Method for controlling welding deformation of joint between inserted large inclined tube and barrel

A control method and welding deformation technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of uncertain effect, large weld volume, long welding cycle, etc., with simple method and high product qualification rate , The effect of welding quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

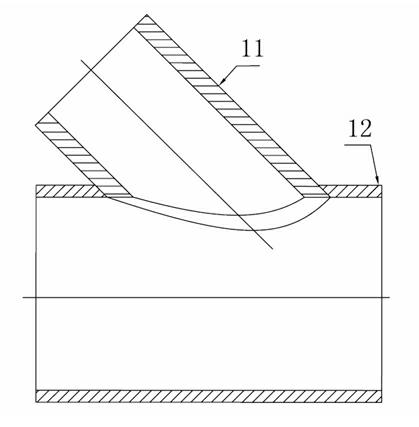

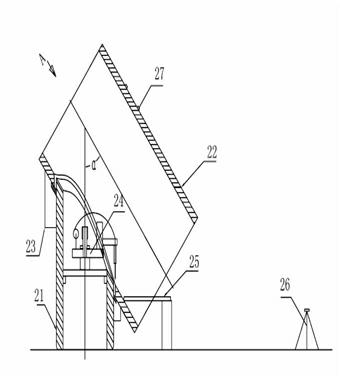

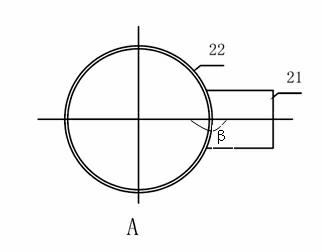

[0022] IGCC gas return chamber plug-in connector 21 size: inner diameter 1620mm, wall thickness 280mm; cylinder body 22 size: inner diameter 4400mm, wall thickness 230mm.

[0023] The method described in the patent CN200610024861.9 is used to weld the joint between the plug-in large inclined pipe 21 and the cylinder 22. During the welding process, the deformation of the joint is controlled. The main steps are:

[0024] Step 1: Drill holes on the side of the cylinder body 22 by means of gas cutting.

[0025] Step 2: If figure 2 As shown, the plug-in large inclined pipe 21 and the cylinder body 22 are assembled, and the deformation-resistant rigid fixed ribs 23 are evenly arranged on the outer circumference of the joint and welded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com