Universal welding tool for sleeper beam of subway rail vehicle and welding method thereof

A rail vehicle and welding tooling technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as poor versatility, shrinkage and deformation quality of corbel welding, unqualified, etc., achieve structural stability, and save tooling adjustment time , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

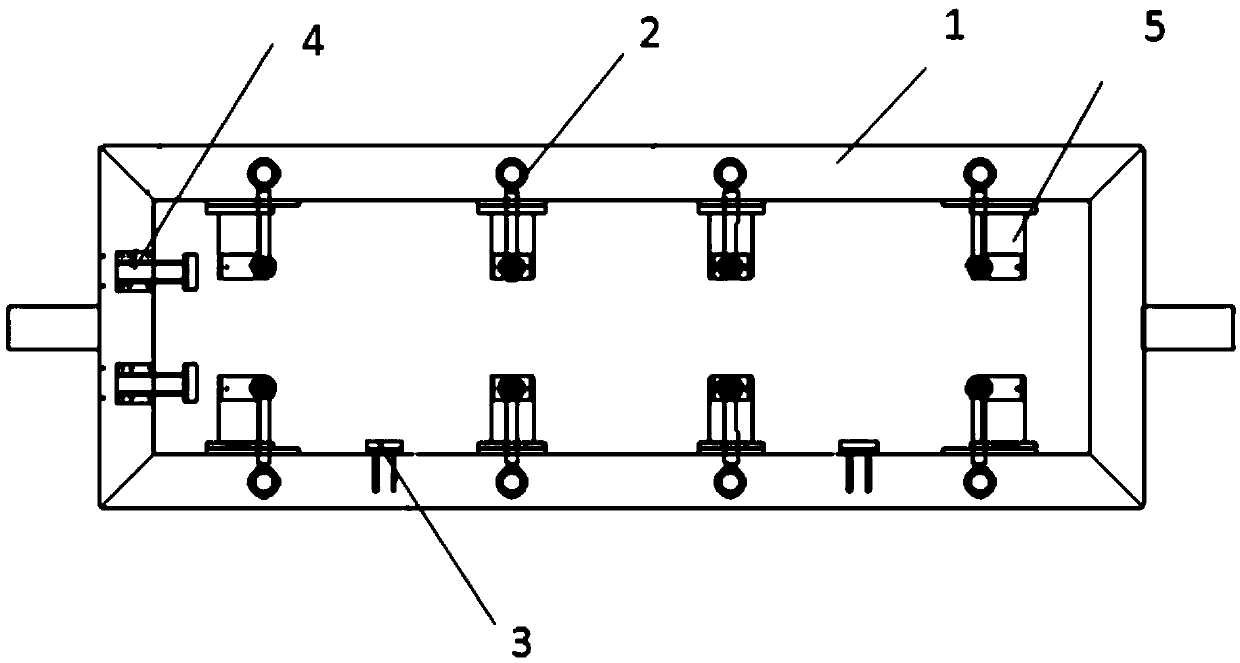

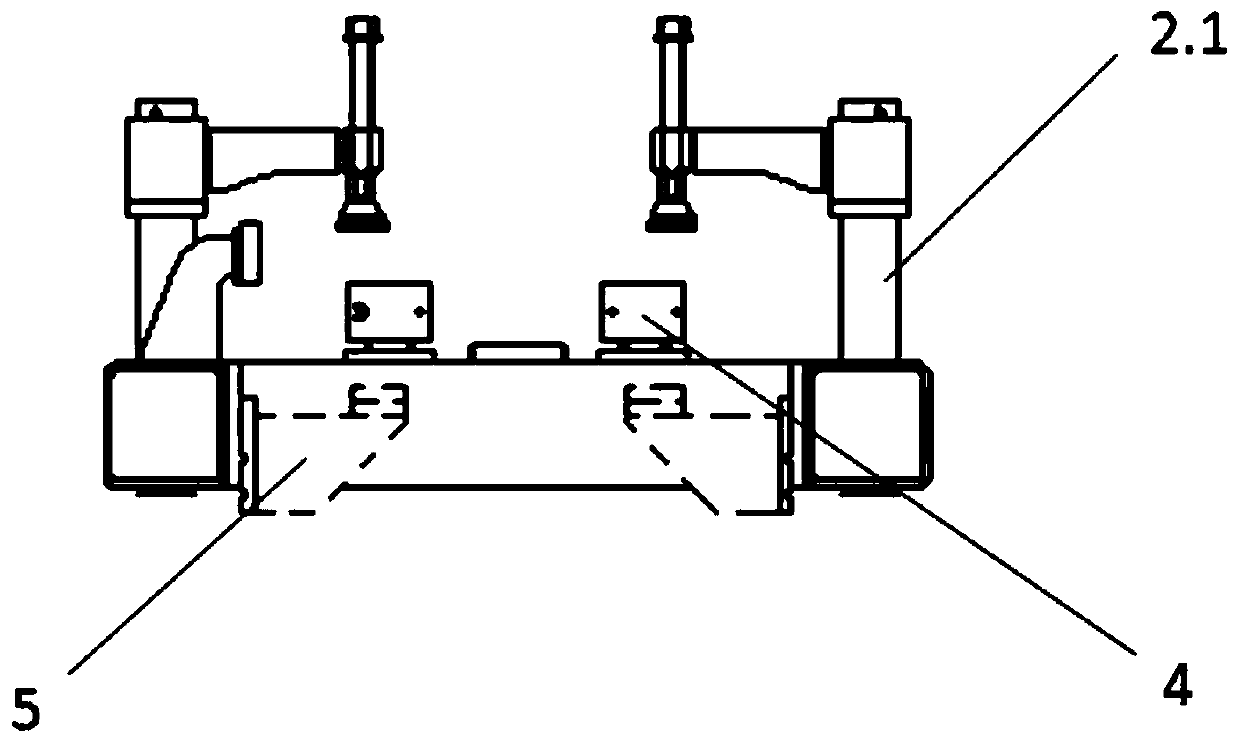

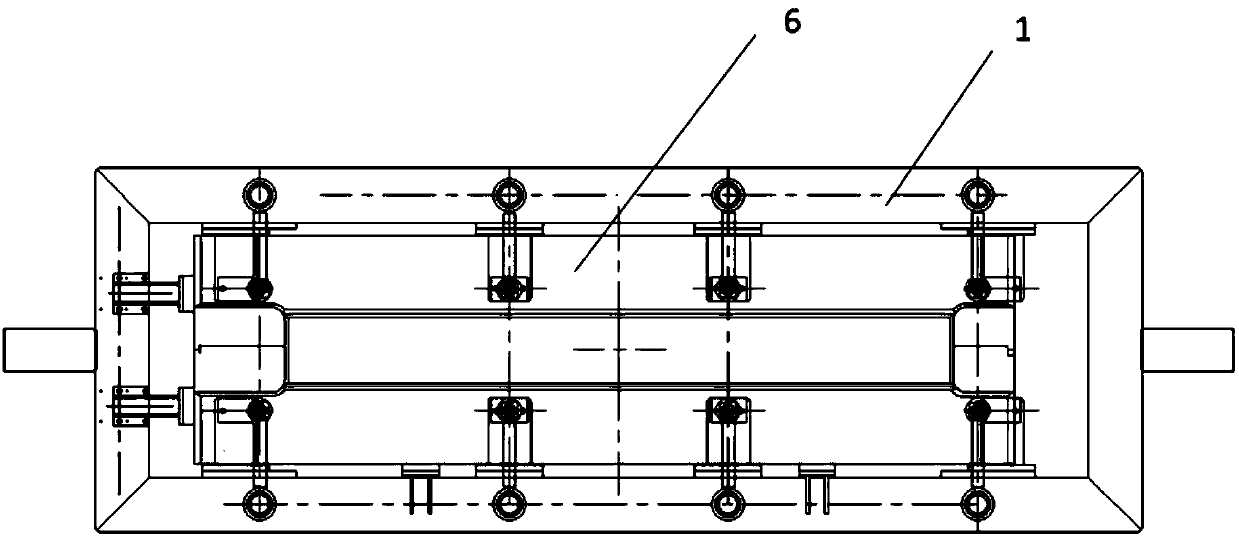

[0039] see Figure 1 to Figure 9 A general welding tool for the corbel of a subway rail vehicle includes a frame 1, a corbel pressing device 2, a longitudinal limiting device 3, a transverse limiting device 4 and a reference adjustment device 5; the corbel pressing device 2 is arranged on the frame 1 on ( figure 1 Among them, four sets of bolster pressing devices 2) are respectively arranged on the two long sides of the frame. On one side in the width direction, the reference adjustment device 5 is located on the inner side of the frame, and the reference adjustment device 5 is provided in one-to-one correspondence with the beam pressing device 2 to adjust the placement height of the beam. Both the longitudinal limiting device 3 and the lateral limiting device 4 are provided with two groups.

[0040] Such as Figure 4 As shown, the frame 1 includes a crossbeam 1.1 and a longitudinal beam 1.2, and the crossbeam 1.1 and the longitudinal beam 1.2 are connected end to end to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com