A kind of precision numerical control grinding machine for inner cone surface of small hole

A precision numerical control and numerical control grinding machine technology, applied in the direction of grinding machines, grinding bed, grinding machine parts, etc., can solve the problems affecting the product processing cycle, shorten the product processing cycle, save manufacturing costs, and design compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

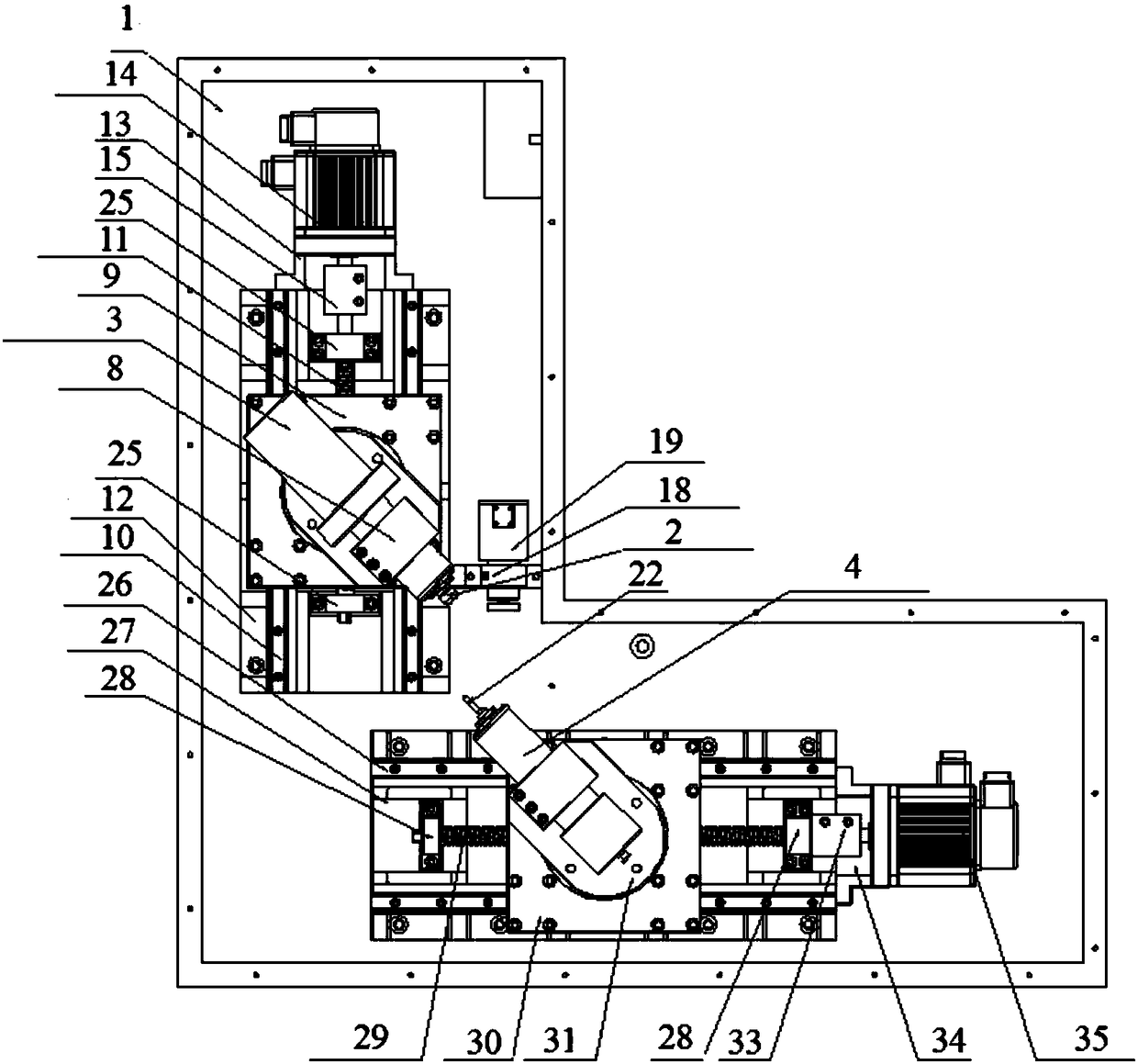

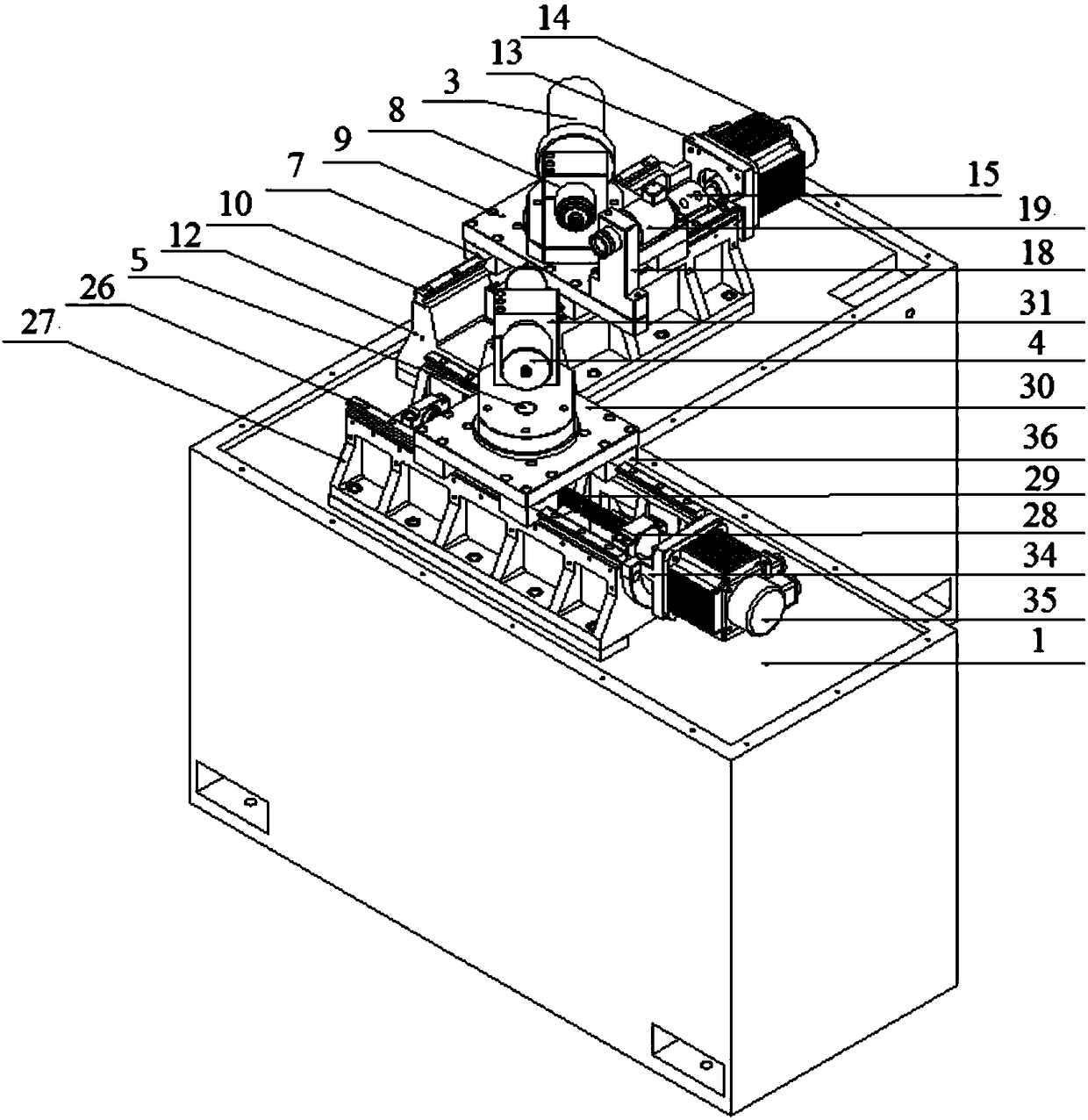

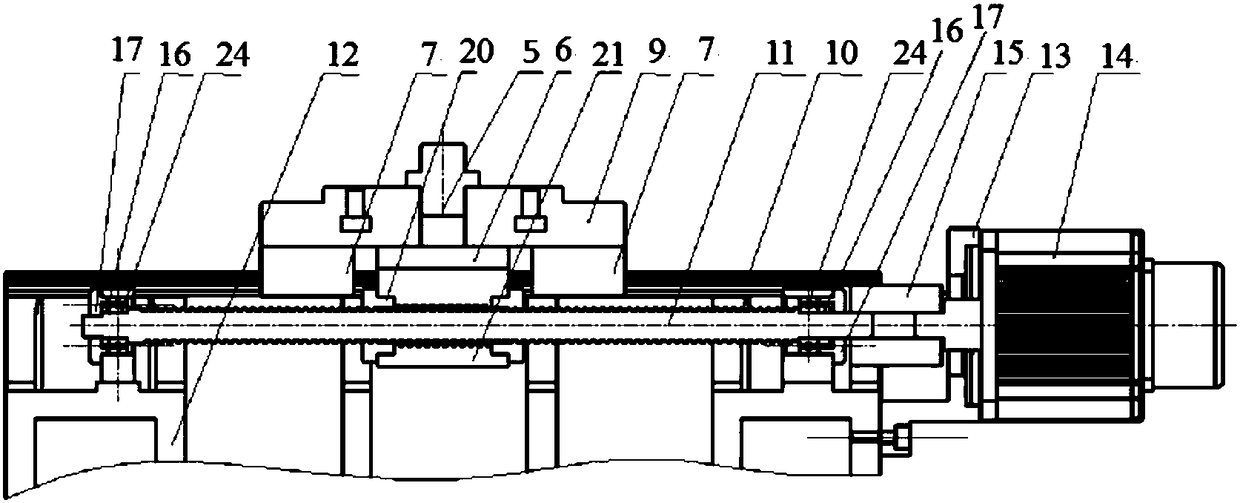

[0053] In order to make those skilled in the technical field of the present invention understand the present invention more clearly, the technical solutions of the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0054] see Figure 1-Figure 2 , a small hole inner cone precision CNC grinding machine provided by an embodiment of the present invention includes a bed 1, a transverse feed unit, a longitudinal feed unit, a first frequency conversion high-speed electric spindle 3, a valve seat precise positioning clamping device 2, The second variable frequency high-speed electric spindle 4.

[0055] Each component is described in detail below.

[0056] The bed 1 is L-shaped, and is mainly used to support various parts installed on the bed 1 .

[0057]The horizontal feed unit and the vertical feed unit, the two feed units are arranged on the bed 1, the two are perpendicular to each other, and are distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com