Air-suspending blower motor cooling structure and cooling method

A motor cooling and blower technology, applied in electromechanical devices, cooling/ventilation devices, magnetic circuit shape/style/structure, etc., can solve problems such as poor cooling effect and inconvenient processing of heat dissipation components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

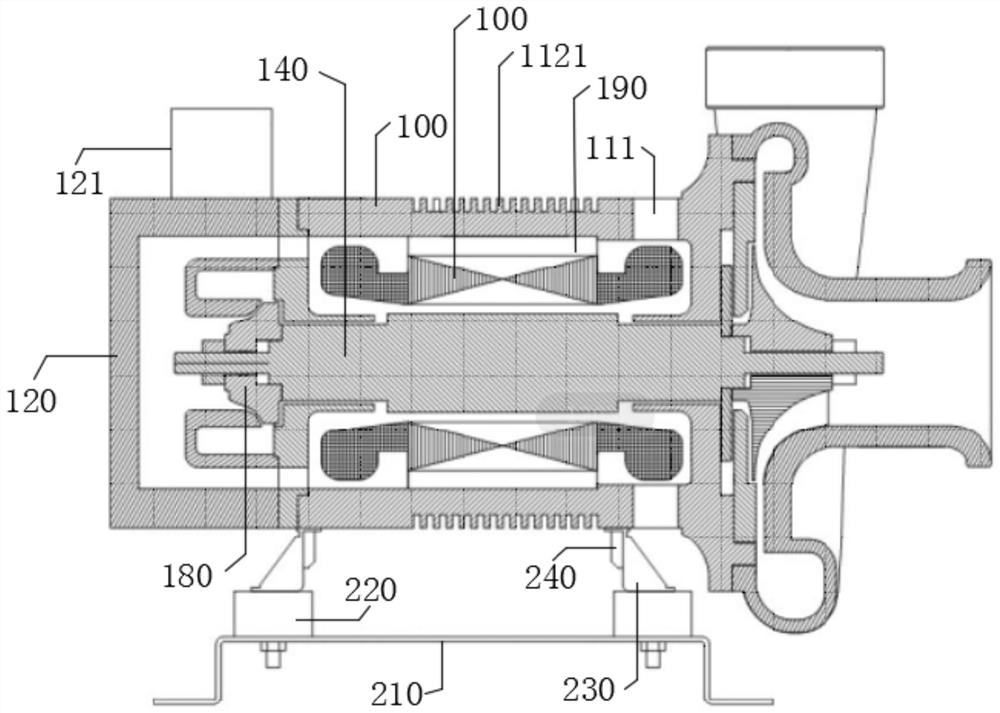

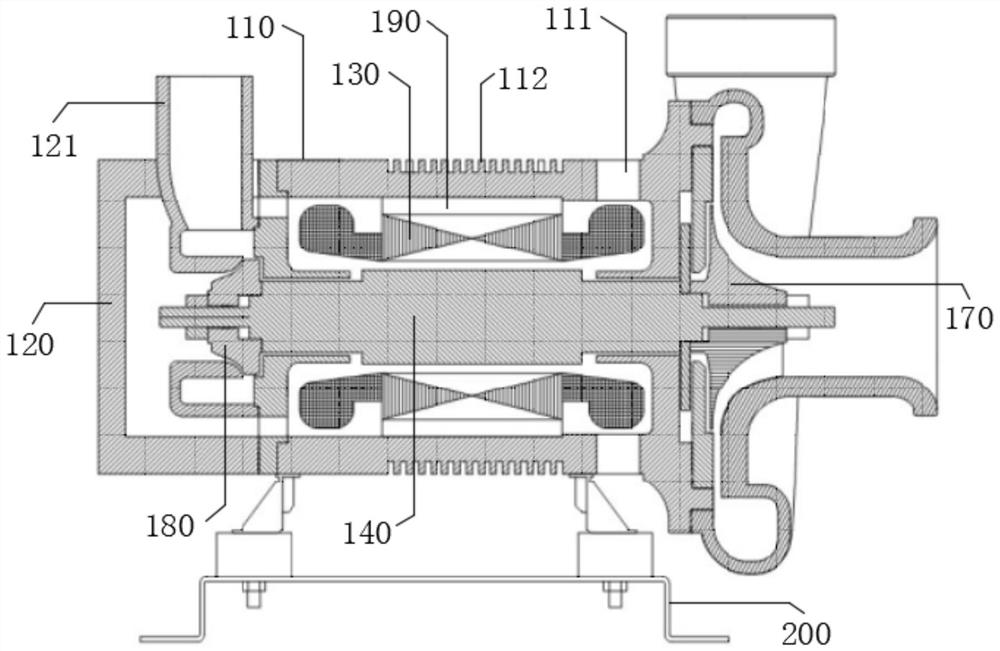

[0031] see Figure 1-4 , the present application provides an air suspension blower motor cooling structure, including: an air suspension blower main body 100 and a support assembly, the air suspension blower main body 100 is installed on the support assembly 200;

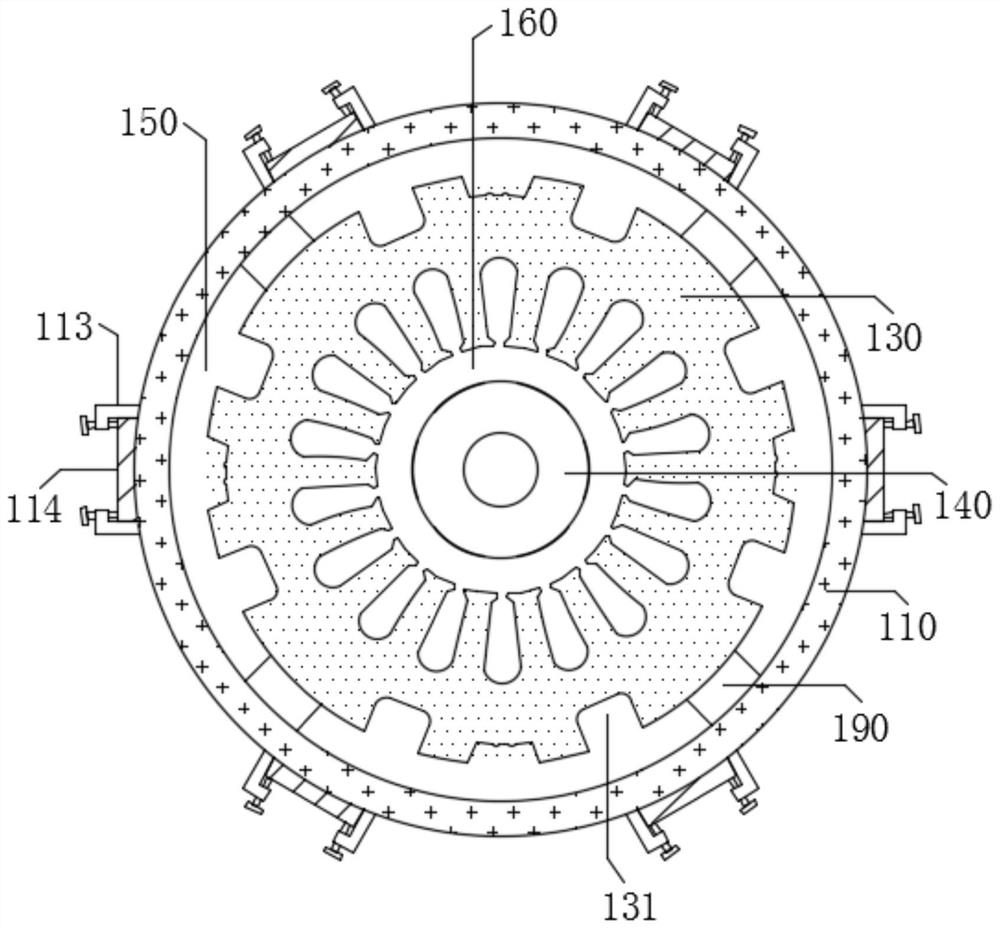

[0032] see figure 1 , figure 2 and image 3The main body 100 of the air suspension blower includes a motor casing 110, a heat dissipation volute 120, a stator 130 and a rotor 140. The rotor 140 is installed inside the motor casing 110 by rotating an air bearing, and the stator 130 is provided with a plurality of cooling grooves 131 for heat dissipation. There are no less than three slots 131, the stator 130 is installed on the inner wall of the motor housing 110, the first air flow passage 150 is formed between the stator 130 and the inner wall of the motor housing 110, and the second air flow passage is formed between the stator 130 and the rotor 140 160, one end of the rotor 140 is keyed to the centrifugal imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com