Novel optimal design method for permanent magnet synchronous linear motor

A permanent magnet synchronous linear and optimization design technology, applied in multi-objective optimization, design optimization/simulation, calculation, etc., can solve the problems of PMLSM thrust fluctuation, and achieve the effect of reducing thrust fluctuation, improving overall situation and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

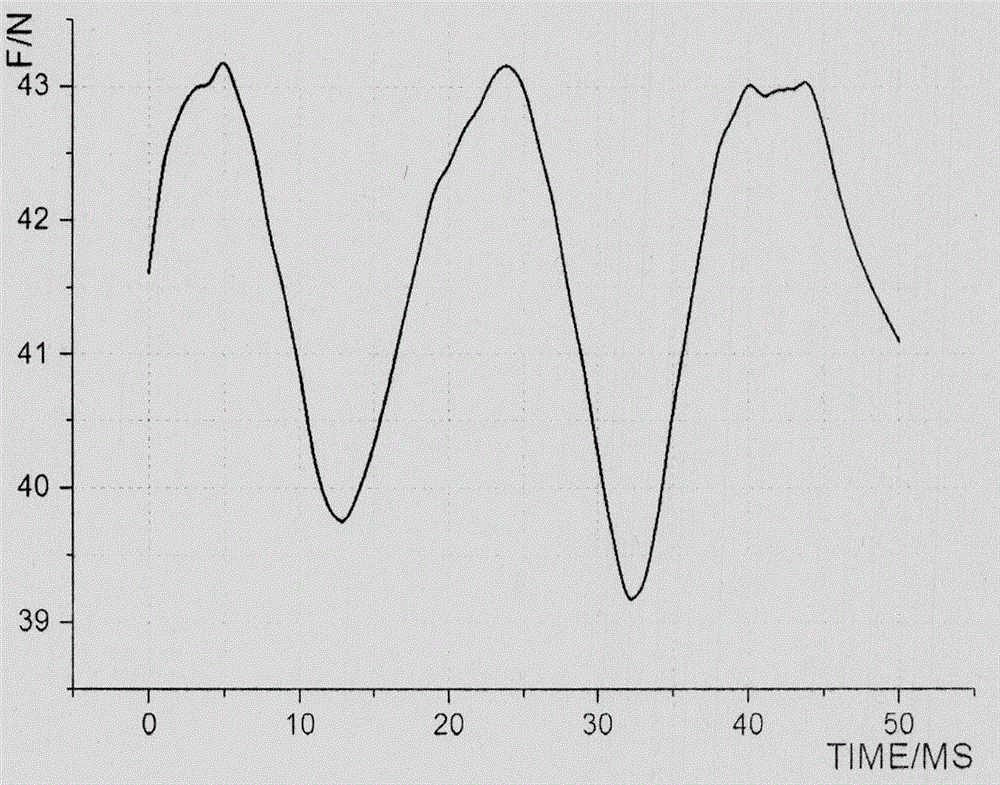

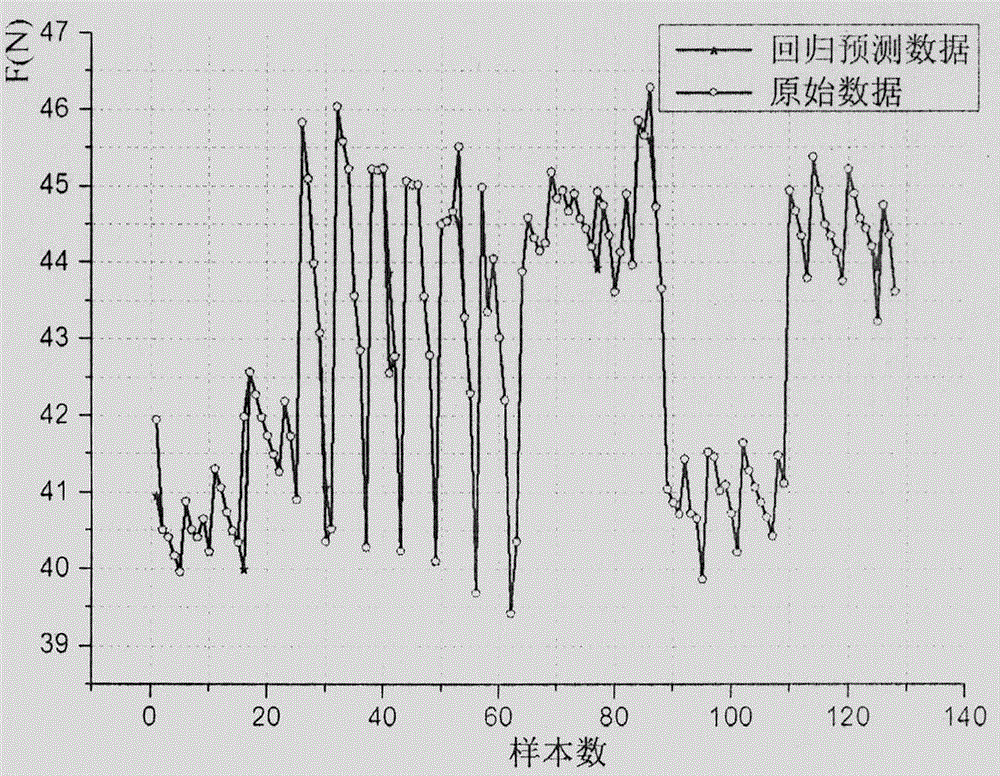

[0021] 1. Finite element analysis:

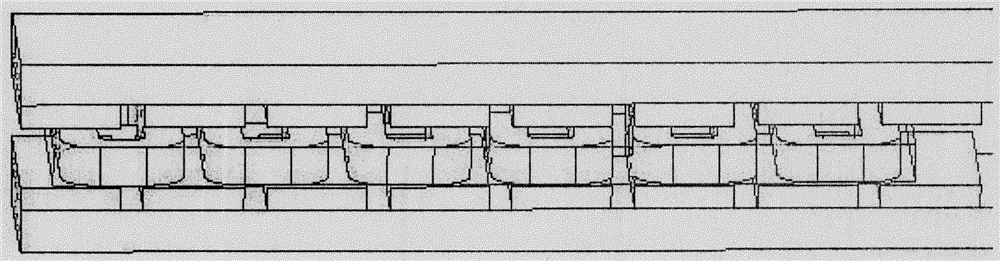

[0022] (1) Prototype analysis: Refer to the seven-pole, twelve-slot fractional-slot double-secondary permanent magnet synchronous linear motor, follow the basic principles of motor design, and determine the spatial value range of the motor structural parameters, including the length of the permanent magnet, the width of the permanent magnet, the permanent magnet The height and the distance between the coils are respectively set as 40mm, 15mm, 3mm, 6.05mm, the pole distance τ, the air gap thickness δ, the coil length s, and the number of coil turns k are used as variables, and the value range is: 18.8mm≤τ≤ 19.4mm, 1.85mm≤δ≤2.4mm, 6.8mm≤s≤7.4mm, 150≤k≤210

[0023] (2) Finite element modeling: Select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com