Patents

Literature

30results about How to "Guaranteed geometric tolerance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

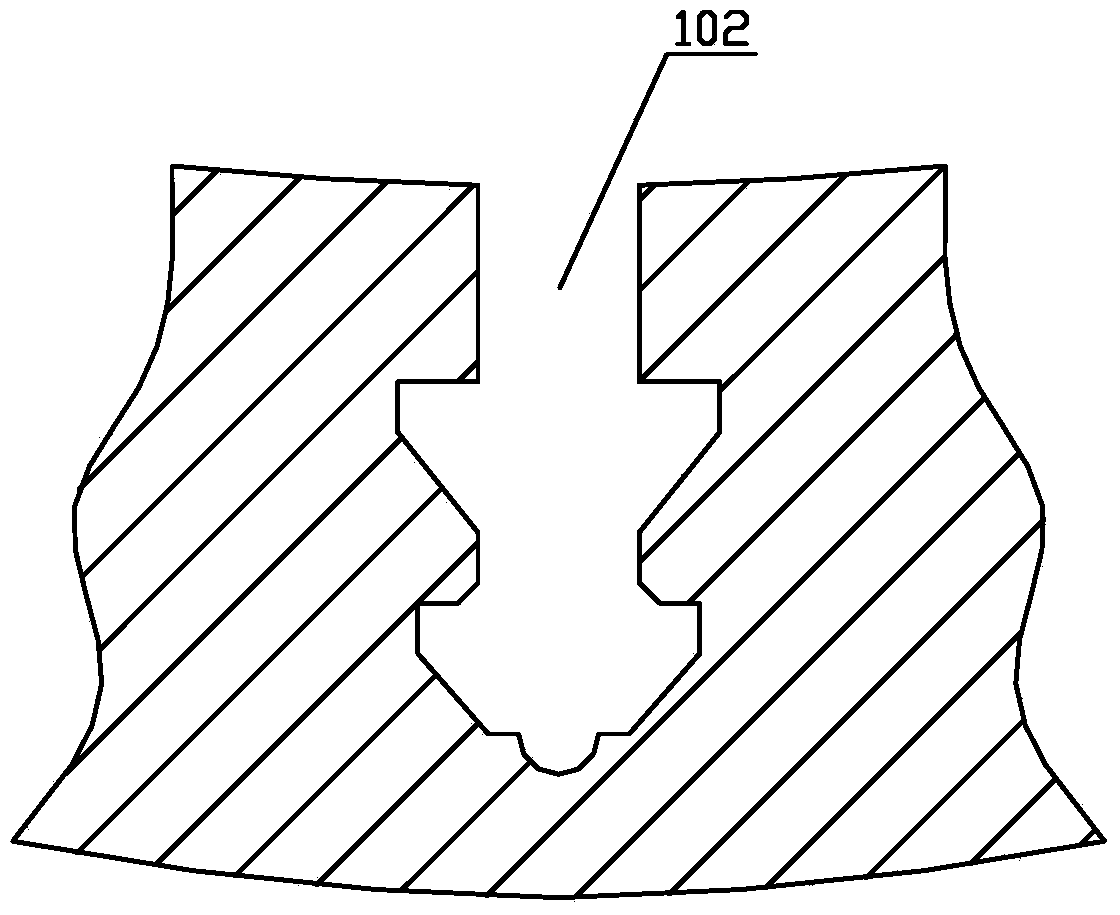

Method for machining gas compressor fixed blade ring of gas turbine

ActiveCN103801912AImprove machining accuracySmall thermal deformationNumerical controlGas compressor

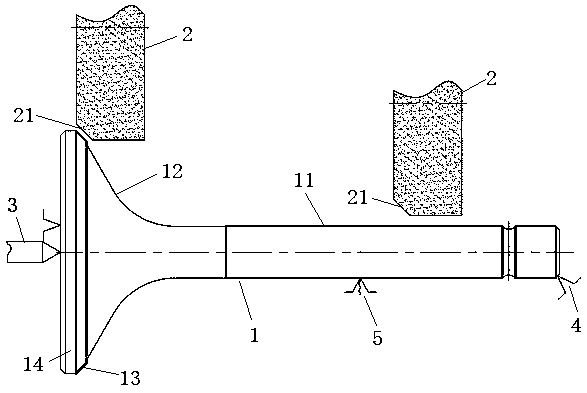

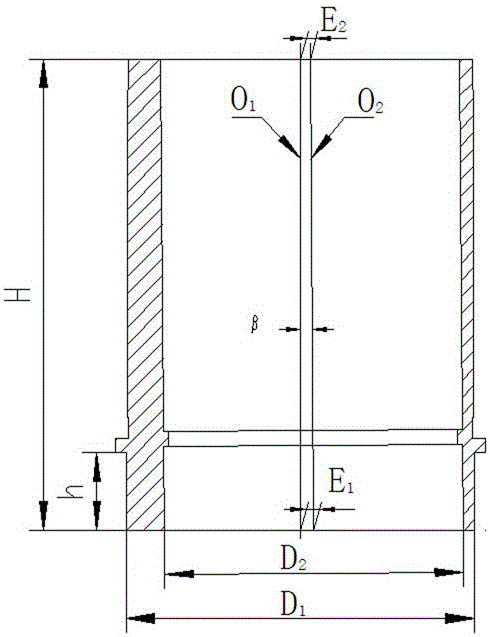

The invention provides a method for machining a gas compressor fixed blade ring of a gas turbine. The method comprises the steps that a fixed blade ring blank is placed on a permanent magnetic chuck workbench of a machine tool, and clamped by the permanent magnetic chuck workbench, and the outer circumferential surface, the annular inner conical surface and the upper end face of the fixed blade ring are turned at a time; the bottom plane is machined; the turned fixed blade ring blank is placed on a working platform of a five-axis numerical control wire cutting machine, the cutting inclination of the five-axis numerical control wire cutting machine ranges from 0 degree to 60 degrees, and is adjustable, and the axis of the fixed blade ring blank coincides with the axis of a rotary platform of the five-axis numerical control wire cutting machine; the cut portion of a wire electrode of the five-axis numerical control wire cutting machine is made to be opposite to a molded line inclined groove in the annular inner conical surface in position by adjusting the rotary platform on a machine tool body, the inclination angle of the cut portion of the wire electrode is equal to the inclination angle of the molded line inclined groove, and the molded line inclined groove is machined; the rotary platform on the machine tool body is adjusted repeatedly, and machining of all the molded line inclined grooves is accomplished. According to the method for machining the gas compressor fixed blade ring of the gas turbine, the machining cost is low, the machining speed is high, the degree of thermal deformation is low, machining stability is good, and machining precision is high.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

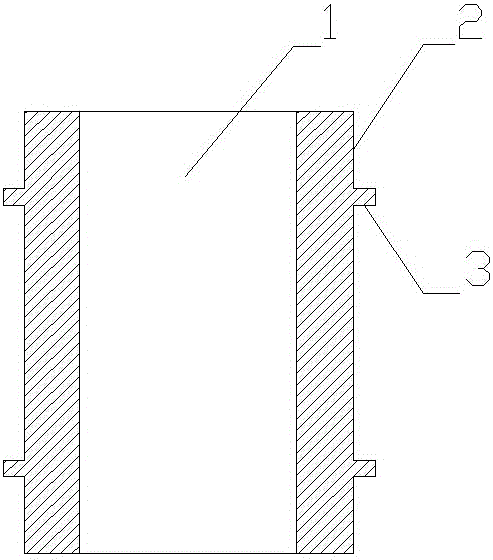

Assembly welding process of muffle pipe double-layer flange

ActiveCN103008844AHigh precision requirementsControl assembly errorArc welding apparatusWorkpiece edge portionsEngineeringWelding deformation

The invention discloses an assembly welding process of a muffle pipe double-layer flange. The strict assembly welding process of an upper flange, a lower flange, a rib plate, a cooling semi-pipe and a muffle pipe tube body is adopted, the welding deformation control key point is fully considered, the form and location tolerance requirements between the muffle pipe and the flanges as well as between the flanges are ensured, the assembly error and the welding deformation of the muffle pipe double-layer flange structure are effectively controlled, the design requirement is reached, and the precision requirement of the muffle pipe is perfectly improved.

Owner:WISDRI WUHAN WIS IND FURNACE

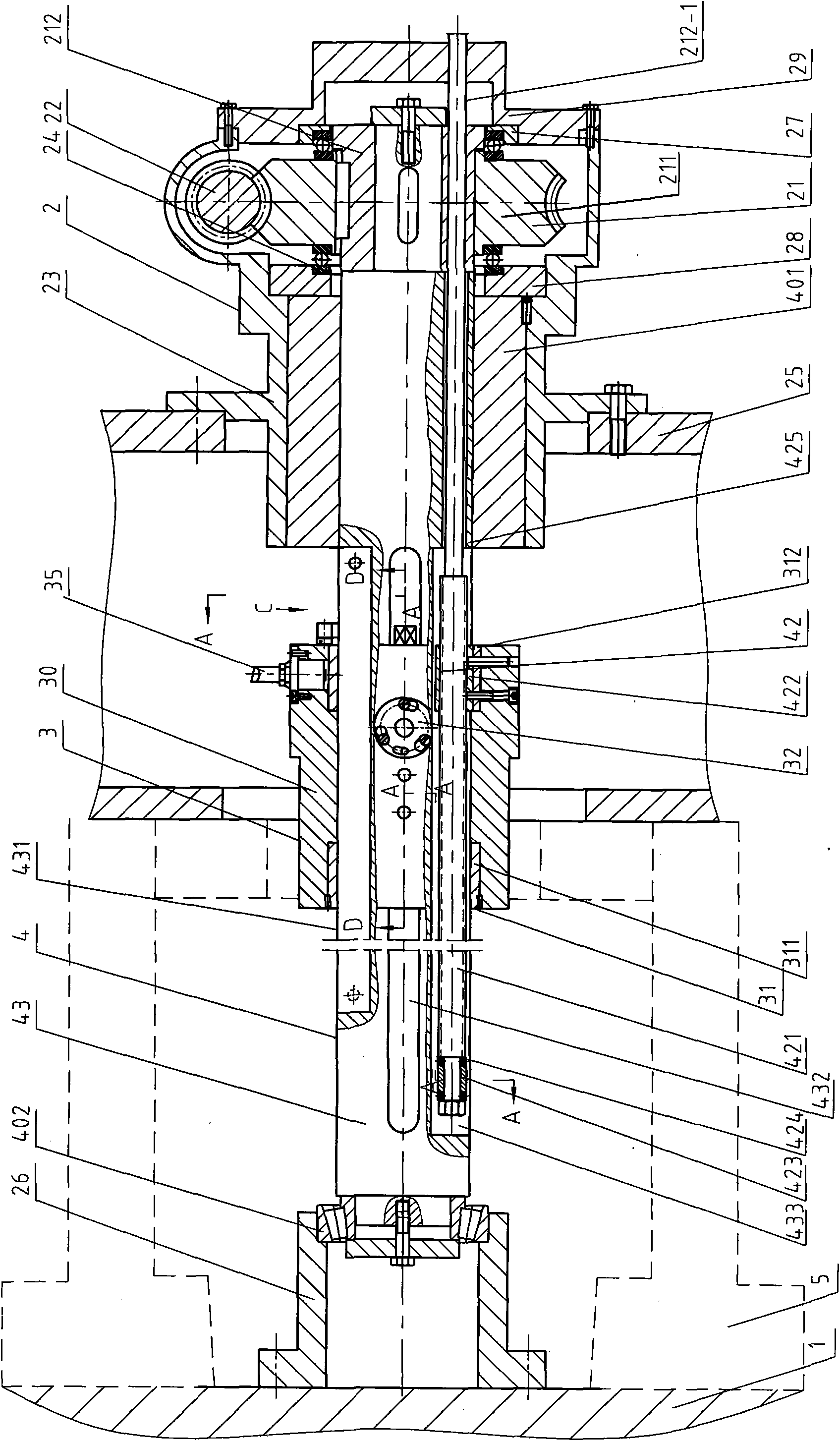

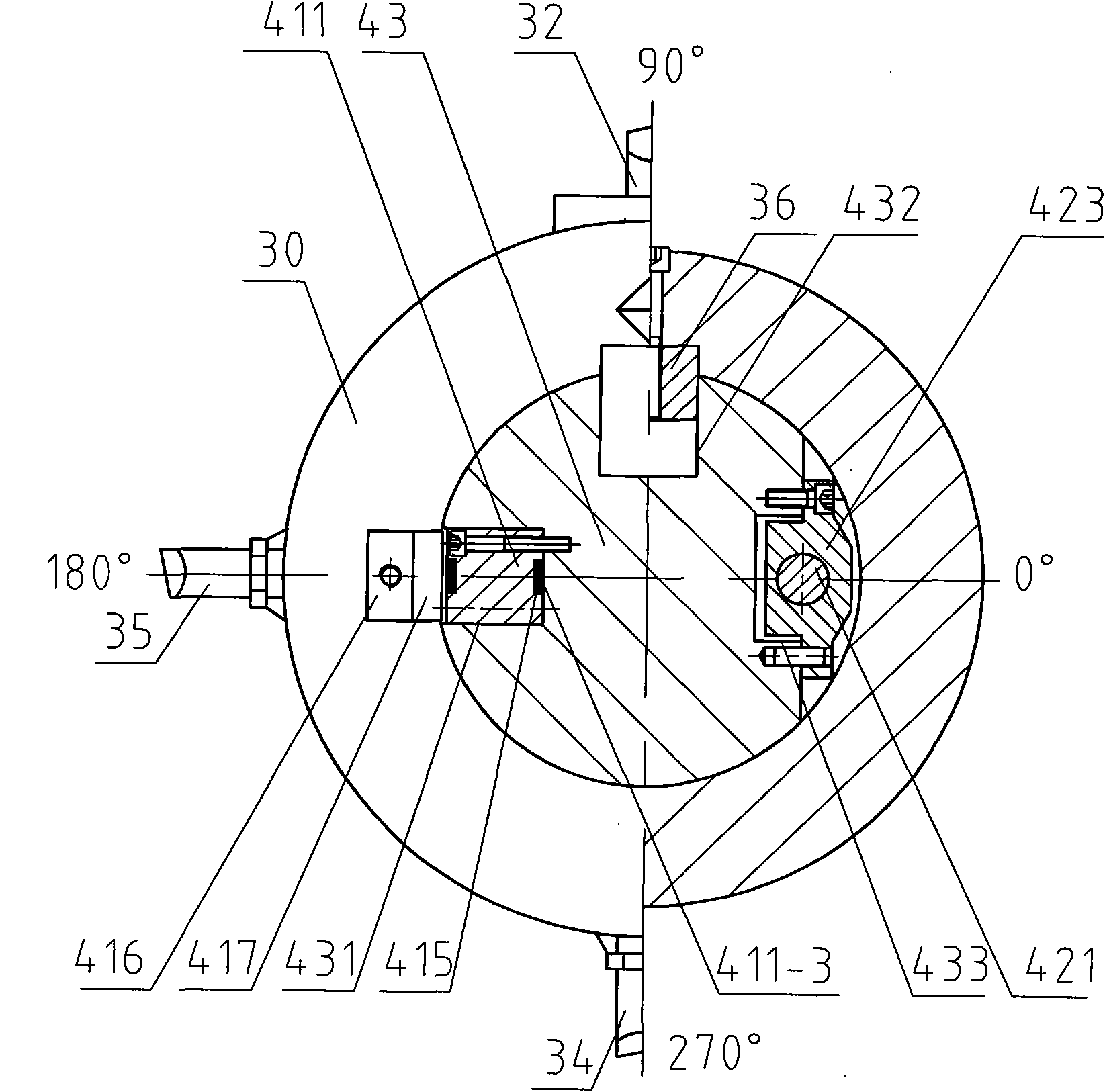

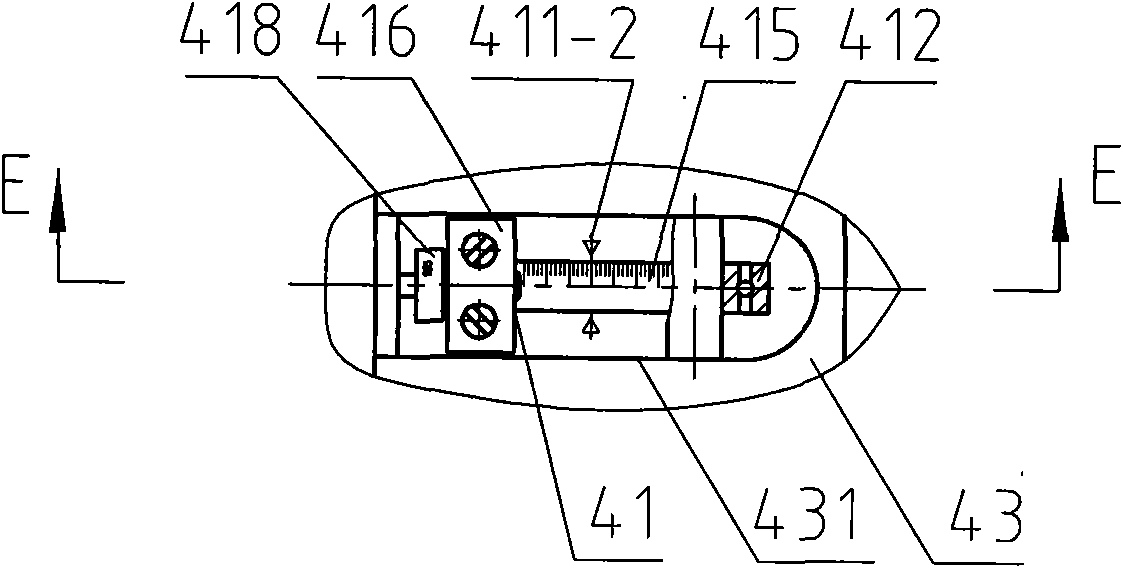

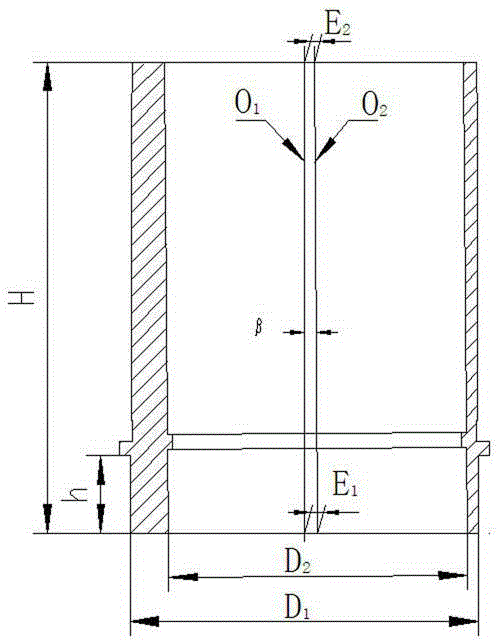

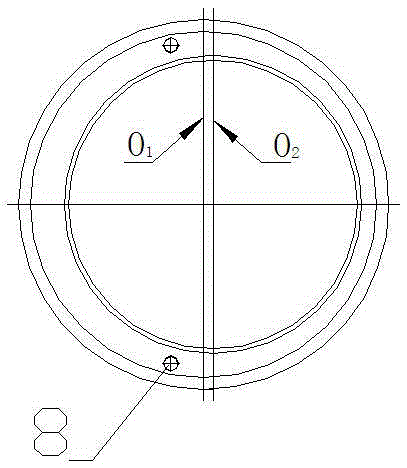

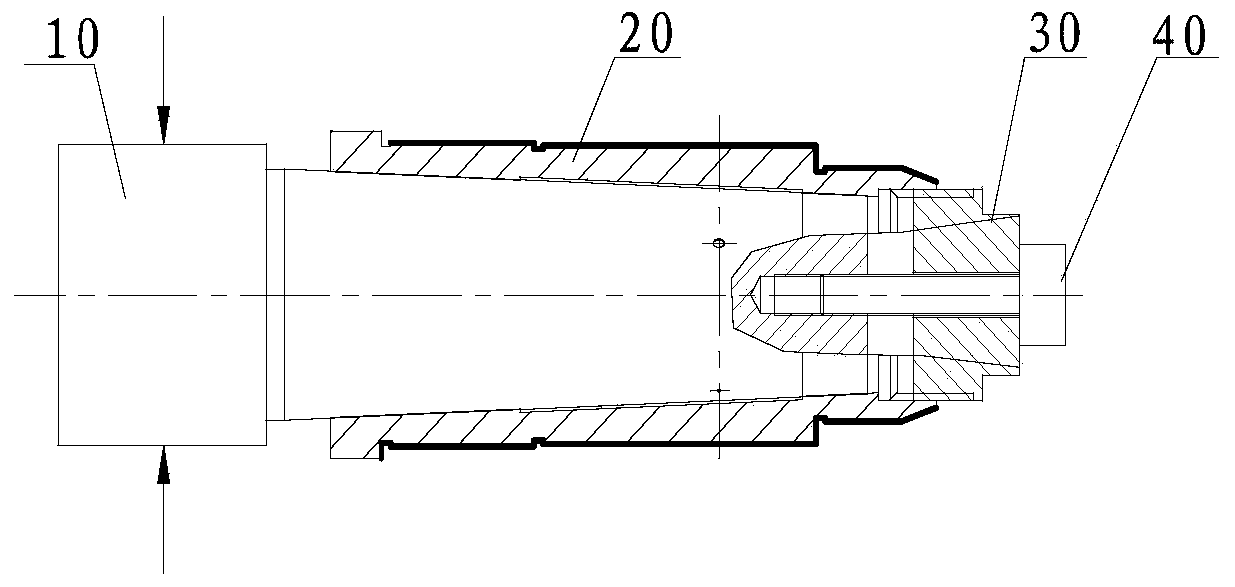

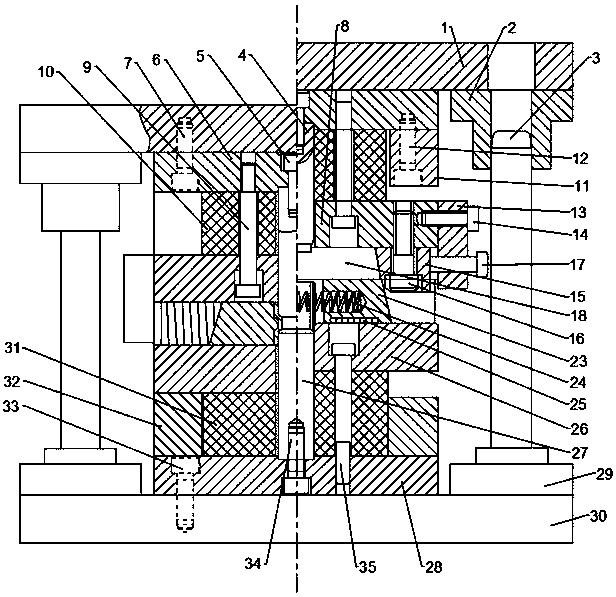

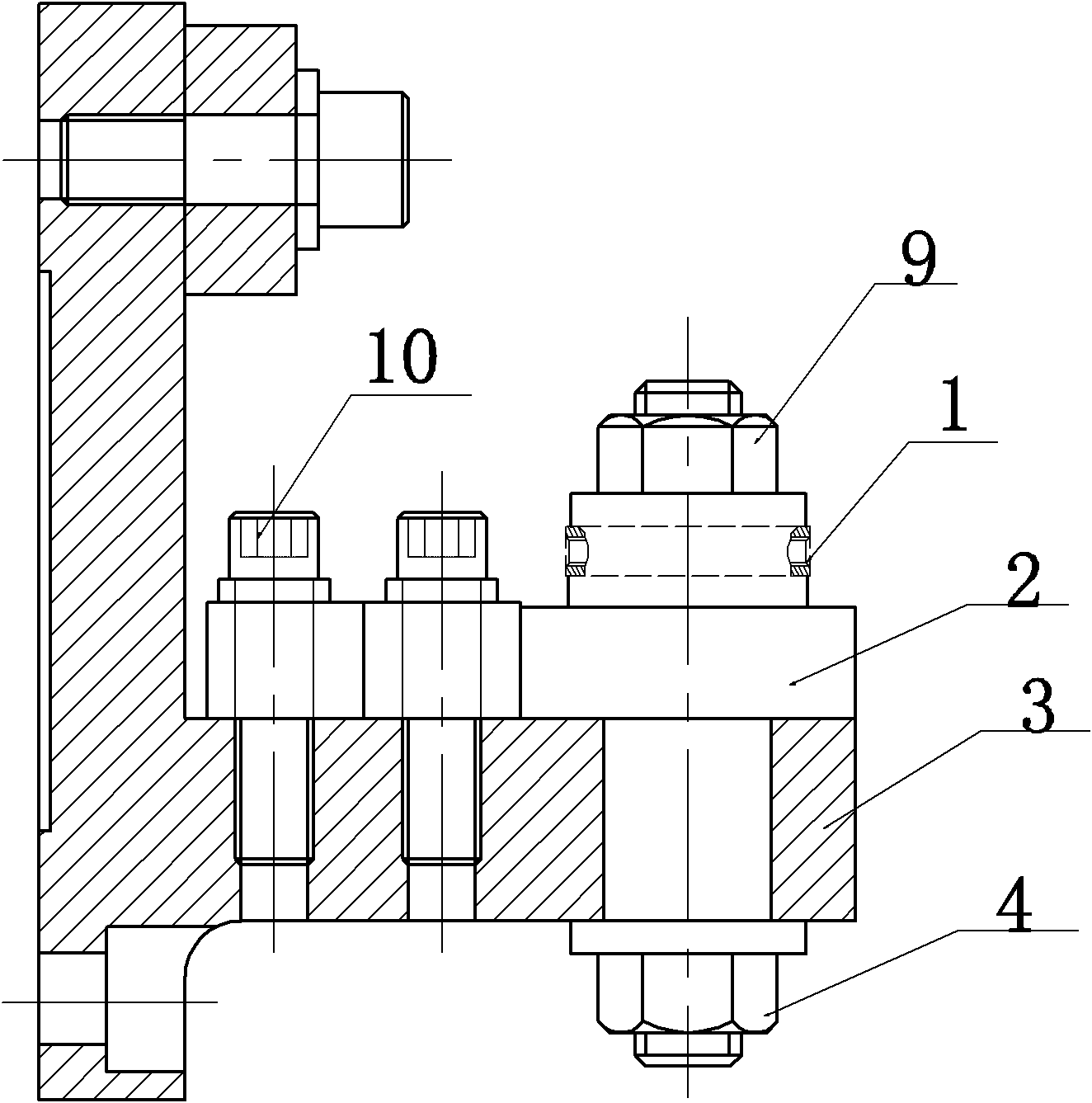

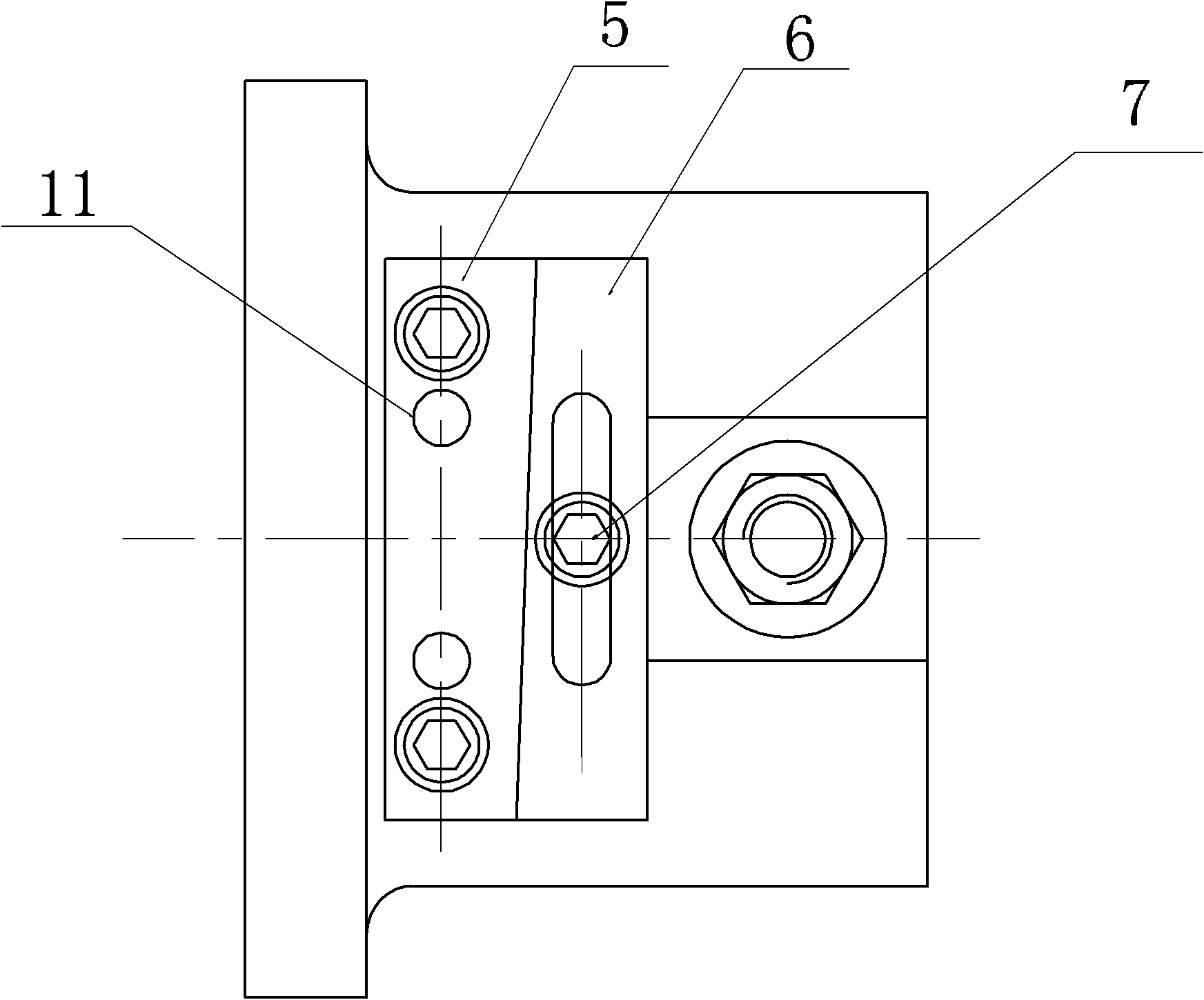

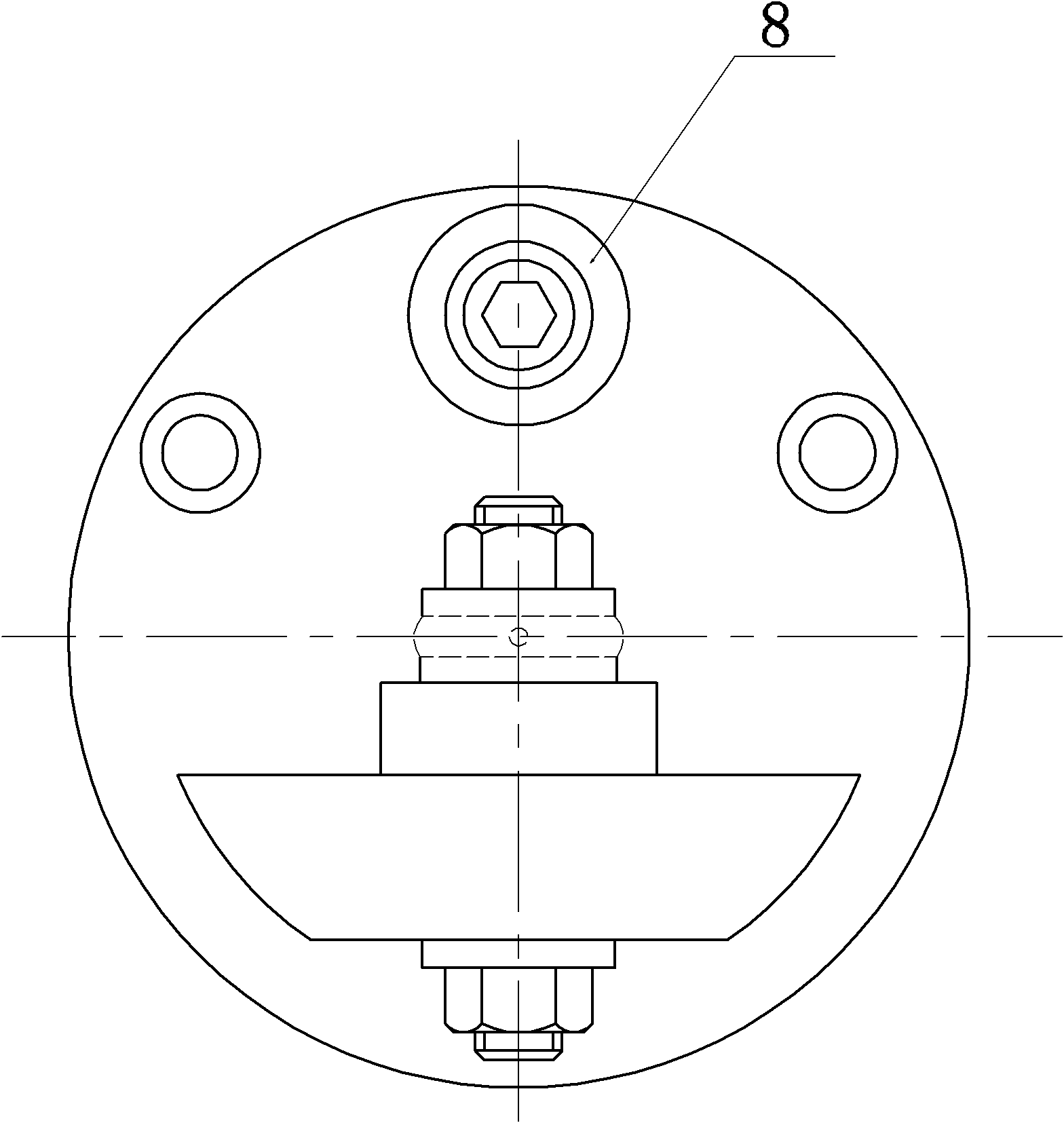

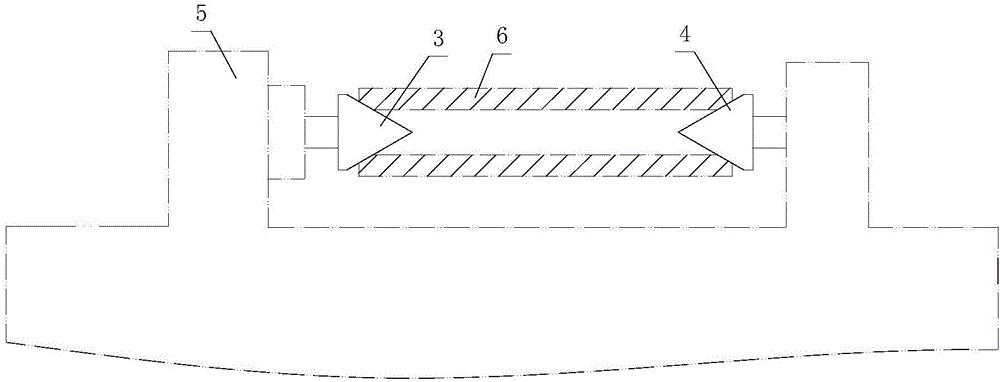

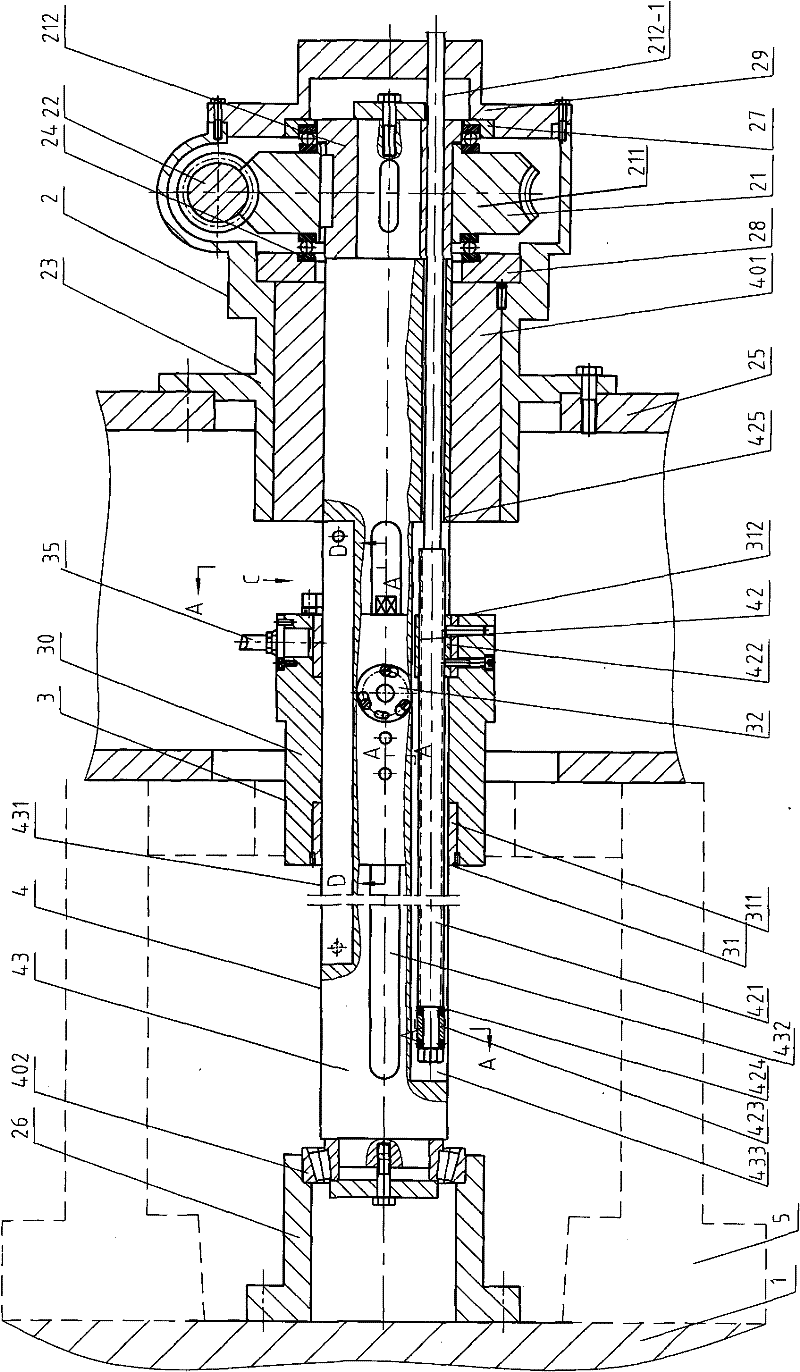

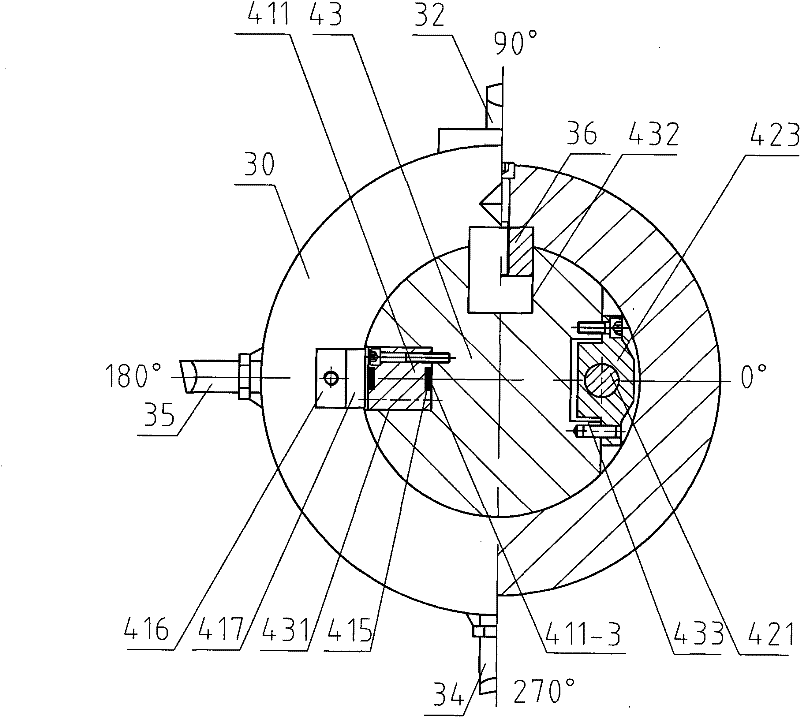

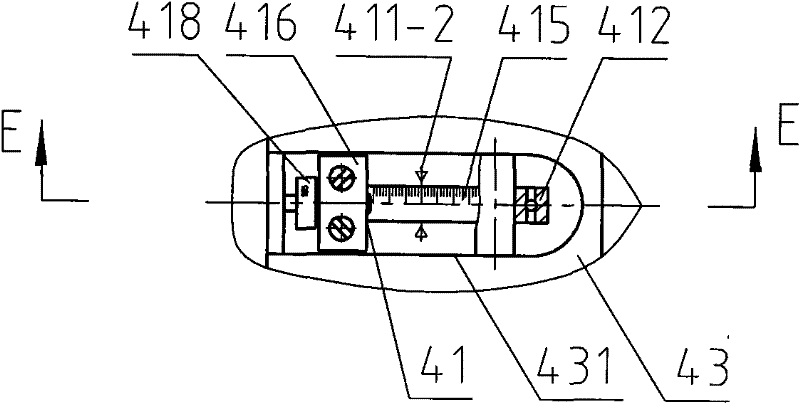

Boring device for cylinder hole of diesel engine stand

InactiveCN101869997AReduce processing costsGuaranteed geometric tolerance requirementsMeasurement/indication equipmentsBoring barsEngineeringBody positions

The invention discloses a boring device for a cylinder hole of a diesel engine stand, which comprises a boring rod transmission mechanism, a boring rod mechanism and a cutter body mechanism, wherein the boring rod transmission mechanism is arranged on one end of a boring rod and comprises a worm gear, a worm, a worm gear case, a pair of supporting bearings, a positioning frame and a positioning seat; the worm gear is fixedly connected with the end of the boring rod; two sides of the worm gear are supported in one end of the worm gear case through the pair of supporting bearings and a retainer ring; the worm is arranged at one side of the worm gear; one end of the boring rod is supported in the other end of the worm gear case through a sliding bearing, and the other end of the boring rod is supported on a machine working table through a conical roller bearing and the positioning seat; the cutter body mechanism can axially move along the boring rod; and a screw rod transmission mechanism and a cutter body position measuring mechanism are also arranged in the boring rod. The invention can enable the cutter body mechanism to automatically and stably feed on the boring rod at constant speed to complete the boring of the cylinder hole, enables the cylinder hole of the diesel engine stand subjected to primary processing to meet the requirements on dimensional tolerance and perpendicularity tolerance of the cylinder hole, and can also measure the boring depth.

Owner:CSSC MARINE POWER

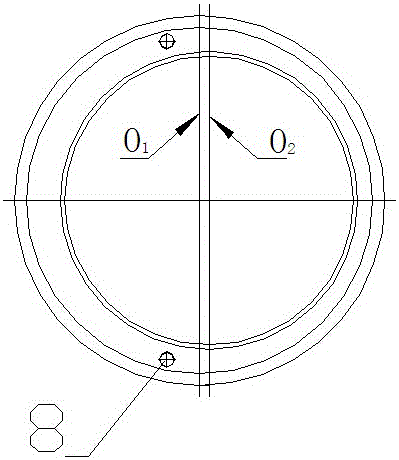

Method for machining large thin-wall inclined eccentric shaft sleeve of gyratory crusher

The invention discloses a method for machining a large thin-wall inclined eccentric shaft sleeve of a gyratory crusher. The boring and turning complementation machining method is adopted, rough turning, semi-finish turning and finish turning are carried out on a workpiece many times, the end face of the workpiece is bored many times to form an eccentric inner hole alignment circle, and the inner hole center of the inclined eccentric shaft sleeve is gradually determined by combing the eccentric inner hole alignment circle machined many times, so that the design requirement for the workpiece is met. The beneficial effects that a numerical control boring machining workbench is high in rotation locating precision, vertical lathe turning efficiency, surface smoothness and the like are fully utilized in the method, and a boring and turning complementation machining mode is formed; the clamping problem of a large thin-wall inclined eccentric part is solved; and the inclined eccentric accuracy of the inner hole and the surface smoothness of the inner hole are guaranteed, and the strict requirements for the form and location tolerance between inner circles and outer circles are met.

Owner:CITIC HEAVY INDUSTRIES CO LTD

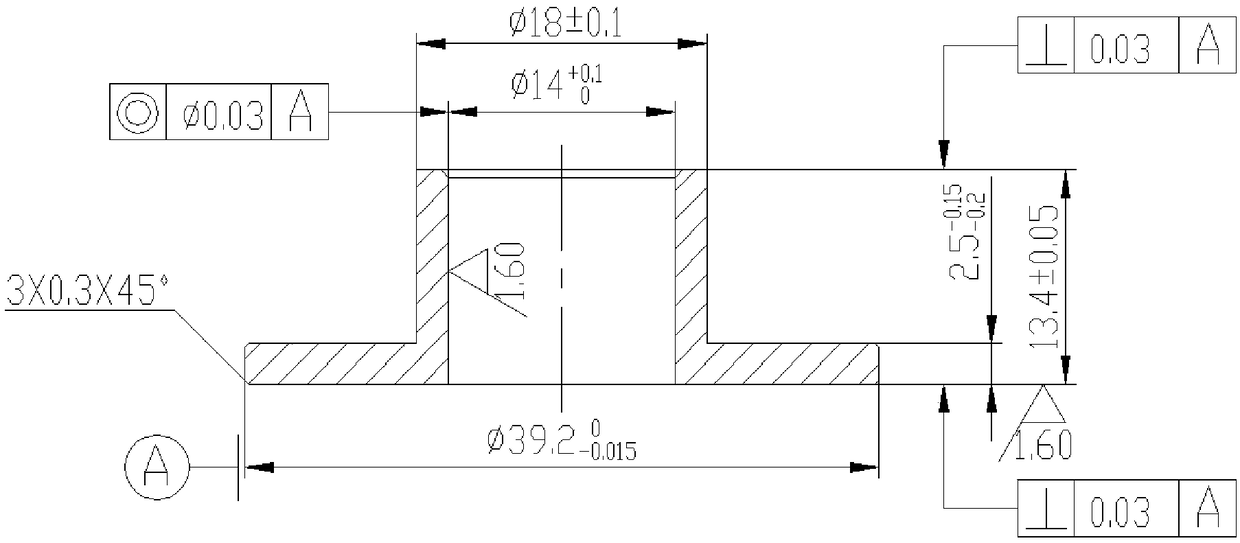

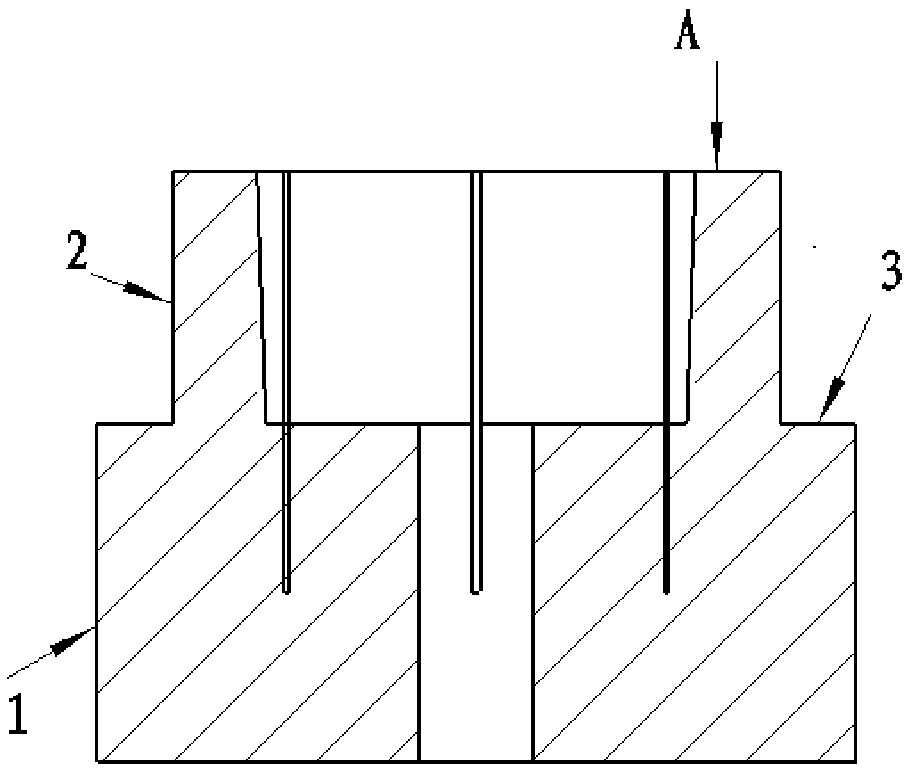

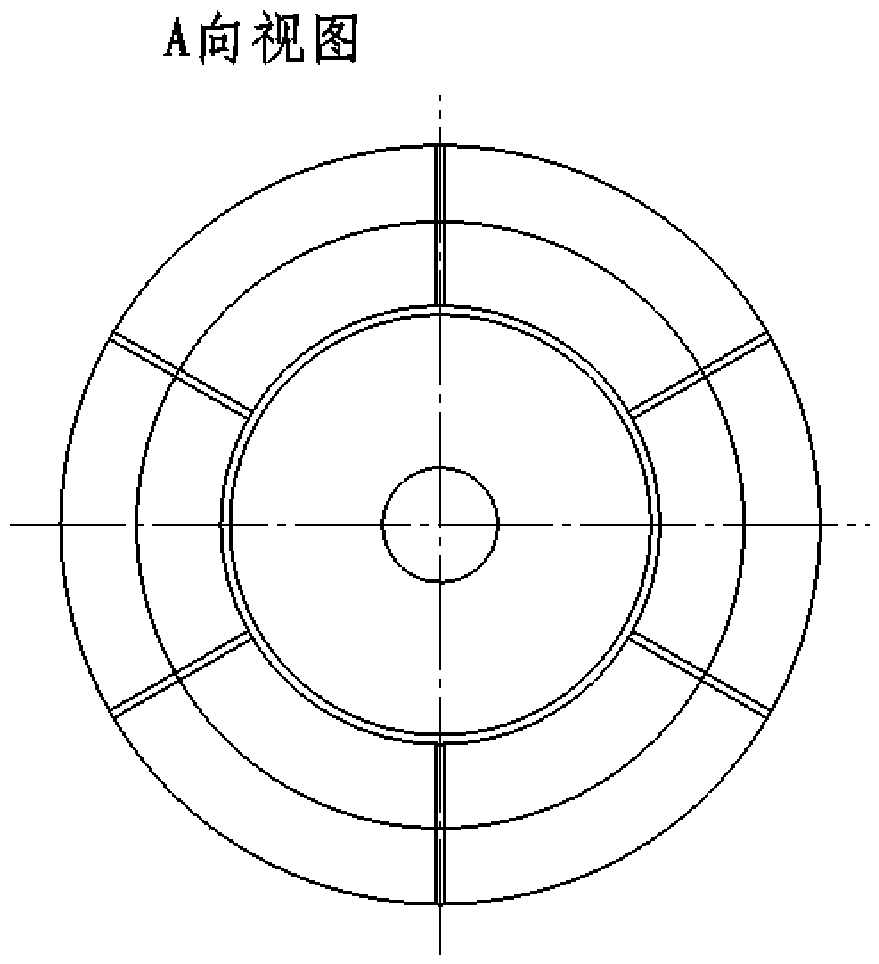

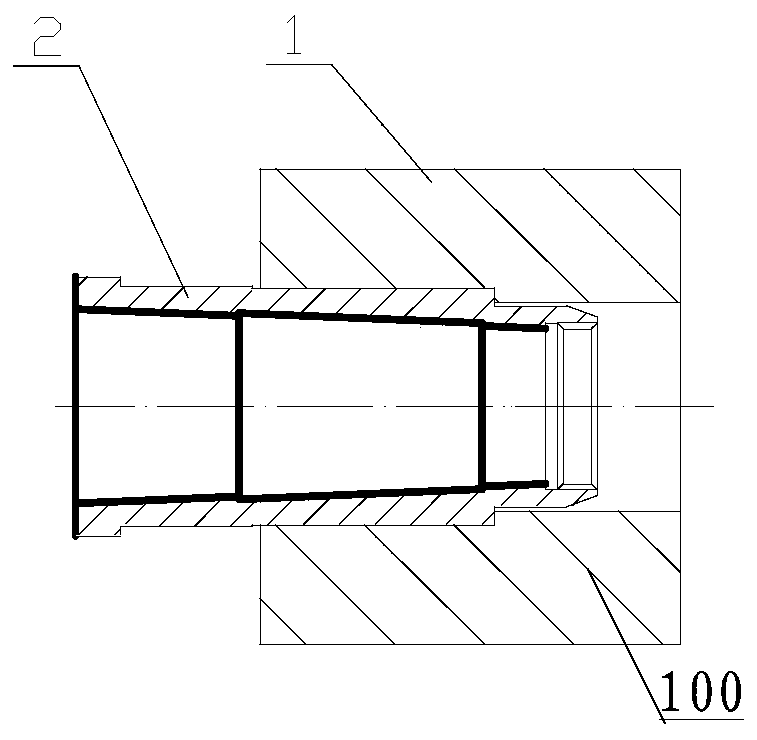

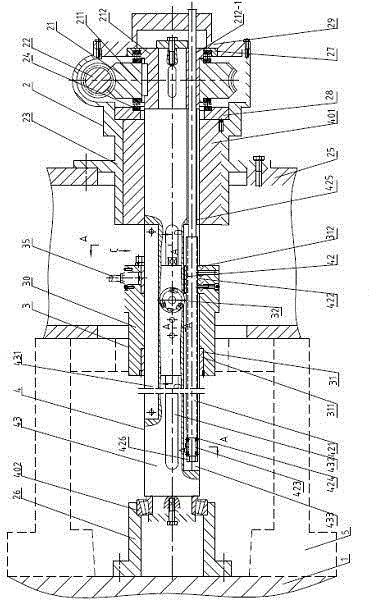

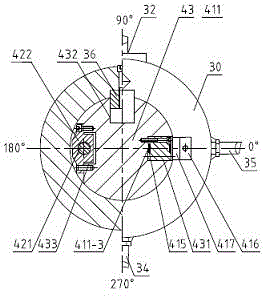

Clamping and machining method for turning of thin-wall weak-rigidity part

InactiveCN109482907AGuaranteed geometric tolerance requirementsImprove quality reliabilityTurning machinesPositioning apparatusEngineeringMachining process

The invention provides a clamping and machining method for turning of a thin-wall weak-rigidity part and belongs to the technical field of the machining process. The clamping and machining method is suitable for a lathe clamping tool for the thin-wall weak-rigidity part. The lathe clamping tool for the thin-wall weak-rigidity part comprises an expansion jig and an expansion bolt. According to themethod, the clamping tool is used for clamping the part. Through the clamping tool, the defects existing in the clamping and machining method of the existing process are overcome, the efficiency of alathe machining the thin-wall part can be improved, and the unqualified rate of products can be reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Machining method of titanium alloy thin-wall part

ActiveCN111037226AImprove stabilityReduce cutting force and control deformationTitanium alloyScrew thread

The invention discloses a machining method of a titanium alloy thin-wall part. The machining method of the titanium alloy thin-wall part comprises the following steps that a holding body holds the small end of a thin-wall shaft sleeve, the inner wall of the thin-wall shaft sleeve is subjected to rough machining operation through a lathe, and the thin-wall shaft sleeve which is subjected to rough machining operation is subjected to heat treatment; semi-finish machining operation and finish machining operation are conducted, and an inner conical hole is obtained through a boring tool; the innerconical hole serves as the standard, and a mandrel is embedded into the inner conical hole; a lathe chuck clamps the large end of the mandrel, internal threads at the tail end of the thin-wall shaft sleeve are connected with external threads of a technological plug head, and a bolt passes through an inner cavity formed in the technological plug head and is connected with the mandrel in a threadedmode; tool withdrawal grooves of excircles of the thin-wall shaft sleeve are subjected to finish machining operation, and then the thin-wall shaft sleeve is separated from the mandrel; the lathe chuckclamps the large end of the mandrel, the internal threads at the tail end of the thin-wall shaft sleeve are connected with the external threads of the technological plug head, and the bolt passes through the inner cavity formed in the technological plug head and is connected with the mandrel in a threaded mode; and the excircles of the thin-wall shaft sleeve are subjected to finish turning operation and finish machining operation. By the adoption of the machining method of the titanium alloy thin-wall part, the dimensional stability and the surface roughness are improved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

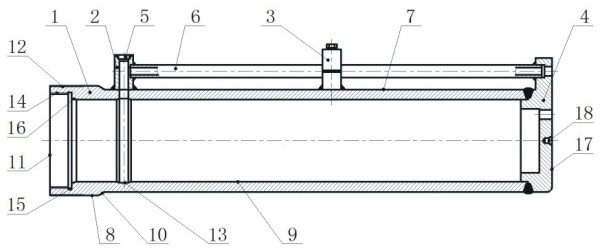

Hydraulic integrated oil cylinder barrel and machining method thereof

ActiveCN114046287AUniform wall thicknessReduce processing difficultyMaterial strength using tensile/compressive forcesFluid-pressure actuatorsNumerical controlEngineering

The invention provides a hydraulic integrated oil cylinder barrel and a machining method thereof. The machining method comprises the steps of workpiece blanking and rough turning machining, primary welding and flaw detection after welding, boring and grinding combination and fractional finish turning, secondary welding and flaw detection after welding, center hole punching and end face turning and grinding, third welding and flaw detection after welding, pressure resistance testing and follow-up treatment. On the premise that special tools, tools and equipment are not needed, an existing numerical control lathe, an existing deep hole boring machine, an existing deep hole honing machine tool and an existing universal cylindrical grinding machine are directly utilized, the technological process is reasonably arranged, technological parameters are determined, the machining precision of workpieces is reliably guaranteed, machining deformation is greatly prevented, and the flatness of the connecting plane of the cylinder bottom valve seat and the control valve set is guaranteed.

Owner:HUBEI JIANGSHAN HEAVY IND

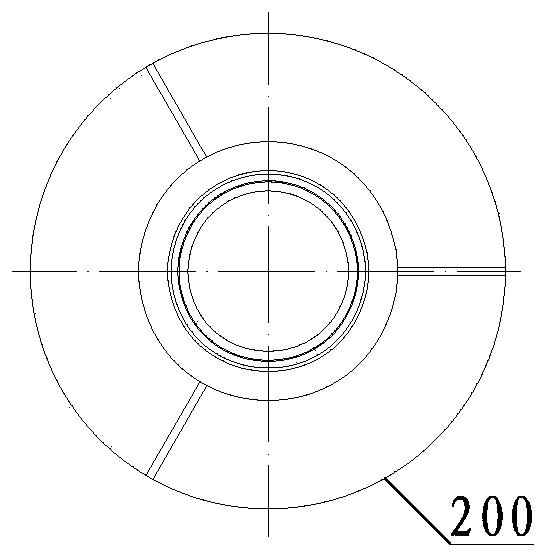

Processing technology of threaded holes of inner ring of position marker

ActiveCN102489970AGuaranteed geometric tolerance requirementsGuaranteed technical specification requirementsThread cutting auxillary apparatusEngineeringMachine tool

The invention relates to a processing technology of inner threaded holes of a position marker. The processing technology adopts the following processing steps: mounting a jig through a numerical control lathe flange plate, adjusting a central position and fastening through a screw; arranging the inner ring of the position marker onto the positioning outer circle of a limiting mandrel, and fixing through a second integral nut; pushing into a regulating plate and fixing the angle phase position of the limiting mandrel; programming a numerical control machine tool program and arranging according to the program: turning a small plane, drilling a bottom hole, drilling and boring a threaded bottom hole and turning a thread through a screwer; loosening a first inner hexagon screw and loosening a first integral nut after completing the processing of the first threaded hole; and performing operation on the premise of not allowing to loosen the second integral nut, withdrawing the regulating plate, rotating the limiting mandrel for 90 degrees, further pushing into the regulating plate, completing the 90-degree equal division and processing the other three threaded holes according to the steps. The processing technology disclosed by the invention can be used for applying the functions of a precision numerical control lathe, realizing hole drilling, hole boring and thread turning and forming, ensuring the requirements of form and position tolerance and ensuring the requirements of various technical indexes, is simple and convenient in operation and stable in quality and can be used for greatly improving the product qualification rate.

Owner:WUXI HANGHU TECH

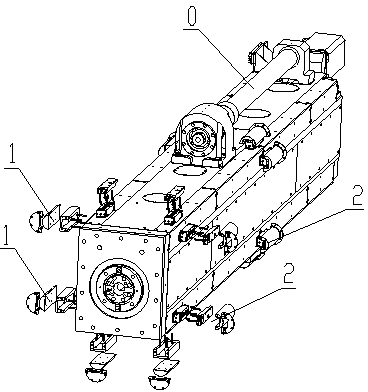

Diesel engine frame air cylinder hole boring device

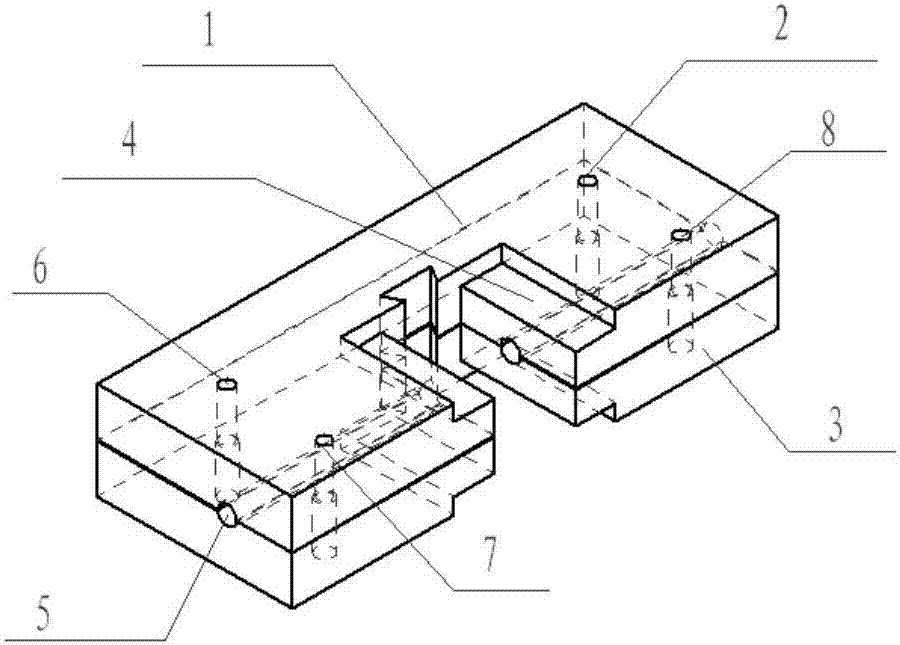

InactiveCN102941364AImprove processing efficiencyReduce processing costsMeasurement/indication equipmentsBoring barsRoller bearingEngineering

The invention discloses a diesel engine frame air cylinder hole boring device, which comprises a boring rod transmission mechanism, a boring rod mechanism and a cutter body mechanism, wherein the boring rod transmission mechanism is arranged on one end of a boring rod and comprises a worm gear, a worm, a worm gear box body, a pair of supporting bearings, a positioning frame and a positioning seat. The worm gear is fixedly connected with the end of the boring rod, two sides of the worm gear are supported inside one end of the worm gear box body through the pair of supporting bearings and a retainer ring, and the worm is arranged on one side of the worm gear. One end of the boring rod is supported inside the other end of the worm gear box body through a slide bearing, the other end of the boring rod is supported on a machine tool worktable through a conical roller bearing and the positioning seat, the cutter body mechanism can move along the axial direction of the boring rod, and a lead screw transmission mechanism and a cutter body position measurement mechanism are also arranged inside the boring rod. Due to the adoption of the diesel engine frame air cylinder hole boring device, the cutter body mechanism can automatically and stably move a cutter on the boring rod at a constant speed so as to boring an air cylinder hole, so that the diesel engine frame air cylinder hole after being machined in one step can meet the size tolerance and verticality tolerance requirements, and the depth of the bored hole also can be measured.

Owner:JIANGSU YAOHUA MECHANICAL & ELECTRICAL TECH

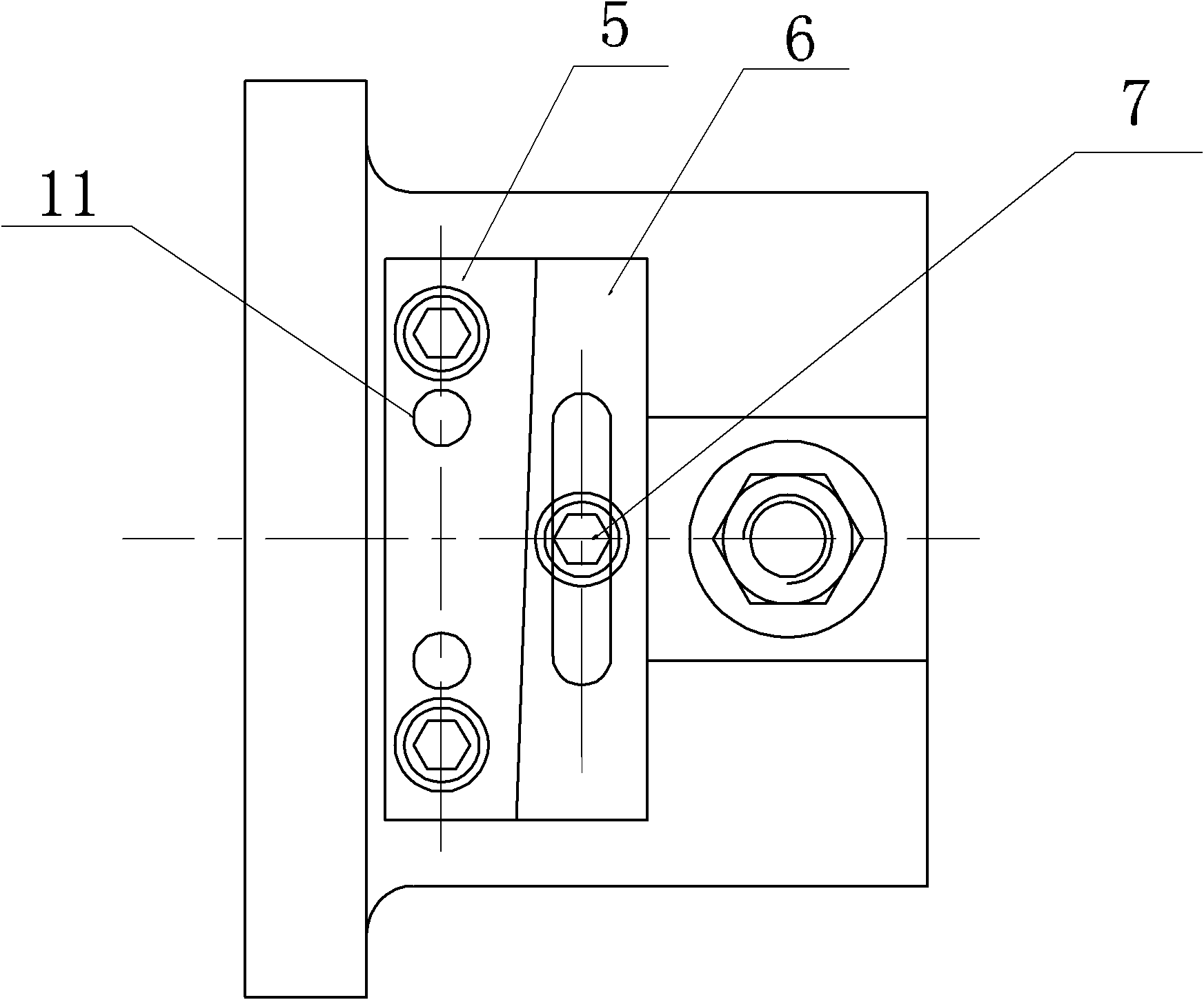

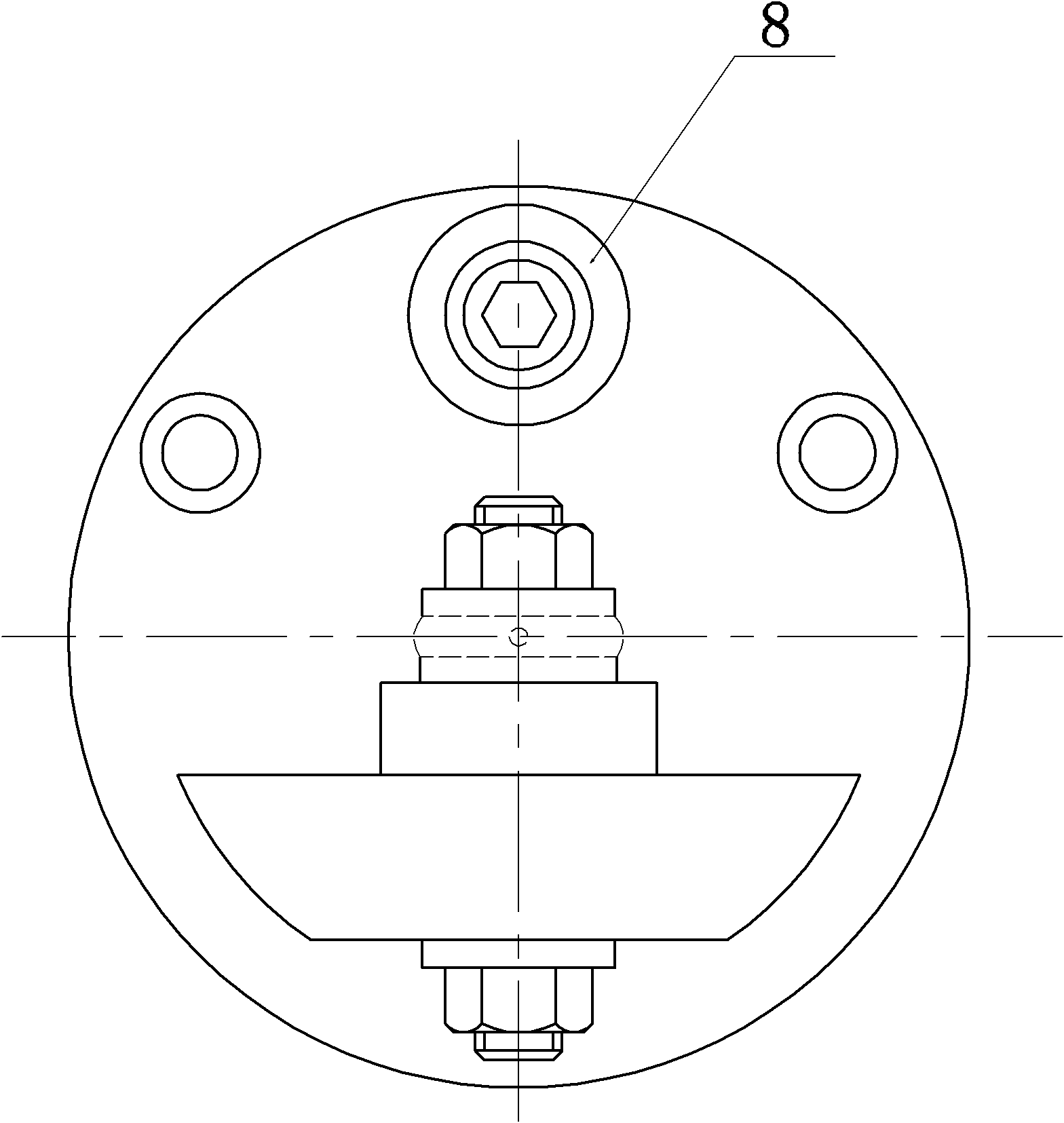

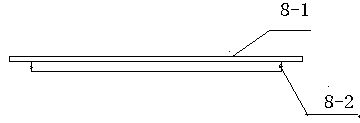

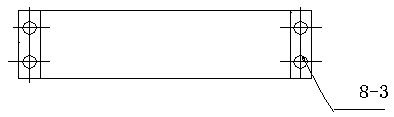

Rolling and sliding compound guide track and manufacturing method thereof

InactiveCN102528467BGuaranteed guide accuracyHigh movement sensitivityLarge fixed membersProcess efficiencyEngineering

The invention discloses a rolling and sliding compound guide track and a manufacturing method thereof. The rolling and sliding compound guide track comprises a rolling and sliding positioning compound guide track and a rolling guide track, wherein the rolling and sliding positioning compound guide track comprises a first positioning block, a second positioning block, a first rolling body and a first positioning baffle plate, the first rolling body is sequentially fixedly connected with the second positioning block and the first positioning block, and the outward surface of the first positioning block is of a circular arc surface; and the rolling guide track comprises a third positioning block, an adjusting wedge block, a second rolling body and a second positioning baffle plate, wherein the second rolling body is sequentially fixedly connected with the adjusting wedge block and the third positioning block, and the outward surface of the third positioning block is of the circular arc surface. The rolling and sliding compound guide track provided by the invention can ensure the guide precision of motion of a ram and the bearing capacity of the guide track, simultaneously reduce the friction force between the ram and a transmission mechanism, and upgrade the sensitivity, the rigidity and the vibration resistance of the motion of the ram by combining the advantages of a rolling guide track and a sliding guide track; and furthermore, not only geometric tolerance requirement of a guide track mounting groove is ensured, but also processing efficiency can be greatly improved.

Owner:SANY GRP

Valve grinding method

InactiveCN111300209AImprove surface qualityReduce processing stressGrinding drivesGrinding machinesPhysicsWheel drive

The invention discloses a valve grinding method. The valve grinding method comprises the following steps that S1, a valve is clamped and fixed to a main shaft of a grinder; S2, the grinder is started,and the main shaft drives the valve to rotate around a valve axis; and S3, the position of a grinding wheel is adjusted so that the plane on which a grinding wheel piece is located is perpendicular to the valve axis, a grinding wheel driving mechanism is started to drive the grinding wheel piece to rotate, the valve is driven to move in the axial direction by the main shaft, the grinding wheel piece feeds radially along the valve, when a valve rod is ground, the radial feed rate of the grinding wheel piece is constant, and when the valve sealing conical surface is ground, the radial feed rateof the grinding wheel piece and the axial movement speed of the valve are completed by programming interpolation program. The grinding of the valve rod and the valve sealing conical surface can be realized by one clamping, the machining quality of the valve sealing conical surface is improved, the machining stress of the high-hardness valve sealing conical surface is eliminated to the maximum extent, the early wear cycle of the valve sealing conical surface is effectively prolonged, the block falling and scouring failure caused by unreliable sealing are reduced, and the service life of the valve is prolonged.

Owner:CHONGQING YUEJIN MACHINERY

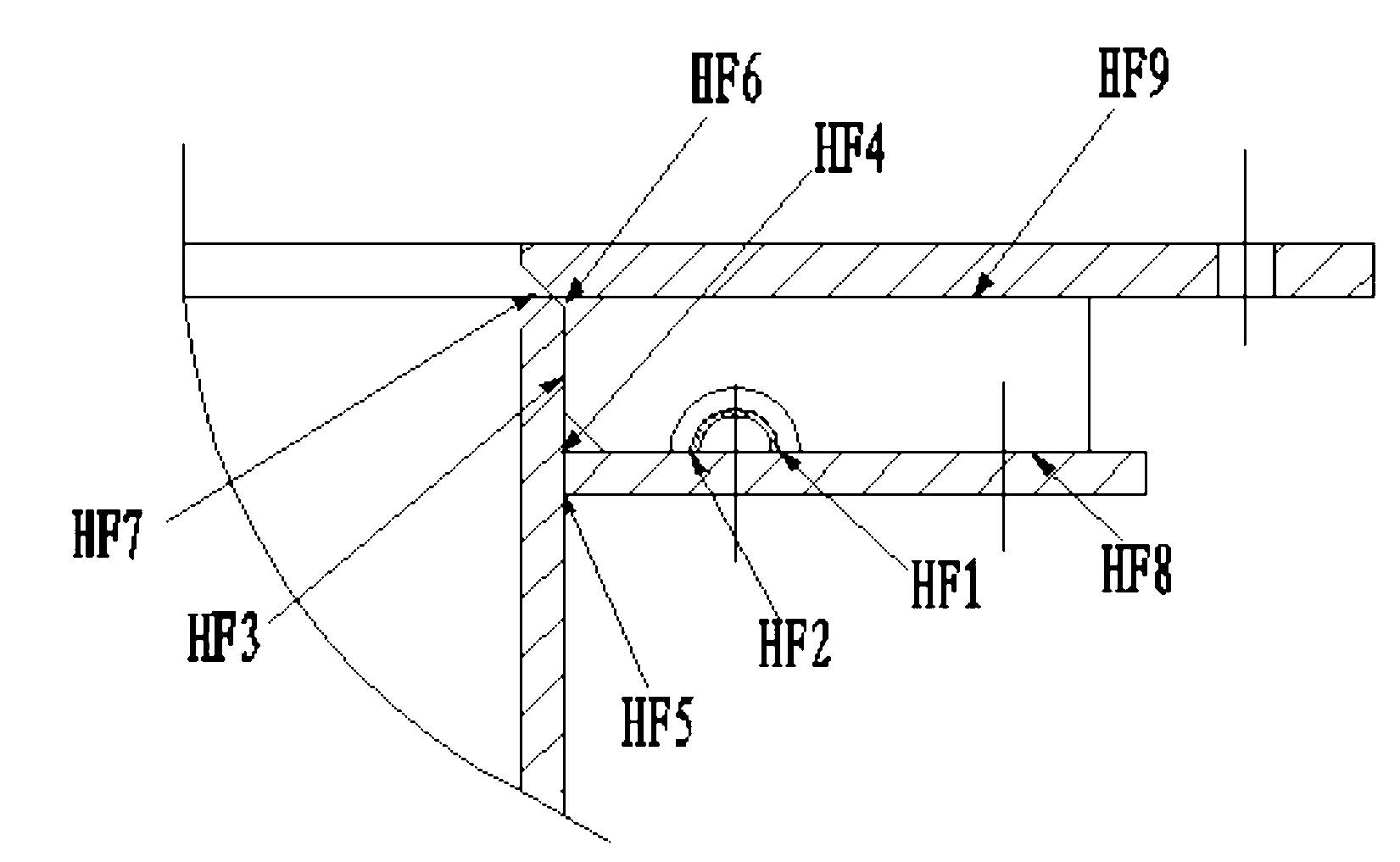

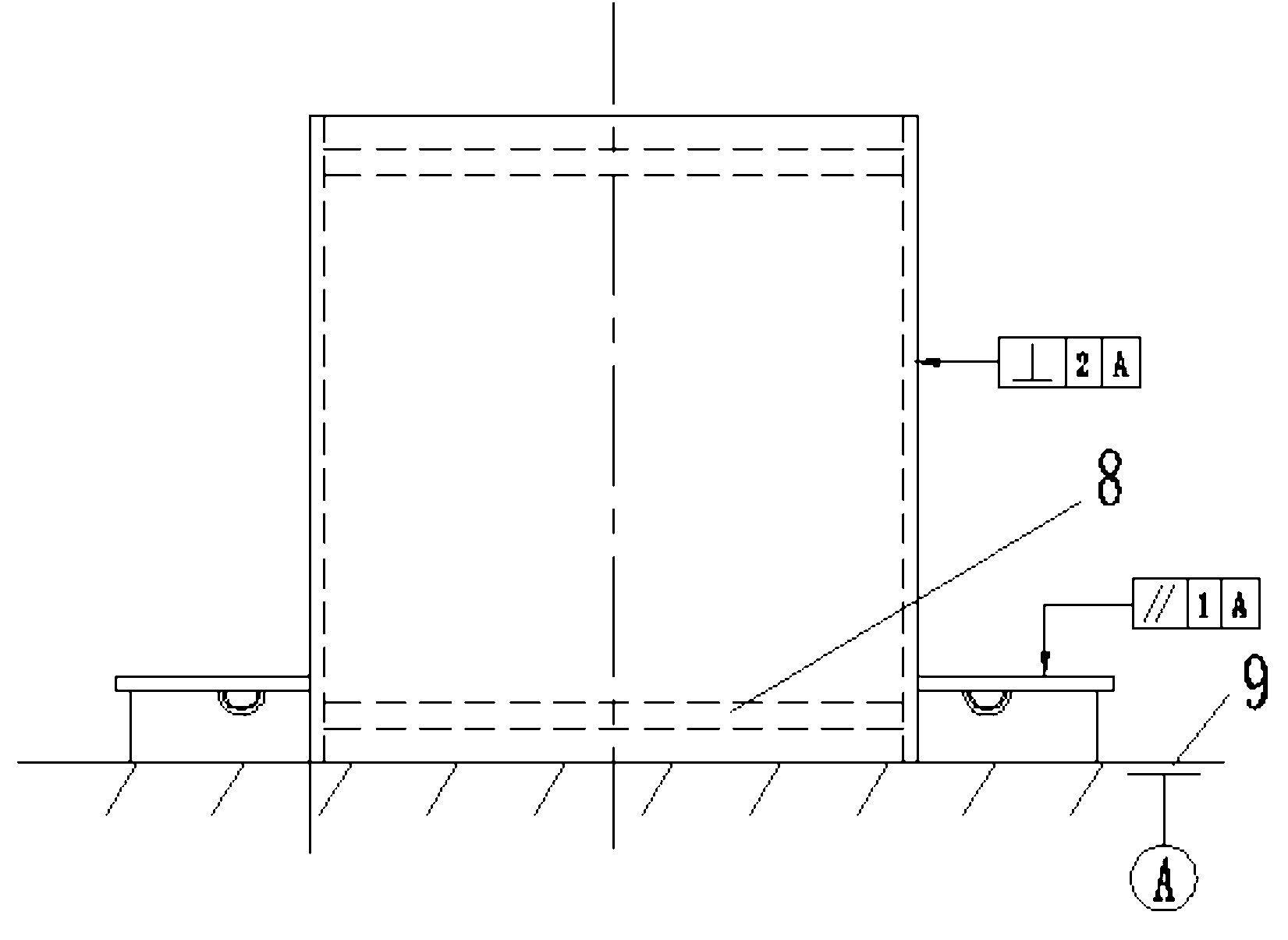

Mounting and clamping tool and method for argon tungsten-arc welding by use of mounting and clamping tool

ActiveCN107470845APrevent oxidationEasy card positioningWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneSurface oxidation

The invention relates to a mounting and clamping tool and a method for argon tungsten-arc welding by use of the mounting and clamping tool. The method ensures small deformation of pipeline welding and belongs to the technical field of welding processes. A spot welding, circumferential welding and follow-up heat treatment universal integrated tool is designed according to products with different external diameters, mounting, clamping and positioning can be conveniently performed, and meanwhile, surface oxidation of a weld joint, repeated mounting and clamping of the tool, and product deformation are avoided during processing. In the method, 2-4 point equipartition is performed on spot welding parameters through welding programming for symmetric programming; and the circumferential welding process comprises repeated subsection, current from the first section to the last section is in the mode of waveform current, and the average current adopts an inclined mode. Through the programming method, the depth of fusion can be well controlled by the programming method, heat input is reduced to the minimum degree on the premise of guaranteeing the welding depth, the uniformity of the fusion depth is realized, and the ranges of surface oxidation and a heat affected zone are reduced to the utmost extent.

Owner:BEIJING INST OF CONTROL ENG

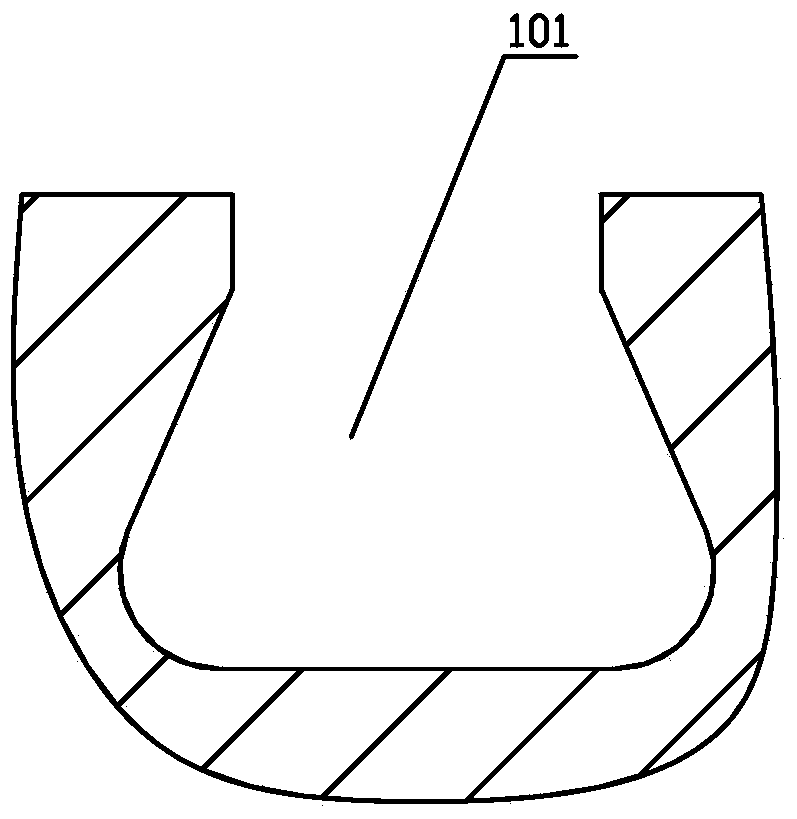

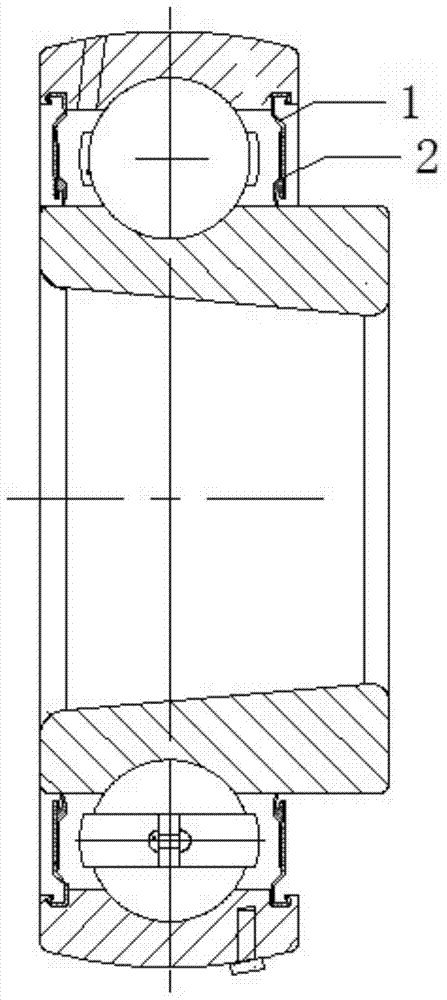

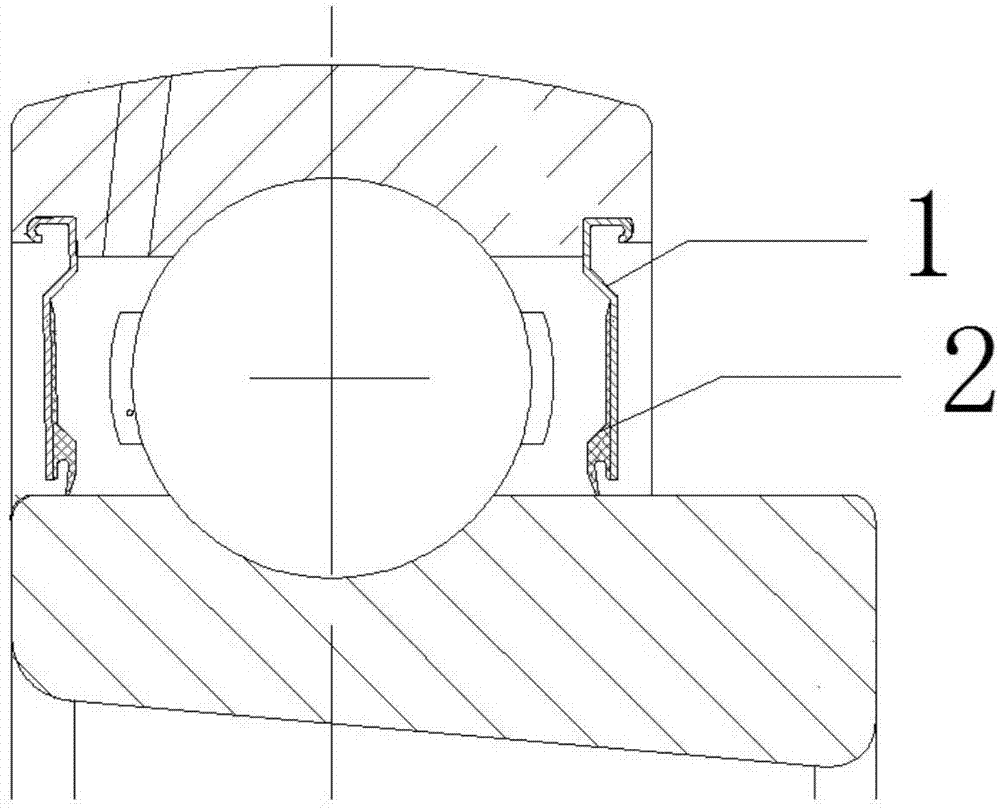

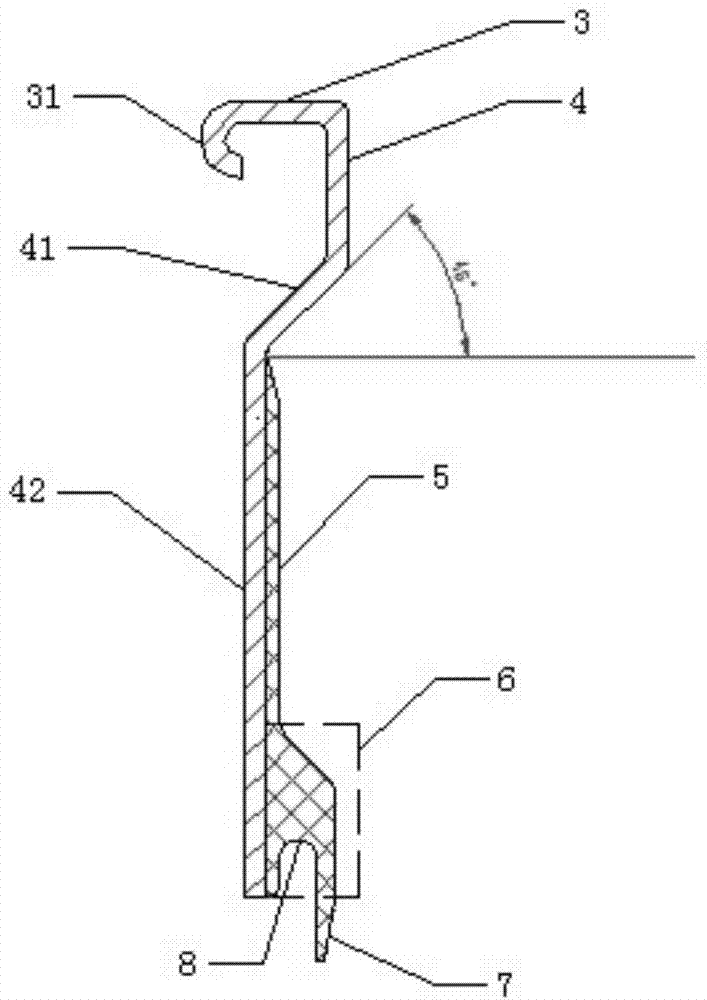

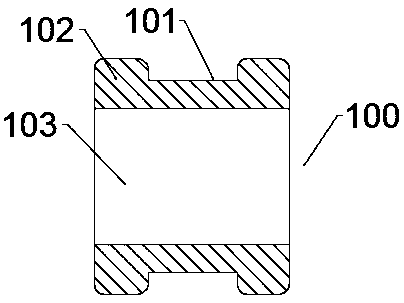

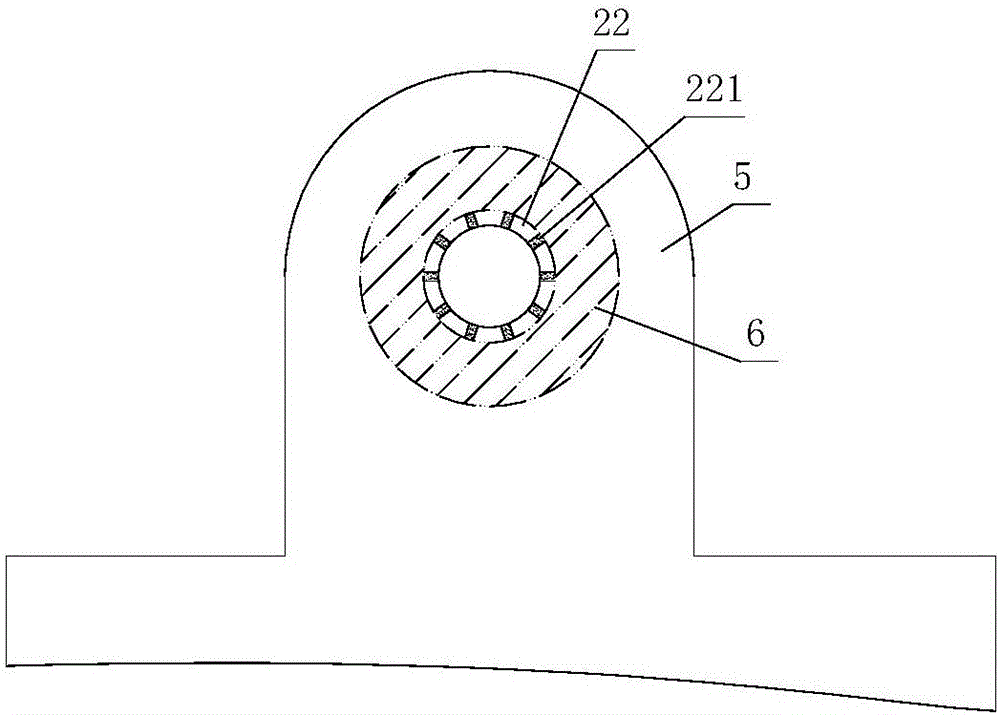

Bearing sealing ring

InactiveCN104847796AImprove elastic deformation abilityGuaranteed geometric tolerance requirementsBearing componentsRubber ringArchitectural engineering

The invention discloses a bearing sealing ring, which comprises a steel ring framework at the outer side and a rubber ring at the inner side, wherein the steel ring framework comprises a top beam and a vertical beam I, the top beam is horizontally arranged; a middle section of the vertical beam I is bent to 45 degrees; the rubber ring comprises a vertical beam II and a bottom beam; the vertical beam II is bonded with the lower section of the vertical beam I of the steel ring framework; a sealing lip is extended out of the bottom beam of the rubber ring; a C-type groove is formed in the bottom of the bottom beam, close to the sealing lip. The elastic deformation capability of the sealing ring can be improved; the service life of the sealing ring can be prolonged; meanwhile, the clamping capability between the sealing ring and a sealing groove opening of the outer ring of a bearing can be improved.

Owner:ANHUI LIDA AUTOMOBILE BEARING MFG

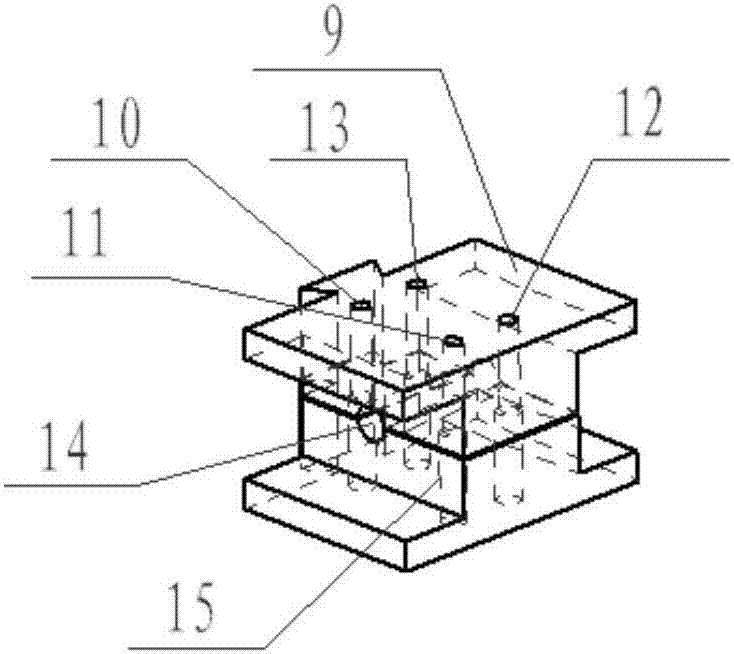

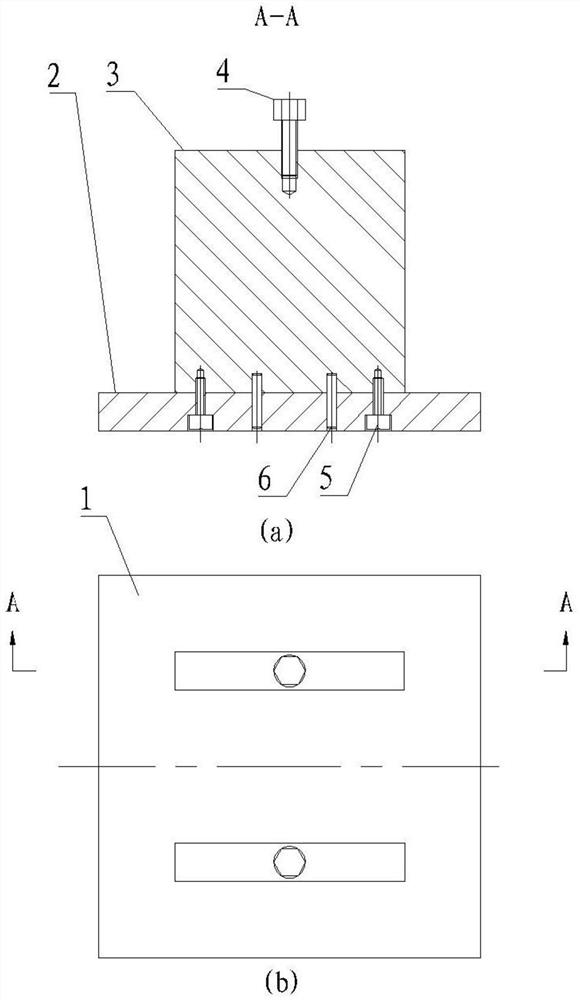

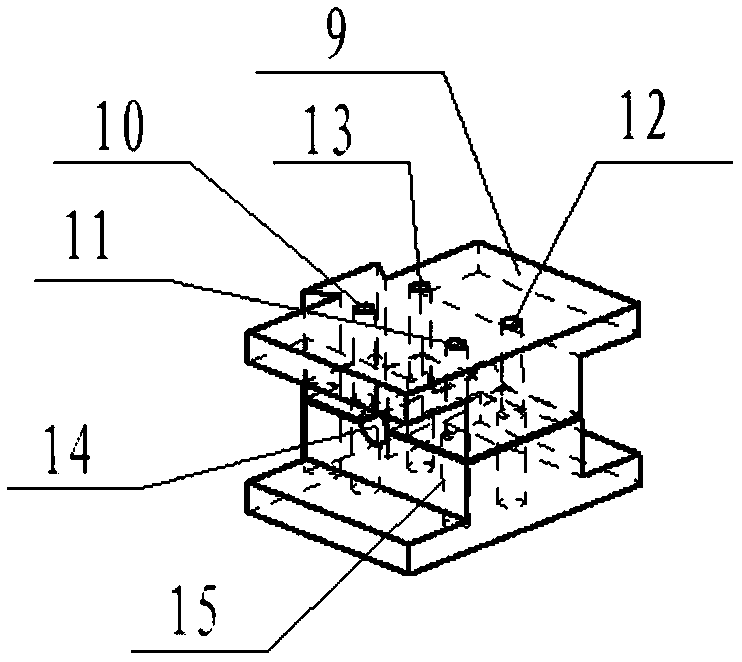

One-time forming processing device of square pipe hoop

InactiveCN110153281AGuaranteed geometric tolerance requirementsQuality assuranceShaping toolsMetal-working feeding devicesPosition toleranceElastomer

The invention discloses a one-time forming processing device of a square pipe hoop. The one-time forming processing device comprises a mold frame mechanism and a linkage extrusion mechanism, wherein the mold frame mechanism comprises a mold frame upper bottom plate, a guide sleeve, a guide column, a guide column fixing seat and a mold frame lower bottom plate; and the linkage extrusion mechanism comprises an upper punch, an upper fixing plate, a middle upper plate, an upper elastic body, a sliding block, a clamping block, a middle lower plate, a lower punch, a lower fixing plate and a lower elastic body. According to the one-time forming processing device of the square pipe hoop, one-time clamping and positioning are adopted in the production process, the positioning consistency is good, and the requirement for the shape and position tolerance of hoop bodies and a square through hole is fundamentally met; and the heights of the hoop bodies at the two ends and the symmetry of the hoop bodies are high, the hoop bodies are regular, the surface roughness is low, no crack distortion defect is caused, the consistency of the hoop bodies of the square pipe hoop is high, and the quality ofiron art subsequent assembly is ensured.

Owner:SHANDONG JINMA IND GRP MECHANICAL FORGING FACTORY +1

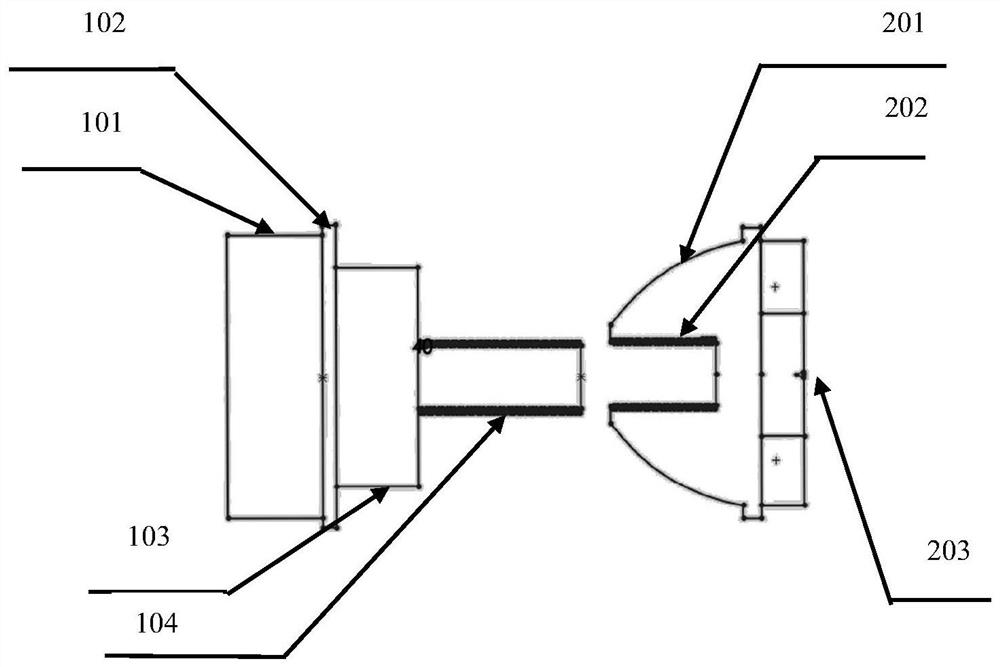

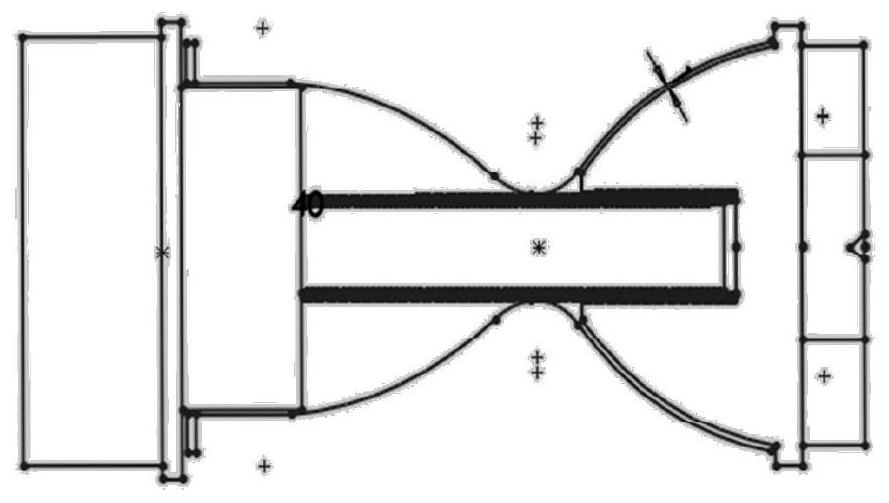

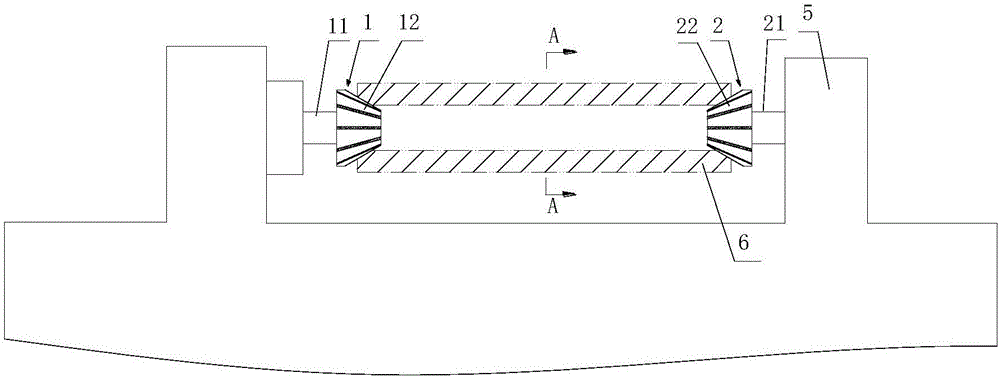

Composite tool for thin-wall thrust chamber and anti-deformation machining method

PendingCN113458831AGuaranteed coaxiality requirementsGuaranteed geometric tolerance requirementsPositioning apparatusMetal-working holdersPhysicsMachining process

The invention relates to a composite tool for a thin-wall thrust chamber and an anti-deformation machining method. The composite tool is characterized by comprising a left half end and a right half end, wherein the left half end comprises a first cylindrical base; a threaded hole is formed in the middle of one side of the first cylindrical base; the right half end comprises a second cylindrical base; a frustum is arranged on one side of the second cylindrical base; and a screw rod matched with the threaded hole in the first cylindrical base is arranged in the middle of the frustum. According to the composite tool for the thin-wall thrust chamber and the anti-deformation machining method, in the thrust chamber shell machining process, the problem that a thrust chamber shell and the center axis of a clamp are not concentric is solved, and the requirements for the coaxiality and form and location tolerance of the thrust chamber are met.

Owner:NINGXIA ORIENT TANTALUM IND

Processing technology of threaded holes of inner ring of position marker

ActiveCN102489970BGuaranteed geometric tolerance requirementsGuaranteed technical specification requirementsThread cutting auxillary apparatusNumerical controlPosition tolerance

The invention relates to a processing technology of inner threaded holes of a position marker. The processing technology adopts the following processing steps: mounting a jig through a numerical control lathe flange plate, adjusting a central position and fastening through a screw; arranging the inner ring of the position marker onto the positioning outer circle of a limiting mandrel, and fixing through a second integral nut; pushing into a regulating plate and fixing the angle phase position of the limiting mandrel; programming a numerical control machine tool program and arranging according to the program: turning a small plane, drilling a bottom hole, drilling and boring a threaded bottom hole and turning a thread through a screwer; loosening a first inner hexagon screw and loosening a first integral nut after completing the processing of the first threaded hole; and performing operation on the premise of not allowing to loosen the second integral nut, withdrawing the regulating plate, rotating the limiting mandrel for 90 degrees, further pushing into the regulating plate, completing the 90-degree equal division and processing the other three threaded holes according to the steps. The processing technology disclosed by the invention can be used for applying the functions of a precision numerical control lathe, realizing hole drilling, hole boring and thread turning and forming, ensuring the requirements of form and position tolerance and ensuring the requirements of various technical indexes, is simple and convenient in operation and stable in quality and can be used for greatly improving the product qualification rate.

Owner:WUXI HANGHU TECH

A processing method for a large thin-walled oblique eccentric shaft sleeve of a gyratory crusher

Owner:CITIC HEAVY INDUSTRIES CO LTD

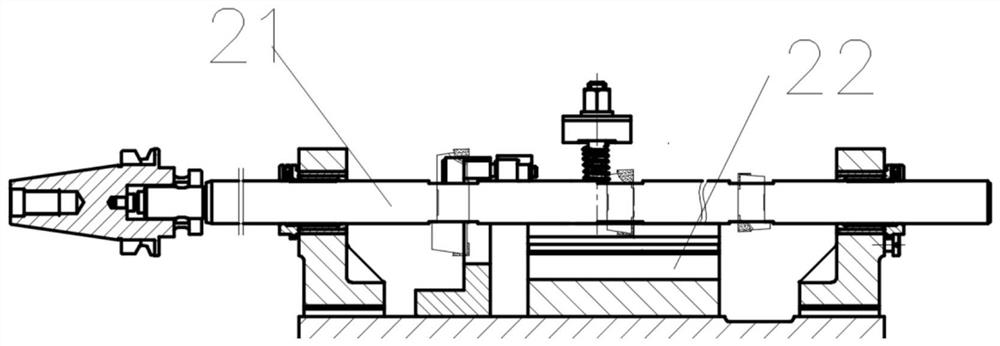

Device for grinding high-precision outer circle

InactiveCN106736906AEliminates the problem of not being in a straight lineGuaranteed dimensional accuracy requirementsRevolution surface grinding machinesGrinding work supportsAlloyHardness

The invention discloses a device for grinding a high-precision outer circle. The device comprises a left centre and a right centre which are arranged on an outer circle grinding machine. The left centre is composed of a left mandrel and a left top connected to the left mandrel, and a hard alloy insert A is arranged on the left top. The right centre is composed of a right mandrel and a right top connected to the right mandrel, and a hard alloy insert B is arranged on the right top. The left centre and the right centre are symmetrically arranged on the outer circle grinding machine, and the center line of the left centre and the center line of the right centre coincide with each other. According to the device, in the machining process, a machine tool drives a workpiece to rotate, and in the rotating process, as the hardness of the hard alloy insert A and the hardness of the hard alloy insert B are higher than the hardness of the workpiece, a material of the workpiece can be removed in a trace manner, inner chamfers at the two ends of the workpiece are amended, the problem that the rotating centers of the inner chamfers at the two ends and the rotating center of the machine tool are not located on the same line is avoided, and the high size precision and form and location tolerance requirements of the outer circle are guaranteed.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

A method for improving the machining accuracy of aluminum alloy thin-walled parts used for gyro frames

The invention relates to a method for improving the machining precision of an aluminum alloy thin-wall part used for a gyroscope frame. The method comprises the specific steps that firstly, a part body is roughly machined; secondly, the part body is subject to first-time heat treatment, and solid-solution aging treatment is adopted in the first-time heat treatment; thirdly, the part body is subject to semi-finish machining; fourthly, the part body is subject to second-time heat treatment, and middle heat treatment of the cold and hot two cycles is adopted in the second-time heat treatment; fifthly, process reinforcing ribs are connected to the compressing face of the part body; sixthly, finishing before surface finish is carried out; seventhly, the part body is subject to third-time heat treatment, and solid-solution aging heat treatment is adopted in the third-time heat treatment; eighthly, finishing of the final size after the surface finish is carried out; and ninthly, the process reinforcing ribs are dismounted. Through the method, the machining quality of the aluminum alloy thin-wall part used for the gyroscope frame can be ensured, the waste caused by unqualified machining is avoided, and the cost is greatly saved.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

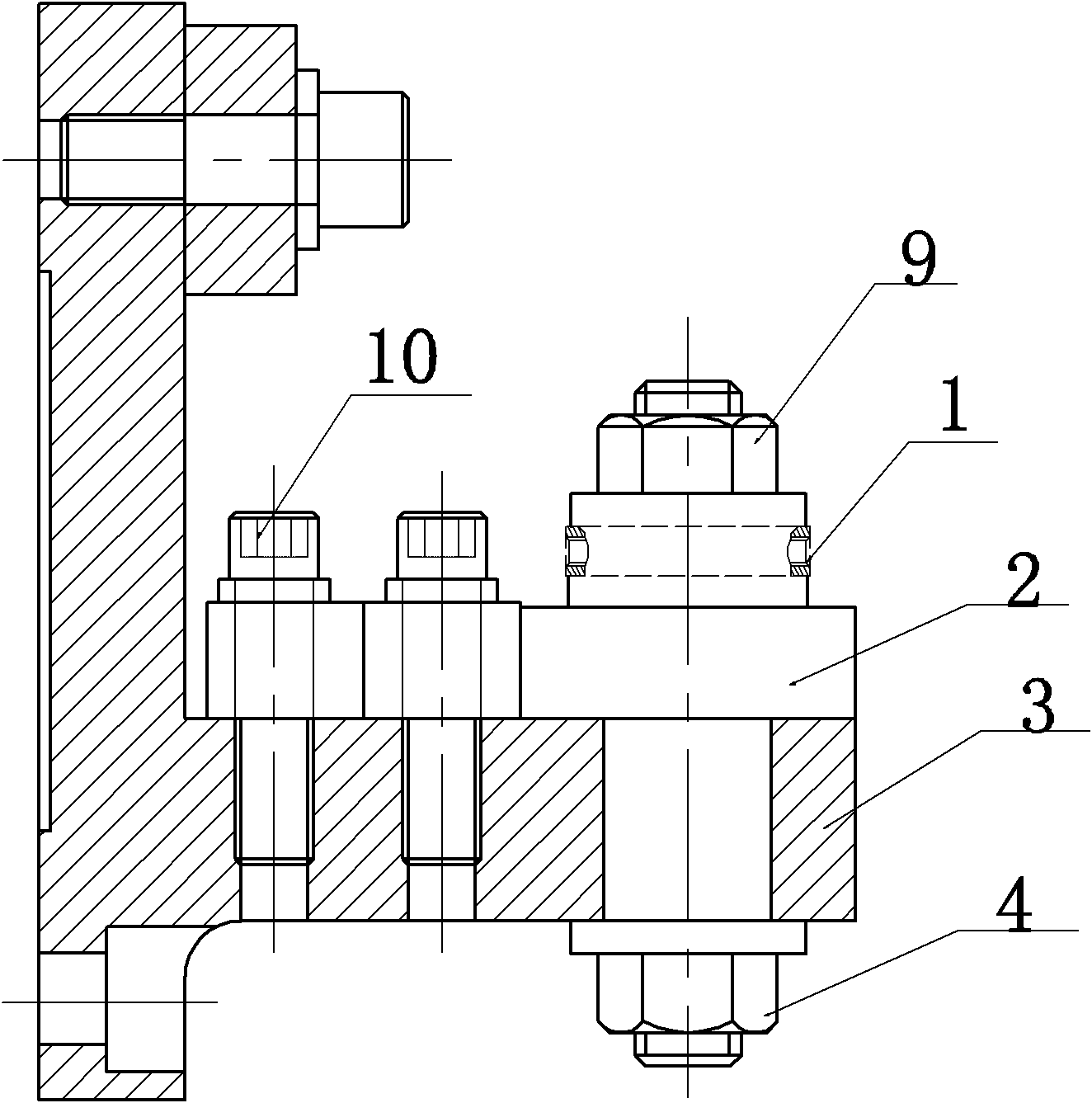

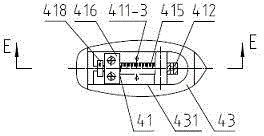

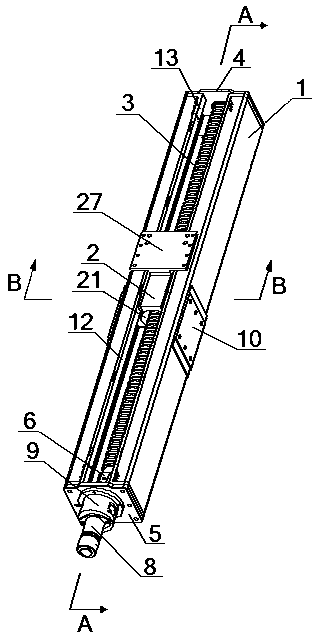

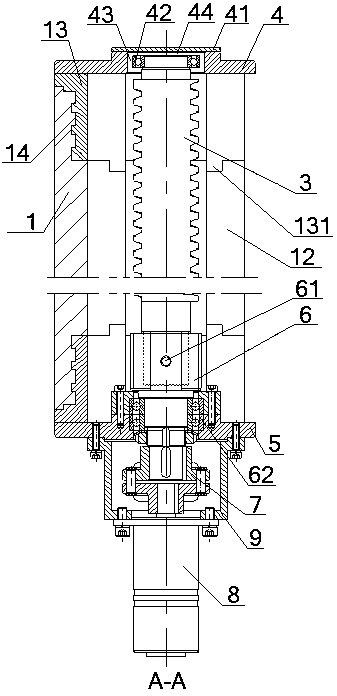

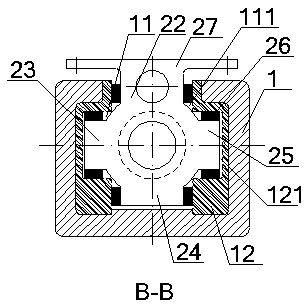

A linear motion device used in a charged environment

ActiveCN103982613BGuaranteed geometric tolerance requirementsReduce the difficulty of production and processingGearingLinear motionCoupling

The invention relates to a linear motion device for a charged environment. The linear motion device comprises an insulating guide device, and a sliding block and an insulating screw rod which are arranged in the insulating guide device, wherein the two ends of the guide device are respectively connected with an end cover No. 1 and an end cover No. 2; the sliding block has a cross-shaped structure, and the outer wall of the sliding block is matched with a convex-shaped sliding groove formed in the guide device in a sliding way; the sliding block is internally provided with a screw rod mounting through hole matched with the outer wall of the screw rod in an inserting way; one end of the screw rod is rotatably matched with the end cover No. 1, and the other end of the screw rod is fixedly connected with a driving motor sequentially by a connecting shaft, the end cover No. 2 and a coupler; the coupler, the connecting shaft and the insulating screw rod are driven to rotate by the driving motor, so that the sliding block is driven to make reciprocating linear motion in the guide device. After the design is adopted, the production cost is lowered, the structural strength is improved, and the insulating property is guaranteed.

Owner:WUHAN POWER EQUIP WORKS

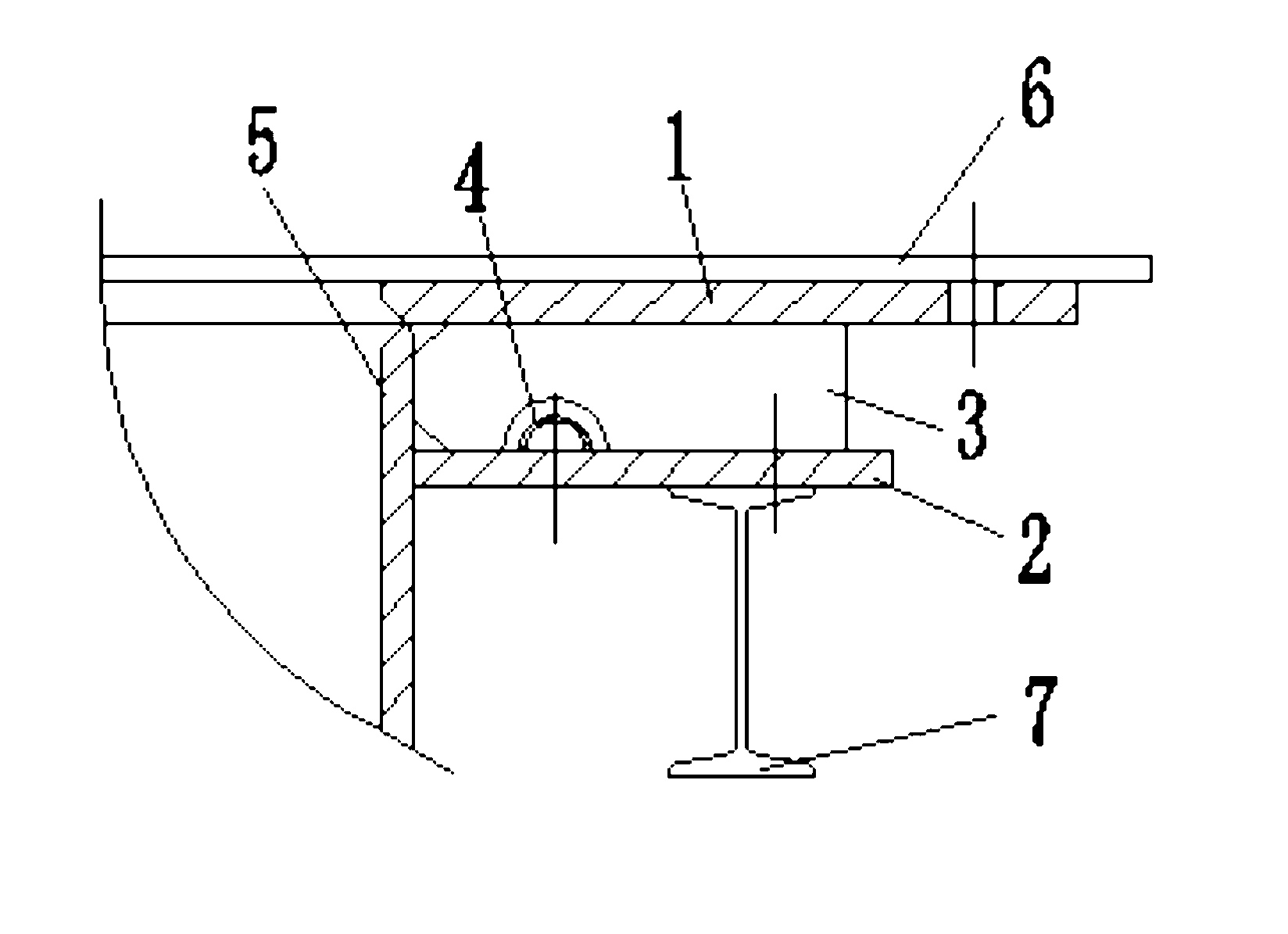

Thrust bearing shell or protector shell machining process

PendingCN114178791AGuaranteed geometric tolerance requirementsImprove processing efficiencyNumerical controlThrust bearing

The invention provides a machining process for a thrust bearing shell or a protector shell. The machining process comprises the following steps that (1) an inner hole of the thrust bearing shell or the protector shell is honed to the required size; (2) one end of the thrust bearing shell or the protector shell is clamped through a lathe chuck, the other end face of the thrust bearing shell or the protector shell is aligned, burrs on the end face are removed through polishing, and after one end is completed, the other end is machined in a U-turn mode; (3) ejecting inner holes in the two ends of the thrust bearing shell or the protector shell by using a tip, and machining and turning an outer circle by using a lathe; and (4) clamping the outer circle part of the thrust bearing shell or the protector shell by using a double-end numerical control lathe, and simultaneously machining spigot parts and thread parts at the two ends of the thrust bearing shell or the protector shell. According to the method, the shape and location tolerance requirements (the coaxiality tolerance is smaller than or equal to 0.02 mm, and the end face parallelism tolerance is smaller than or equal to 0.01 mm) of the shell are met, the machining efficiency is high, and raw materials are saved; working efficiency is high, operation is easy, learning is easy, and machining difficulty is low.

Owner:SHANDONG BAOSHIDA GASOLINEEUM EQUIP MFG

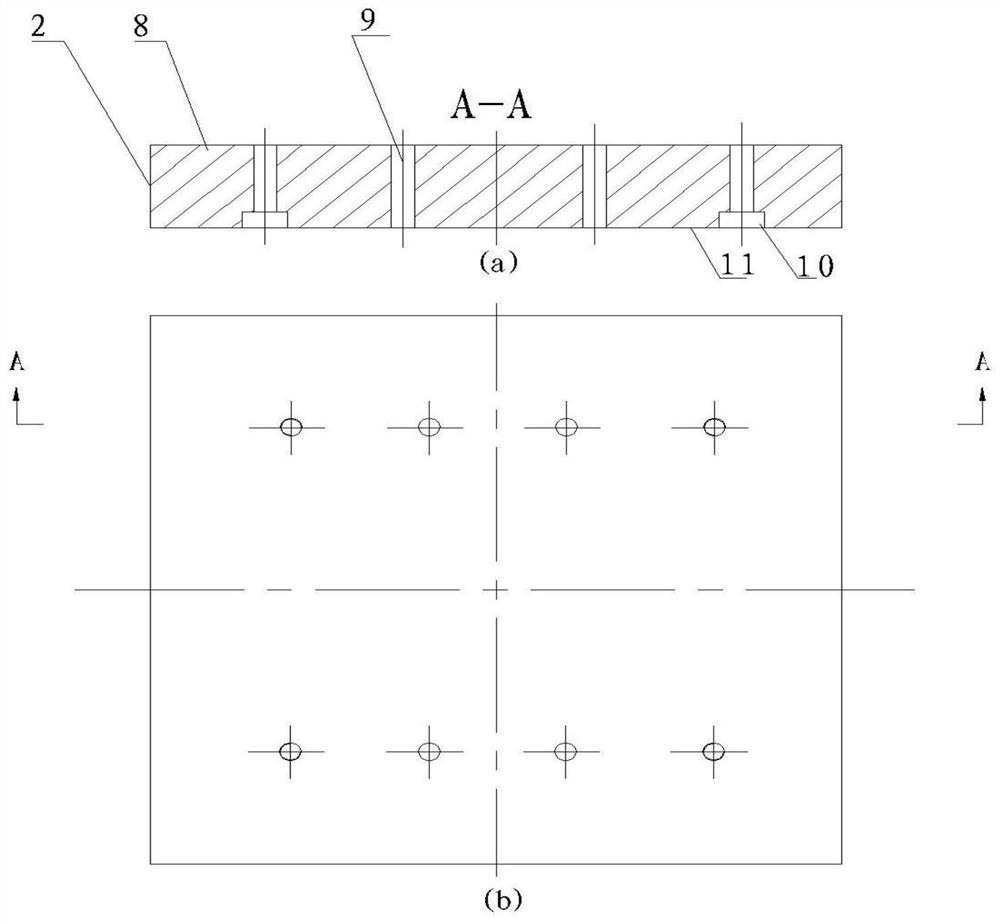

Base part machining method and tool

The invention relates to a base part machining method and clamp. The method comprises the following steps: (1) roughly machining a base part in multiple feeding amounts, and removing large machining allowance; (2) carrying out first vacuum heat treatment; (3) fixing and aligning a machine tool faceplate, and carrying out semi-finishing on the base part in multiple feeding amounts by controlling the rotating speed, the cutting depth and the feeding amount of a machine tool; (4) carrying out second-time deep cooling and heating treatment; (5) carrying out clamping and positioning by adopting a grinding clamp, and then the size requirement for finishing of the base part is met through a grinding machining method; (6) placing the processed base part connected with a gyroscope body on a specialmeasuring tool to measure the size and the position of holes, and judging whether the size and the position of the holes meet technical requirements or not; and (7) if the measurement shows that thetechnical requirements are not met, carrying out finishing on the location degree and the size of the holes connected with a gyro frame, and returning to the step (6) after finishing, and if the measurement shows that the technical requirements are met, turning to the next procedure. According to the method, the machining precision is guaranteed, the pressure damage and deformation of the part areprevented, the machining and measuring efficiency is improved, and the cost is saved.

Owner:云南航天红云机械有限公司

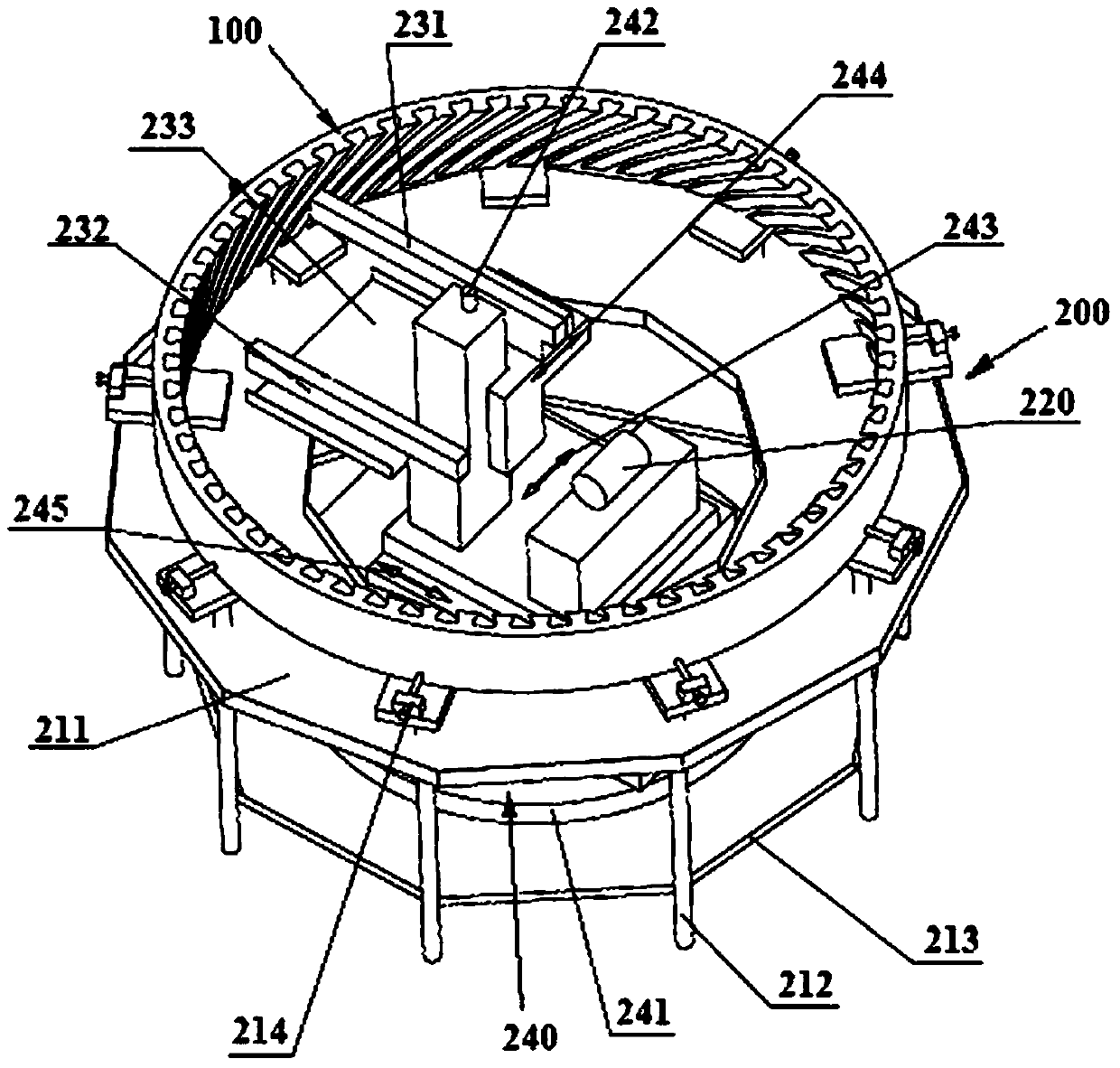

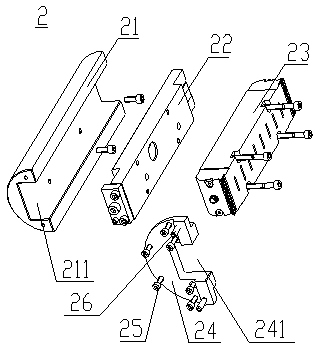

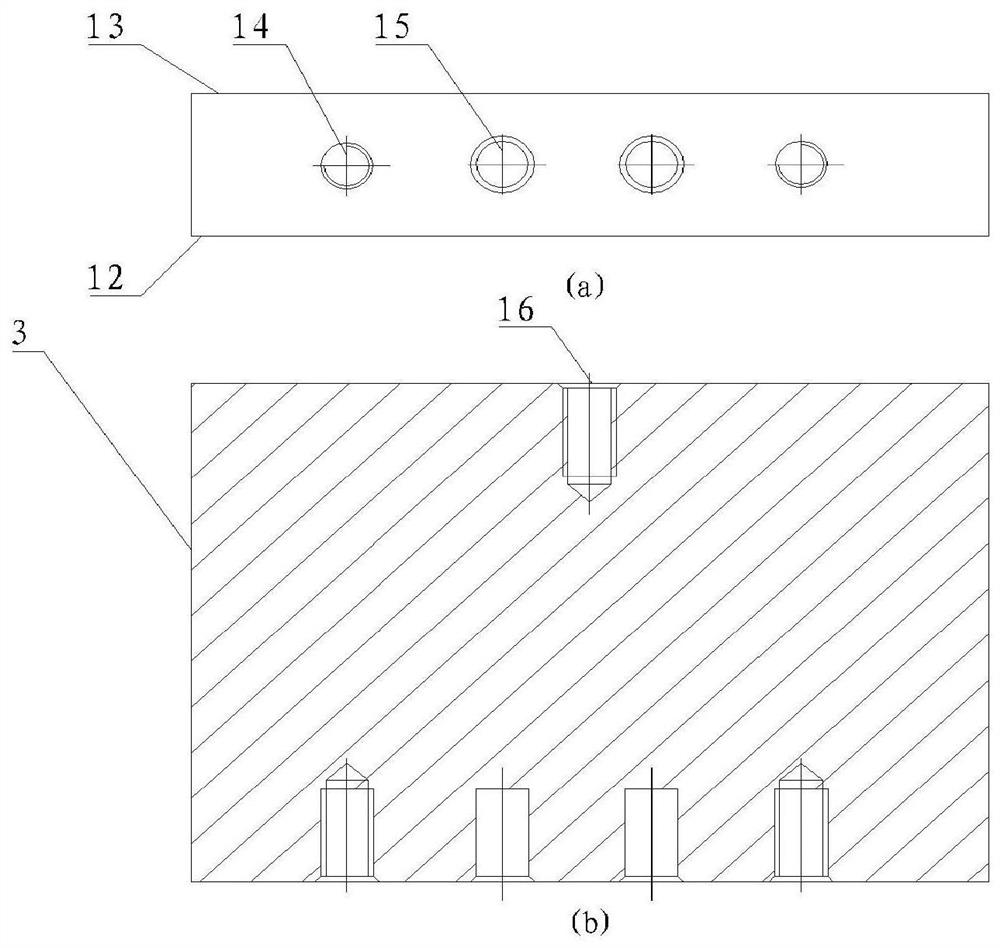

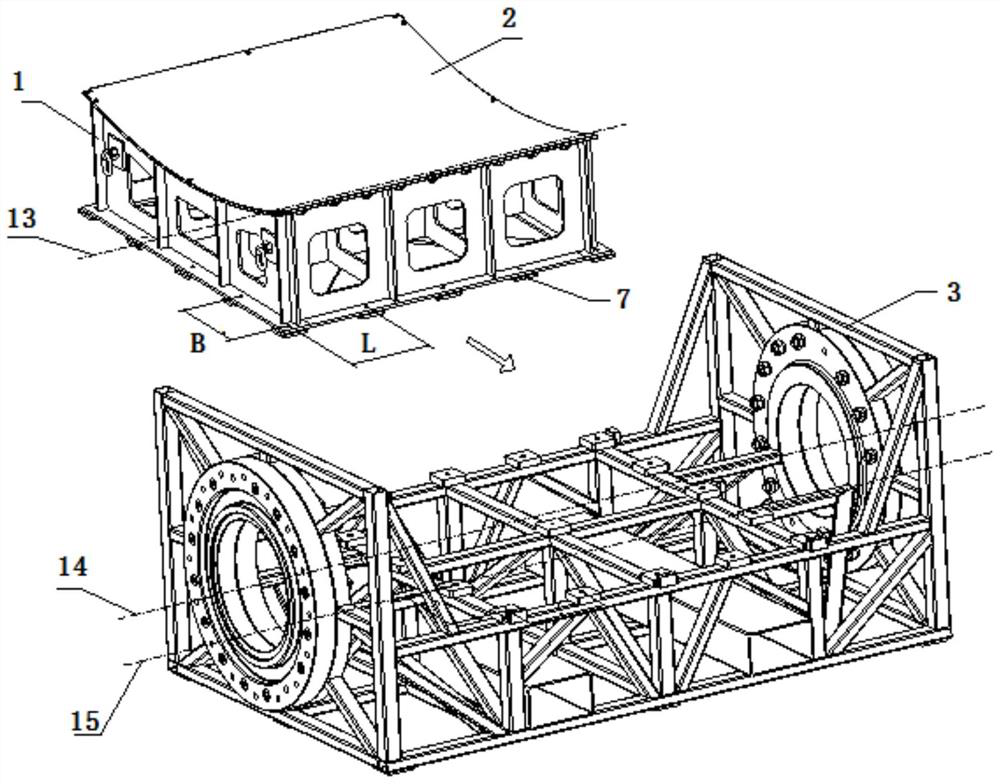

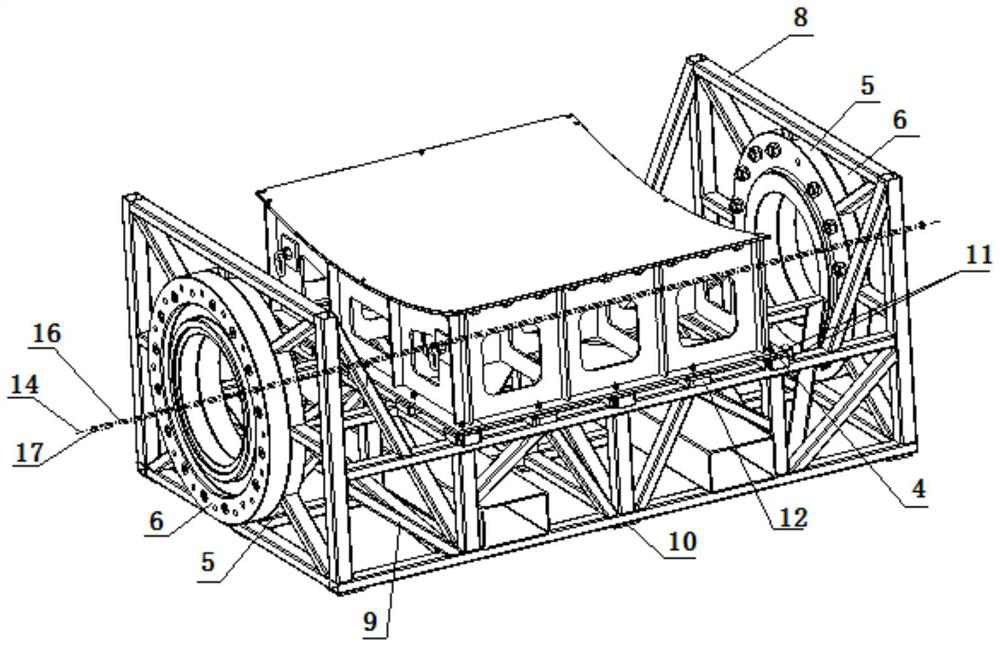

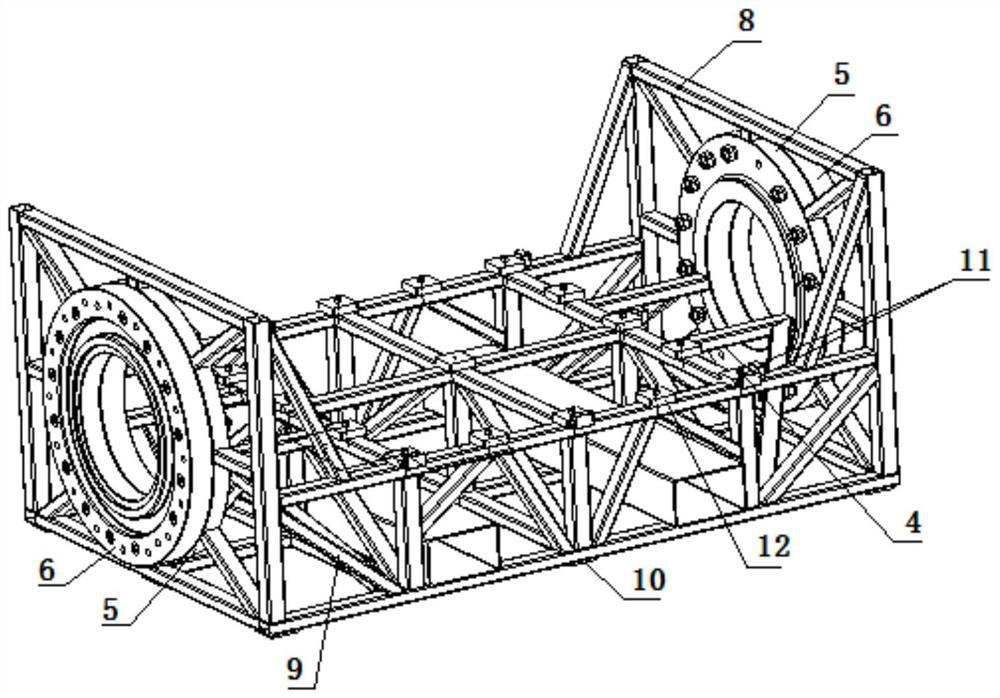

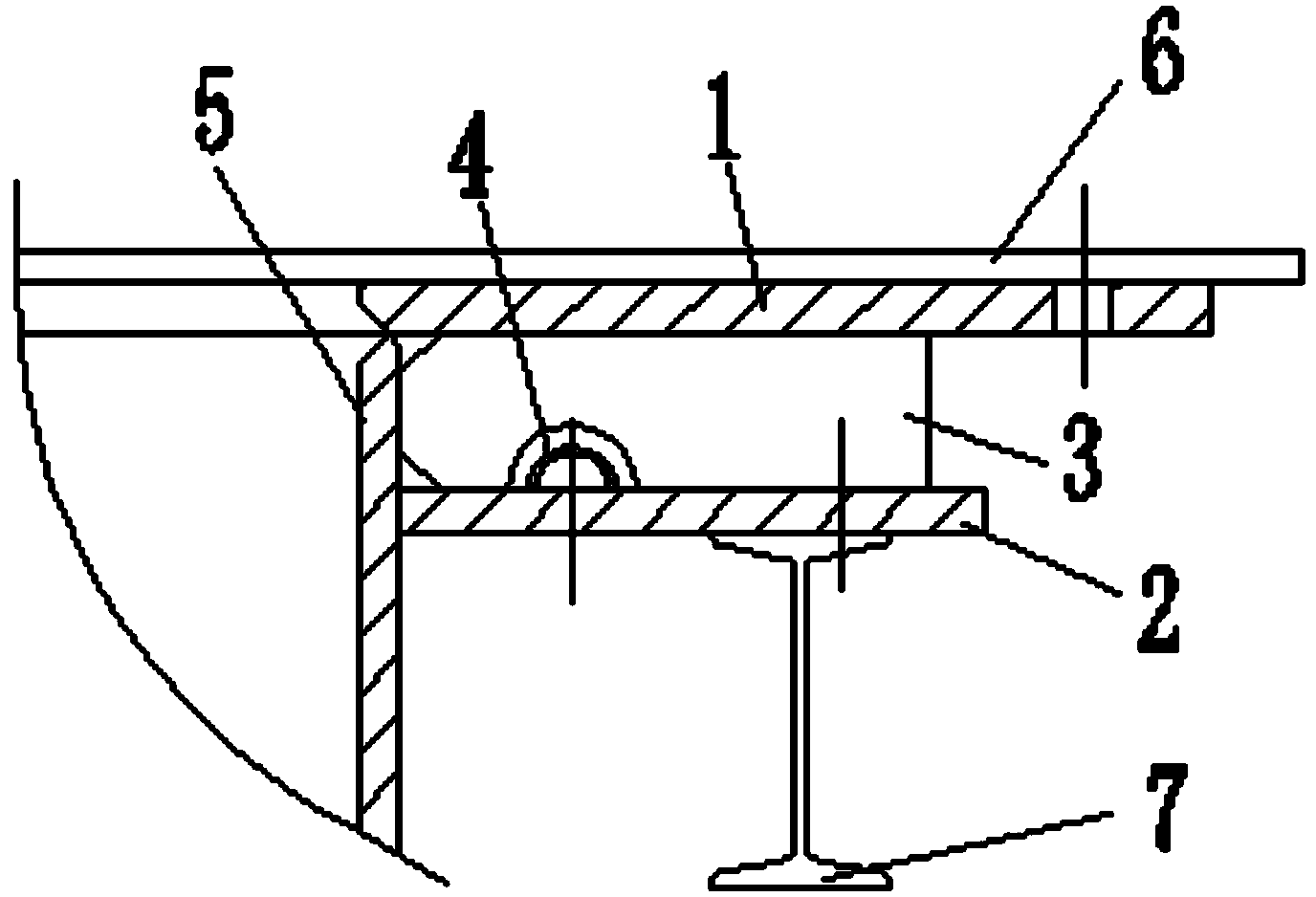

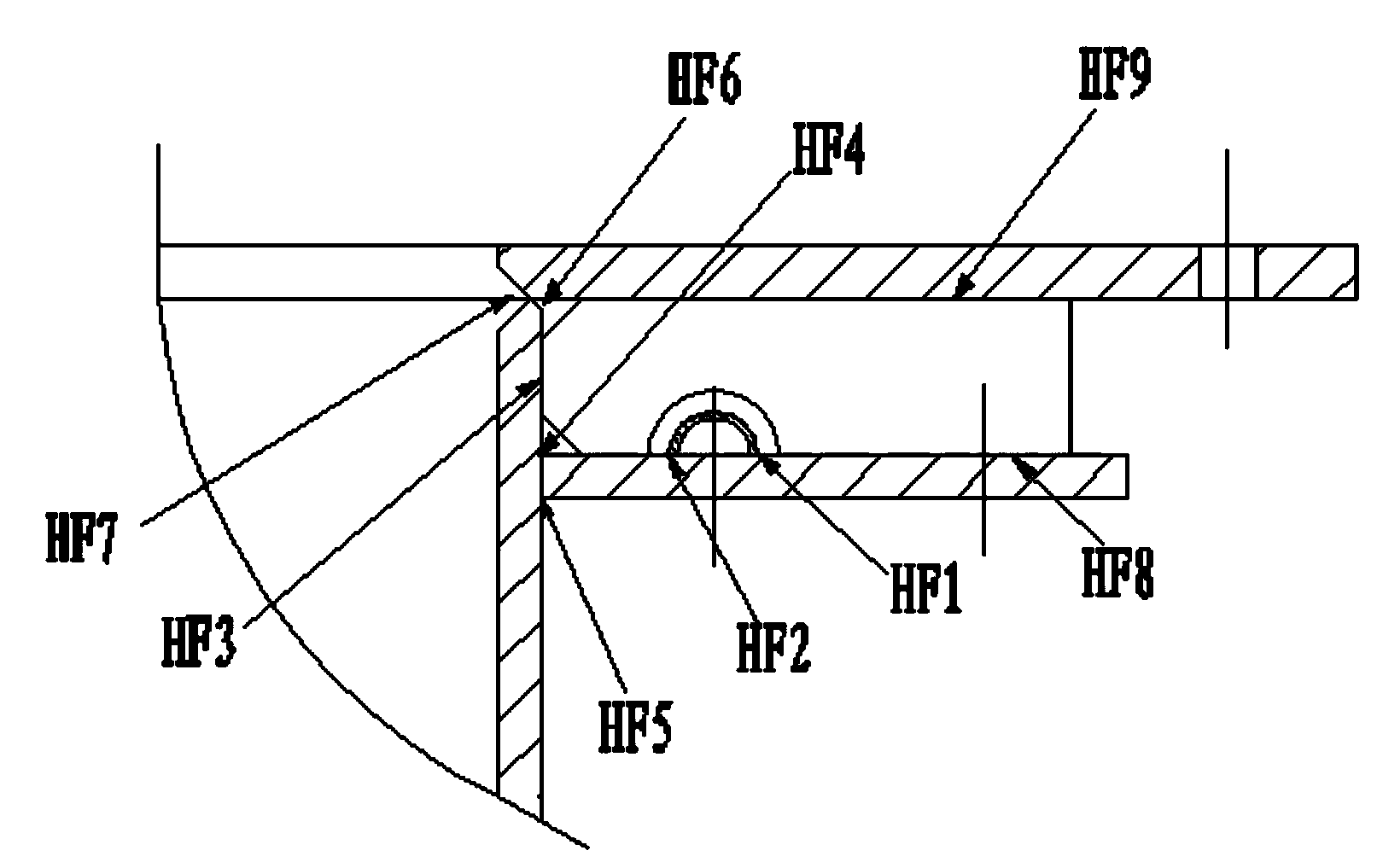

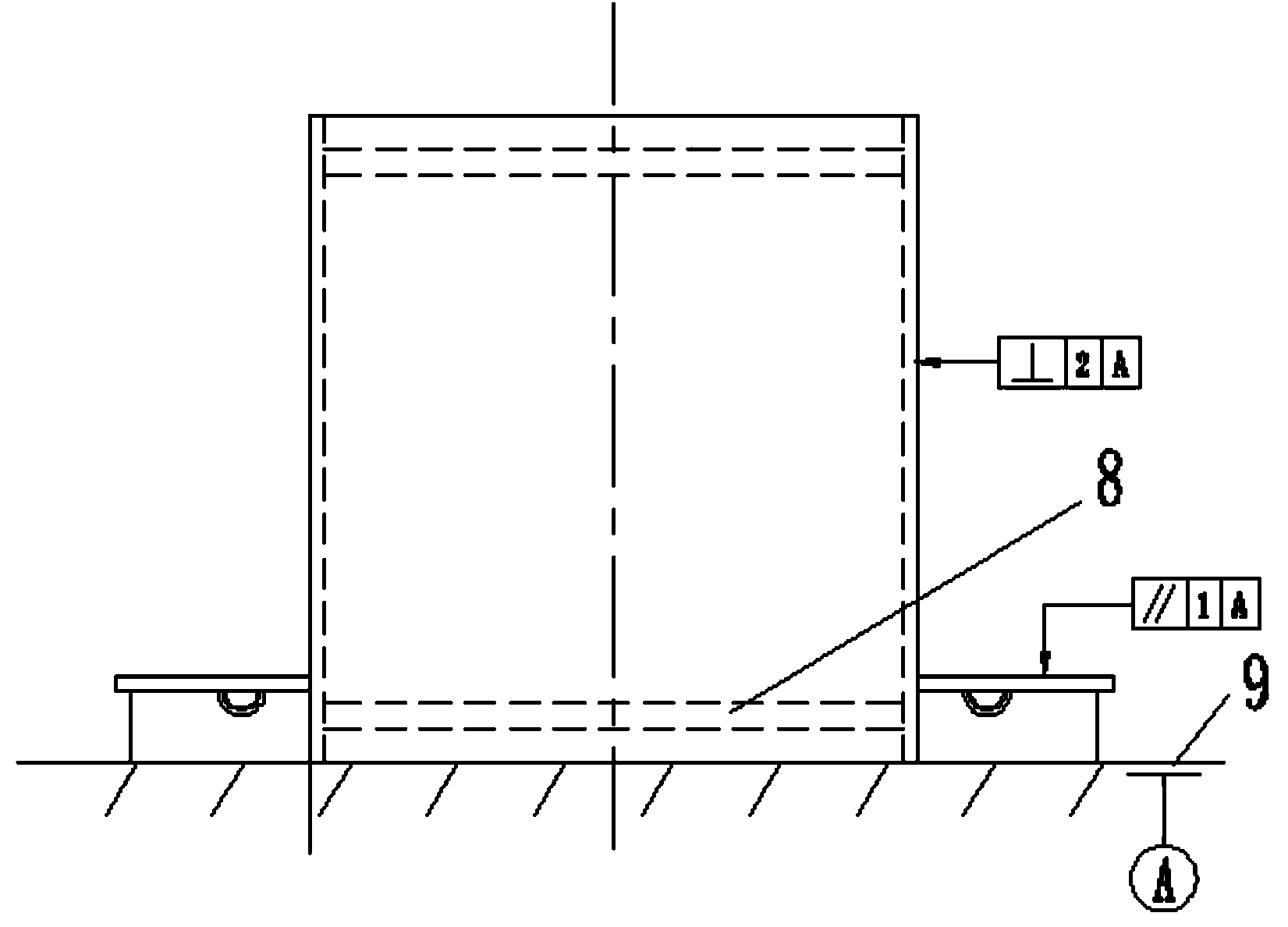

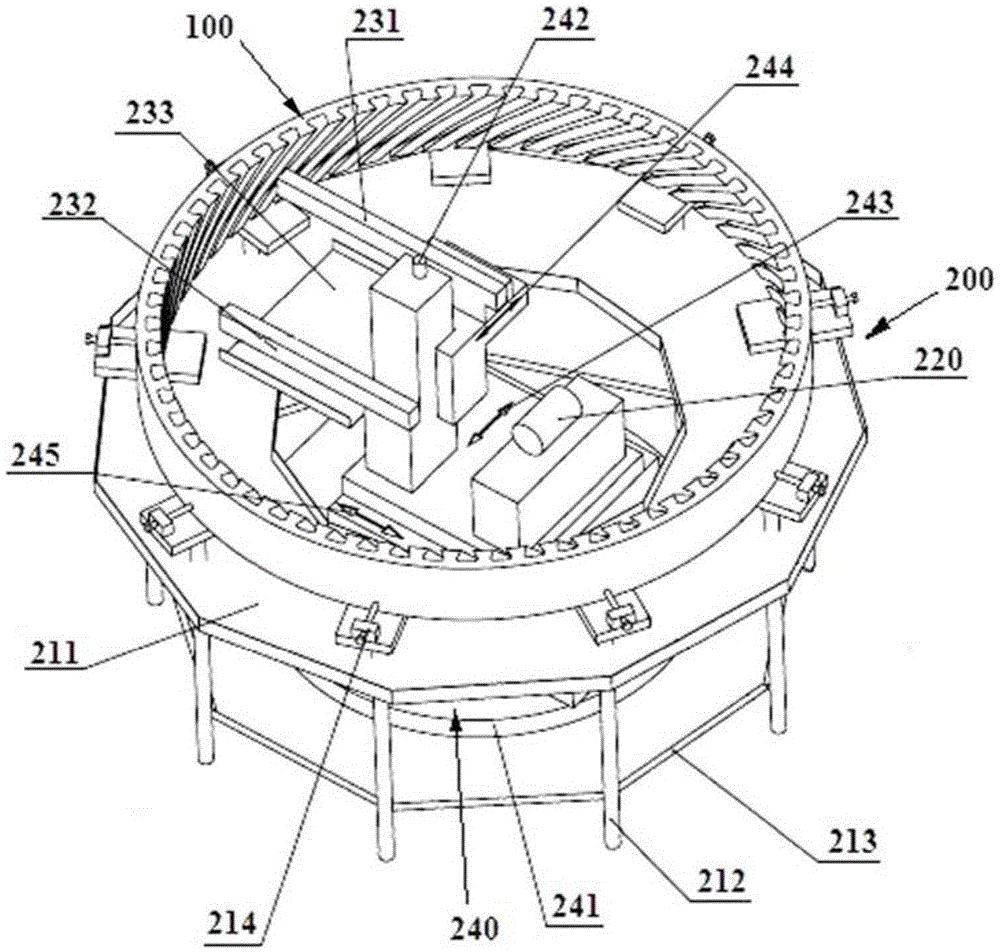

Composite material rotary fiber placement device and use method

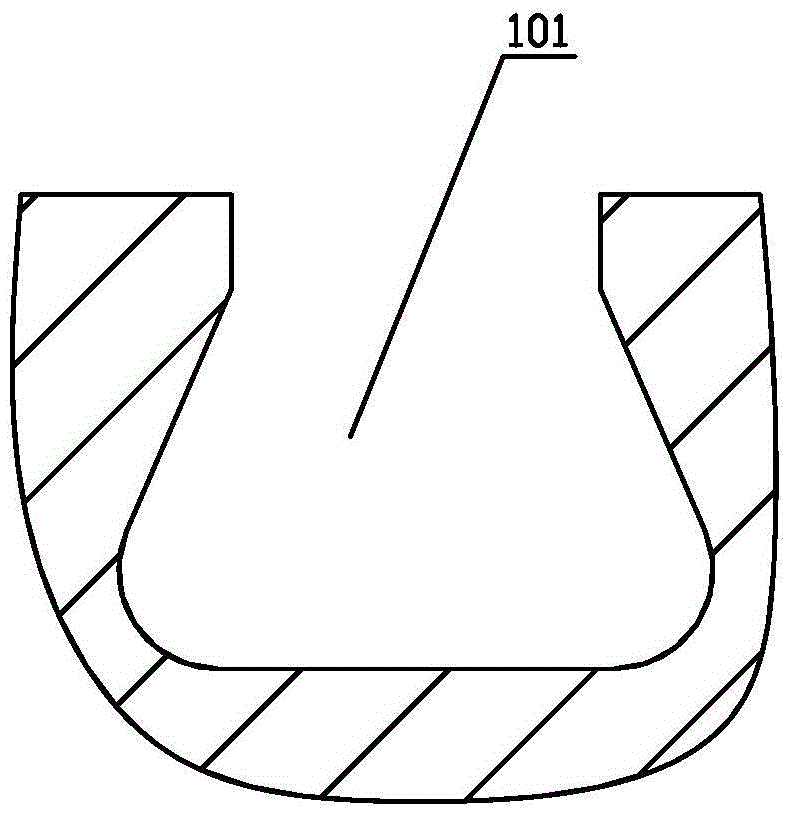

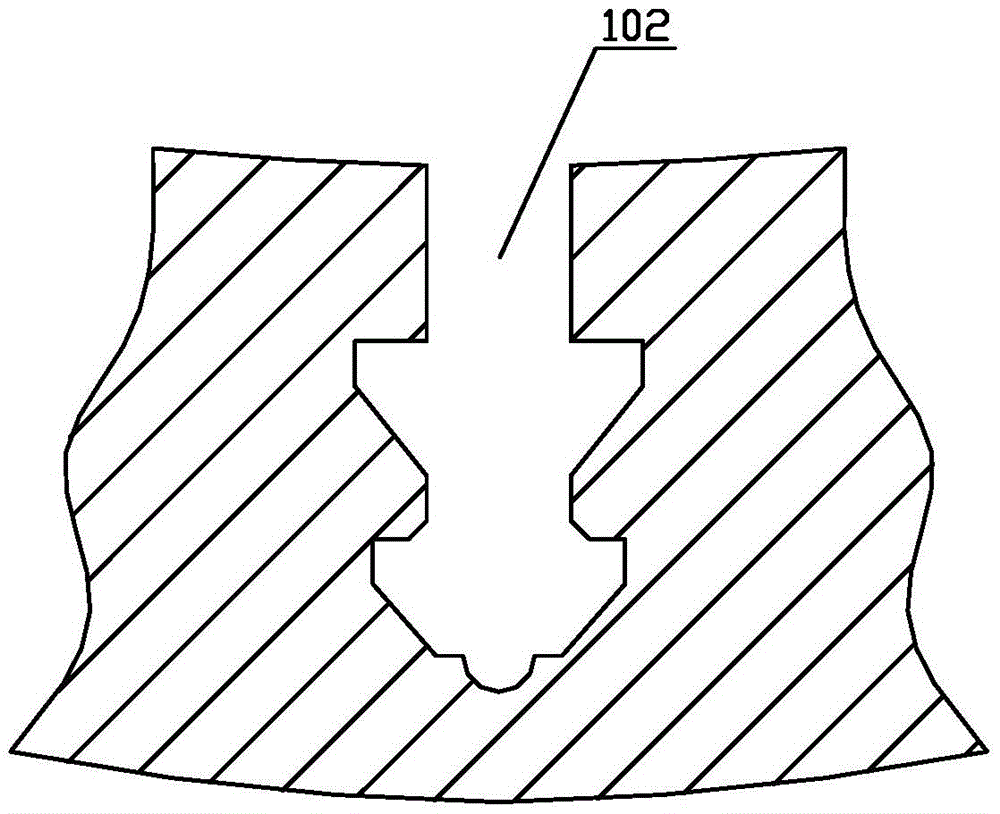

ActiveCN114043749AGuaranteed geometric tolerance requirementsReduce designWeight reductionFiberRotational axis

The invention discloses a composite material rotary fiber placement device and a use method. The composite material rotary fiber placement device comprises a U-shaped bottom frame, adapter flange plates and a flange plates. The two adapter flange plates and the two flange plates are arranged at the two ends of the U-shaped bottom frame respectively. The flange plate is fixedly connected to the outer side of the adapter flange plate; the forming die is mounted on the U-shaped bottom frame to form an integral die; the rotation axis formed by the integral die is overlapped with the central axis of the two flange plates or is within the required maximum tolerance range; the integral die and the five-coordinate fiber placement machine are clamped, a flange plate of the five-coordinate fiber placement machine drives the integral die to ascend, descend and rotate, and rapid and automatic fiber placement of the forming die is achieved. Through adjusting and installing the adapter flange plate, the form and location tolerance requirement of the U-shaped bottom frame is ensured; the assembly requirement of the five-coordinate fiber placement machine is ensured by adjusting the flange plate; the forming dies can be quickly exchanged and installed only by disassembling and assembling the screws; the U-shaped bottom frame has universality, so that more than 50% of rotary wire placement of the non-rotary body forming die is realized; and the production and economic benefits are improved.

Owner:XI'AN AIRCRAFT INTERNATIONAL

A welding process for double-layer flange of muffle pipe

ActiveCN103008844BHigh precision requirementsControl welding deformationArc welding apparatusWorkpiece edge portionsEngineeringWelding deformation

The invention discloses an assembly welding process of a muffle pipe double-layer flange. The strict assembly welding process of an upper flange, a lower flange, a rib plate, a cooling semi-pipe and a muffle pipe tube body is adopted, the welding deformation control key point is fully considered, the form and location tolerance requirements between the muffle pipe and the flanges as well as between the flanges are ensured, the assembly error and the welding deformation of the muffle pipe double-layer flange structure are effectively controlled, the design requirement is reached, and the precision requirement of the muffle pipe is perfectly improved.

Owner:WISDRI WUHAN WIS IND FURNACE

Boring device for cylinder hole of diesel engine stand

InactiveCN101869997BReduce processing costsGuaranteed geometric tolerance requirementsMeasurement/indication equipmentsBoring barsBody positionsMachine tool

The invention discloses a boring device for a cylinder hole of a diesel engine stand, which comprises a boring rod transmission mechanism, a boring rod mechanism and a cutter body mechanism, wherein the boring rod transmission mechanism is arranged on one end of a boring rod and comprises a worm gear, a worm, a worm gear case, a pair of supporting bearings, a positioning frame and a positioning seat; the worm gear is fixedly connected with the end of the boring rod; two sides of the worm gear are supported in one end of the worm gear case through the pair of supporting bearings and a retainerring; the worm is arranged at one side of the worm gear; one end of the boring rod is supported in the other end of the worm gear case through a sliding bearing, and the other end of the boring rod is supported on a machine working table through a conical roller bearing and the positioning seat; the cutter body mechanism can axially move along the boring rod; and a screw rod transmission mechanism and a cutter body position measuring mechanism are also arranged in the boring rod. The invention can enable the cutter body mechanism to automatically and stably feed on the boring rod at constant speed to complete the boring of the cylinder hole, enables the cylinder hole of the diesel engine stand subjected to primary processing to meet the requirements on dimensional tolerance and perpendicularity tolerance of the cylinder hole, and can also measure the boring depth.

Owner:CSSC MARINE POWER

A clamping tool and a method for argon tungsten arc welding using the tool

ActiveCN107470845BPrevent oxidationEasy card positioningWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneAverage current

The invention relates to a mounting and clamping tool and a method for argon tungsten-arc welding by use of the mounting and clamping tool. The method ensures small deformation of pipeline welding and belongs to the technical field of welding processes. A spot welding, circumferential welding and follow-up heat treatment universal integrated tool is designed according to products with different external diameters, mounting, clamping and positioning can be conveniently performed, and meanwhile, surface oxidation of a weld joint, repeated mounting and clamping of the tool, and product deformation are avoided during processing. In the method, 2-4 point equipartition is performed on spot welding parameters through welding programming for symmetric programming; and the circumferential welding process comprises repeated subsection, current from the first section to the last section is in the mode of waveform current, and the average current adopts an inclined mode. Through the programming method, the depth of fusion can be well controlled by the programming method, heat input is reduced to the minimum degree on the premise of guaranteeing the welding depth, the uniformity of the fusion depth is realized, and the ranges of surface oxidation and a heat affected zone are reduced to the utmost extent.

Owner:BEIJING INST OF CONTROL ENG

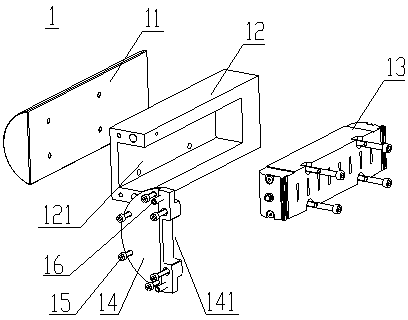

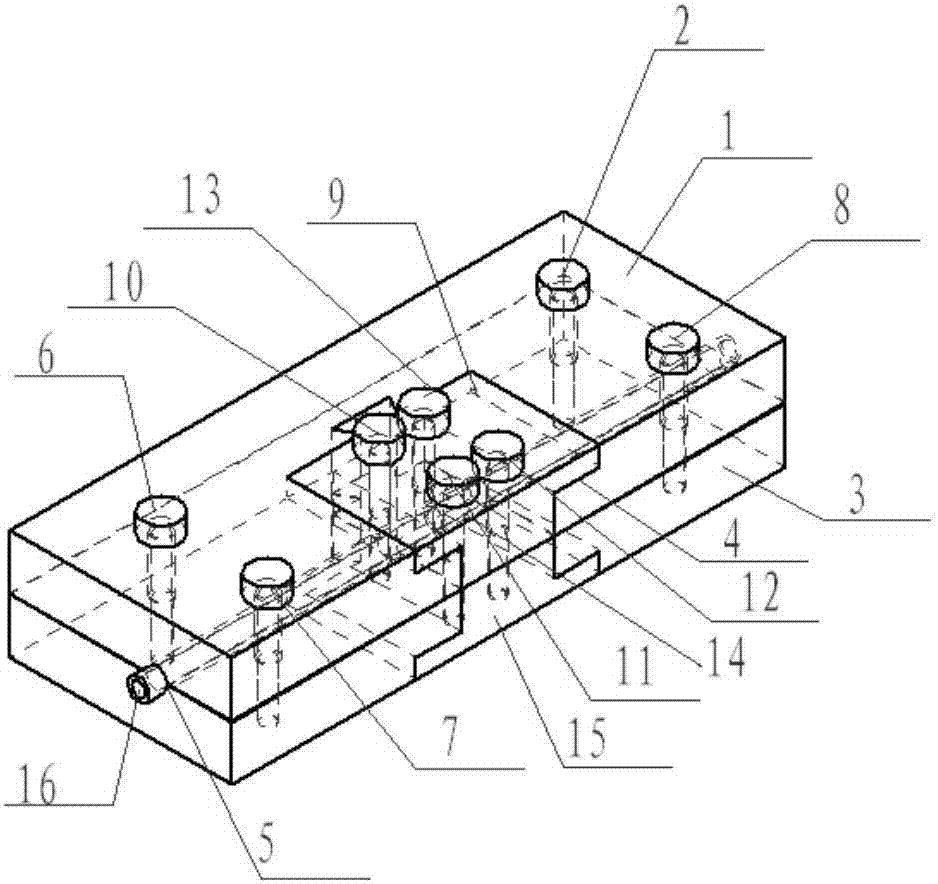

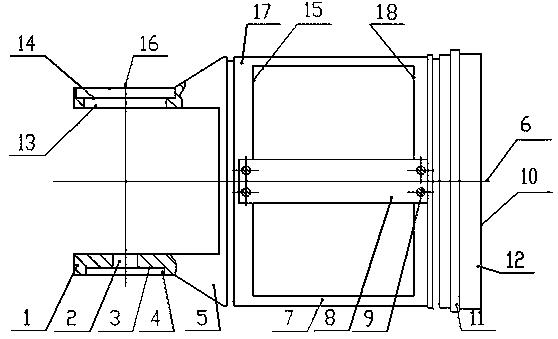

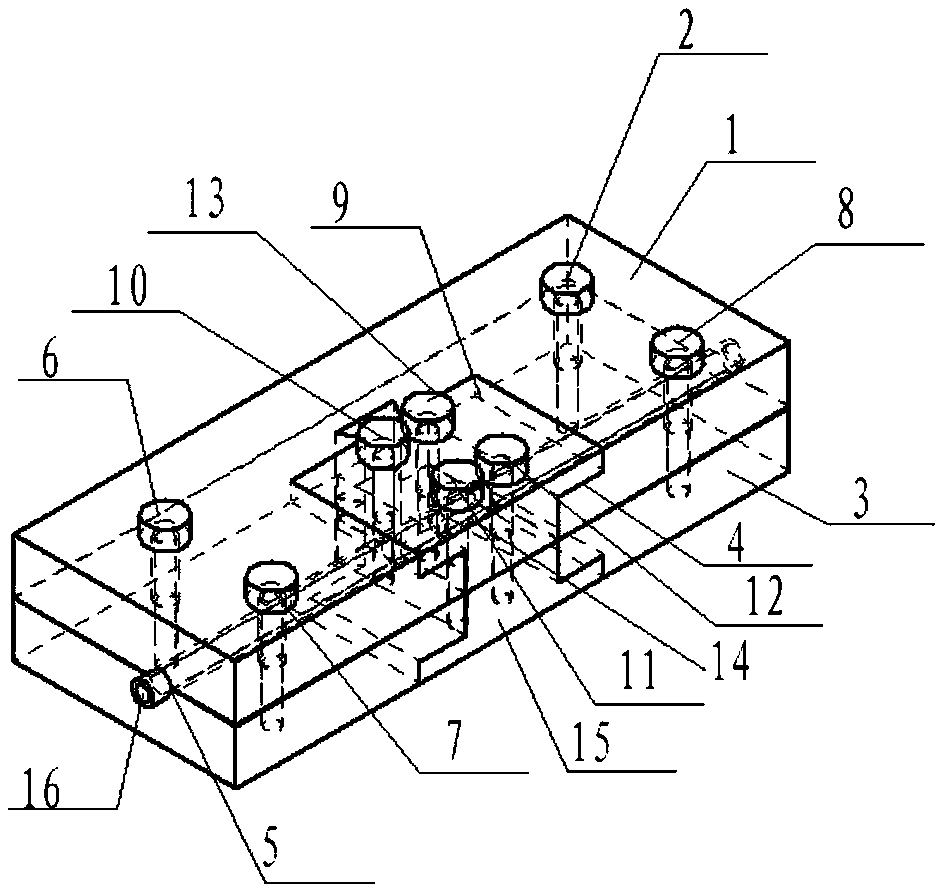

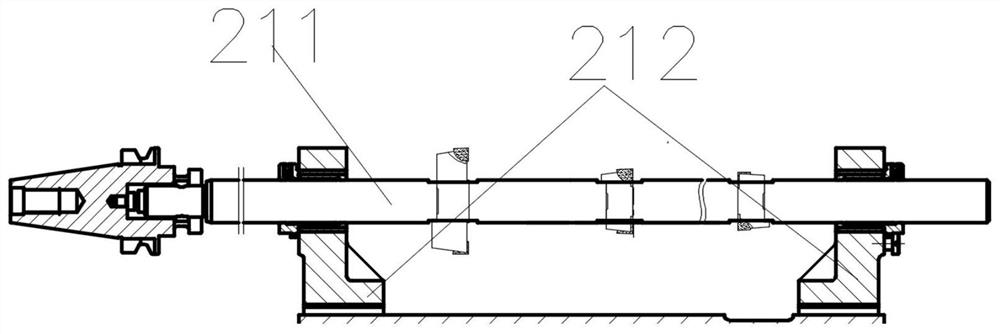

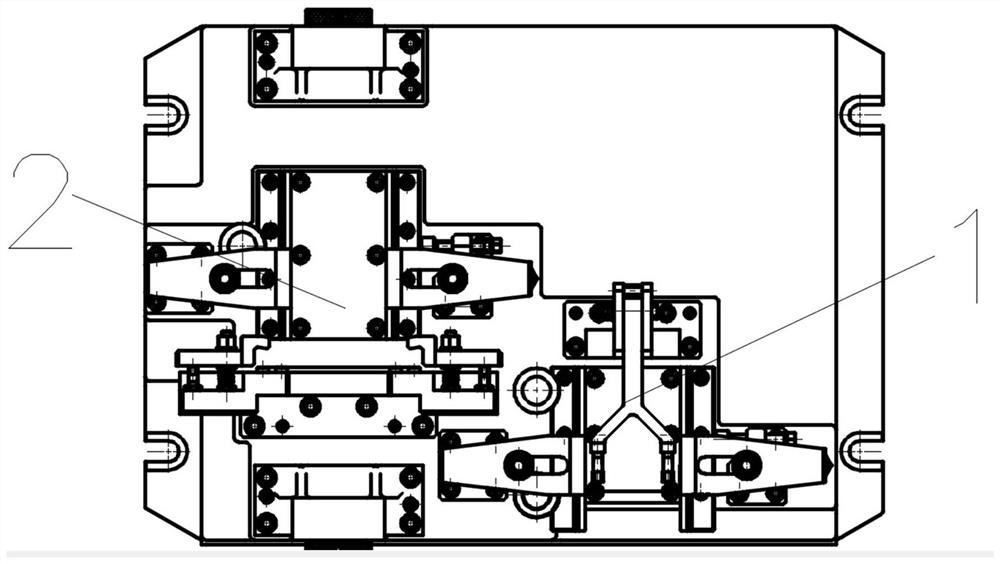

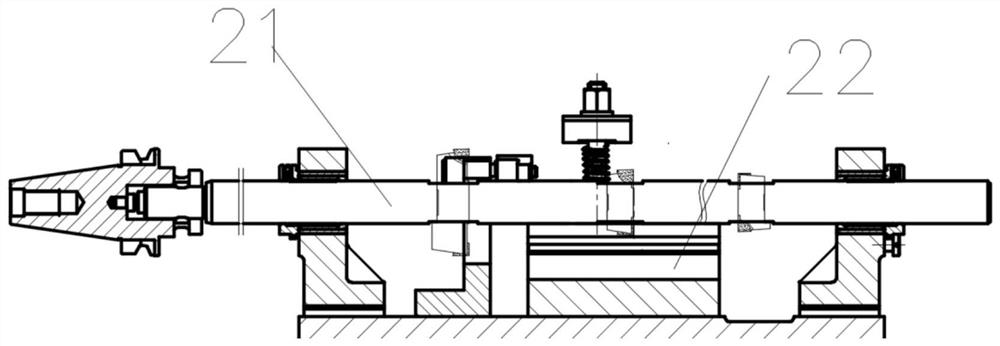

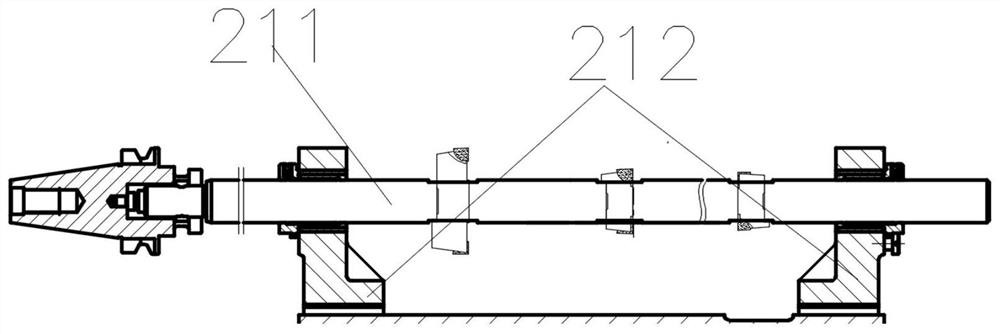

A method of using a motor seat tooling

ActiveCN112207310BImprove stabilityGuaranteed geometric tolerance requirementsOther manufacturing equipments/toolsPositioning apparatusBlade plateElectric machinery

The invention discloses a motor seat tooling and a method of using the same. A motor seat tooling is characterized in that it includes a rough machining tool and a fine machining tool, and the rough machining tool and the fine machining tool are arranged on the same horizontal axis on the frame, and the fine machining tool has the same horizontal axis. The processing tool includes a boring part and a tooling part, the boring part and the tooling part are respectively arranged on the upper end of the frame, the tooling part is arranged inside the boring part, the boring part includes a boring tool and a bracket, and the boring tool is arranged on the bracket; The finishing process is separated, and the rotary cutting of the workpiece should be changed to a fixed cutting mode. The original turning sequence is changed to the boring sequence machining process mode, but instead of the single-tool feed of the boring tool, it is changed to the semi-fine boring and fine boring machining mode with double-supported toolholders and forming blade plates, and one pass is completed for one job. Step processing to improve the original processing route.

Owner:福建省威诺数控有限公司

Motor base tool and using method thereof

ActiveCN112207310AImprove stabilityGuaranteed geometric tolerance requirementsOther manufacturing equipments/toolsPositioning apparatusBlade plateElectric machinery

The invention discloses a motor base tool and a using method thereof. The motor base tool is characterized by comprising a rough machining tool and a fine machining tool, wherein the rough machining tool and the fine machining tool are arranged on a frame and are provided with same horizontal axes; the fine machining tool comprises a boring part and a tool part; the boring part and the tool part are arranged at the upper end of the frame respectively; the tool part is arranged on the inner side of the boring part; the boring part comprises a boring cutter and a support frame; and the boring cutter is arranged on the support frame. Rough machining and fine machining processes are separated; a rotary cutting mode of a workpiece is changed into a fixed cutting mode; the original turning process is changed into a boring machining process mode; the single-cutter feeding of the boring cutter is not needed; the processing mode is changed into a semi-fine boring and fine boring machining modewhich is carried out by double support cutter rods and forming cutter plates; and the original machining process route is improved by completing machining of one process step through one-time cutter feeding.

Owner:福建省威诺数控有限公司

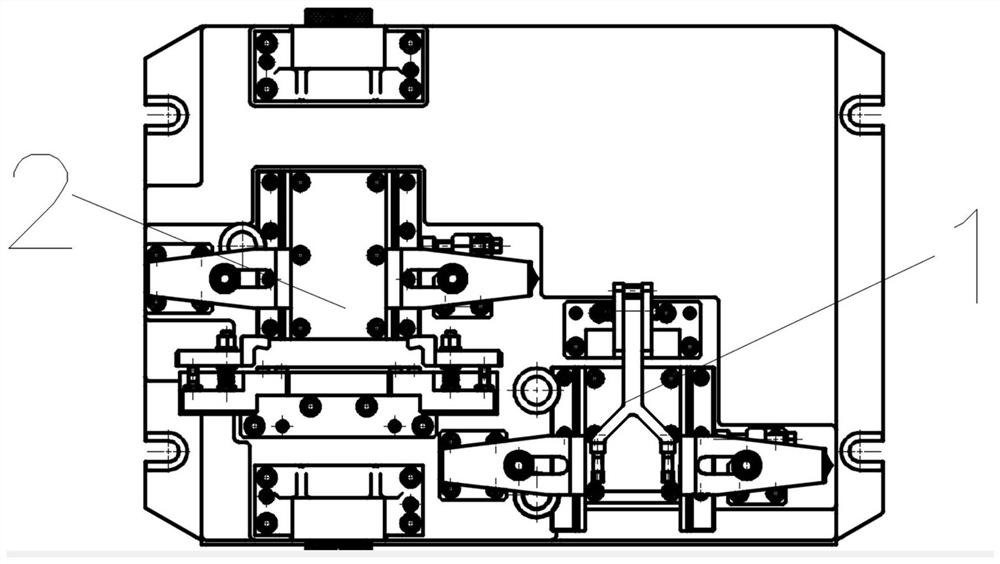

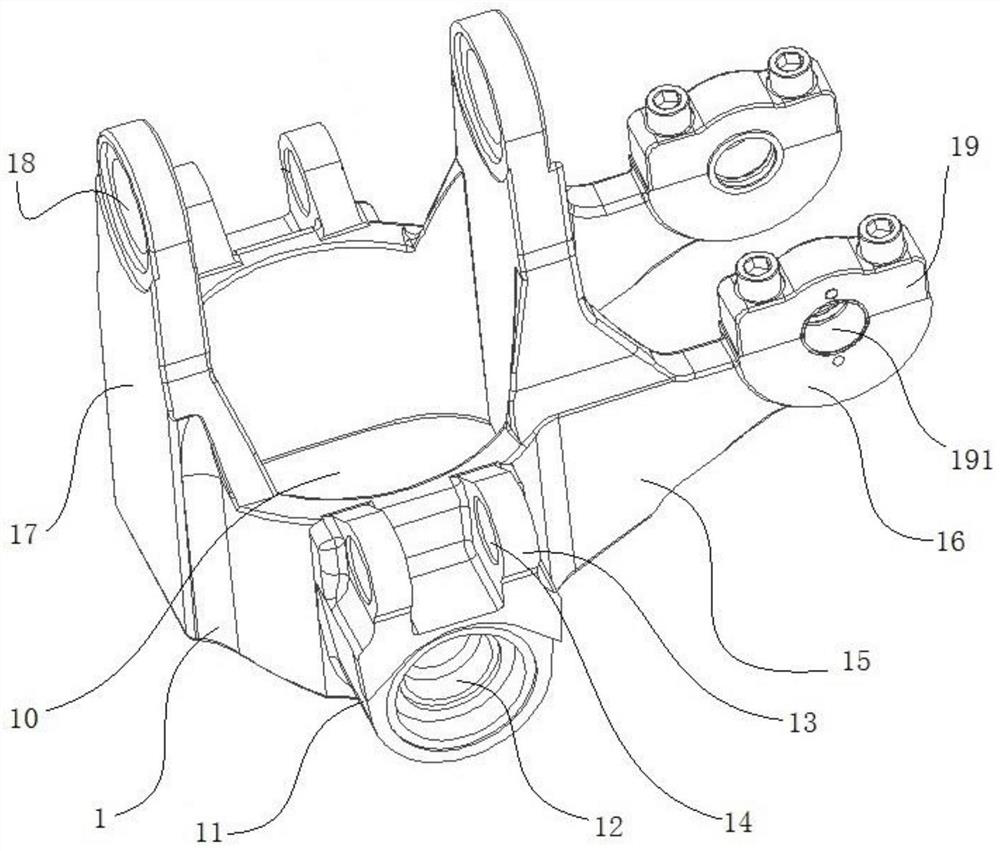

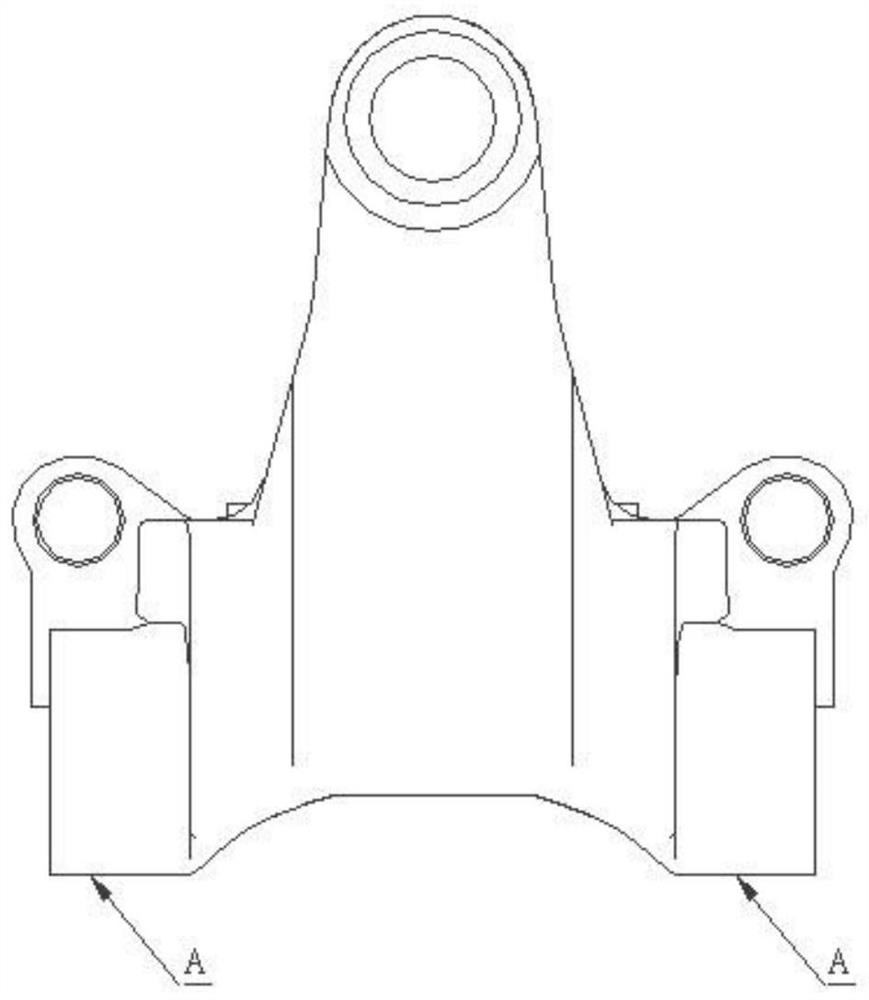

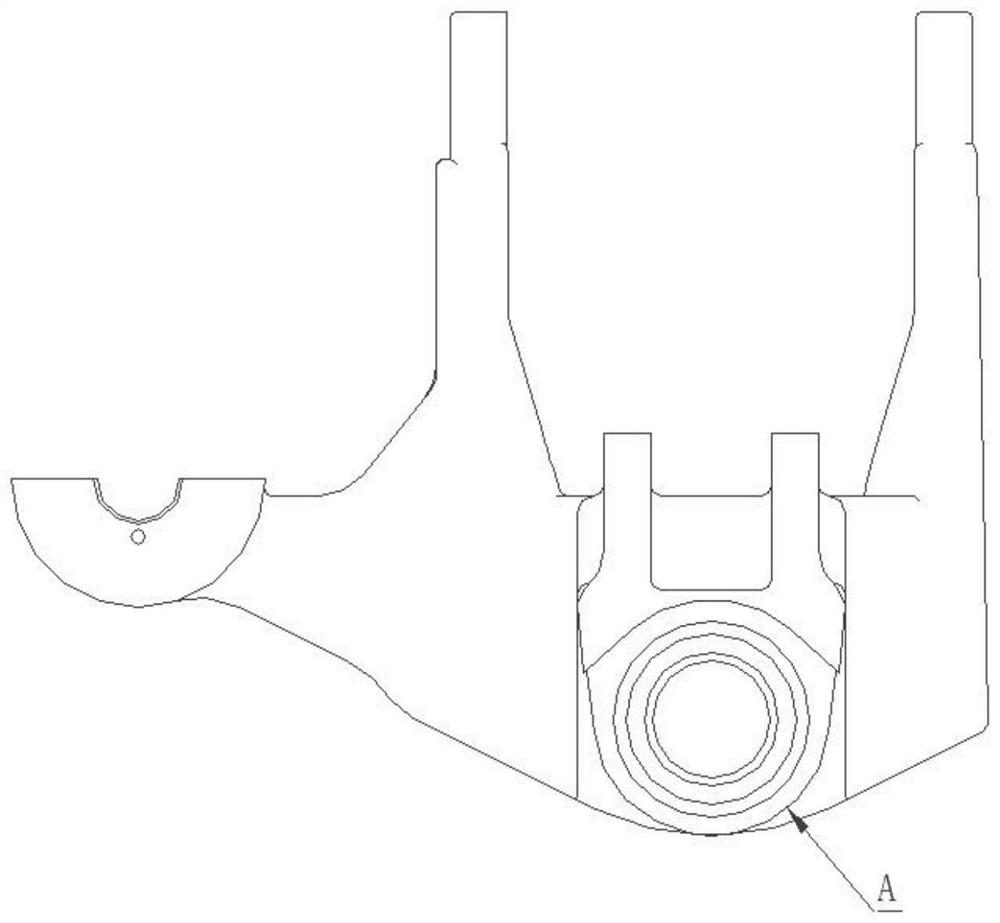

Machining method of front connecting seat of five-degree-of-freedom steering mechanism and front connecting seat

The invention discloses a machining method of a front connecting seat of a five-degree-of-freedom steering mechanism and the front connecting seat. The machining method comprises the two steps of S1, lineation positioning; and S2, machining and forming, wherein a positioning clamp is used for clamping and positioning. The front connecting seat comprises a connecting seat body, a first cantilever, an extending cantilever, a second cantilever, a third cantilever, a cover seat and a cover. The positioning clamp is used for one-time clamping, the situation that the cantilever state happens the front connecting seat in the machining process is avoided, the problem that due to the cantilevers, the strength is insufficient, vibration is generated, and deformation is caused or precision cannot be guaranteed is solved, the requirements for form and location tolerance and dimensional accuracy of machined parts are guaranteed, due to contact type limiting, no stress is released when a locking clamp is dismounted, and parts cannot deform.

Owner:GUIZHOU JONYANG KINETICS

Processing method of gas turbine compressor stator ring

ActiveCN103801912BImprove machining accuracySmall thermal deformationNumerical controlGas compressor

The invention provides a method for machining a gas compressor fixed blade ring of a gas turbine. The method comprises the steps that a fixed blade ring blank is placed on a permanent magnetic chuck workbench of a machine tool, and clamped by the permanent magnetic chuck workbench, and the outer circumferential surface, the annular inner conical surface and the upper end face of the fixed blade ring are turned at a time; the bottom plane is machined; the turned fixed blade ring blank is placed on a working platform of a five-axis numerical control wire cutting machine, the cutting inclination of the five-axis numerical control wire cutting machine ranges from 0 degree to 60 degrees, and is adjustable, and the axis of the fixed blade ring blank coincides with the axis of a rotary platform of the five-axis numerical control wire cutting machine; the cut portion of a wire electrode of the five-axis numerical control wire cutting machine is made to be opposite to a molded line inclined groove in the annular inner conical surface in position by adjusting the rotary platform on a machine tool body, the inclination angle of the cut portion of the wire electrode is equal to the inclination angle of the molded line inclined groove, and the molded line inclined groove is machined; the rotary platform on the machine tool body is adjusted repeatedly, and machining of all the molded line inclined grooves is accomplished. According to the method for machining the gas compressor fixed blade ring of the gas turbine, the machining cost is low, the machining speed is high, the degree of thermal deformation is low, machining stability is good, and machining precision is high.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com