Assembly welding process of muffle pipe double-layer flange

A technology of muffle tube and muffle tube is applied in manufacturing tools, welding equipment, arc welding equipment and other directions, which can solve the problems of reducing product quality, unattainable flatness, and large deviation of parallelism between two flanges. Achieve the effect of ensuring shape and position tolerance requirements, controlling welding deformation, and controlling assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

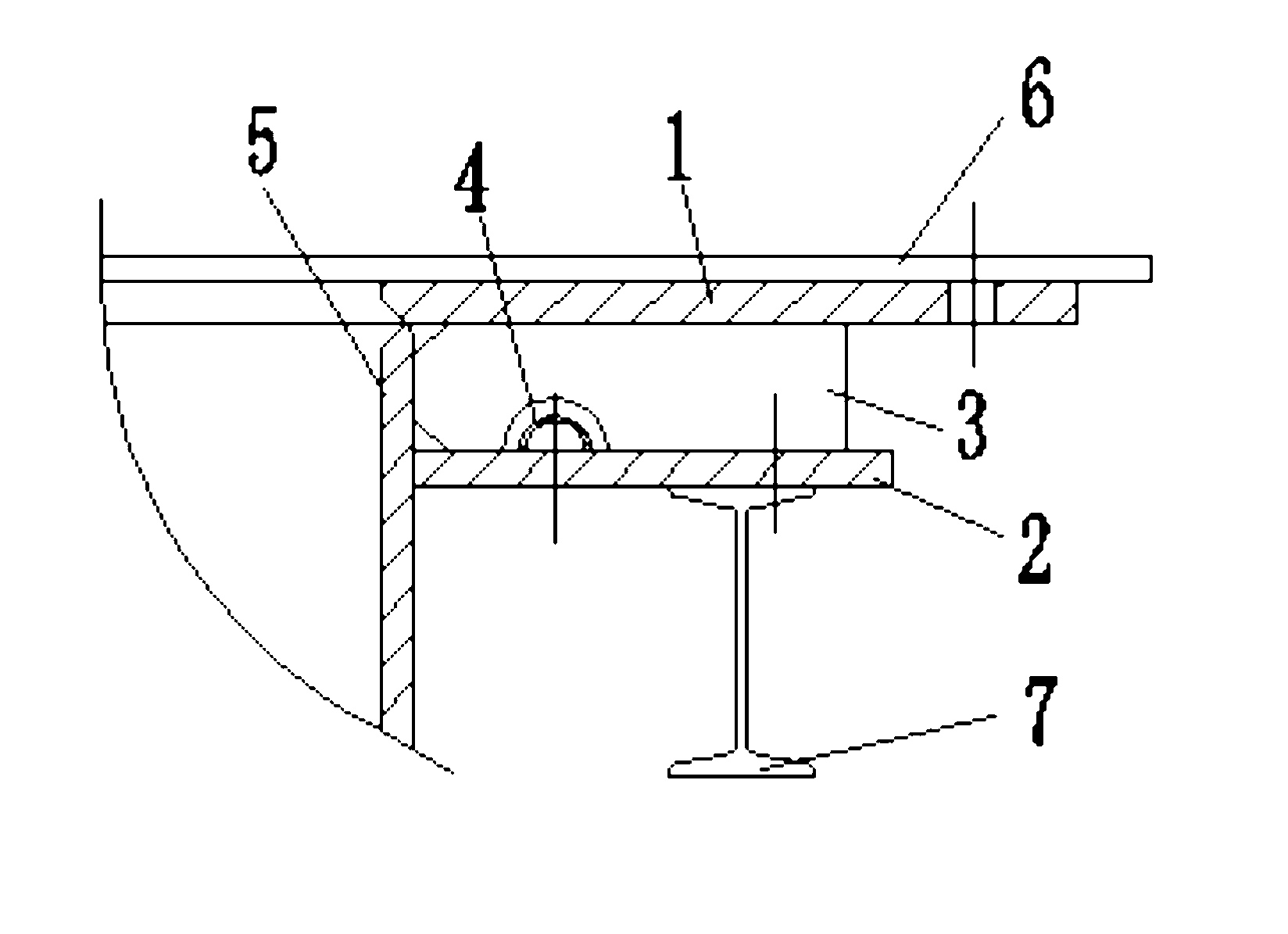

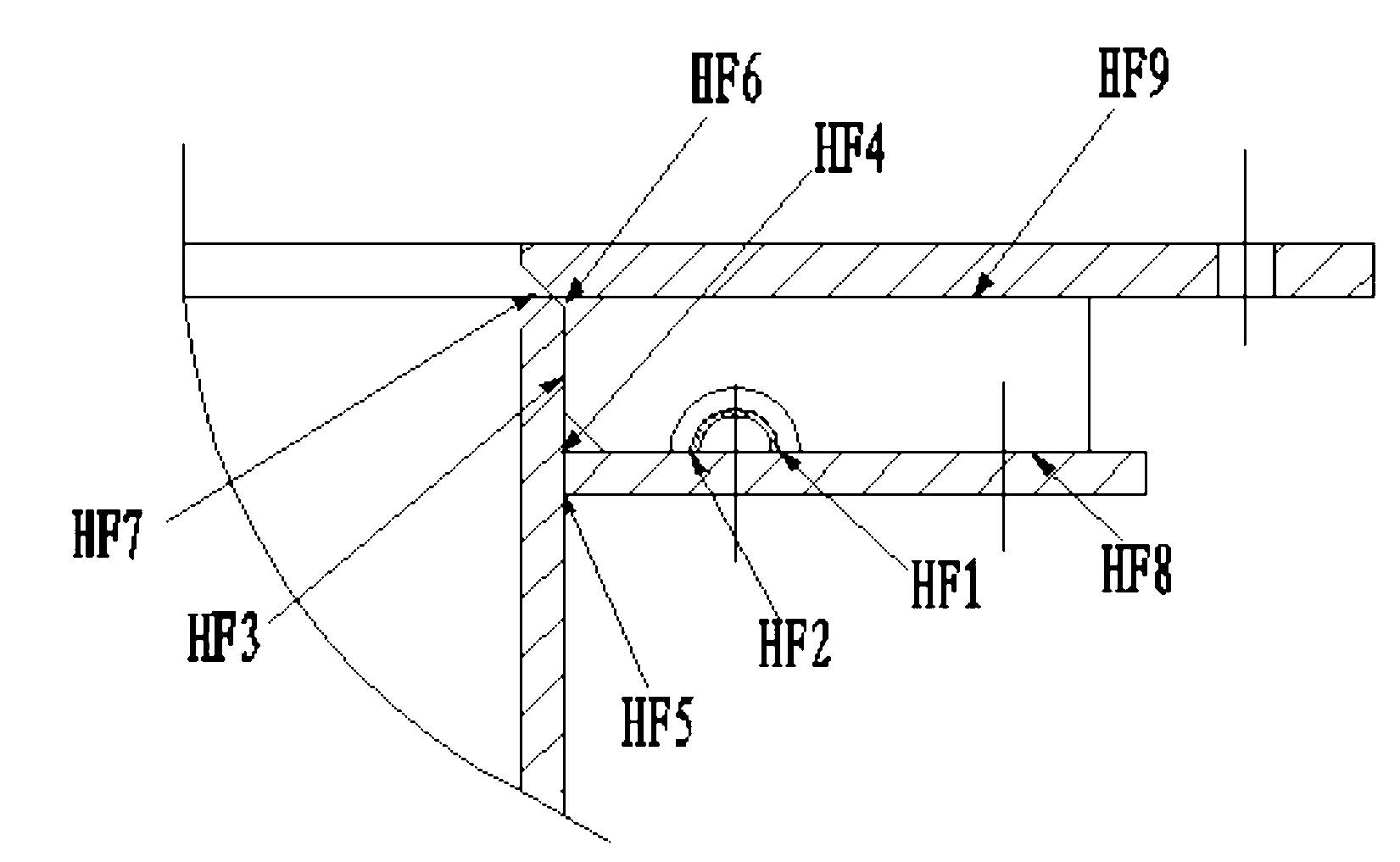

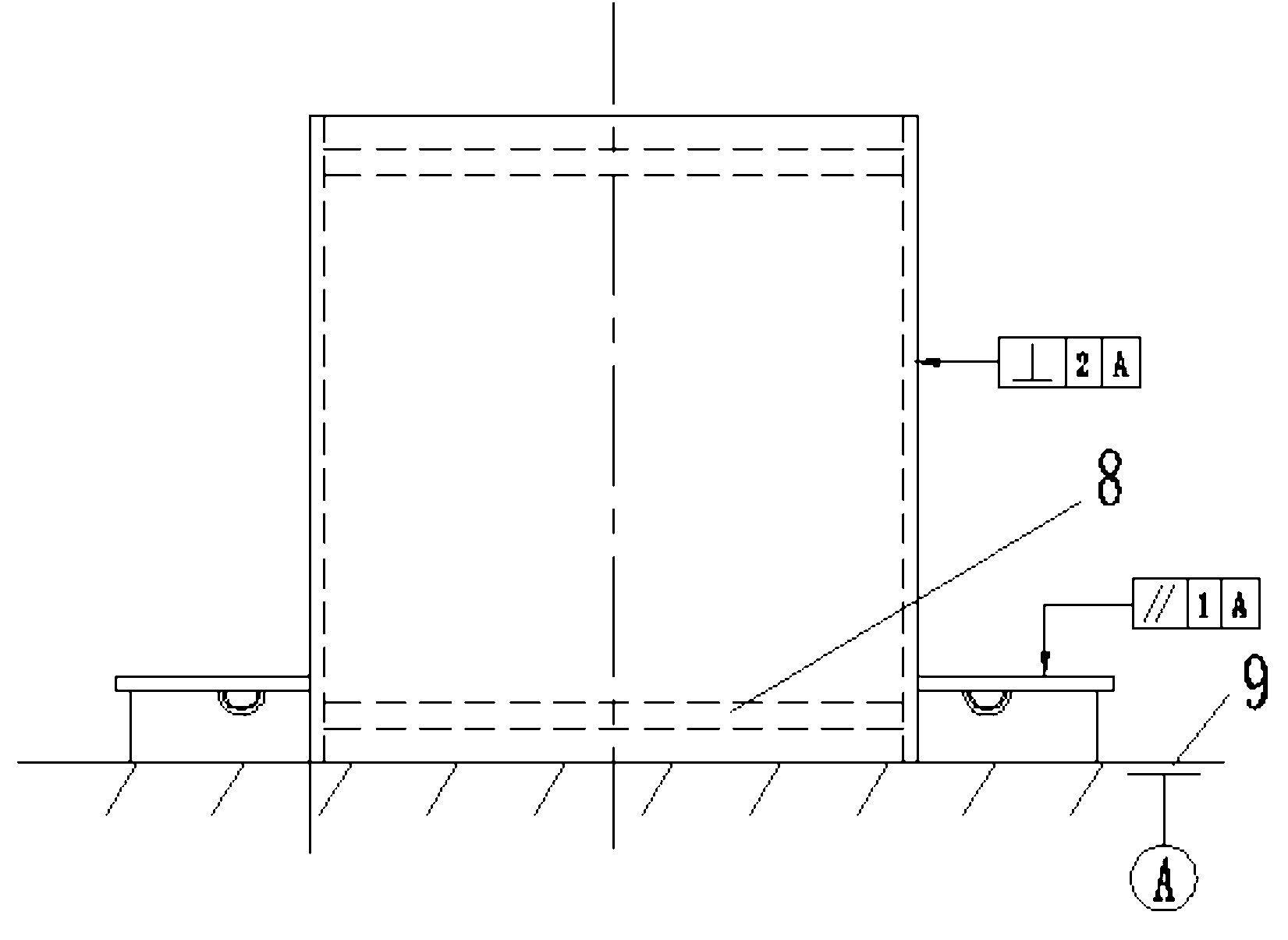

[0030] Such as Figures 1 to 5 As shown, the assembly and welding process of the double-layer flange of the muffle tube, the specific assembly and welding process is as follows:

[0031] A. Place the lower flange 2 after machining on the assembly platform 9. After drawing the center line of the flange, check the flatness of the lower flange 2 in 12 equal parts, mark the error of each equal part, and then according to the cooling half The assembly position of the pipe 4 and the rib plate 3 is set out and marked on the lower flange 2;

[0032] B. Predict the outer diameter of the assembly contact position between the muffle tube body 5 and each rib plate 3, compare the inner diameter of the flange 2, determine the radial installation position error of each rib plate 3, and then use the argon arc according to the marking position The cooling half-pipe 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com