Patents

Literature

310 results about "Motor processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

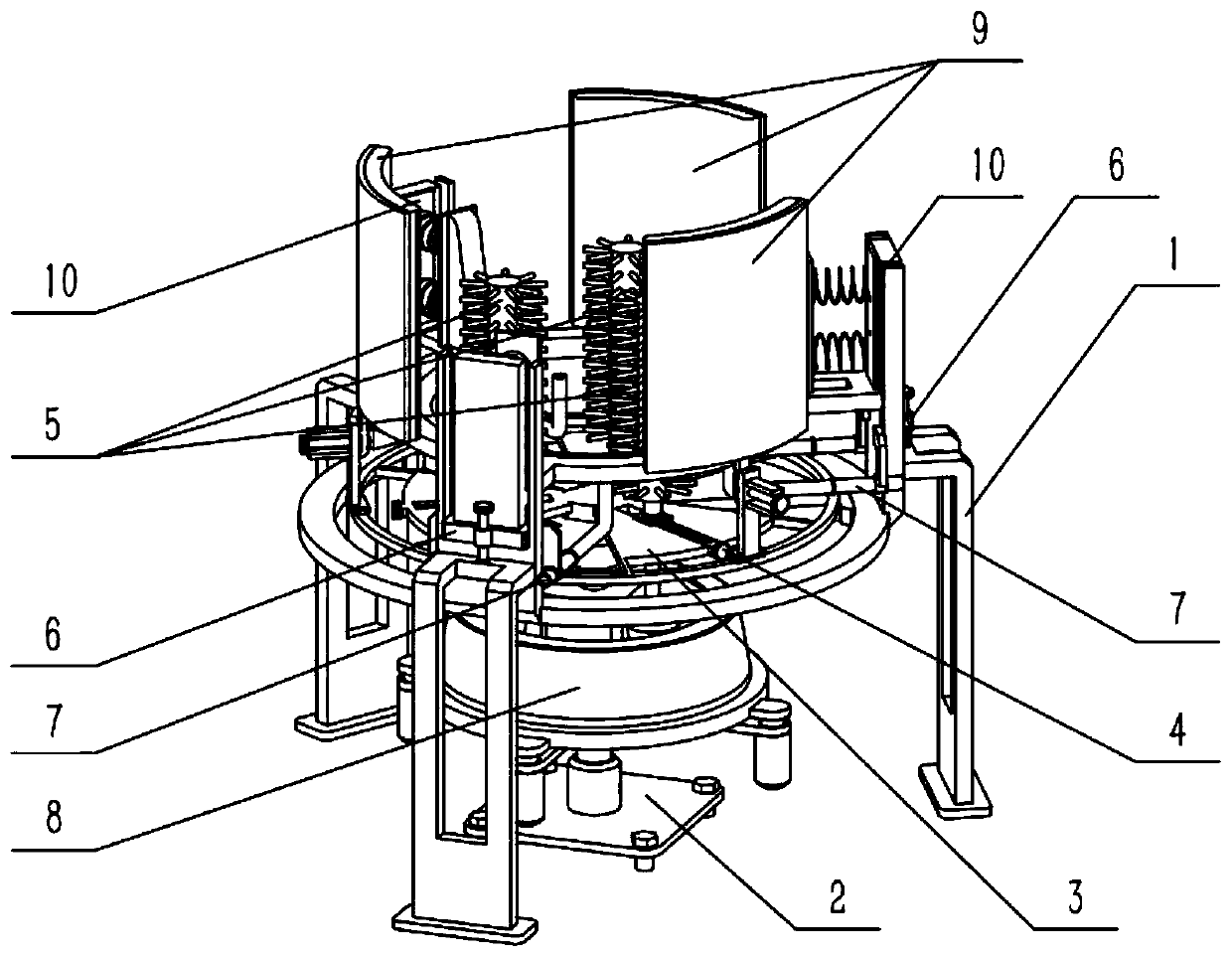

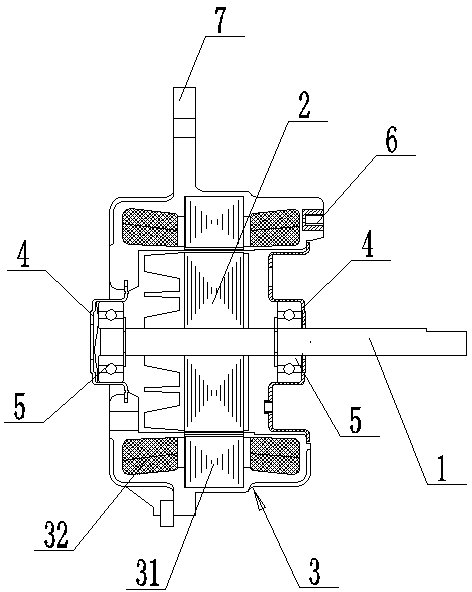

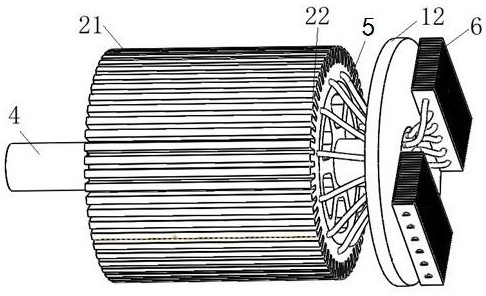

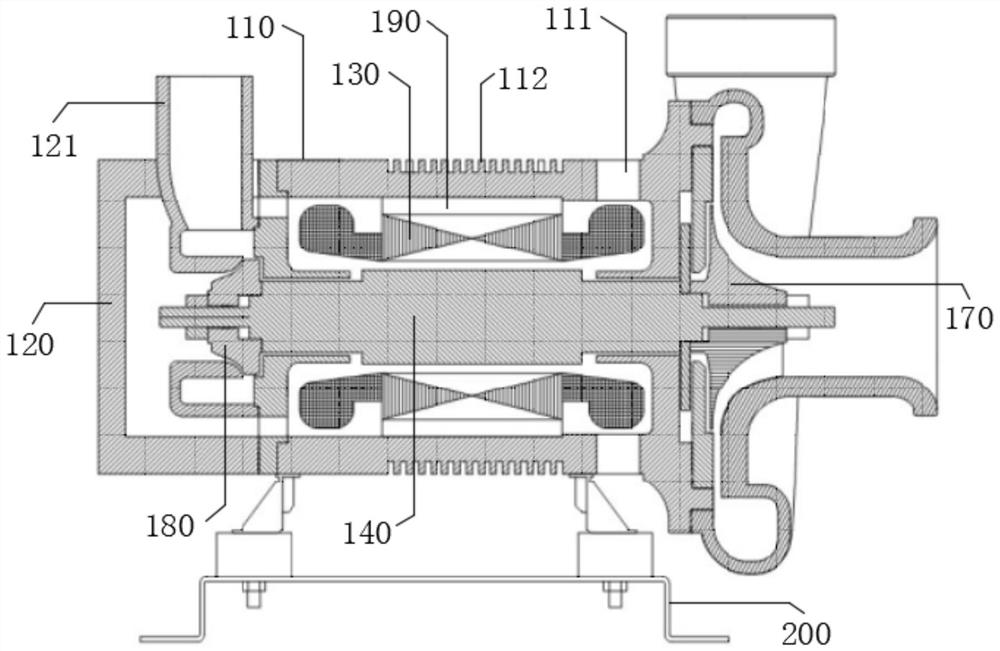

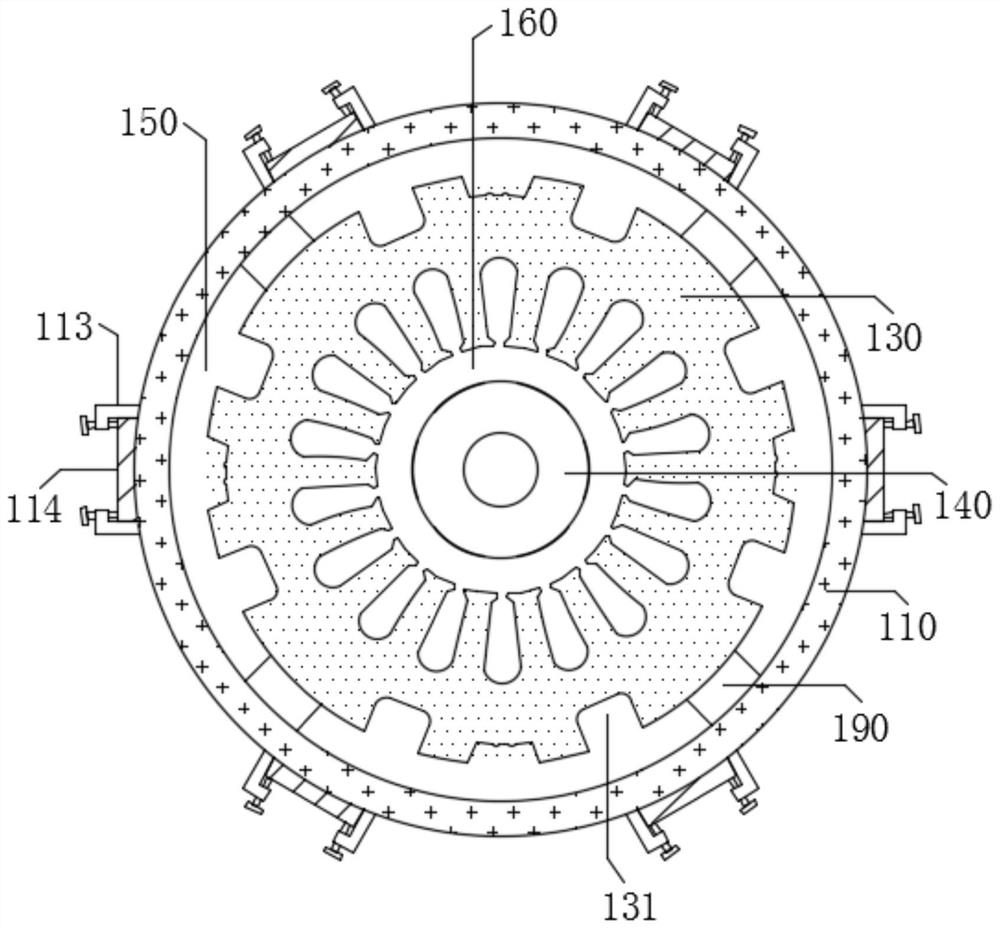

Motor with separated permanent magnet torque and reluctance torque and its optimal efficiency control

ActiveUS20180323665A1Reduce processing difficultyGreater reluctance torqueElectronic commutation motor controlAC motor controlSurface mountingReluctance motor

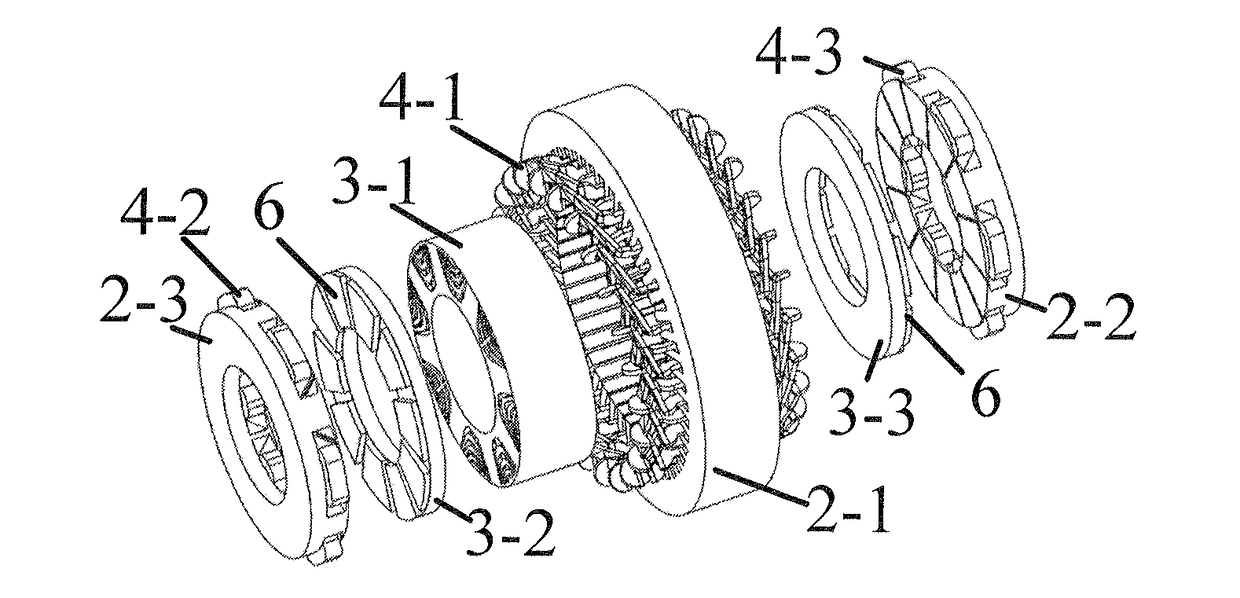

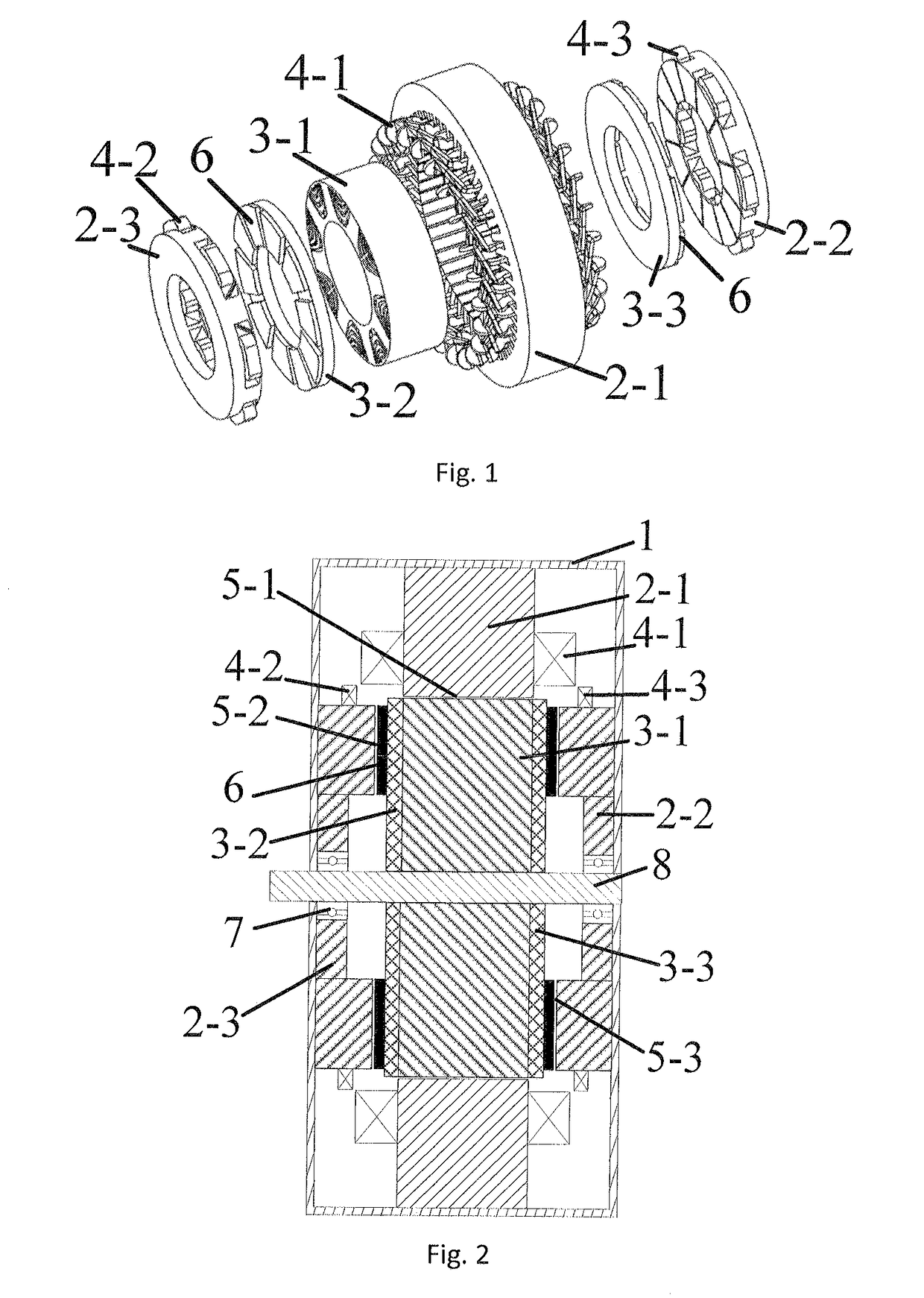

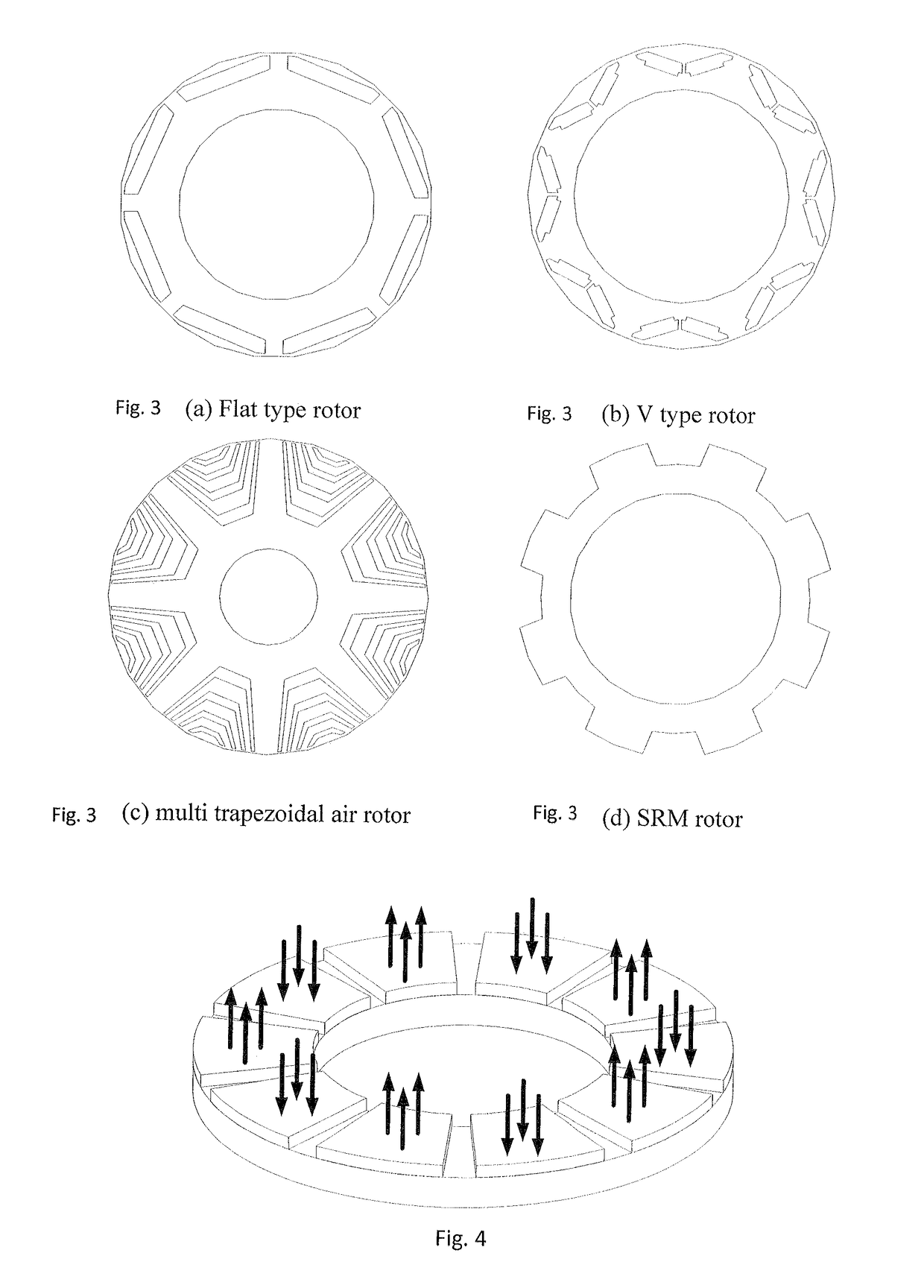

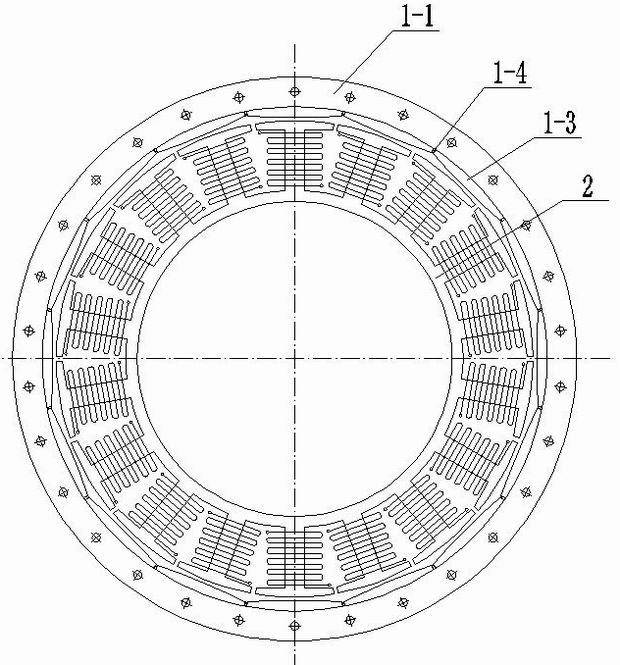

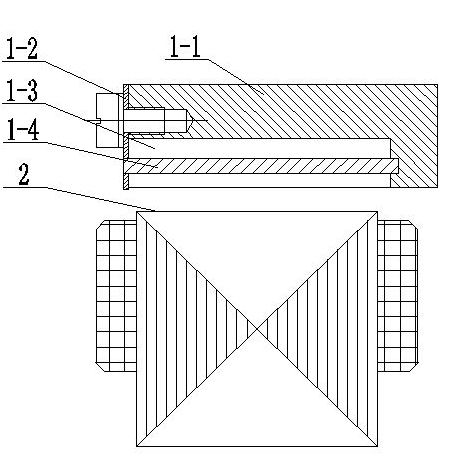

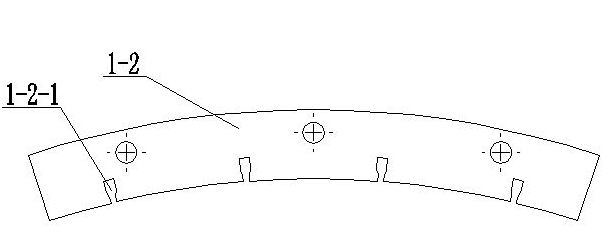

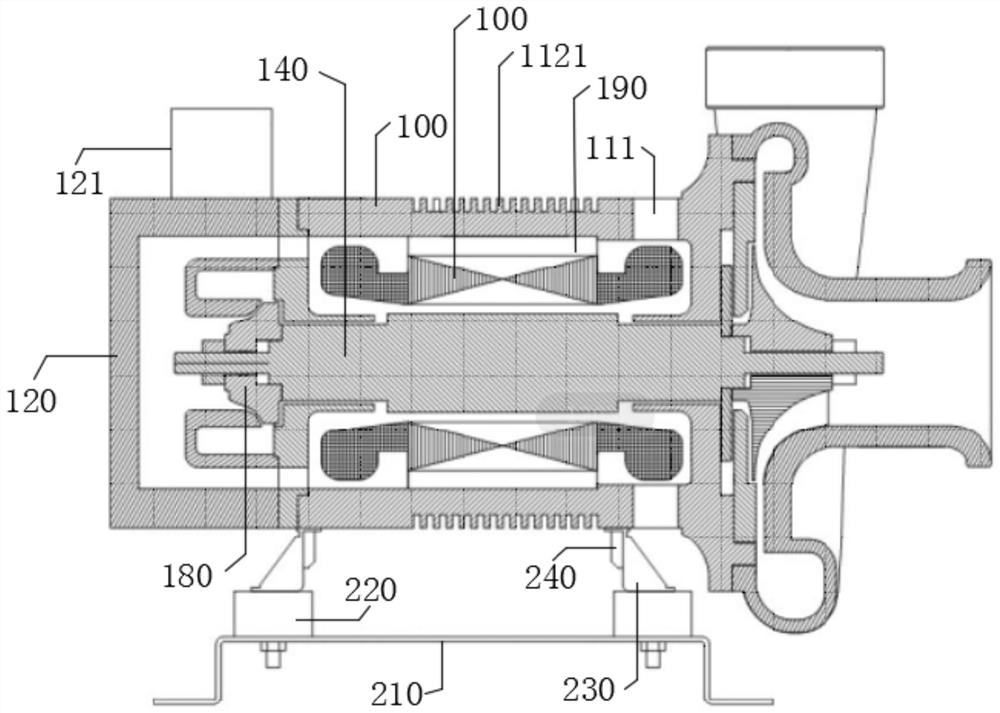

The invention proposes a new motor with separated permanent magnet torque and reluctance torque. Meanwhile, the optimal efficiency control method for this motor is proposed. This invention belongs to the field of motor and its drive system. The proposed motor includes 3 stators and 1 rotor (composed of 2 axial rotors and 1 radial rotor), the radial stator employs distributed winding, the axial stator adopts concentrated winding. The distributed winding and the radial reluctance rotor structure contribute to higher reluctance torque, while the concentrated winding and the surface mount permanent magnet structure offer higher permanent magnet torque. In the view of the magnetic circuit, the axial magnetic circuit generates the permanent magnet torque, and the radial magnetic circuit generates the reluctance torque. By using the decoupling of axial and radial magnetic circuits, the separation and the independent control of the permanent magnet torque and the reluctance torque are realized. Each stator and rotor of the invention can be processed independently, and the modular installation can be processed, thereby reducing the difficulty of the motor processing.

Owner:JIANGSU UNIV

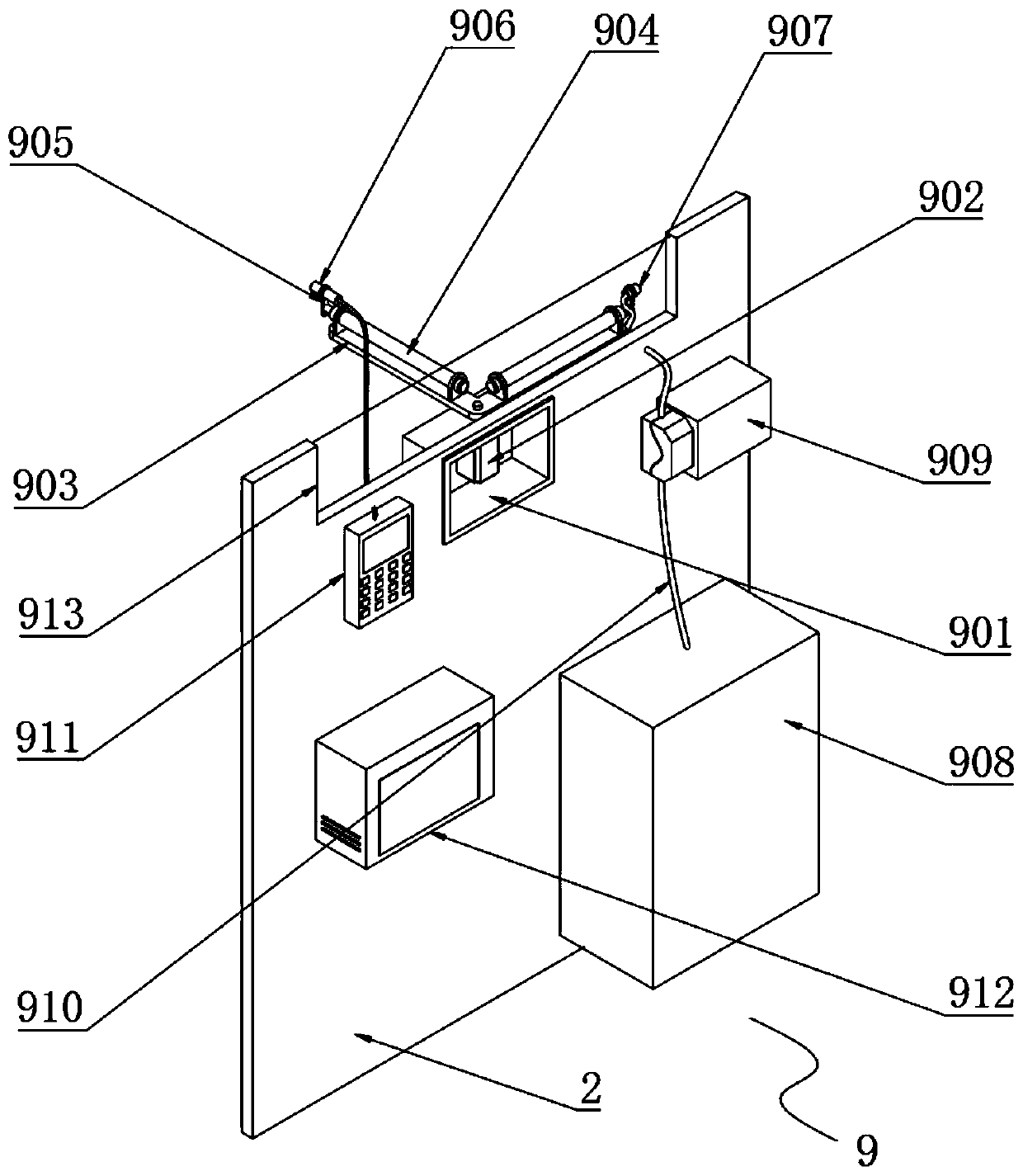

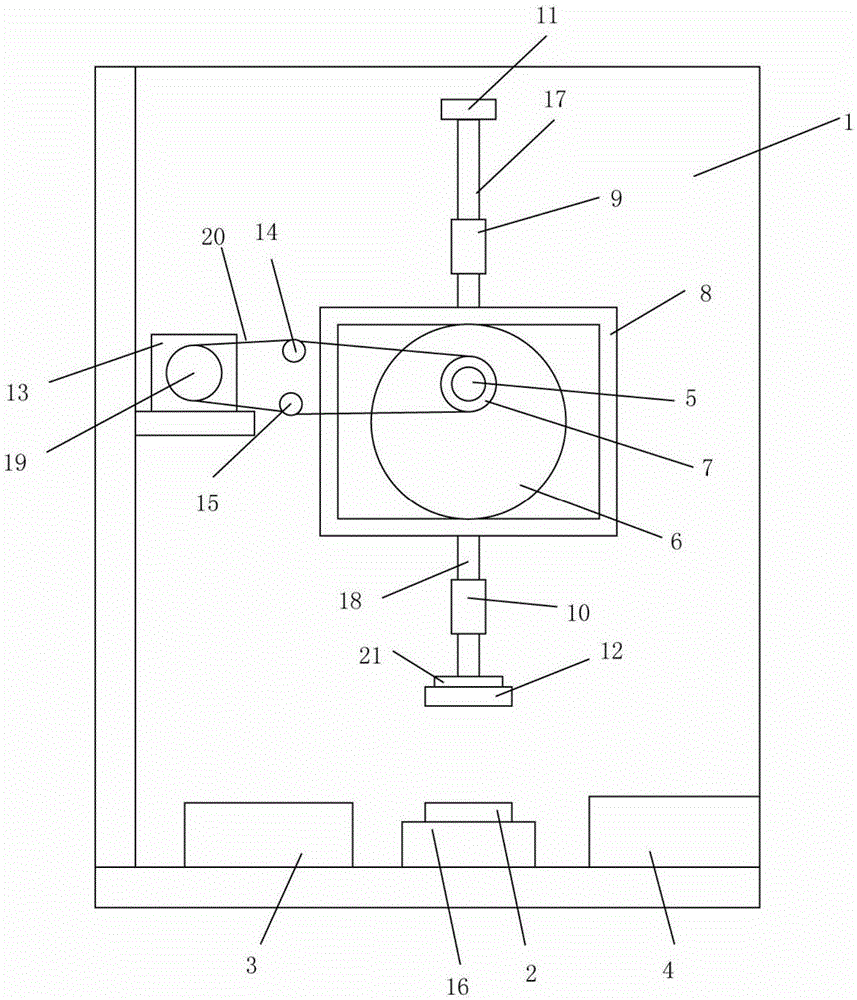

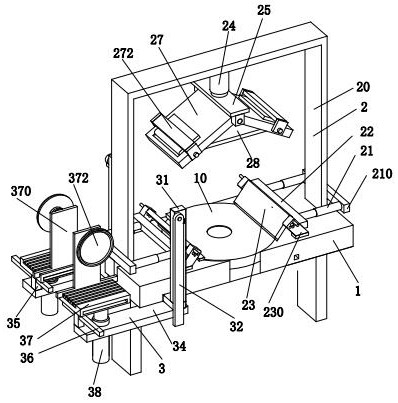

Boring device for automobile motor processing

InactiveCN111299645AAchieve phase translationRealize phase translation, advanceFeeding apparatusPositioning apparatusControl engineeringElectric machinery

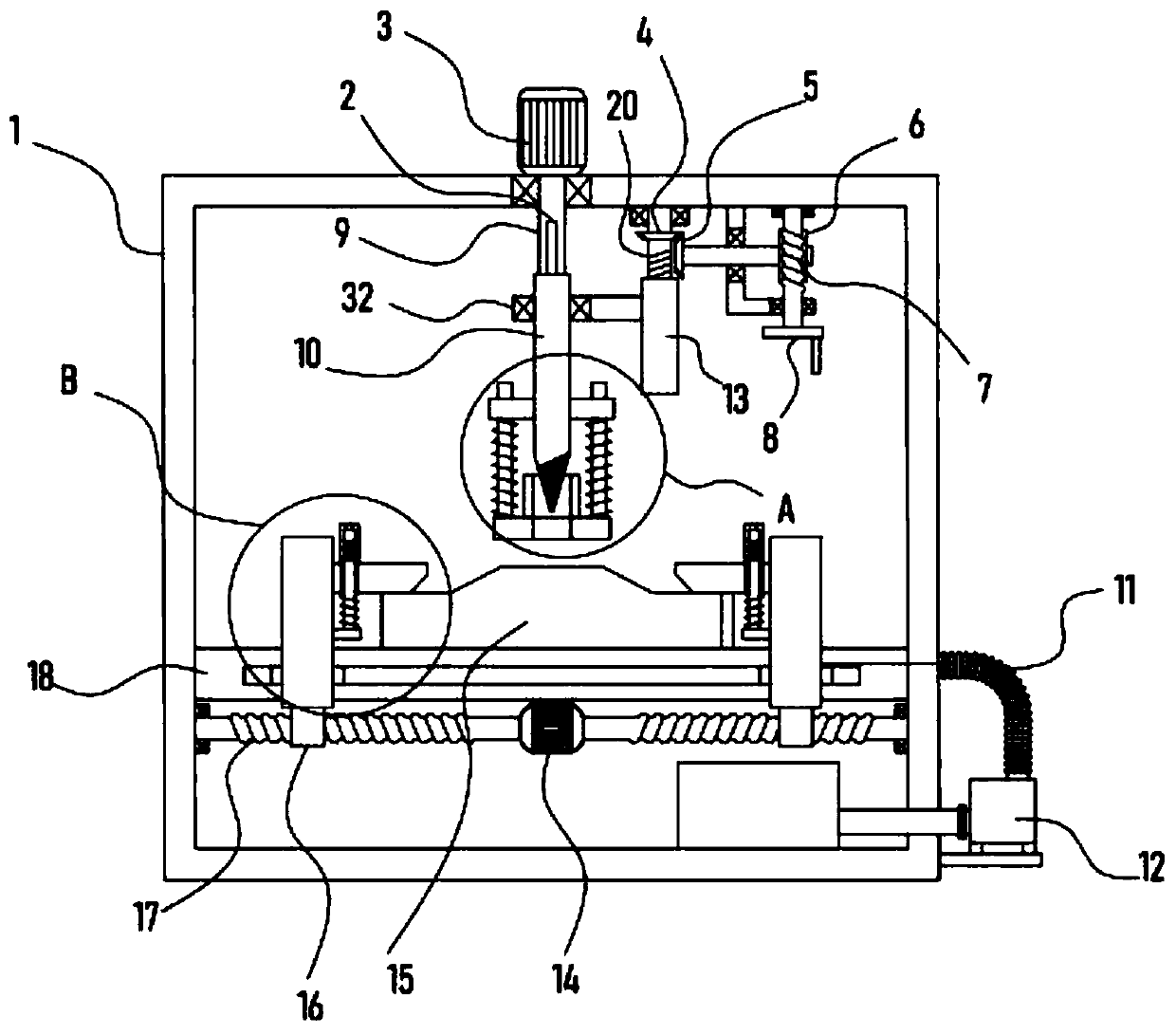

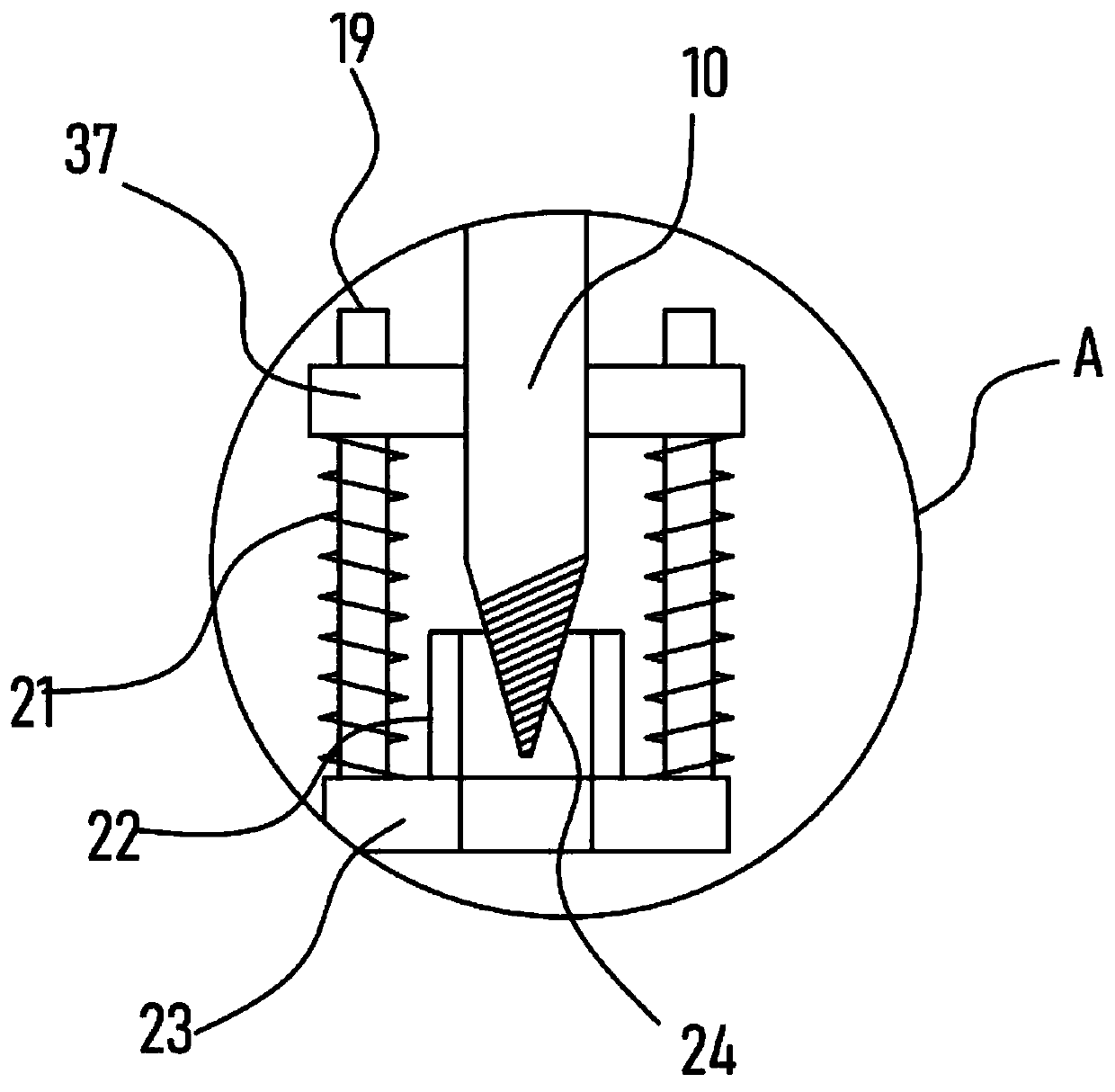

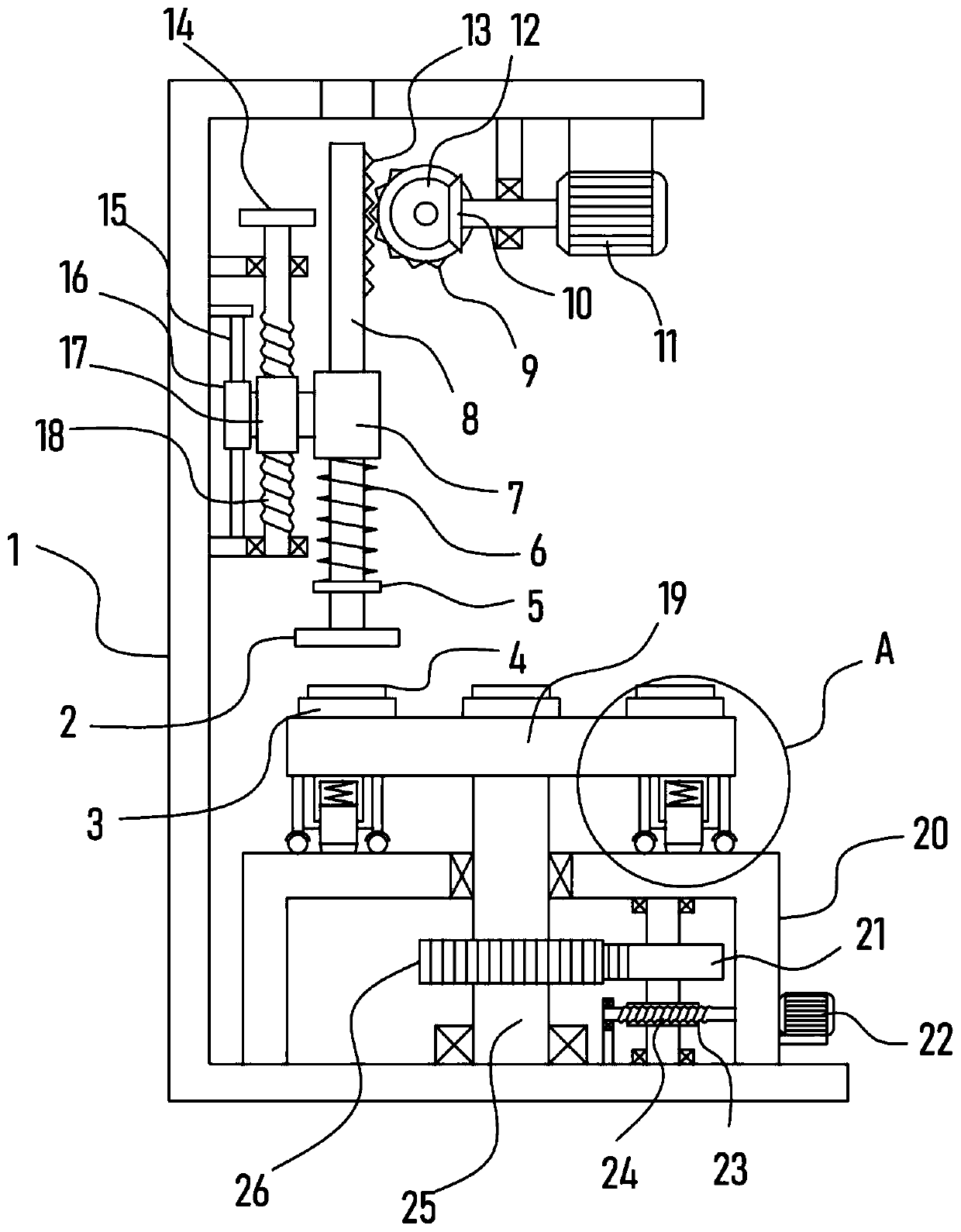

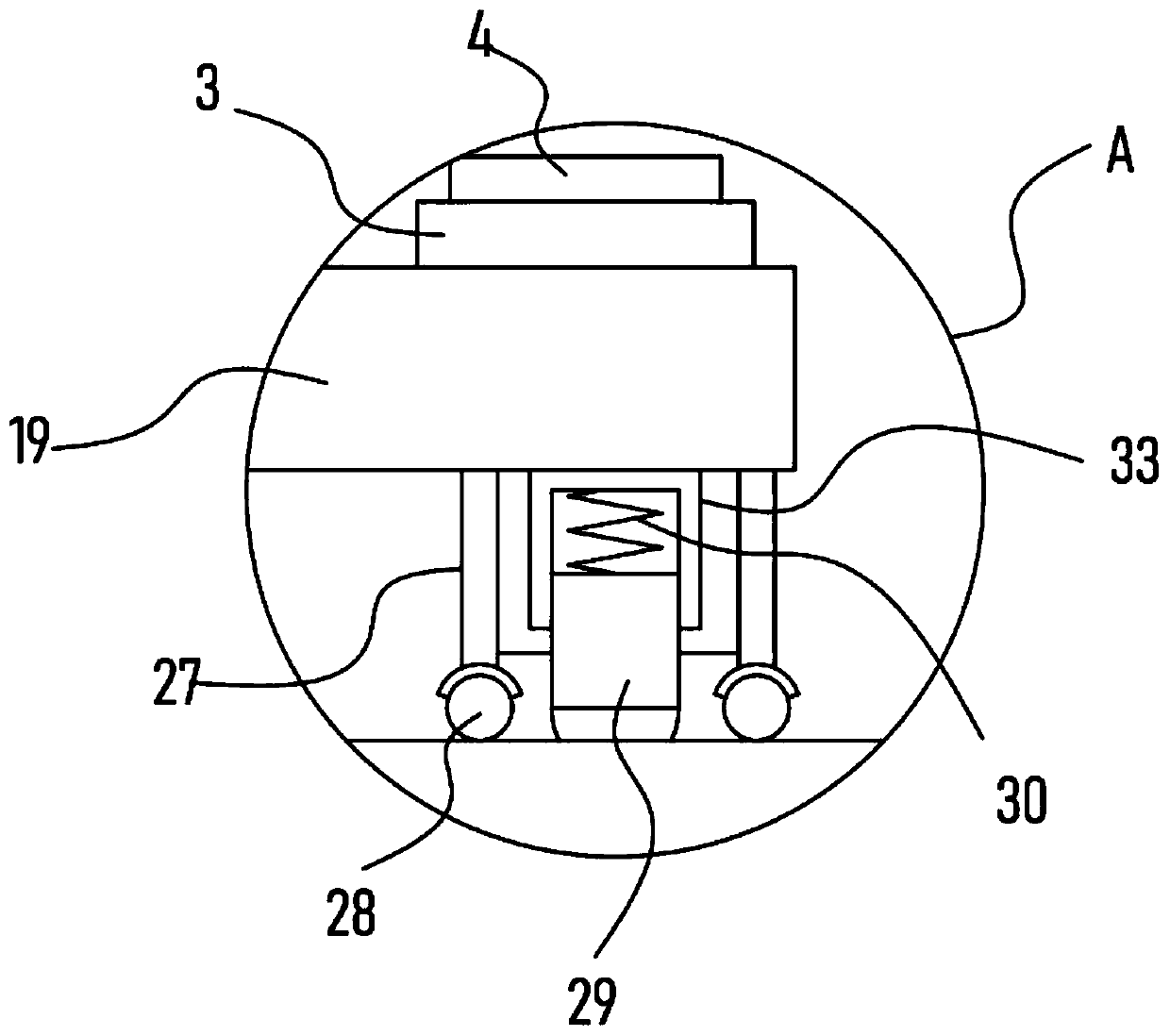

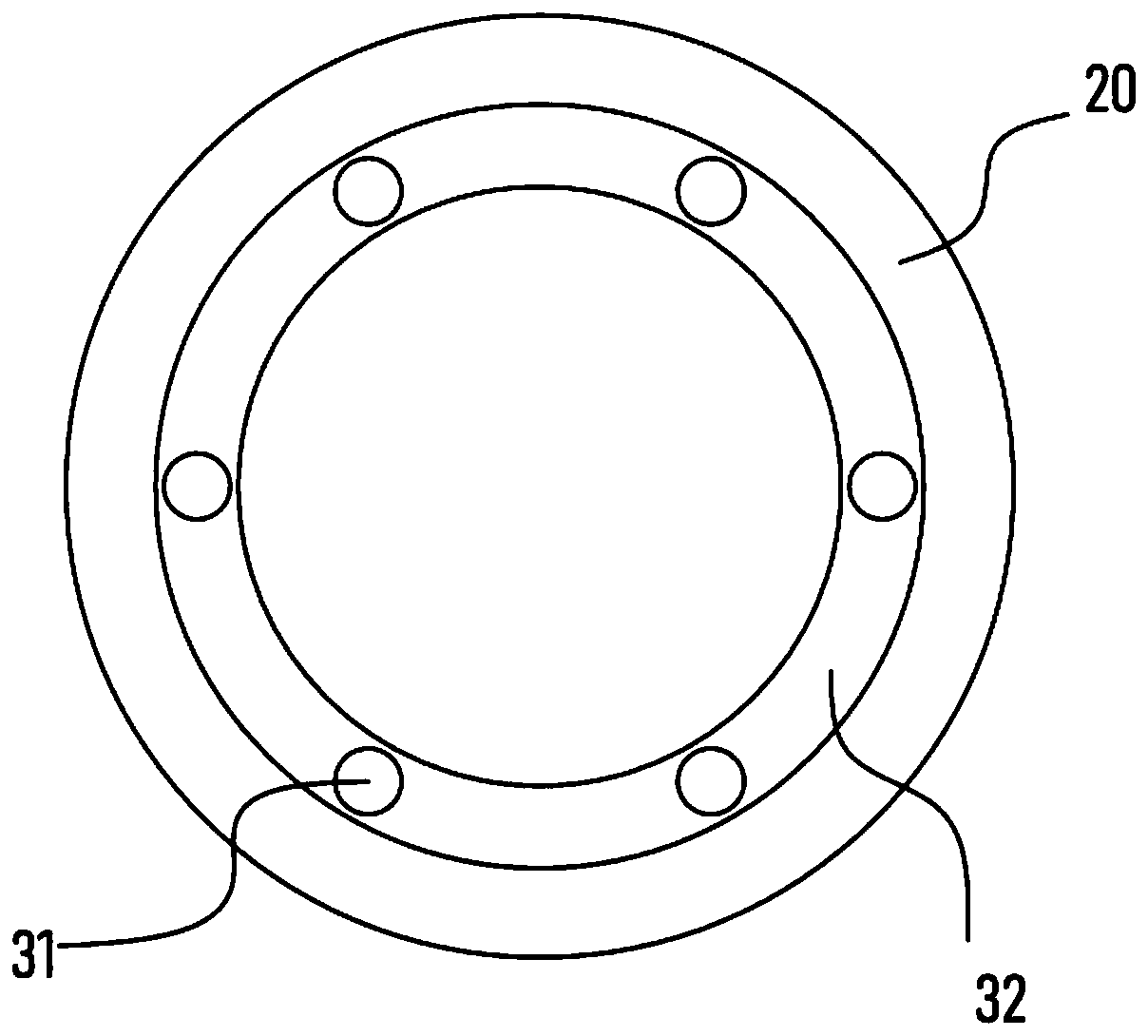

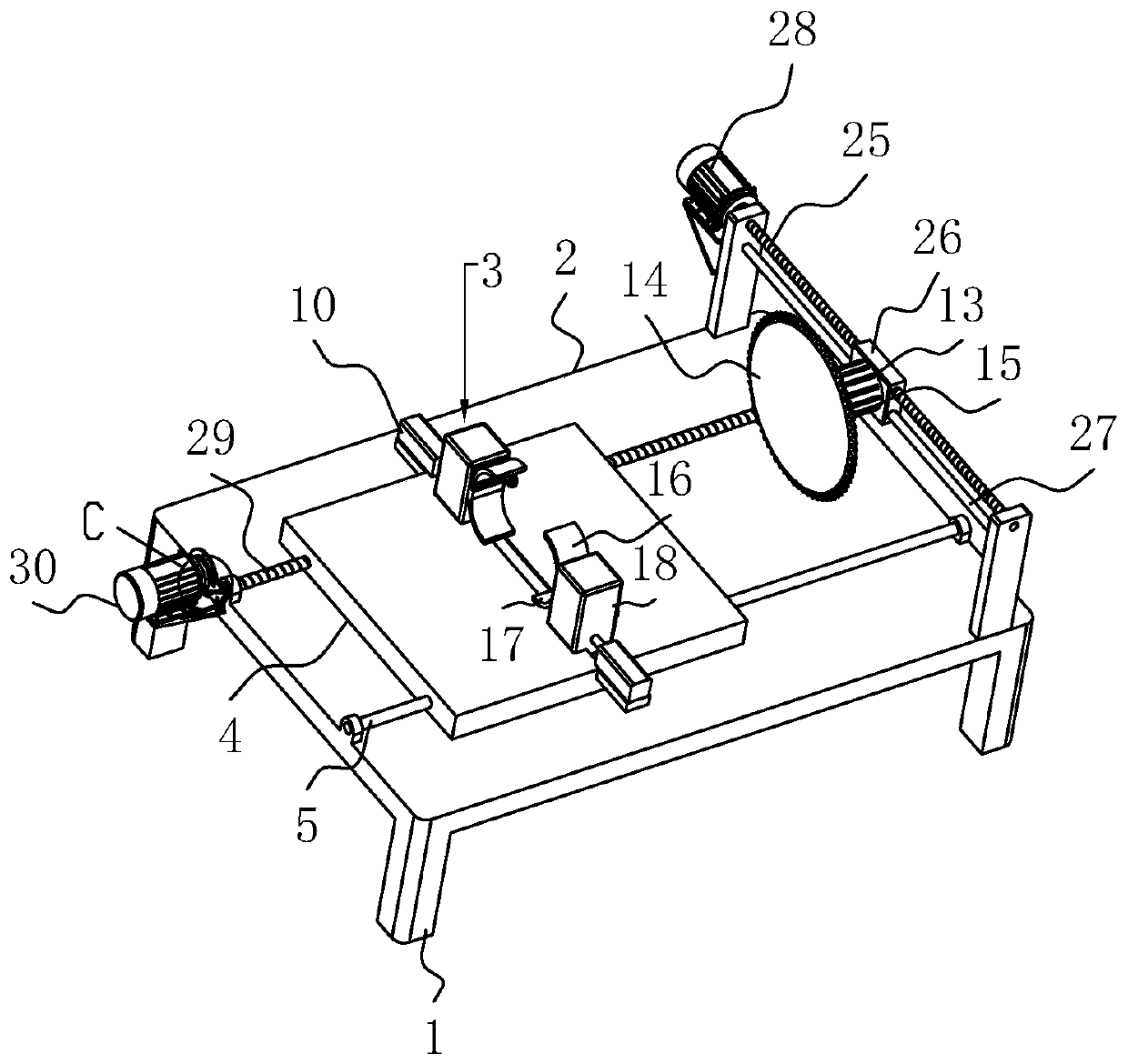

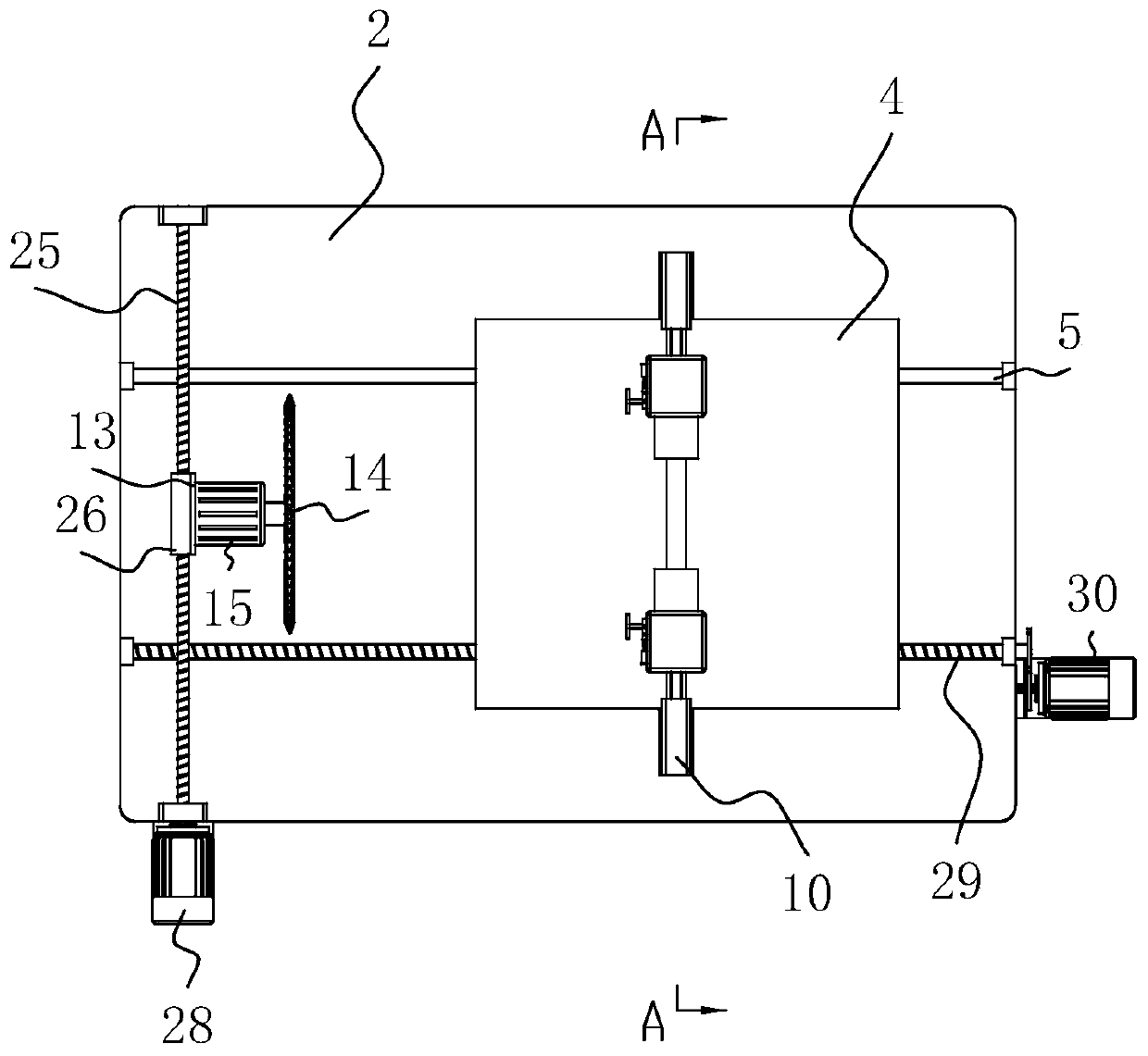

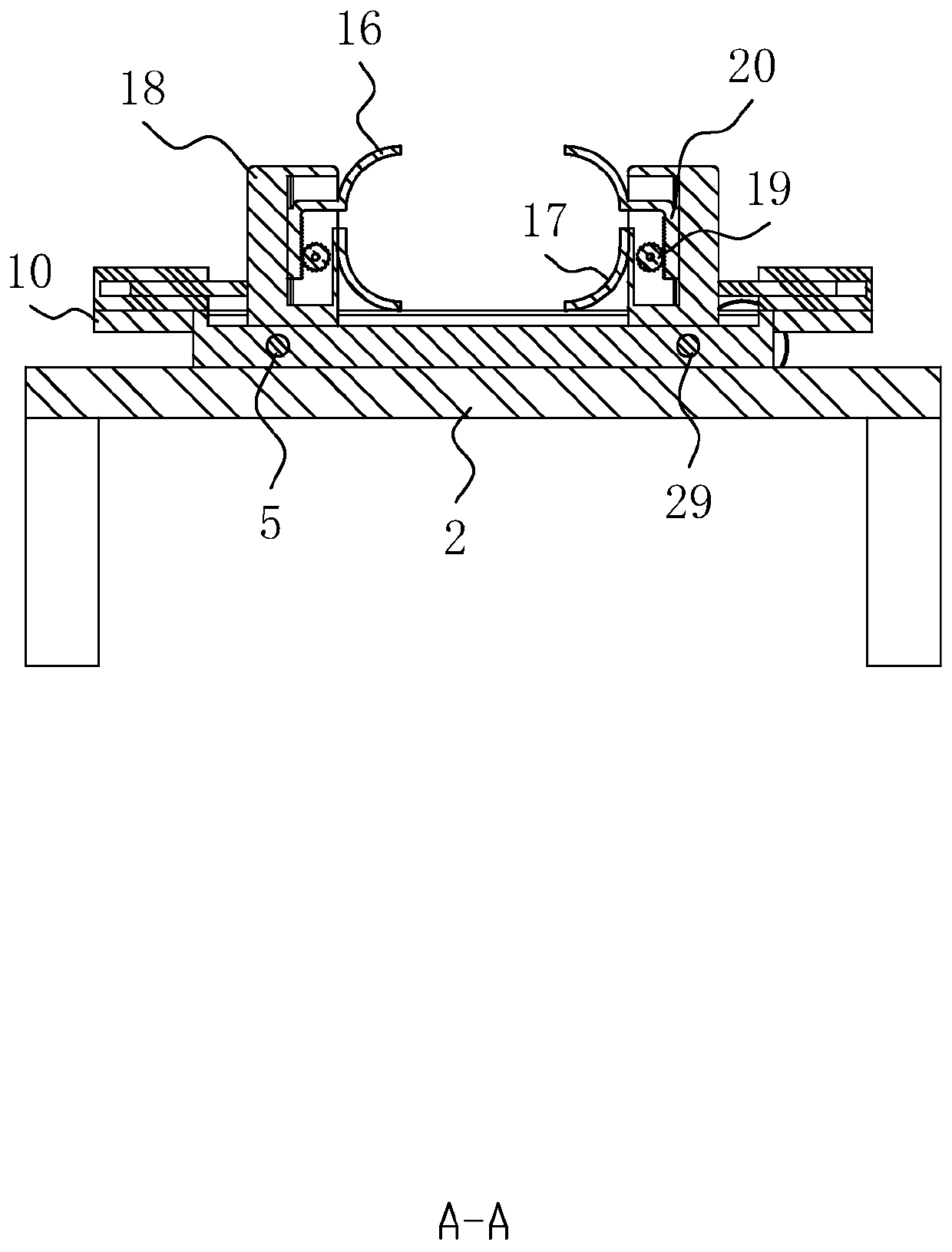

The invention discloses a boring device for automobile motor processing, and relates to the technical field of motor processing. The boring device for automobile motor processing comprises a support frame, wherein a pair of locking mechanisms used for clamping and fixing a motor end cover are arranged on an opposite translation mechanism; a driving motor is fixed on the top of the support frame; an ascending and descending mechanism used for regulating a drill bit to ascend and descend is arranged on the support frame; and a dust collection mechanism is arranged on the support frame. Through the arrangement of the translation mechanism, the face-to-face translation of two sliding frames is realized under the driving effect of a double-shaft motor; the face-to-face movement of the locking mechanism is further realized; the motor end cover can be firmly and reliably locked and fixed; through the arrangement of an elastic support mechanism, the motor end cover can be firmly and reliably pressed and fixed during boring; the boring process of the motor end cover is more stable and precise; through the arrangement of the dust collection mechanism, chippings and dust generated in the boring process can be extracted and absorbed in time; and the efficient and environment-friendly boring operation on the motor end cover is realized.

Owner:黄国普

Shell stamping device for machining motor

InactiveCN111496052AImprove stamping efficiencyMetal-working feeding devicesPositioning devicesStampingElectric machinery

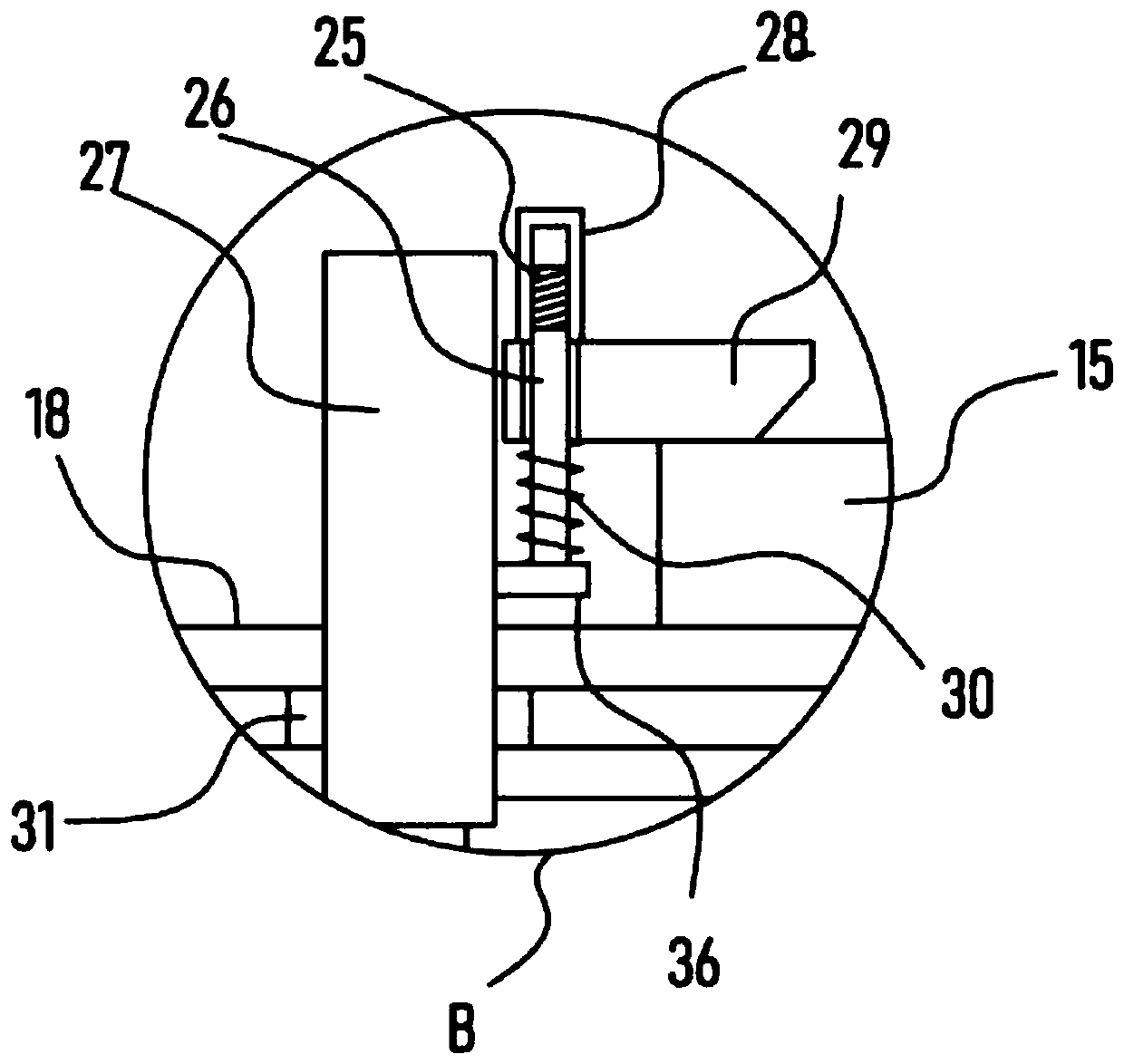

The invention discloses a shell stamping device for machining a motor, and relates to the technical field of motor machining. The shell stamping device comprises a supporting frame, an elastic positioning mechanism is arranged between a rotary disc and a fixed frame, a motor I is fixed to the supporting frame, the motor I is in driving connection with a vertical lifting mechanism, upper dies intermittently corresponding to lower dies are connected to the vertical lifting mechanism, and an adjusting mechanism is arranged on the supporting frame. According to the shell stamping device for machining the motor, the vertical lifting mechanism can drive a stamping rod to vertically rise and fall with the upper dies, and the stamping operation of the upper dies on motor shells of the lower dies is realized through elastic force of a spring ring; the adjusting mechanism can adjust the impact force that is the initial length of the spring ring, and sufficient stamping of the motor shells is convenient to realize; and the rotary disc can realize marching type rotation under the driving of a rotation mechanism, so that the motor shells of the multiple lower dies are subjected to stamping operation one by one, and the stamping efficiency of the motor shells is greatly improved.

Owner:黄国普

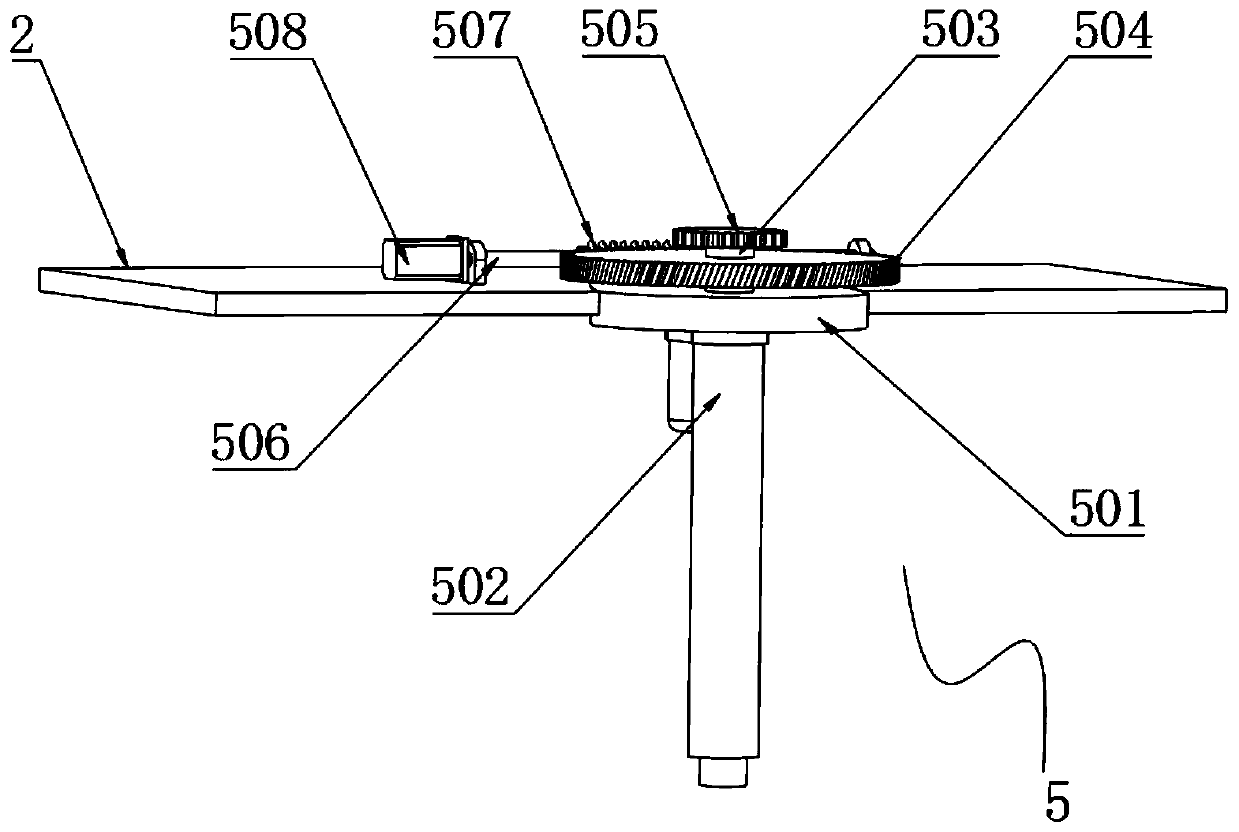

Polyvinyl chloride (PVC) pipe cutting device

InactiveCN110948552AAchieve fixed size cutting effectTo achieve a stable positionMetal working apparatusPolyvinyl chlorideElectric machinery

The invention relates to a polyvinyl chloride (PVC) pipe cutting device. The PVC pipe cutting device comprises a machine body and a machining table, wherein two clamping arms are arranged on the machining table in a sliding manner, a sliding plate is arranged on the machining table in a sliding manner, and an adjusting assembly is arranged on the sliding plate; a first screw rod is rotationally connected to the machining table, the machining table is fixedly connected with a slide bar, a transmission disc is arranged on the first screw rod coaxially, a plurality of transmission grooves are circumferentially formed in the driving disc at equal intervals, the transmission grooves are arranged in the radial direction of the end surface circle of the transmission disc, a drive disc is rotationally arranged on the machining table, and the machining table is fixedly connected with a fourth motor; bulges are fixedly connected to the drive disc, and an intermittent assembly is arranged betweenthe drive disc and the transmission disc; and a cutting table is arranged on the machining table in a sliding manner, a cutter is rotationally connected to the cutting table, the cutting table is fixedly connected with a first motor, and a cutting assembly is arranged on the machining table. By the technical scheme, the clamping and fixation effects on different pipes are realized, the fixed-sizecutting effect on the pipes is achieved conveniently, and the accuracy of pipe cutting sizes is enhanced.

Owner:武汉亚联塑业有限公司

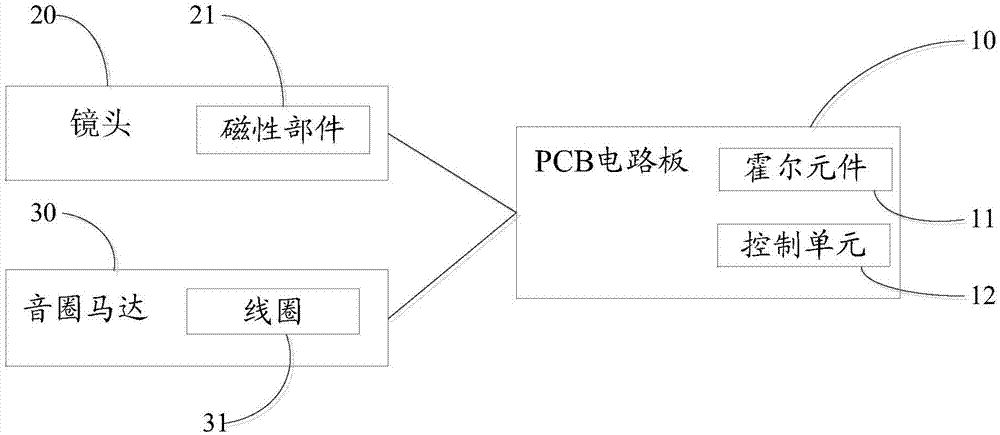

Camera module and electronic device

InactiveCN107197124AReduce manufacturing costSimple processing technologyTelevision system detailsColor television detailsDriving currentPower flow

The invention discloses a camera module, which comprises a PCB and a hall element arranged on the PCB, wherein the hall element is connected with a control unit arranged on the PCB and sensing current is outputted according to the sensed position of a magnetic part arranged on a lens; according to the sensing current, the control unit controls driving current outputted to the coil of a voice coil motor, and the position of the lens is controlled. Besides, the invention also discloses an electronic device. The electronic device comprises the above camera module. According to the camera module and the electronic device, through arranging the hall element on the PCB and being connected with the control unit, as the hall element is not arranged inside the voice coil motor independently, connection with the control unit through a lead is only needed, the voice coil motor processing process becomes simple, the yield improvement is improved, and the manufacturing cost of the camera module and the manufacturing cost of the electronic device are reduced.

Owner:TRULY OPTO ELECTRONICS

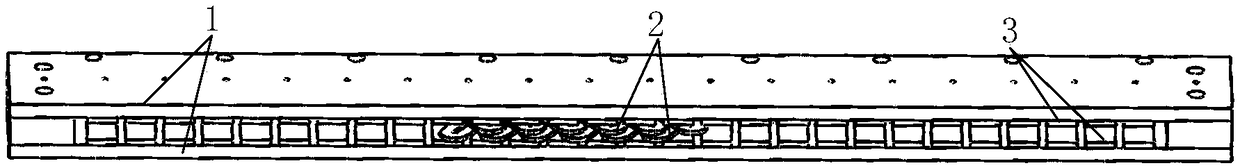

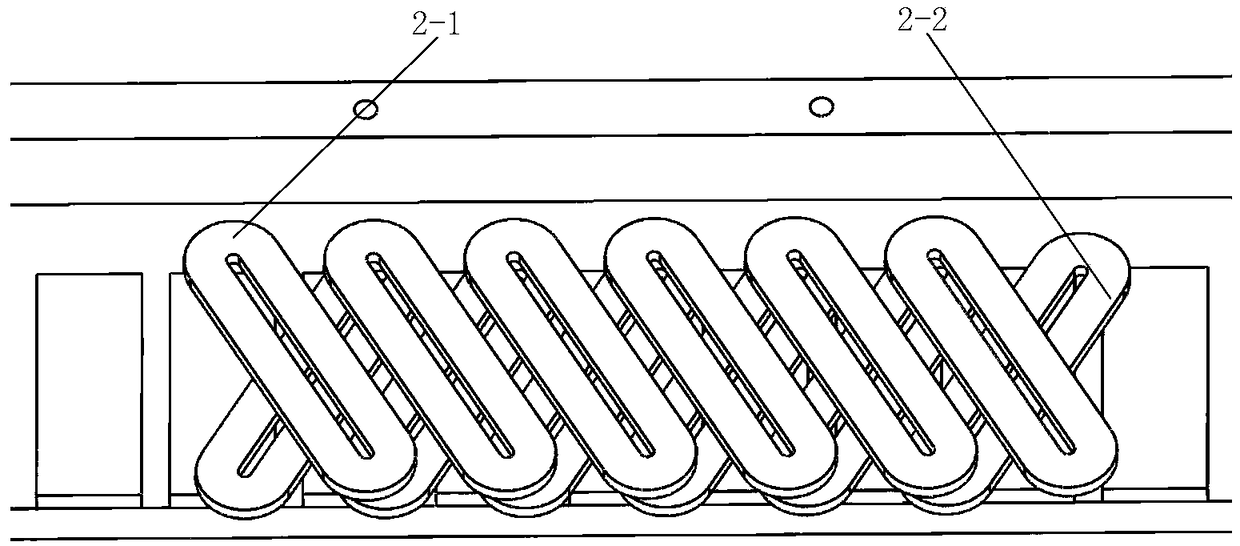

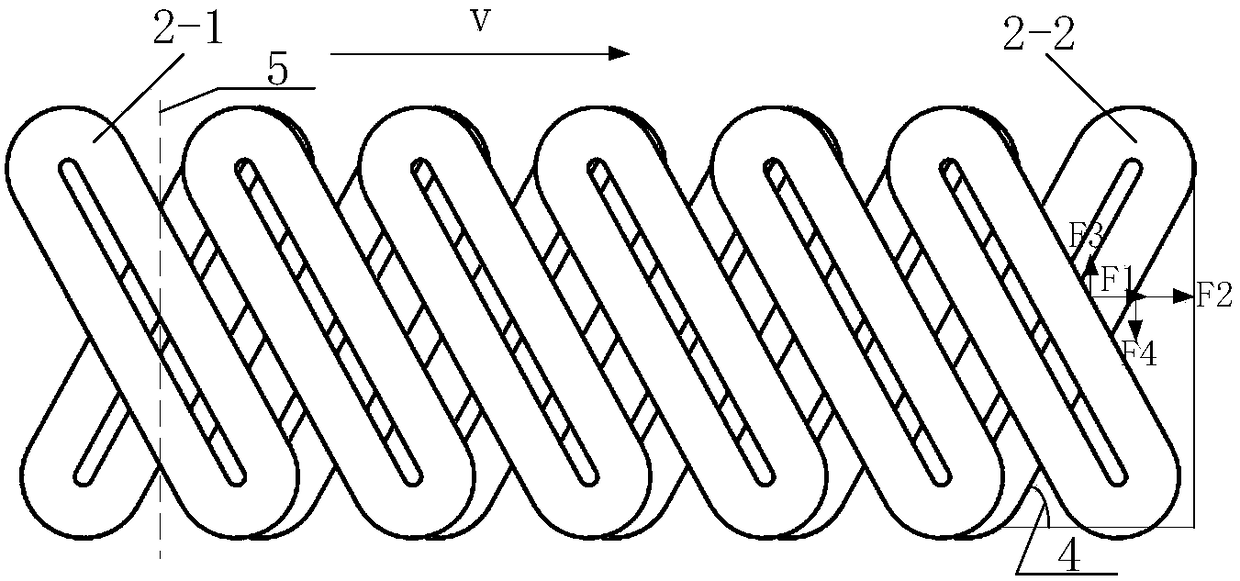

Coreless permanent magnet synchronous linear motor with double-layer reversely tilting windings

InactiveCN109462320AReduce thrust fluctuationReduce lateral forcePropulsion systemsWindings conductor shape/form/constructionPermanent magnet synchronous motorLinear motor

The invention discloses a coreless permanent magnet synchronous linear motor with double-layer reversely tilting windings. Mover coils in the permanent magnet synchronous linear motor are set as double-layer coil windings: upper-layer coil windings and alower-layer coil windings. The upper-layer coil windings and the lower-layer coil windings are set in planes where the upper-layer coil windings and lower-layer coil windings are in a tilting mode. Each pair of windings at upper and lower corresponding positions in the upper-layer coil windings and the lower-layer coil windings symmetrically tilt towards opposite directions by taking a center line as a symmetric center, thereby forming a double-layer reversely tilting winding form. According to the coreless permanent magnet synchronous linear motor with the double-layer reversely tilting winding, thrust ripples of the motor are clearly reduced, thrust density of the motor is improved, motor operation is relatively stable, motor processing precision is improved, and the motor is widely applied to precision machining.

Owner:ANHUI UNIVERSITY

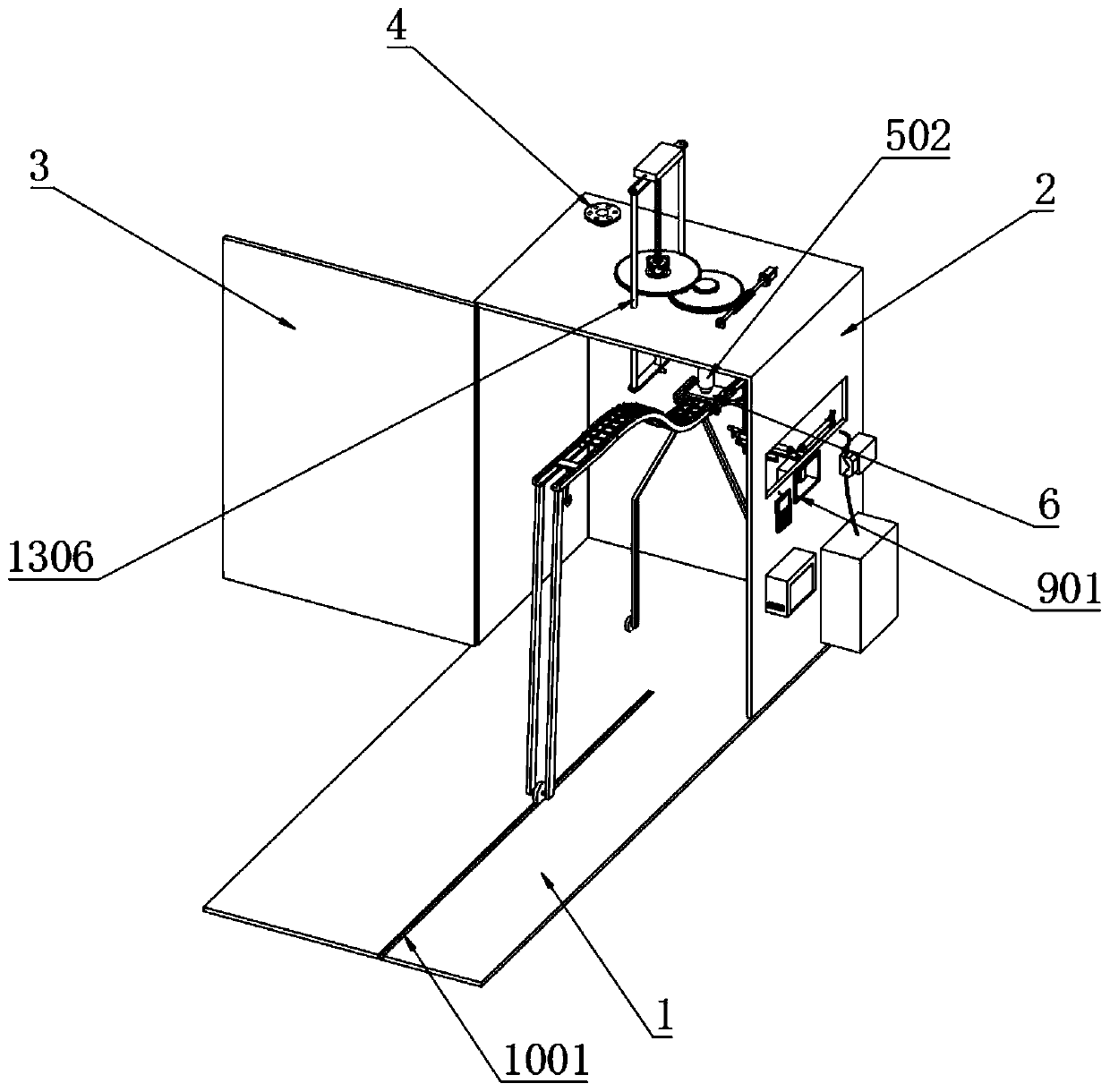

Intelligent paint spraying device applied to motor processing

ActiveCN110614186AEasy to useRapid Paint Thickness DetectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSpray boothsEngineeringExhaust pipe

The invention discloses an intelligent paint spraying device applied to motor processing. The device comprises a baseplate, wherein a paint spraying room is welded to one end part of the top end of the baseplate; a seal door is hinged to the front end edge part of the paint spraying room by a hinge; sealed paint spraying space is constituted of the baseplate, the paint spraying room and the seal door and used for avoiding environmental pollution caused by scattering of a paint liquid in air; an exhaust pipe passes through and is installed on the top end of the paint spraying room; and the exhaust pipe is connected to a filtering exhaust system of a plant to discharge polluted air inside the paint spraying room. The intelligent paint spraying device disclosed by the invention has the beneficial effects that the problem that efficiency of motor spraying is greatly reduced when a paint thickness of a motor shell cannot be detected in time during paint spraying in motor processing, the thickness shall be detected with relevant instructions after completion of paint spraying and additional painting shall be conducted on unqualified parts after detection; and the device is applicable forgeneralization and use.

Owner:建首(山东)钢材加工有限公司

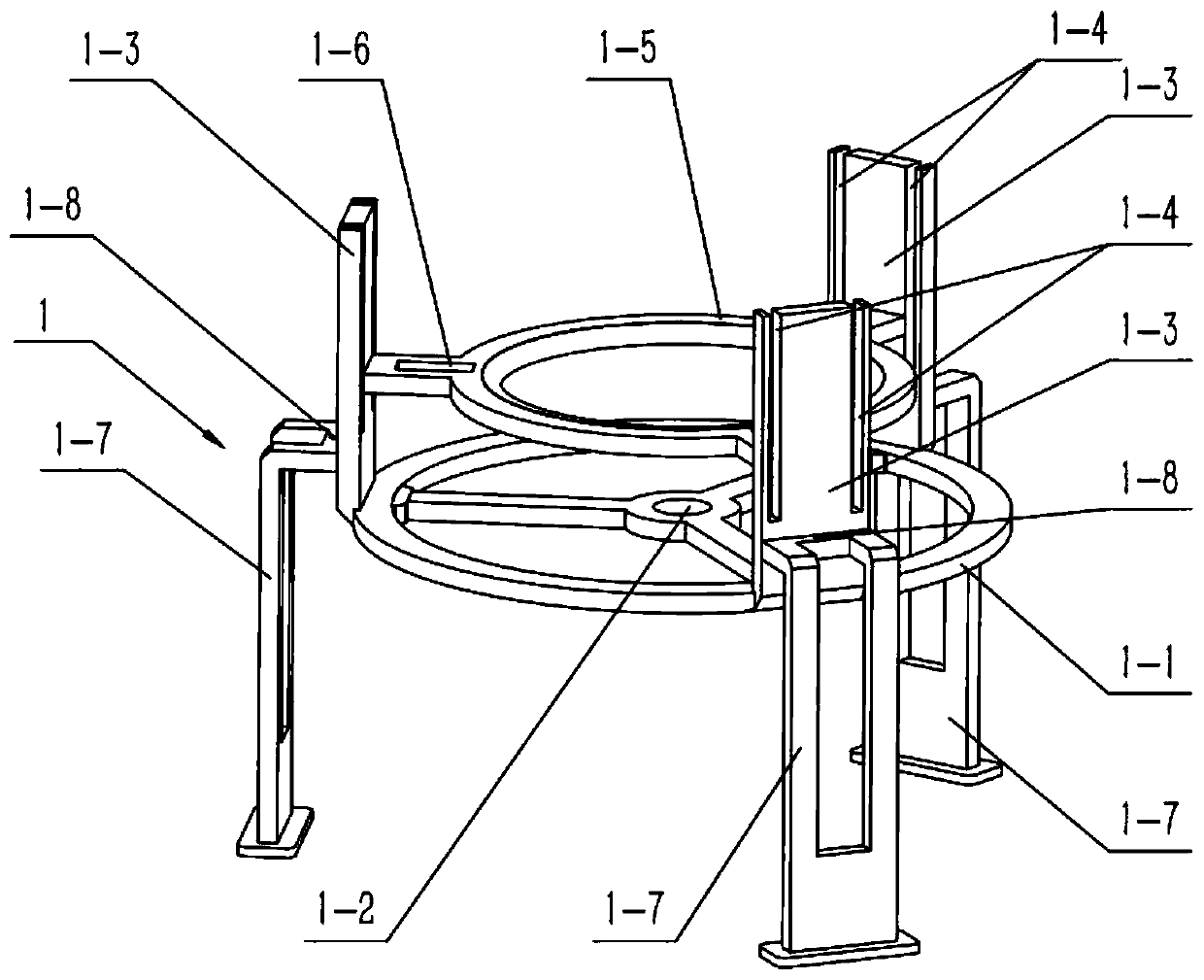

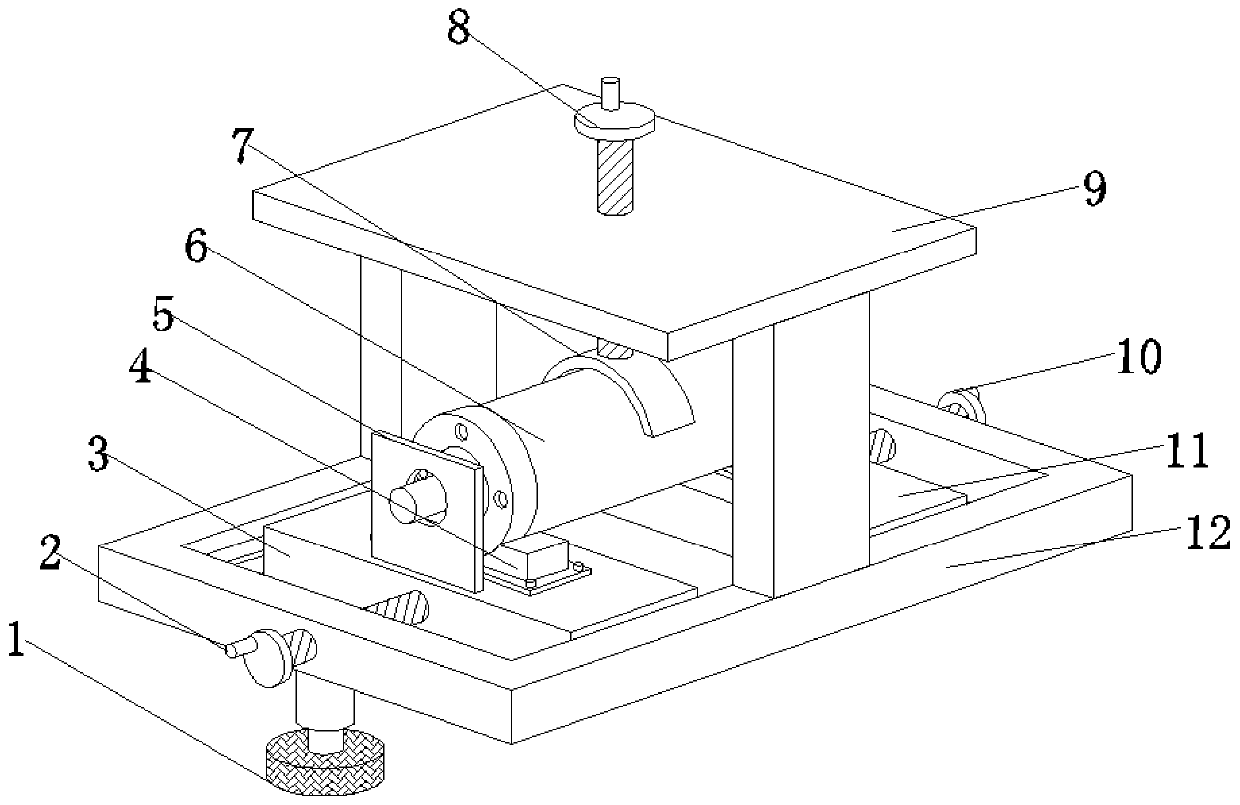

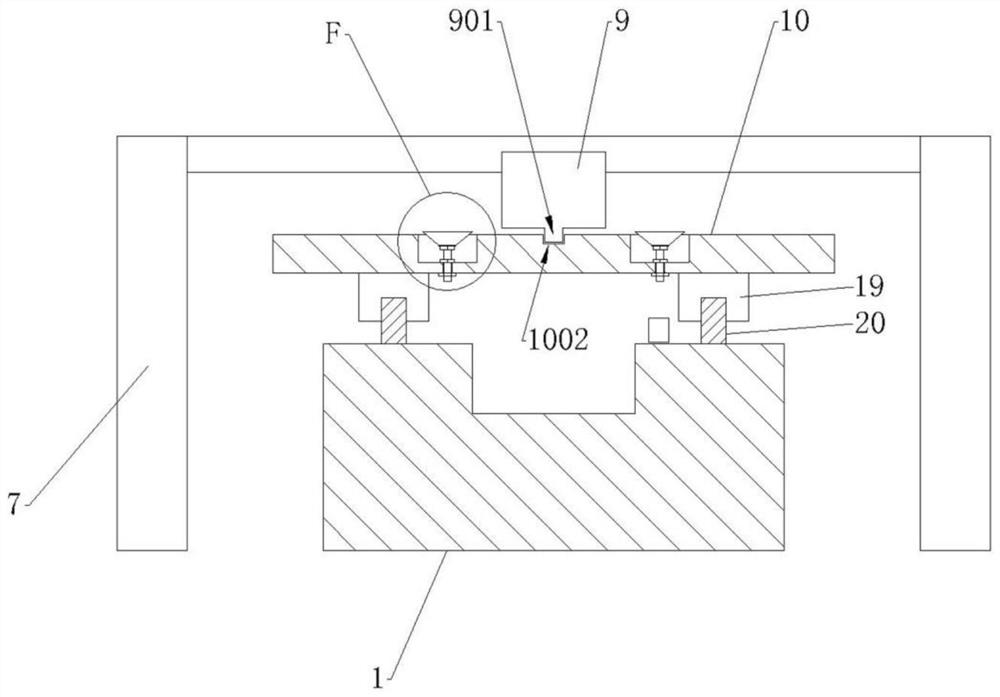

Numerically-controlled machine tool positioning structure for motor machining

InactiveCN111482831AGuaranteed centering clampingImprove processing efficiencyPositioning apparatusMetal-working holdersNumerical controlElectric machinery

Owner:孙雪峰

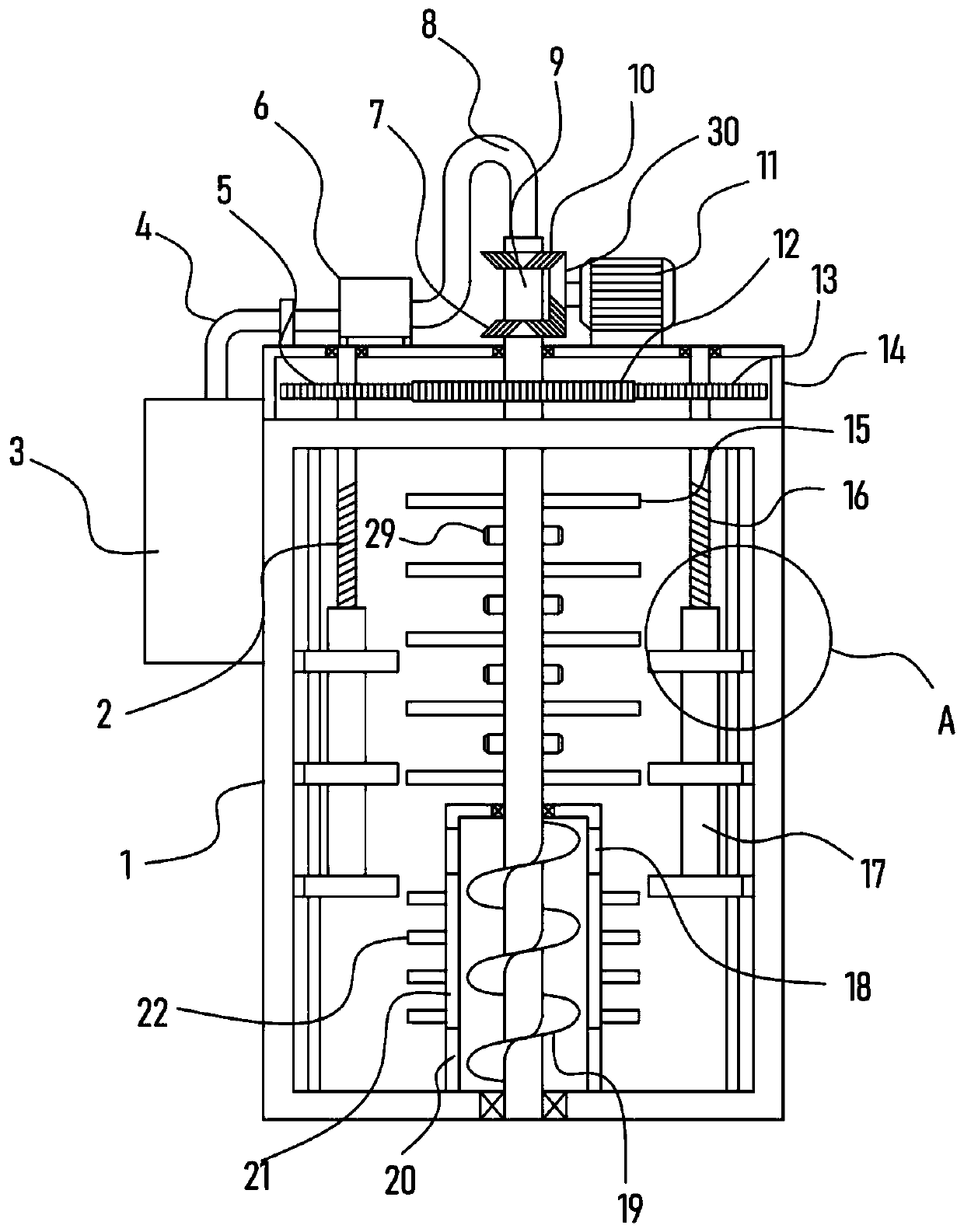

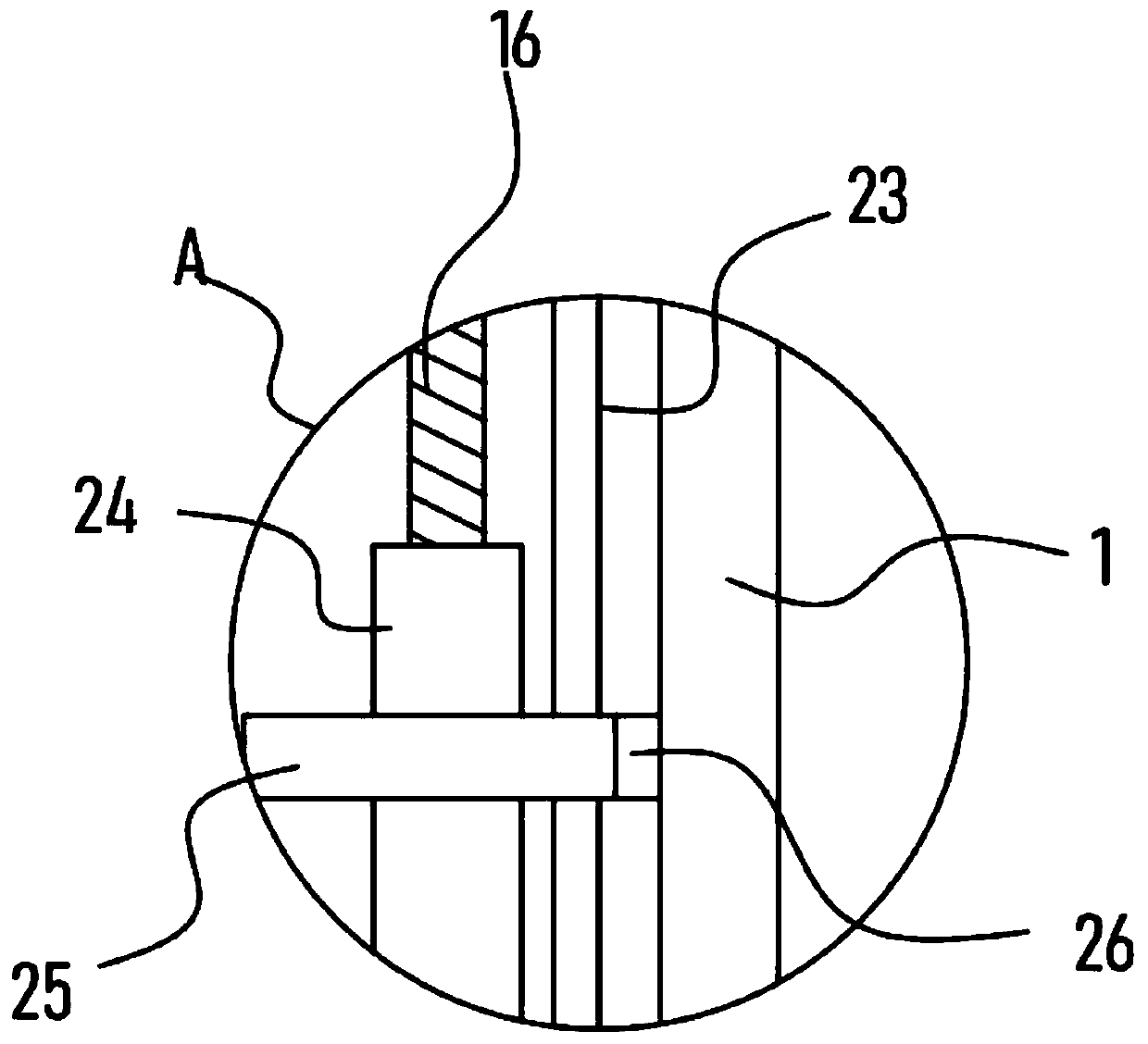

Motor shell cleaning equipment for industrial motor machining

ActiveCN111215378AEasy to cleanCleaning effect plusCleaning using toolsCleaning using liquidsElectric machineryEngineering

The invention relates to the technical field of industrial cleaning equipment, in particular to motor shell cleaning equipment for industrial motor machining. When the motor shell cleaning equipment is used, a motor shell can be fixed in the motor shell cleaning equipment through a main body frame and a positioning structure, and the relative position of each cleaning structure is adjusted througha radius adjusting mechanism and a bottom supporting mechanism, so that the best cleaning effect is achieved; the relative position of a friction transmission ring seat is adjusted, so that the friction transmission ring seat, the lower part of each cleaning structure and the inner wall of the friction transmission ring seat are in a good friction transmission state, and a driving mechanism rotates forwards and backwards in a reciprocating manner while driving the cleaning structures to revolve forwards and backwards in a reciprocating manner, so that the cleaning effect is better; and a water spraying pipe is connected with a water pump, the water spraying pipe can spray water into the motor shell through the water pump to assist the cleaning structures in cleaning the inner wall of themotor shell, and the driving mechanism drives outer wall cleaning structures to clean the outer wall of the motor shell at the same time. According to the equipment, the motor shell is convenient to clean, and the cleaning effect is good.

Owner:上海雷祥压铸有限公司

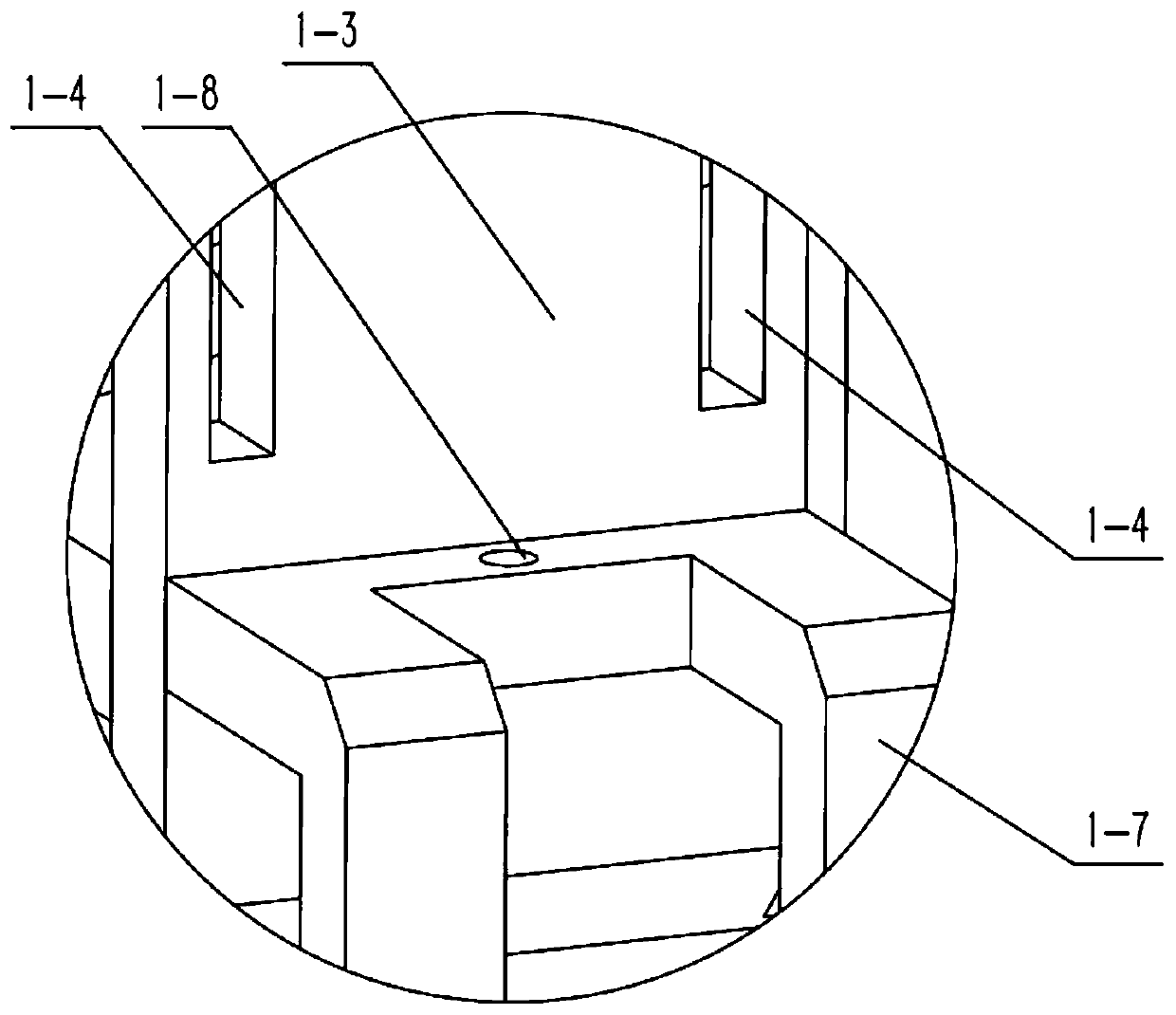

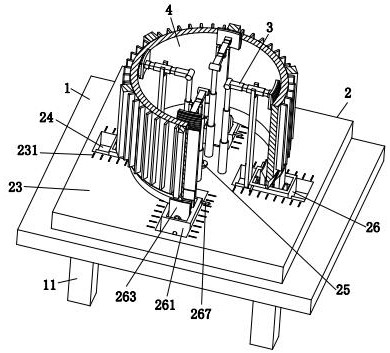

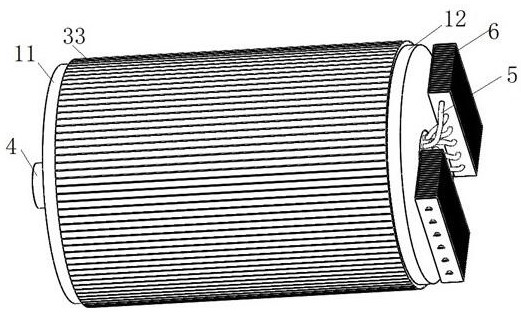

Plastic package motor for washing machine

InactiveCN103746492AImprove airtightnessReduce distortionSupports/enclosures/casingsEngineeringMotor processing

The invention relates to the field of motor processing, in particular to a plastic package motor for a washing machine. The plastic package motor comprises a rotating shaft, a rotor assembly, a plastic package stator assembly and end covers, wherein the plastic package stator assembly comprises a stator iron core, a stator winding and an injection molding case, the rotor assembly is arranged on the rotating shaft, the plastic package stator assembly is nested outside the rotor assembly, the two ends of the plastic package stator assembly are provided with the end covers, the end covers are provided with bearing chambers, bearings are arranged in the bearing chambers, the end covers comprise a front end cover and a back end cover, and the plastic package stator assembly and the back end cover are formed into an integral plastic package stator via a plastic package material mold through molding pressing plastic package. The plastic package motor has the advantages that the plastic sealing stator and the end covers are formed into an integral structure through plastic package, and the waterproof performance of the motor is ensured. During the plastic package, the concentricity of the bearings arranged in the end covers of the two ends of the plastic package stator is ensured through the precision of a plastic package mold, so the vibration during the rotor rotation is reduced, and the generation of noise is reduced.

Owner:HUZHOU YONGCHANG BEISHITUO ELECTRIC APPLIANCE INDAL

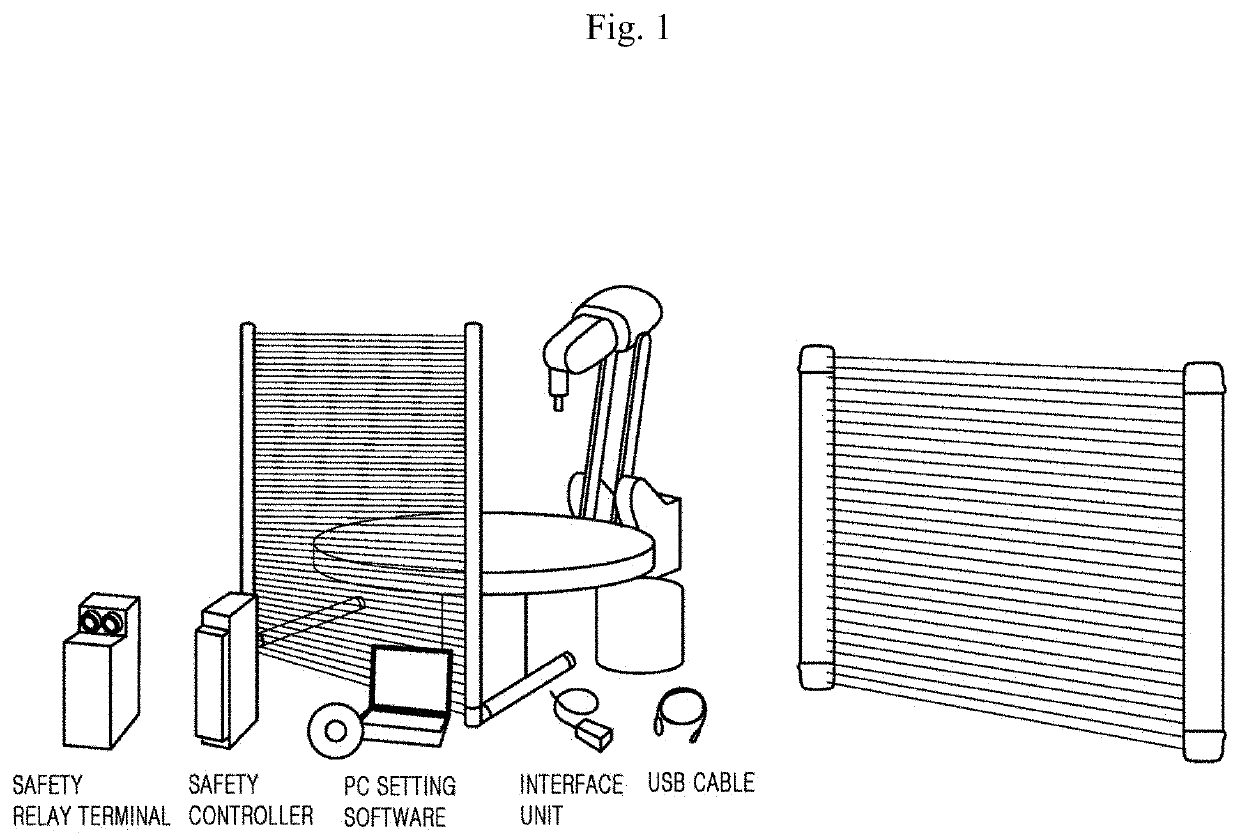

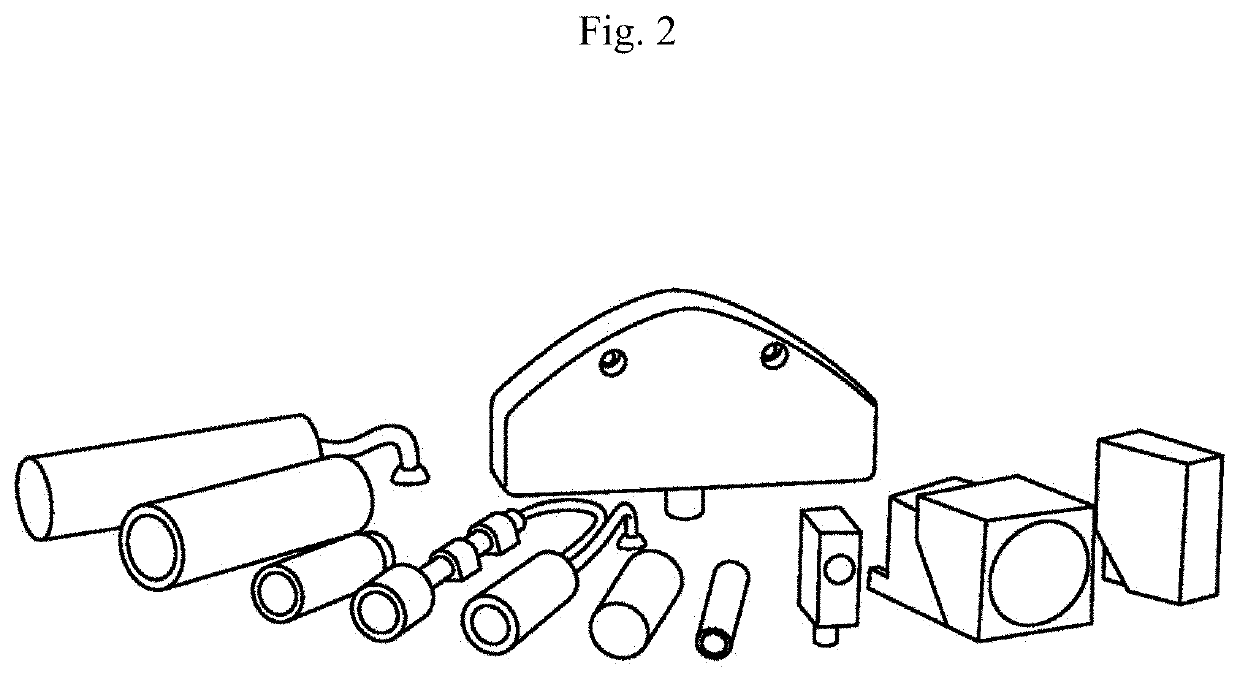

Accident monitoring system using uwb-based real-time positioning

ActiveUS20200206930A1Avoid accidentsProgramme-controlled manipulatorData processing applicationsElectric machineryMonitoring system

An accident monitoring system based on UWB-based real-time positioning comprises a UWB tag, a plurality of UWB anchors installed around a processing line and receiving the worker's position from the UWB tag and sensing predetermined information for the processing line, an AP receiving the worker's position and the predetermined information for from the plurality of UWB anchors, a server receiving the worker's position and the predetermined information for from the AP, storing the worker's position and the predetermined information for, and determining whether the worker is in a preset access-limited area, and a programmable logic control (PLC) box, upon receiving proximity information indicating that the worker is the access-limited area from the server through the AP, controlling to stop the industrial robot, the conveyor belt, and the motor in the processing line.

Owner:SUN HST CO LTD

Double-solid-shaft motor single planet row hybrid power system

InactiveCN104015605ASolve the difficult problems of processing and manufacturingImprove sealingGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingMotor driveGear wheel

The invention relates to a double-solid-shaft motor single planet row hybrid power system. The double-solid-shaft motor single planet row hybrid power system comprises an engine, a first motor, a second motor, a sun wheel, a planet wheel, a planet carrier, a gear ring, a first motor driving gear, a first motor driven gear, a second motor driving gear, a second motor intermediate shaft driven gear, a second motor intermediate shaft driving gear, a second motor driven gear, a first motor driving gear shaft, a first motor driven gear shaft, a second motor driving gear shaft, a second motor intermediate shaft, a second motor driven gear shaft and a planet carrier shaft. Compared with the prior art, the first motor and the second motor are solid shaft motors, the structure is simple, the motors are easy to machine and manufacture, the problems that due to the fact that a motor MG1 and a motor MG2 in the prior art are hollow shaft motors, the structures of the motors are complex, and the motors are difficult to machine and manufacture are solved, cost is reduced, and a box body is easy to seal.

Owner:SHANGHAI SYNETEC POWER SYST

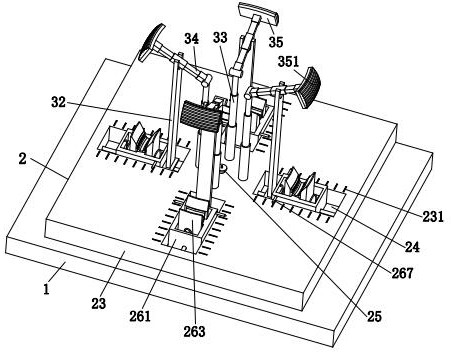

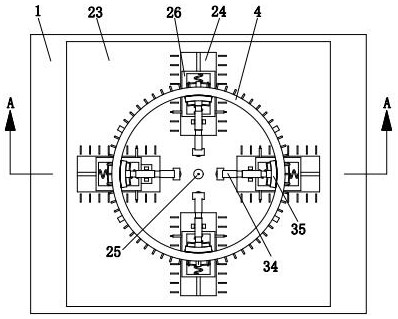

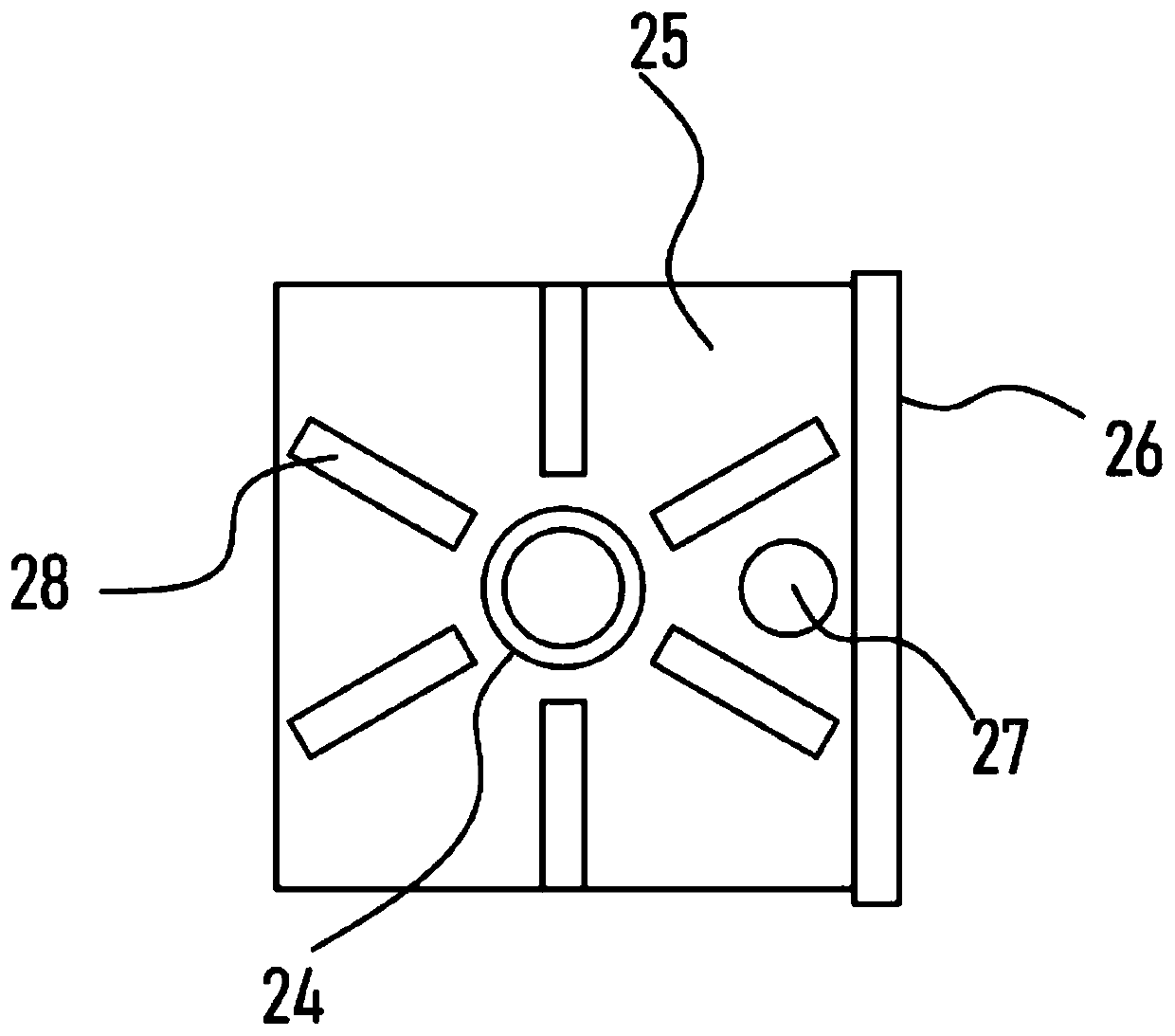

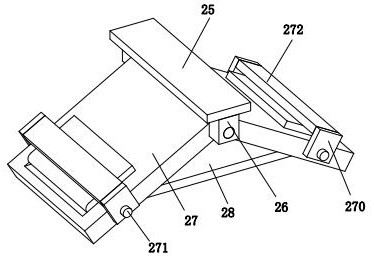

Novel stamping equipment used for motor processing

PendingCN106849560AReduce manufacturing costSimple structureManufacturing dynamo-electric machinesDrive wheelClassical mechanics

The invention belongs to the field of motor processing equipment, and particularly relates to novel stamping equipment used for motor processing. The novel stamping equipment is characterized in that a rotating rod is mounted on a rack; a rotating shaft of an eccentric wheel is mounted on the rotating rod; a driven wheel is mounted on the rotating rod; a frame body is arranged outside the eccentric wheel; an upper upright rod is arranged at the upper end of the frame body; a lower upright rod is arranged at the lower end of the frame body; an upper fixed sleeve is mounted on the rack, and sleeves the outside of the upper upright rod; a lower fixed sleeve is mounted on the rack, and sleeves the outside of the lower upright rod; a limiting plate is positioned above the upper fixed sleeve, and is connected with the tail end of the upper upright rod; an upper mold is arranged between the lower fixed sleeve and a lower mold, and is connected with the tail end of the lower upright rod; the output shaft of a motor is connected with a driving wheel; the driving wheel and the driven wheel are driven through a belt; and an upper tensioning wheel and a lower tensioning wheel adhere to the belt.

Owner:SILVER DIAMOND ELECTRIC CO LTD TIANJIN

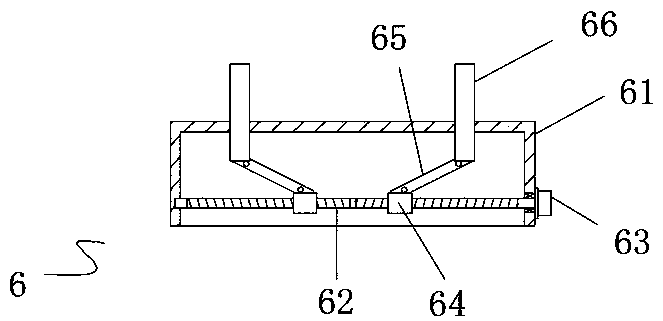

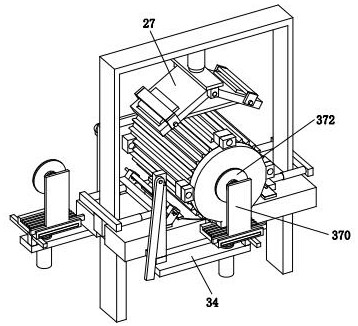

Pressing device for motor machining

ActiveCN113824283AImprove the pressing effectAvoid shakingWork holdersManufacturing dynamo-electric machinesElectric machineStructural engineering

The invention relates to the technical field of motor machining, and particularly relates to a pressing device for motor machining. The device comprises a base, a bearing unit and a pressing unit, the bearing unit is mounted at the upper end of the base, and the pressing unit is arranged on the bearing unit; a traditional pressing device cannot effectively fix a motor shell through an extrusion mode so that the motor shell lacks stability during machining; and due to the fact that the motor shell is prone to small-amplitude deviation in the machining process, mutual friction is prone to occurring between the pressing table and the motor shell, the pressing table causes pressing marks to the two ends of the motor shell, and later assembling of the motor shell is affected. According to the invention, motor shells with different diameters can be supported, and meanwhile, the stability of the motor shells can be ensured so that the fixing effect of the motor shells can be ensured; and the motor shell can be fixed in multiple directions, and a condition that indentation is caused to the upper end of the motor shell, and later assembling of the motor shell is affected is avoided.

Owner:方泰(广东)科技有限公司

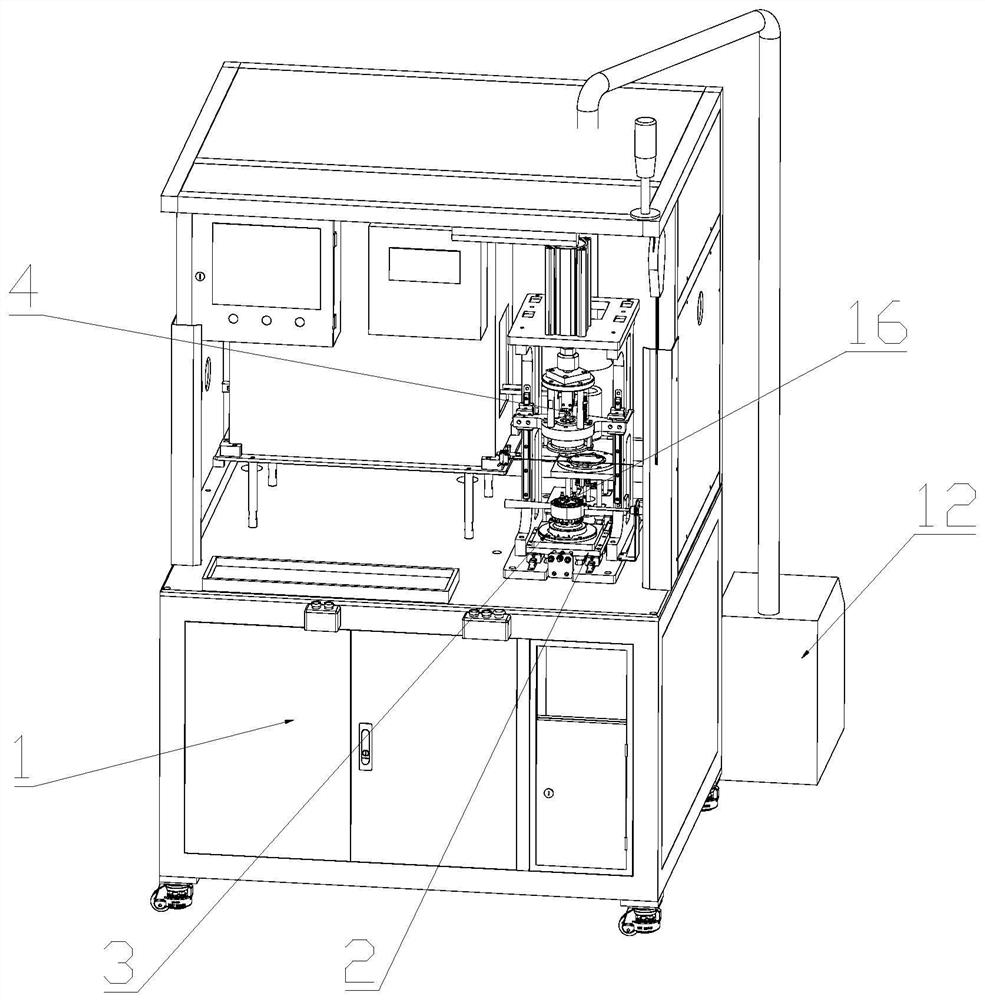

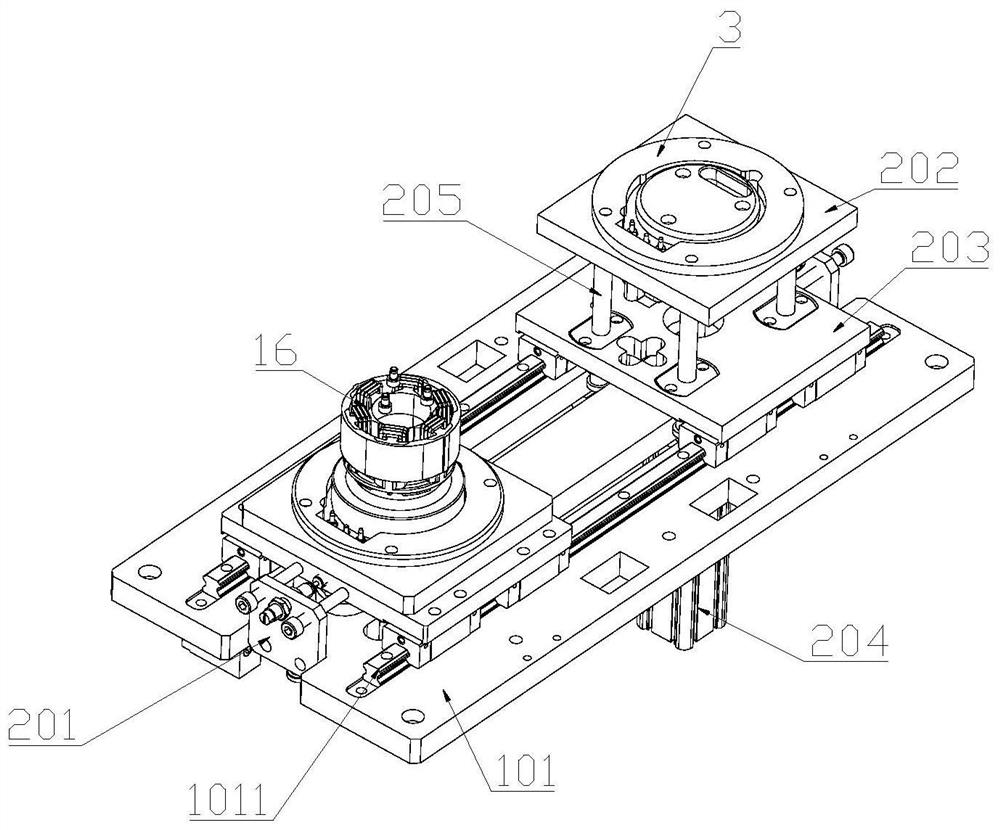

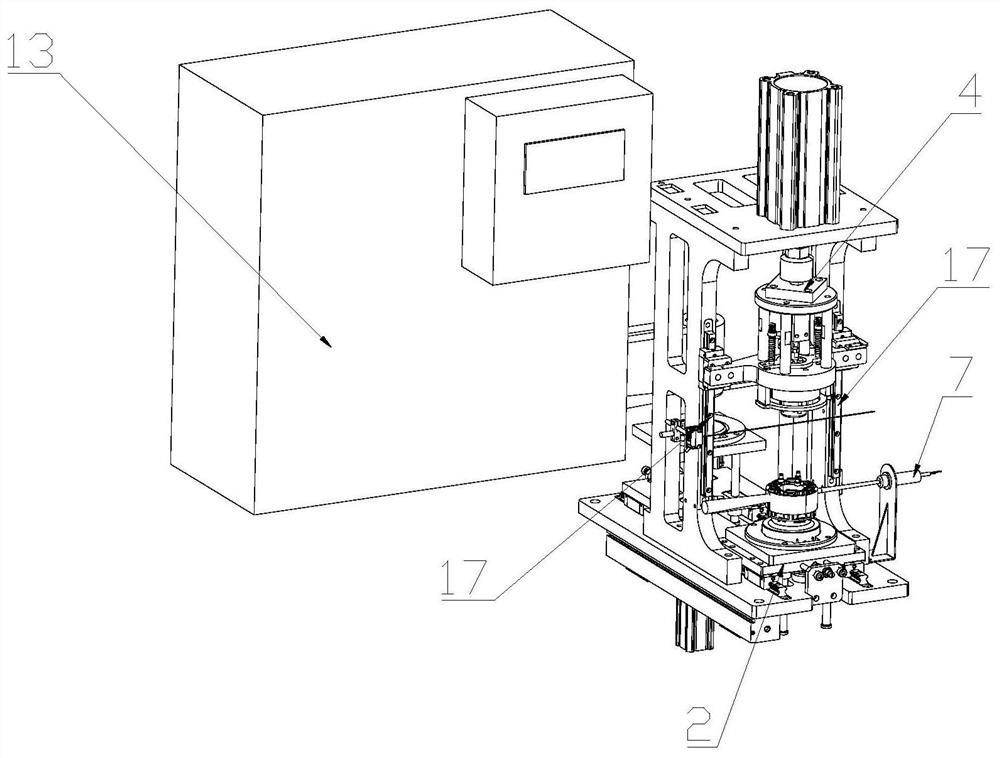

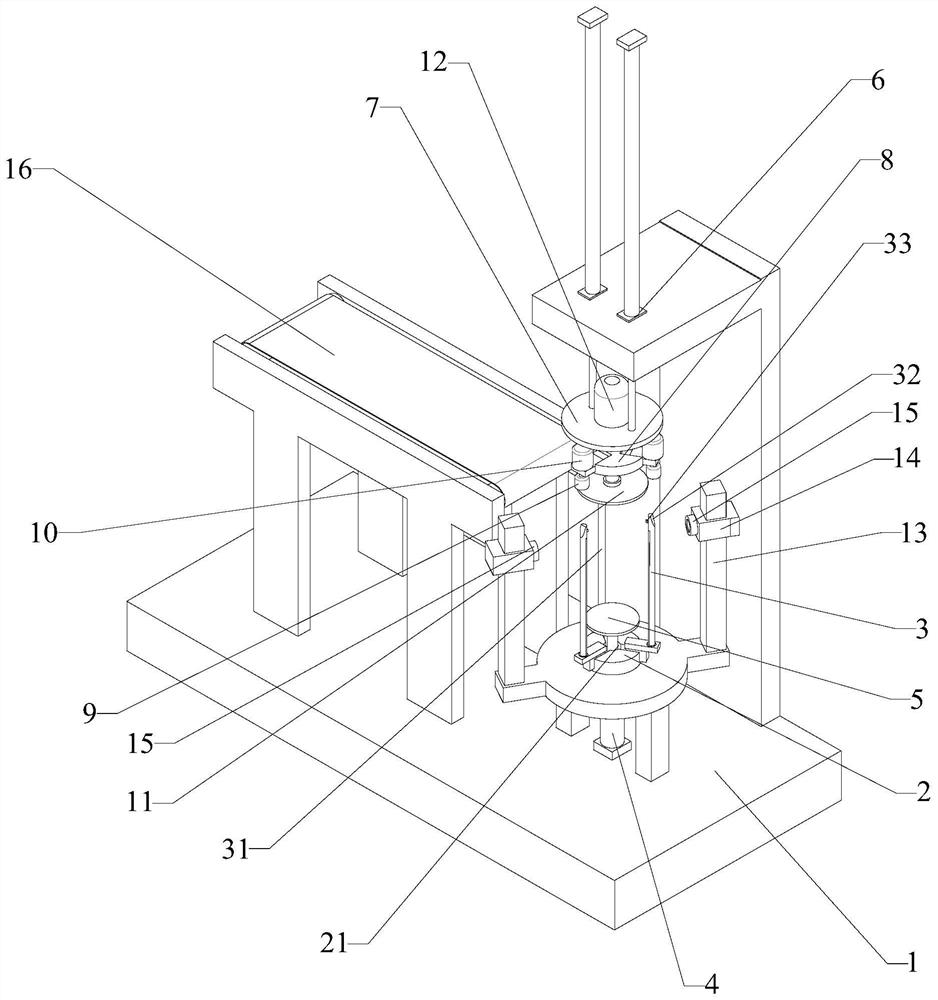

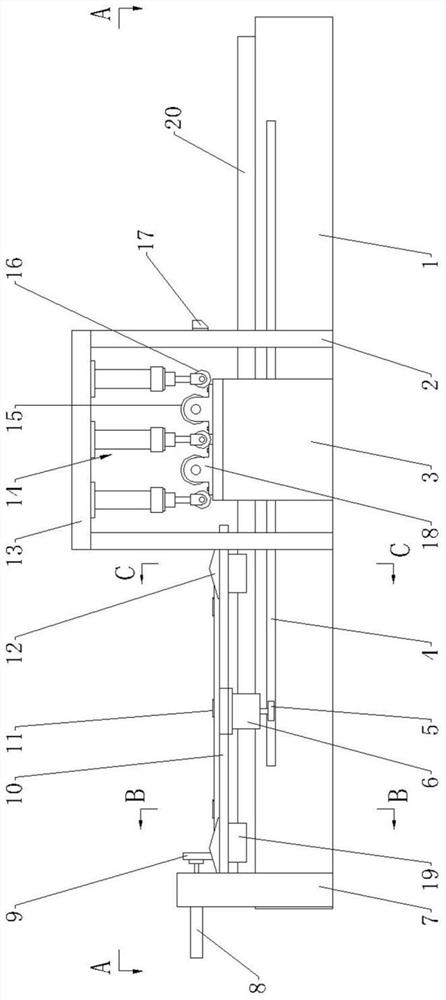

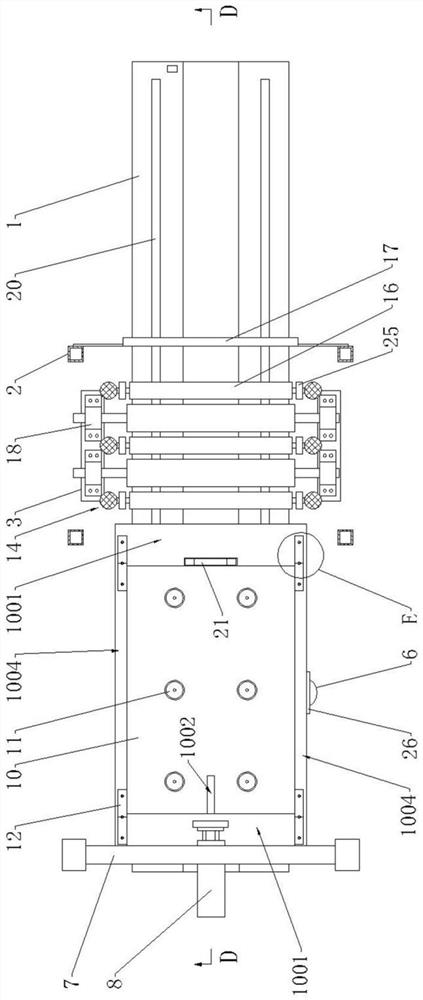

Hot charging equipment for motor stator

The invention discloses hot charging equipment for a motor stator, relating to the technical field of motor processing. The hot charging equipment comprises a horizontal sliding assembly, a casing positioning fixture, a stator positioning fixture and a heating device, in the specific use process, the motor is arranged on the casing positioning fixture, the motor stator is arranged on the stator positioning fixture, the horizontal sliding assembly conveys the machine shell to the heating device to be heated initially, after heating is completed, the horizontal sliding assembly conveys the machine shell to the position under the stator positioning clamp, and then the stator positioning fixture works to press the motor stator into the motor shell. The hot charging equipment for the motor stator replaces manual work to complete press fitting of the motor stator, and manpower is effectively saved.

Owner:CHONGQING FORYS AUTOMATION EQUIP

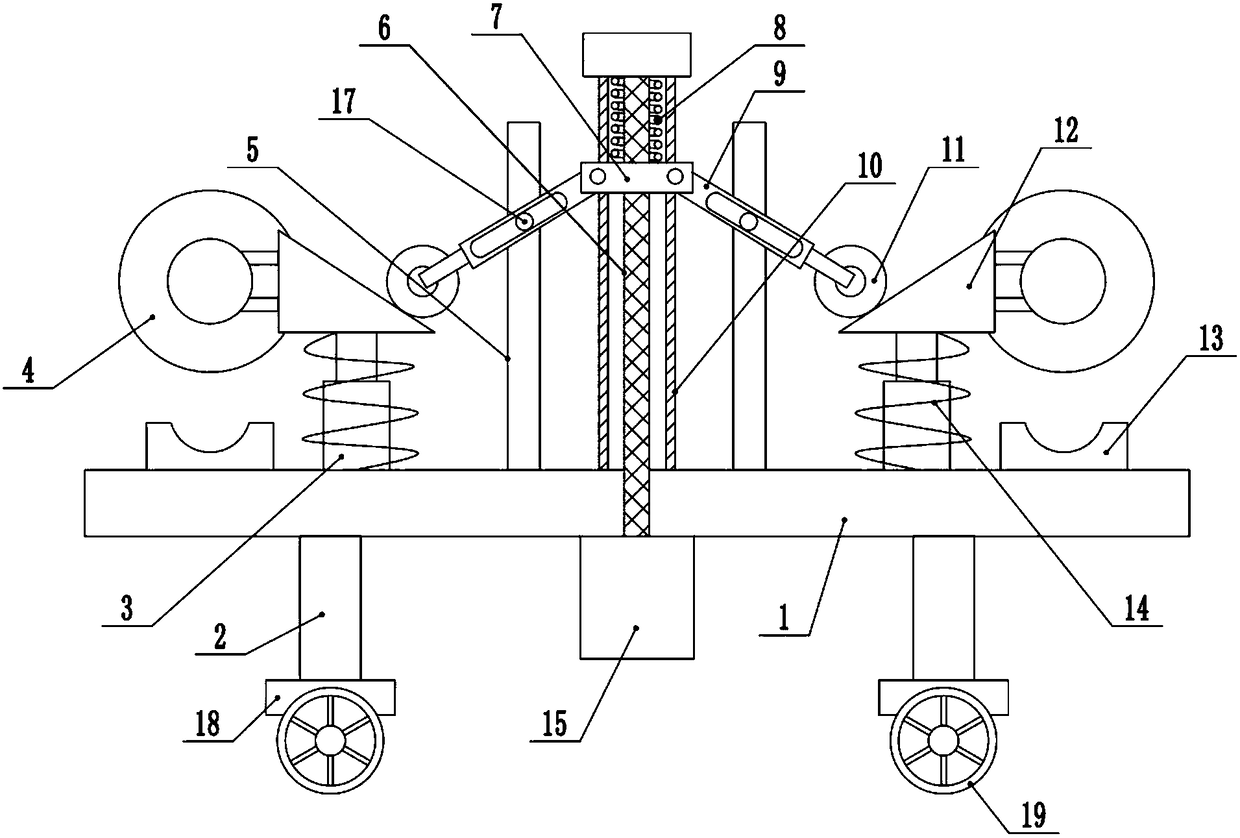

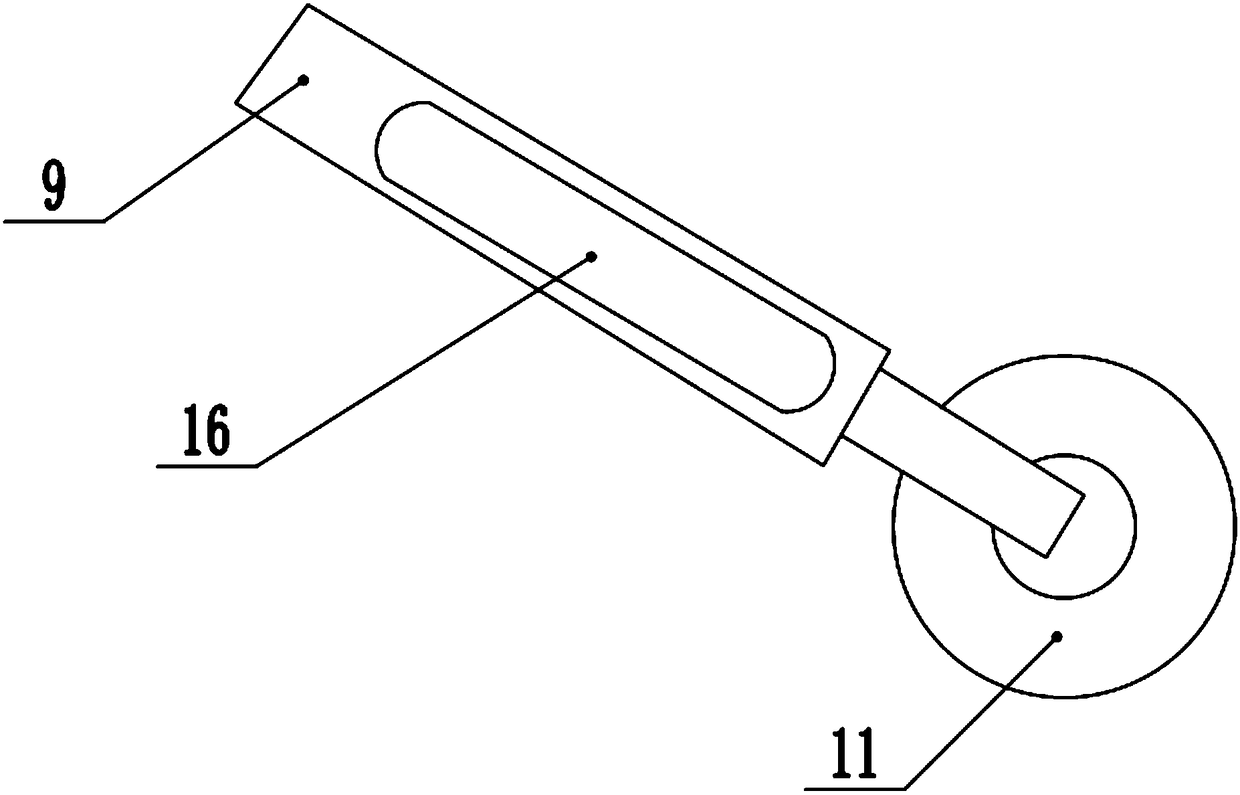

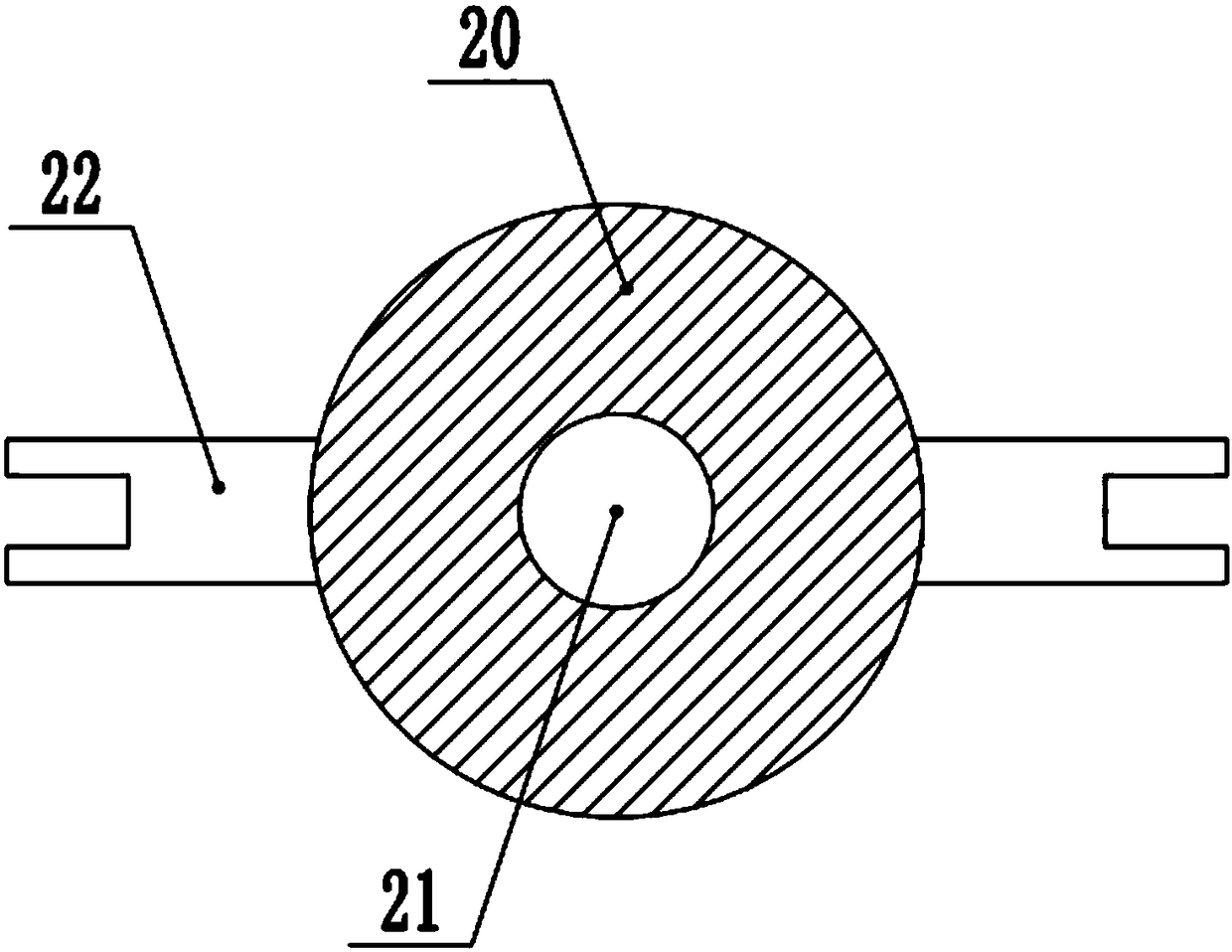

Motor mounting equipment capable of self-adaptively adjusting support balance according to uneven ground

InactiveCN110868012AReduce vibrationCancel noiseSupports/enclosures/casingsControl engineeringElectric machinery

The invention relates to the technical field of motor processing, and discloses motor mounting equipment capable of self-adaptively adjusting support balance according to the uneven ground. The motormounting equipment comprises a fixing frame. Adjusting bases are fixedly connected to the front side and the rear side of the bottom of the fixing frame; a first screw rod is rotatably connected to the front face of the fixing frame; the first screw rod extends into the fixing frame, and a first sliding block is rotatably connected to the end of the first screw rod; and a third screw rod extends into the fixing frame, and a second sliding block is rotatably connected to the end of the third screw rod. According to the motor mounting equipment capable of self-adaptively adjusting the support balance according to the uneven ground, an adjusting cylinder is limited through a third bolt, so that the stability of a mounting frame to the ground is enhanced, the working stability of the motor isindirectly improved, the mounting frame is firmer, and the motor mounting equipment is suitable for different ground mounting environments; and an arc-shaped plate is fixed to the upper surface of themotor by rotating the second screw rod, so that the mounting stability and firmness of the motor are ensured.

Owner:邹锁方

Circular sheet stacking and polishing device and stacking and polishing method thereof

ActiveCN113579891AAutomatic grindingEfficient grindingEdge grinding machinesFinal product manufactureElectric machinePolishing

Owner:福安市中虹机电技术开发有限公司

Reaction device for processing motor silicon steel sheet coating liquid

InactiveCN111482152AStir fully and comprehensivelyImprove reaction processing efficiencyShaking/oscillating/vibrating mixersRotary stirring mixersElectric machineReaction rate

The invention discloses a reaction device for processing motor silicon steel sheet coating liquid, and relates to the technical field of motor processing. The reaction device comprises a reaction cylinder, a liquid storage tank is communicated with the interior of the reaction cylinder through a transmission mechanism, a vertical reciprocating mechanism is connected to the transmission mechanism,a lifting plate is connected to the vertical reciprocating mechanism, and a circulating lifting mechanism is arranged in the reaction cylinder; a sleeve is driven by the transmission mechanism to drive stirring blades to rotate and stir coating liquid, the reaction processing efficiency of the coating liquid is improved, the arranged vertical reciprocating mechanism can drive the lifting plate tovertically ascend and descend in a reciprocating mode, the stirring range of the coating liquid in the reaction cylinder is widened, and the reaction rate is further improved; the arranged circulatinglifting mechanism can achieve circulating up-and-down stirring of the coating liquid in the reaction cylinder, the coating liquid can be repeatedly stirred by cutting blades in the stirring process,stirring of the coating liquid is more sufficient and comprehensive, and the production reaction efficiency is effectively improved.

Owner:黄国普

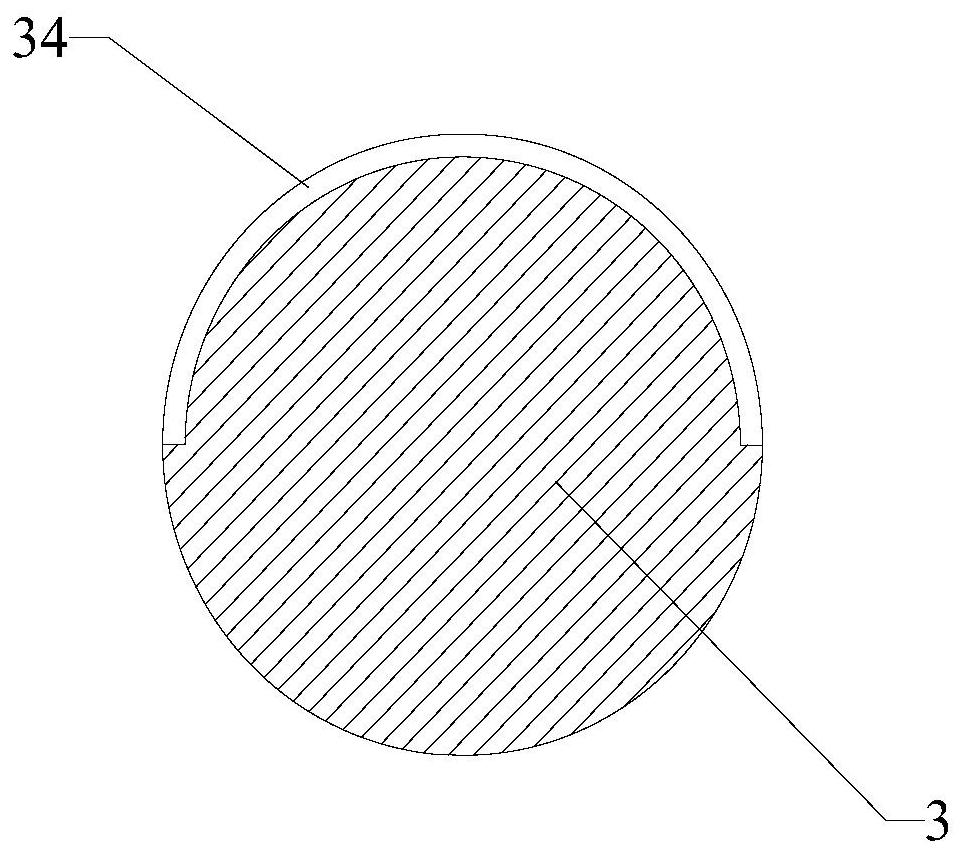

Outer rotor motor cooling structure

InactiveCN112491171AImprove reliabilityIncrease the difficultyMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineCooling effect

The invention belongs to the technical field of motors, and relates to an outer rotor motor cooling structure, which comprises a stator cooling assembly and a rotor cooling assembly, and is characterized in that the stator cooling assembly comprises a heat pipe mounted on a stator core close to a stator slot, one end of the heat pipe is positioned in a cooling hole of the stator core close to thestator slot; and the other end of the heat pipe is located in a cooling fin outside the motor end cover, and the rotor cooling assembly comprises a rotor fan located at the end part of the rotor core.The outer rotor motor cooling structure has the advantage that the cooling effect on the motor stator and rotor can be improved on the basis of not obviously increasing the motor machining process difficulty and the manufacturing cost.

Owner:QILU UNIV OF TECH

Double-station cutting device for automobile pipe fitting processing

InactiveCN108568561AReasonable structureInnovative designTube shearing machinesShearing machine accessoriesPressure systemPipe fitting

The invention discloses a double-station cutting device for automobile pipe fitting processing. The double-station cutting device comprises a base, wherein the middle part of the upper end of the baseis connected with a fixing tube; a rotating screw rod is arranged in the middle part of the fixing tube; the middle part of the rotating screw rod is connected with an ascending and descending blockthrough a threaded hole; the two ends of the ascending and descending block are connected with a connecting rod; the middle part of the connecting rod is provided with a sliding groove; a fixing shaftis arranged in the middle part of the sliding groove; the back end of the fixing shaft is connected with a support rod; the bottom end of the connecting rod is connected with a rolling wheel; the lower end of the rolling wheel is in contact with a wedge-shaped block; the middle part of the lower end of the wedge-shaped block is connected with a telescopic rod; the outer side of the wedge-shaped block is provided with a cutting wheel; cutting grooves are fixed at the two sides of the upper end of the base; support legs are connected at the two sides of the lower end of the base. The double-station cutting device realizes the vertical movement on the ascending and descending block, so that the requirements of a cutting wheel on the automobile pipe fitting cutting can be met; the vertical movement of the cutting wheel is realized through a pure mechanical structure; the use of a hydraulic or air pressure system is avoided; the reliability of the whole system and the whole motor processing production efficiency are improved; meanwhile, the manufacturing cost is also reduced.

Owner:HEFEI LIANSEN YUTENG NEW MATERIAL TECH DEV CO LTD

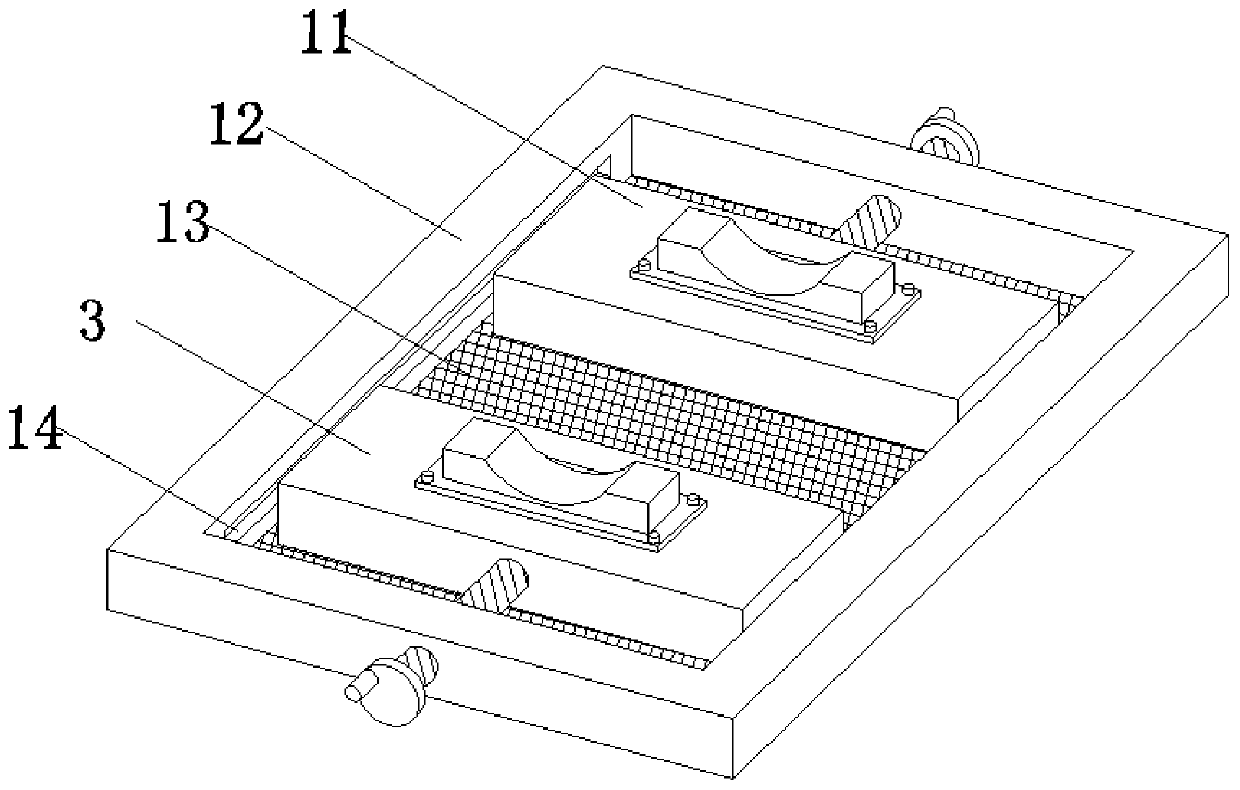

Positioning tool for assembling motor shell

ActiveCN114505807AImprove stabilityImprove assembly accuracyWork holdersManufacturing dynamo-electric machinesElectric machineryMachining

The invention relates to the technical field of motor machining, in particular to a positioning tool for assembling a motor shell, which comprises a workbench, a fixing mechanism and positioning mechanisms, the workbench is arranged on the ground, the fixing mechanism is arranged on the upper end face of the workbench, and the positioning mechanisms are symmetrically arranged at the left end of the workbench front and back; according to the fixing mechanism, under the condition that the main body of the motor shell is combined to be of a cylindrical structure, the stability of the motor shell is improved by increasing the number of pressure bearing points on the surface of the motor shell, and meanwhile the motor shell is subjected to buffering and damping effects; according to the invention, the positioning mechanism plays a role in guiding and positioning the connection between the end cover and the motor shell so as to improve the assembly precision and the assembly speed of the motor shell, and can further limit the motion range of the motor shell so as to improve the stability of the motor shell.

Owner:丰县飞洋金属制品有限公司

Aluminum plate surface polishing device

InactiveCN112355840AFully automatedImprove polishing efficiencyPolishing machinesGrinding drivesPolishingElectric machinery

The invention discloses an aluminum plate surface polishing device which comprises a base, a machining platform, a rack, elastic columns, flattening rollers and polishing rollers. A linear guide railand a rack are arranged on the base. A sliding block is arranged on the linear guide rail. The machining platform is fixed above the sliding block, and a first motor is arranged below the machining platform; a stepped hole is formed in the machining platform, and a vacuum chuck is arranged in the stepped hole; a longitudinal milling groove and a transverse milling groove are formed in the machining platform, and an inclined wedge is arranged in the longitudinal milling groove; the rack is composed of a supporting beam and a top plate, and the top plate stretches across the base; at least two flattening rollers are provided, and the two ends of each flattening roller are connected with the lower ends of the elastic columns, and the upper ends of the elastic columns are fixed to the top plate; and rigid rolling wheels are arranged at the two ends of each flattening roller. The polishing roller is arranged between every two adjacent flattening rollers, liftable racks are arranged on the two sides of the base, and the two ends of each polishing roller are connected with the racks. According to the aluminum plate surface polishing device, automatic polishing operation of an aluminum plate is achieved, and the aluminum plate surface polishing device benefits improvement of the polishing efficiency and the polishing quality.

Owner:河南龙盛新材料科技有限公司

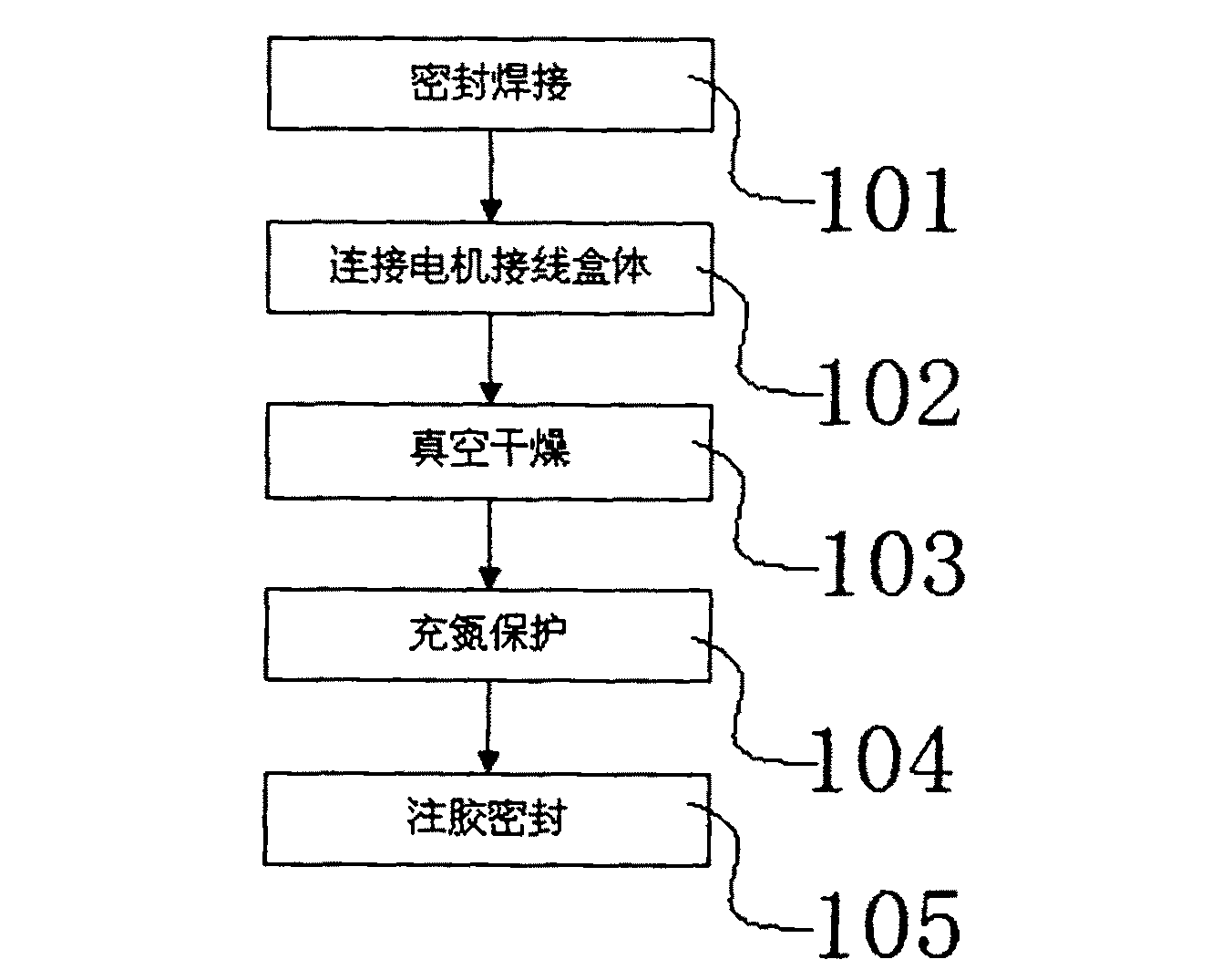

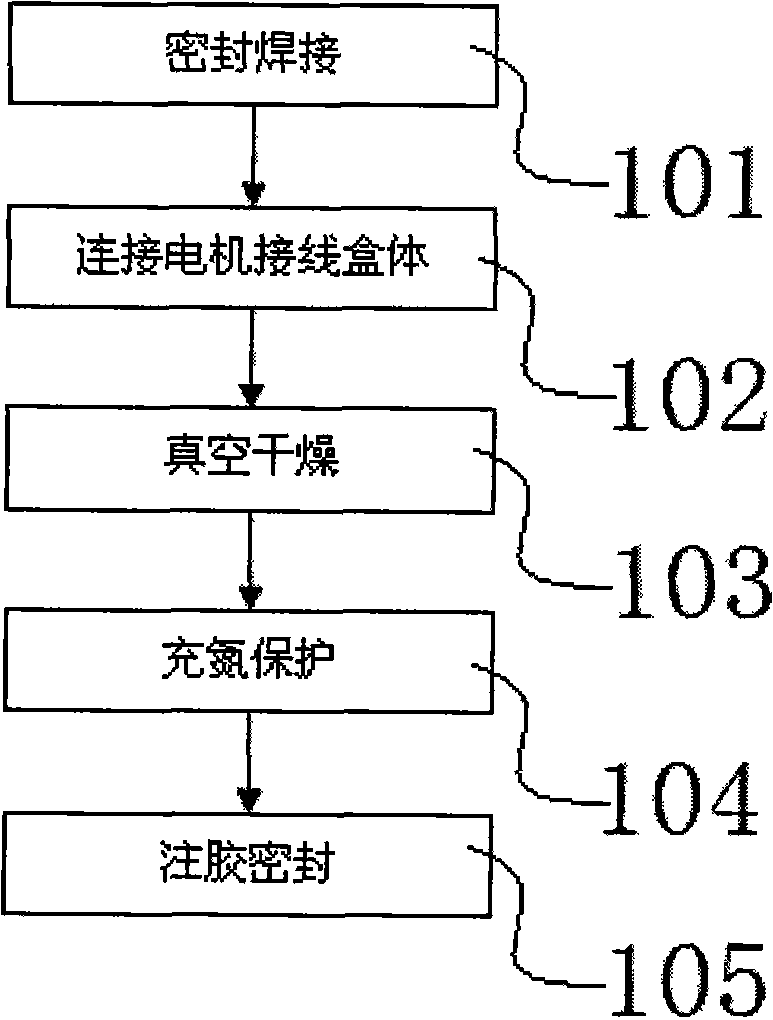

Vacuum drying technology in motor processing method

ActiveCN101989797ASolve legacy problemsSolve the drum phenomenonManufacturing dynamo-electric machinesStator coilNitrogen

The invention discloses vacuum drying technology in a motor processing method, which is implemented by the following steps of: pressing a stator coil into a motor shell assembly, pressing a stator shielding sleeve into the stator coil, and performing seal welding; connecting a power supply to an outgoing line of the motor, vacuumizing a sealed motor cavity, electrifying to raise the temperature according to set parameters, and pumping humidity in the motor cavity from a vacuum tube into a vacuum pump at high temperature for exhaust; and after drying, introducing nitrogen for oxidation-resistant protection; and finally injecting glue into a junction box body of the motor for sealing, and curing for 12 hours. The problem of humidity residue in motor processing can be effectively solved.

Owner:HEFEI XINHU CANNED MOTOR PUMP

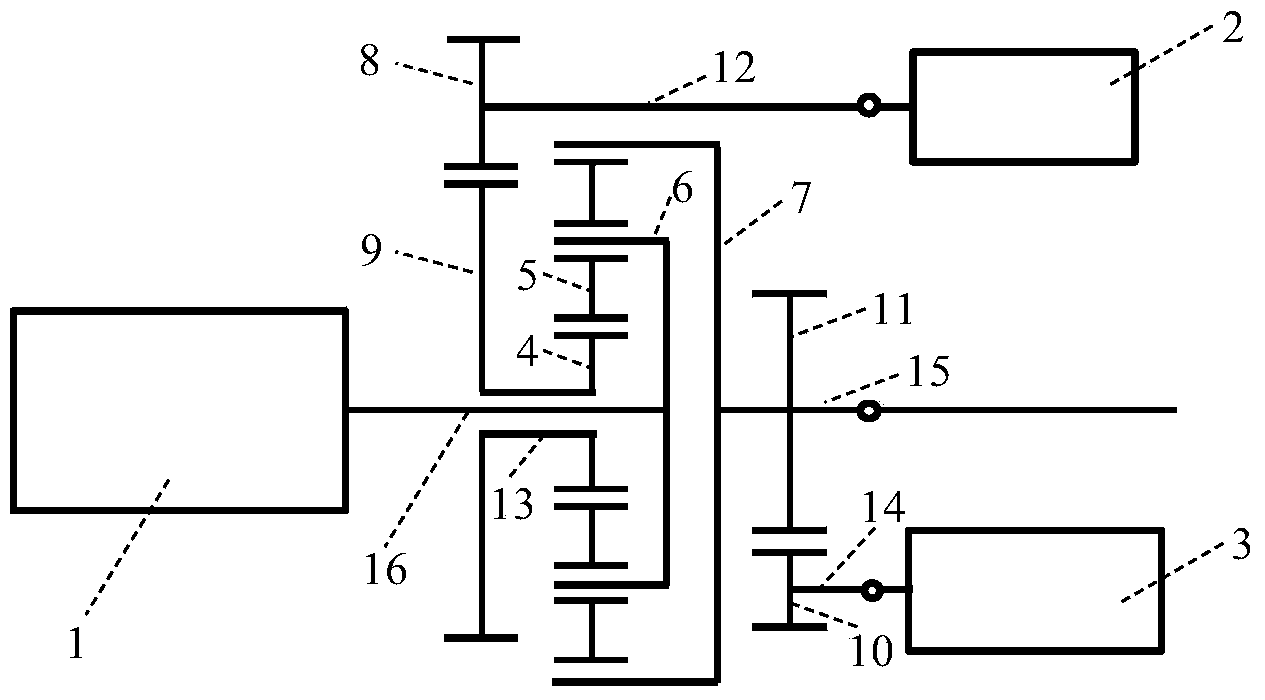

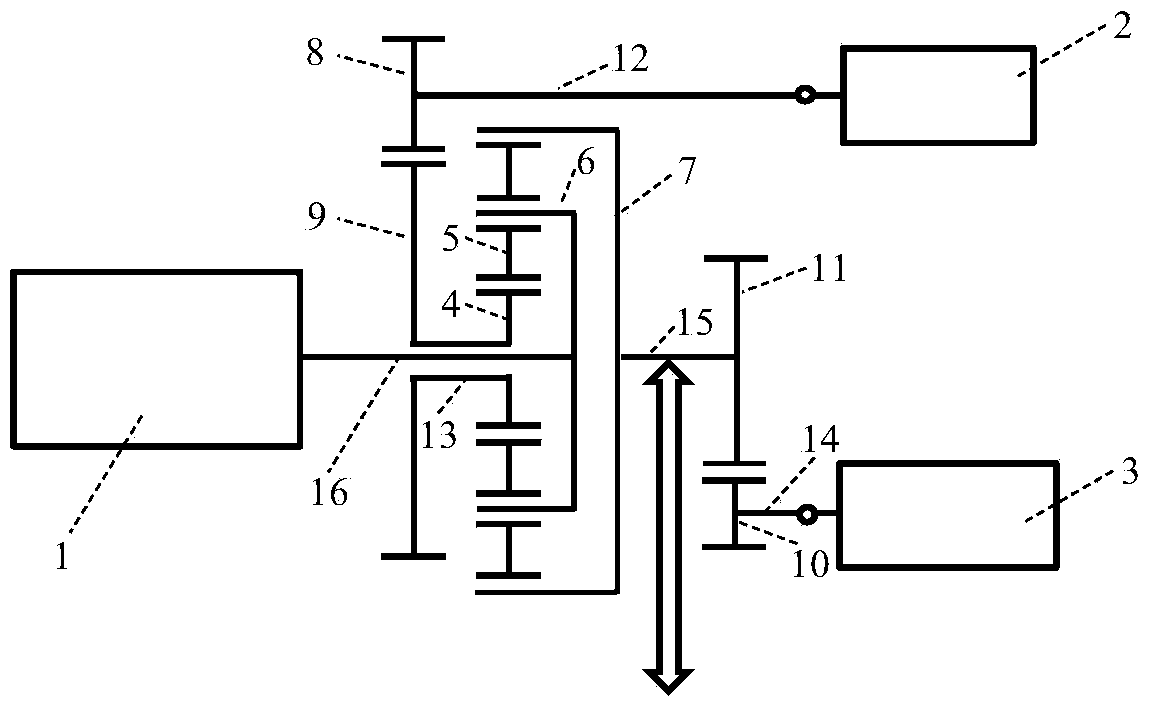

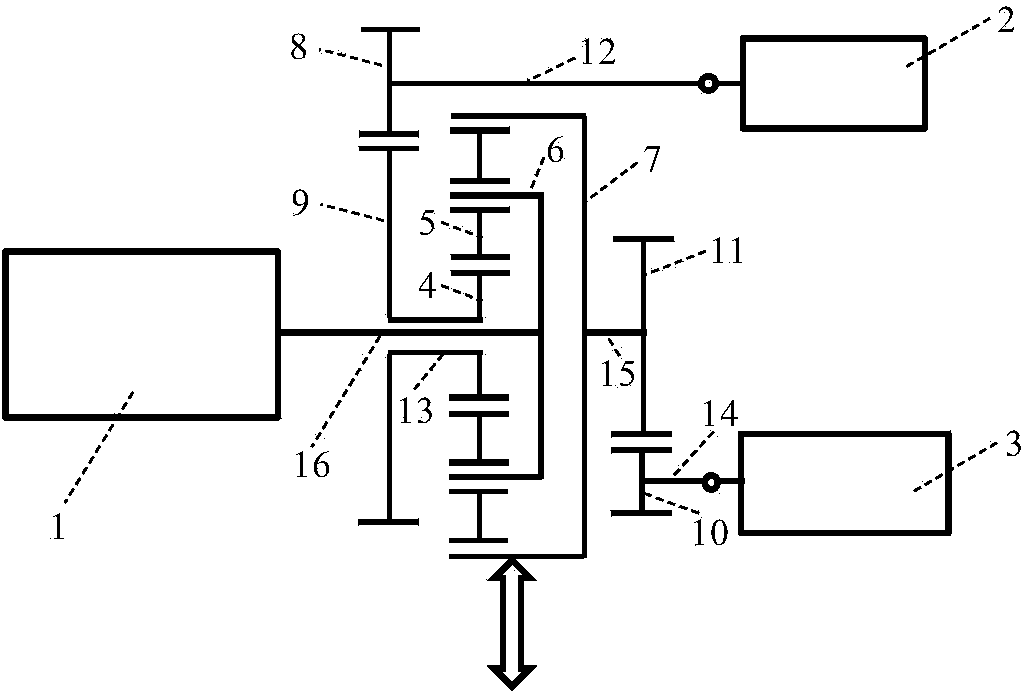

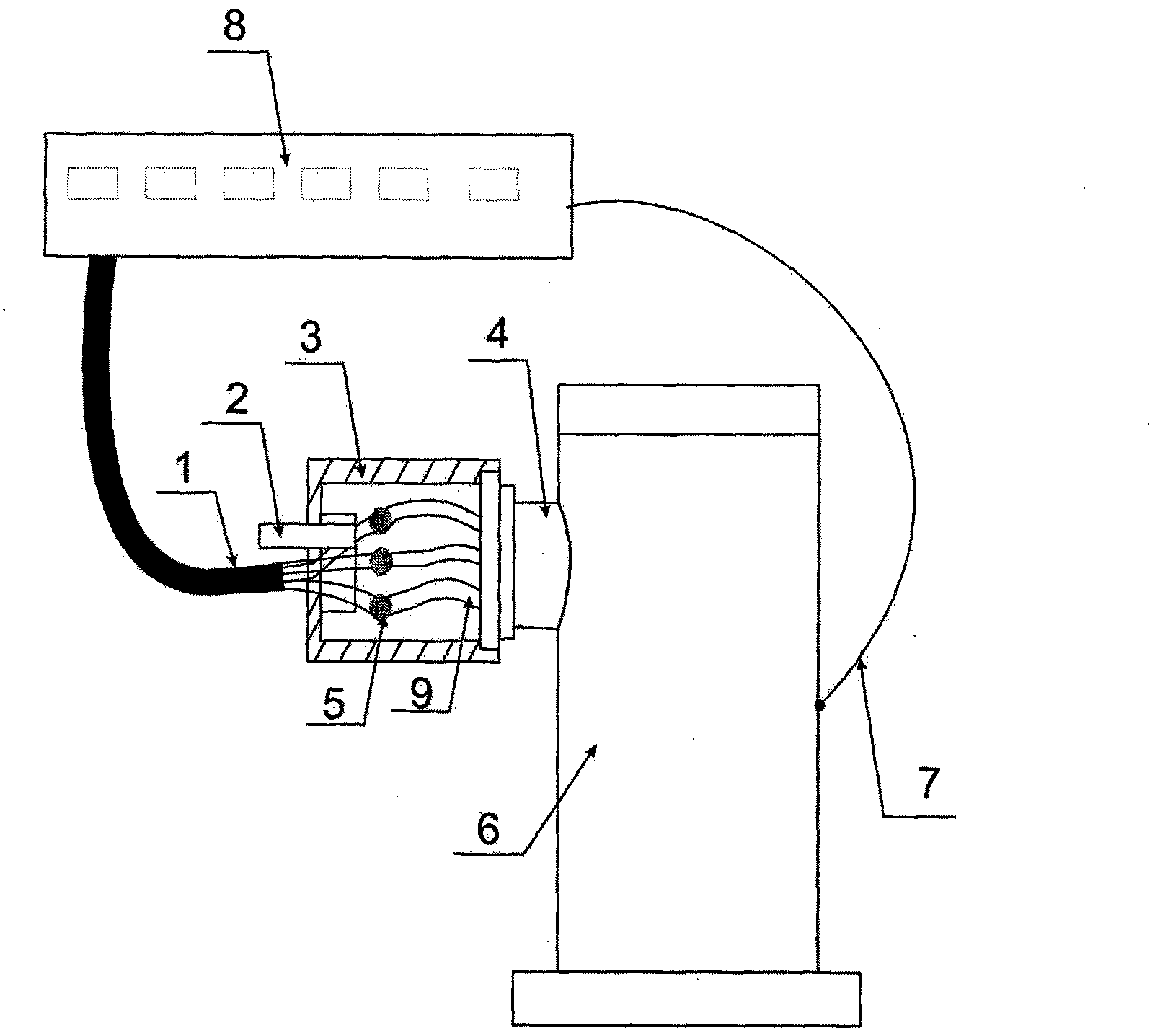

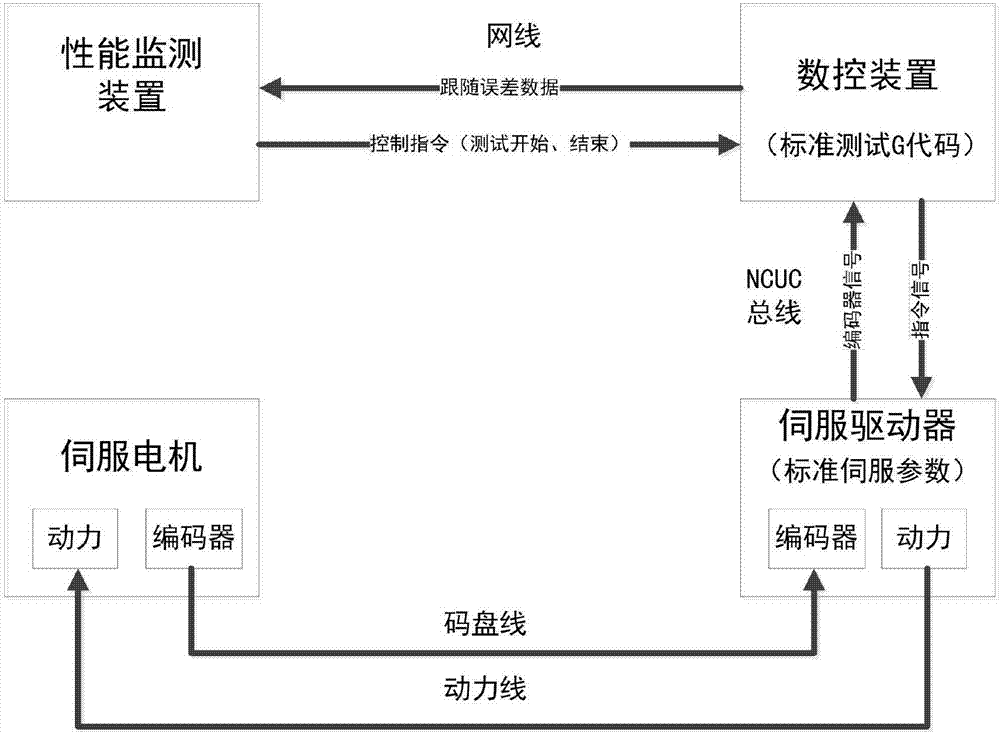

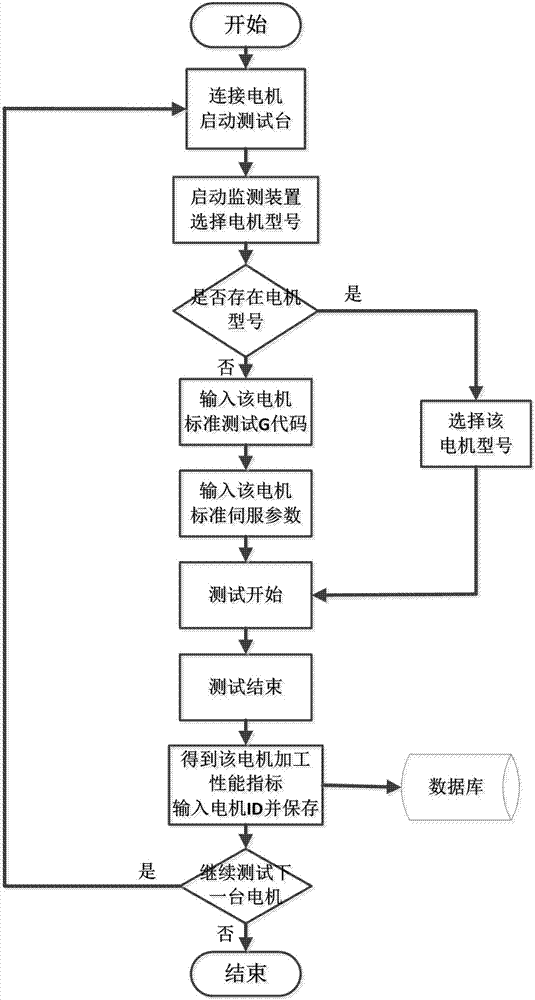

System and method for monitoring the processing performance indexes of motor

ActiveCN106909125AAccurate and intuitive performance evaluationEasy to buildProgramme controlComputer controlMonitoring systemElectric machinery

The invention discloses a system and a method for monitoring the processing performance indexes of a motor. The system comprises a numerical control apparatus, a servo driver, a performance monitoring device and a tested servo motor. The servo driver is used to receive the instruction signals from the numerical control apparatus and controls the servo motor to transmit the actual position data fed back by an encoder; the numerical control apparatus is used to run the standard testing G codes and obtains the actual position data fed back by the servo motor encoder. According to the difference between the instruction position data generated from the running and moving of the tested servo motor and the actual position data, following error fluctuation data are generated and transmitted to the performance monitoring device. The performance monitoring device evaluates the processing performance of the tested servo motor according to the following error fluctuation data and makes statistics and saves the performance index of the tested servo motor. The monitoring system of the invention can be created easily; the measurement can be automatically performed; the operation is easy; the measurement time is shortened; and the measurement result is accurate.

Owner:WUHAN HUAZHONG NUMERICAL CONTROL

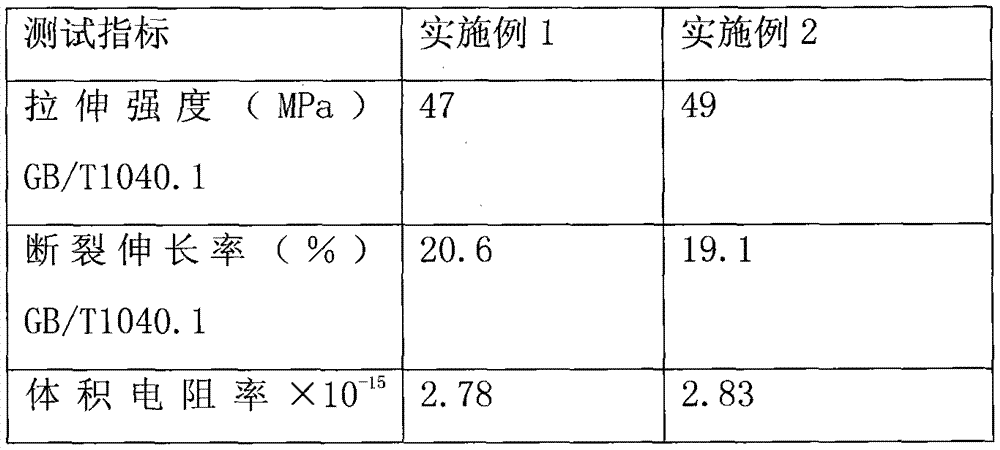

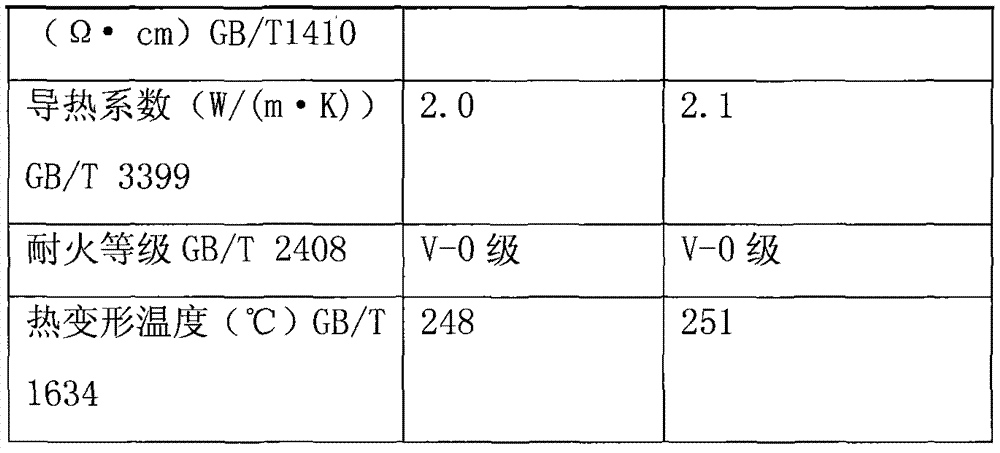

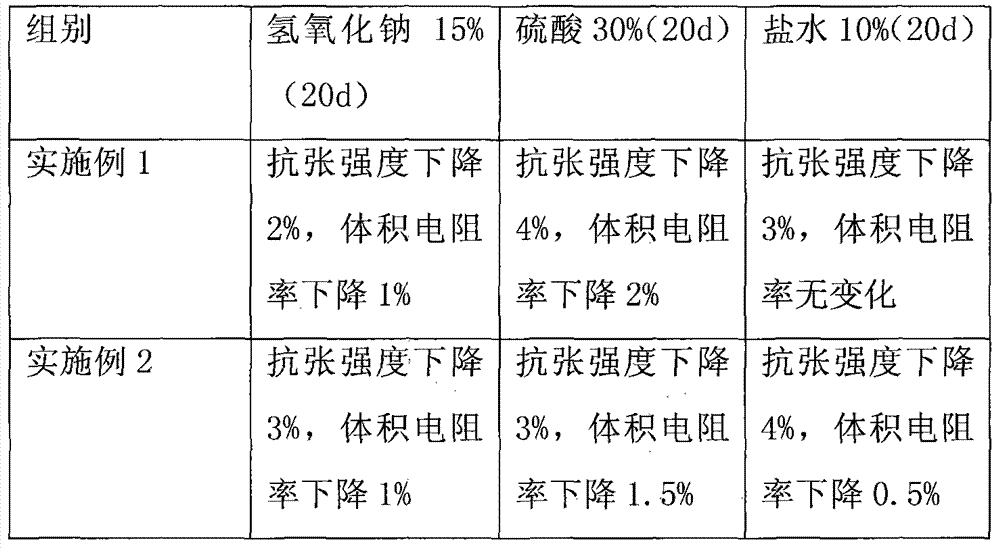

Shell of small and special electrical machine and application of shell

InactiveCN104497543AImprove mechanical propertiesImprove insulation performancePolyethylene glycolPolyvinyl chloride

The invention belongs to the technical field of electrical machine processing and discloses a shell of a small and special electrical machine. The shell is prepared from the following raw materials in parts by weight: 100-120 parts of polyphenylether resin, 40-50 parts of polyvinyl chloride, 30-40 parts of styrene-butadiene rubber, 25-30 parts of polycarbonate, 18-20 parts of polyethylene glycol terephthalate, 15-18 parts of chlorinated paraffin, 12-15 parts of glyceryl tristearate, 8-10 parts of polybenzimidazole, 8-10 parts of ethylene-octylene copolymer, 8-10 parts of silicon carbide, 5-7 parts of silicon nitride, 4-5 parts of white carbon black, 3-4 parts of talcum powder, 2-3 parts of triphenyl phosphate and 1-2 parts of antimony trioxide. The shell of the small and special electrical machine, disclosed by the invention, has the advantages of high mechanical properties, good electrical insulation properties, good flame retardance, good corrosion resistance, good heat dissipating performance and the like.

Owner:STATE GRID CORP OF CHINA +1

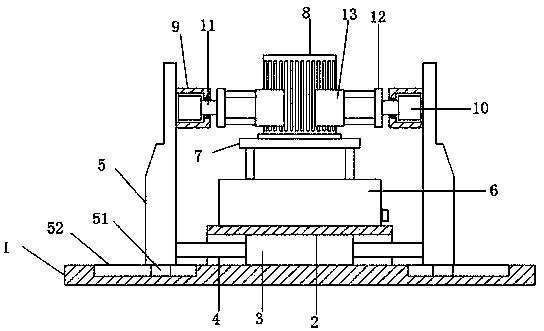

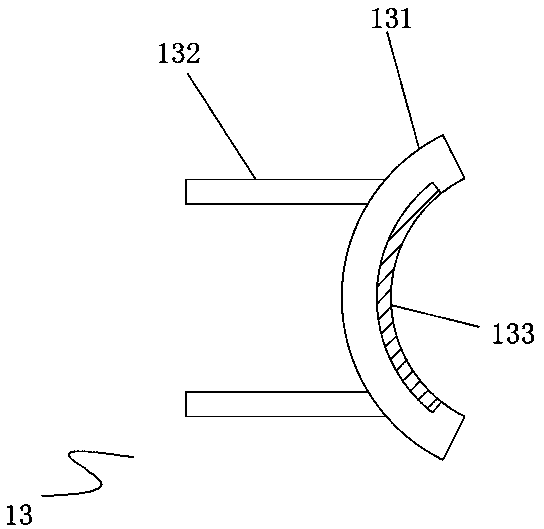

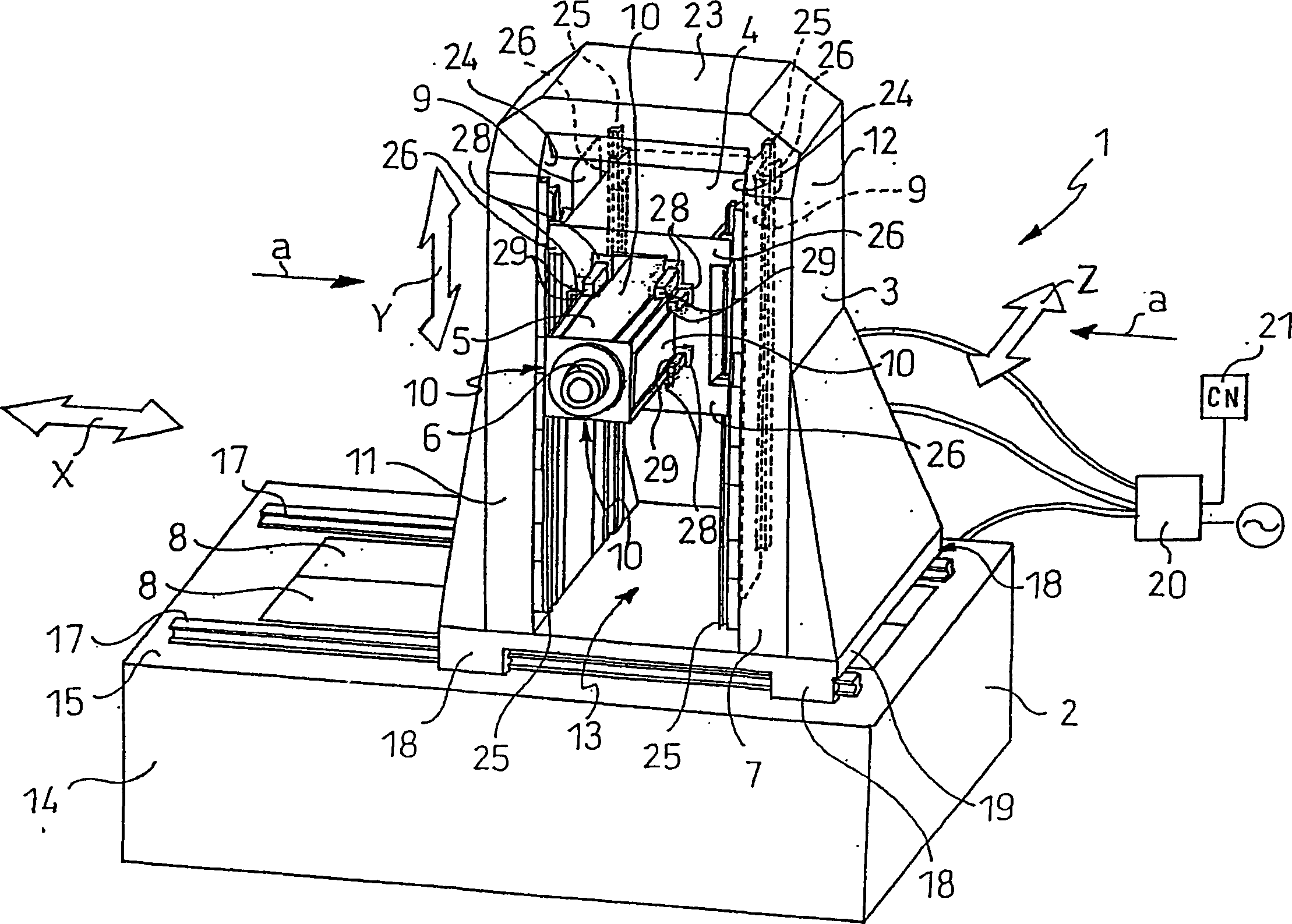

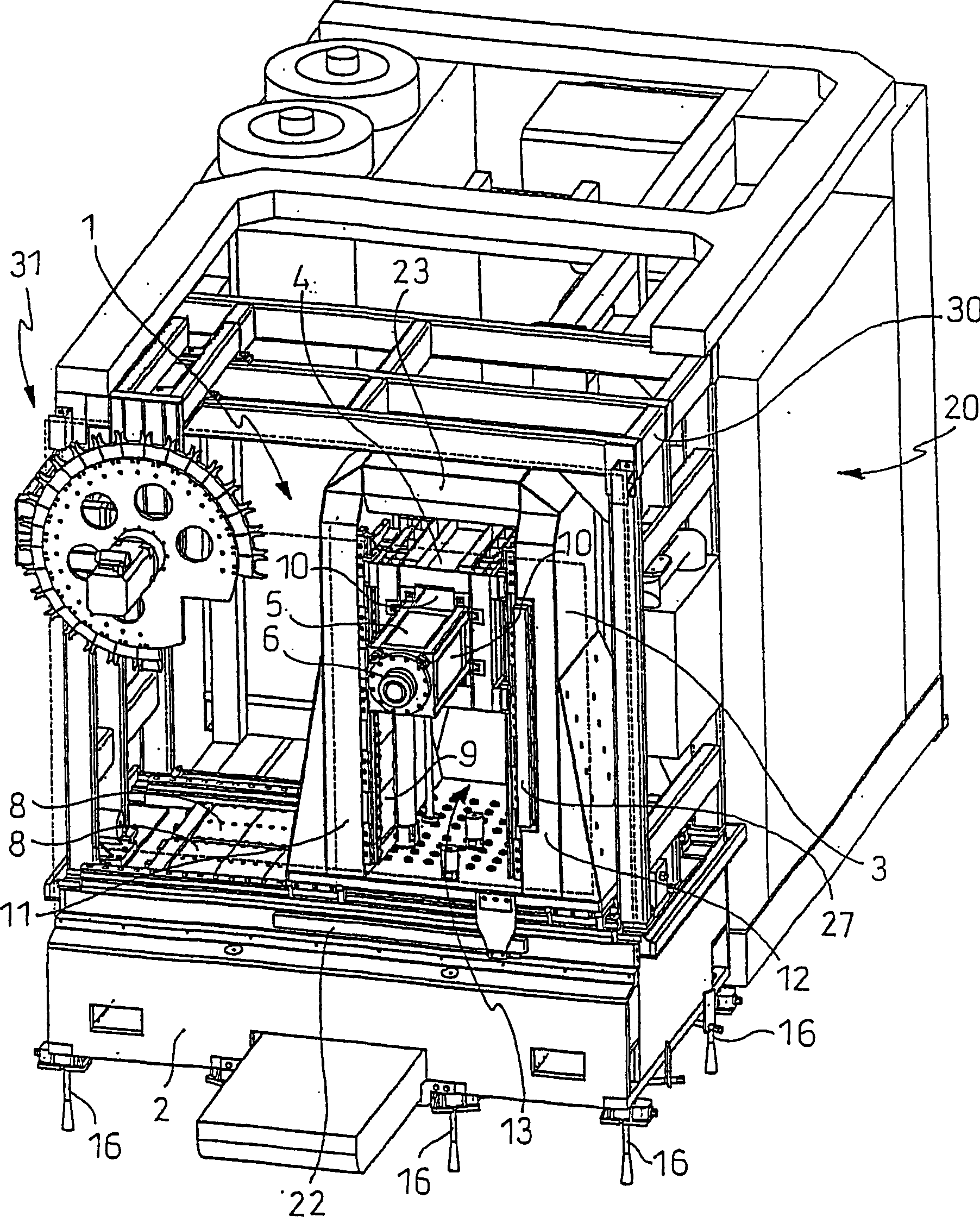

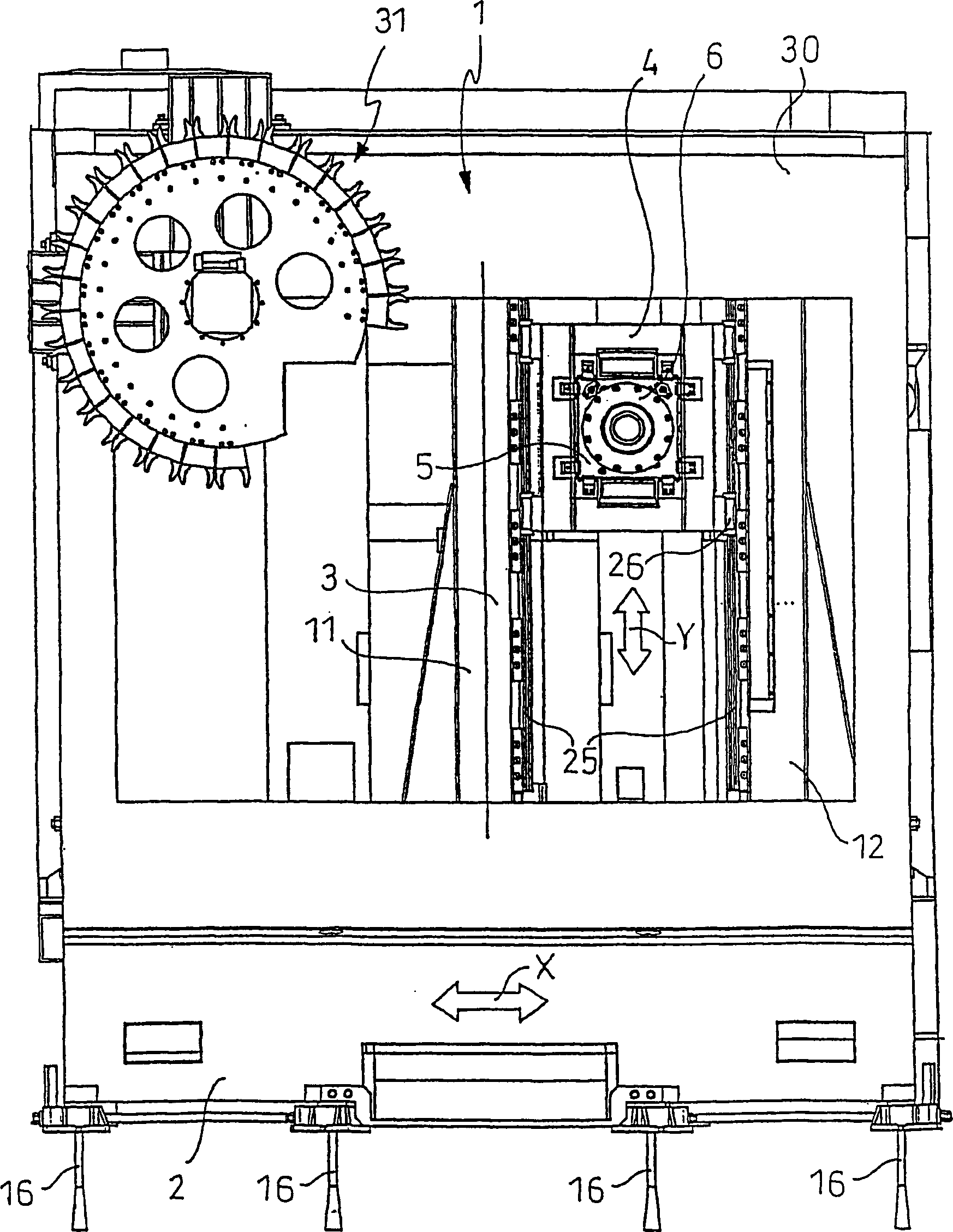

Multi-axial electric machinery process equipment

InactiveCN1273264CTo overcome the above-mentioned defects that existTool changing apparatusFeeding apparatusProcess equipmentElectric machinery

A machine tool (1) driven by linear motors (8, 9, 10) along a plurality of axes (X, Y, Z) and unusually robust and rigid, comprises a bed (2) which defines at least a first axis (X), at least one column (3) operably connected and supported only at one of its ends (7) by said bed (2), for its guided movement along the first axis (X), said at least one column (3) extending away from the bed (2) to define a second axis (Y), at least one saddle mount (4), for its guided movement along a third axis (Z) and supporting a spindle (6) for the movement of a tool, wherein said at least one column (3) comprises a portal structure having a first shoulder (11) opposed to a second shoulder (12) such as to define a window (13) within which the saddle mount (4) is arranged, and wherein, between said opposed shoulders (11, 12) and the saddle mount (4), linear motors (9) are interposed such as to move the saddle mount (4) along said second axis (Y), producing an effect of attraction of the shoulders (11, 12) towards the saddle mount (4).

Owner:CAMOZZI MACHINE TOOLS

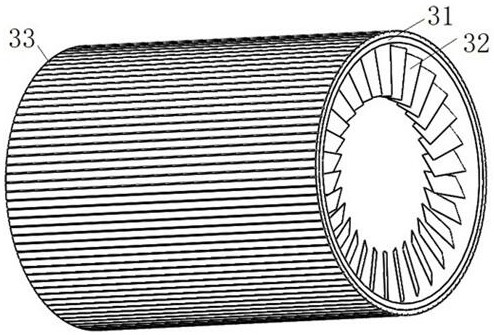

Outer rotor permanent magnetic synchronous motor

InactiveCN101860157AHigh torqueIncrease the moment of inertiaMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSynchronous motorPermanent magnet synchronous motor

The invention relates to an outer rotor permanent magnetic synchronous motor, belonging to the technical field of motors, and solves the problems that in the current permanent magnetic synchronous motor with the outer rotor structure, a permanent magnet is positioned and installed through a magnetic pole positioning sleeve, so that the installation process is complex and the processing of the motor is time-consuming. The outer rotor permanent magnetic synchronous motor comprises a stator and a rotor and adopts a structure that the stator is inside and the rotor is outside, wherein an air gap is formed between the outer ring surface of the stator and the inner ring surface of the rotor; the rotor is composed of a rotor yoke, a rotor press plate, permanent magnets and keys; the rotor yoke and the rotor press plate are fixed together to form an inner circular ring surface with a groove; the groove is evenly divided into a plurality of containing spaces by a plurality of axially set keys; and one permanent magnet is respectively embedded in each containing space. The invention is used as a permanent magnetic synchronous motor.

Owner:HARBIN INST OF TECH

Air-suspending blower motor cooling structure and cooling method

PendingCN111917202AIncrease design difficultyIncrease the difficulty of the processMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineEngineering

The application discloses an air suspension blower motor cooling structure and cooling method. The air suspension blower motor cooling structure comprises an air suspension blower main body and a support assembly; the air suspension blower main body is installed on the support assembly, the air suspension blower main body comprises a motor shell, a heat dissipation volute, a stator and a rotor, wherein the rotor is rotatably installed in the motor shell through an air suspension bearing; the stator is provided with a plurality of heat dissipation grooves, the stator is installed on the inner wall of the motor shell, a first airflow channel is formed between the stator and the inner wall of the motor shell, and a second airflow channel is formed between the stator and the rotor. The supportassembly comprises a bottom support, a support block, angle iron and a connecting block, wherein the support block is installed on the upper portion of the bottom support through bolts, the angle iron is installed on the upper portion of the support block through bolts, one side of the connecting block is installed on the side wall of the angle iron through bolts, and the upper end of the connecting block is fixedly connected with the bottom of the motor shell through bolts. According to the scheme, the heat dissipation efficiency of the motor can be effectively improved under the condition that the machining difficulty of the motor is not increased.

Owner:北京智拓博科技有限公司

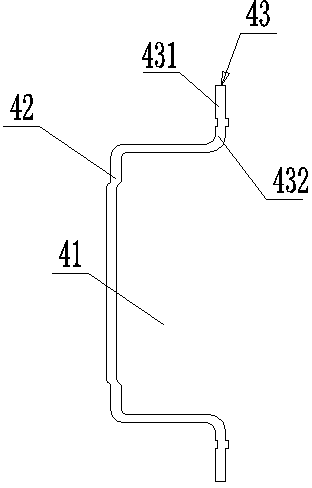

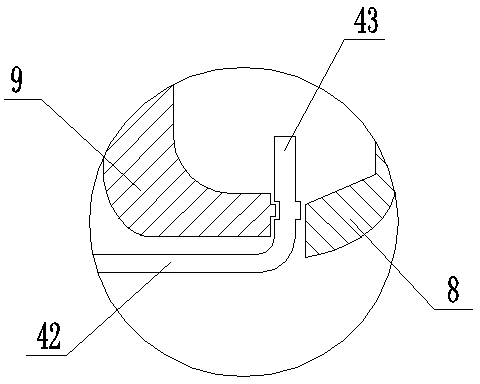

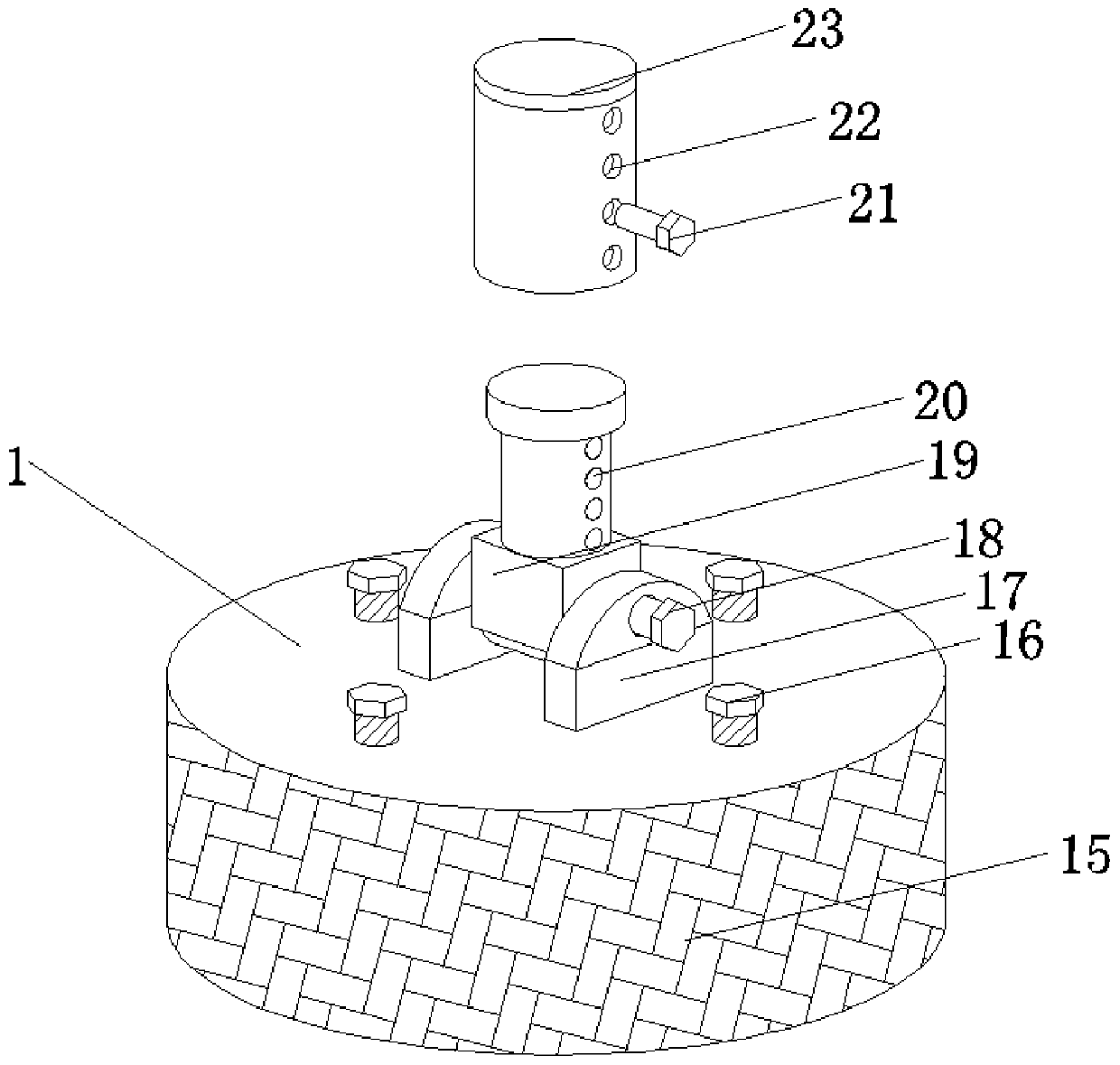

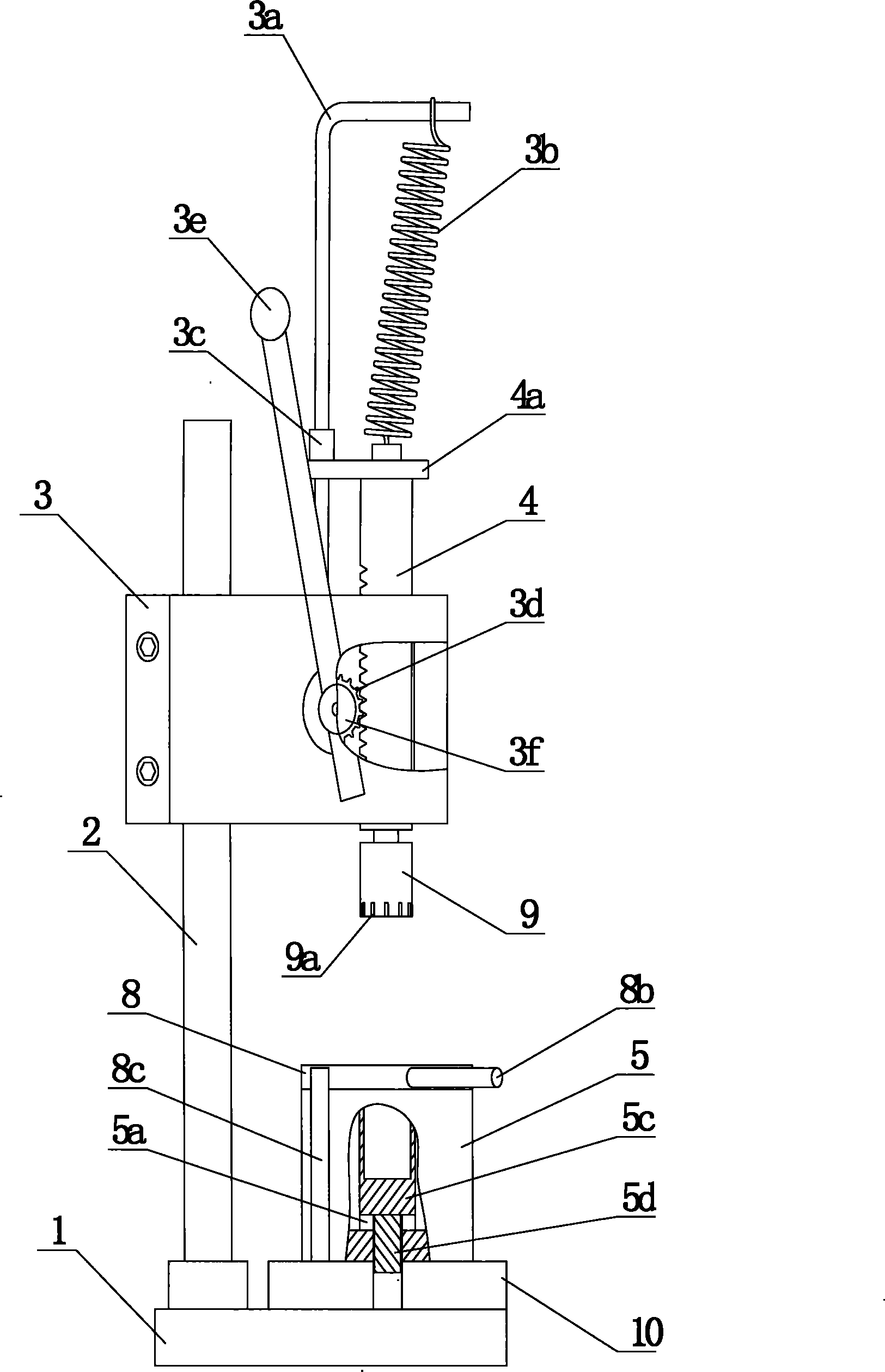

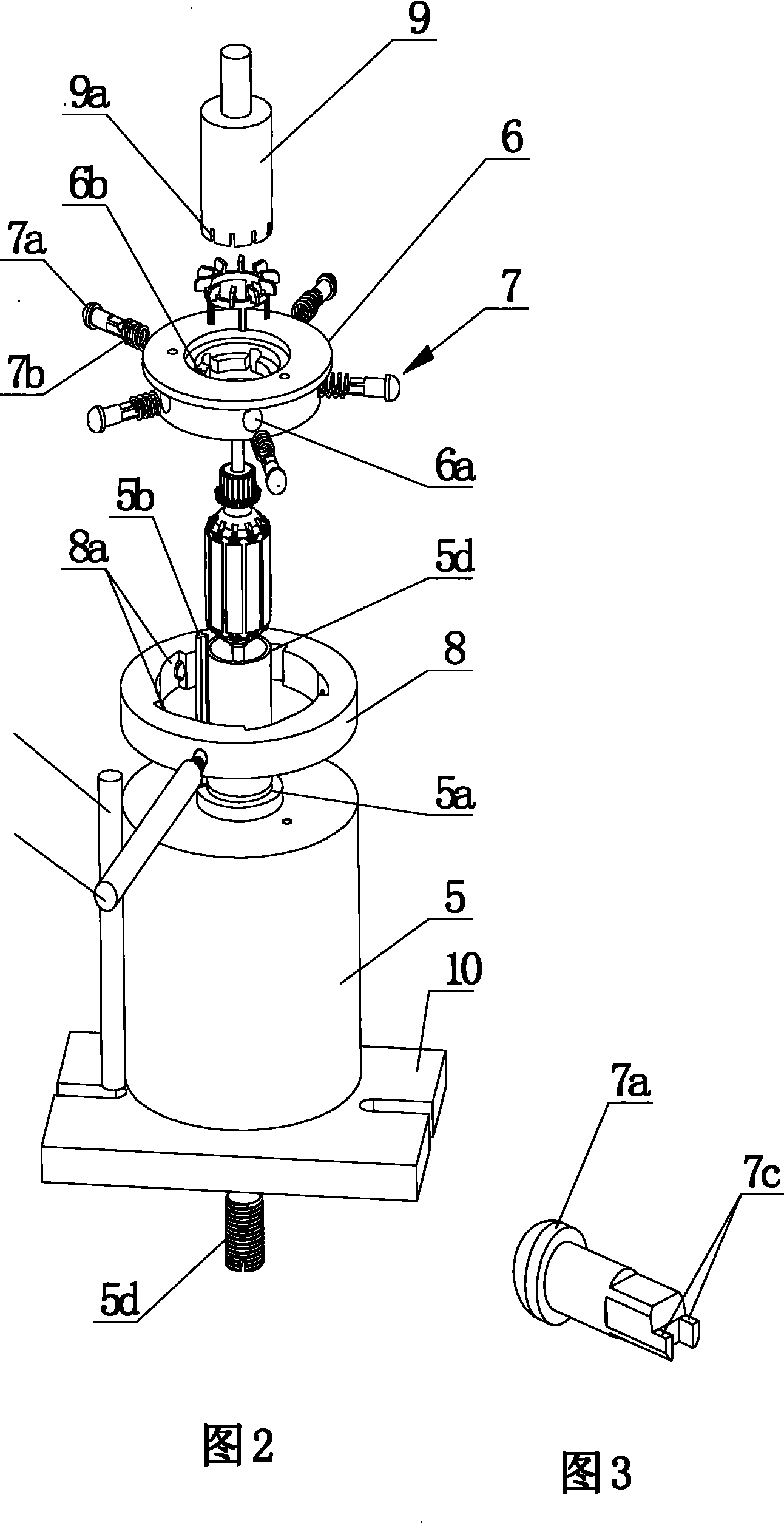

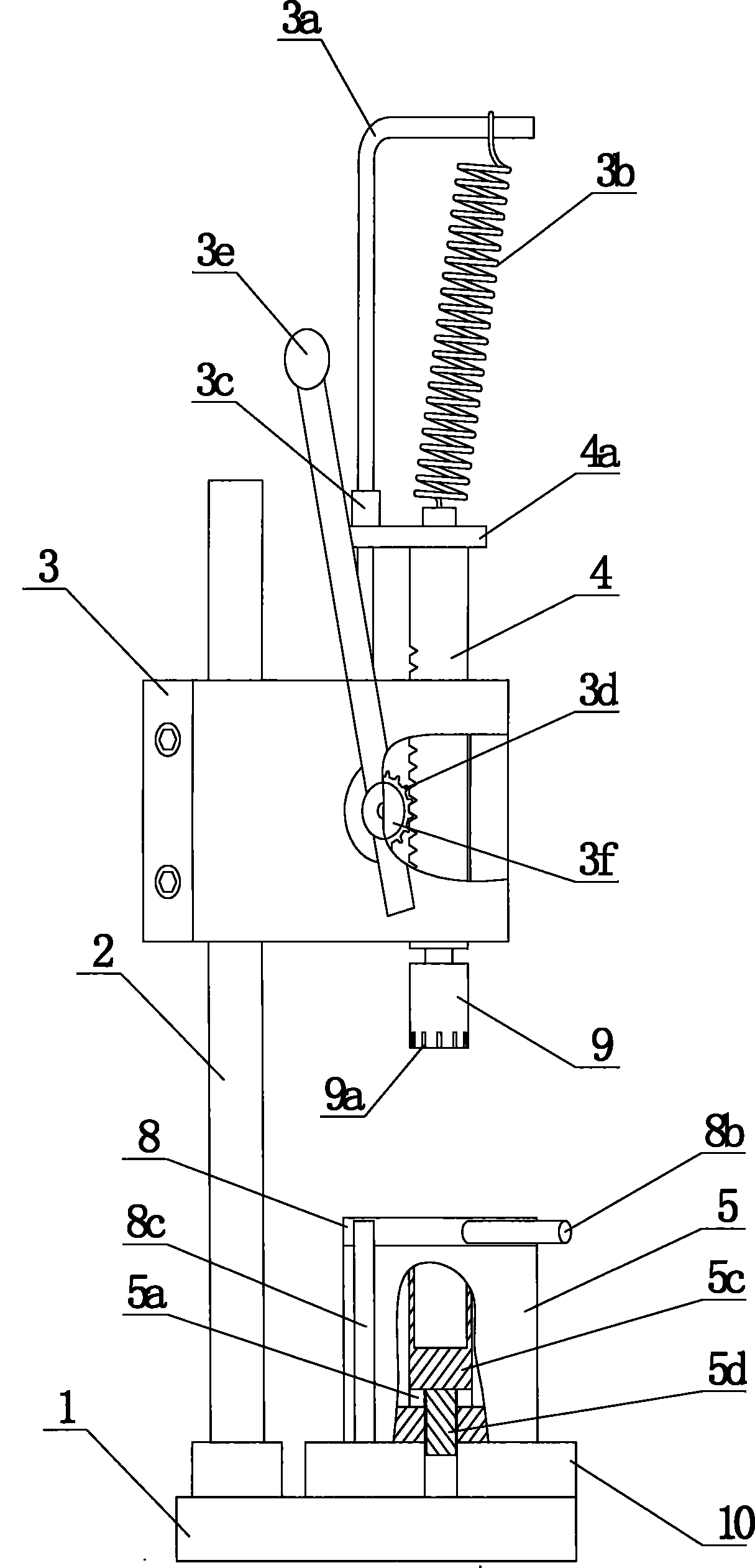

Armature wind wheel press mounting device of motor

ActiveCN101951085ANo occurrenceEasy to operateManufacturing stator/rotor bodiesEngineeringMotor processing

The invention discloses an armature wind wheel press mounting device of a motor, belonging to the technical field of motor processing. The device is characterized by comprising a base, wherein a vertical guide rail is arranged on the base, and an upper punch die seat is arranged on the vertical guide rail; a lower punch rod is arranged on the upper punch die seat; a positioning seat is arranged on the base, and the middle part of the positioning seat is provided with a positioning hole; the top of the positioning seat on the periphery of the positioning hole is provided with a guide ring, and horizontal guide through holes are distributed on the periphery of the side wall of the guide ring; the horizontal guide through holes are respectively and internally provided with an elastic push rod, and the inner end of each elastic push rod corresponds to an armature slot wedge; a rotary extrusion ring is movably sleeved on the periphery of the guide ring, and arc slots corresponding to the rear ends of the elastic push rods one to one are arranged on the inner wall of the rotary extrusion ring; the lower end of the lower punch rod is provided with a wind wheel clamping sleeve; and the lower end of the side wall of the wind wheel clamping sleeve is provided with a plurality of positioning slots corresponding to wind wheel blades one to one. The armature wind wheel press mounting device of the motor has the advantages of convenient use and high production efficiency and is used for mounting an armature wind wheel.

Owner:GUANGDONG JIAHE MICROMOTOR

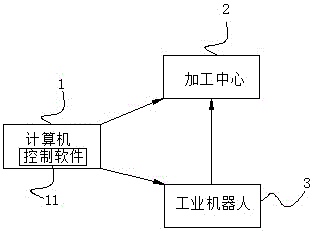

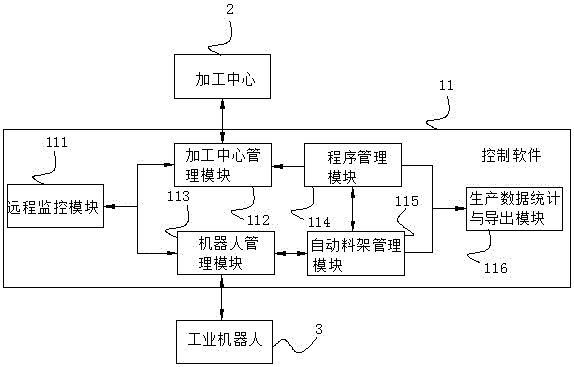

Electrode processing unmanned control system and control method

ActiveCN105843193AAvoid processing defectsImprove productivityTotal factory controlProgramme total factory controlProduction rateControl system

The invention provides an electrode processing unmanned control system and control method, and relates to the technical field of electrode processing. The electrode processing unmanned control system is composed of a computer, control software which is nested in the internal part of the computer, a processing center and an industrial robot. A processing program is compiled for each electrode blank to be processed. Then the processing program is corresponding to the electrode blank in a one-to-one way through RFID or a barcode. Finally unmanned control of the electrode processing process is realized by the control effect on the processing center and the industrial robot through control software. The processing defects of each electrode caused by difference of the shape of raw materials and the processing program can be solved, unmanned electrode processing is enabled to be possible and productivity can be enhanced and production cost can be reduced.

Owner:SHENZHEN X TEC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com