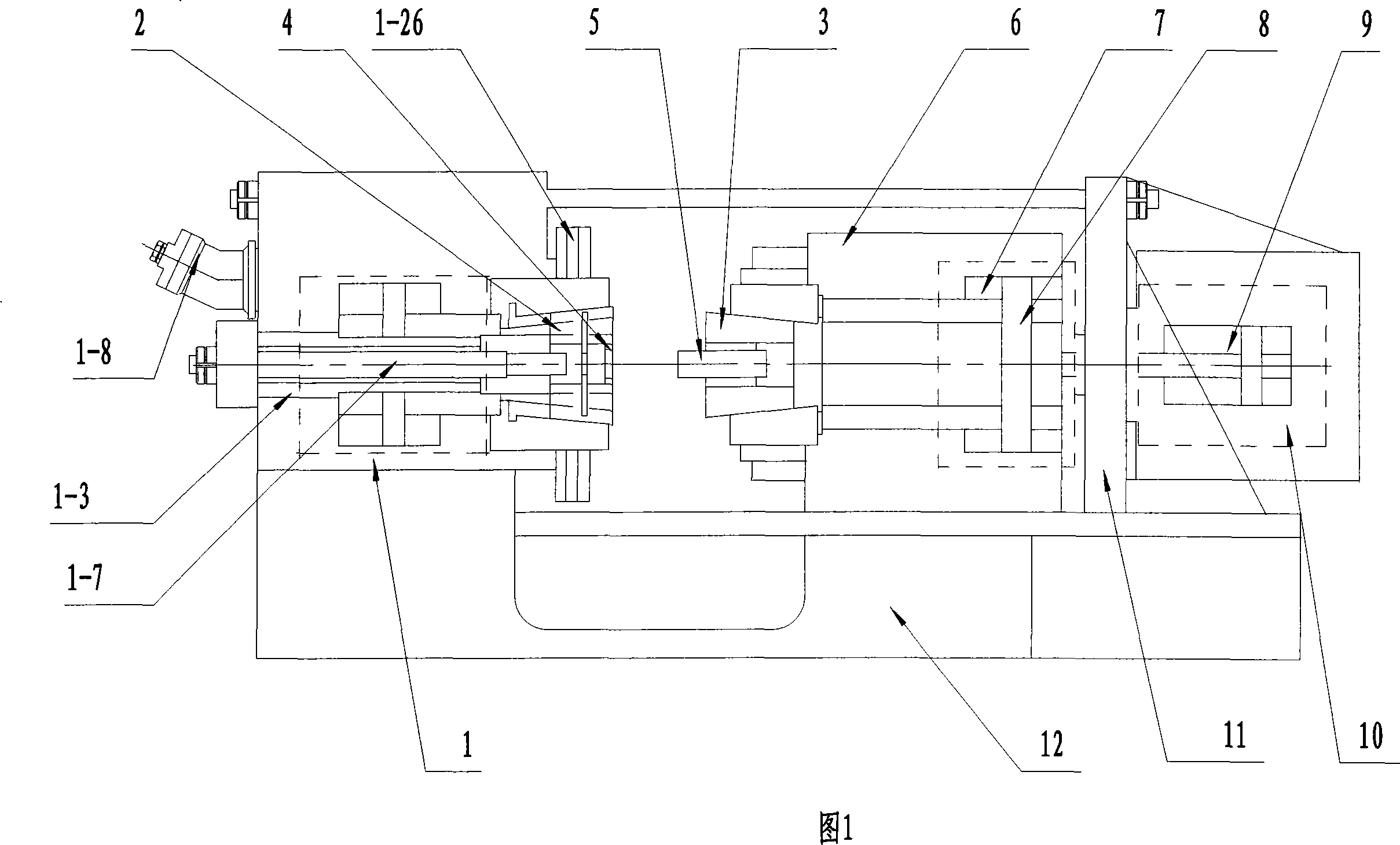

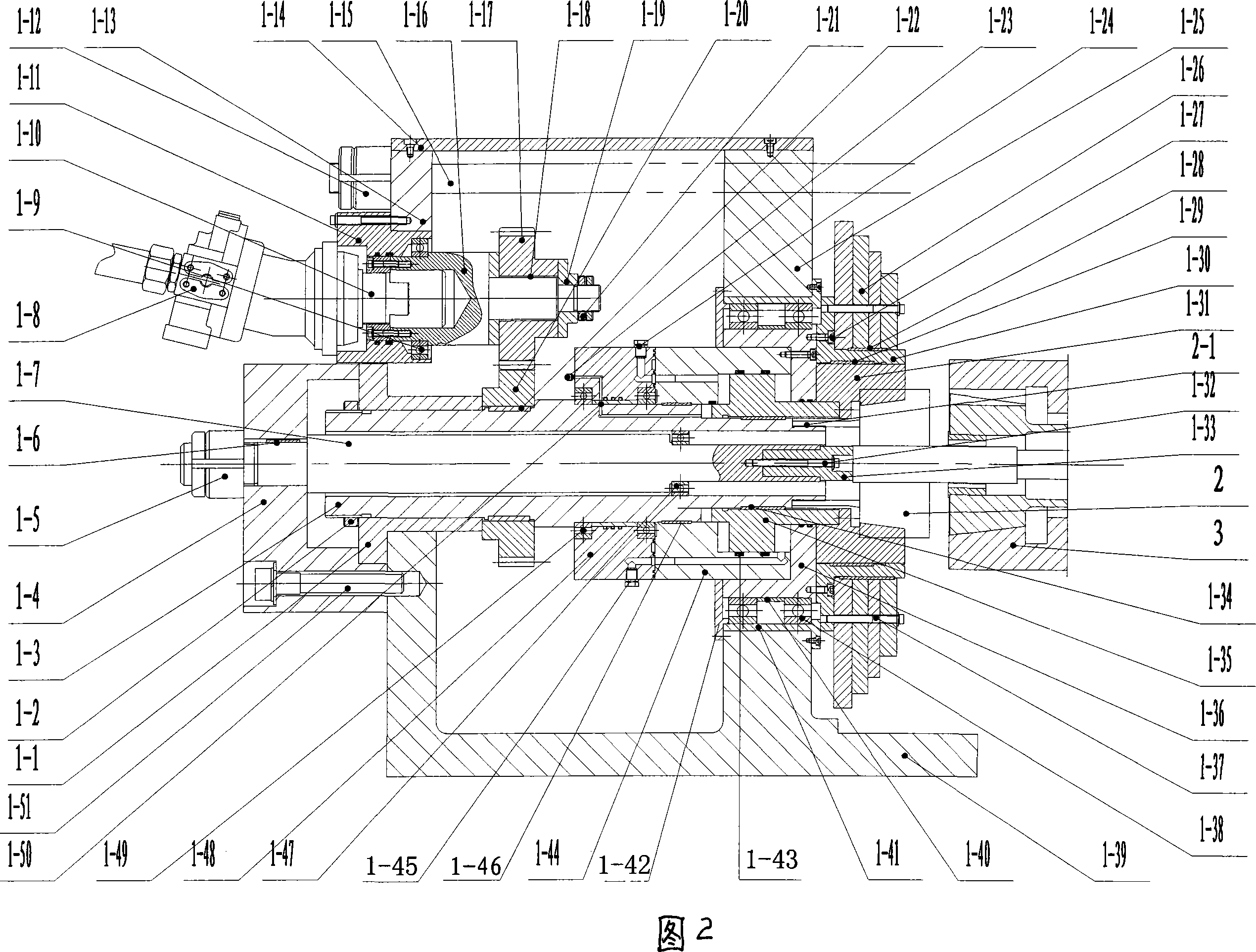

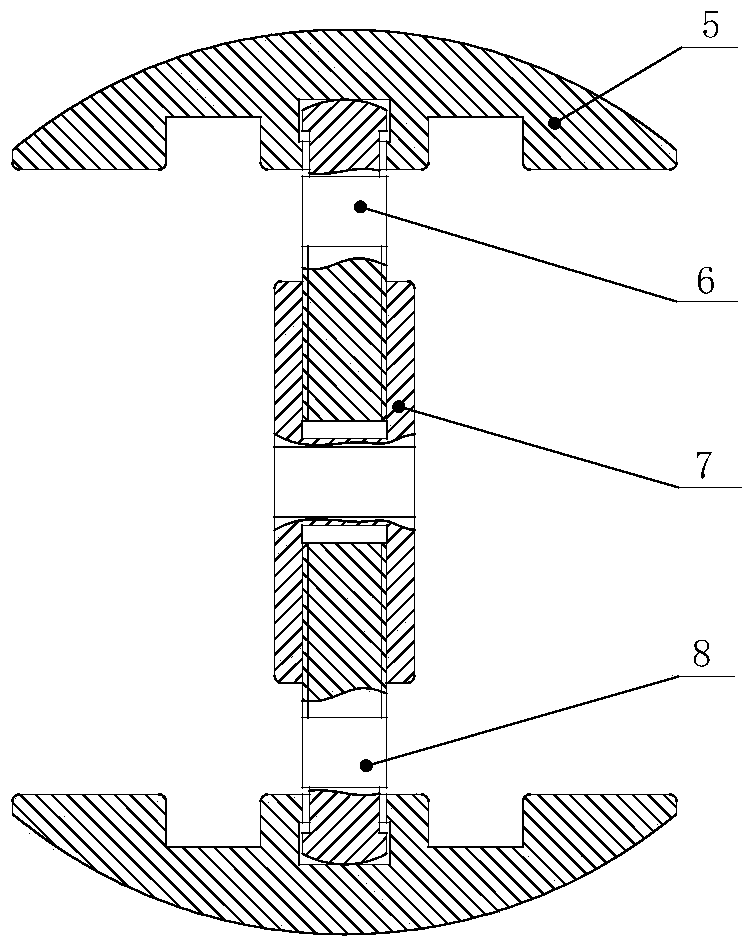

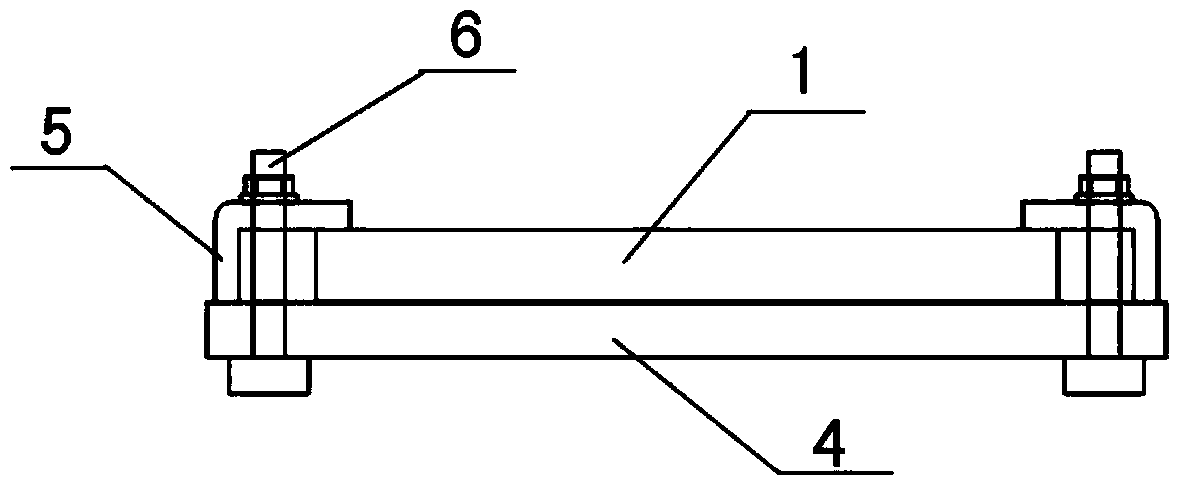

Inertia friction welding machine

InactiveCN101224522AAxial welding is convenientPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention relates to an inertia friction welding equipment, comprising a frame (1-39), a mainshaft box (1) which is formed by the connecting of a left bracket (1-13) and a right bracket (1-25), a transmission mainshaft (1-3) arranged in the mainshaft box (1), and a flywheel (1-26) which is rotated together with the transmission mainshaft (1-3); the invention is characterized in that the front circumference of the transmission mainshaft (1-3) is provided with a hydraulic device which rotates with the transmission mainshaft (1-3) and is pressed axially. The equipment which is provided by the invention and can be used for the radial inertia friction welding on the circumference surface of a cirque part and a cylindrical and round pipe-shaped part has simple and reasonable structure, and safe and convenient application, can realize the radial pressurization in the rotation, realizes the pre-clamping and the exact positioning of any positions of the cirque welding part, controls the welding deformation, ensures that the surface of the clamped workpiece is not damaged by the rotation inertia of the frock device in the welding process, thus greatly improving the working efficiency.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Tank fabricating and welding method

ActiveCN102848087AControl welding deformationAdvantages of making welding methodsWelding apparatusStructural engineeringSeam welding

The invention discloses a tank fabricating and welding method, which is characterized by comprising the following steps of: a. fabricating and welding a tank soleplate, wherein the step comprises: (1) paving the soleplate, and (2) welding the soleplate; and b. fabricating and welding a tank wall board, wherein the step comprises: (1) paving the wall board, and (2) welding the wall board, and the step of welding the wall board comprises: 1) temporarily not welding 300mm of the lower edge of a longitudinal weld and welding the lower edge together with a circular seam after being paired with a next sine wall board; 2) when welding the circular seam, enabling welders to be uniformly distributed on the surrounding of the tank and welded in the same direction; 3) selecting the setting distance of an anti-deformation fixture according to the thickness of the wall board before welding the circular seam, the distance of the fixture of the wall board with delta equal to 6mm being 300mm; and 4) selecting an even number of welders when welding the wall board, the levels of the welders being close, and welding with the same vertical seam and circular seam welding parameters. The tank fabricating and welding method disclosed by the invention has the advantages of simple and convenient operation, strong maneuverability and the capability of effectively controlling the welding deformation of the tank.

Owner:MCC5 GROUP CORP SHANGHAI

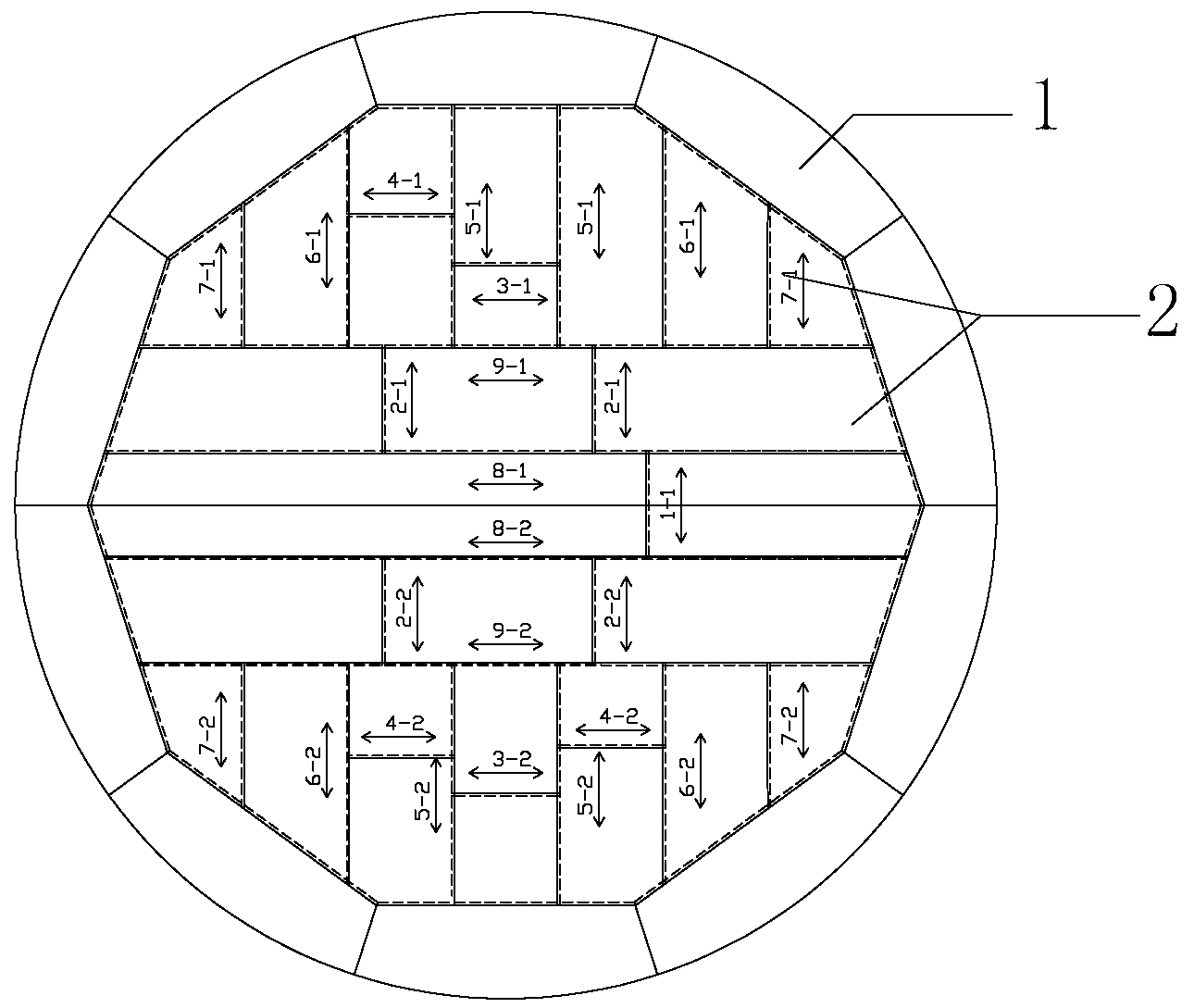

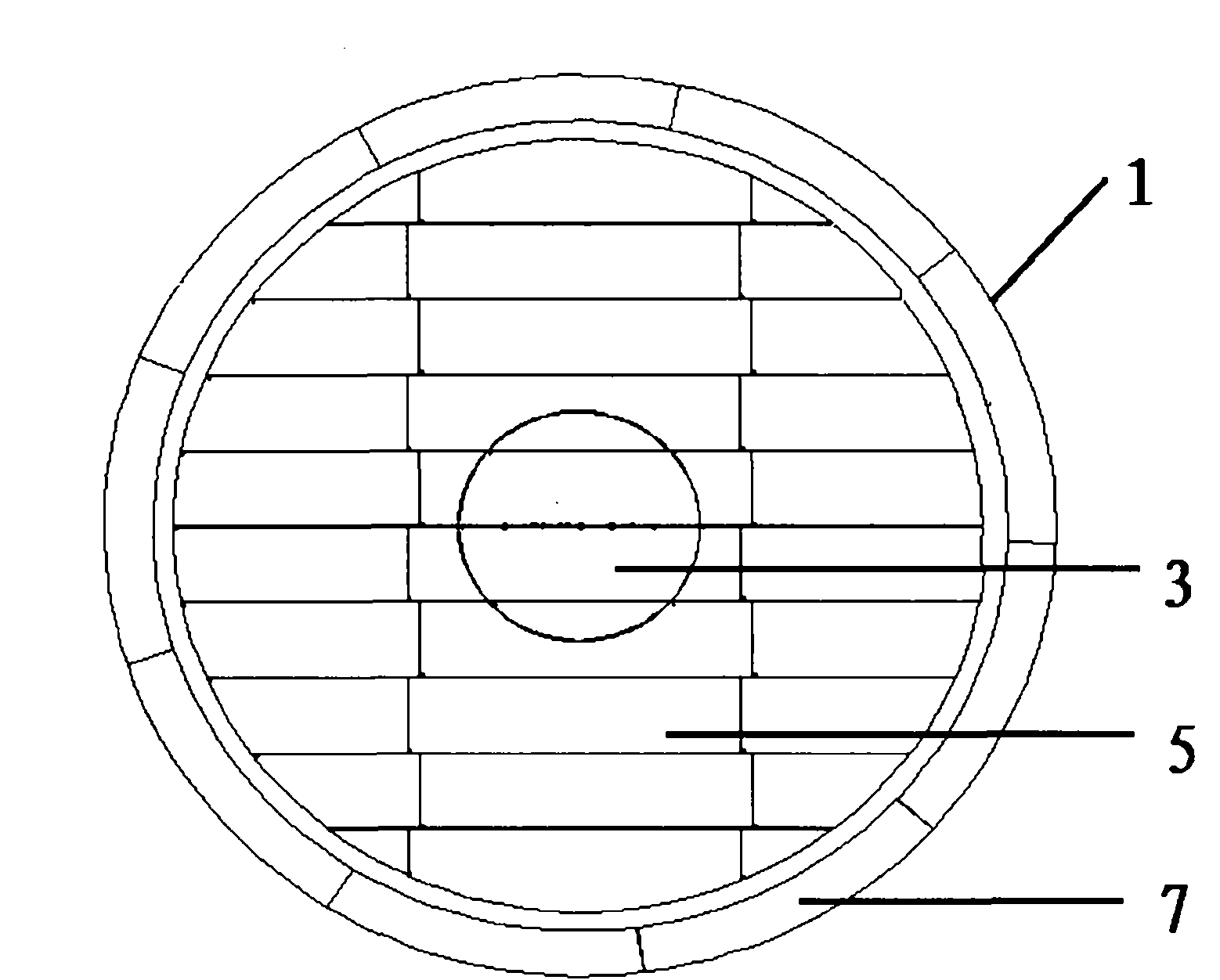

Method for mounting bottom plates and cylinder of steel lining of nuclear power plant

ActiveCN102061788AShort construction periodShorten the construction periodCovering/liningsArc welding apparatusSupporting systemArchitectural engineering

The invention provides a method for mounting bottom plates and a cylinder of a steel lining of a nuclear power plant. The bottom plates are basically circular, and are divided into circular center bosses, annular intermediate annular plates and annular edge plates which consist of a plurality of precast slabs from inside to outside; the cylinder comprises frustums and cylinder wall plates which are formed by splicing the plurality of precast slabs; and the cylinder wall plates are divided into a plurality of layers. The mounting method sequentially comprises the following steps of: mounting a bottom plate support system; putting the bottom plates on the bottom plate support system; putting the frustums; welding the bottom plates and the frustums in pairs; and mounting each layer of cylinder wall plates from bottom to top respectively. By rationally setting a welding process and a construction assembly process, a mounting construction period of the steel lining is effectively shortened, and the sealability of welding seams of the steel lining is ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

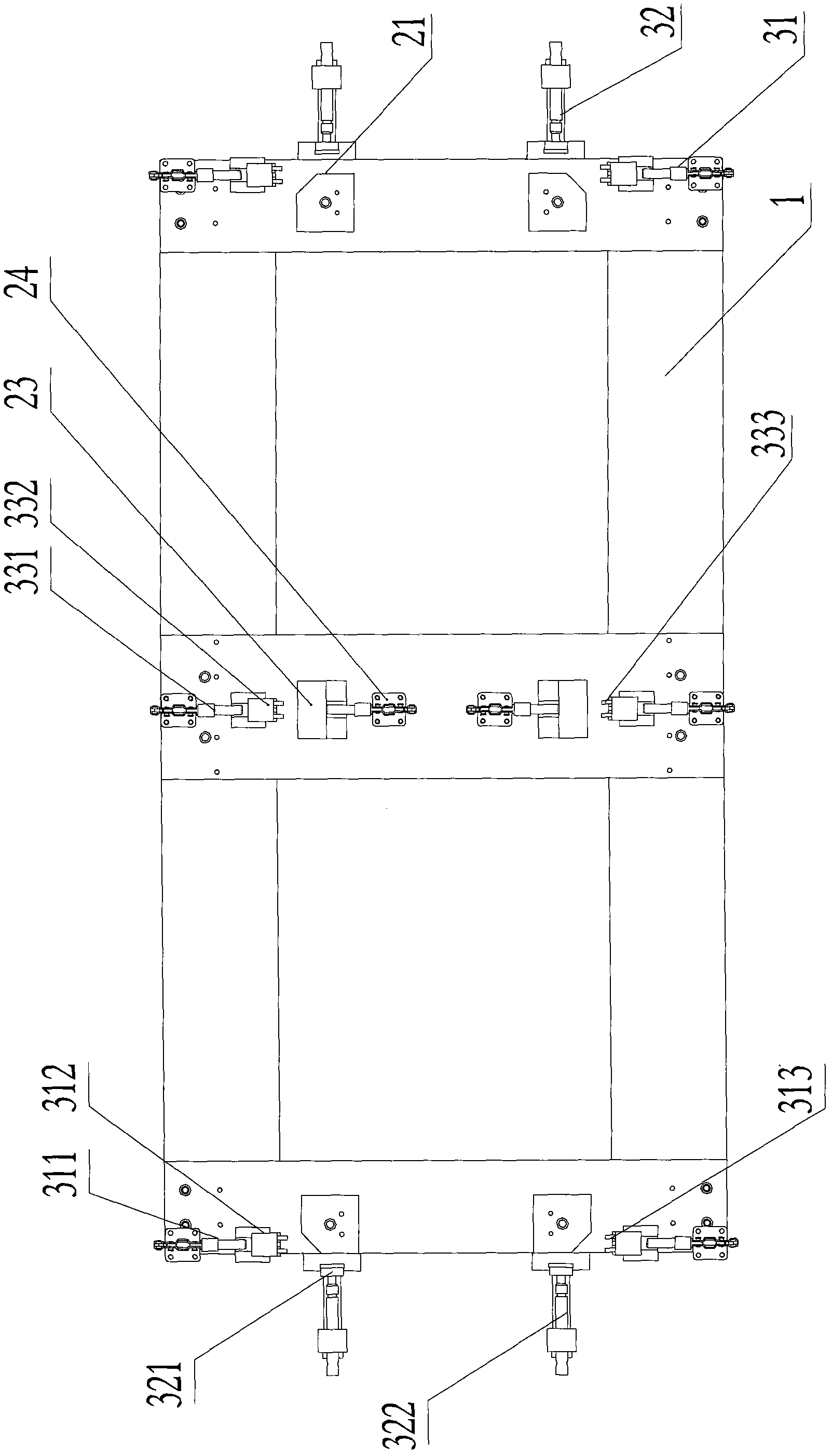

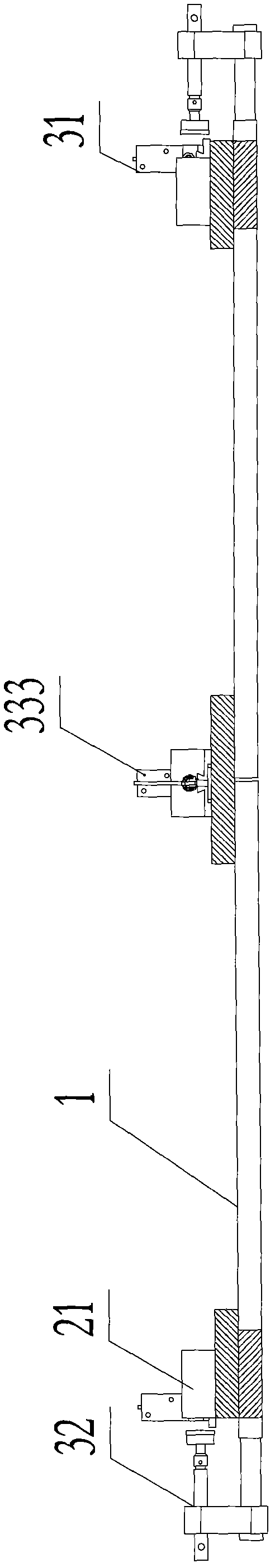

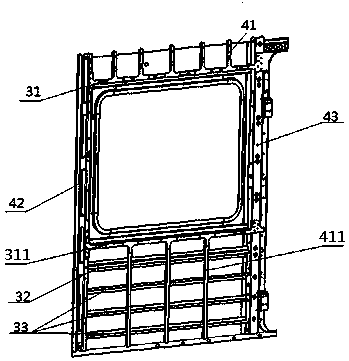

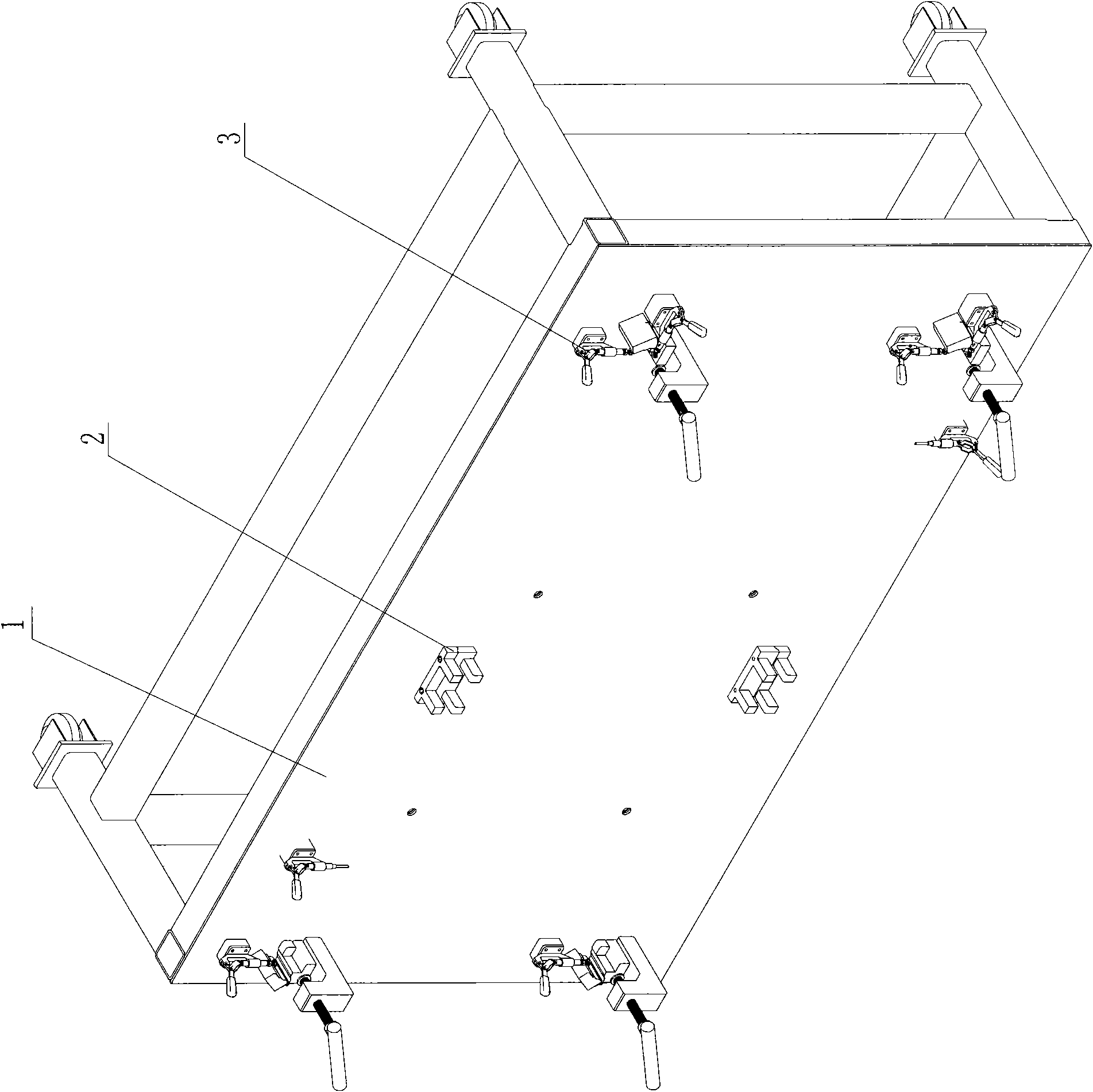

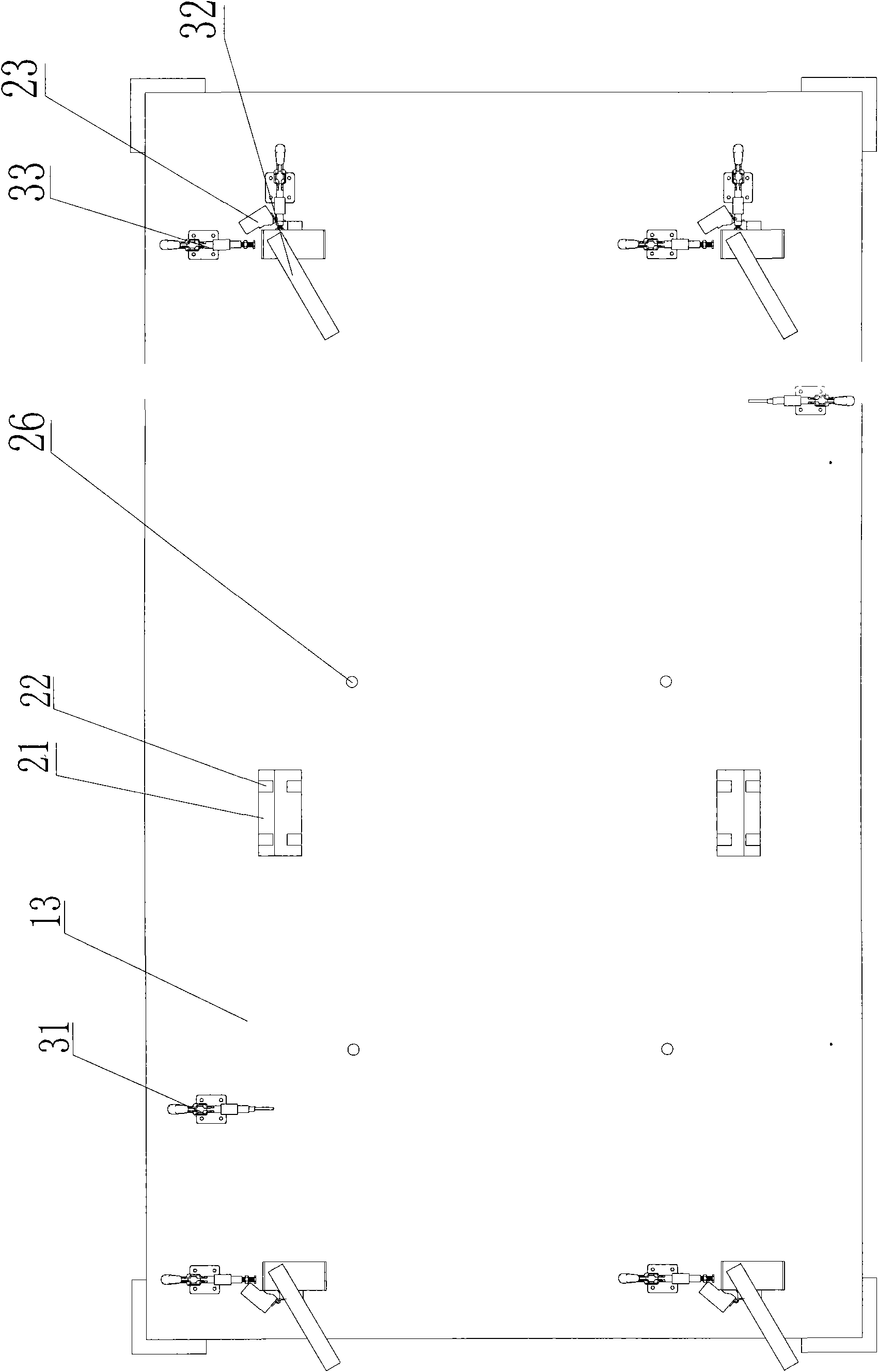

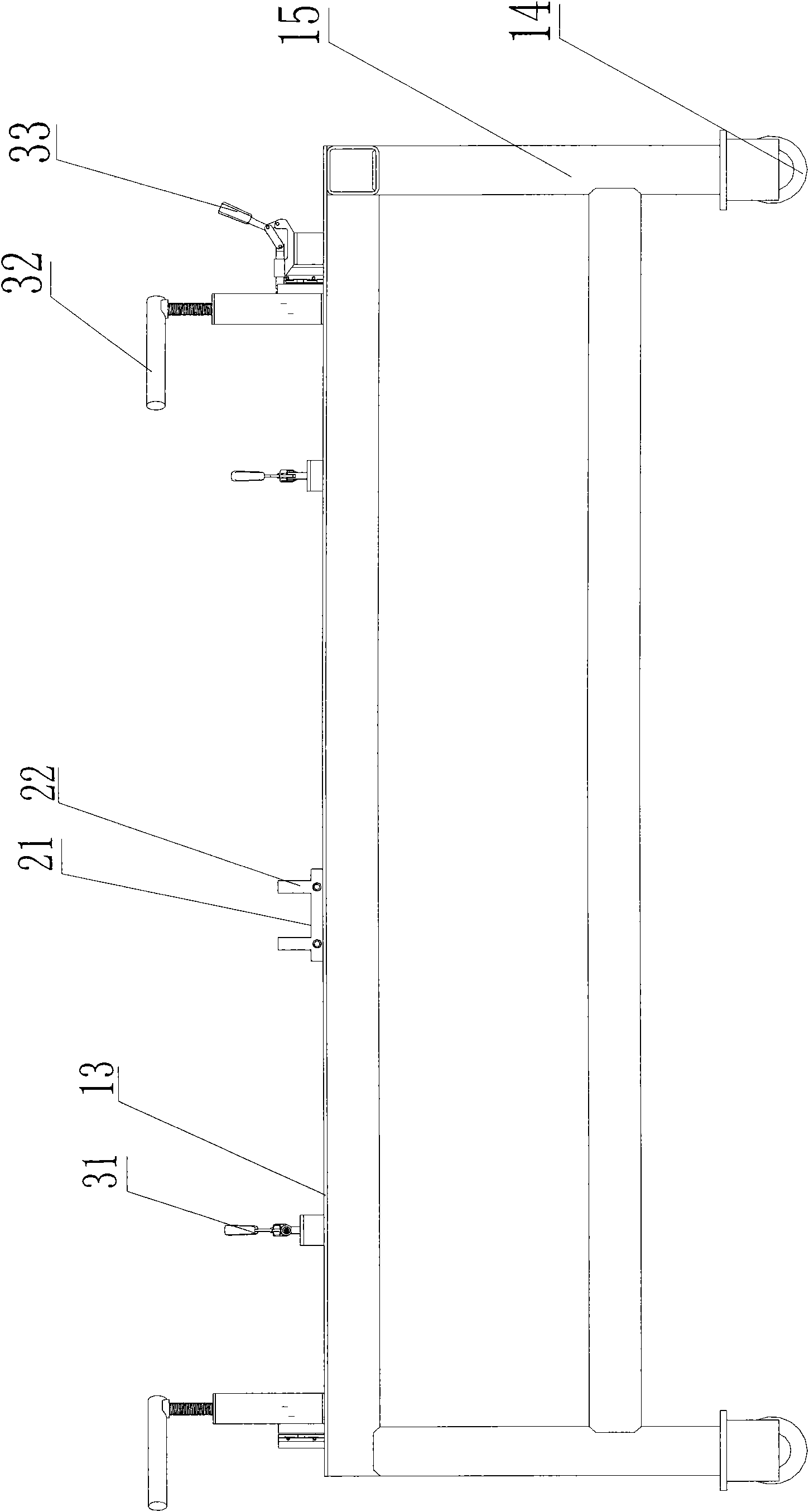

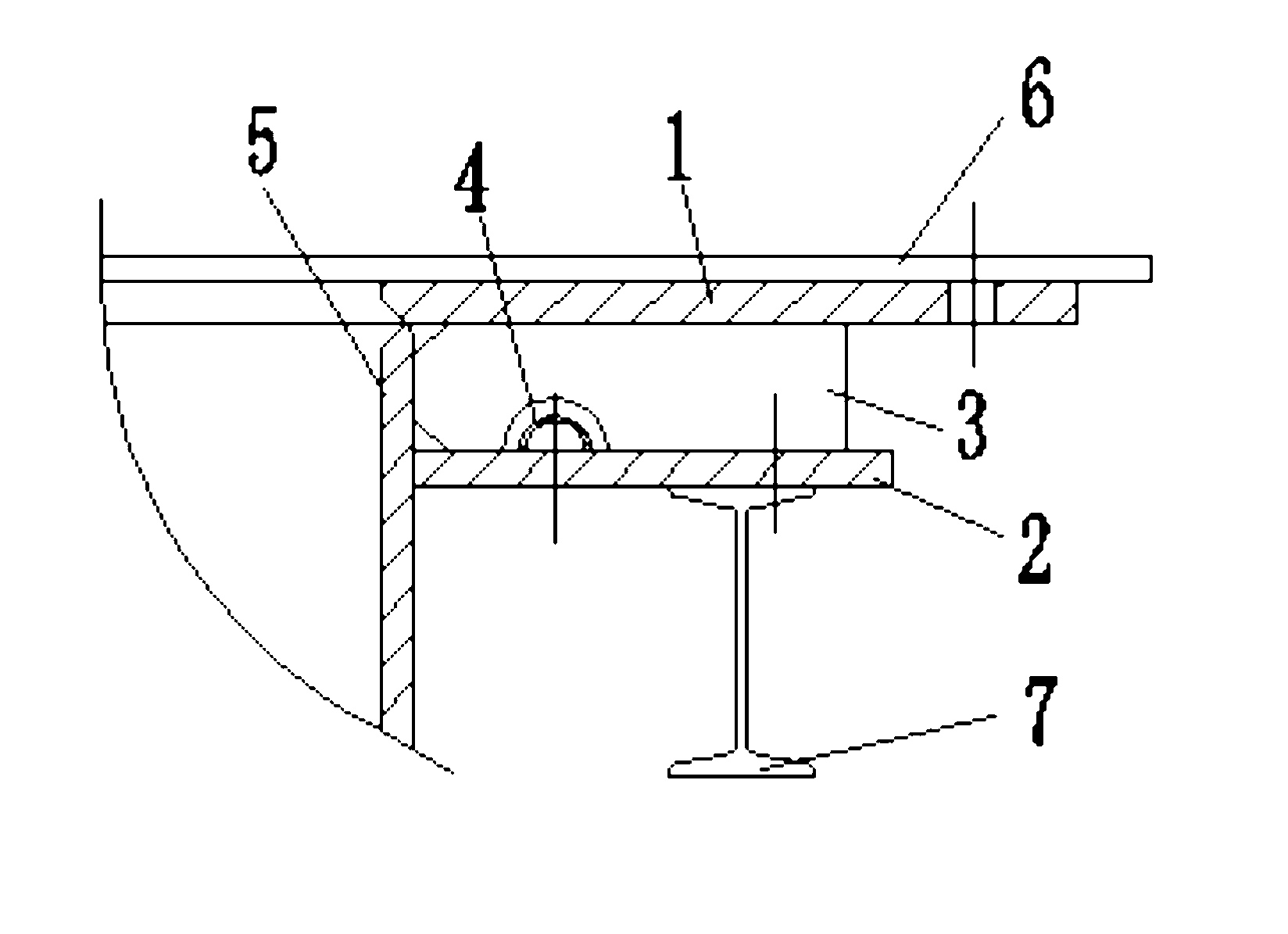

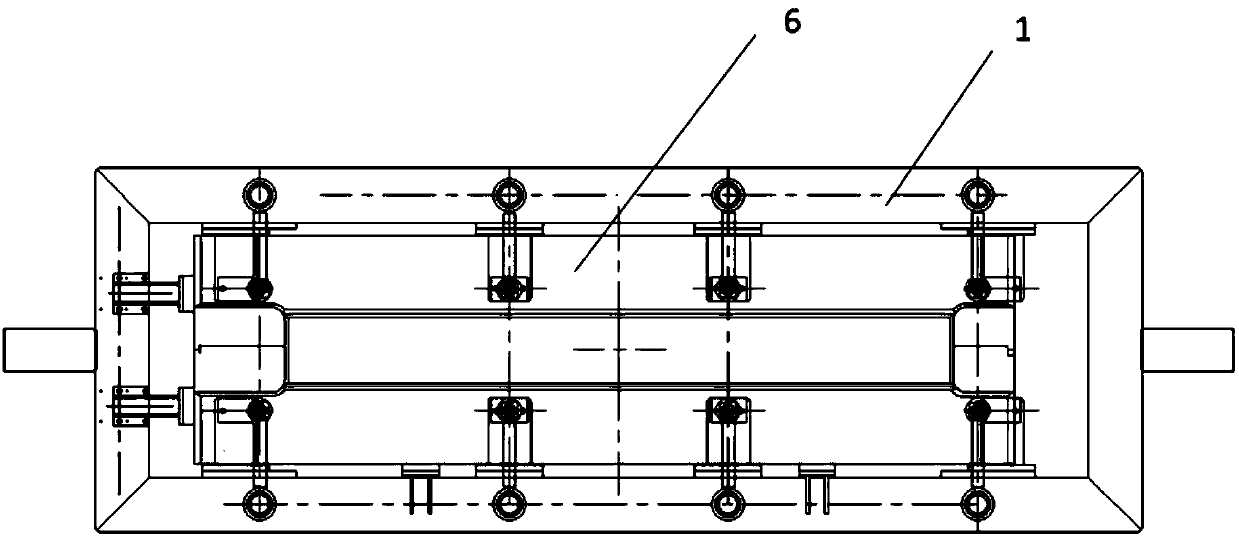

Welding tooling device for pillar frame of machine cabinet and assembly method of device

InactiveCN102029497AReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAuxillary welding devicesInstabilityEngineering

The invention discloses a welding tooling device for a pillar frame of a machine cabinet and an assembly method of the device, wherein the device comprises a clamp body (1) and is characterized in that a positioning element (2) and a clamping device (3) are fixedly arranged on the clamp body, the positioning element (2) is used for horizontal position limitation of all parts of the pillar frame of the machine cabinet, and the clamping device (3) is matched with the positioning element (2) for clamping all the parts of the pillar frame of the machine cabinet in the horizontal direction. By adopting the device and the method disclosed by the invention, the physical labor of operation staff can be greatly reduced, and the assembly and welding efficiency can be improved; and the welding thermal deformation of a workpiece can be controlled or eliminated, and the instability of manual welding can be reduced.

Owner:Jiangsu Boamax Technologies Group Co Ltd

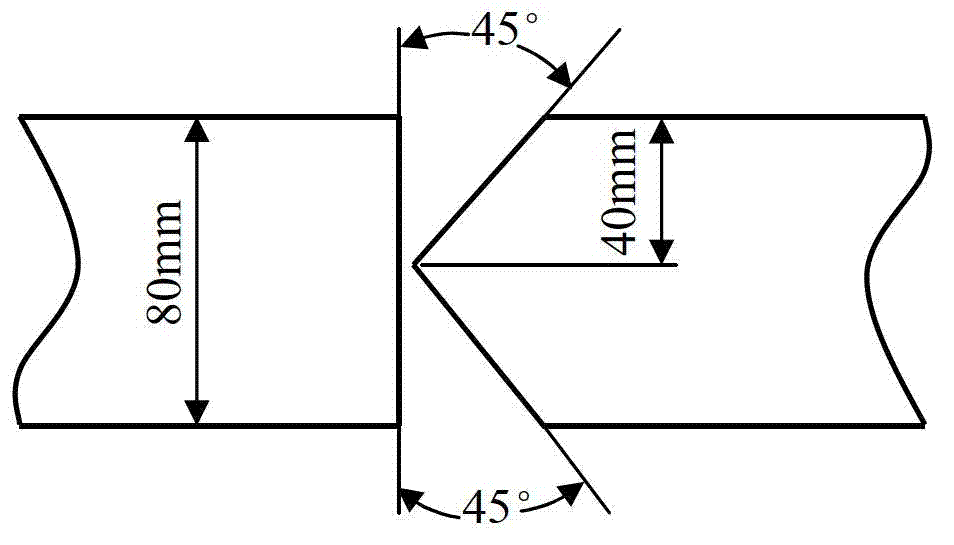

Submerged arc welding method for K-shaped groove of 80mm extra-thick steel plate with excellent plate shape after welding

InactiveCN102922103AReduce peak residual stressOffset deformationArc welding apparatusWorkpiece edge portionsResidual deformationMixed gas

Owner:NANJING IRON & STEEL CO LTD

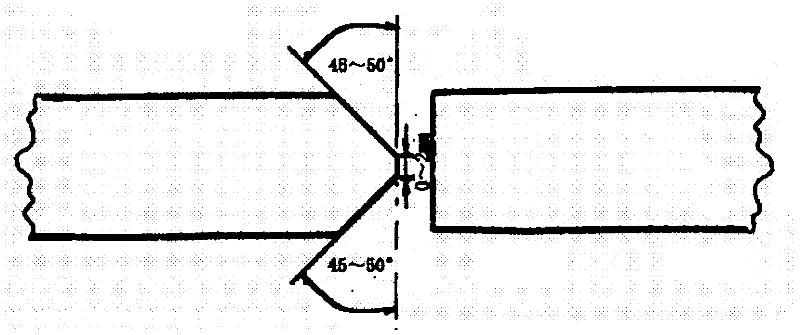

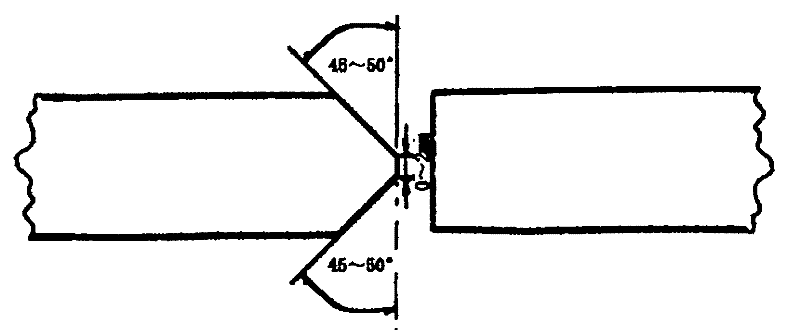

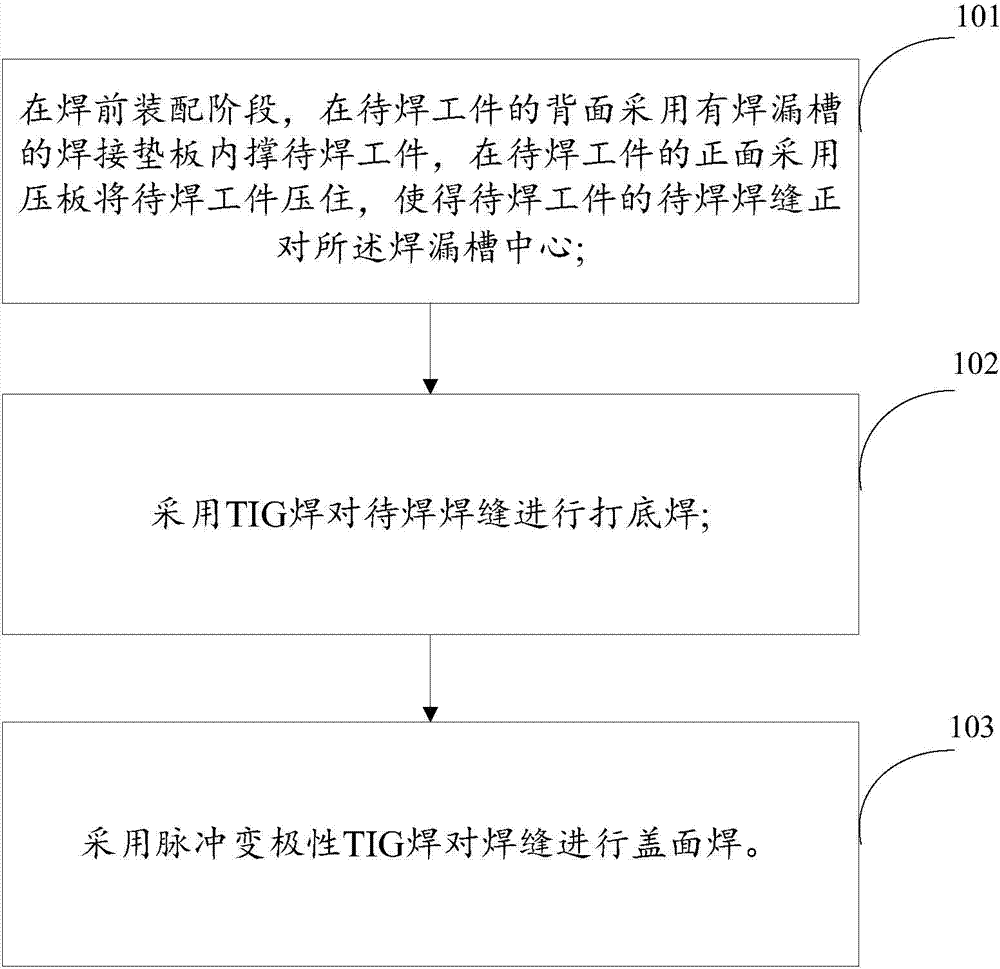

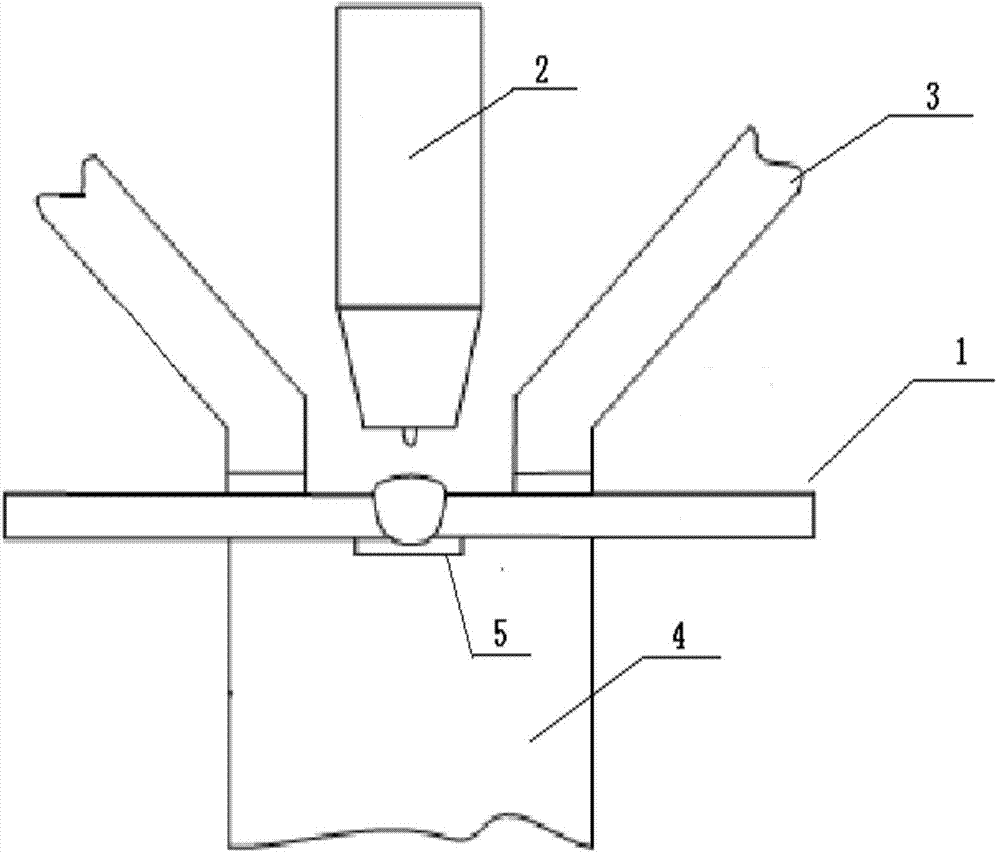

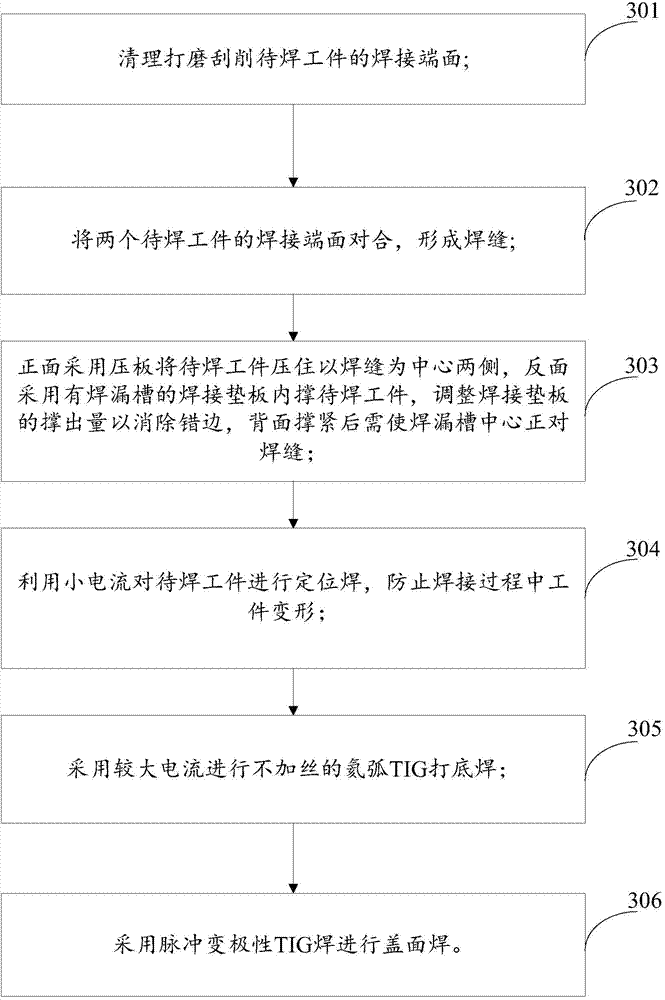

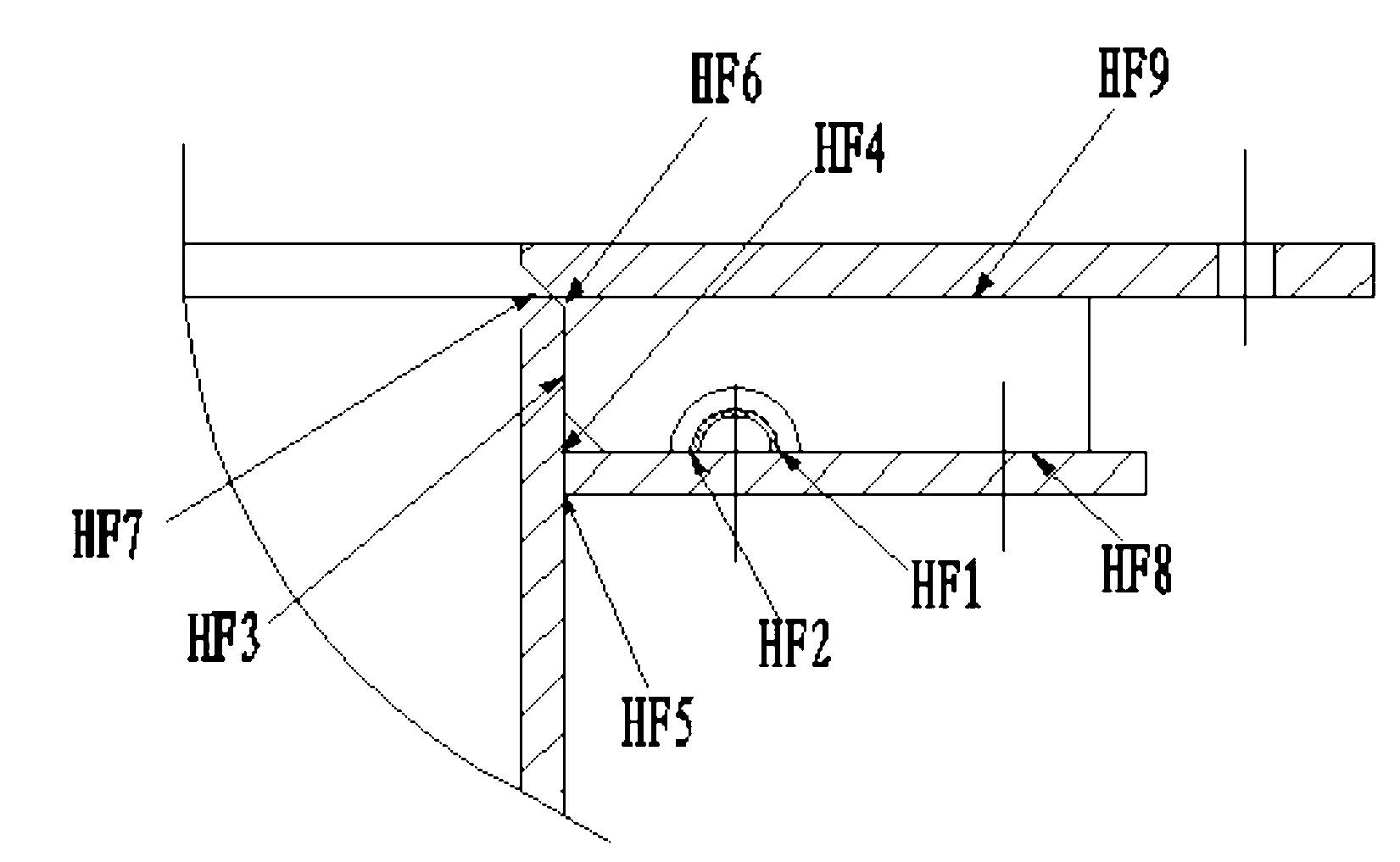

TIG welding method applicable to moderately thick aluminum alloy

ActiveCN104722895ALittle impact on performanceStrong penetrating powerWelding/cutting auxillary devicesAuxillary welding devicesMechanical propertyPulse polarity

The embodiment of the invention provides a TIG welding method applicable to moderately thick aluminum alloy. On the condition that beveling is not carried out, the effect of single-face welding and two-face forming effect is achieved. The connector mechanical property and welding efficiency can be greatly improved. The aluminum alloy TIG welding method is used for welding a weld joint between two workpieces and comprises the steps that an outer pressing block is adopted on the front faces of workpieces to be welded, a welding base plate with a welding leakage groove is arranged on the back faces of the workpieces to be welded to tightly support the workpieces, and therefore a weld joint to be welded of the two workpieces to be welded is right opposite to the center of the welding leakage groove; the two steps of backing welding and cosmetic welding are carried out, wherein the TIG welding is adopted for carrying out backing welding on the weld joint to be welded, so that welding leakage is formed on the back face of the weld joint to be welded, and direct forming is achieved; pulse polarity variation TIG welding is adopted for carrying out cosmetic welding.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH +2

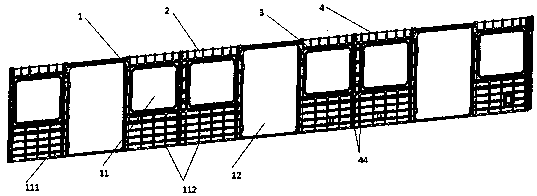

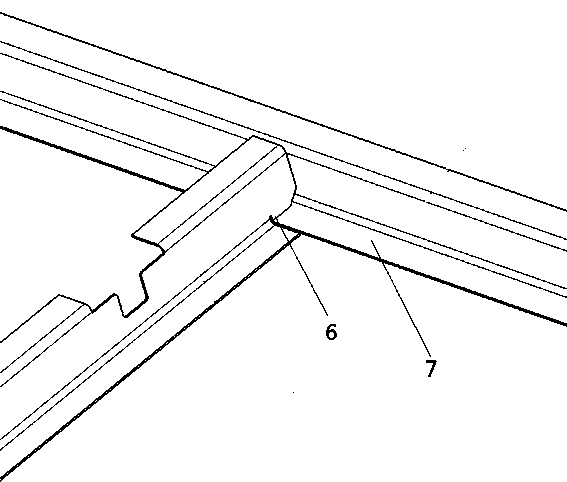

Novel stainless steel side wall structure and mounting method of novel stainless steel side wall

InactiveCN107901932AReduce welding processGuarantee the appearance qualityAxle-box lubricationRailway bodiesStructural engineeringEngineering

The invention provides a novel stainless steel side wall structure and a mounting method of a novel stainless steel side wall. The novel stainless steel side wall structure comprises a side wall skeleton. The side wall skeleton is formed by connecting a plurality of cross beams and a plurality of vertical columns in a mutually-crossing mode, and the cross beams and the vertical columns are fixed through mutual inserting; end vertical columns are arranged on the left and right sides of the side wall skeleton correspondingly; door vertical columns are arranged on the left and right sides of doorframes correspondingly; a window upper cross beam is arranged on the upper portion of each window frame, and a window lower cross beam is arranged on the lower portion of each window frame; a waist cross beam is arranged below each window lower cross beam; three lower cross beams are arranged below each waist cross beam; a window upper vertical column is connected to each window upper cross beam;skeleton connecting plates are welded inside the connecting positions of the window upper cross beams and the window upper vertical columns in the side wall skeleton; window lower vertical columns are connected among each window lower cross beam, the corresponding waist cross beam and the three corresponding lower cross beams; and skeleton connecting plates are welded inside the connecting positions of the window lower cross beams and the window lower vertical columns in the side wall skeleton. The cross beams and the vertical columns of the novel stainless steel side wall structure are fixedthrough mutual inserting connection, the deformation problem caused by welding of a skeleton is solved, the production cost is saved, and the assembly production efficiency is improved.

Owner:CRRC NANJING PUZHEN CO LTD

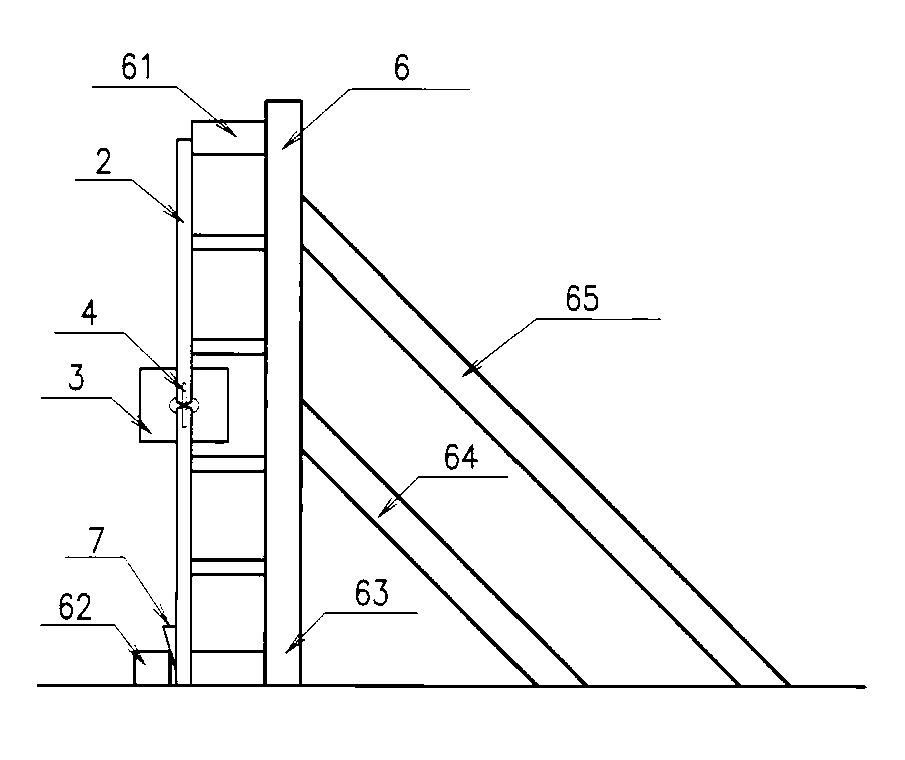

Welding method for vertically spliced super-thick steel plate

ActiveCN102861972AControl welding deformationReduce turning timesWelding/cutting auxillary devicesArc welding apparatusSheet steelTurnover time

A welding method for a vertically spliced super-thick steel plate is a welding method for a super-thick steel plate with the thickness ranging from 60mm to 120mm. The method is characterized by including: hoisting a primarily spliced super-thick steel plate onto a special jig frame for horizontal welding, fixing the super-thick steel plate with a waler of the jig frame by welding prior to fastening the super-thick steel plate with a ground abutting floor stand by the aid of a wedge, then using carbon dioxide arc welding for sequential symmetry horizontal welding on the front side and the back side of the super-thick steel plate respectively by even welders until spliced plate welding is finished, and finally performing postheat treatment to prevent cracks. The method has the advantages that welding deformation of the spliced super-thick steel plate can be well controlled, welding deformation correction is avoided, welding cracks are prevented, welding quality is improved, and construction requirements are met. The carbon arc air gouging process for back gouging is omitted, welding procedure is simplified, turnover times of the super-thick steel plate are decreased, workload is reduced, labor intensity is relieved, and production efficiency is improved.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

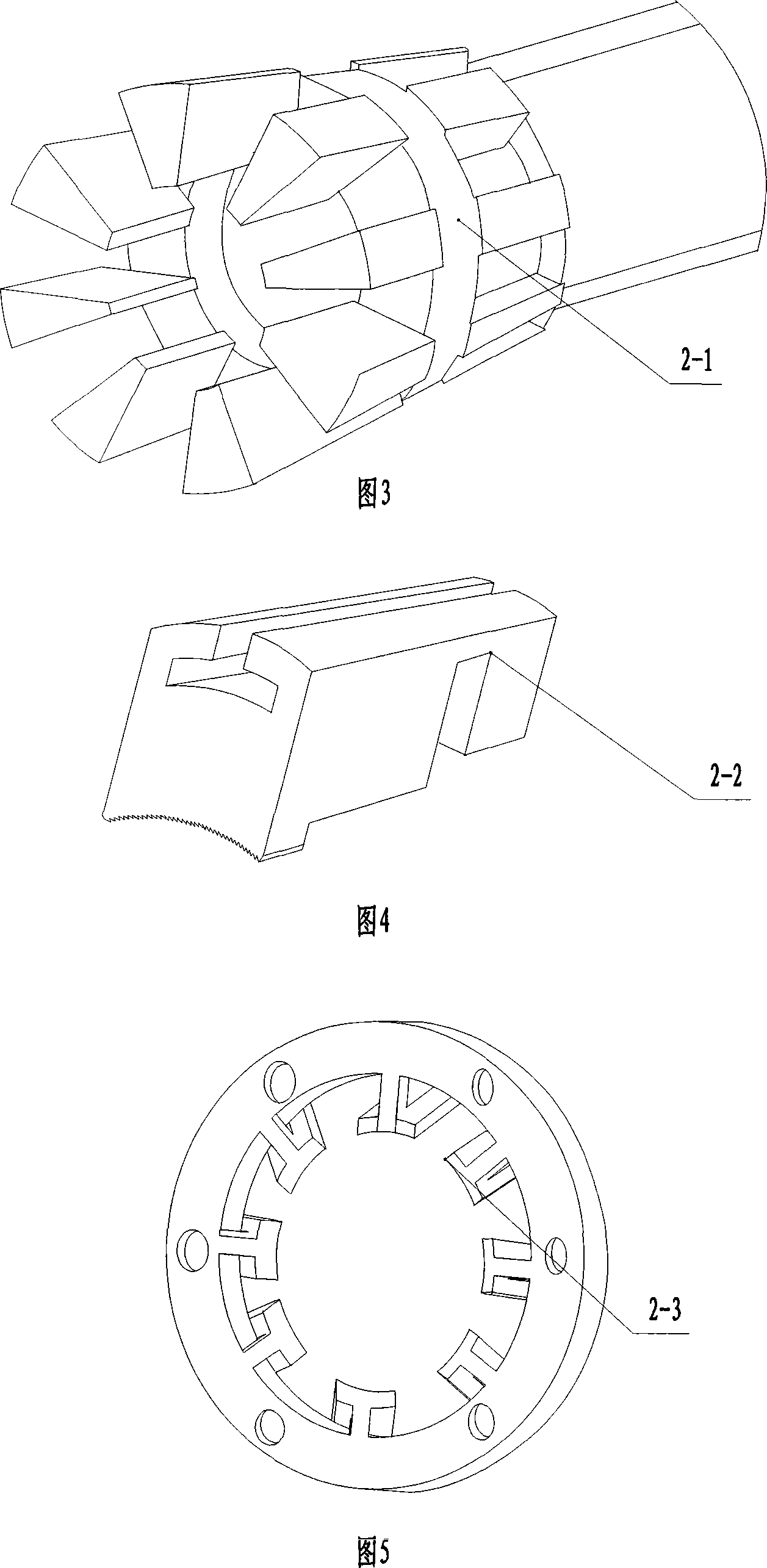

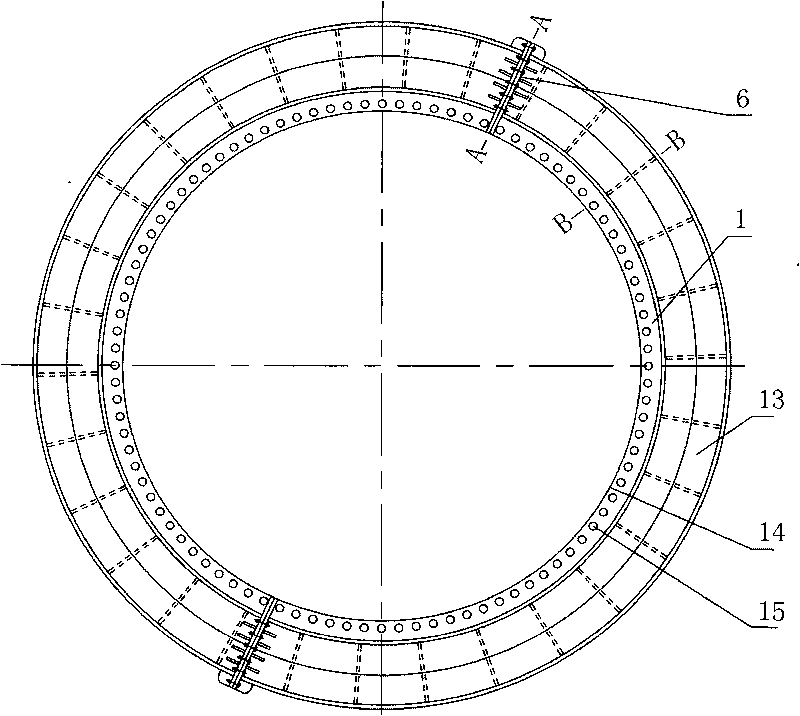

Dual-dovetail type unmovable key bar assembling and welding process for water turbine generator

InactiveCN101758323AReduce radial bending welding distortionGuaranteed Radius ToleranceArc welding apparatusWater turbineSkew angle

The invention provides a dual-dovetail type unmovable key bars assembling and welding process for a water turbine generator, which adopts a large-span equal division method to install key bars and welds the other key bars by lap welding the template within each large span. The key bar radius, radial skew angle, radius difference of adjacent bars and chord length difference of adjacent bars are adjusted up to standards by a support block C-shaped clip and other tools. The support block is welded by CO2 arc welding, the welding direction is from inner side to outer side, in order to whole controlling the welding deformation direction of the key bar chord length. The support block among each base ring plate are welded by skip welding, the radial bending welding deformation of the key bar is reduced. The invention has the advantages of simple and concise welding process, convenient assembly operation, high precision of key bar welding, high production efficiency and short assembly circle.

Owner:HARBIN ELECTRIC MASCH CO LTD

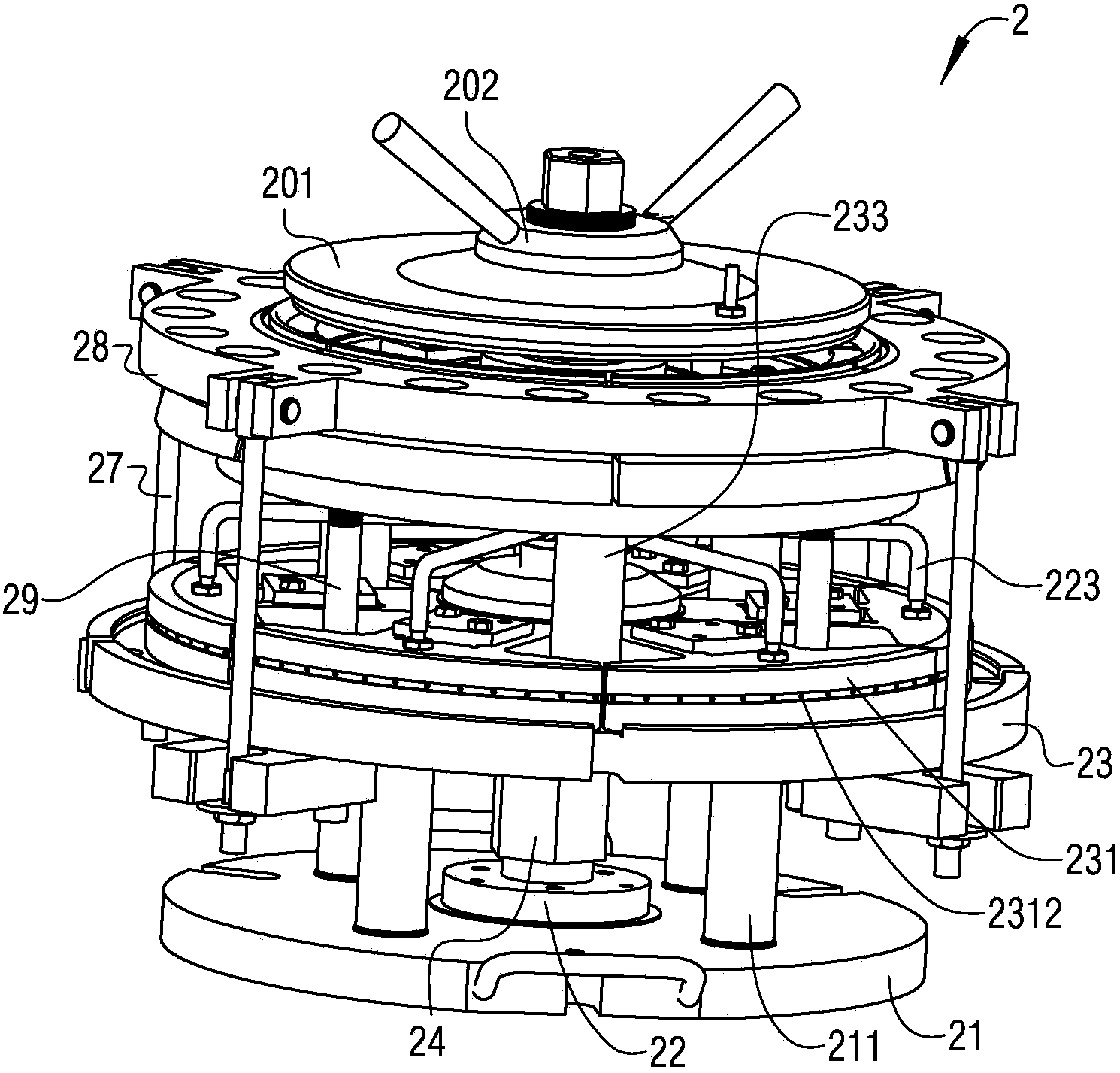

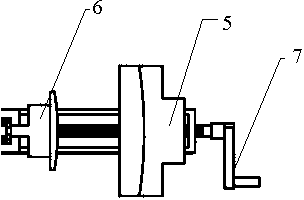

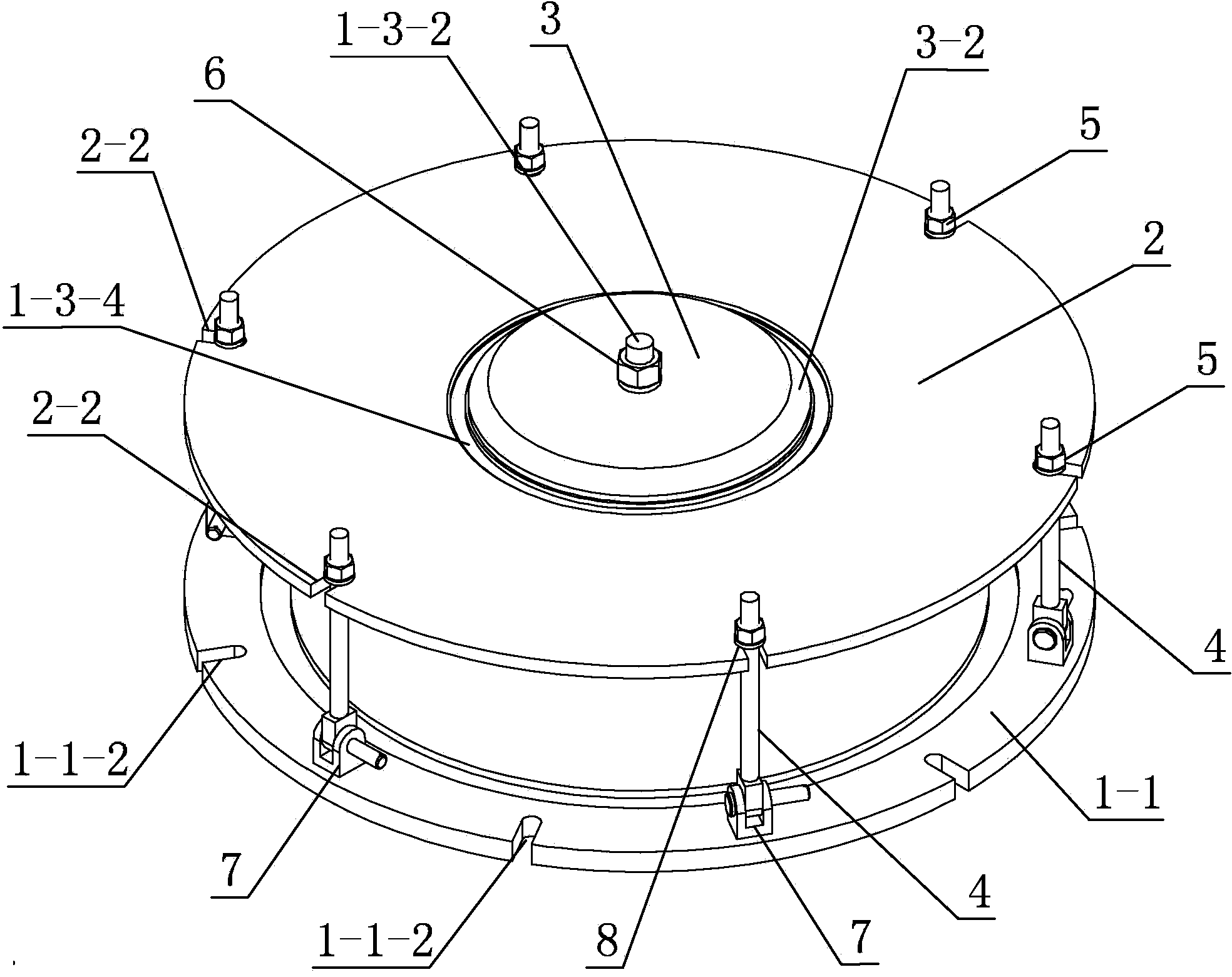

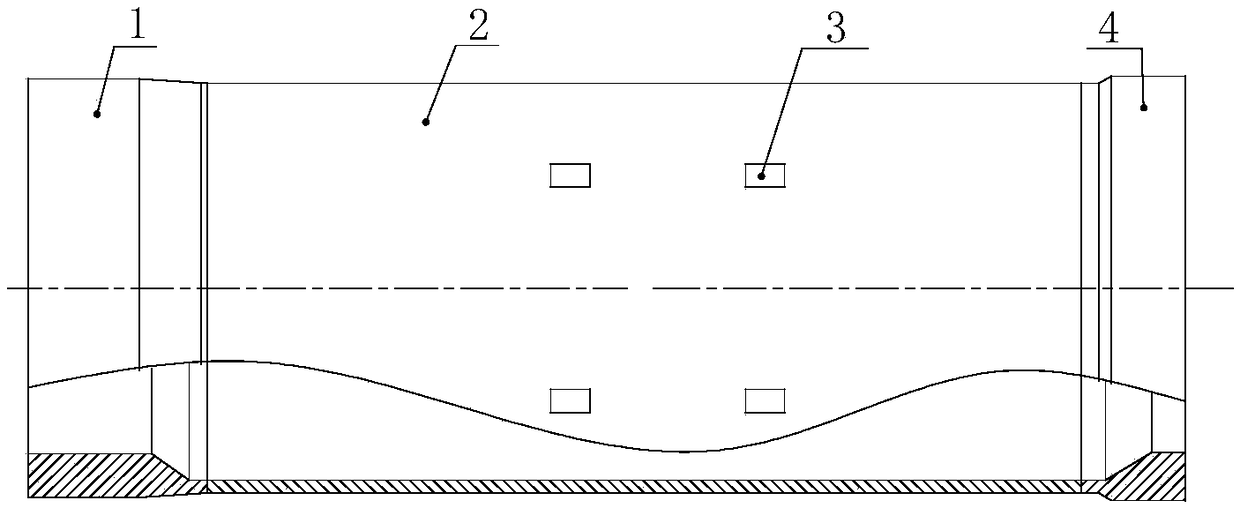

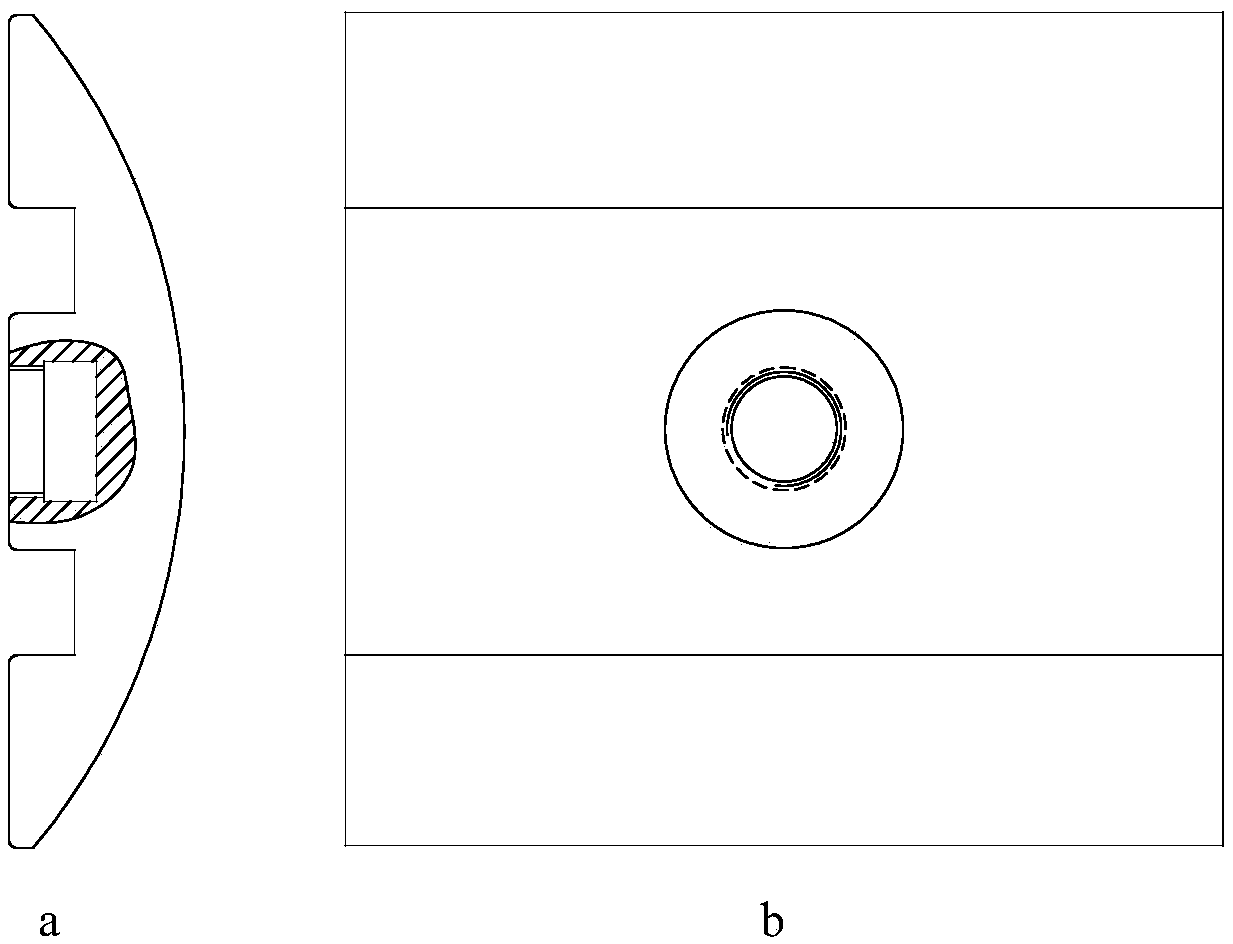

Circular seam laser welding jig for thin-walled aluminum alloy end socket flange plates

InactiveCN103831571AUniform fasteningCooperate accuratelyWelding/cutting auxillary devicesAuxillary welding devicesWelding deformationMaterials science

The invention relates to a welding jig, in particular to a circular seam laser welding jig for thin-walled aluminum alloy end socket flange plates. The circular seam laser welding jig aims to solve the problems that as no special circular seam laser welding jig for the thin-walled aluminum alloy end socket flange plates exists in the prior art, welding deformation is serious, and the welding accuracy cannot meet the welding requirement. An inner platen is located at the upper end face of an inner platen base, a first circular center groove corresponds to a second circular center groove in an up-and-down mode, a first annular groove is machined in the upper end face of the outer edge of the inner platen base in the circumferential direction, a second annular groove is formed in the lower end face of the inner ring of an outer platen in the circumferential direction, the second annular groove of the outer platen is combined with the first annular groove in a pressed mode, an annular interval is reserved between the outer platen and the inner platen, a plurality of hinge bases are evenly distributed and fixedly installed at the outer edge of a lower disc in the circumferential direction, the lower end of each screw rod is hinged to the corresponding hinge base, and the upper end of each screw rod penetrates through the outer edge of the outer platen and is in threaded connection with a second nut. The circular seam laser welding jig is used for welding the thin-walled aluminum alloy end socket flange plates.

Owner:HARBIN INST OF TECH

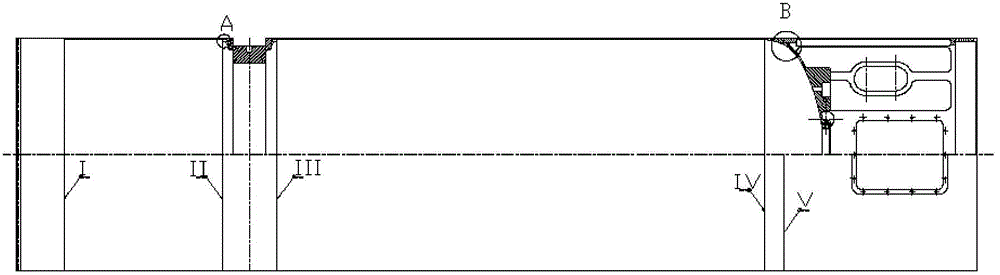

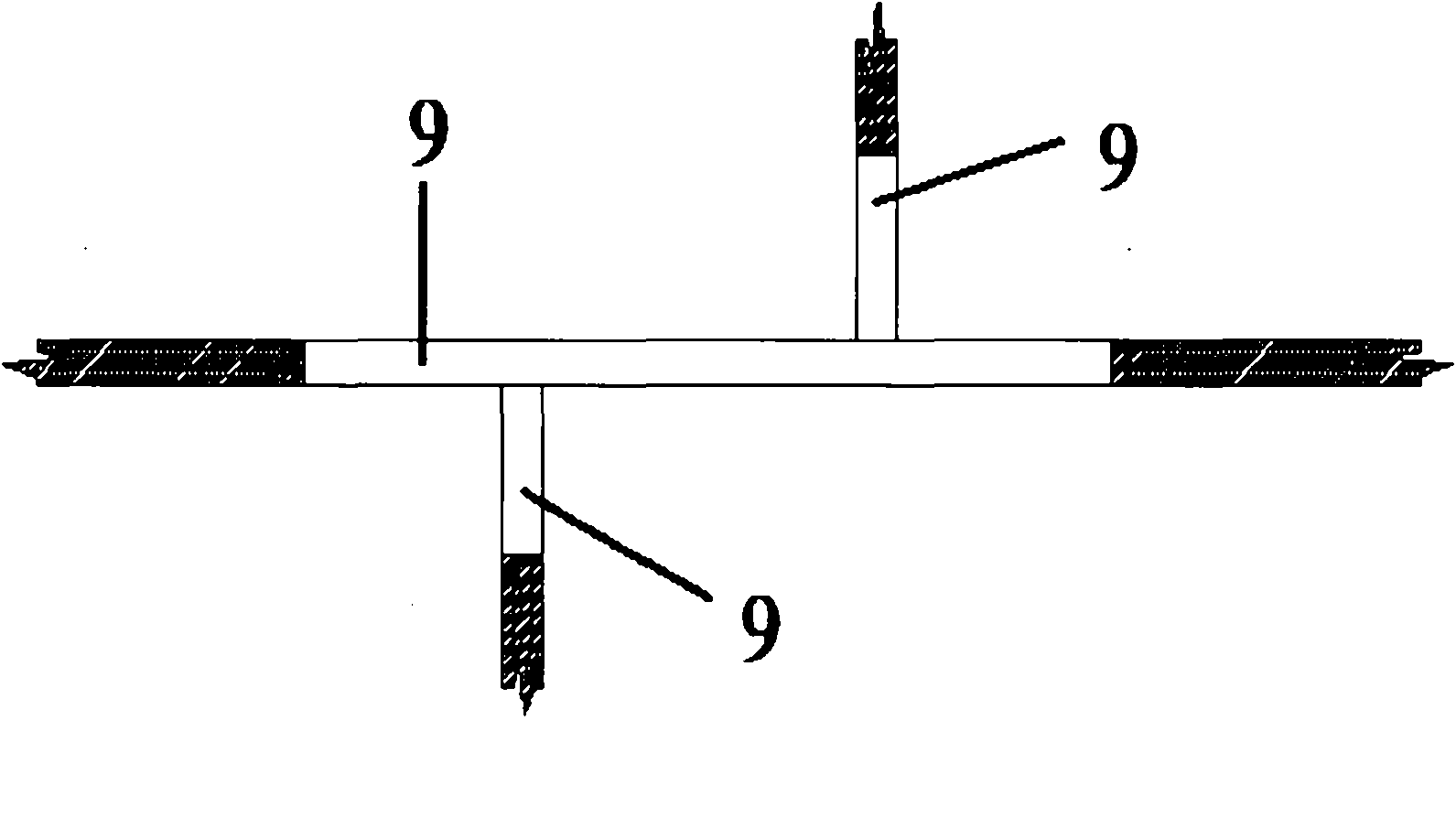

Extensible and retractable inner supporting tool

ActiveCN109366052ALarge stretchEasy accessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

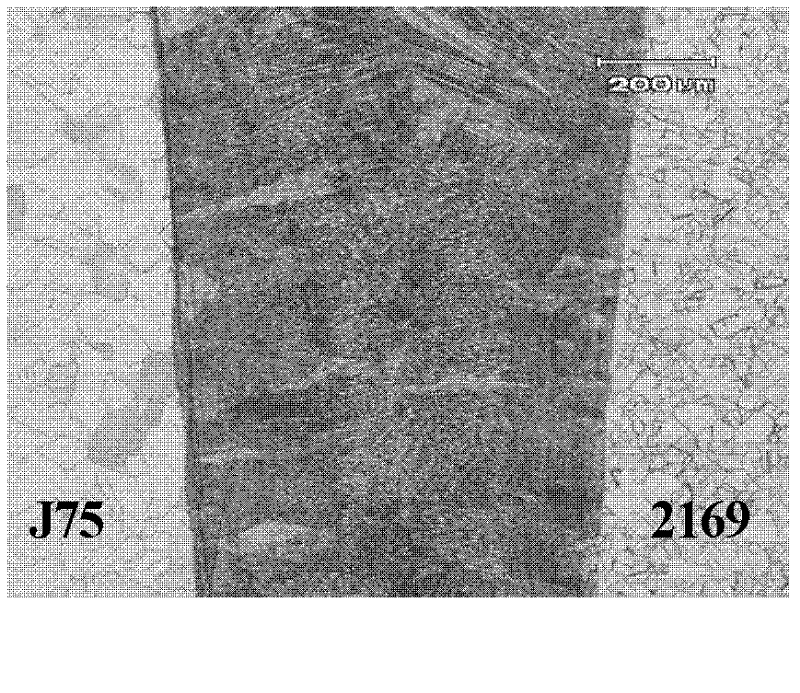

Method for welding heterogeneous austenitic stainless steel plates

InactiveCN102500906APrevent dent defectsControl welding deformationElectron beam welding apparatusHeat-affected zoneAlloy

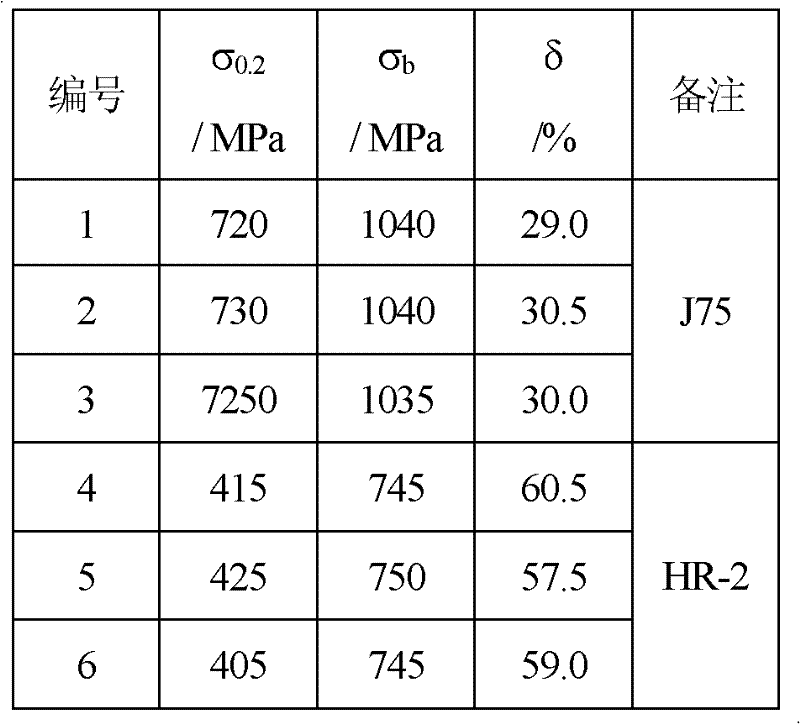

The invention relates to the field of heterogeneous steel welding, in particular to a vacuum electron beam welding method for single-phase austenitic stainless steel (HR-2) and precipitation strengthening austenitic stainless steel (J75) heterogeneous plates (which have the thickness of between 2.0 and 5.0 millimeters). According to the vacuum electron beam welding method for the HR-2 and J75 stainless steel heterogeneous plates, a process comprises the following steps of: performing pre-welding treatment on parent metals, clamping and fixing in a vacuum welding chamber, vacuumizing the welding chamber, welding in a positioning mode, welding by using electron beams in a single circulation mode (the electron beams scan in a deflection mode) and scanning weld joints by using the electron beams in a defocusing mode after welding. According to HR-2 and J75 heterogeneous metal joints, the defects of pores, entrainment and the like are overcome in the joints, and poor gama' areas are not formed in a welding molten pool and a heat affected zone on one side of J75 alloy. The joints of the HR-2 and J75 stainless steel heterogeneous plates welded by the method have good formed surfaces, the strength of the joints is higher than 680 to 700 MPa, and the strength factor of the HR-2 stainless steel can reach over 0.9.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Limb type circular tube node transferring structure and manufacturing method thereof

InactiveCN104847020AReduce deformation stressReduce residual stressBuilding constructionsMechanical engineeringIndustrial engineering

The invention belongs to the technical field of building steel structure, in particular relates to a limb type circular tube node transferring structure and a manufacturing method thereof. The limb type circular tube node transferring structure comprises a trunk circular tube, a fork transitional node which is connected to one end of the trunk circular tube, a limb supporting rod circular tube and a space bracket which is installed on the external surface of the integral node; the fork transitional node is formed by two sections of special cone tubes through a central pull rod and a transverse insertion plate by penetrating; two half tiles at the bottom of the fork transitional node are combined to be an integral circle which is connected with the trunk circular tube; the end portion of the fork transitional node is connected with the two fork supporting rod circular tubes. The limb type circular tube node transferring structure has the advantages of solving the design problem of the circular tube fork connecting node, being simple and reasonable in structural design, attractive in appearance design and the like.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Multi-wire submerged-arc multi-layer multi-pass welding process

InactiveCN102581450AAvoid embrittlementPrevents solder joint softening problemsArc welding apparatusHeat-affected zoneEngineering

The invention provides a multi-wire submerged-arc multi-layer multi-pass welding process, which includes the steps: firstly, making preweld preparation including preparing and cleaning a welding joint groove, preheating a welding position before welding and selecting proper welding materials; secondly, setting reasonable welding parameters; and thirdly, performing multi-wire submerged-arc multi-layer multi-pass welding. By means of reasonably selecting welding materials, setting the reasonable welding parameters and controlling heat input, preheating temperature and interlayer temperature, the problems of welding cracks, embrittlement of a heat-affected zone and softening of a welding joint are effectively prevented, welding deformation is effectively controlled, the workload of post-weld correction and deformation adjustment is decreased, and welding efficiency and quality are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

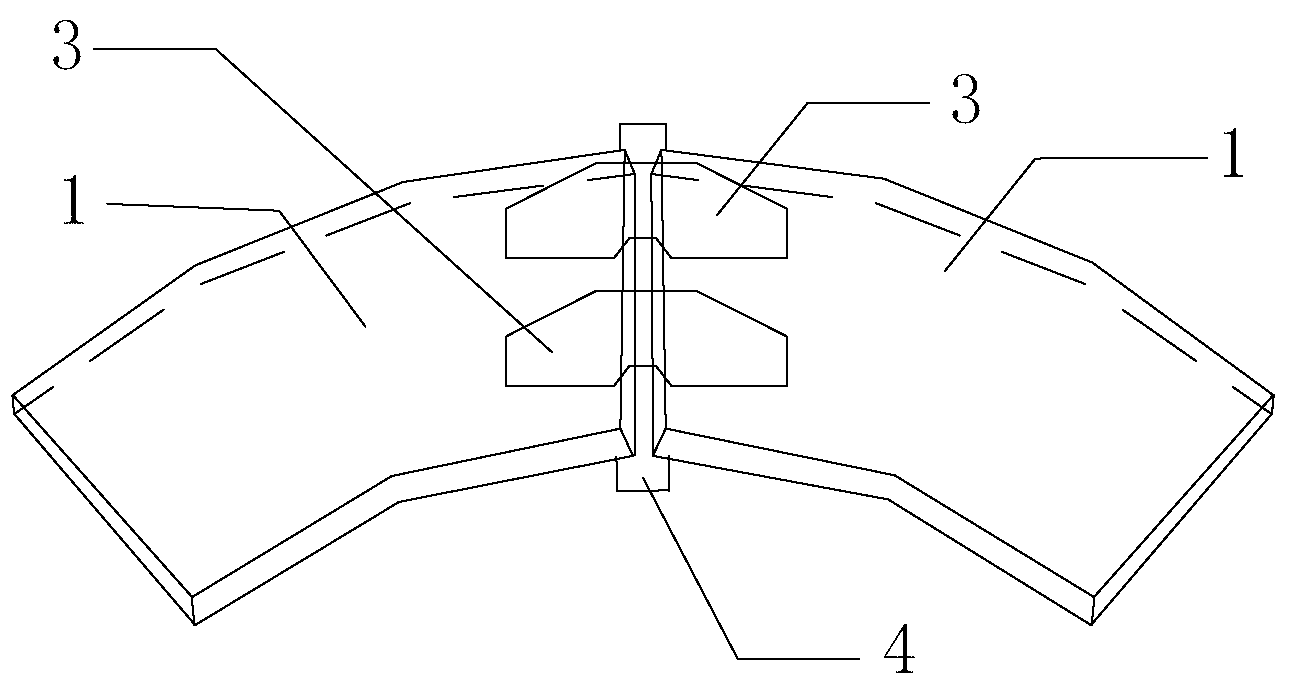

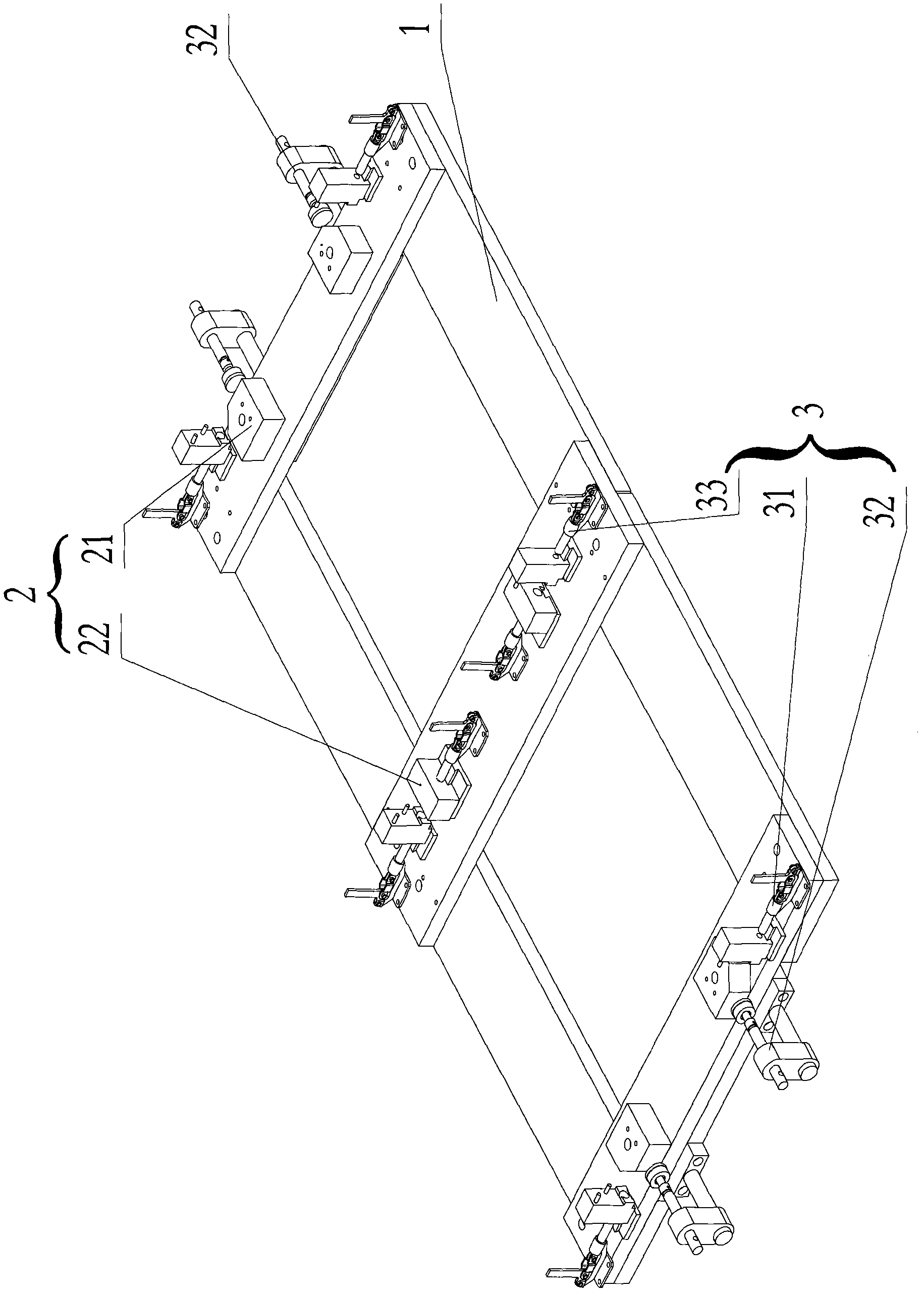

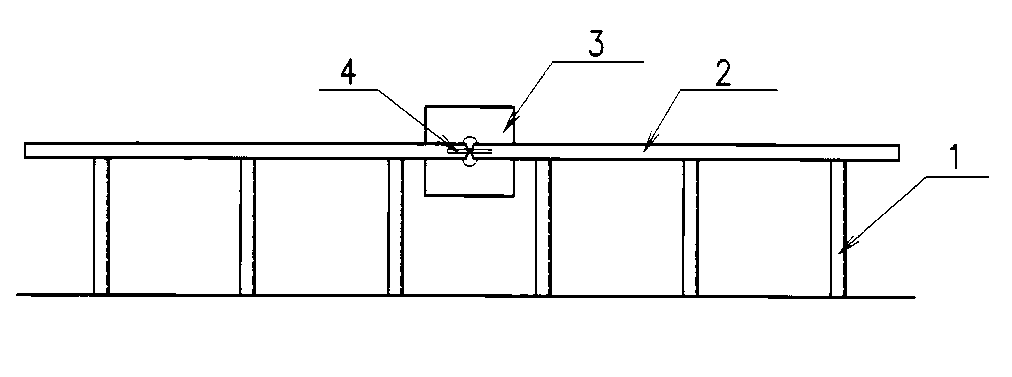

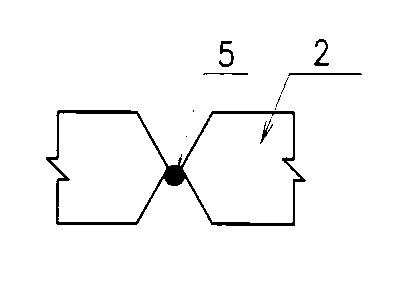

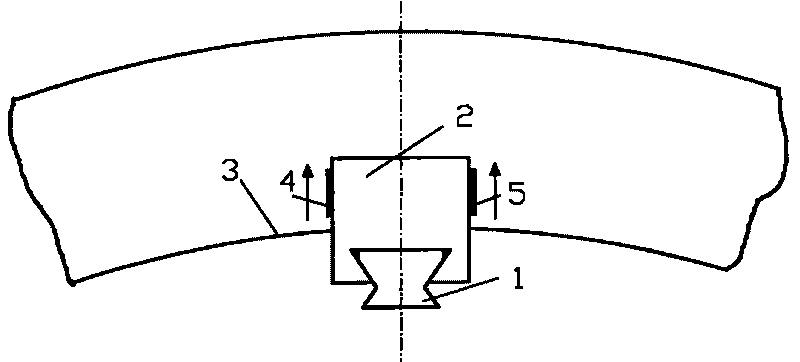

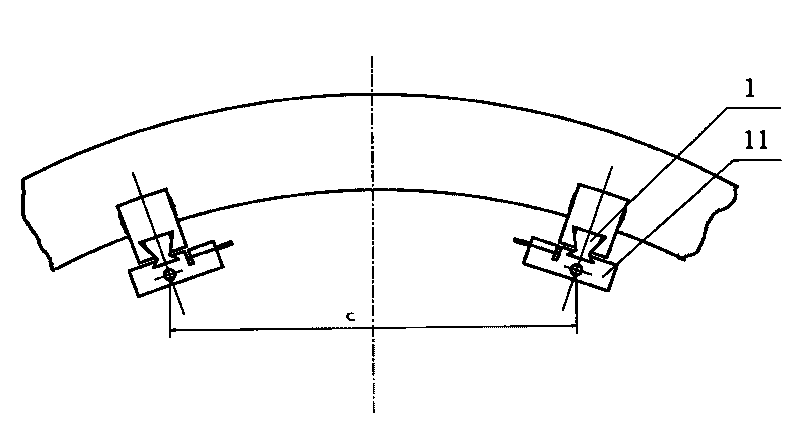

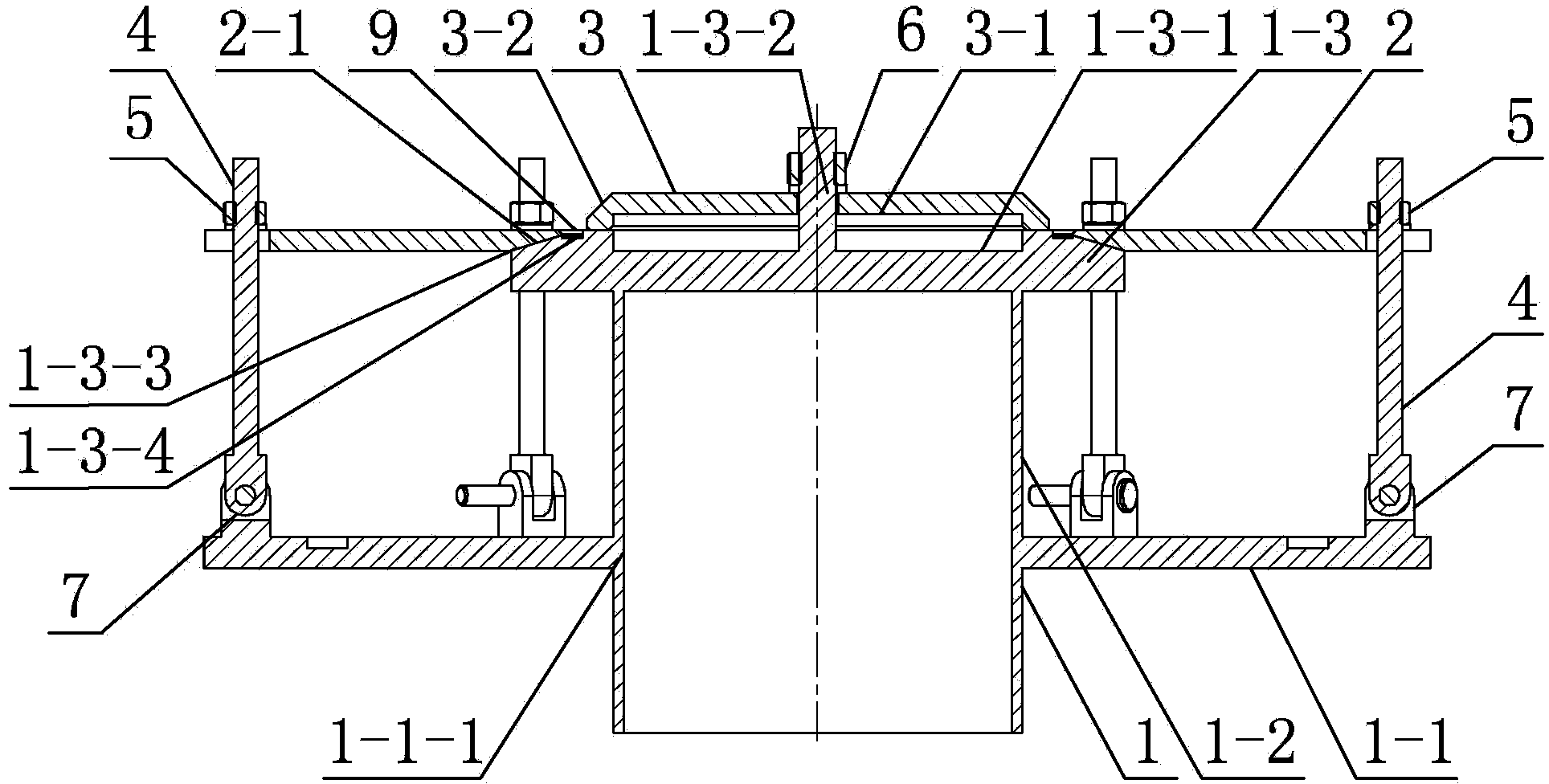

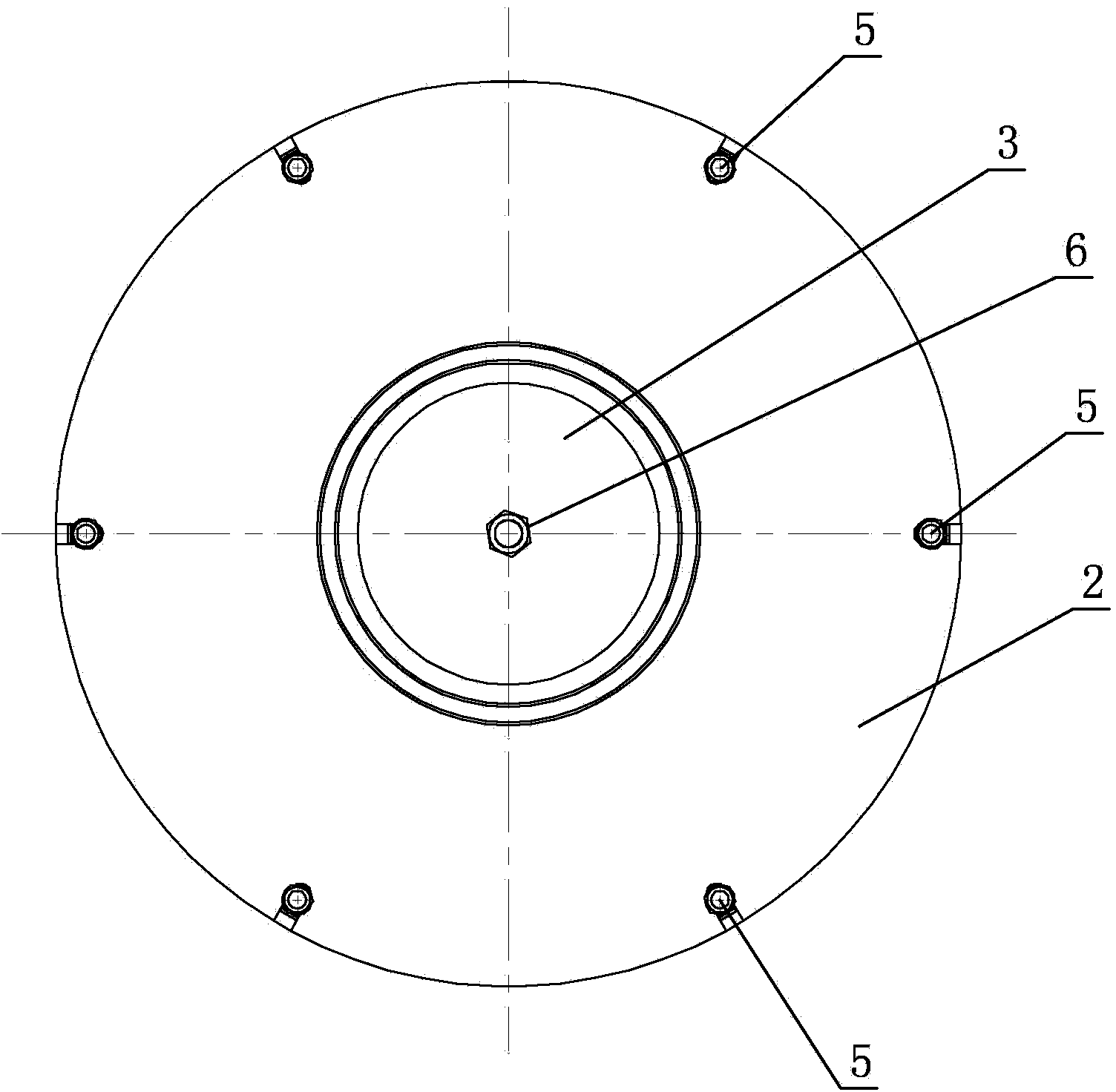

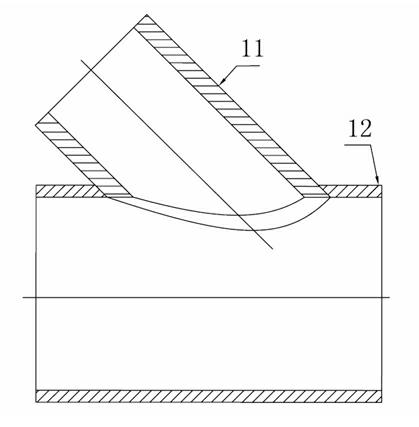

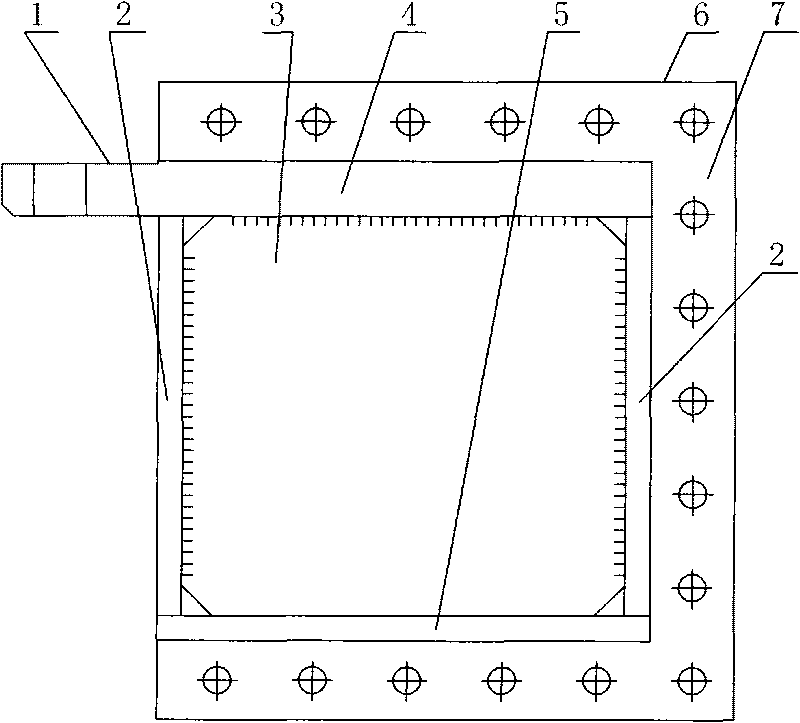

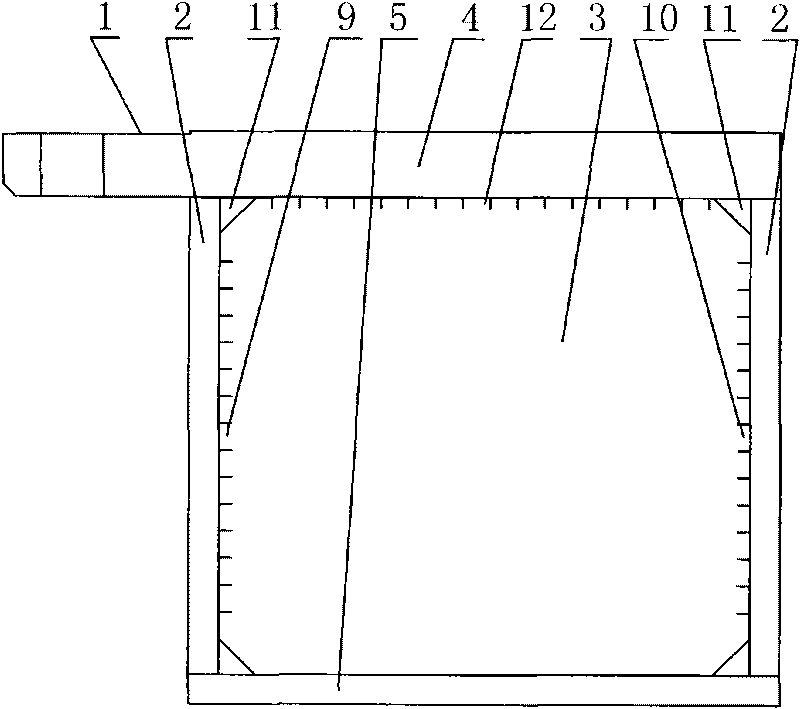

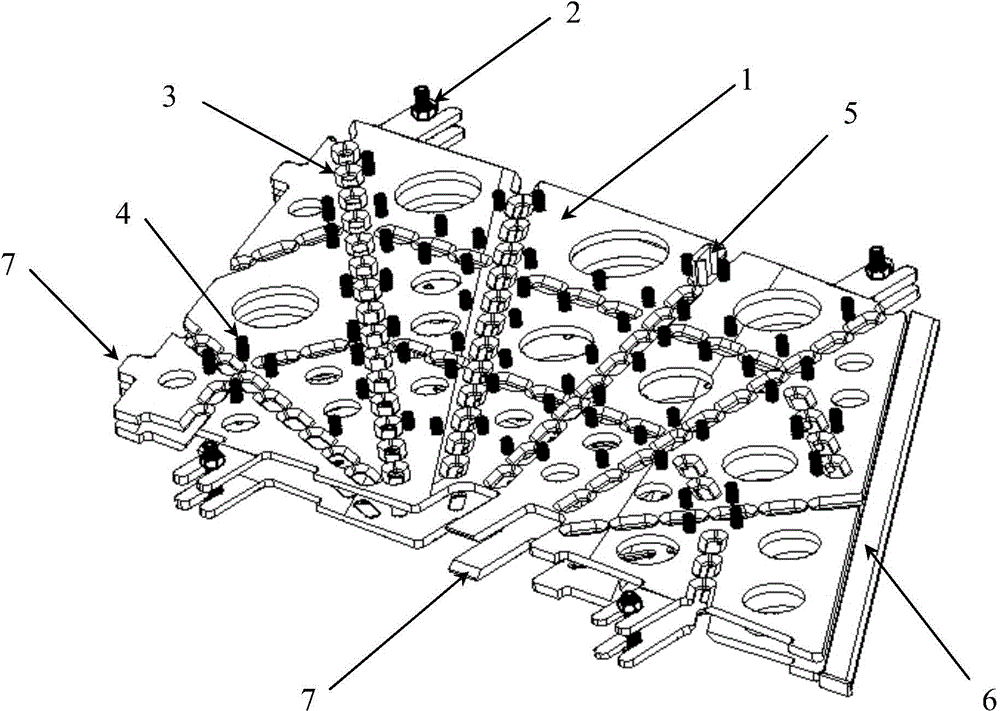

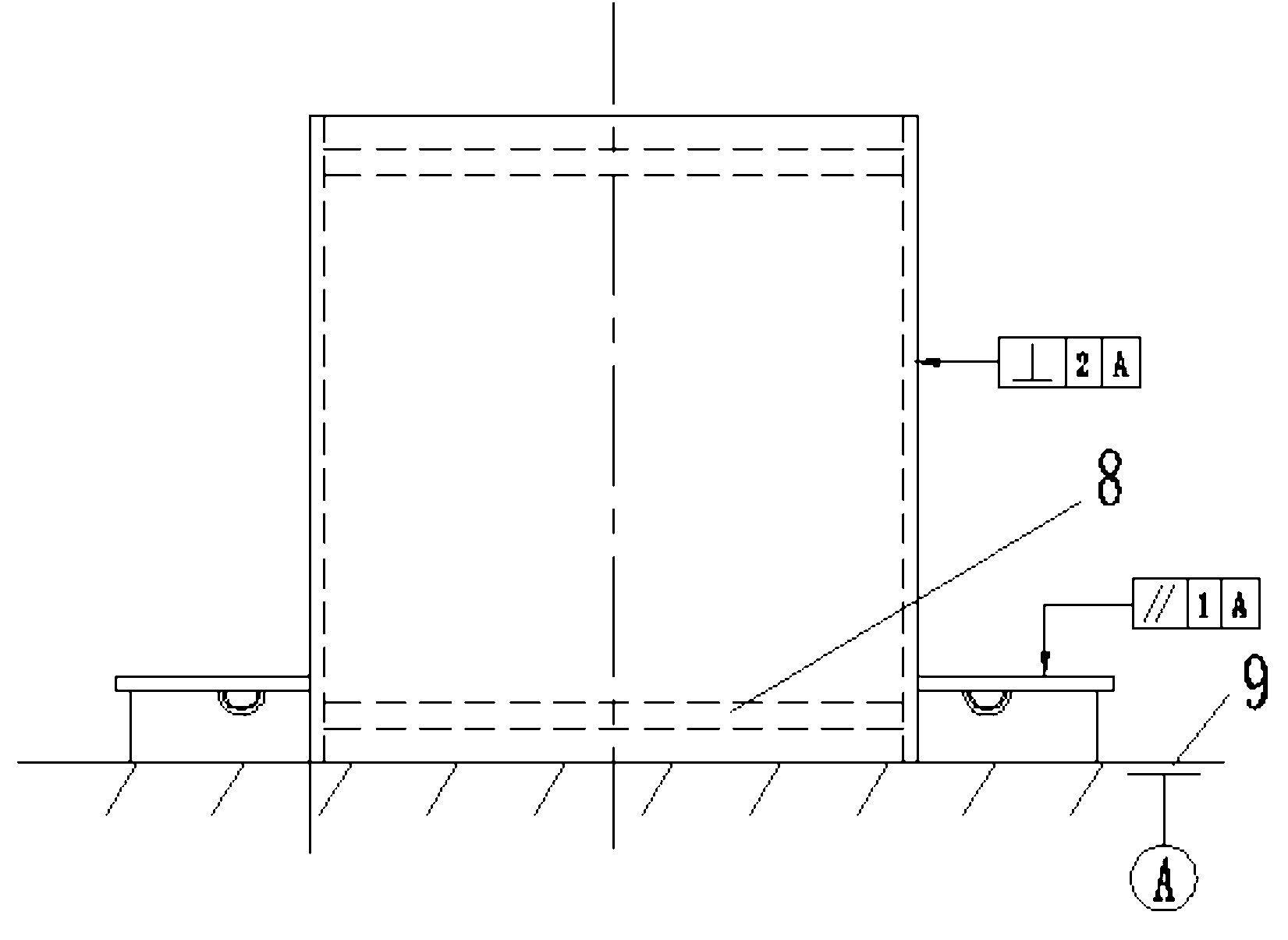

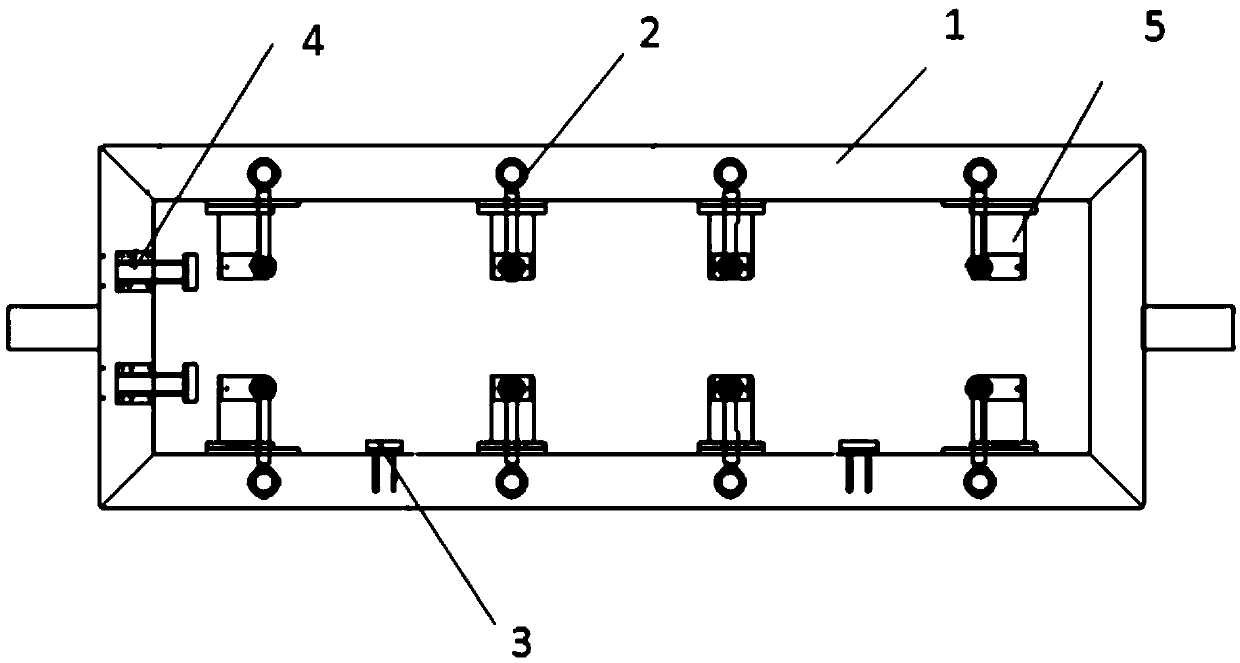

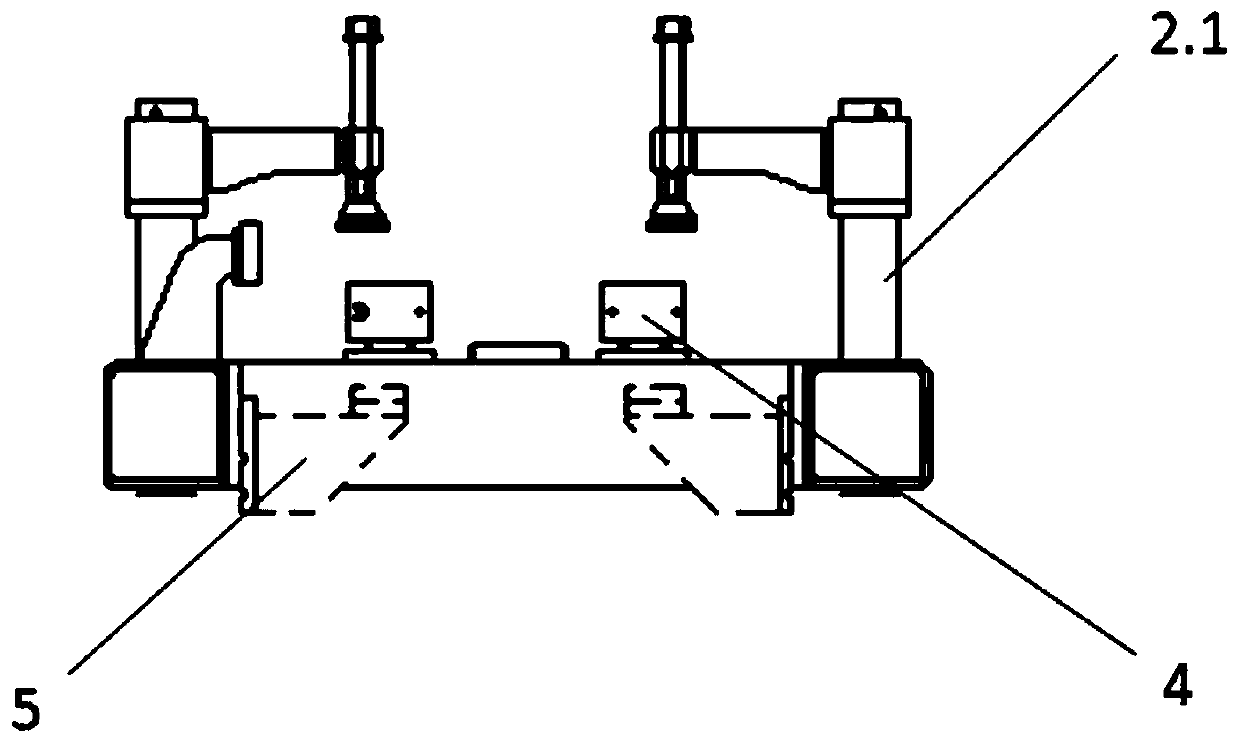

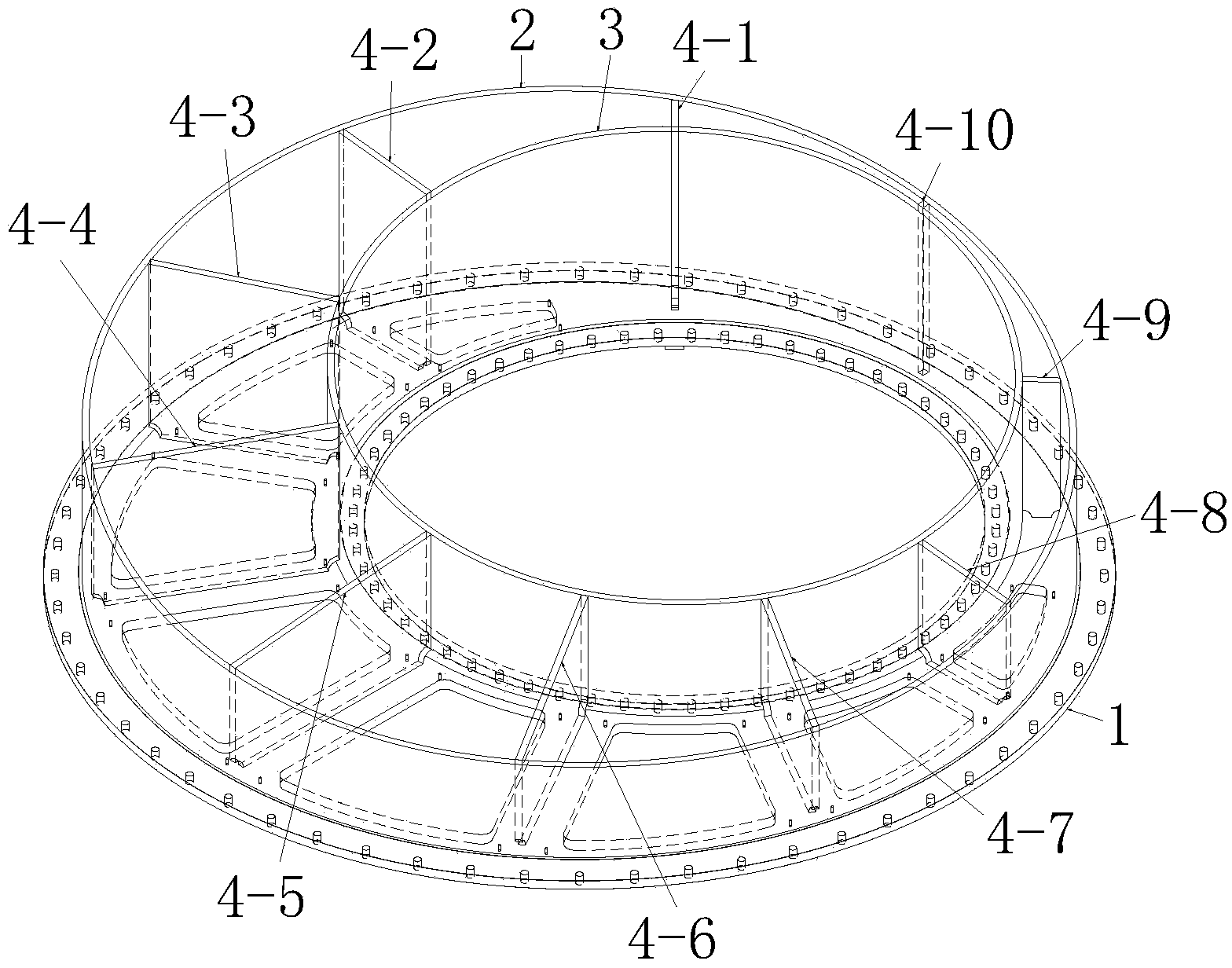

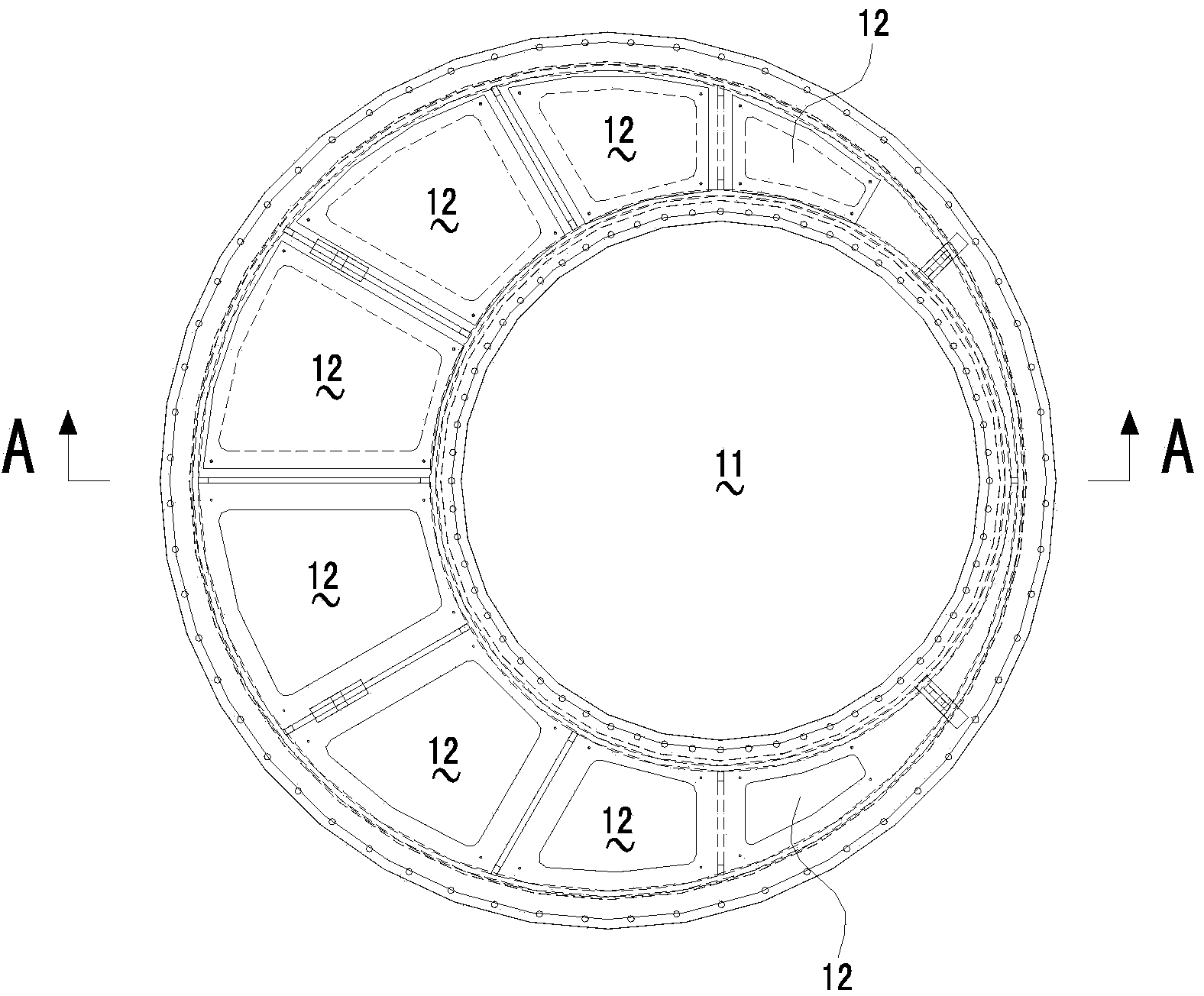

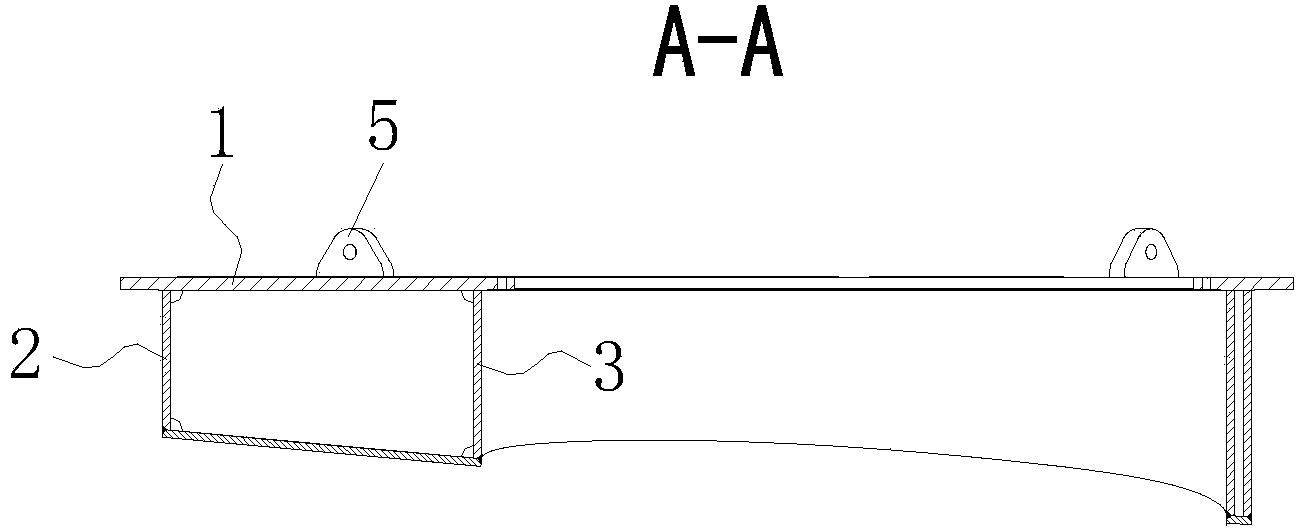

Method for assembling pedestal body of overhead cell support of hybrid vehicle and clamp thereof

ActiveCN101618493AReduce physical laborImprove assembly and welding efficiencyWelding/cutting auxillary devicesAssembly machinesInstabilityThermal deformation

The invention discloses a method for assembling a pedestal body of an overhead cell support of a hybrid vehicle and a used welding frock clamp thereof. The welding tool clamp comprises a clamp body (1), and the pedestal body of the overhead cell support of the hybrid vehicle comprises two pedestal crossbeams (11) and a plurality of middle supporting plates (12); the clamp is characterized in that a positioning element (2) is fixedly arranged at the upper end of the clamp body and horizontally limits the positions of the pedestal crossbeams (11), and a clamping device (3) is arranged at the outer sides of the pedestal crossbeams (11) and clamps the two pedestal crossbeams (11) and the middle supporting plates (12) arranged between the two pedestal crossbeams. The clamp greatly lightens the physical work of the operating staff, improves the assembling and welding efficiency, controls or eliminates the thermal deformation of workpieces caused by welding, and reduces the instability of manual welding.

Owner:苏州宝馨智能制造有限公司

Ring crane corbel for nuclear power station and manufacturing method thereof

ActiveCN101875475AReasonable structureMeet support requirementsLoad-engaging girdersBuilding constructionsNuclear powerArchitectural engineering

The invention relates to a ring crane corbel for a nuclear power station and a manufacturing method thereof, belonging to the technical field of building construction facilities. In the ring crane corbel, a box-type frame main body comprises a rectangular main body plate, wherein an upper cover plate and a lower cover plate are respectively soldered and fixed on one side of the main body plate; a left lateral plate, a right lateral plate and a middle stiffened plate are soldered between the upper cover plate and the lower cover plate; the left lateral plate, the right lateral plate and the middle stiffened plate are soldered with the main body plate; the two ends of one side of the lower cover plate are soldered with the two bottom edges of an external baffle; the upper part of the external baffle extends between the left lateral plate and the right lateral plate after the upper part of the external baffle is bent; the two lateral edges of the upper part of the external baffle are respectively soldered with the inner surfaces of the left lateral plate and the right lateral plate; the other side of the main body plate is soldered with a bent bar; and horizontal and vertical stiffened plates are respectively soldered on corresponding positions on the main body plate, which are soldered with the upper cover plate, the lower cover plate, the left lateral plate, the right lateral plate and the middle stiffened plate. After the ring crane corbel is adopted, the use requirement can be met, and reasonable assembly and soldering sequence are adopted, so the final quality of the ring crane corbel component can be ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Aero-engine stator assembly vacuum electron beam welding technology

ActiveCN104475959AMeet weldingMeet the performance stability requirements after weldingElectron beam welding apparatusManufacturing technologyDirect effects

The invention discloses an aero-engine stator assembly vacuum electron beam welding technology and belongs to the technical field of aero-engine part manufacturing. Formerly, an aero-engine stator assembly is welded through a brazing method, the brazing intensity is lower than the base metal intensity, the stator assembly performance stability is directly influenced, and a traditional welding method is excessively large in welding deformation. Compared with the prior art, after a large amount of soldering tests, the aero-engine stator assembly vacuum electron beam welding technology has the advantages that welding of the aero-engine stator assembly can be completely satisfied, brand new welding parameters are provided, the welding parameters are obtained after a large amount of welding parameter tests, welding of different thickness weld joints can be satisfied maximally, and thermal input is guaranteed uniform, the welding deformation is effectively controlled, and the requirement for stable postwelding performance of the stator assembly is satisfied due to sequence welding of the two weld joints at symmetrical positions.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

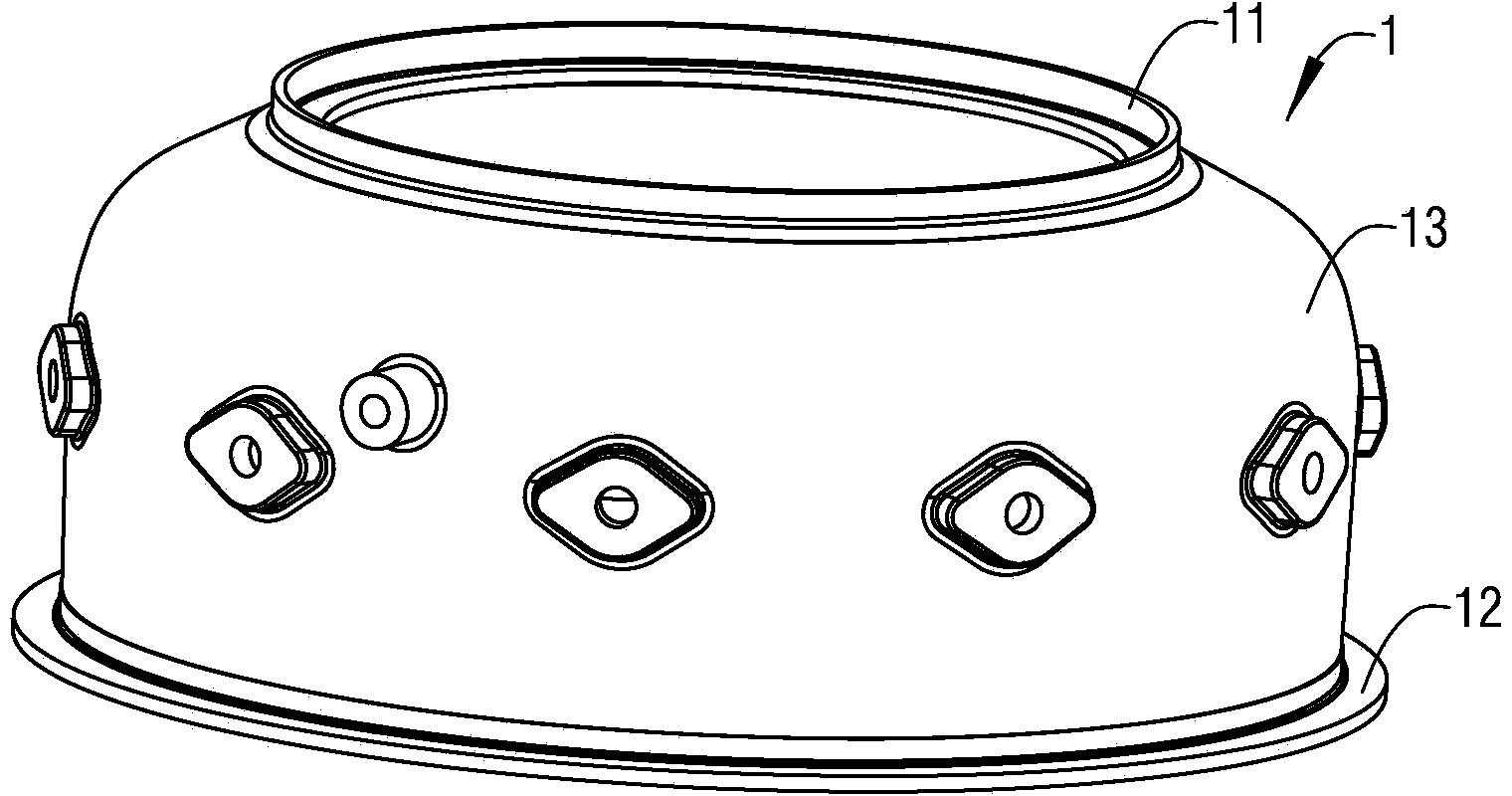

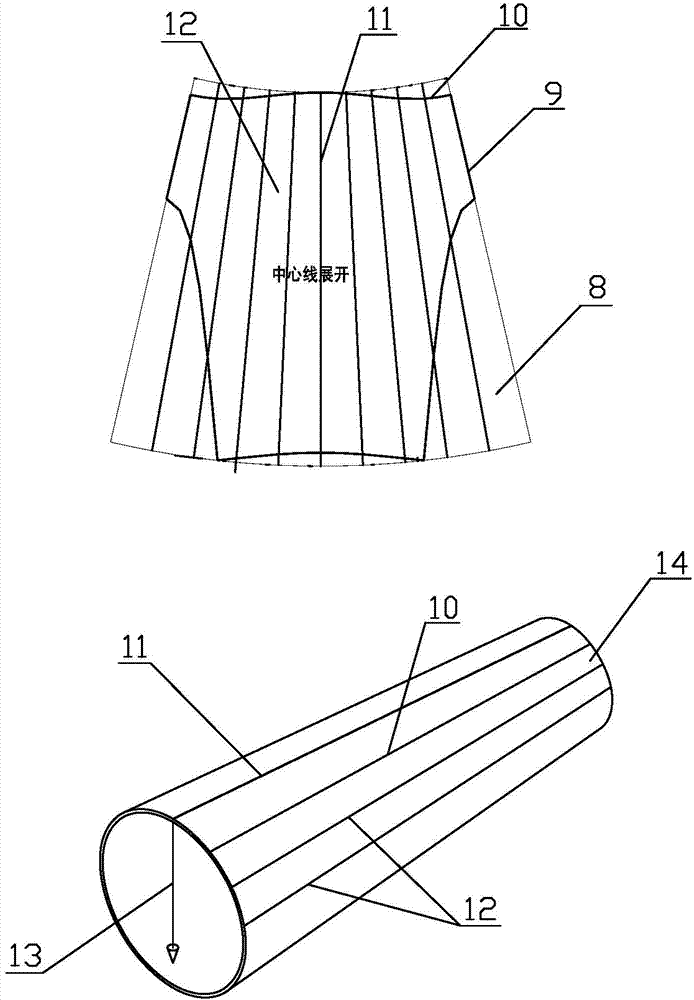

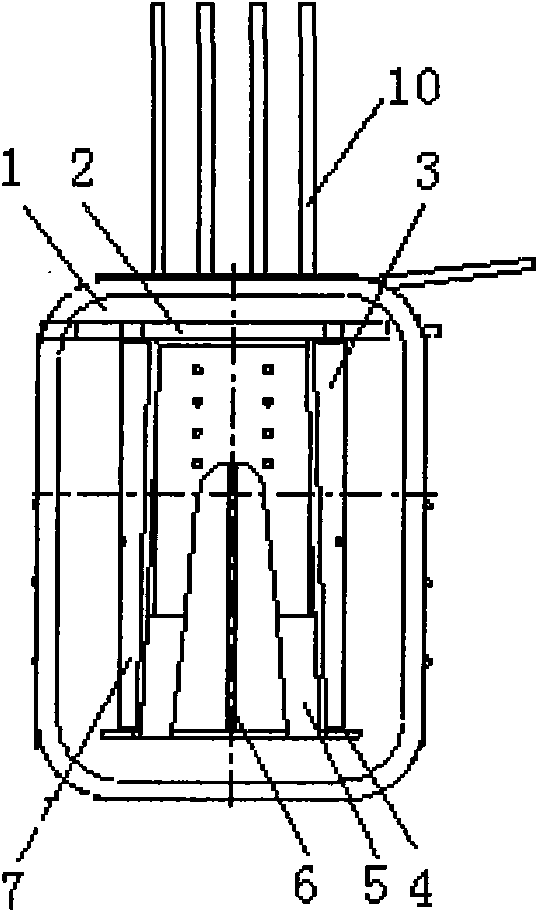

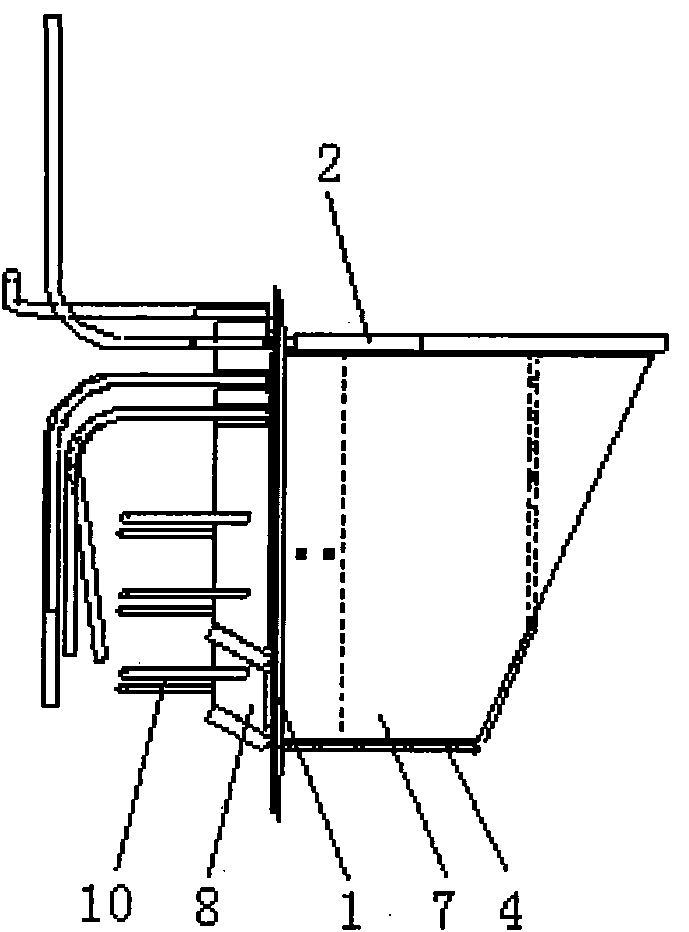

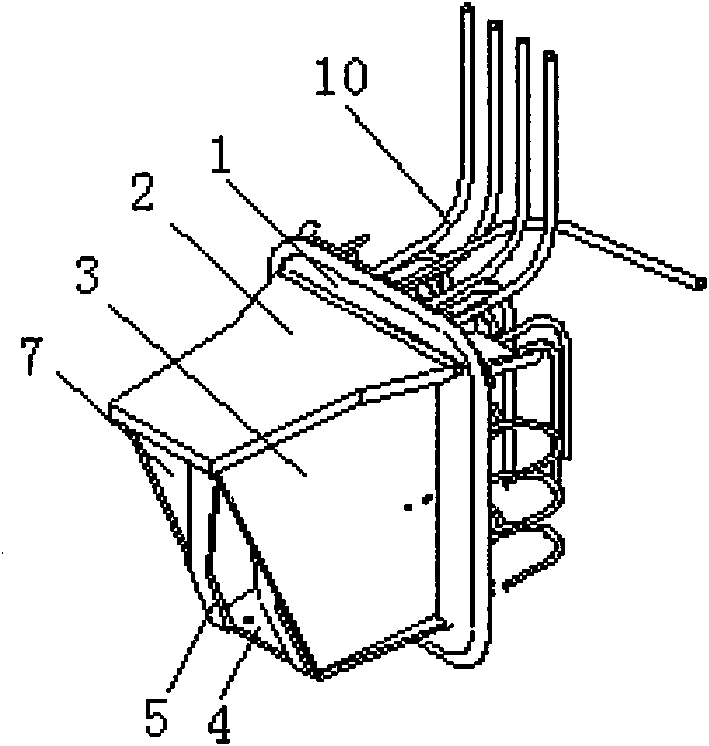

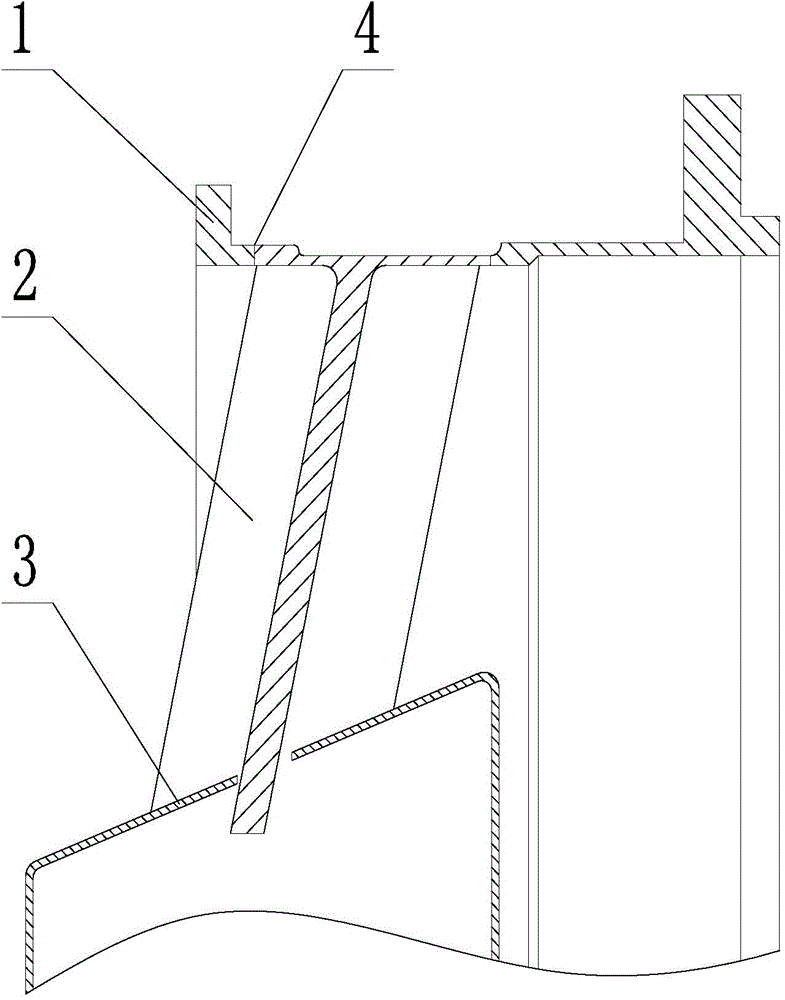

Method for manufacturing inner barrel of combustor of gas turbine and fixture

ActiveCN103862146AImprove protectionNo oxidationWelding/cutting auxillary devicesAuxillary welding devicesCombustorWelding deformation

The invention discloses a method for manufacturing an inner barrel of a combustor of a gas turbine and a welding fixture of the inner barrel. The method and the welding fixture are characterized in that an N-2-1 positioning method and a symmetrical wandering welding method are achieved through the fixture, and welding deformation of thin-walled barrels such as the inner barrel of the combustor of the gas turbine can be controlled within 1 mm.

Owner:DONGFANG TURBINE CO LTD

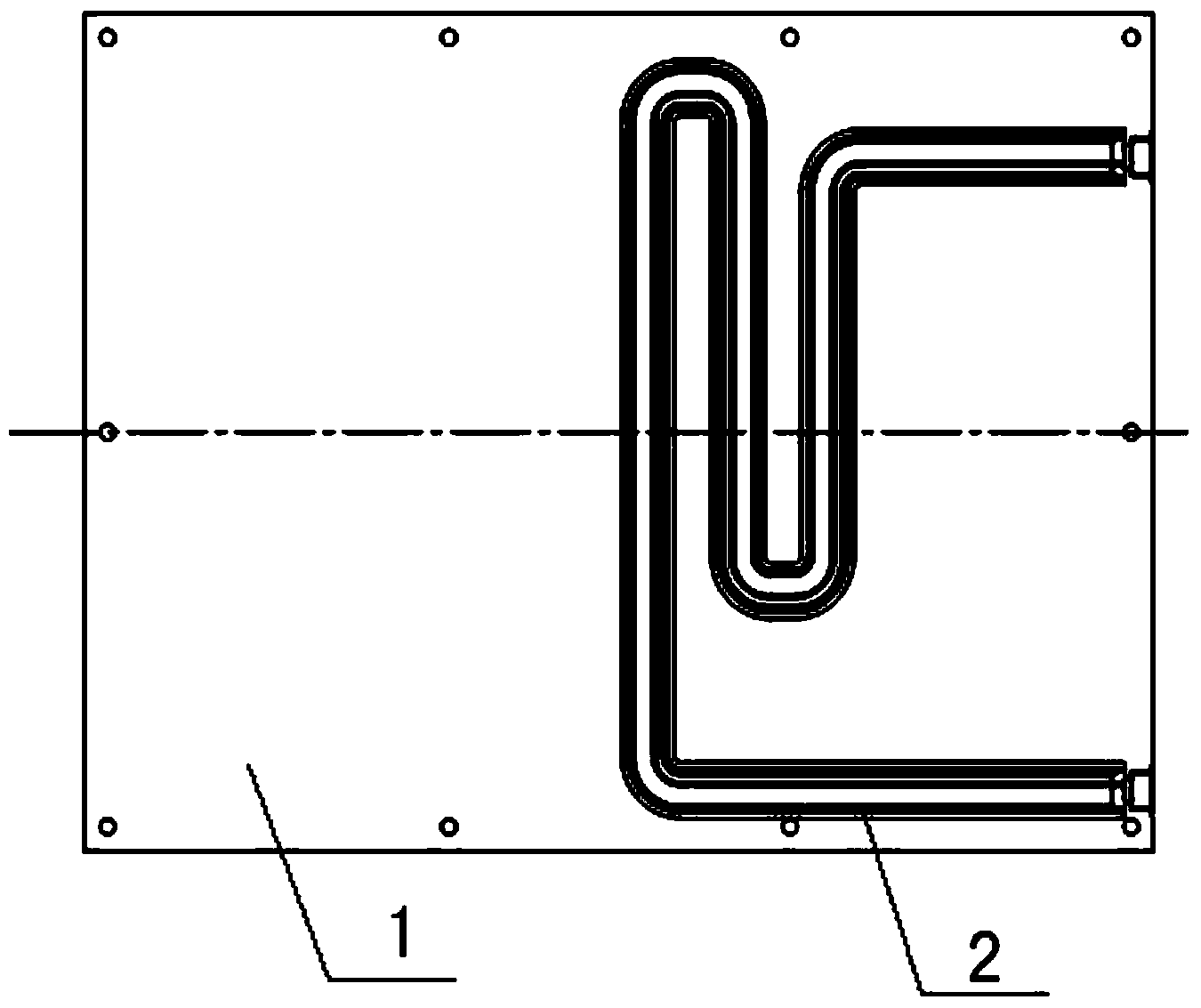

Method for welding heat dissipation base plates

ActiveCN103659184AImprove pass rateGuarantee welding qualityArc welding apparatusNon-electric welding apparatusAnodizingEngineering

The invention discloses a method for welding heat dissipation base plates, and belongs to the technical field of aluminum alloy welding detection. The method includes the steps that heat dissipation base plate parts are machined, the heat dissipation base plate parts and welding tools are assembled, and tack welding, continuous welding, stress annealing, shape correction, friction repair and surface anodizing are performed. According to the method, the quality of welding joints is guaranteed, and the percent of pass of the heat dissipation base plates is improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

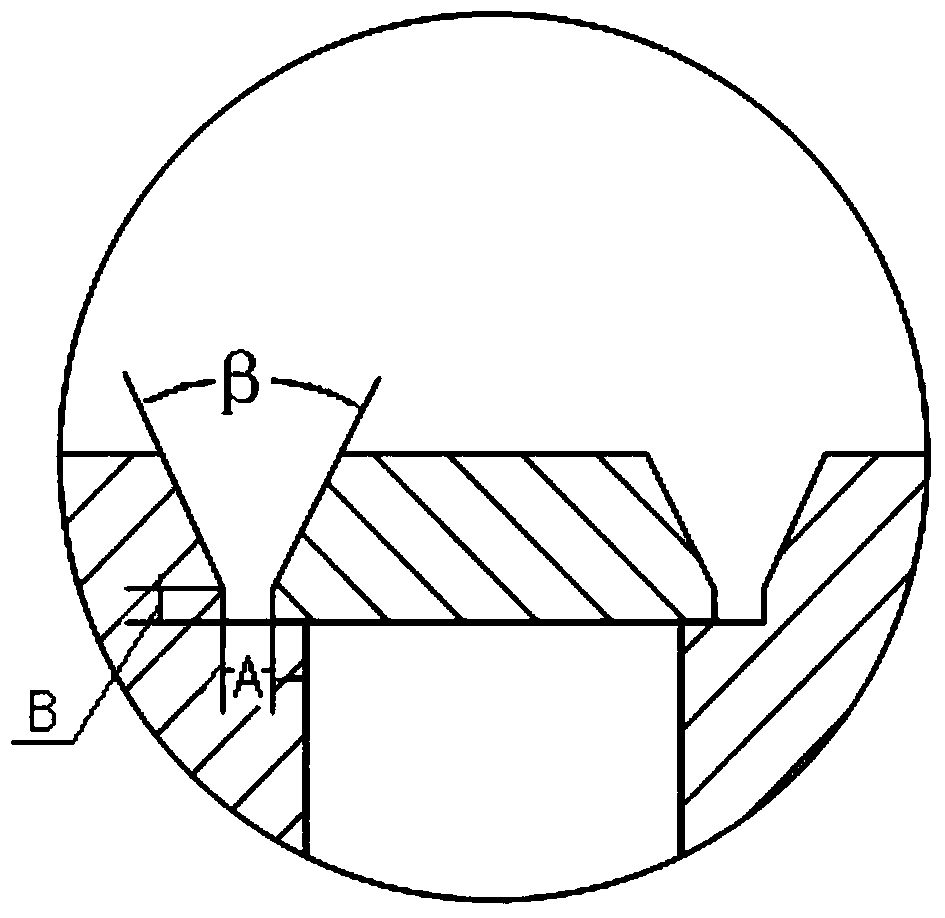

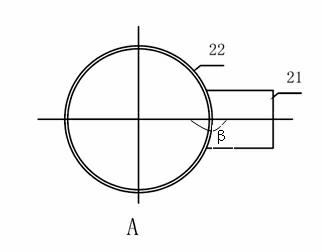

Method for controlling welding deformation of joint between inserted large inclined tube and barrel

InactiveCN102380690AControl welding deformationImprove pass rateArc welding apparatusEngineeringTotal station

The invention discloses a method for controlling welding deformation of a joint between an inserted large inclined tube and a barrel. The method comprises the following steps of: 1, forming a hole on the side part of the barrel; 2, assembling the inserted large inclined tube and the barrel, and welding a fixing rib plate on the outer side of the joint; 3, measuring the size of the joint between the barrel and the large inclined tube, and forming an angle alpha for counteracting the distortion allowance; 4, welding a lower welding line; 5, welding a middle lower welding line, measuring an included angle beta with a total station electronic tacheometer, and controlling the included angle beta at 180 degrees in the welding process; 6, welding a middle upper welding line, measuring an included angle beta, and controlling the included angle beta at 180 degrees in the welding process; and 7, welding an upper welding line. In the invention, the total station electronic tacheometer is used together with a rigid fixing method, and the welding deformation of the joint is controlled in the welding process of the inserted large inclined tube and the barrel, so that the product qualified rate is high, and the welding quality is effectively ensured; and the method is simple, and is very effective for controlling the welding deformation of a large inserted joint.

Owner:SHANGHAI BOILER WORKS

Technique for processing circular ring box type beam of lifting tool

Owner:ZHEJIANG DADI STEEL STRUCTURE

Welding device for titanium alloy skin structural member for framework

ActiveCN104400283AEnsure that the shape meets the requirementsGuaranteed complianceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTitanium alloy

The invention discloses a welding device for a titanium alloy skin structural member for a framework. The welding device mainly comprises a molded surface pressing plate, clamping components, pressing parts, line marking blocks and a plug block, wherein welding grooves are formed in the molded surface pressing plate having welding positioning references; the molded surface pressing plate presses and fixes an outer skin of a to-be-welded part under the effect of the clamping components; the plug block is disposed at the edge of the skin for preventing welding deformation; the pressing parts are arranged near welding lines and are used for performing multi-point fixation for the titanium alloy skin so as to guarantee effective and tight fit of the skin and the framework and to guarantee the precision and the quality of the welding lines. The welding device is made of austenitic stainless steel, so that the welding device is suitable for different high-energy beam welding methods. The contour precision of the part reaches 0.1-0.2 mm. By the positioning references and the welding grooves, time for determining welding line positions is largely shortened and the welding efficiency is improved by more than two times. The welding device is suitable for the welding of large-size titanium alloy skin structural members for frameworks.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Assembly welding process of muffle pipe double-layer flange

ActiveCN103008844AHigh precision requirementsControl assembly errorArc welding apparatusWorkpiece edge portionsEngineeringWelding deformation

The invention discloses an assembly welding process of a muffle pipe double-layer flange. The strict assembly welding process of an upper flange, a lower flange, a rib plate, a cooling semi-pipe and a muffle pipe tube body is adopted, the welding deformation control key point is fully considered, the form and location tolerance requirements between the muffle pipe and the flanges as well as between the flanges are ensured, the assembly error and the welding deformation of the muffle pipe double-layer flange structure are effectively controlled, the design requirement is reached, and the precision requirement of the muffle pipe is perfectly improved.

Owner:WISDRI WUHAN WIS IND FURNACE

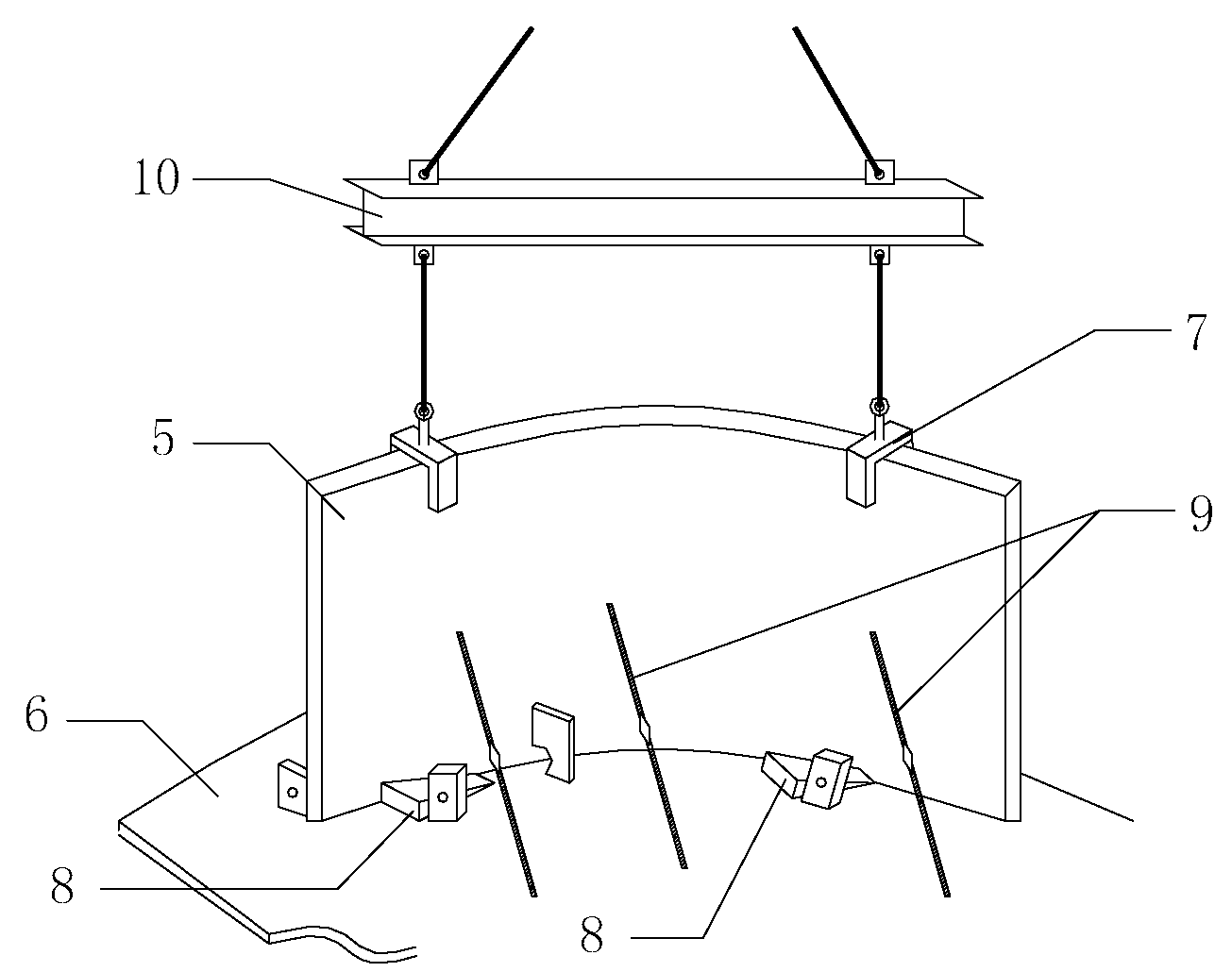

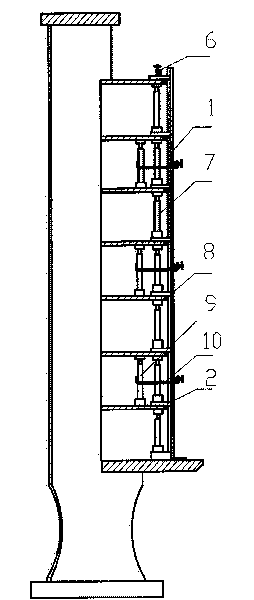

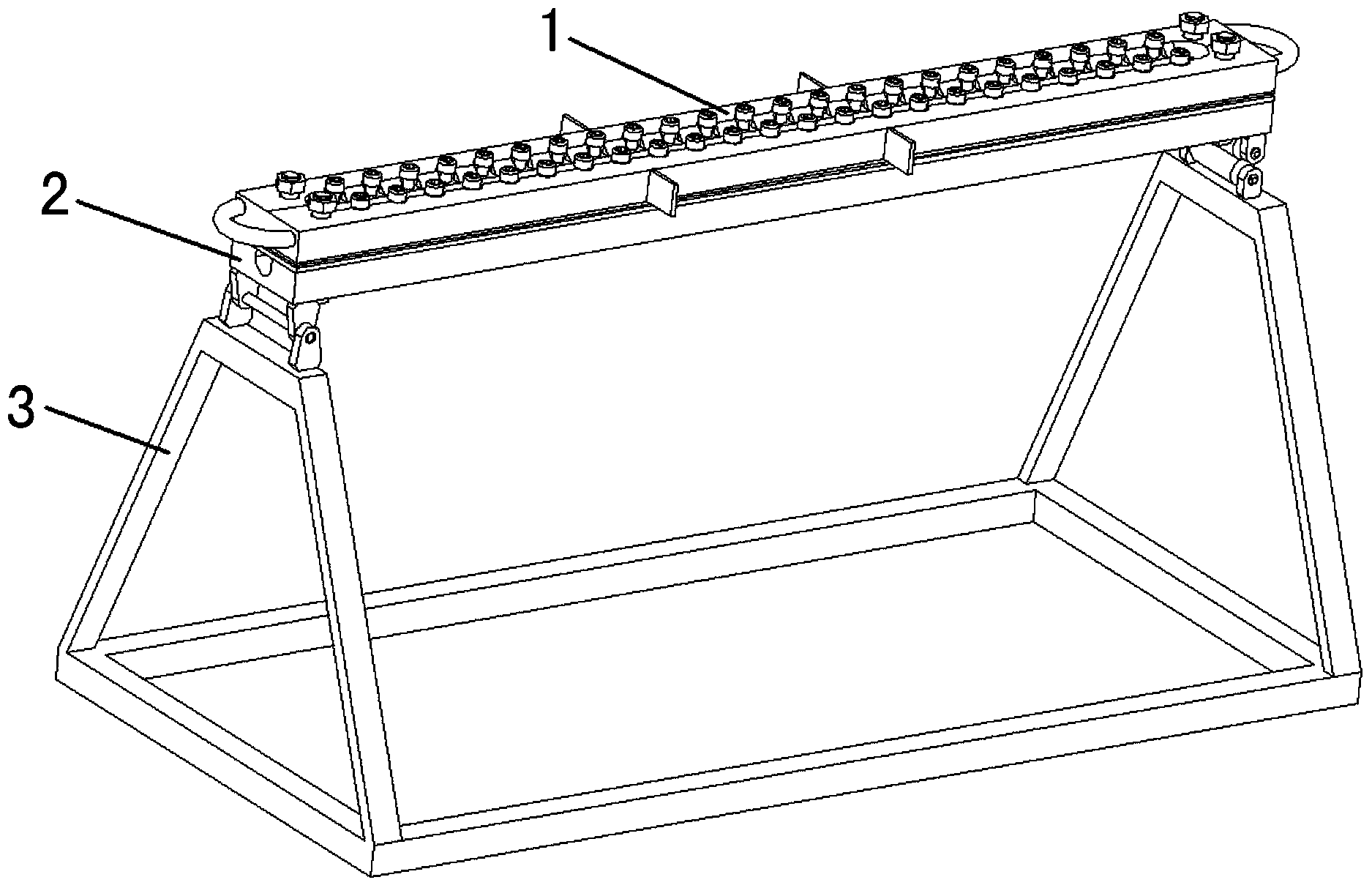

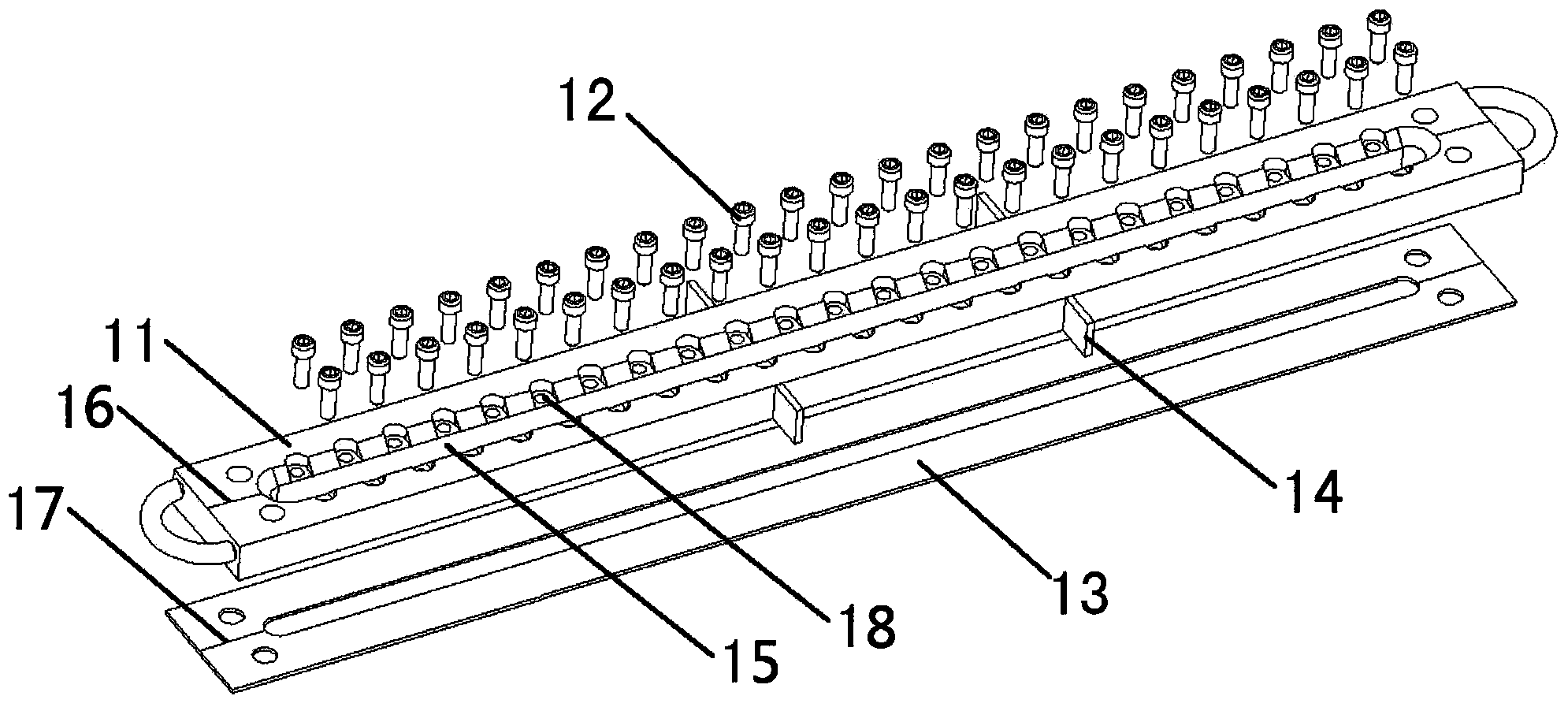

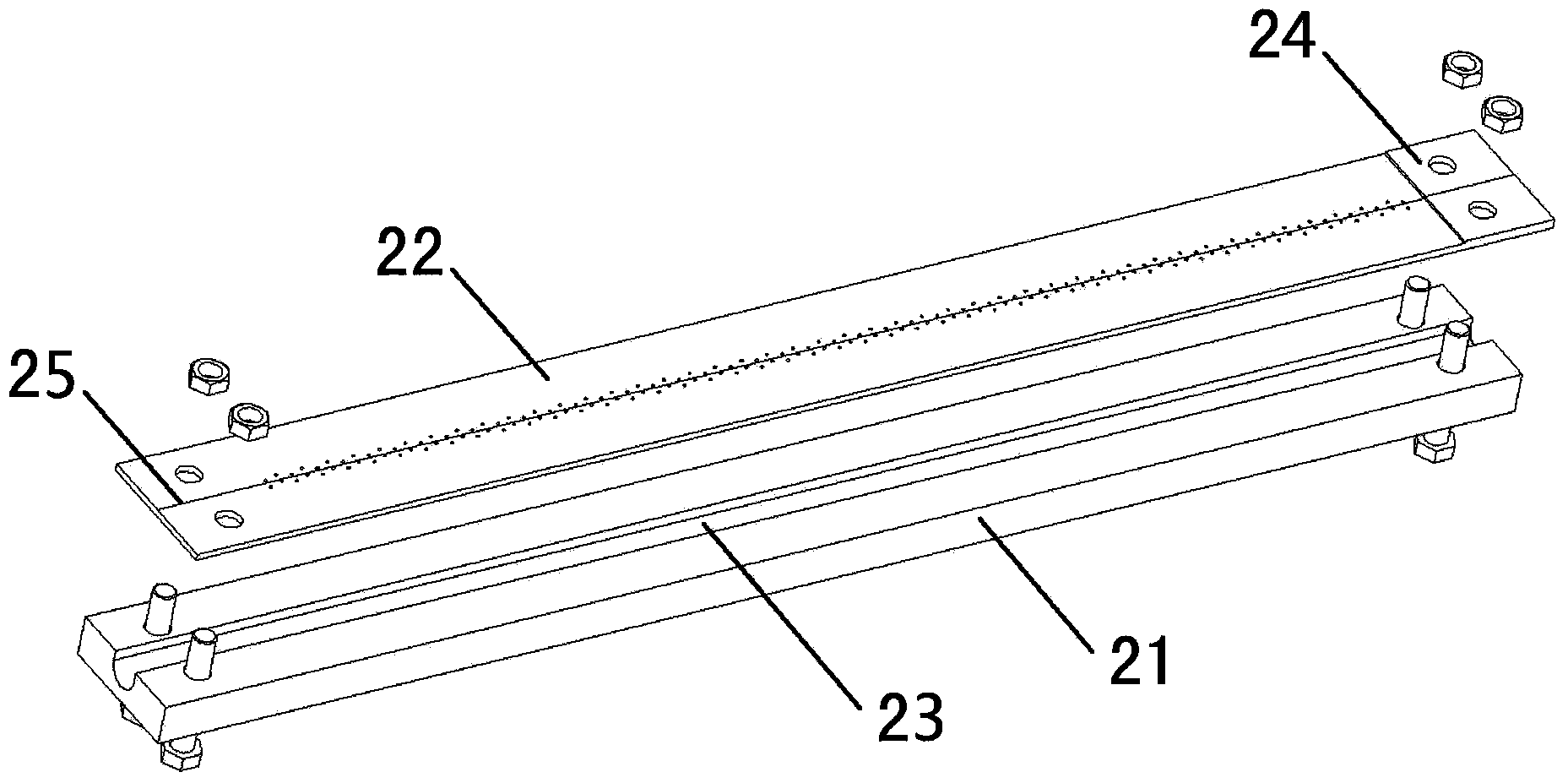

Universal welding tool for sleeper beam of subway rail vehicle and welding method thereof

PendingCN109676299ASave tuning timeImplement anti-morphingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention provides a universal welding tool for a sleeper beam of a subway rail vehicle, comprising a frame, a sleeper beam pressing device, a longitudinal limiting device, a transverse limiting device and a reference adjusting device; the sleeper beam pressing device is arranged on the frame to press the sleeper beam, the longitudinal limiting device is arranged on the frame to limit the sleeper beam in a longitudinal direction, the transverse limiting device is arranged on the frame to limit the sleeper beam in a transverse direction, the reference adjusting device is positioned on the inner side surface of the frame, and the reference adjusting device corresponds to the sleeper beam pressing device one by one to adjust the placing height of the sleeper beam. The invention relates toa welding method for a sleeper beam of a subway rail vehicle, which comprises the following steps of adjusting too before welding, welding and assembling the sleeper beam, and standing after weldingto eliminate stress. The welding tool provided by the invention has a simple structure, novel design, convenient operation and strong universality; double functions of workpiece positioning and welding deformation reduction are simultaneously realized by matching the welding method, and the production efficiency is greatly improved.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

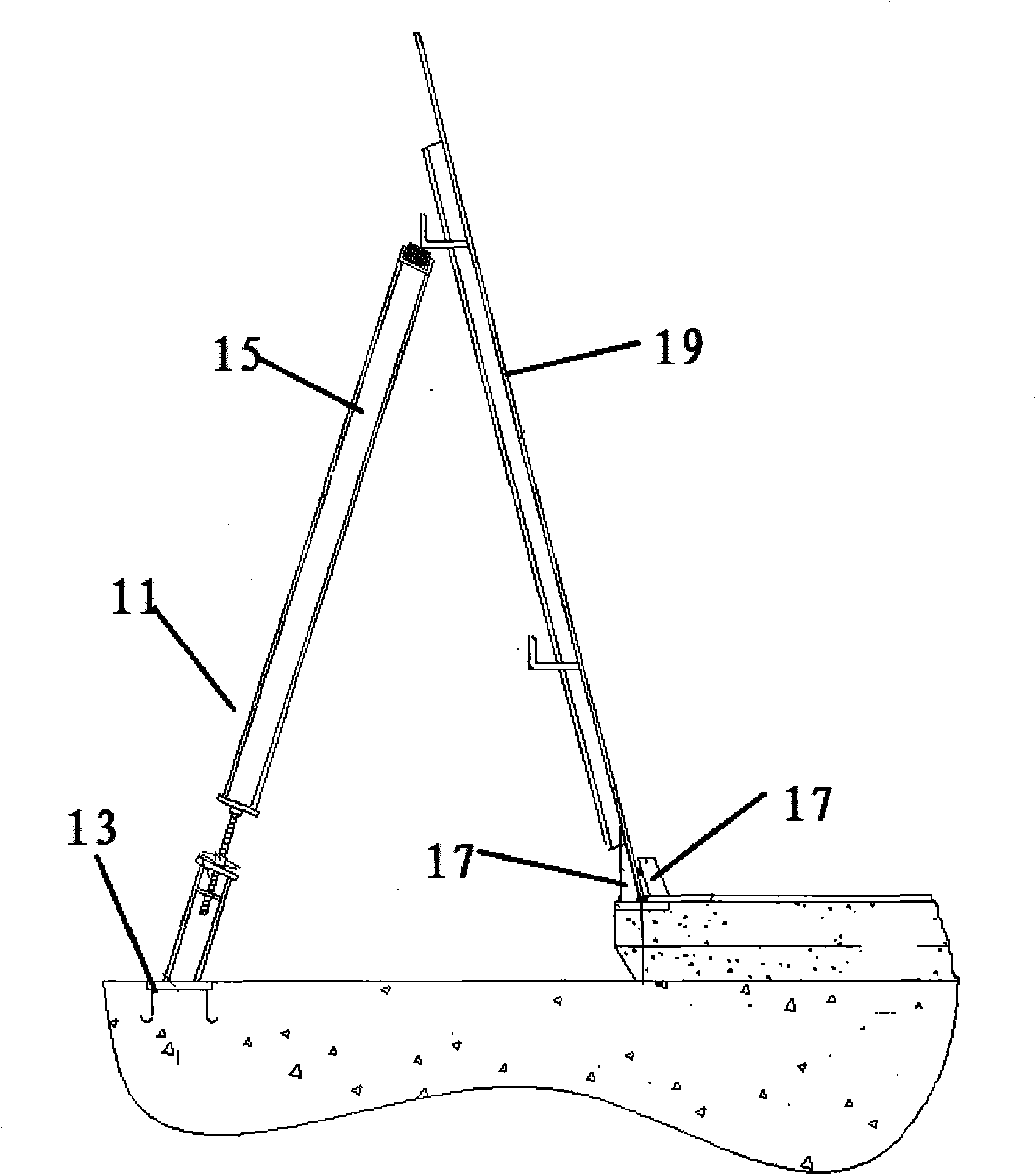

Processing method of eccentric full-revolving steering oar device base

InactiveCN103818540AIncrease profitReduce consumptionSteering by propulsive elementsEngineeringMachining time

The invention relates to a processing method of an eccentric full-revolving steering oar device base. The eccentric full-revolving steering oar device base comprises a round base panel, wherein the base panel is provided with an eccentric round hole and is in an annular shape, the bottom surface of the base panel is provided with an inner tube body and an outer tube body, the axial line of the inner tube body is coincident with the axial line of the eccentric round hole, the axial line of the outer tube body is coincident with the axial line of the peripheral wall of the base panel, and a knee plate is arranged between the inner tube body and the outer tube body. The processing method is characterized by comprising the following steps of 1, a processing step of the base panel, the inner tube body and the outer tube body; 2, a combination positioning step; 3, a whole welding step; and 4, a machining and hole drilling step. Compared with the prior art, the processing method has the following advantages that 1, the utilization rate of materials is improved, and the consumption of welding materials is reduced; 2, the welding deformation is perfectly controlled, and the precision requirement of equipment is met; 3, the node production requirement is met through reducing the manufacturing and processing time; 4, the transportation cost is reduced; 5, the integral manufacturing cost is reduced.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com