Circular sheet stacking and polishing device and stacking and polishing method thereof

A wafer and driving device technology, which is applied in the direction of grinding driving device, grinding machine, grinding feed movement, etc., can solve the problems of labor cost and burrs on the edge of the wafer, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

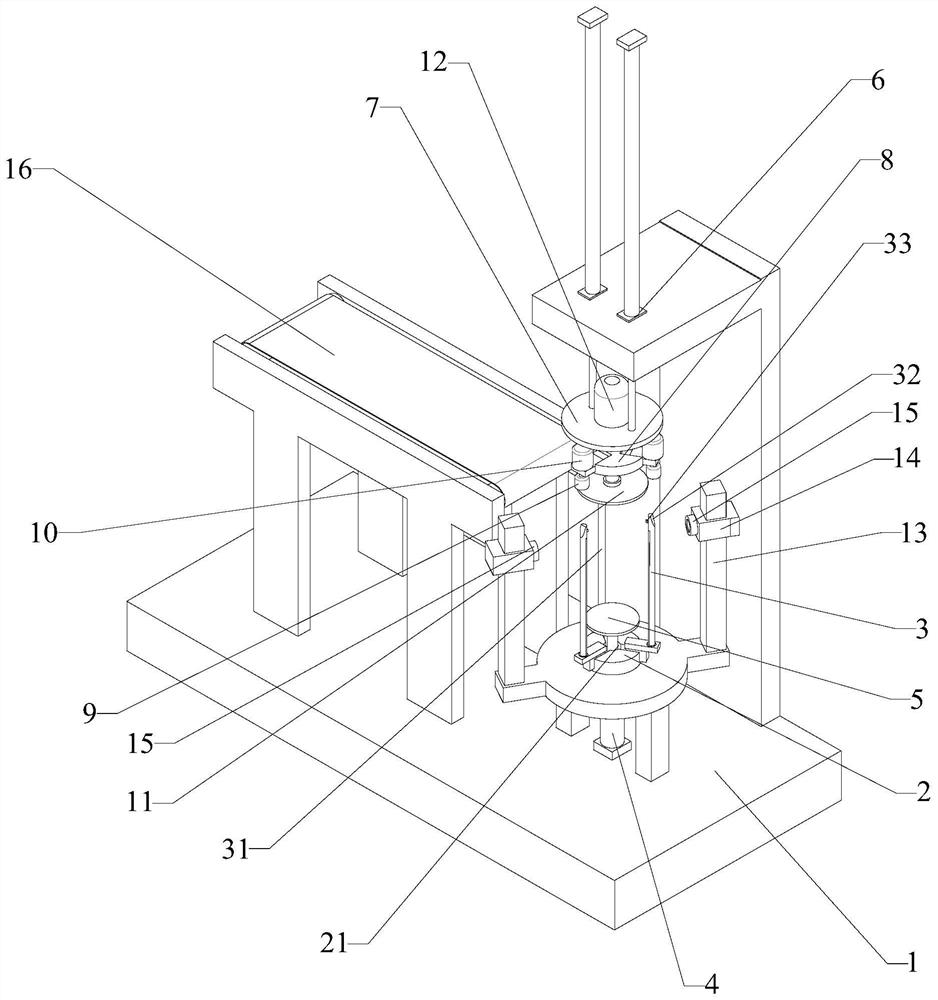

Embodiment 1

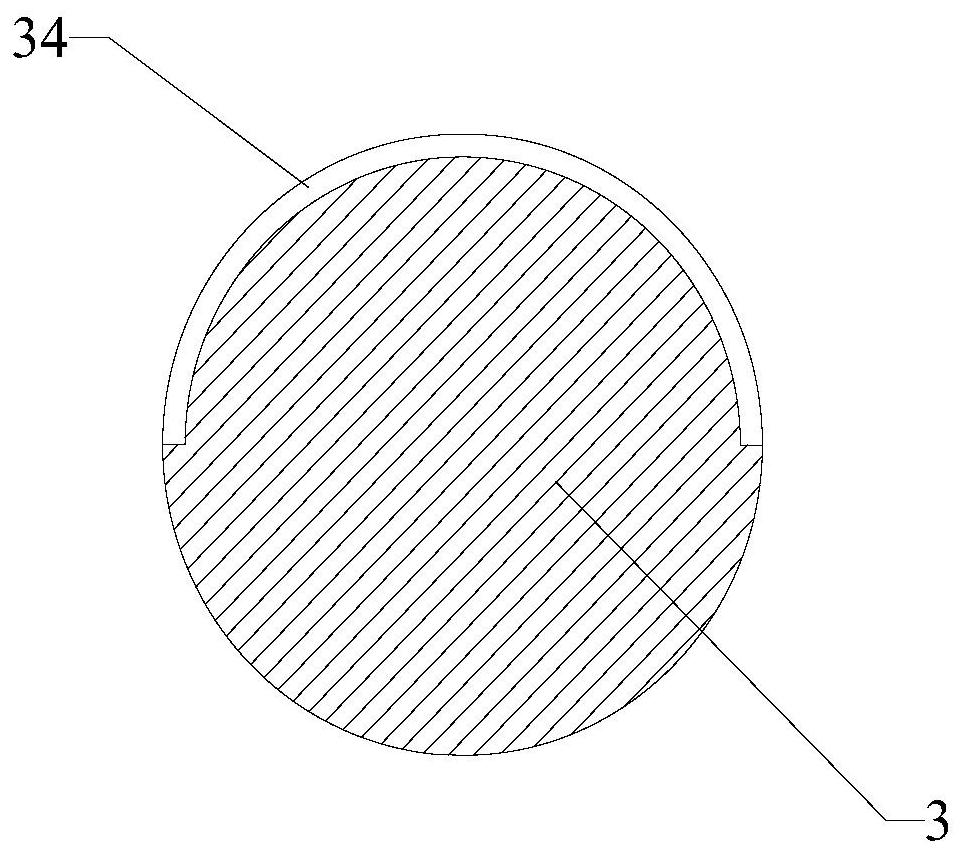

[0071] A wafer stacking and grinding device, comprising:

[0072] The base 1; the first three-jaw chuck 2, the first three-jaw chuck 2 is connected to the upper part of the base 1, and the middle part of the first three-jaw chuck 2 is provided with a first through hole 21 in a vertical direction; Positioning posts 3, the three limiting posts 3 are respectively vertically and rotatably connected to the upper part of the jaws of the three-jaw chuck, one side of the limiting posts 3 is provided with a frosted layer 31; the limiting posts 3 The other side is a smooth surface; the first cylinder 4, the cylinder body of the first cylinder 4 is fixed on the base 1, and the piston rod of the first cylinder 4 passes through the first through hole 21 vertically; A turntable 5, the first turntable 5 is connected to the top of the piston rod of the first cylinder 4; the second cylinder 6, the second cylinder 6 is arranged vertically downwards above the turntable; connecting plate 7, the c...

Embodiment 2

[0076] The wafer stacking and grinding method of the above-mentioned wafer stacking and grinding device includes the following steps:

[0077] Step 1: Adjust the first three-jaw chuck 2 and the second three-jaw chuck 8, so that the diameter of the cylinder on the inner side of the three limit posts 3 is equal to the diameter of the disc, and make each limit sleeve 9 and each limit The upper ends of the columns 3 correspond one by one, and at this time, the side of each limiting column 3 with the frosted layer 31 faces outward;

[0078] Step 2: PLC controls the first cylinder 4 to drive the first turntable 5 up to a preset height, and the wafers drop to the first turntable 5 continuously, and are stacked on the upper part of the first turntable 5 under the limit action of the limit column 3 , when the height of the wafer stack is higher than the height of the photoelectric sensor 15, the receiving end of the photoelectric sensor 15 does not receive the light signal, and the PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com