Permanent-magnet linear motor based on arc-shaped and inner-step shaped hybrid structure of stator

A technology of permanent magnet linear motor and hybrid structure, which is applied in the fields of motors and electrical engineering, and can solve problems such as deterioration of servo operation characteristics, mechanical vibration, noise speed oscillation, etc., and achieve improved optimization design time, good magnetic shielding effect, and reduced thrust fluctuations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

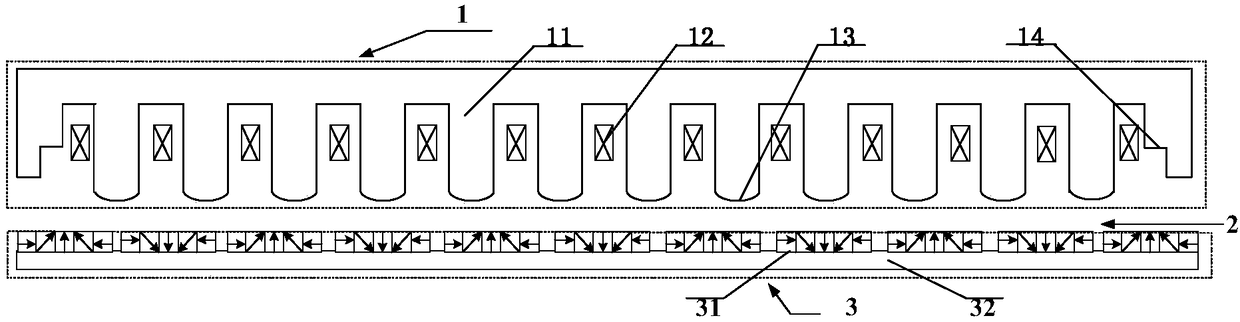

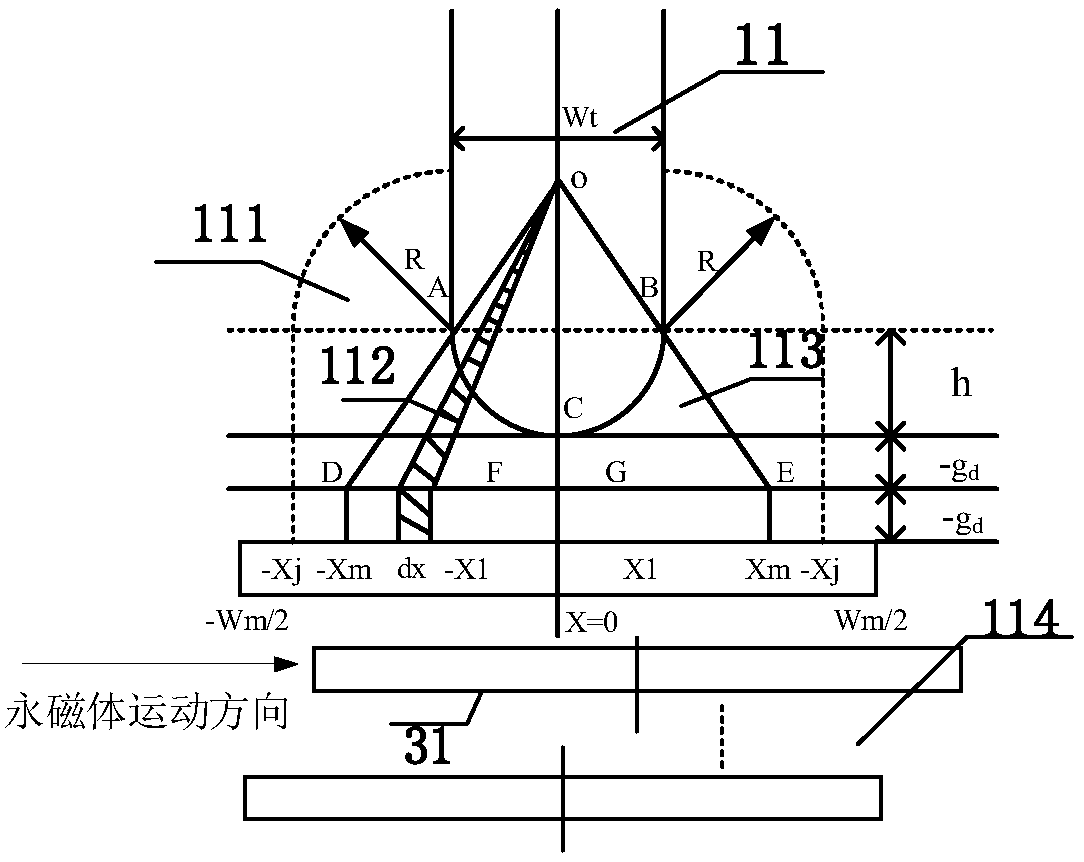

[0032] The permanent magnet linear motor with a stator of the present invention adopts a mixed structure of an arc shape and an inner ladder shape. Layer 2, permanent magnet mover secondary side 3. The stator armature primary side 1 includes a stator core 11, an armature winding 12 placed in a slot on the inner surface of the stator core 11, stator teeth 13 and stator end teeth 14; the stator teeth 13 on both sides of the slot adopt Arc-shaped structure; the secondary side 3 of the permanent magnet mover includes a permanent magnet mover core 32 and a permanent magnet 31 pasted on the surface of the mover core, and the surface-mounted permanent magnet 31 adopts a Halbach irregular permanent magnet array .

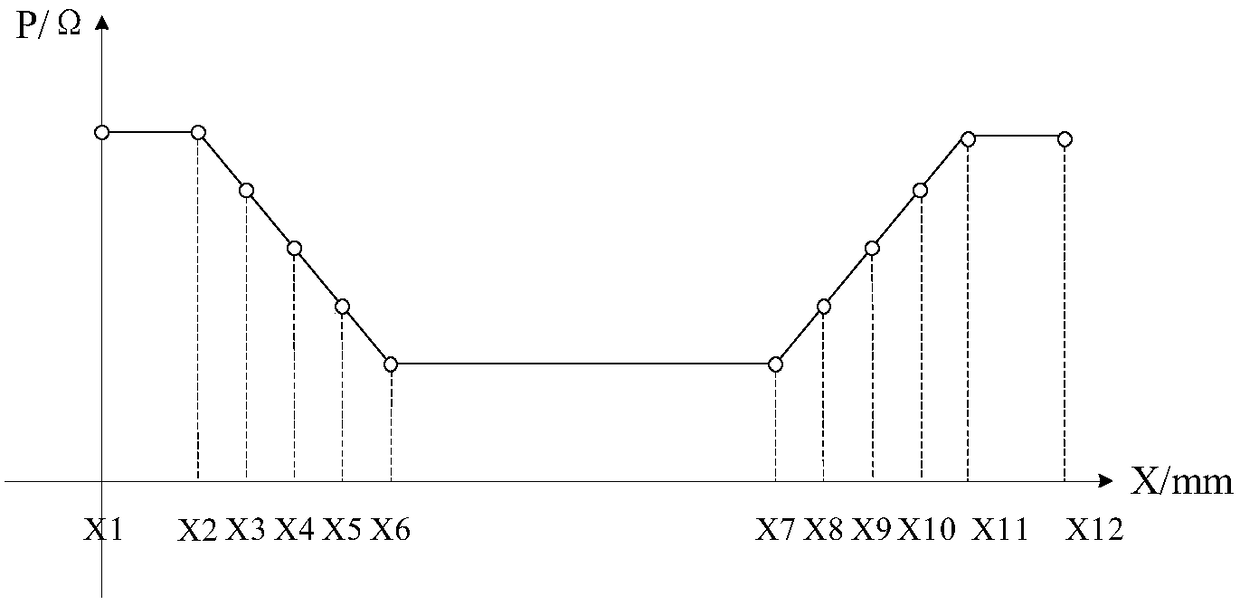

[0033] In the permanent magnet linear motor based on the mixed structure of the stator arc and the inner ladder type of the present invention, the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com