A method of using a motor seat tooling

A motor seat and tooling technology, applied in manufacturing tools, positioning devices, metal processing equipment, etc., can solve the problems of excessive cylindricity, excessive verticality between the motor handle and the positioning stop, etc., to increase stability, The effect of saving tool wear and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

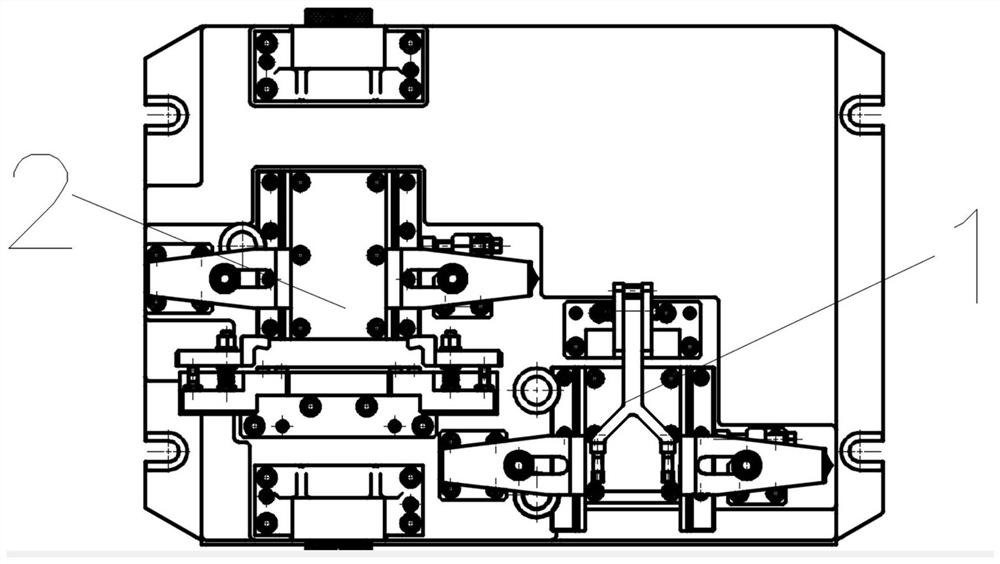

[0047] like figure 1 As shown, a motor seat tooling includes a rough machining tool 1 and a fine machining tool 2, and the rough machining tool 1 and the fine machining tool 2 are arranged on the frame with the same horizontal axes.

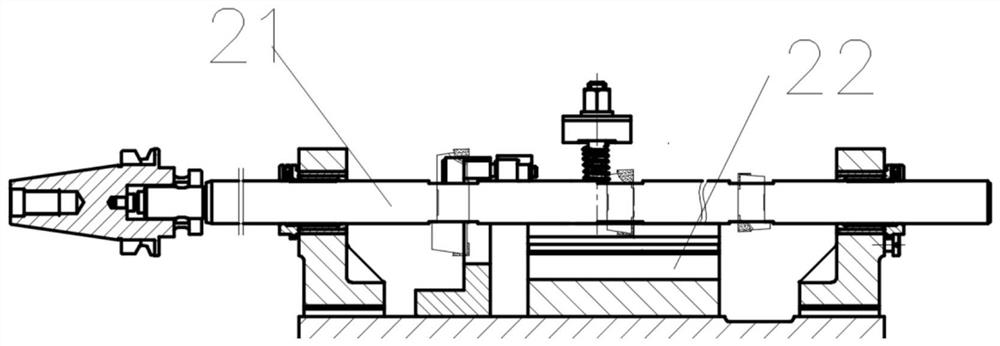

[0048] like figure 2 As shown, the fine machining tool 2 includes a boring part 21 and a tooling part 22 , the boring part 21 and the tooling part 22 are respectively arranged on the upper end of the frame, and the tooling part 22 is arranged inside the boring part 21 .

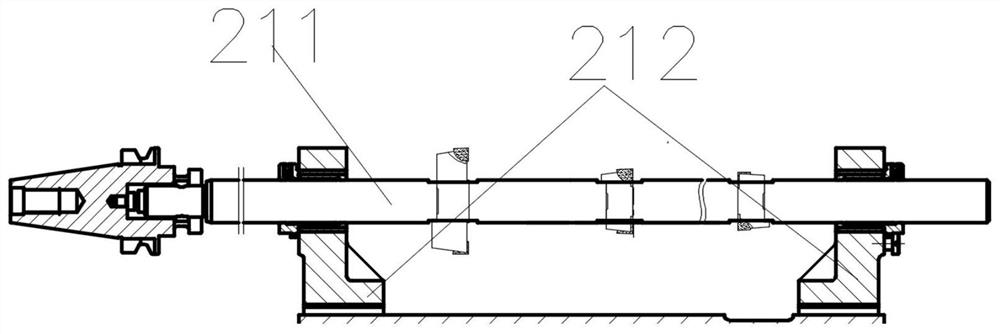

[0049] like image 3 As shown, the boring part 21 includes a boring tool 211 and a bracket 212 , and the boring tool 211 is arranged on the bracket 212 .

[0050] like Figure 4 As shown, the boring tool 211 includes a special handle 2111, a tool shank 2112 and at least one boring plate 2113. The special handle 2111 is arranged on one end of the tool shank 2112, and the boring tool plate 2113 is arranged in the middle of the tool shank 2112. The upper half of the handle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com