Coreless permanent magnet synchronous linear motor with double-layer reversely tilting windings

A permanent magnet synchronous straight line, reverse tilt technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve problems such as weakening thrust fluctuations, high processing costs, and reducing motor thrust density. The effect of increasing thrust density, improving machining accuracy and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

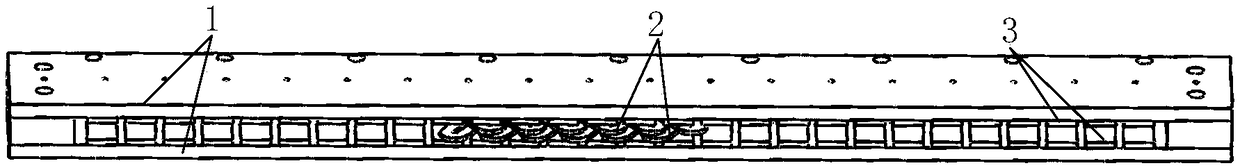

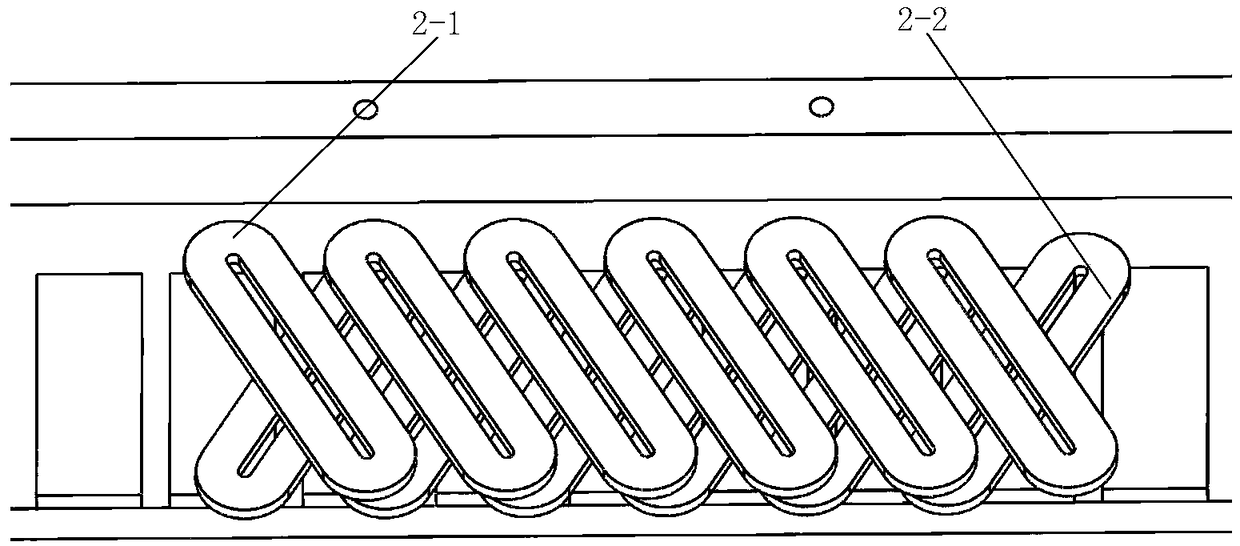

[0020] see figure 1 and figure 2 In this embodiment, the double-layer reverse inclined winding coreless permanent magnet synchronous linear motor has a back iron 1 as the stator, a permanent magnet 3 , and a double-layer reverse inclined ironless core winding 2 as the mover.

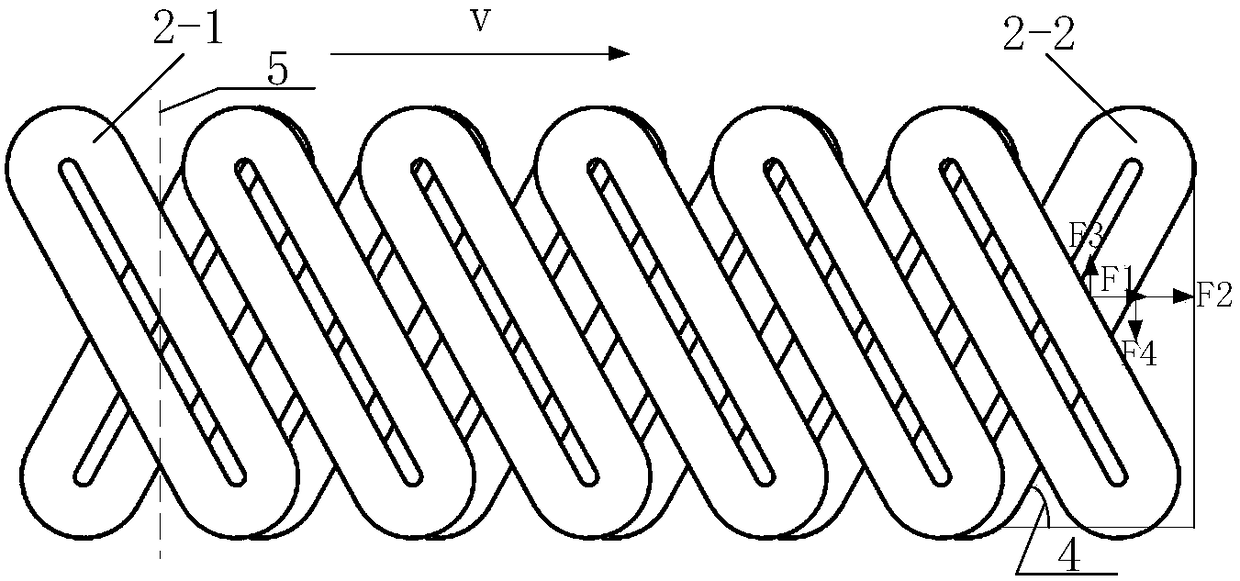

[0021] see figure 2 , image 3 and Figure 4 , in this embodiment, the mover coil 2 in the permanent magnet synchronous linear motor is set as a double-layer coil winding, which are respectively the upper coil winding 2-1 and the lower coil winding 2-2, and the upper coil winding 2-1 and the lower coil winding 2-2 are arranged obliquely in their respective planes, and each pair of windings in the upper and lower coil windings 2-1 and the lower coil windings 2-2 are symmetrically centered on the center line 5 and facing opposite directions symmetrically. The direction is inclined to form a double-layer reverse-inclined winding form. The center line 5 refers to a straight line that passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com