Shell of small and special electrical machine and application of shell

A micro-motor and housing technology, applied in the field of motor processing, can solve problems such as the need to improve insulation performance, insufficient corrosion resistance and heat dissipation performance, and limit the use and promotion of polyethylene materials, etc., to achieve simple and feasible preparation process and good flame retardancy , the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A micro-motor housing, which is prepared from the following raw materials in parts by weight:

[0018] 100 parts of polyphenylene ether resin, 40 parts of polyvinyl chloride, 30 parts of styrene-butadiene rubber, 25 parts of polycarbonate, 18 parts of polyethylene terephthalate, 15 parts of chlorinated paraffin, 12 parts of glyceryl tristearate 8 parts, polybenzimidazole 8 parts, ethylene octene copolymer (POE) 8 parts, silicon carbide 8 parts, silicon nitride 5 parts, white carbon black 4 parts, talcum powder 3 parts, triphenyl phosphate 2 parts, three 1 part antimony oxide;

[0019] The preparation method of the above-mentioned micro-motor housing comprises the following steps:

[0020] Step 1) taking each raw material by weight for subsequent use;

[0021] Step 2) First, silicon carbide, silicon nitride, white carbon black and talcum powder are respectively ground into 100-mesh powder, and then mixed uniformly to obtain a modifier;

[0022] Step 3) polyphenylene e...

Embodiment 2

[0026] A micro-motor housing, which is prepared from the following raw materials in parts by weight:

[0027] 120 parts of polyphenylene ether resin, 50 parts of polyvinyl chloride, 40 parts of styrene-butadiene rubber, 30 parts of polycarbonate, 20 parts of polyethylene terephthalate, 18 parts of chlorinated paraffin, 15 parts of glyceryl tristearate 10 parts of polybenzimidazole, 10 parts of ethylene octene copolymer (POE), 10 parts of silicon carbide, 7 parts of silicon nitride, 5 parts of white carbon black, 4 parts of talcum powder, 3 parts of triphenyl phosphate, three 2 parts of antimony oxide;

[0028] The preparation method of the above-mentioned micro-motor housing comprises the following steps:

[0029] Step 1) taking each raw material by weight for subsequent use;

[0030] Step 2) First, silicon carbide, silicon nitride, white carbon black and talcum powder are respectively ground into 200-mesh powder, and then mixed uniformly to obtain a modifier;

[0031] Step...

Embodiment 3

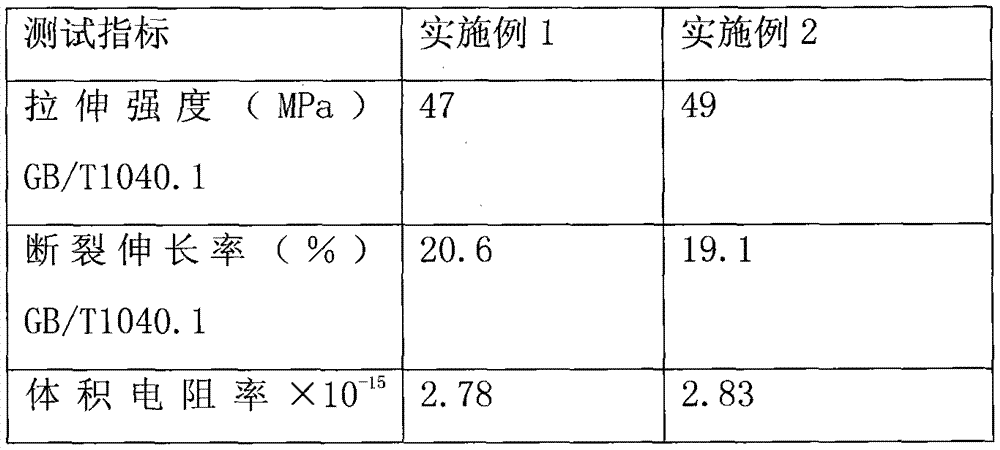

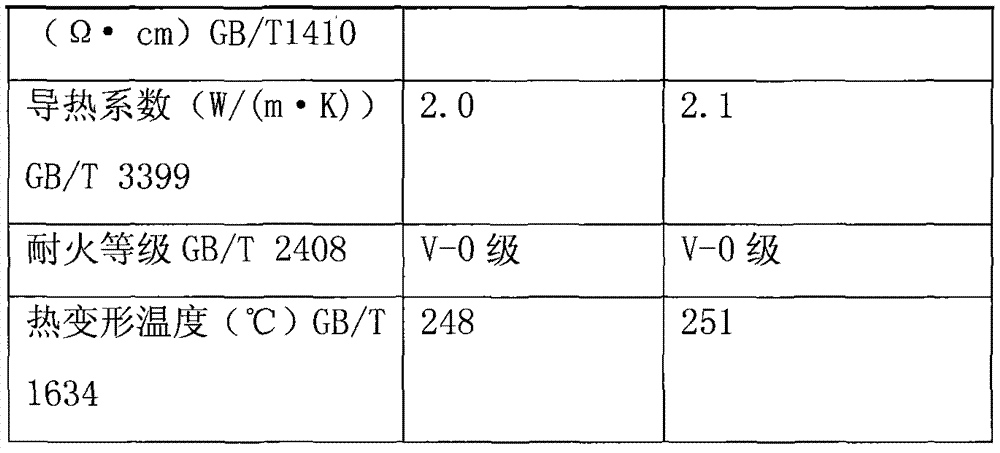

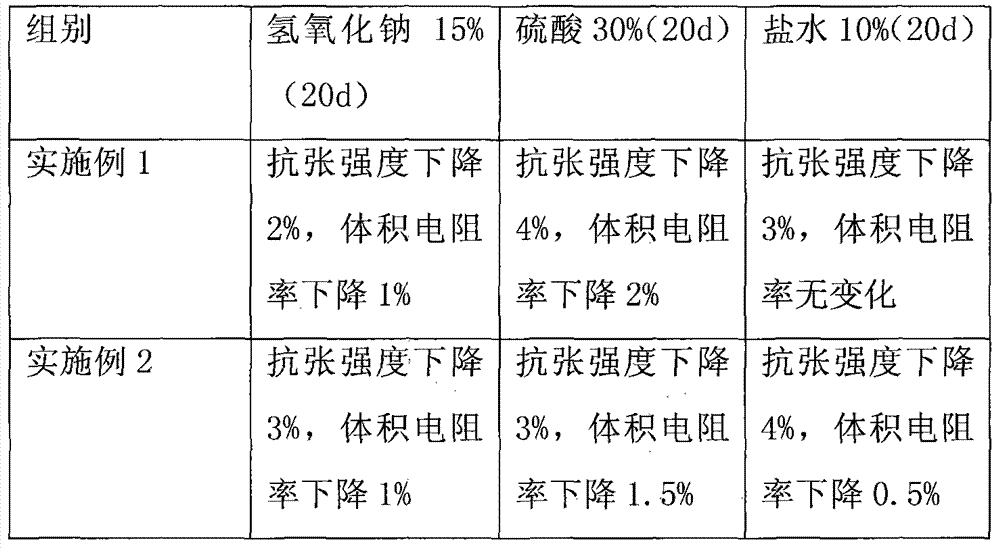

[0035] The performance test of the micro-motor housing prepared in Example 1 and Example 2 of the present invention, the specific test results and reference standards are shown in Table 1 and Table 2:

[0036] Table 1

[0037]

[0038]

[0039] Corrosion Resistance Test Table 2

[0040]

[0041] Conclusion: The micro-motor casing prepared by the invention has good mechanical properties and electrical insulation properties, and at the same time, the corrosion resistance and thermal conductivity are also greatly improved, which fully meets the relevant standards; and the preparation process is simple and feasible, and is suitable for industrial production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com