Low-COD (Chemical Oxygen Demand) high-ammonia-nitrogen livestock wastewater treatment process

A livestock and poultry breeding wastewater and treatment process technology, applied in the field of low COD and high ammonia nitrogen livestock and poultry breeding wastewater treatment process, can solve the problems of difficult wastewater treatment, difficulty in meeting discharge standards, high content of suspended solids, etc., and achieve ideal actual operation effect, The effect of relatively low investment and operating costs and short process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

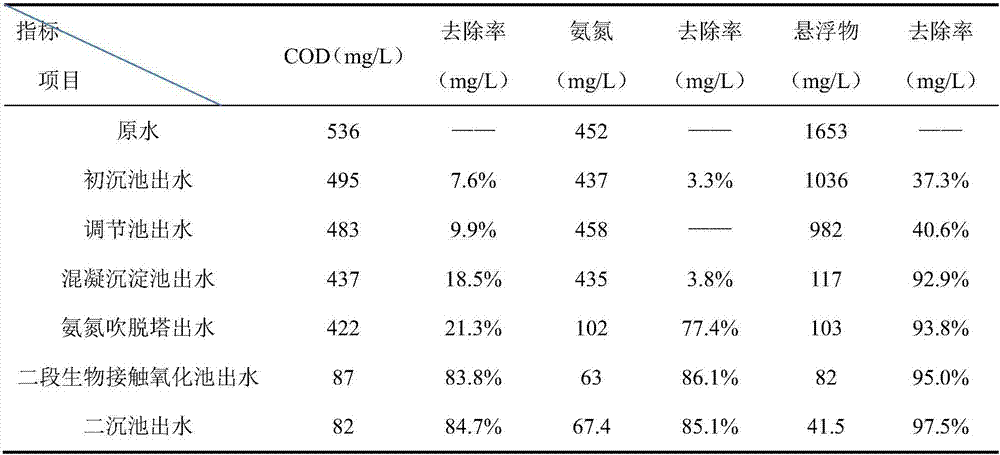

Embodiment 1

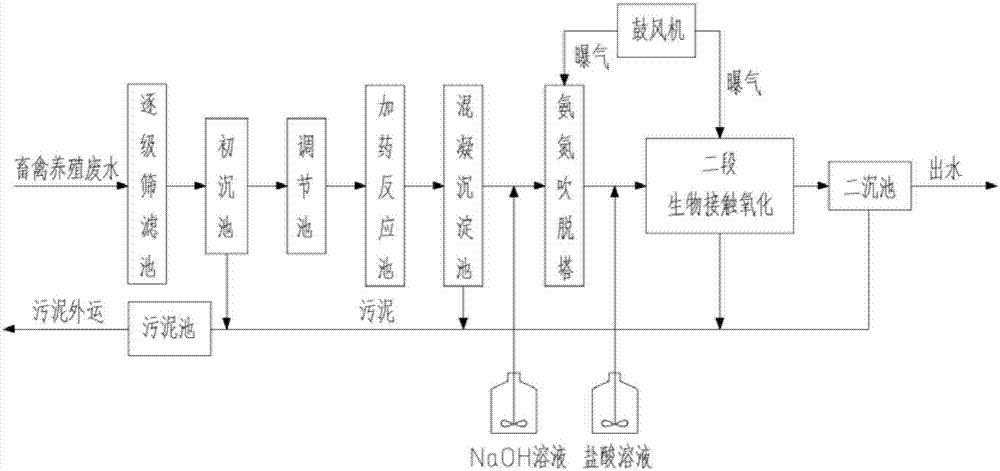

[0029] This embodiment provides a low-COD high-ammonia-nitrogen livestock and poultry breeding wastewater treatment process. Based on this process, the devices used include sequentially connected sieve filter tanks, primary sedimentation tanks, adjustment tanks, dosing reaction tanks, coagulation sedimentation tanks, Ammonia nitrogen stripping tower, secondary biological contact oxidation tank, secondary sedimentation tank, sludge tank.

[0030] Specifically, the outlet pipe of the sieve filter tank is connected with the water inlet pipe of the primary sedimentation tank, the inner bottom of the primary sedimentation tank is connected with the inlet of the sludge self-priming pump through a sewage pipe, and the outlet pipe of the primary sedimentation tank is connected with the adjustment tank The water inlet pipe is connected, and the bottom of the regulating pool is provided with a lifting pump, which is connected to the water inlet pipe of the dosing reaction tank, and the l...

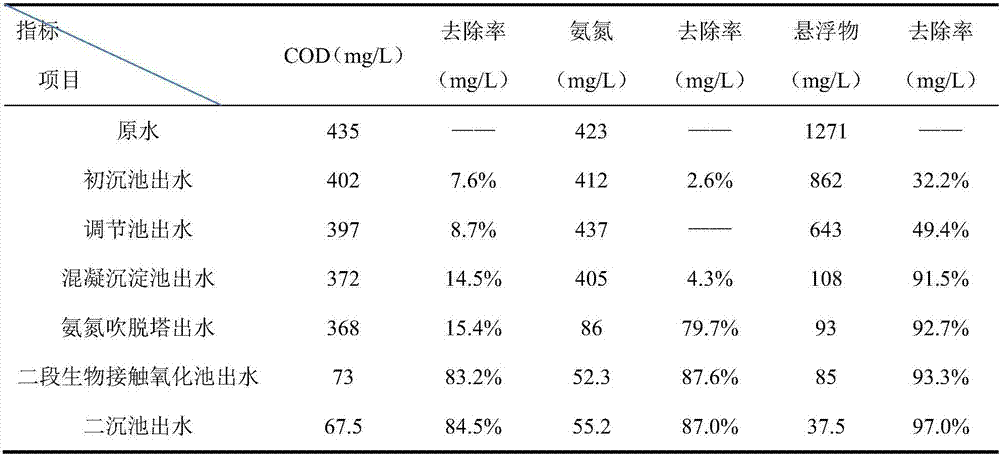

Embodiment 2

[0038] In this embodiment, low-COD high-ammonia nitrogen livestock and poultry breeding wastewater is treated, and the process includes the following steps:

[0039] (1) Livestock and poultry breeding wastewater with a COD content of 350-450 mg / L, an ammonia nitrogen content of 400-500 mg / L, and a suspended solid content of 1000-2000 mg / L first passes through a step-by-step sieve filter pool composed of multi-stage screens To remove large particles, the sieve filter pool is provided with 2mm aperture stainless steel fine screen mesh, 1mm aperture stainless steel fine screen mesh, and 1mm aperture stainless steel fine screen mesh along the water flow direction. There is no power in the whole process and no energy loss. Just clean up the dung on a regular basis.

[0040] The effluent from the step-by-step sieve filter tank enters the primary sedimentation tank. Inclined pipes are installed in the tank, and the sedimentation efficiency is high. Most of the suspended solids can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com