Patents

Literature

32results about How to "Avoid chromatography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

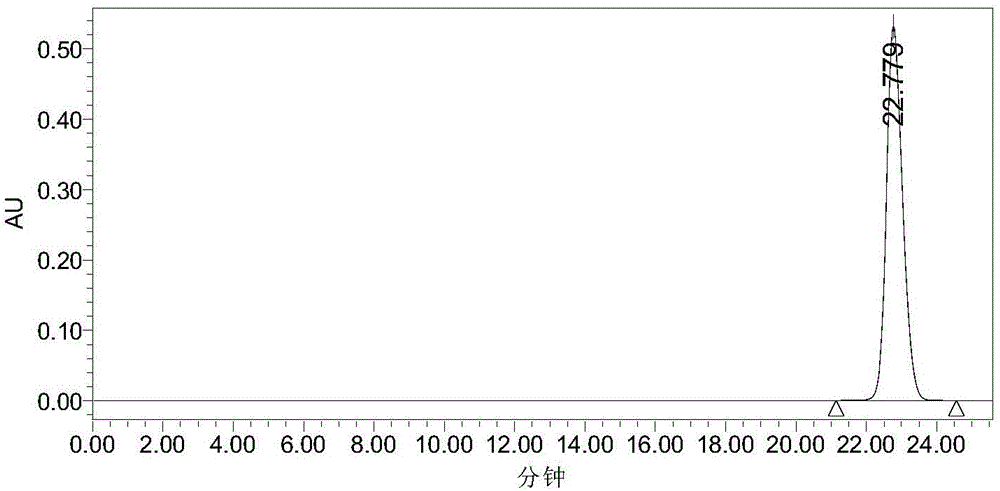

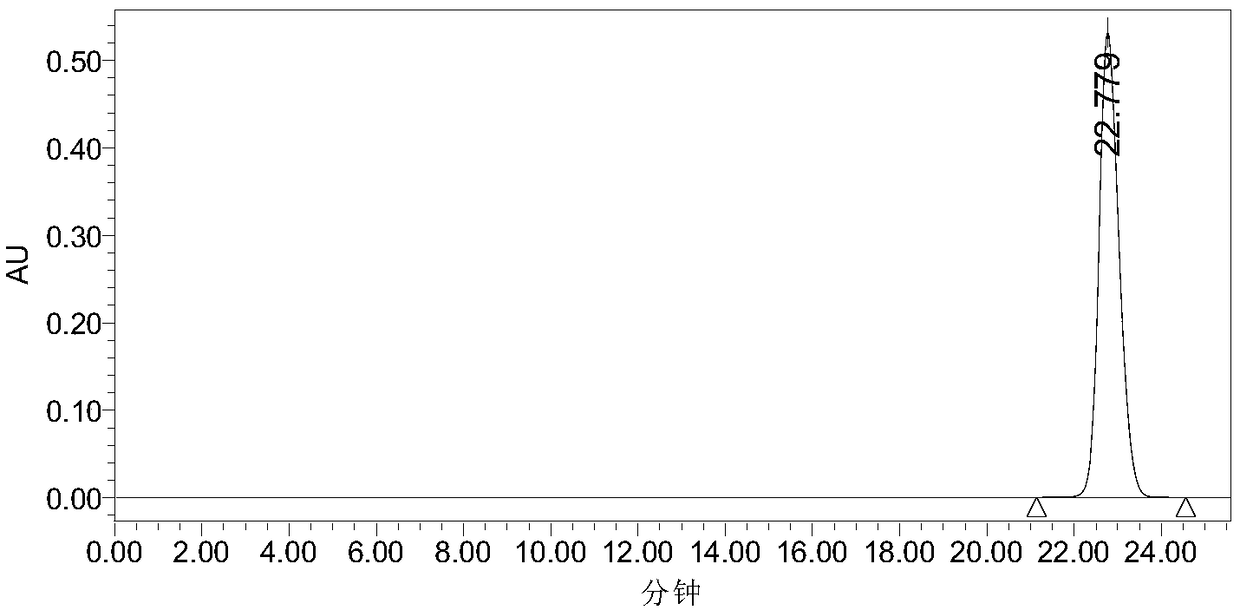

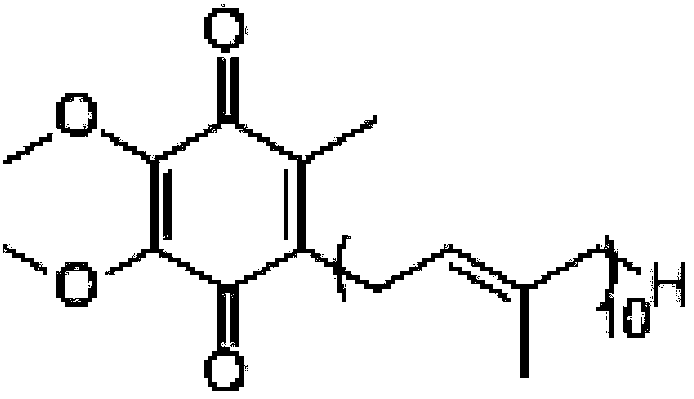

Process for extracting and separating coenzyme Q10 from mushroom dregs

The invention discloses a process for extracting and preparing high-purity coenzyme Q10 from mushroom dregs. The mushroom dregs serve as raw materials to be subjected to percolation extraction, and a coenzyme Q10 percolation extracting solution is obtained; the coenzyme Q10 percolation extracting solution is subjected to multilevel extraction for purification, and raffinate is obtained; the raffinate is subjected to crystallization treatment, finally, the high-purity coenzyme Q10 with the purity reaching 98% or above is obtained, and the yield is 95% or above. The whole process is simple, reliable and easy to operate and achieve, and parameters are convenient to control.

Owner:ZHEJIANG UNIV

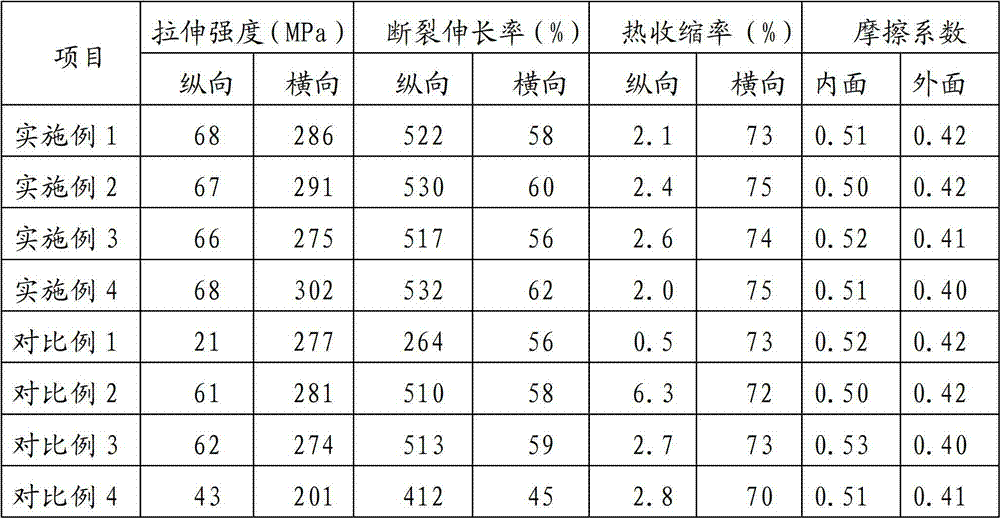

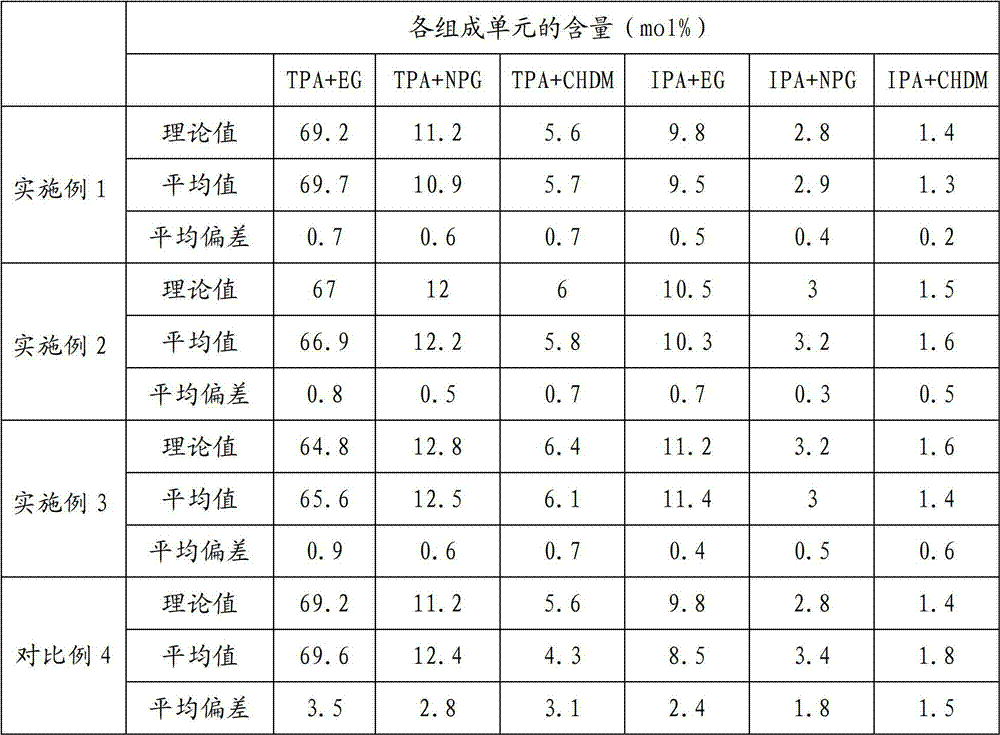

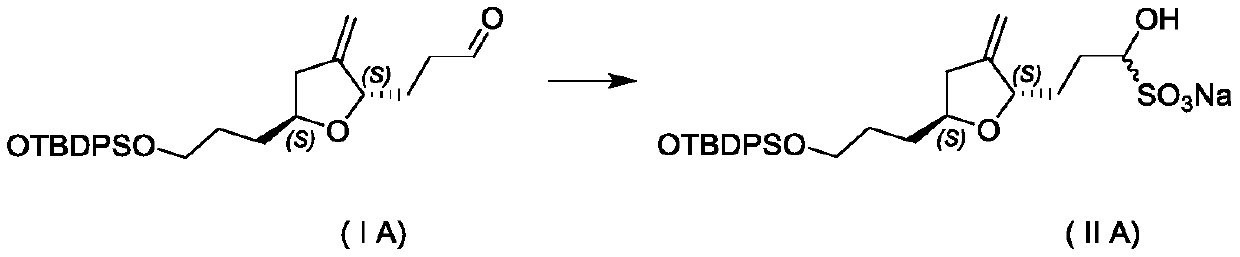

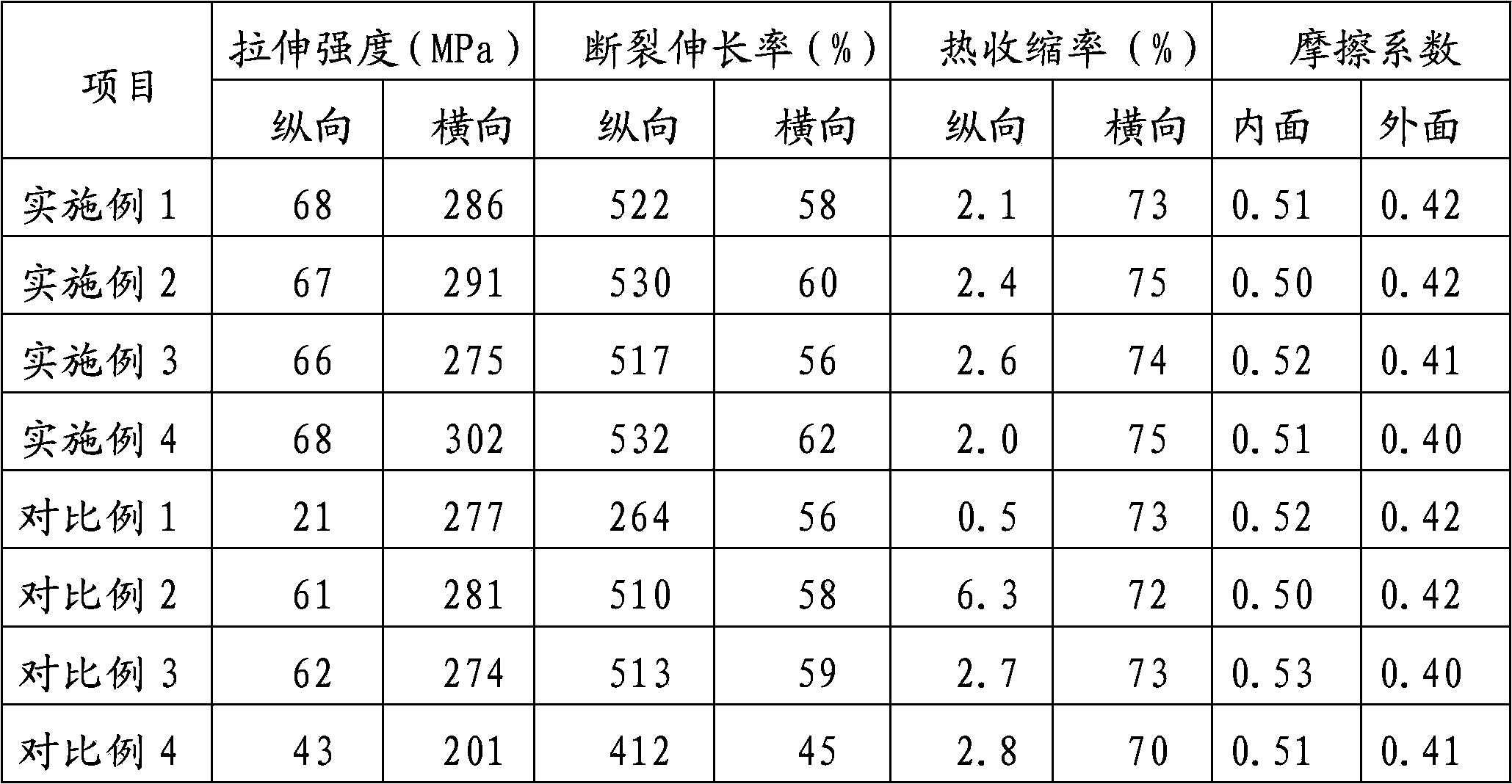

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

Method for synthesizing N-substitute-1, 2, 3, 6-tetrahydropyridine-5-boric acid ester

ActiveCN105503924AElimination of isomersSuitable for mass productionGroup 3/13 element organic compoundsHalogenBoronic acid

The invention discloses a method for synthesizing N-substitute-1, 2, 3, 6-tetrahydropyridine-5-boric acid ester. According to the method, N-substitute-1, 2, 3, 6-tetrahydropyridine-5-carboxylic acid (ester) serves as the raw material, conducts addition with halogen and then is subjected to alkaline condition elimination to form alkenyl halide and then subjected to coupling with al boron ester under the condition of metal palladium catalyzation, and the N-substitute-1, 2, 3, 6-tetrahydropyridine-5-boric acid ester is obtained. According to the method, the obtained midbody alkenyl halide does not contain isomer, separation is easy to conduct, purity of an obtained product is high, and the method provides a simple way for synthesis of compounds of the type.

Owner:CANGZHOU PURUI DONGFANG SCI & TECH

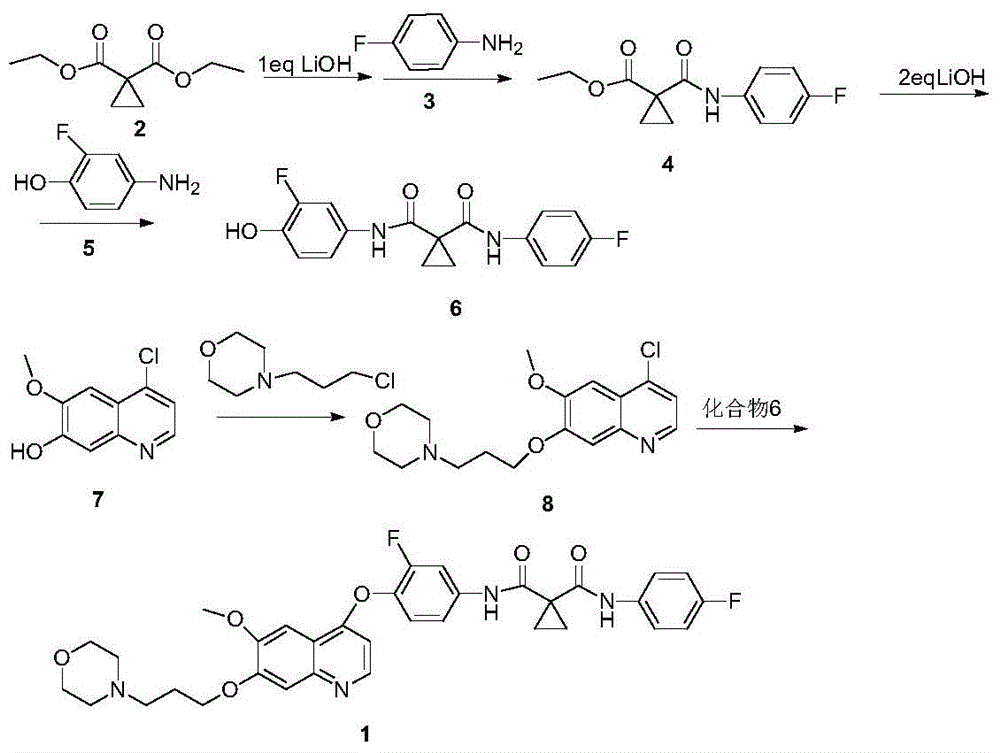

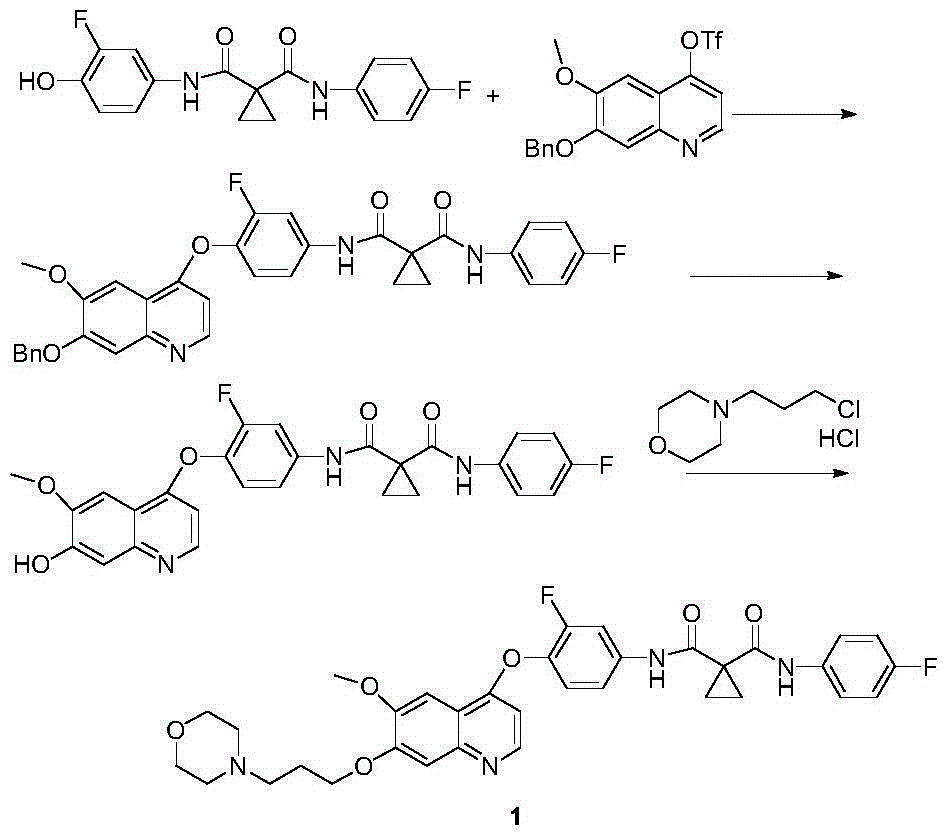

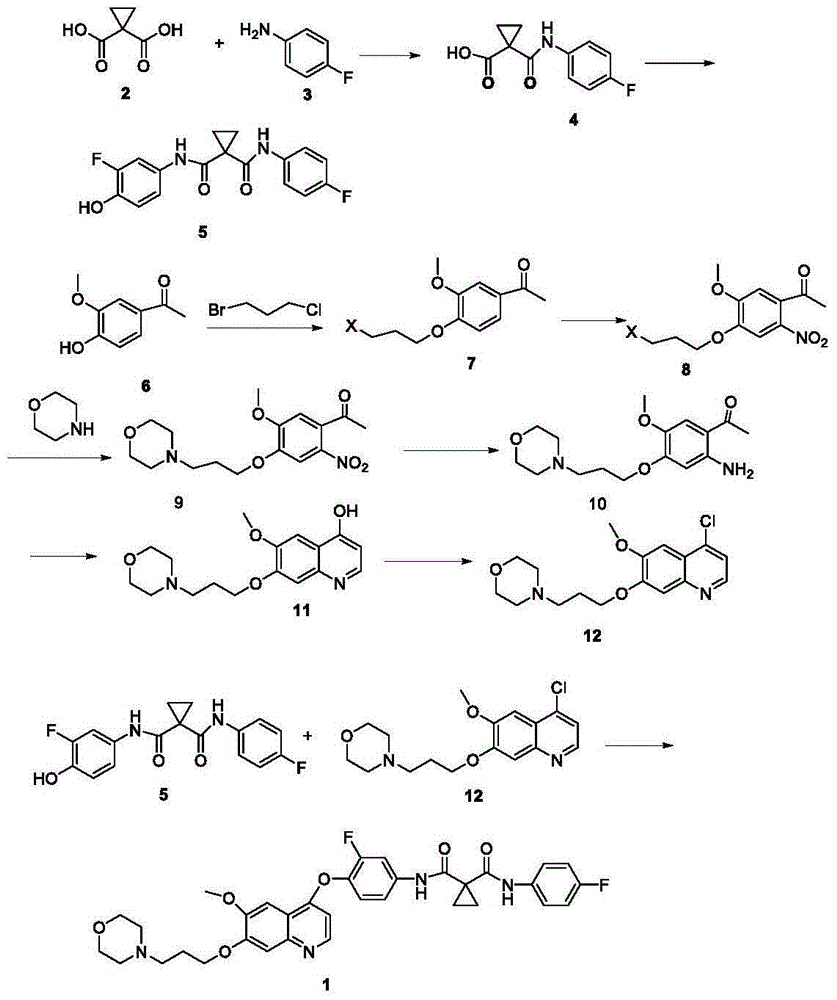

Preparation method of tyrosine enzyme inhibitor Foretinib

The present invention provides a preparation method of a tyrosine enzyme inhibitor Foretinib. The method is as below: subjecting 1,1-cyclopropyl dicarboxylic acid diethyl ester to selective hydrolysis; amidating with p-fluoro aniline to obtain a compound shown in a formula 4; hydrolyzing and amidating with 4-amino-2-fluorophenol to obtain a compound shown in a formula 6; conducting substitution on 4-chloro-6-methoxy-7-quinolinol and N-(3-chloropropyl) morpholine to obtain a compound shown in formula 8; conducting substitution on the compound in formula 6 and compound shown in the formula 8 to obtain a target product N-[3-fluoro-4-({6-(methyl oxy)-7-[(3-morpholine-4-yl phenyl)-oxy] quinoline-4-yl}oxy)phenyl]-N'-(4-fluorophenyl) cyclopropane-1,1-dicarboamide crude product. The crude product is re-crystallized in an ethanol / acetone solution to obtain a high purity product with an overall yield of 44-55%. The method has the advantages of easy and feasible process, easily available raw materials, high overall yield and good product quality, and is applicable to industrial production.

Owner:JIANGSU ZHONGBANG PHARMA

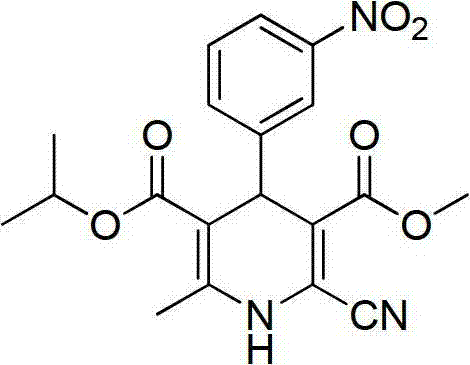

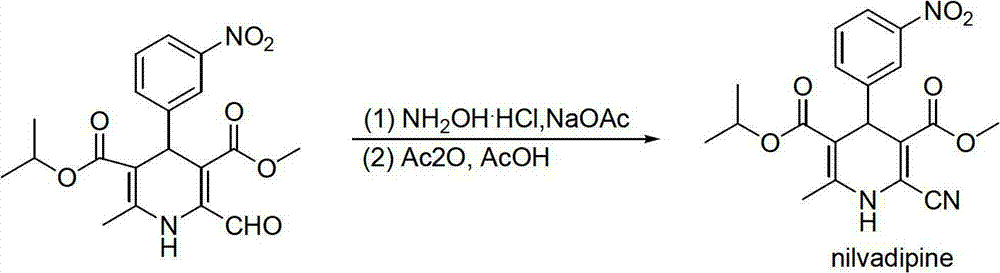

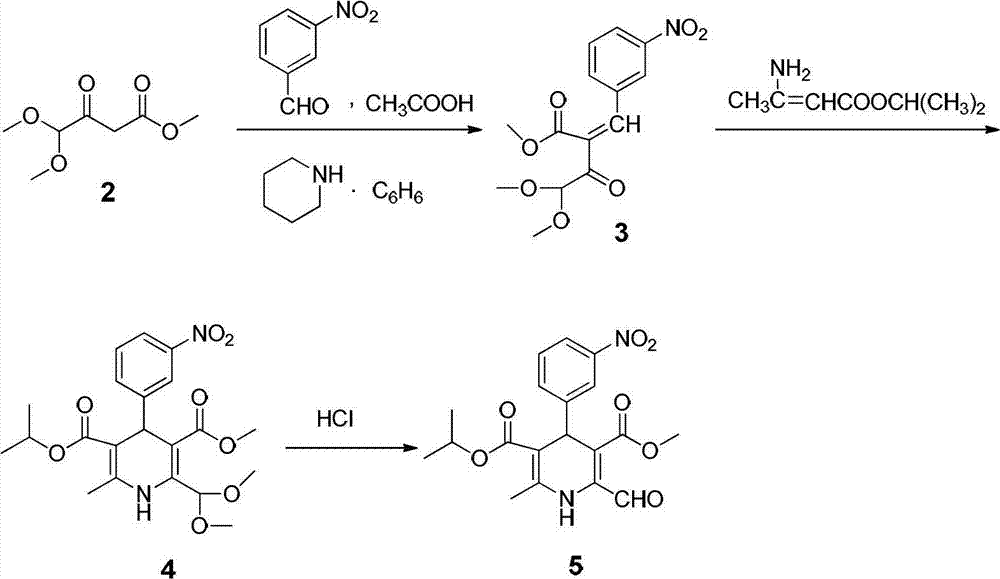

Preparation method of nilvadipine intermediate

InactiveCN102816110AHigh purityAvoid purification processOrganic chemistryDimethyl acetalNitrobenzene

The invention provides a preparation method of 3-methoxycarbonyl-6-methyl-4-(3-nitrophenyl)-2-formyl-1, 4-dihydropyridine-5-isopropyl carbonate. The method comprises the following steps that condensation and amination reactions between pyruvic aldehyde dimethyl acetal and dimethyl carbonate are carried out under the catalysis of a strong base to obtain 3-amino-4, 4-dimethoxyl-methyl crotonate; dehydration condensation reaction between isopropyl acetoacetate and nitrobenzaldehyde is carried out under the catalysis of a weak base to obtain 2-(3-nitrobenzylidene)-isopropyl acetoacetate; dehydration condensation and hydrolysis reactions between 3-amino-4, 4-dimethoxyl-methyl crotonate and 2-(3-nitrobenzylidene)-isopropyl acetoacetate are carried out to obtain 3-methoxycarbonyl-6-methyl-4-(3-nitrophenyl)-2-formyl-1, 4-dihydropyridine-5-isopropyl carbonate. The method provided by the invention solves the technical problems in the prior art including complex preparation process, low purity and less yield during the preparation of nilvadipine intermediate 3-methoxycarbonyl-6-methyl-4-(3-nitrophenyl)-2-formyl-1, 4-dihydropyridine-5-isopropyl carbonate.

Owner:HUNAN FANGSHENG PHARMACEUTICAL CO LTD

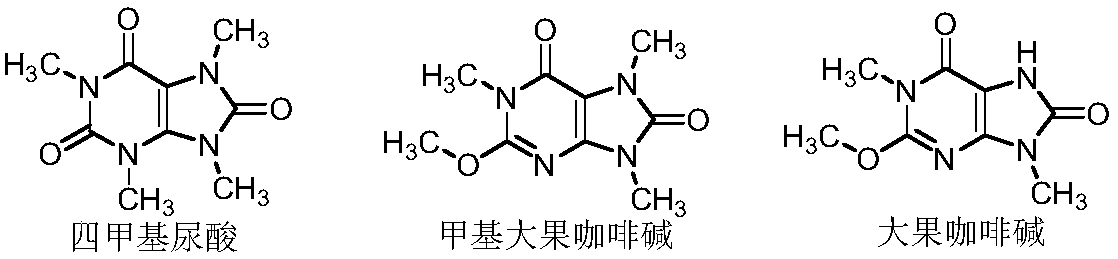

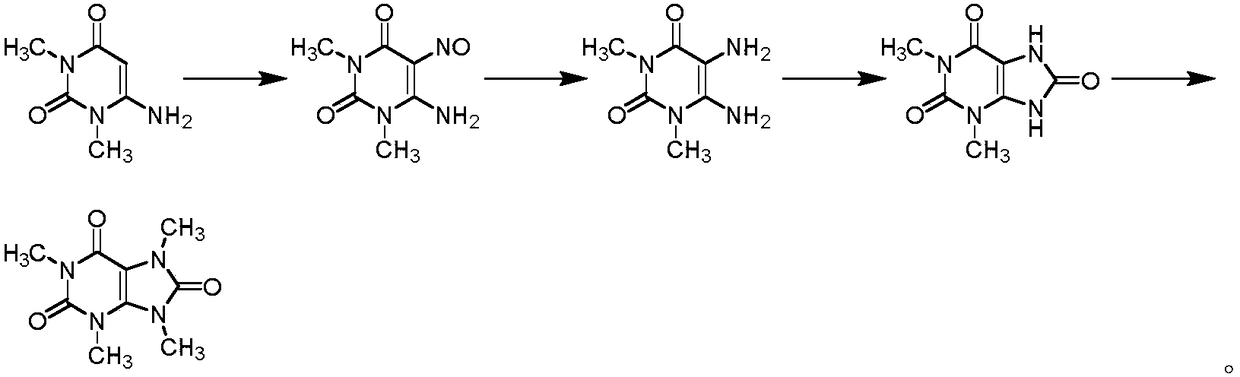

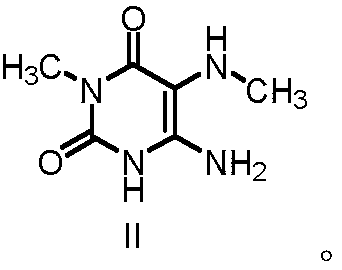

Preparation methods of three kinds of methyl uric acid compounds, intermediate and preparation method of the intermediate

InactiveCN108912121AAvoid chromatographySimple and fast operationNervous disorderOrganic chemistryMethyl groupImpurity

The invention provides preparation methods of three types of compounds which can be extracted from plants such as tea trees and have the effects of resisting depression, tranquilizing and hypnosis, resisting inflammation and easing pain, reducing stress damage of the liver cells and improving the exercise ability, an intermediate and a preparation method of the intermediate. The method is simple and convenient to operate, high in safety, high in atom economy and less in three wastes, and the raw and auxiliary materials are cheap and easy to obtain, low in toxicity, safe and stable; the reaction conditions are mild, the impurities are few, and the yield is high. The product is purified by crystallization, column chromatography is avoided, the operation is simple and feasible, and the process is stable, easy to control and convenient in reaction after-treatment, and can be economically and conveniently used for industrial production.

Owner:NANJING NUTRABUILDING BIO TECH CO LTD

Method for separating and purifying beta-thymidine from fermentation liquor

ActiveCN107383135AEfficient removalAvoid chromatographySugar derivativesSugar derivatives preparationReverse osmosisMicrofiltration

The invention discloses a method for separating and purifying beta-thymidine from fermentation liquor. The method comprises the following steps: carrying out microfiltration, ultrafiltration, ion exchange resin chromatography, reverse osmosis concentration and vacuum concentration on beta-thymidine fermentation liquor in sequence to obtain a beta-thymidine crude product, and finally carrying out decoloration and recrystallization on the crude product to obtain a beta-thymidine competitive product. The extraction and purification technology disclosed by the invention is good in impurity removal effect and high in degree of automation, the chemical purity of the obtained beta-thymidine competitive product is greater than or equal to 99.5%, the content of the obtained beta-thymidine competitive product is greater than or equal to 99.5%, the total recovery of the obtained beta-thymidine competitive product is greater than or equal to 80%, and the method is extremely applicable for industrial mass production.

Owner:JIANGSU CHUANGUO PHARMA CO LTD

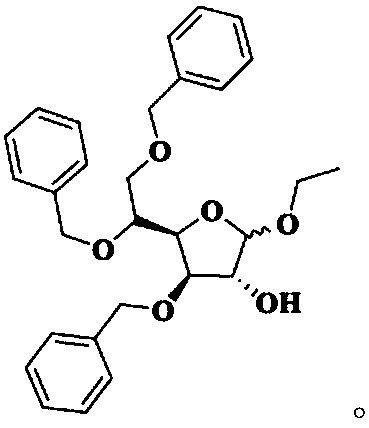

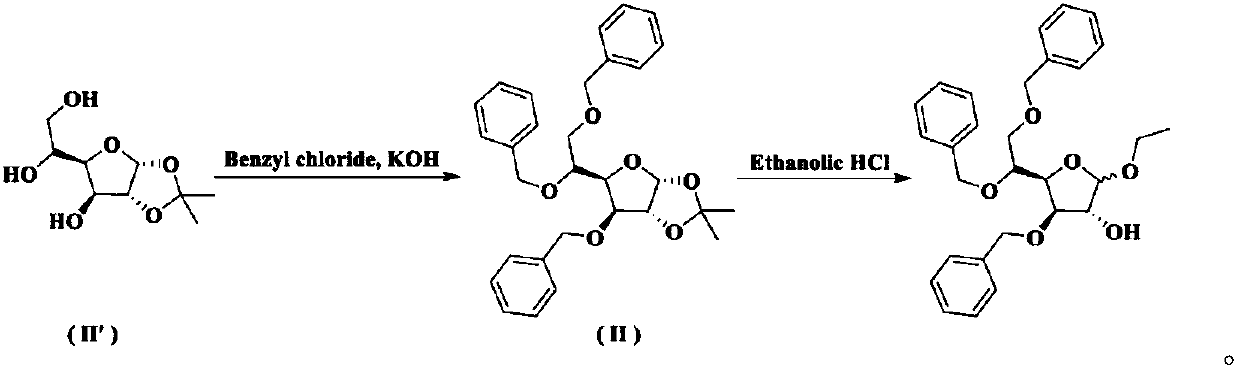

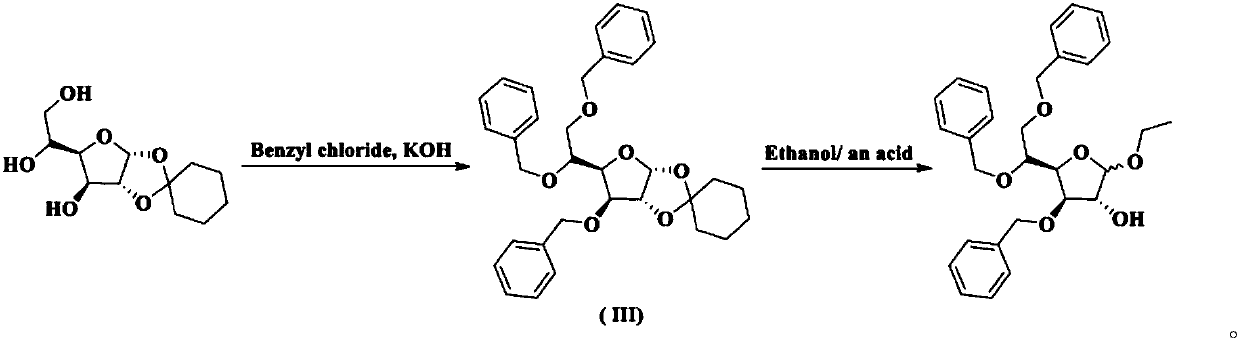

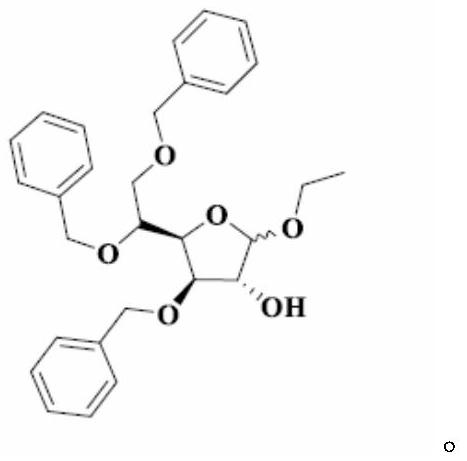

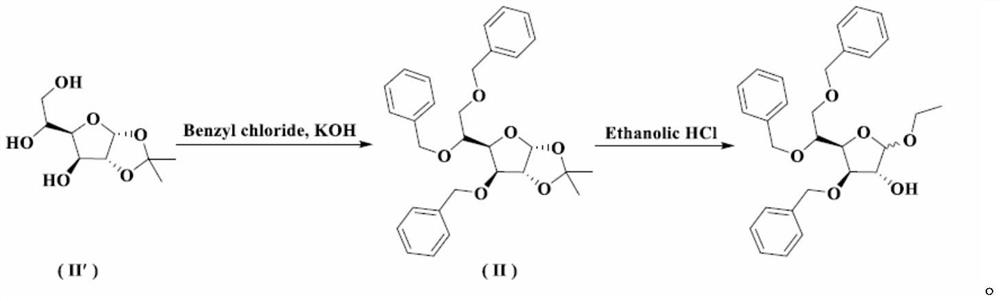

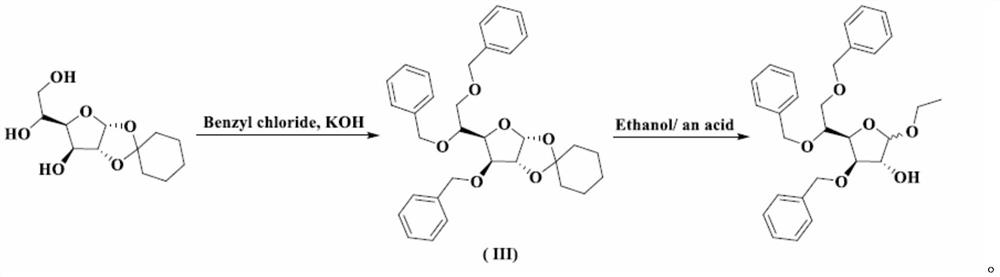

Method for preparing tribenoside

ActiveCN109776624ASynthesis and separation and purification are easy to operateAvoid column chromatographySugar derivativesSugar derivatives preparationEthyl phosphateChemistry

The invention belongs to the technical field, and concretely relates to a method for preparing tribenoside. The method comprises the specific steps: 3,5,6-tribenzyloxy-1,2-oxygen-isopropylidene-alpha-D-furanose is taken as a starting reactant, a deprotection reaction is carried out under acidic conditions to generate a 3,5,6-tribenzyloxy-D-glucofuranose crude product, two-time refining purification is carried out to obtain a 3,5,6-tribenzyloxy-D-glucofuranose pure product, and finally, ethyl-3,5,6-tribenzyloxy-D-glucopyranoside is obtained by etherification under acidic conditions. The methodof is used for preparing the tribenoside, and intermediate synthesis, separation and purification processes are simple and convenient, which avoid column chromatography operation, and the final product has good quality and high purity, and the production cycle can be shortened obviously.

Owner:LUNAN BETTER PHARMA

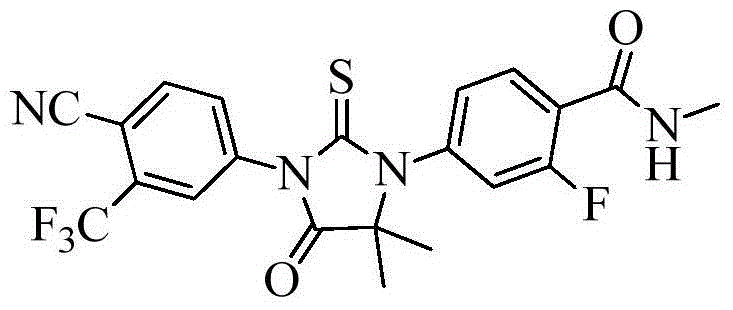

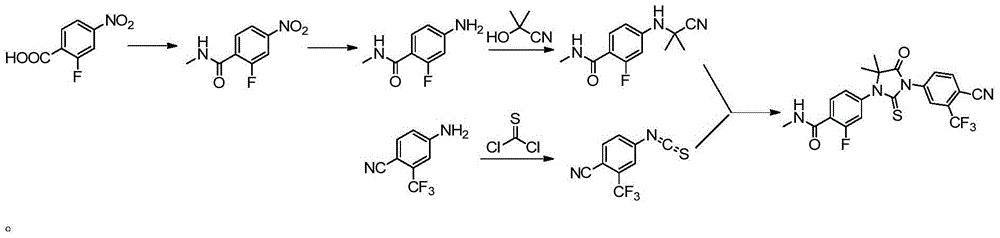

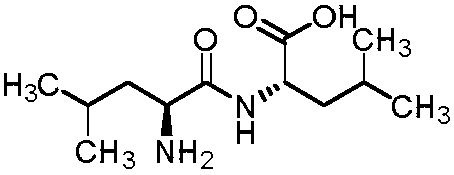

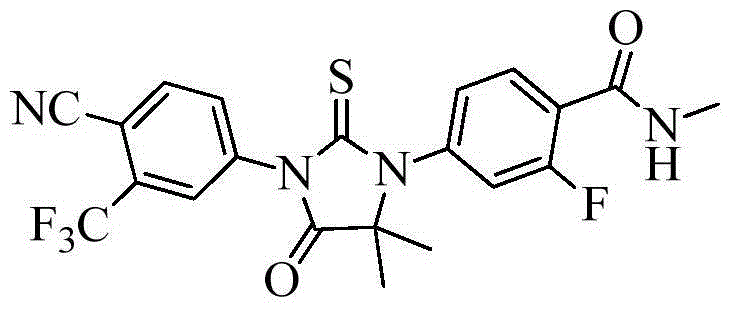

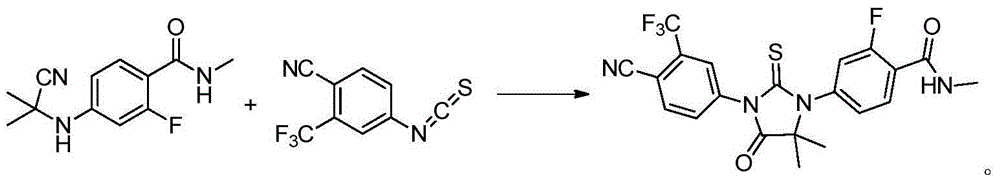

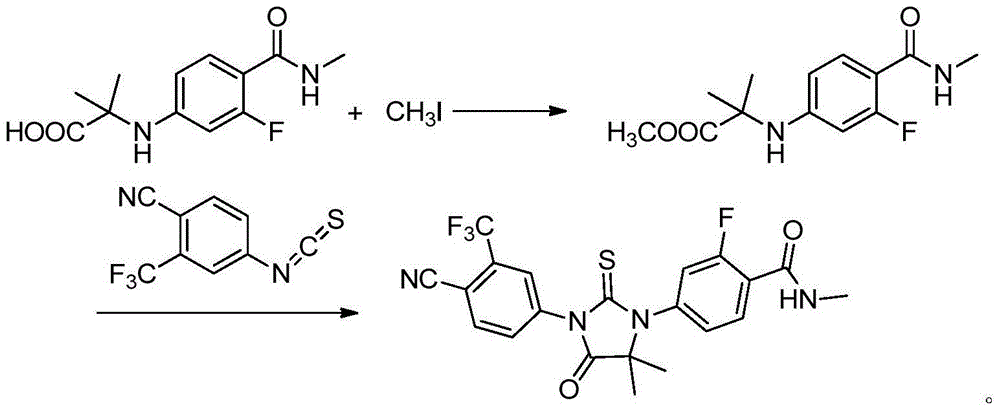

Enzalutamide preparation method

InactiveCN105461633AReduce generationReduce manufacturing costOrganic chemistryOrganic solventPropanoic acid

The present invention provides an enzalutamide preparation method, wherein 2-((3-fluoro-4-(methylcarbamoyl)phenyl)amino)-2-methyl propionic acid is adopted as a starting raw material, and reacts with 4-isothiocyanato-2-(trifluoromethyl)benzonitrile in a non-protonic organic solvent environment in the presence of an inorganic or organic base to obtain the target product. The method of the present invention has characteristics of simple operation, high yield and high product purity, and is suitable for industrial production.

Owner:JIANGSU HANSOH PHARMA CO LTD

Method for preparing 1-hydroxyl-dimethyl adamantane

InactiveCN101293814AAvoid chromatographyReduce manufacturing costPreparation by hydrolysisBromineSilica gel

The invention relates to a method for preparing 1-hydroxy-3,5-dimethyl adamantine. The method comprises the steps as follows: (1) reacting 1,3-dimethyl adamantine and bromine at 40-100 DEG C for 0.25-10 hours with water being hydrolytic reaction reagent, and recovering bromine when the reaction is finished to obtain 1-bromo-3,5-dimethyl adamantine; and (2) reacting 1-bromo-3,5-dimethyl adamantine with water at 50-100 DEG C for 1-10 hours, cooling, vacuum filtering, water washing and collecting to obtain the target product. The obtained product has a yield of 95% or higher and a purity of more than 99.0%. Compared with the prior art, the method has the advantages that expensive chemical reagents and a silica gel column chromatography are not adopted, thus facilitating reducing production cost and improving yield.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

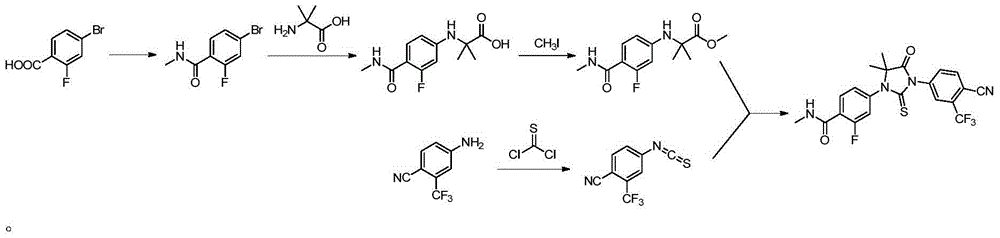

Preparation method of aripiprazole lauroxil

PendingCN110204488AImprove conversion rateResidue reductionOrganic chemistryAripiprazole lauroxilOrganic solvent

The invention belongs to the technical field of medicine synthesis methods, and provides a preparation method of aripiprazole lauroxil. The preparation method comprises the following steps: (1) carrying out a hydroxymethylation reaction: contacting and reacting aripiprazole, an aqueous formaldehyde solution having a mass concentration of 35-40 wt% and an alkali in an organic solvent to obtain hydroxymethyl aripiprazole; and (2) carrying out a lauroylation reaction: contacting and reacting the hydroxymethyl aripiprazole, an organic alkali and lauroyl chloride in a solvent which is immiscible with water at 20-30 DEG C, and then recrystallizing the obtained reaction product in a crystallization solvent to obtain the aripiprazole lauroxil. The method of the invention can improve the yield of the two-step reaction of hydroxymethylation and lauroylation and the purity of the product, and also can shorten the reaction time, simplify the post-treatment process and reduce the material cost.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

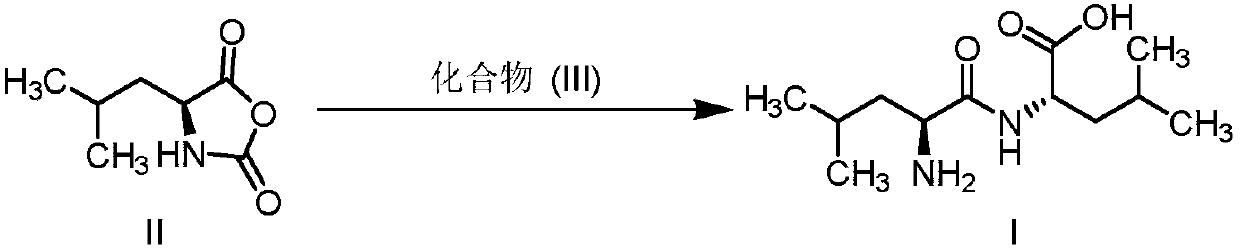

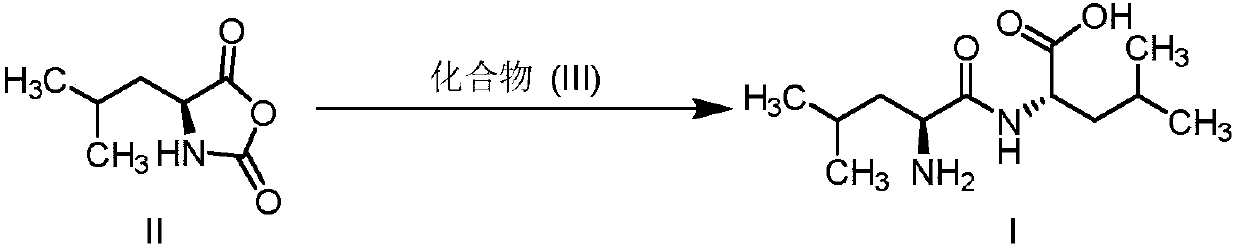

Preparation method of leucine dipeptide

The invention provides a preparation method of leucine dipeptide. L-leucine-N-carboxyl cyclic anhydride is dissolved in a certain solvent to react with a compound (which is described in the spefication) to produce leucine dipeptide. The preparation method provided by the invention has the beneficial effects that the route is short, the operation is simple and convenient, the atomic economy is highand three wastes are less; raw materials and auxiliary materials are low in price and easy in obtaining or preparation; the reaction conditions are mild, the impurities are fewer and the yield is high; by crystallization and purification of a product, the column chromatography is avoided, the process is stable, the control is easy, the treatment after reaction is convenient and the preparation method can be economically and conveniently used for industrial production.

Owner:NANJING NUTRABUILDING BIO TECH CO LTD

Preparation method of enzalutamide

InactiveCN105461634AReduce generationImprove reaction efficiencyOrganic chemistryStereochemistryEnzalutamide

The invention provides a preparation method of enzalutamide. The method comprises the following steps: condensing an initial raw material 2-((3-fluoro-4-(methylcarbamoyl)phenyl)amino)-2-methylpropioric acid and enol to obtain an intermediate I, and reacting the intermediate I with The method has the advantages of simple operation, suitableness for industrial production, high yield and high purity.

Owner:JIANGSU HANSOH PHARMA CO LTD

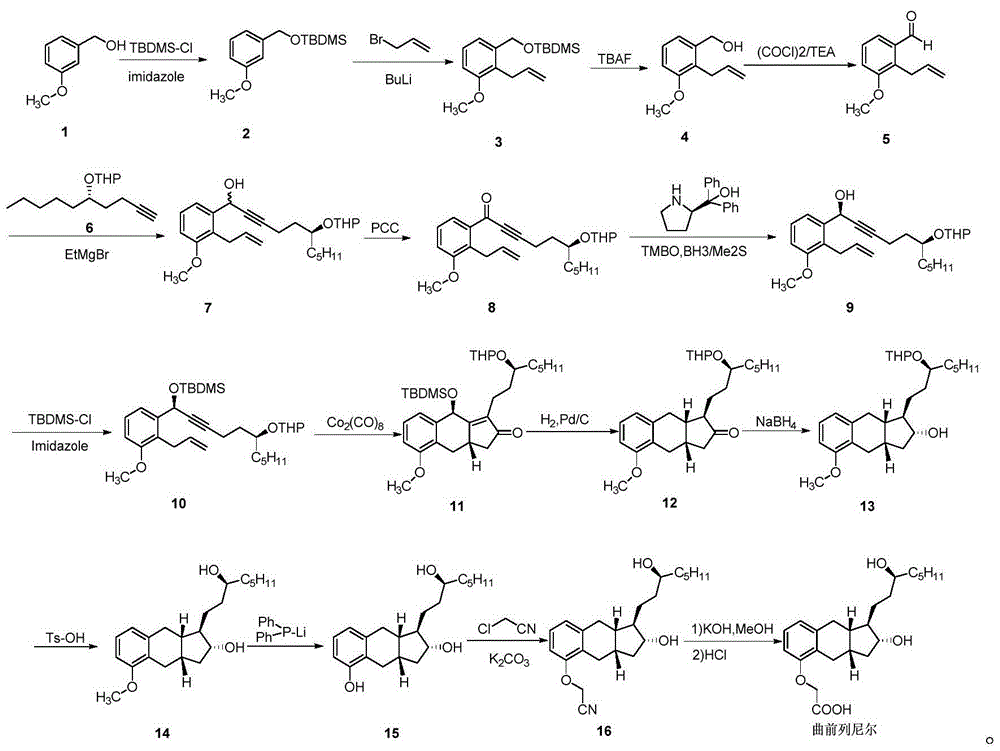

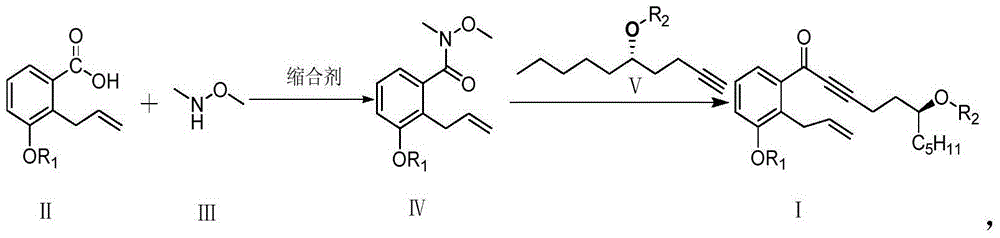

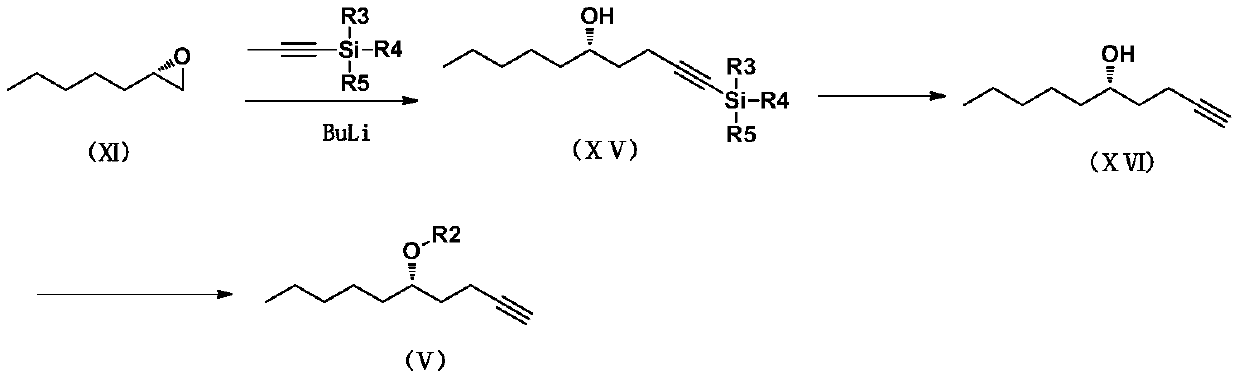

Preparation method for treprostinil intermediate

ActiveCN104892555AMild reaction conditionsEasy recrystallization purificationOrganic chemistryBulk chemical productionTreprostinilKetone

The invention relates to a preparation method for a treprostinil intermediate (I). The preparation method comprises the steps that: a compound of a formula (II) and a compound of a formula (III) or acidic salt thereof react in the presence of a condensing agent to obtain a compound of a formula (IV); the compound of the formula (IV) and a compound of a formula (V) react to obtain a compound of a formula (I). According to the preparation method for the treprostinil intermediate, weinreb amide and alkyne negative ions react to directly obtain a ketone compound (I), so that environment pollution caused by heavy metal (a PCC oxidant) is avoided, and the adoption of a butyl lithium low-temperature reaction method is also avoided. The preparation method for the treprostinil intermediate has the advantages that reaction conditions are mild, the yield is high, the purity of products is high, and the industrial application prospect is wide. (Formulae (I), (II), (III), (IV) and (V) are shown in the specification)

Owner:JIANGSU HANSOH PHARMA CO LTD +1

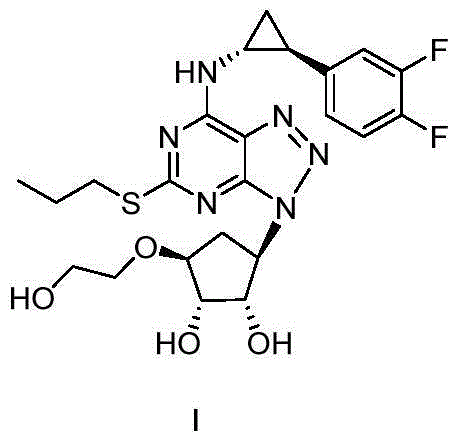

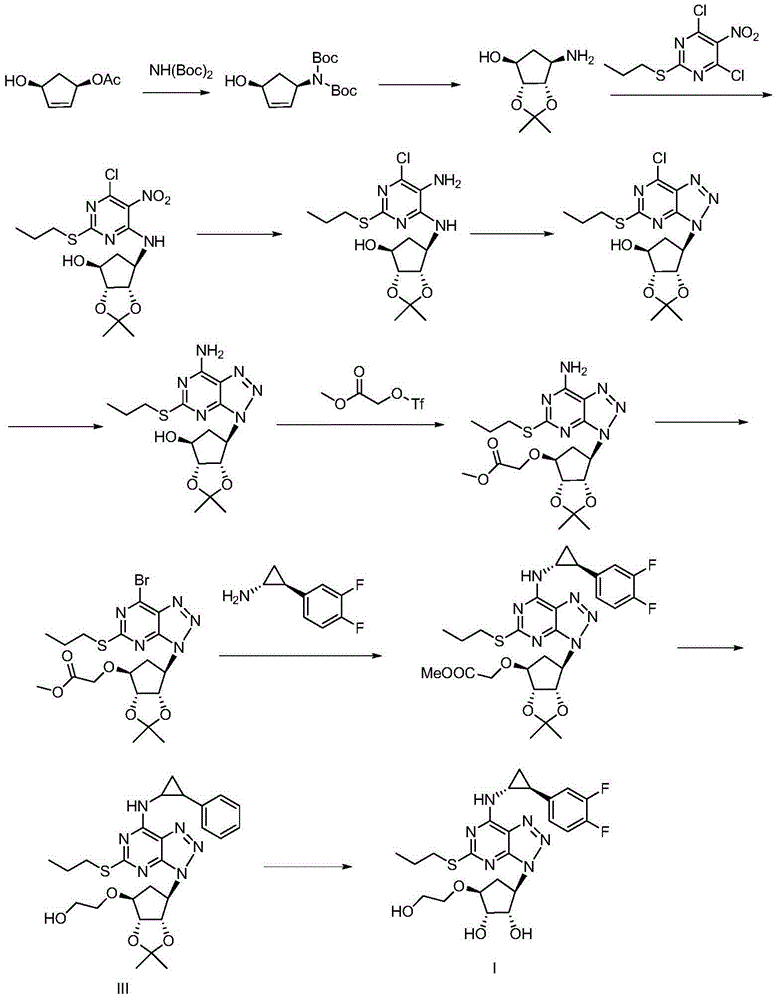

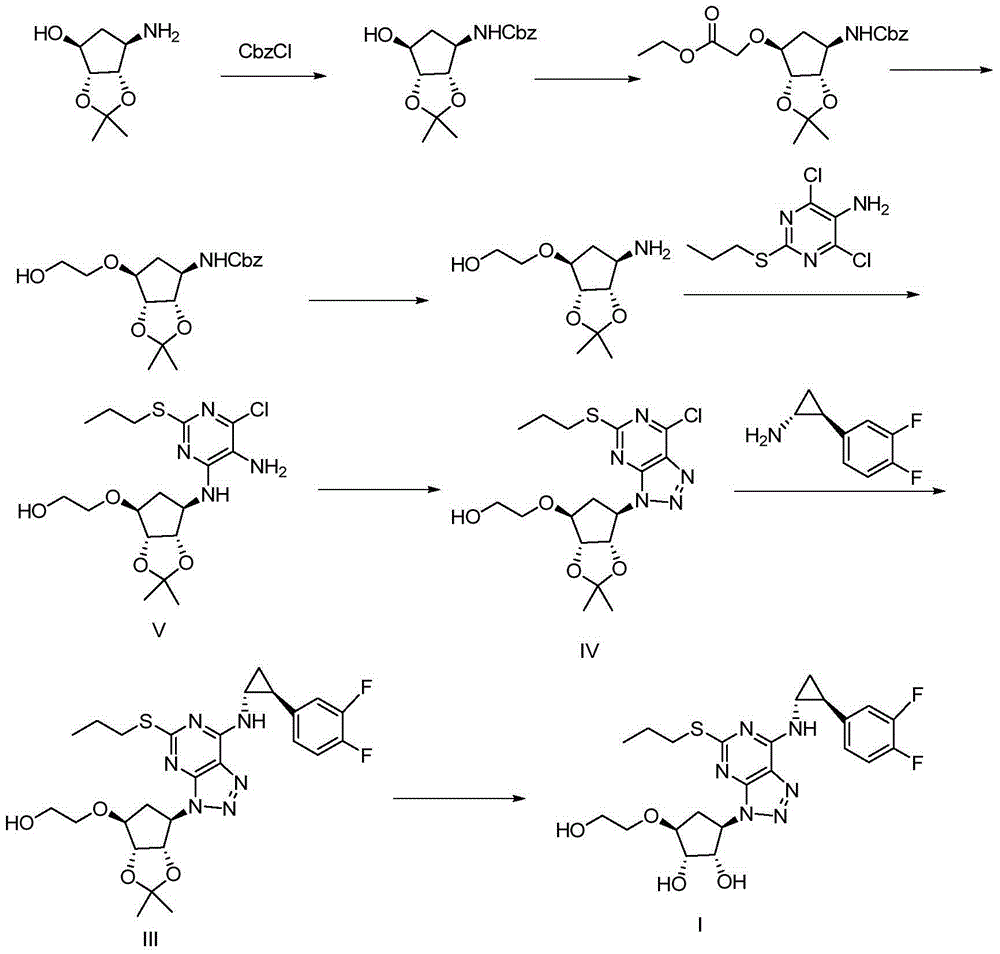

Method for preparing ticagrelor solution

InactiveCN105859720AGood physical propertiesPromote crystallizationOrganic active ingredientsPharmaceutical delivery mechanismSolventBy-product

The invention discloses a method for preparing a ticagrelor solution. According to the invention, hydroxy of a ticagrelor I crude product is protected by a protective group, then a crude product of a compound II is separated and purified to obtain the high purity compound II; the hydroxy protective group of the high purity compound II is removed under proper reaction conditions, a reaction mixture is post-processed and then the by-product is removed to obtain the high purity ticagrelor I, the ticagrelor I, a solvent or / and pharmaceutic adjuvant form a solution, after the solvent is removed, ticagrelor or a mixture containing ticagrelor and accessory with medicinal requirement can be obtained. The method has the advantages of mild reaction condition, simple operation, low cost, and environmental protection, and is suitable for industrial production.

Owner:SHANGHAI FANGNAN PHARMA

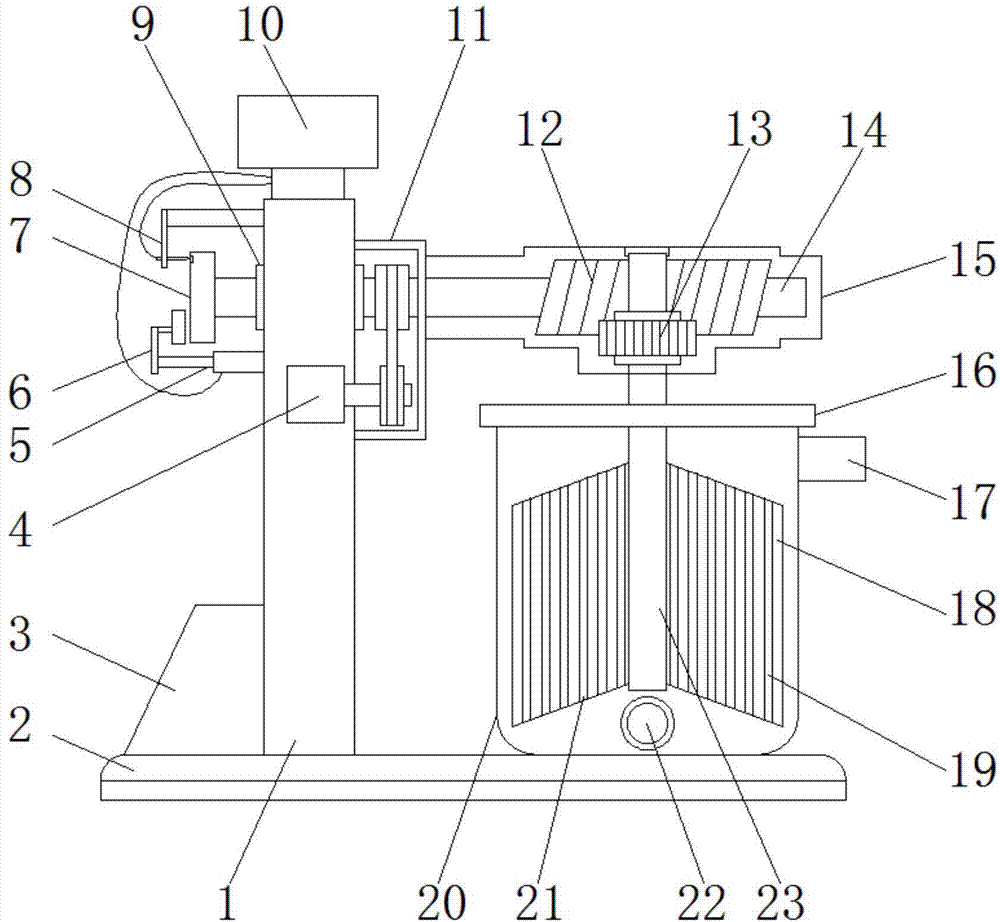

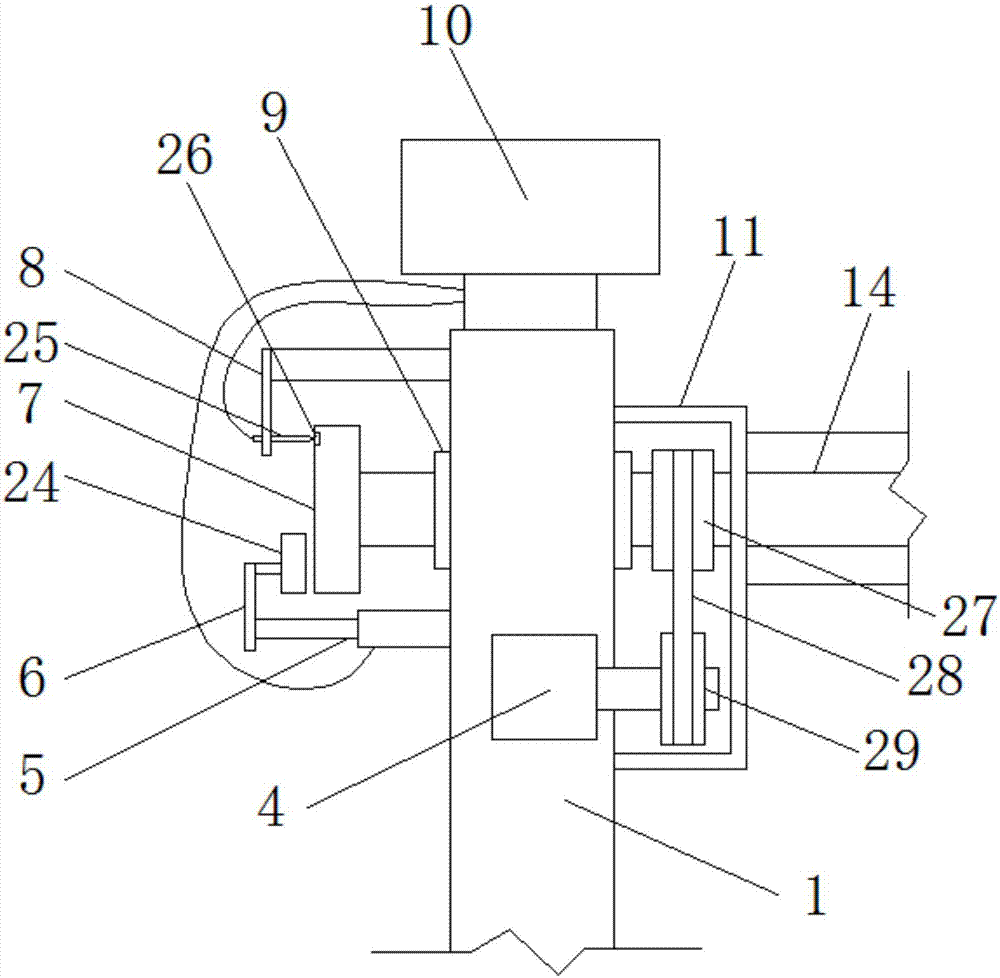

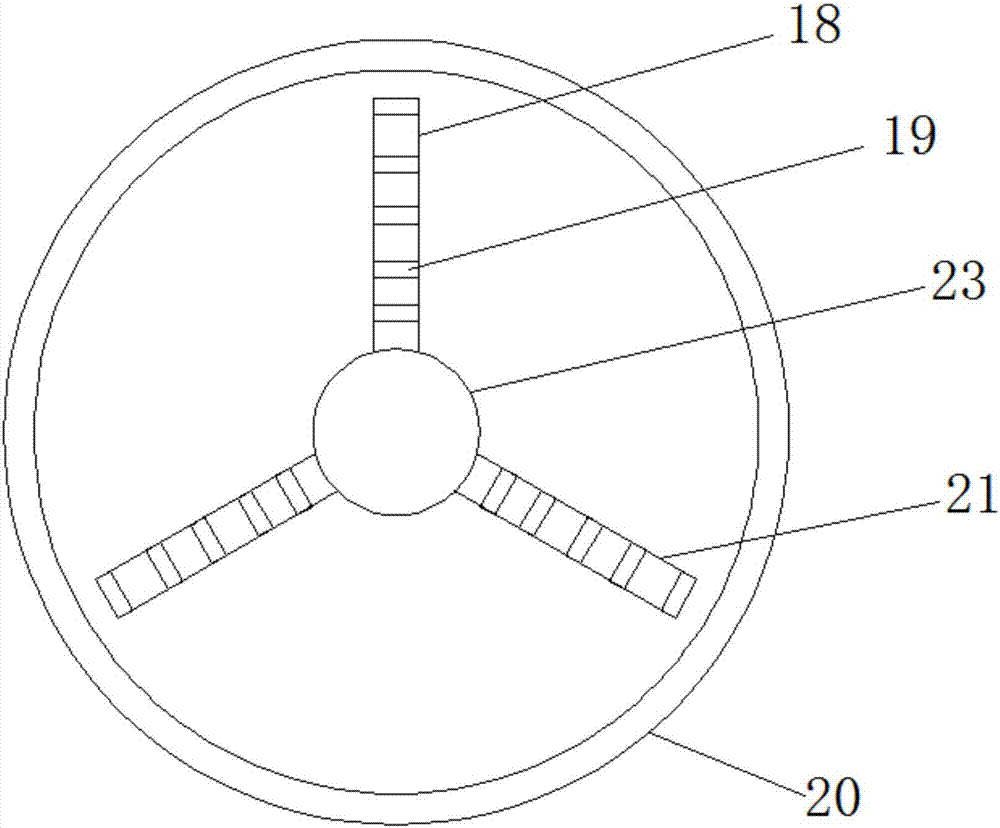

Disturbance agitator for asphalt joint filling factice for building

InactiveCN107185437AStable structureWeld firmlyRotary stirring mixersTransportation and packagingEngineeringAsphalt

The invention discloses a disturbance agitator for asphalt joint filling factice for a building. The disturbance agitator comprises an upright column, a base, a brake wheel, a heat-preservation tank body, a turbulence agitator and a friction plate, wherein the upright column is welded at the upper end of the base; the upper end of the upright column is provided with a revolving shaft; the brake wheel is welded at the end of the revolving shaft on the outer side of the upright column; the outer side of the brake wheel is provided with the friction plate; the friction plate is fixedly arranged on a brake frame; the brake frame is welded on a push rod of an electric push rod; a magnet is inlaid in the brake wheel; the outer side of the magnet is provided with an inductive probe. The disturbance agitator for the asphalt joint filling factice for the building is stale in structure, is firmly welded, is convenient for driving a rotating shaft of an agitating shaft; while a plurality of agitating rods on the turbulence agitator are used for agitating the mixed liquor of asphalt and oily slurry, the mixed liquor of the asphalt and the oily slurry flows out from a turbulence groove to form a plurality of interference flows; the mixing uniformity of the mixed liquor of the asphalt and the oily slurry is further enhanced; the generation of laminar precipitation or separation is avoided; the mixing sufficiency is guaranteed.

Owner:阮霞伟

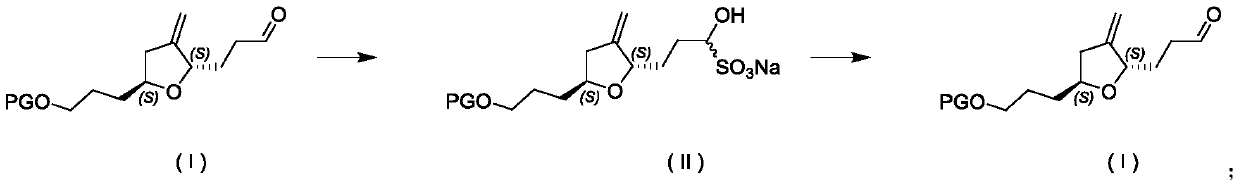

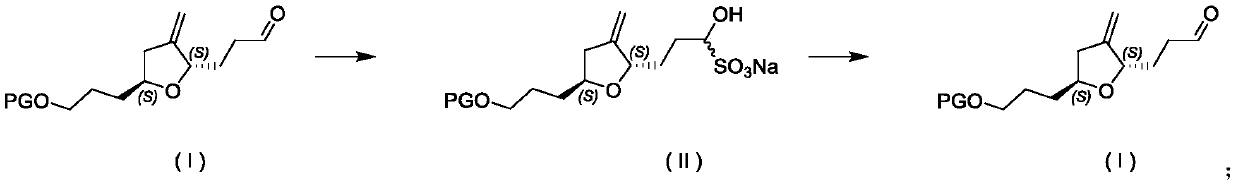

Refining method for improving optical purity of eribulin intermediate compound

InactiveCN110981903AAvoid chromatographyHigh optical purityGroup 4/14 element organic compoundsOrganic chemistry methodsChemical compoundPhysical chemistry

The invention discloses a refining method for improving optical purity of an eribulin intermediate compound. The refining method specifically comprises the following steps: (1) reacting a free compound (I) with sodium hydrogen sulfite to obtain a solid compound (II); and (2) recrystallizing the compound (II) and then dissociating into a compound (I). The reaction is a process of recrystallizationafter dissolution, column chromatography is avoided, and the method is safe, environmentally friendly, high in speed, clean in reaction process, free of redundant products, high in optical purity of products and suitable for large-scale production.

Owner:ZENJI RES LAB

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

Refining method of fasudil hydrochloride

The invention discloses a refining method of fasudil hydrochloride. The method comprises the following steps: reacting homopiperazine with 5-isoquinoline sulfonyl chloride to obtain Fasudil free alkali, dissolving the Fasudil free alkali in a solvent A, uniformly mixing, dropwise adding hydrochloric acid into the solution at a constant temperature to adjust the pH value, stirring the solution at alow temperature to crystallize, filtering, drying a filter cake to constant weight to obtain Fasudil dihydrochloride, dissolving fasudil dihydrochloride in a solvent B, mixing, adding sodium hydroxide to adjust the pH value, separating the liquid, filtering the organic phase to obtain a filtrate, adding hydrochloric acid into the filtrate at constant temperature, stirring to crystallize, filtering, and drying the filter cake to obtain the fasudil hydrochloride refined product. According to the method, impurities in the fasudil hydrochloride can be effectively removed, the total impurity content is controlled to be 0.1% or below, the single impurity content is controlled to be 0.05% or below, the content is 99% or above, the pH value of the fasudil hydrochloride is effectively controlled to be 4.5-6.0, traditional column chromatography operation is avoided, and industrial production is facilitated.

Owner:SHANDONG WEIGAO PHARM CO LTD

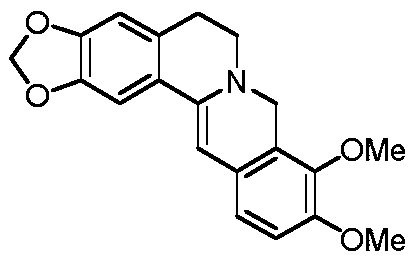

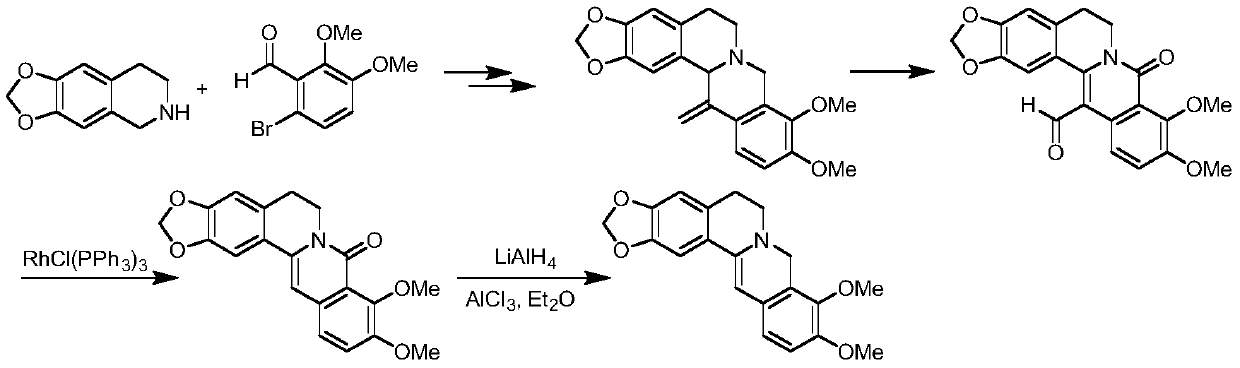

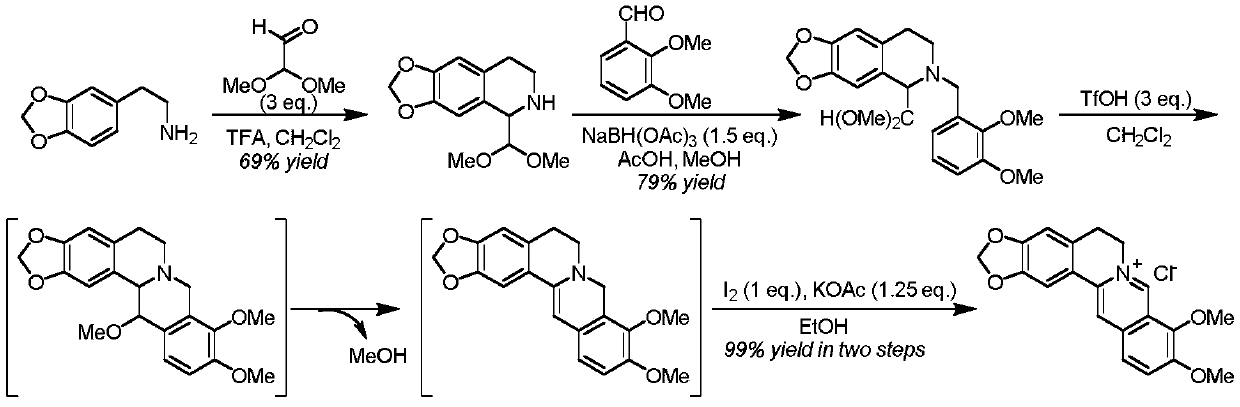

A kind of preparation method of dihydroberberine

ActiveCN108997332BHigh yieldAvoid chromatographyOrganic chemistryPtru catalystBiochemical engineering

The invention provides a preparation method of dihydroberberine. The preparation method comprises the following steps: in the presence of a catalyst, performing catalytic transfer hydrogenation on a compound (described in the specification) and a hydrogen donor in a certain solvent to obtain the compound (described in the specification) dihydroberberine. In the method, the raw material, berberinesalt, is cheap and easily available; reaction conditions are mild, the selectivity is good, and the yield is high; and intermediates and products are purified by crystallization to avoid column chromatography. The method disclosed by the invention is simple and easy to operate, stable in process, easy to control, easy to treat after reaction, high in product yield, and high in purity, and can be used in industrial production economically and conveniently.

Owner:NANJING NUTRABUILDING BIO TECH CO LTD

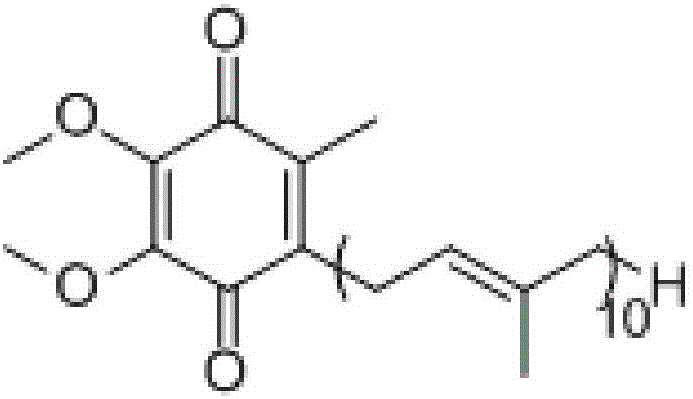

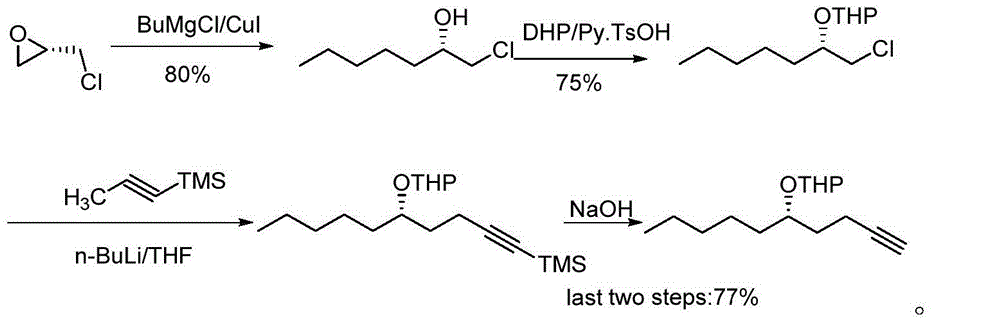

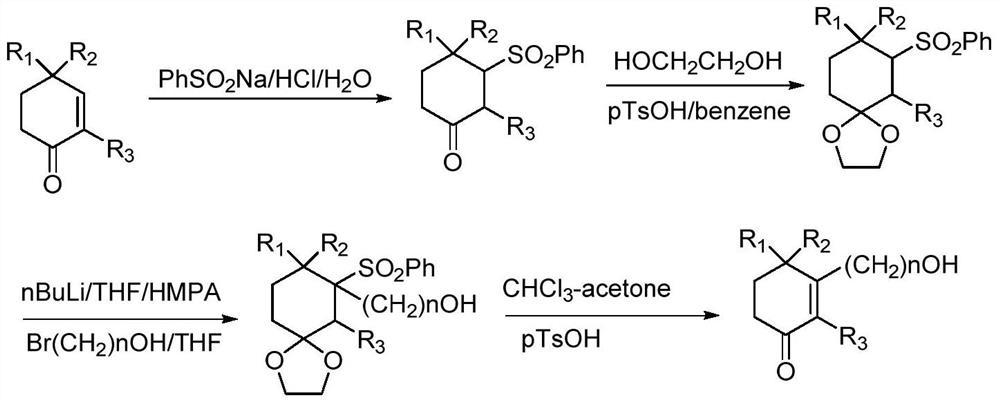

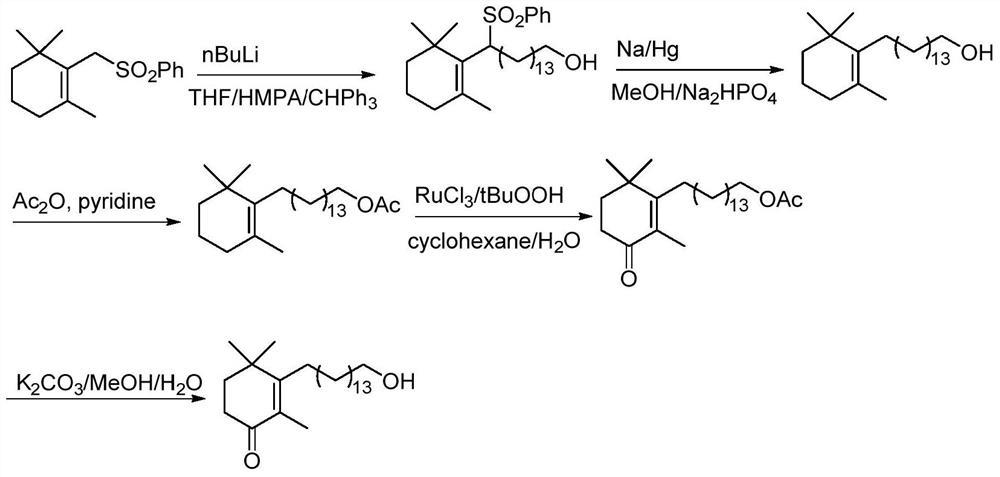

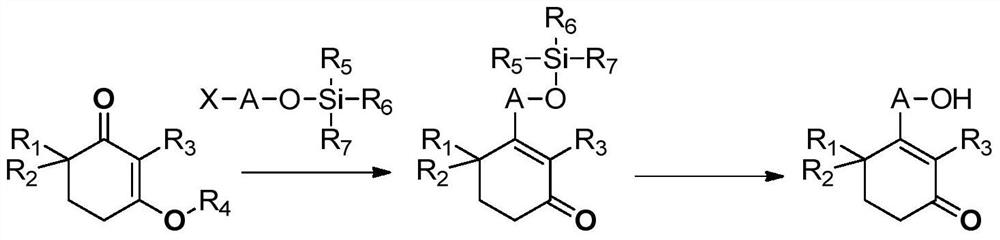

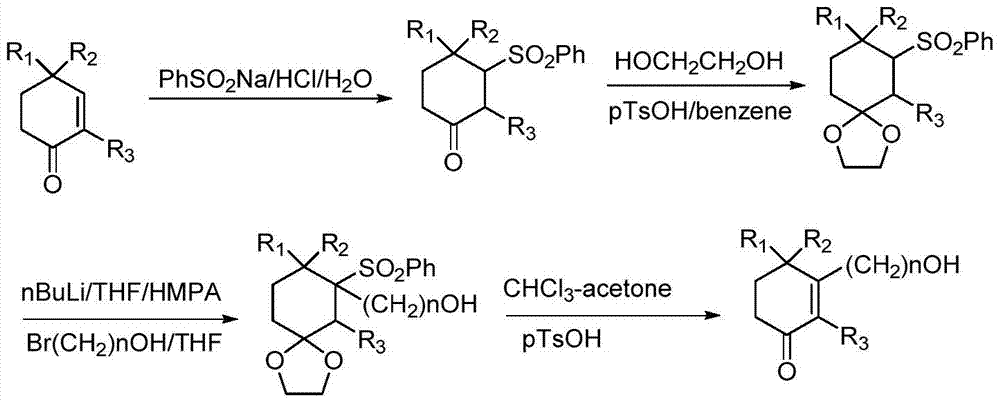

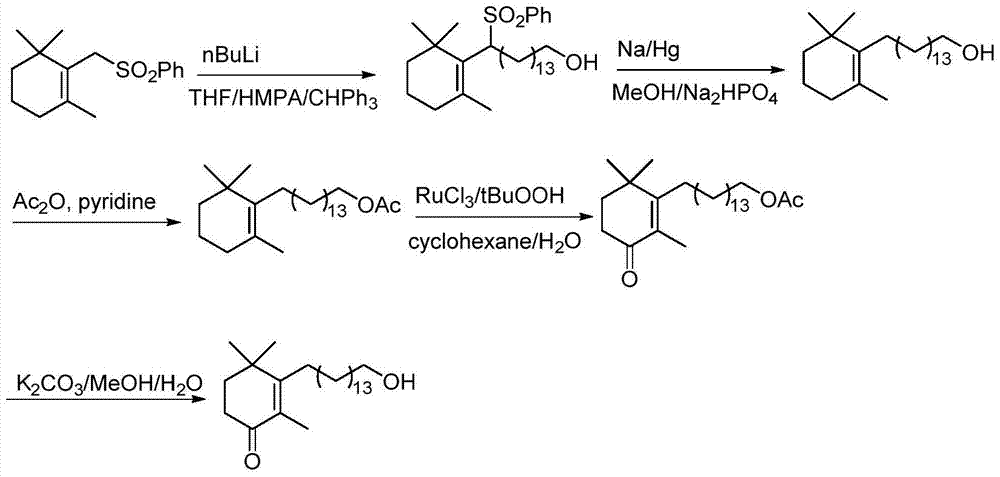

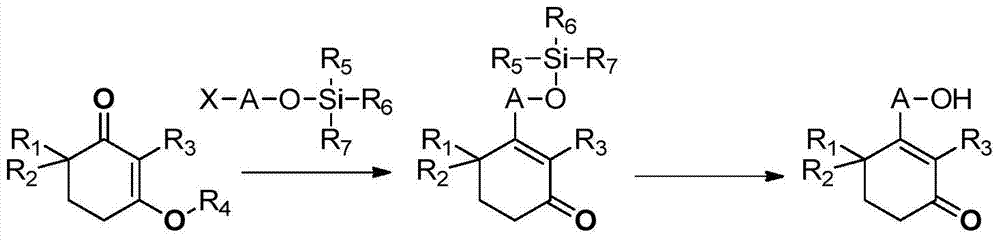

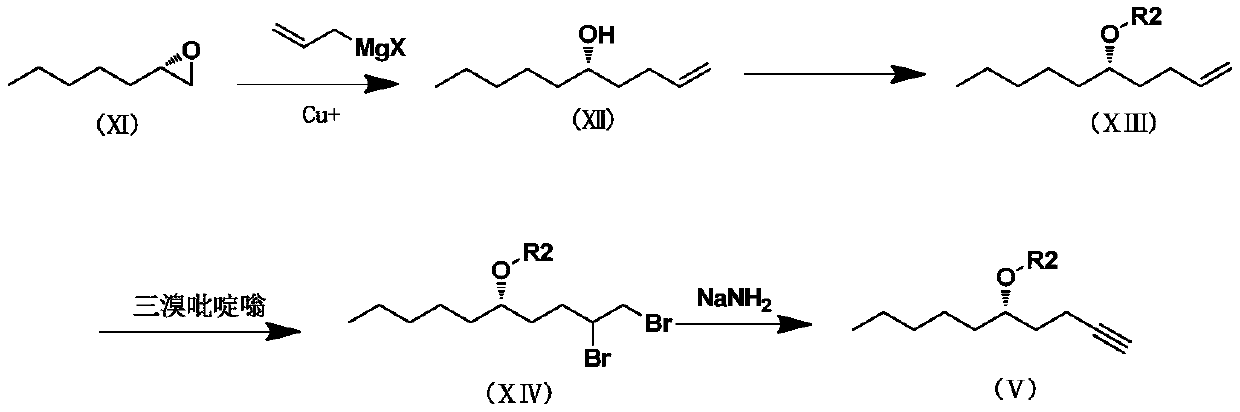

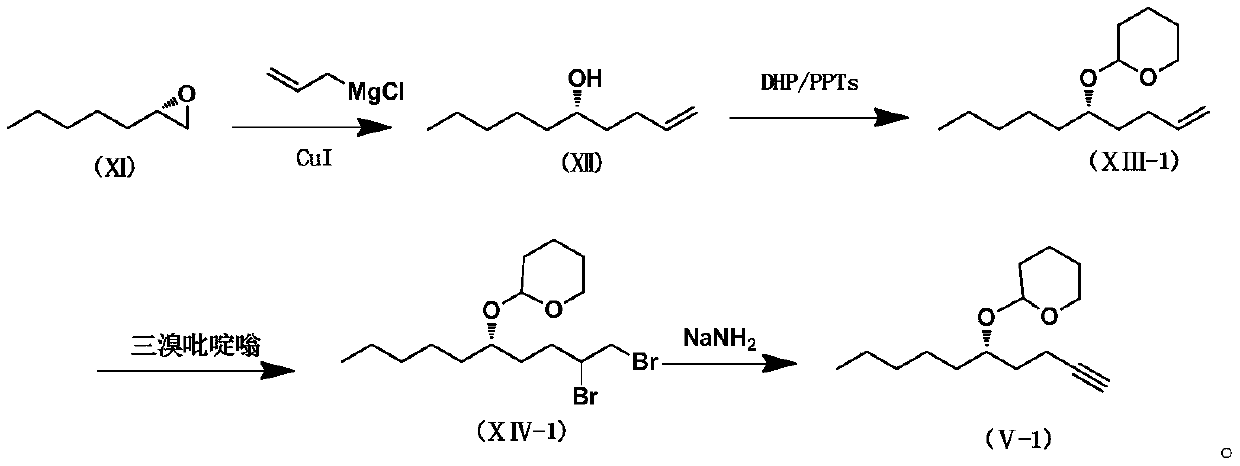

A kind of preparation method of high-purity cyclohexenone long-chain alcohol

ActiveCN107032975BAvoid chromatographyHigh purityOrganic compound preparationSulfonic acid amide preparationCyclohexenoneAlcohol

The invention relates to a preparation method of high-purity cyclohexenone long-chain alcohol represented by formula I. The compound of formula I is prepared by metal-mediated Barbier reaction. The method of the invention has the following advantages: short route, high yield, high product purity, and is suitable for industrial amplification.

Owner:TAIHO PHARMA CO LTD

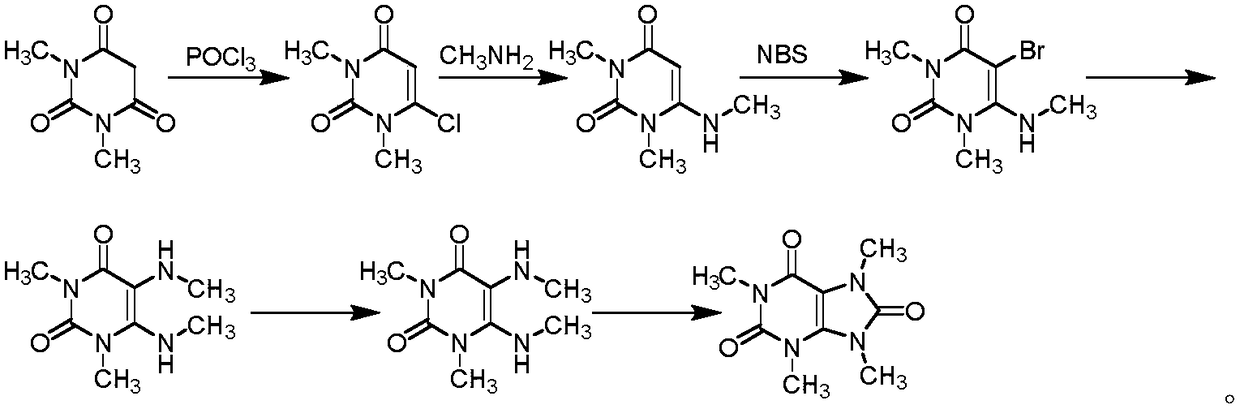

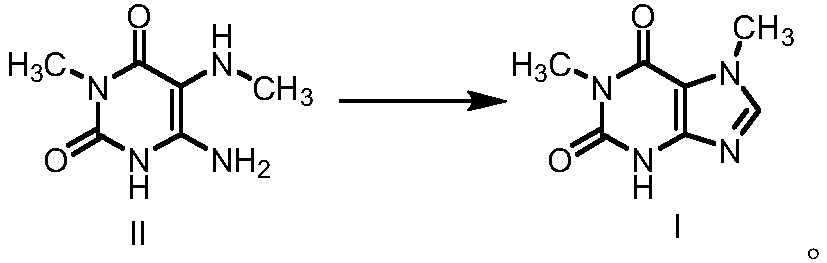

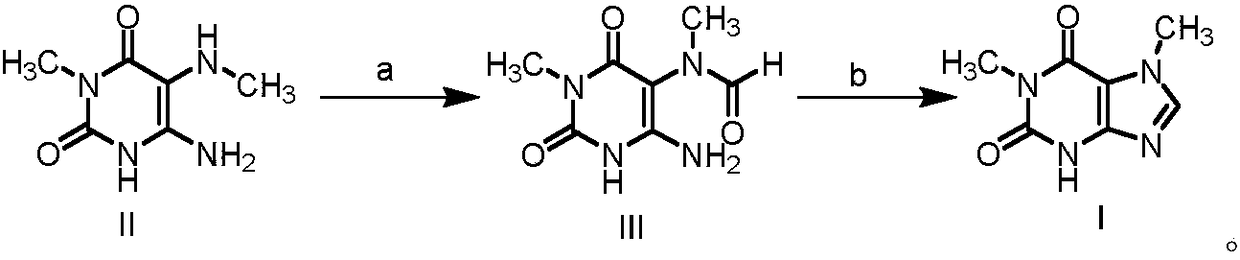

Preparation methods of 1, 7-dimethylxanthine and intermediate thereof, and intermediate

InactiveCN109503583AAvoid chromatographyMild reaction conditionsOrganic chemistryChemistryColumn chromatography

The invention provides two preparation methods of 1, 7-dimethylxanthine, an intermediate thereof and a preparation method of the intermediate. The two preparation methods of 1, 7-dimethylxanthine, provided by the invention, have advantages of convenient operation, high safety, high atomic economy, fewer three wastes, cheapness, easy availability, low toxic, safe and stable raw and auxiliary materials, mild reaction conditions, fewer impurities and high yield; the preparation methods provided by the invention purify products by crystallization or beating, avoid column chromatography, and have advantages of simple and feasible operation, stable process, easy control, convenient reaction and post-treatment, and economical and convenient use for industrial production. The invention also provides a novel compound II and a preparation method of the compound II.

Owner:NANJING NUTRABUILDING BIO TECH CO LTD

Method for separating and purifying β-thymidine from fermentation broth

ActiveCN107383135BEfficient removalAvoid chromatographySugar derivativesSugar derivatives preparationBiotechnologyReverse osmosis

The invention discloses a method for separating and purifying beta-thymidine from fermentation liquor. The method comprises the following steps: carrying out microfiltration, ultrafiltration, ion exchange resin chromatography, reverse osmosis concentration and vacuum concentration on beta-thymidine fermentation liquor in sequence to obtain a beta-thymidine crude product, and finally carrying out decoloration and recrystallization on the crude product to obtain a beta-thymidine competitive product. The extraction and purification technology disclosed by the invention is good in impurity removal effect and high in degree of automation, the chemical purity of the obtained beta-thymidine competitive product is greater than or equal to 99.5%, the content of the obtained beta-thymidine competitive product is greater than or equal to 99.5%, the total recovery of the obtained beta-thymidine competitive product is greater than or equal to 80%, and the method is extremely applicable for industrial mass production.

Owner:JIANGSU CHUANGUO PHARMA CO LTD

A kind of preparation method of tribenzyl glycoside

ActiveCN109776624BAvoid chromatographyQuality improvementSugar derivativesSugar derivatives preparationGlycosideEthyl group

The invention belongs to the technical field of medicine, and in particular relates to a preparation method of tribenzyl glycoside. The specific steps include: using 3,5,6-tribenzyloxy-1,2-oxygen-isopropylidene-α-D-glucofuran as the starting reactant, deprotection reaction occurs under acidic conditions to generate 3, The crude product of 5,6-tribenzyloxy-D-glucofuran was refined and purified twice in turn to obtain the pure product of 3,5,6-tribenzyloxy-D-glucofuran, which was finally prepared by etherification under acidic conditions. Get ethyl-3,5,6-tribenzyloxy-D-glucofuranoside. The method of the invention prepares tribenzyl glucoside, the intermediate synthesis and separation and purification are simple and convenient, avoids column chromatography operation, and the final product has good quality and high purity, and the production cycle can be obviously shortened.

Owner:LUNAN BETTER PHARMA

Preparation method of high-purity cyclohexenone long-chain alcohol

ActiveCN107032975AAvoid chromatographyHigh purityOrganic compound preparationSulfonic acid amide preparationCyclohexenoneAlcohol

The invention relates to a preparation method of high-purity cyclohexenone long-chain alcohol shown in formula I. The compound shown in the formula I is prepared with a metal mediated Barbier reaction. The method has the advantages that the route is short, the yield and product purity are high, and the method is suitable for industrial expanding.

Owner:TAIHO PHARMA CO LTD

Treprostinil intermediate and preparation process thereof

ActiveCN111116419AMild reaction conditionsEasy recrystallization purificationOrganic chemistryBulk chemical productionTreprostinilCombinatorial chemistry

The invention relates to a treprostinil intermediate and a preparation process thereof. The preparation process comprises the following steps: reacting a compound as shown in a formula (II) with a compound as shown in a formula (III) or an acidic salt thereof in the presence of a condensing agent to obtain a compound as shown in a formula (IV); and reacting the compound as shown in the formula (IV) with a compound as shown in a formula (V) to obtain a compound as shown in a formula (I). According to the invention, the ketone compound (I) is directly obtained by a reaction of Weber amide and alkyne anions, environmental pollution caused by use of a heavy metal (a PCC oxidant) is avoided, and a low-temperature reaction method adopting butyl lithium is also avoided; and the method is mild inreaction conditions, high in yield, good in product purity and wide in industrial application prospects.

Owner:JIANGSU HANSOH PHARMA CO LTD +1

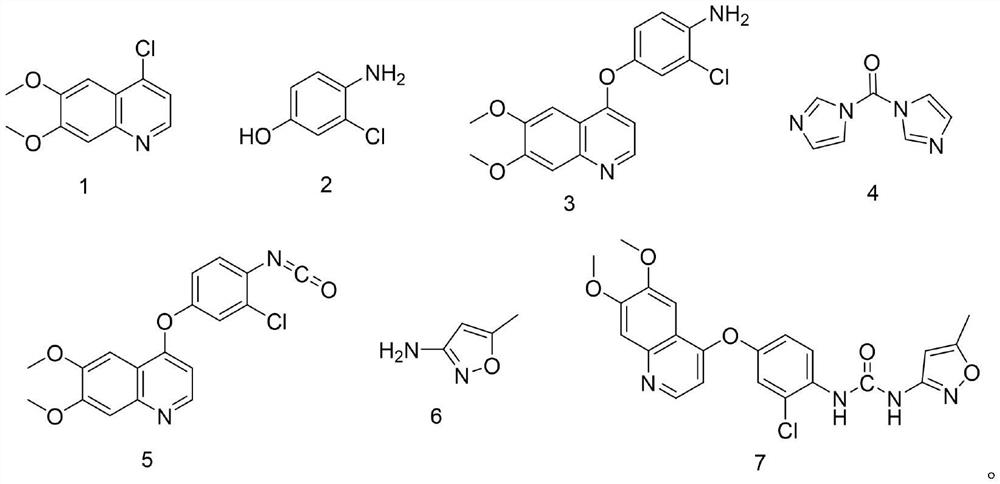

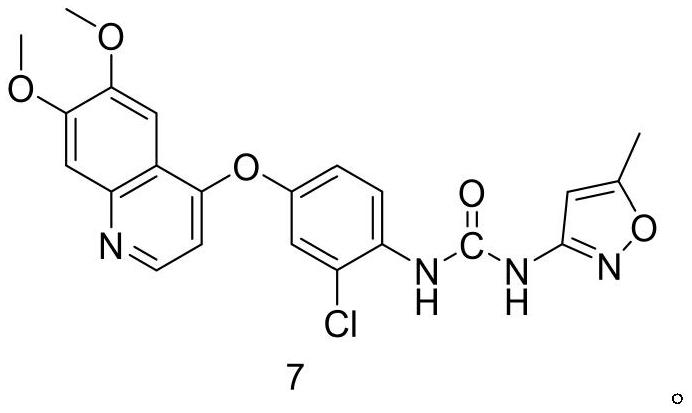

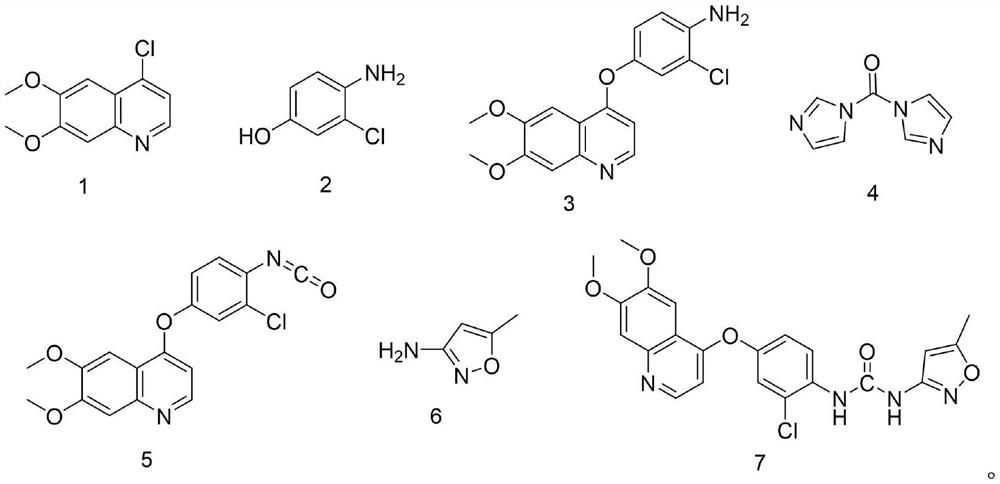

Synthesis process of VEGFR inhibitor tevozanib

The invention relates to a synthesis process of a VEGFR (vascular endothelial growth factor receptor) inhibitor tevozanib. According to the invention, commercially available raw materials are subjected to a halogenation reaction, an esterification reaction and an addition reaction to synthesize a target product. Generally speaking, according to the synthetic route and the synthetic process, the synthetic steps are simplified, the reaction yield of each step is high, the treatment after the reaction is simple, pulping purification is mostly adopted for purification, the use of column chromatography is avoided, the operation process is simple and cheap, and the synthetic route and the synthetic process are favorably applied to industrial mass production.

Owner:武汉九州钰民医药科技有限公司

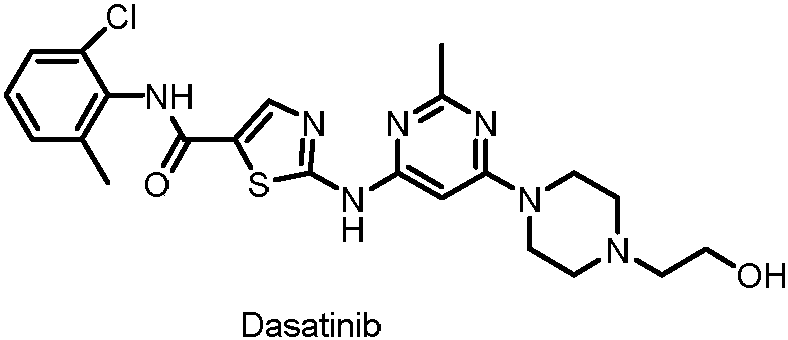

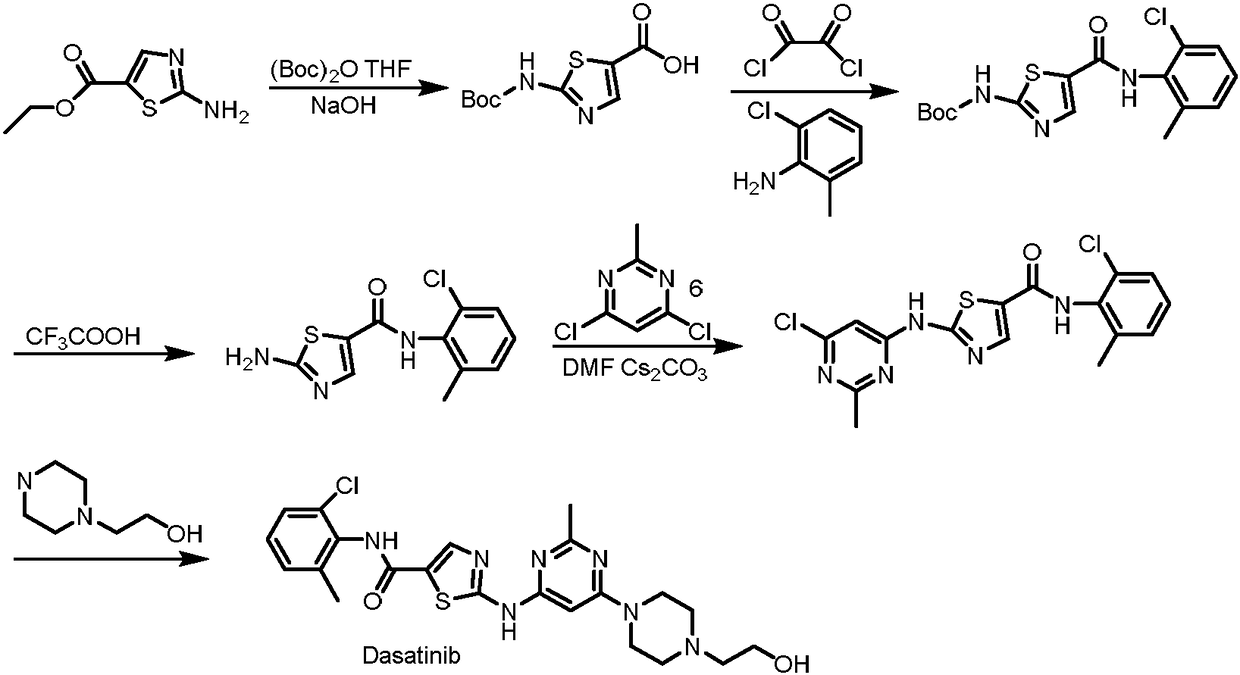

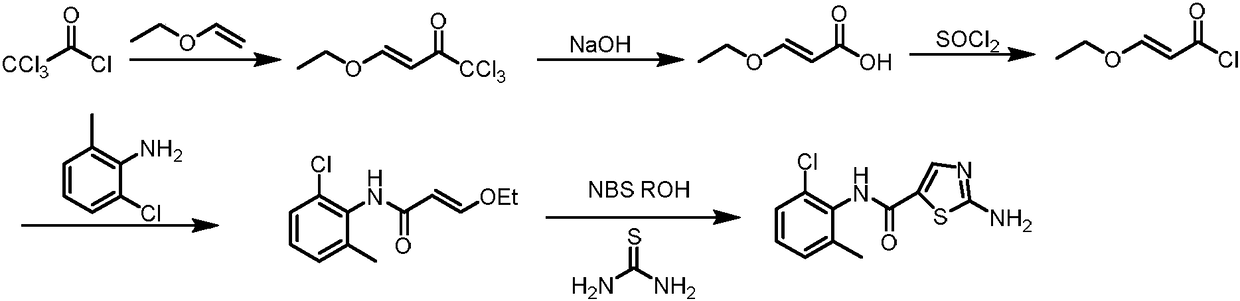

Synthesis method of dasatinib key intermediate

InactiveCN108299417AReaction raw materials are readily availableSimple stepsOrganic chemistrySide reactionCondensation reaction

The invention discloses a synthesis method of a dasatinib key intermediate. The synthesis method comprises the step of carrying out dehydration condensation reaction on a compound 2 and a compound 3 to generate a compound 4, i.e., the dasatinib key intermediate. By adopting the synthesis method of the dasatinib key intermediate, disclosed by the invention, the occurrence of side reaction is greatly reduced, the selectivity of the reaction is improved, and the final yield of dasatinib is improved; the synthesis method is suitable for industrial production. A formula is shown in the description.

Owner:安庆奇创药业有限公司

A method for synthesizing n-substituted-1,2,3,6-tetrahydropyridine-5-boronate

ActiveCN105503924BAvoid chromatographyElimination of isomersGroup 3/13 element organic compoundsHalogenCarboxylic acid

The invention discloses a method for synthesizing N-substitute-1, 2, 3, 6-tetrahydropyridine-5-boric acid ester. According to the method, N-substitute-1, 2, 3, 6-tetrahydropyridine-5-carboxylic acid (ester) serves as the raw material, conducts addition with halogen and then is subjected to alkaline condition elimination to form alkenyl halide and then subjected to coupling with al boron ester under the condition of metal palladium catalyzation, and the N-substitute-1, 2, 3, 6-tetrahydropyridine-5-boric acid ester is obtained. According to the method, the obtained midbody alkenyl halide does not contain isomer, separation is easy to conduct, purity of an obtained product is high, and the method provides a simple way for synthesis of compounds of the type.

Owner:CANGZHOU PURUI DONGFANG SCI & TECH

A process for extracting and isolating coenzyme q10 from fungus residue

The invention discloses a process for extracting and preparing high-purity coenzyme Q10 from mushroom dregs. The mushroom dregs serve as raw materials to be subjected to percolation extraction, and a coenzyme Q10 percolation extracting solution is obtained; the coenzyme Q10 percolation extracting solution is subjected to multilevel extraction for purification, and raffinate is obtained; the raffinate is subjected to crystallization treatment, finally, the high-purity coenzyme Q10 with the purity reaching 98% or above is obtained, and the yield is 95% or above. The whole process is simple, reliable and easy to operate and achieve, and parameters are convenient to control.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com