Processing method of eccentric full-revolving steering oar device base

A processing method and full-rotation technology, which is applied in the direction of steering and steering with propulsion components, can solve the problems of high production cost, difficult production accuracy, inconvenient transportation, etc., to meet the requirements of production nodes, reduce production and processing time, and meet the The effect of equipment accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

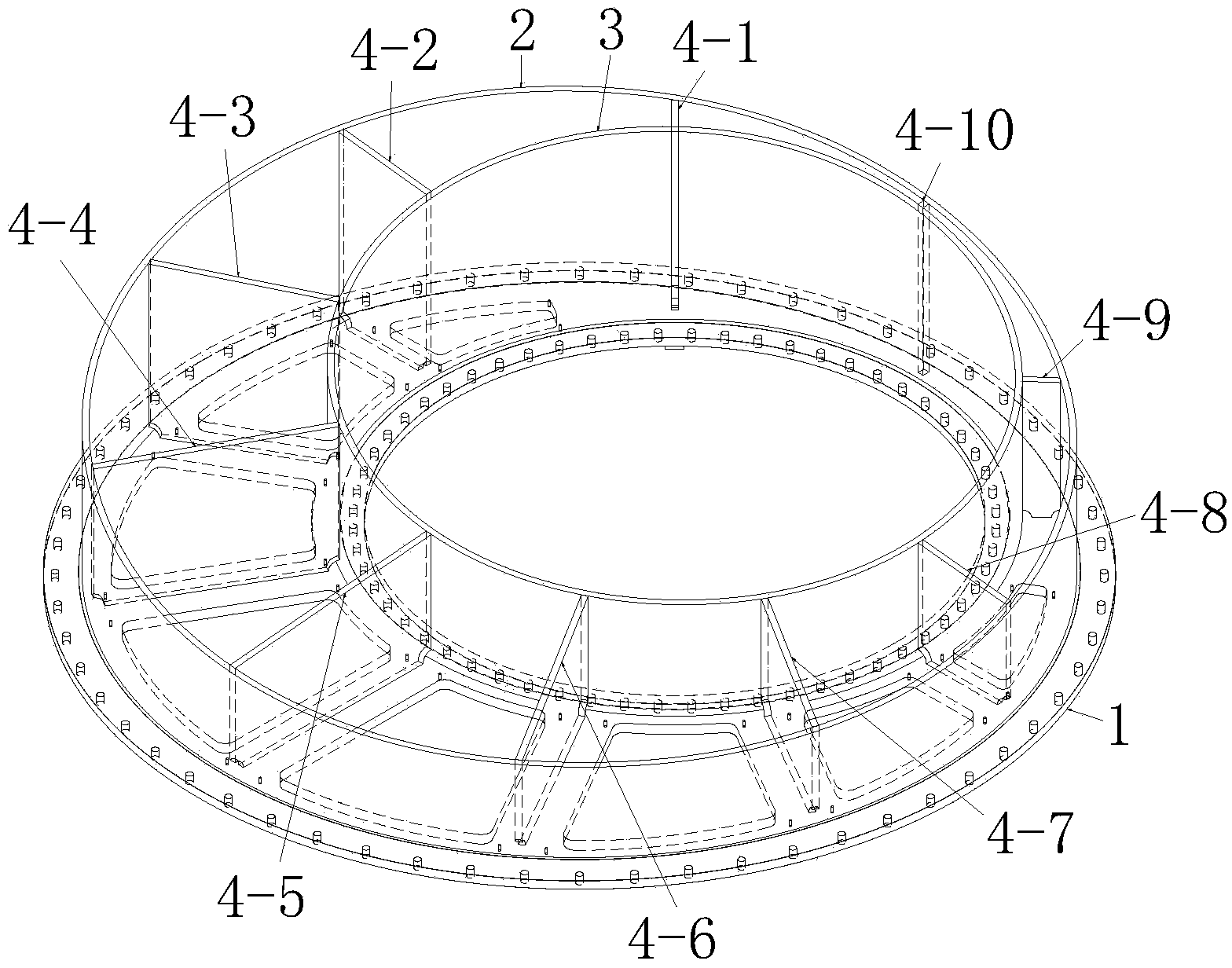

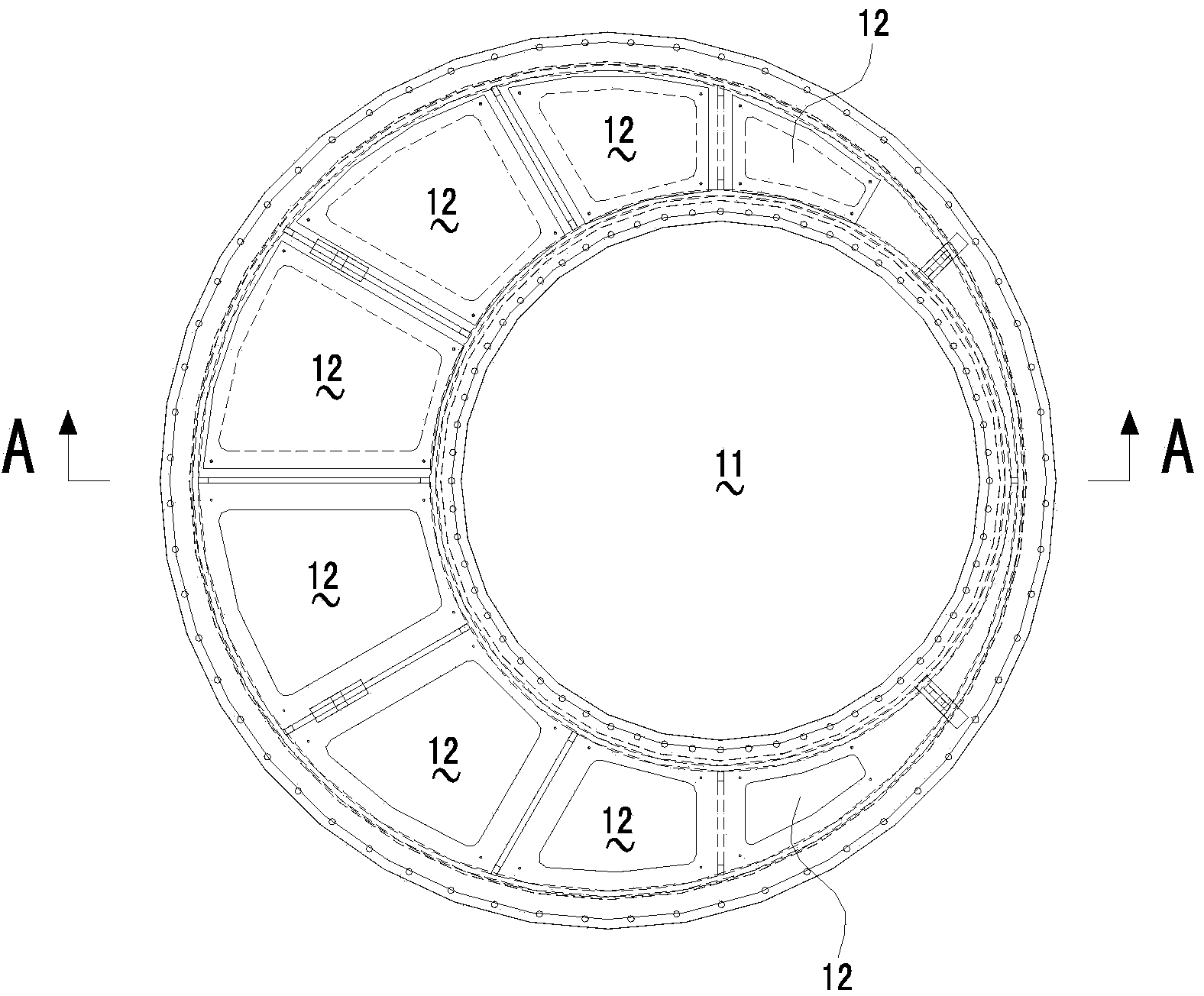

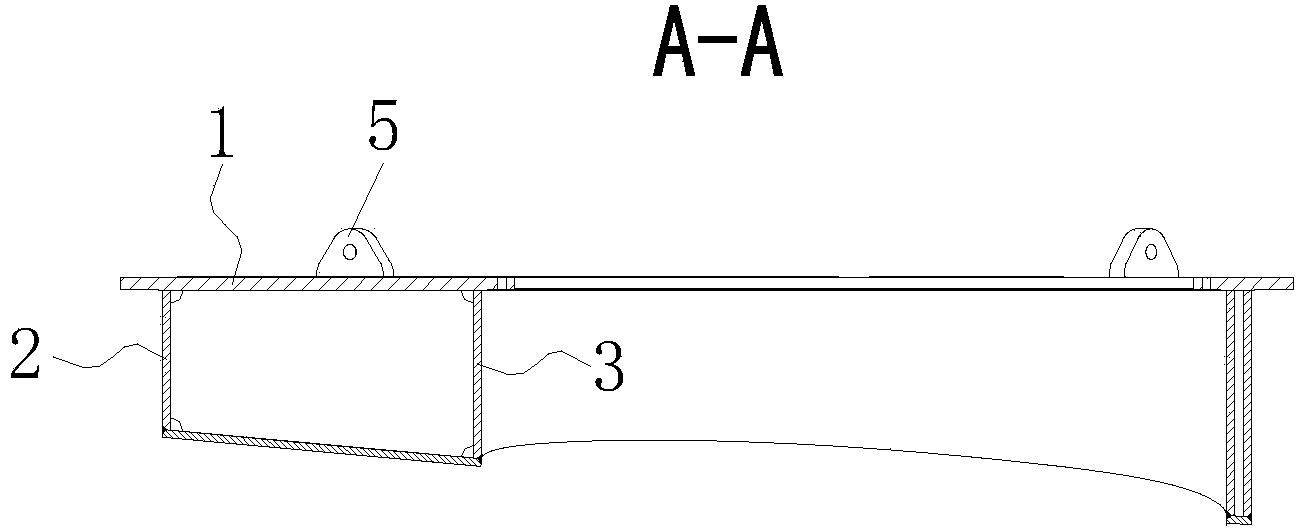

[0040] Such as Figure 1 to Figure 15 As shown, a method for processing the base of an eccentric full-turn rudder device according to the present invention, the base of the eccentric full-turn rudder device includes a circular base panel 1, and the base panel 1 is provided with an eccentric circular hole in the form of a ring shape, the bottom surface of the base panel 1 is provided with an inner cylinder 3 and an outer cylinder 2, the axis of the inner cylinder 3 coincides with the axis of the eccentric circular hole, the axis of the outer cylinder 2 coincides with the axis of the peripheral wall of the base panel, and the inner and outer cylinders A bracket 4 is provided between the outer cylinders, specifically, 10 brackets are provided between the inner and outer cylinders, and the method includes the following steps:

[0041] 1. Processing steps of base panel, inner cylinder and outer cylinder:

[0042] Divide the entire base panel 1 into three sections for blanking, ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com