Technique for processing circular ring box type beam of lifting tool

A hoisting tool and processing technology technology, which is applied in the manufacturing technology field of wind turbine hoisting tools, can solve the problems of cost increase, construction period delay, low efficiency, etc., and achieve reduction of machining cost, simple and effective control, and reduction of welding workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

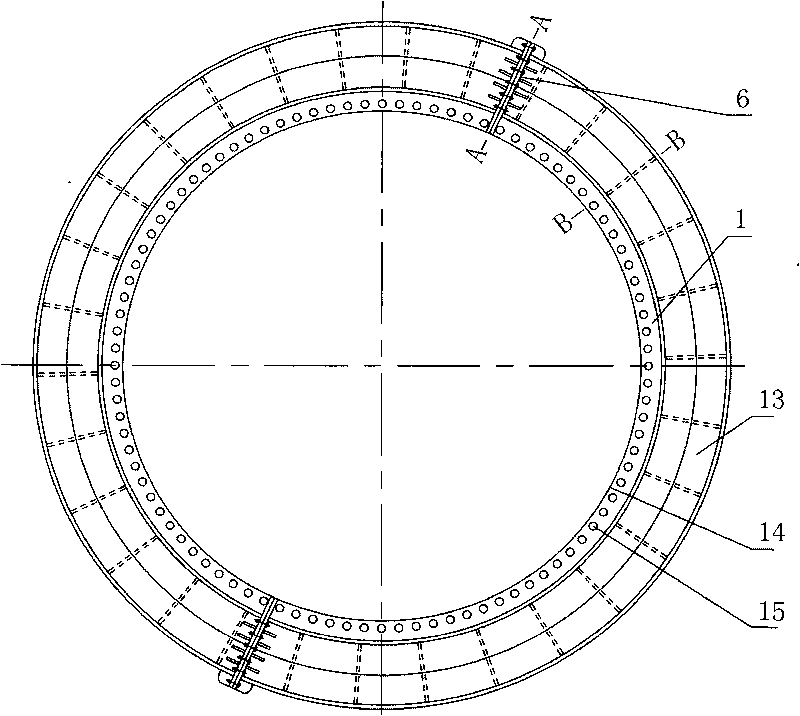

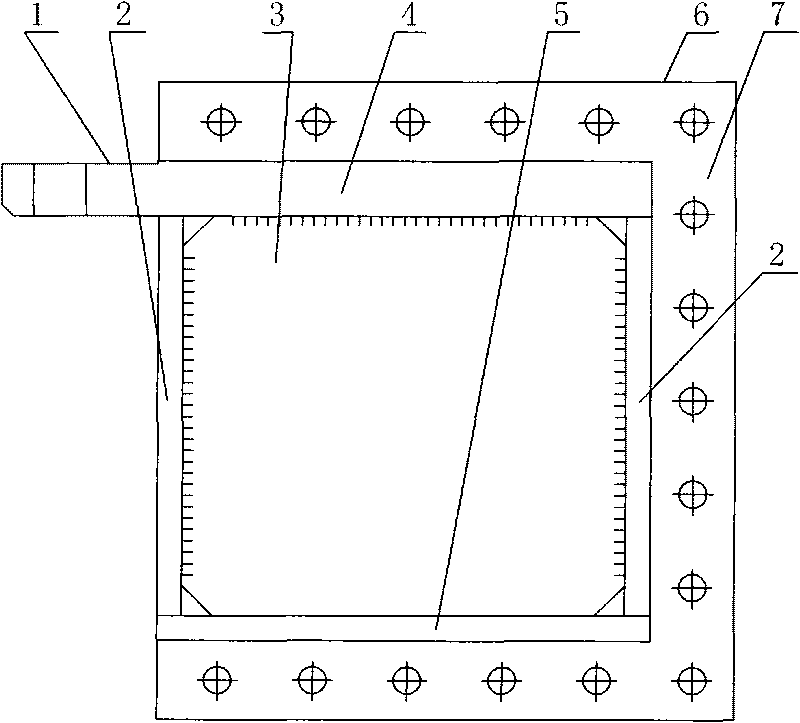

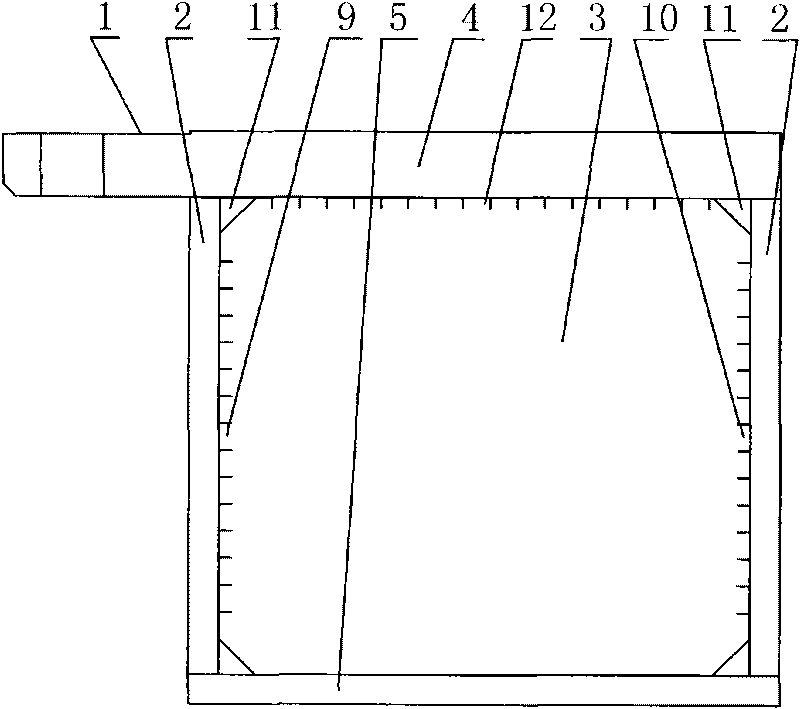

[0022] Embodiment 1: refer to Figure 1~3 . The ring box girder processing technology for hoisting tools, the ring box girder is divided into two semi-ring box girders 13, and the semi-ring box girder 13 includes two webs 2, an inner partition 3, an upper The wing plate 4, the lower wing plate 5 and the joint plate 6 are formed, and the making of the semicircular box girder 13 comprises the following steps:

[0023] a. First, the two webs 2, the inner partition 3, the upper wing 4 and the lower wing 5 are blanked respectively, and the abdominal pole 2 is blanked in straight strips, and then arc-shaped processing is performed according to the radian requirements;

[0024] b. Build an assembled tire mold on the steel platform, assemble the upper wing plate 4, two webs 2 and inner partitions 3 on the assembled tire mold, and the inner partitions 3 are evenly distributed on the upper wing 4 and two webs 2 In the rectangular groove formed, and the inner partition 3 is perpendicul...

Embodiment 2

[0029] Embodiment 2: refer to Figure 1~3 . After the two semicircular box girders 13 are assembled and welded, the following processing steps are also included:

[0030] a. On the milling and boring machine, the joint plates 4 at the two ends of the two semi-circular box beams 13 are milled out at one time and 7;

[0031] b. Connect the joint plates 6 by bolts, thereby connecting two semicircular box girders 13 to form a circular box girder;

[0032] c, the inner circle 14 of the upper wing plate 4 of the car ring box beam 13, and then the upper side flange plane 1 of the upper wing plate 4 protruding inwardly;

[0033] d. Use the numerical control system of the lathe to draw the center line of the hole position required by the design on the flange plane 1, and point out the equal points according to the center line of the hole position;

[0034] e. Drill holes at the equal points with an ordinary drill press.

Embodiment 3

[0035] Embodiment 3: refer to Figure 1~3 . The specific production of the ring box girder of the hoisting tool also includes: the blanking of the two webs 2, a 35-degree bevel needs to be made, and the bevel should be as uniform as possible, and the single side should be 2mm smaller to ensure that the welding bevel is uniform during assembly. , The upper wing plate 4, the lower wing plate 5 and the web plate 2 have been derusted as a single piece, except that no anti-corrosion is carried out within the range of 50mm of the welding groove, and the others are painted with shop primer.

[0036] Build and assemble the tire mold on the steel platform, first assemble the upper flange 4, two webs 2 and the inner partition 3 on the tire mold, and weld the fillet weld between the inner partition 3 and the upper flange 4 in turn. Seam 11, then vertical welds 9 and 10, and finally flat weld 12, measure the welding deformation at any time during welding, adjust the welding sequence in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com