Patents

Literature

46results about How to "Improves strength uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

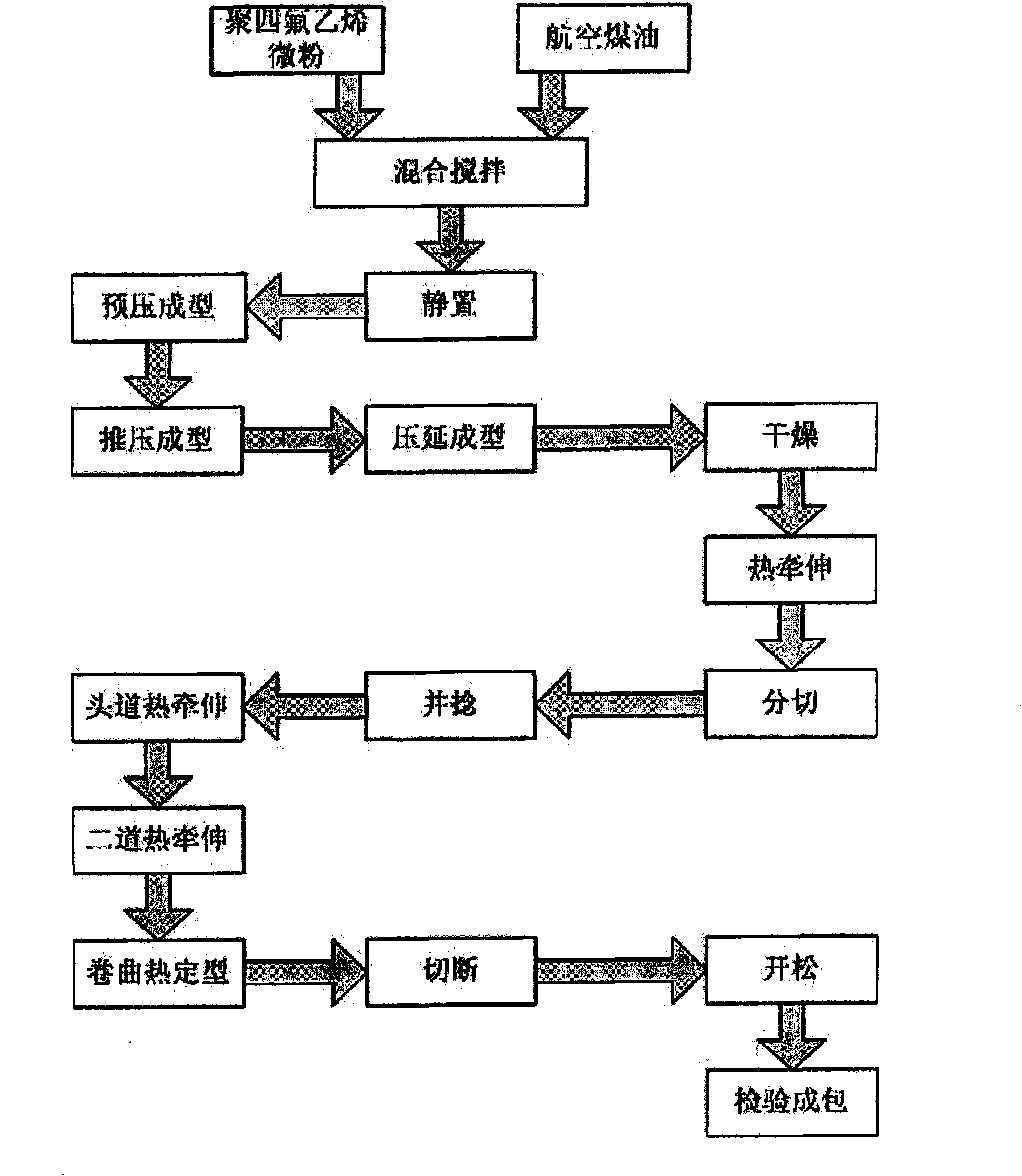

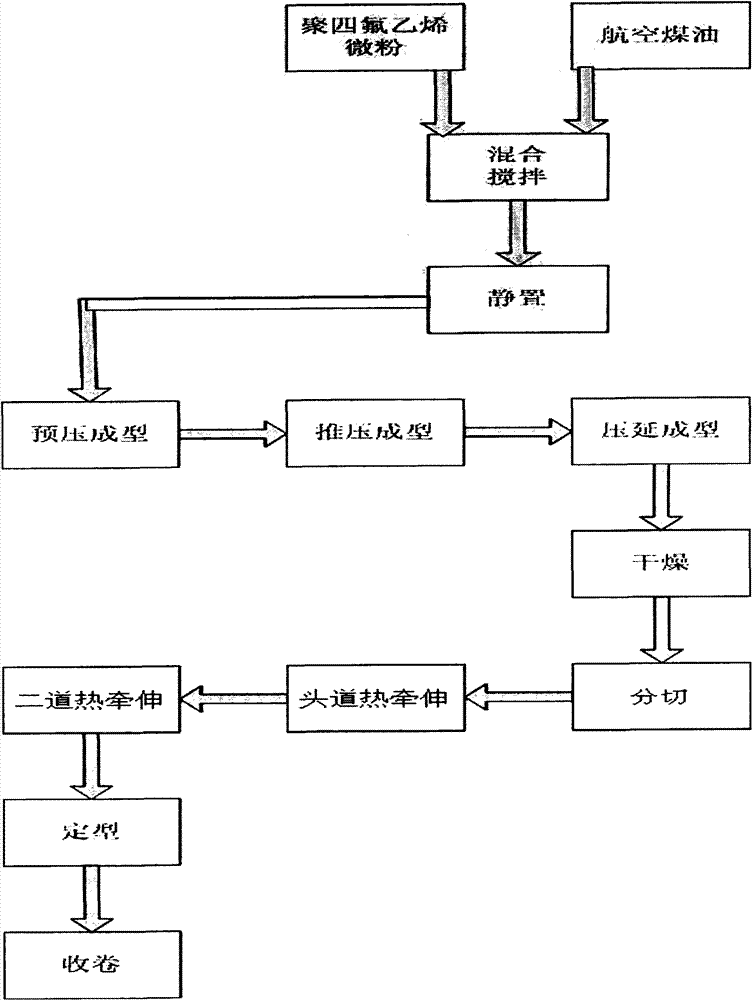

Preparation method of polytetrafluoroethylene chopped fiber

InactiveCN102071483ASimple processing equipmentEasy to operateFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentFiberPre compression

The invention aims to provide polytetrafluoroethylene chopped fiber with high intensity, high uniformity and low production cost and preparation technology thereof. A process flow comprises the following steps of: mixing polytetrafluoroethylene micro powder and a lubricating agent; stirring; standing; performing pre-compression molding; performing push molding; performing rolling molding; drying; performing hot stretching; parting off; twisting; performing primary hot drawing; performing secondary hot drawing; curling and thermally forming; cutting off; loosening; and inspecting and packaging so as to obtain high-intensity polytetrafluoroethylene chopped fiber. In a manufacturing process, the temperature rises gradually from the primary hot stretching to the secondary hot stretching to the curling and thermally forming.

Owner:宋朋泽

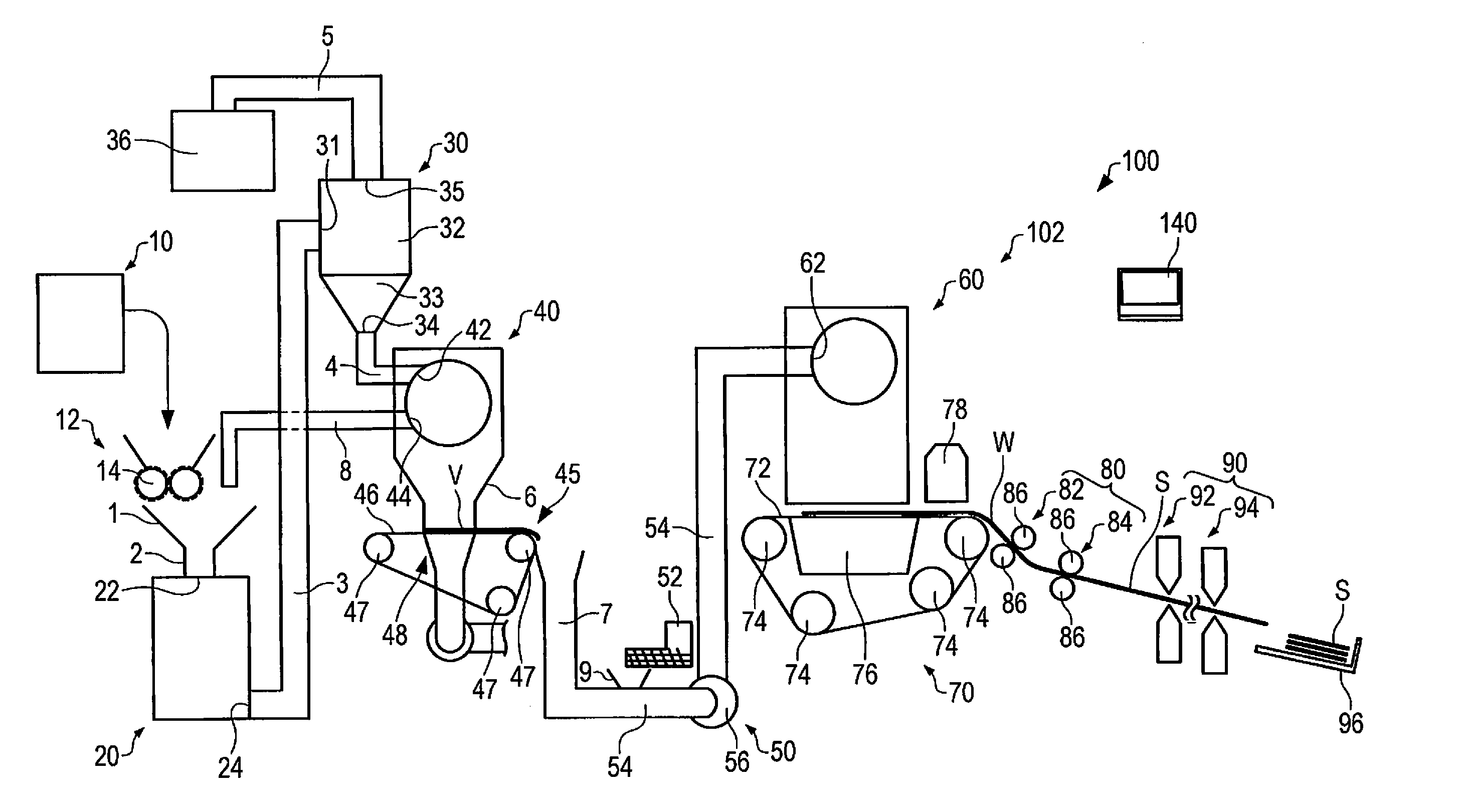

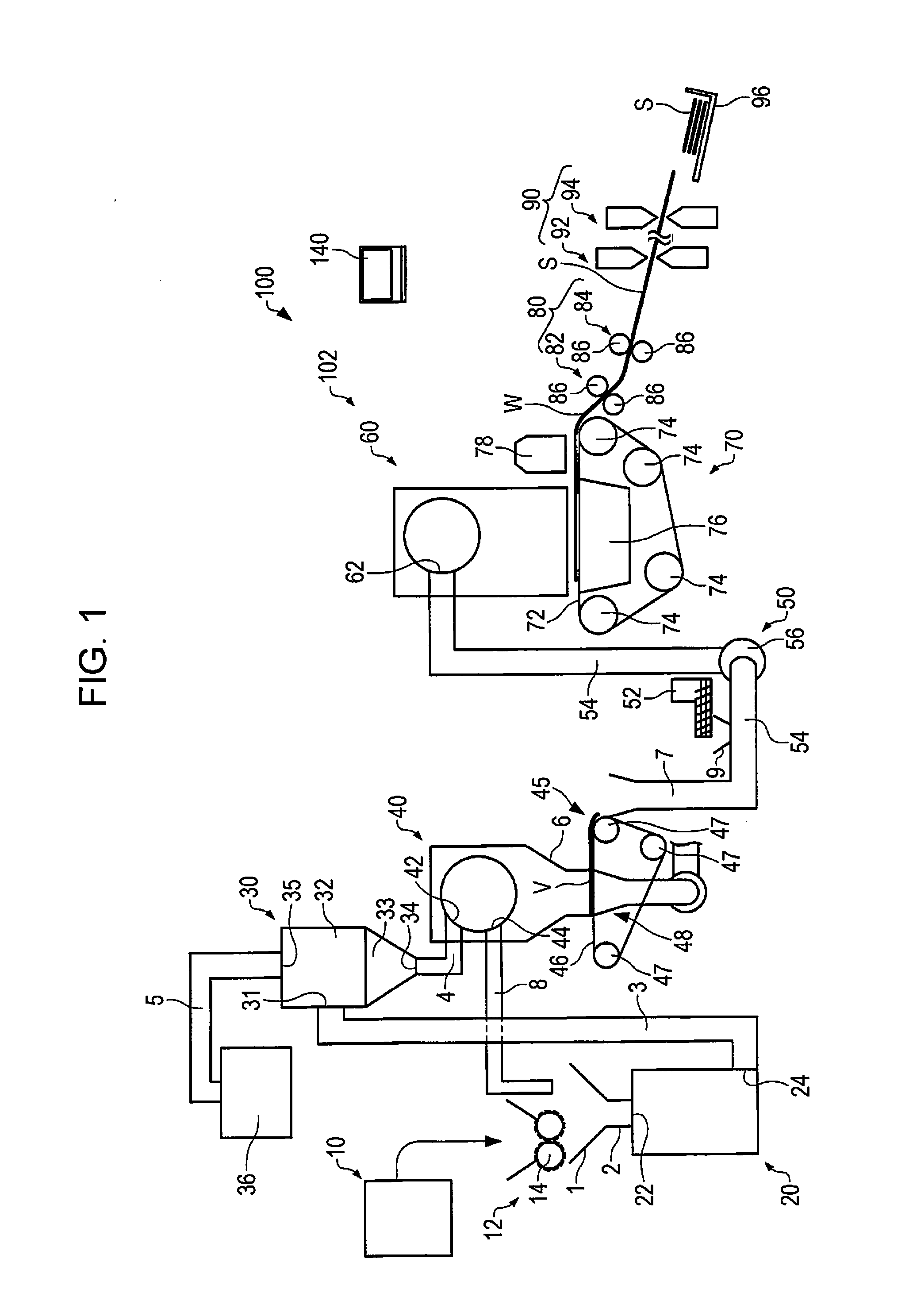

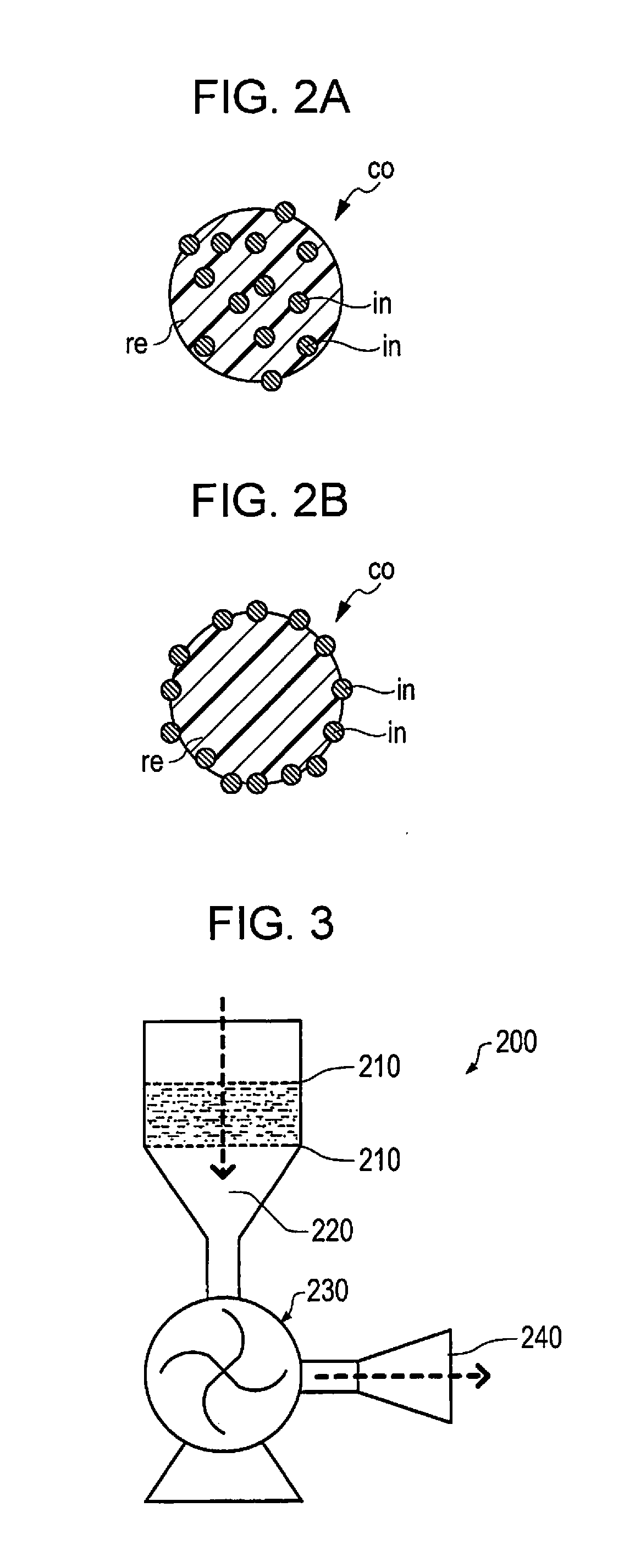

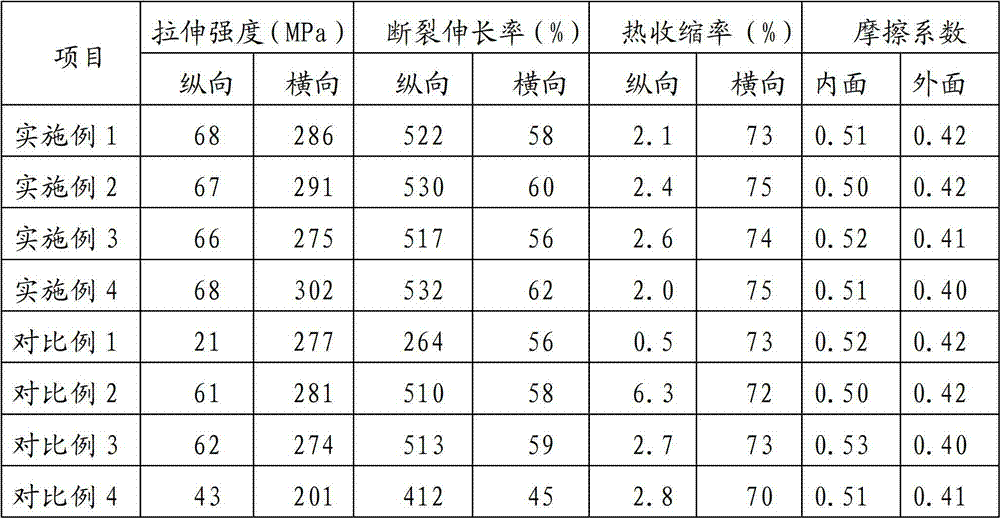

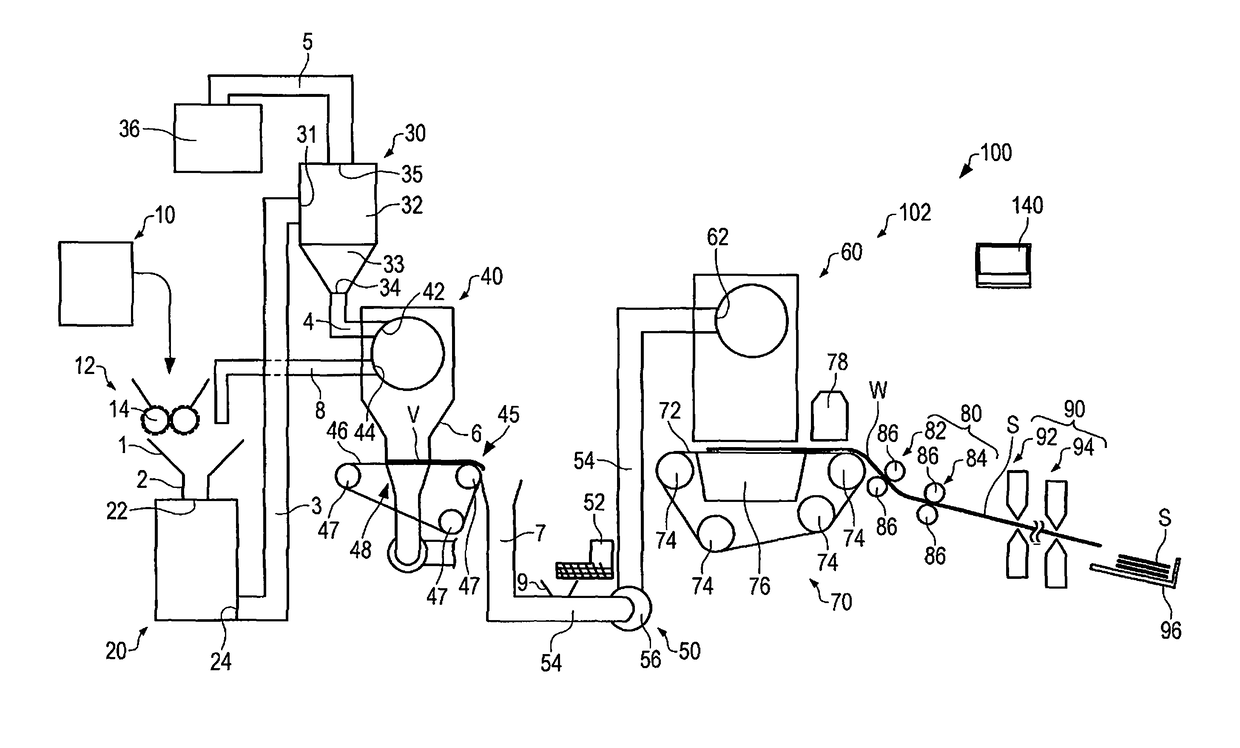

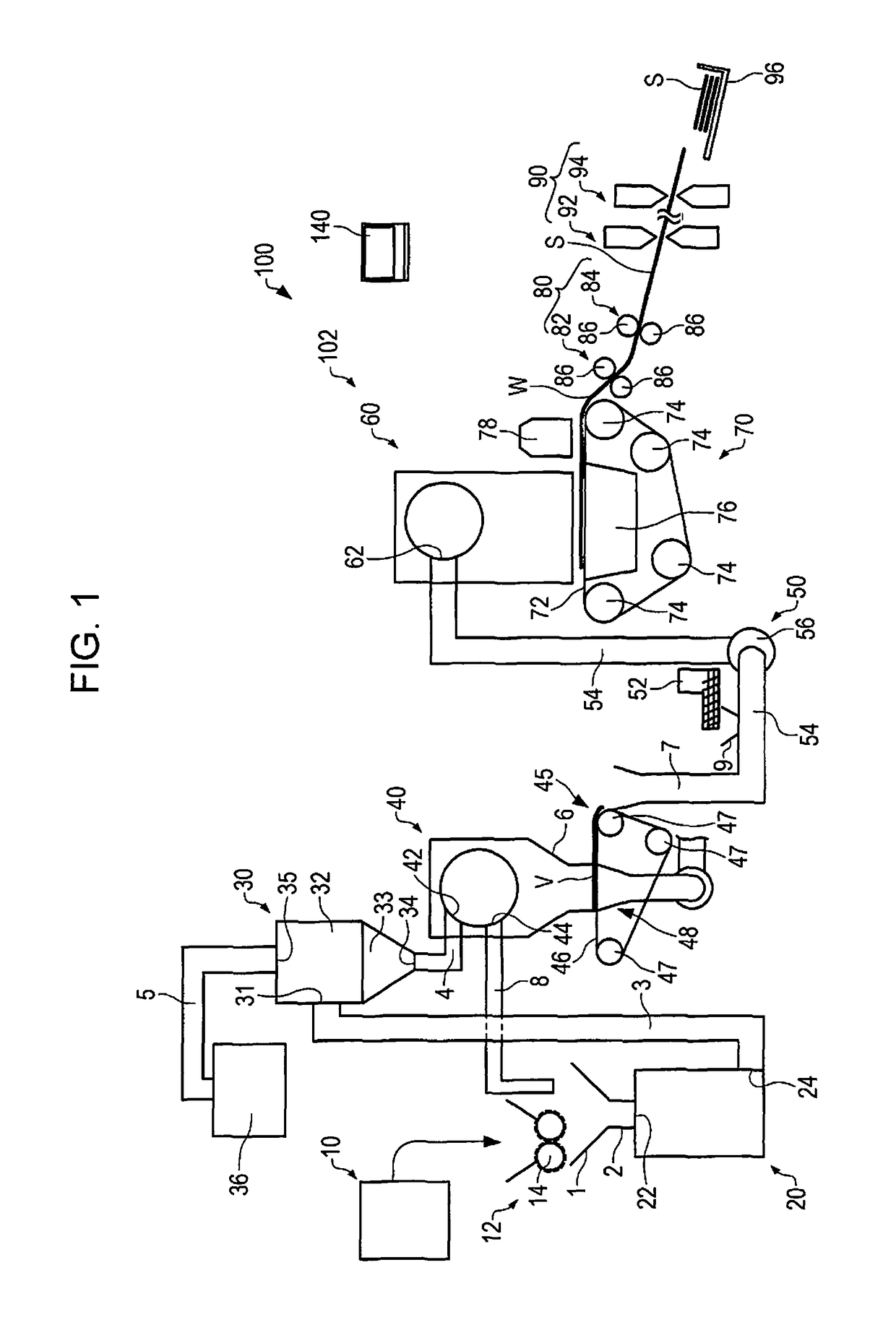

Sheet manufacturing apparatus and sheet manufacturing method

ActiveUS20160229129A1Good dispersionUniform strengthMachine wet endFibrous raw materialsFiberMaterials science

A sheet manufacturing apparatus includes a mixing unit that mixes fibers and a composite in the atmosphere, a forming unit that deposits and heats a mixture mixed by the mixing unit to form a sheet; in which the composite is resin particles with at least a portion of a surface coated by inorganic fine particles, and an absolute value of an average charging amount of the composite is 40 μC / g or higher.

Owner:SEIKO EPSON CORP

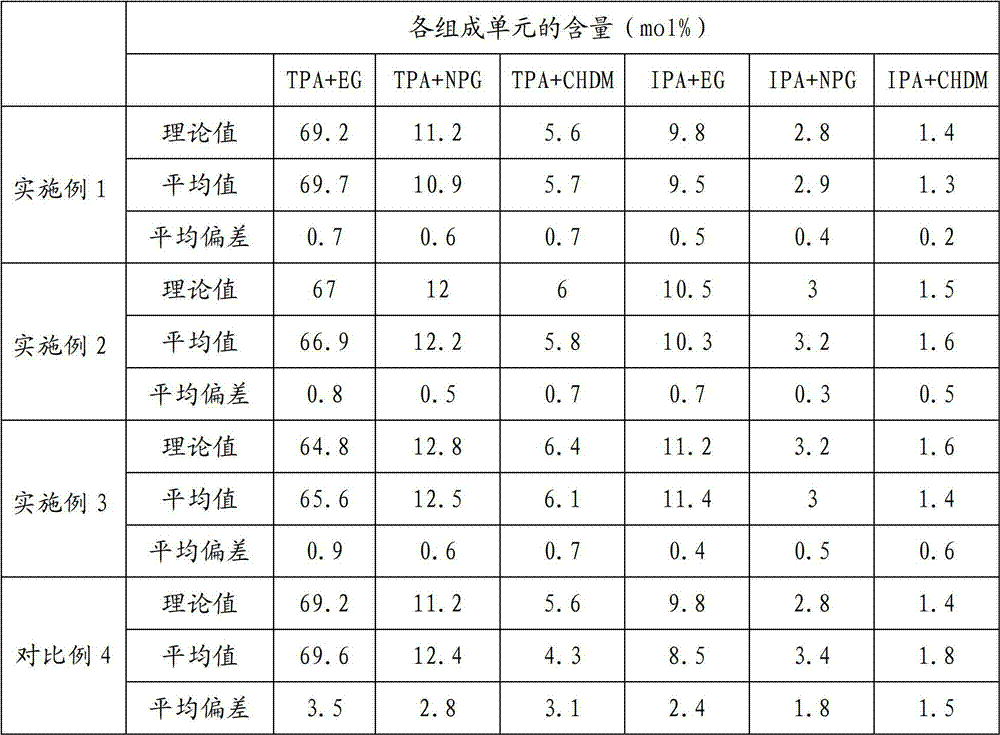

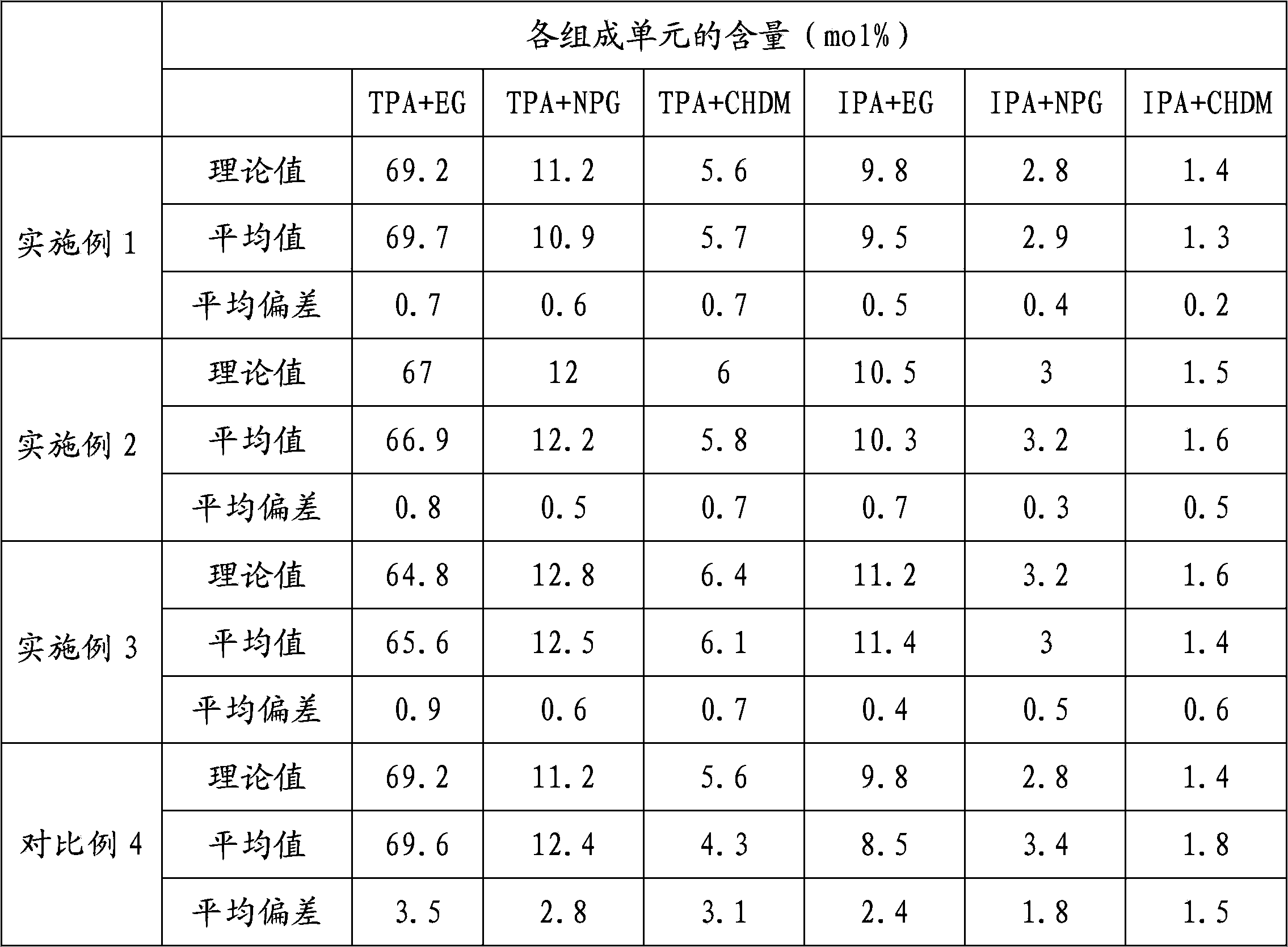

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

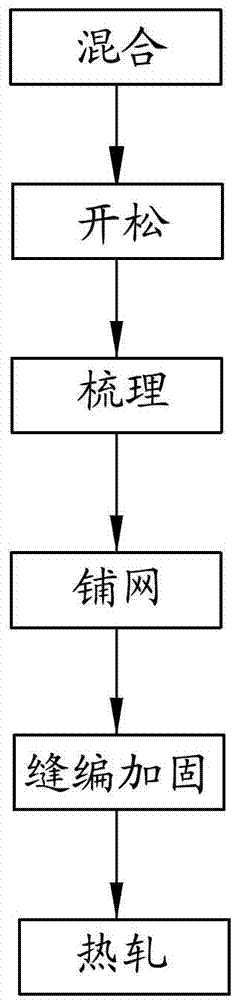

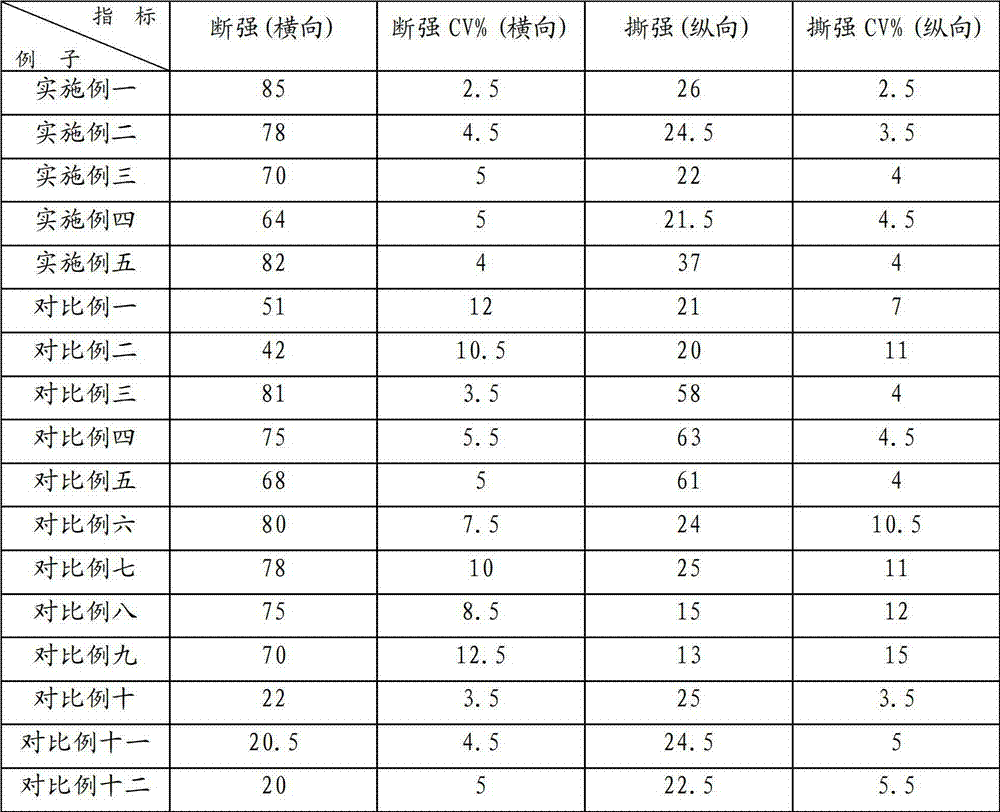

Stitch knitting non-weaving cloth for electrical tape base cloth and production method thereof

InactiveCN102965852AImprove transverse breaking strengthEasy to processNon-woven fabricsBreaking strengthGram

The invention discloses stitch knitting non-weaving cloth for electrical tape base cloth and a production method thereof. The production method comprises the following steps of: oploosening and carding polyester staple fibers with specified fineness and paving and laminating the carded polyester staple fibers to form a fiber web with specified monomer gram weight; reinforcing stitches with fine denier polyester filaments formed by a specified warping mode by adopting an active warp let-off mode; and carrying out stitching knitting and reinforcing on a stitch knitting machine adjusted by a process and then carrying out hot pressing to form the stitch knitting non-weaving cloth. Compared with a general product, the stitch knitting non-weaving cloth produced by adopting the production method disclosed by the invention has the characteristics that transverse breaking strength is great so as to facilitate the next coating processing of the product; longitudinal tearing strength is small so as to ensure the advantage of convenience for tearing with hand in actual application of next terminal product; the service performance of products is greatly improved; and the stitch knitting non-weaving cloth can be widely applied to base cloth of electrical tapes and the like of various cables and electronic elements and has wide popularization significance.

Owner:海东青非织工业(福建)有限公司 +1

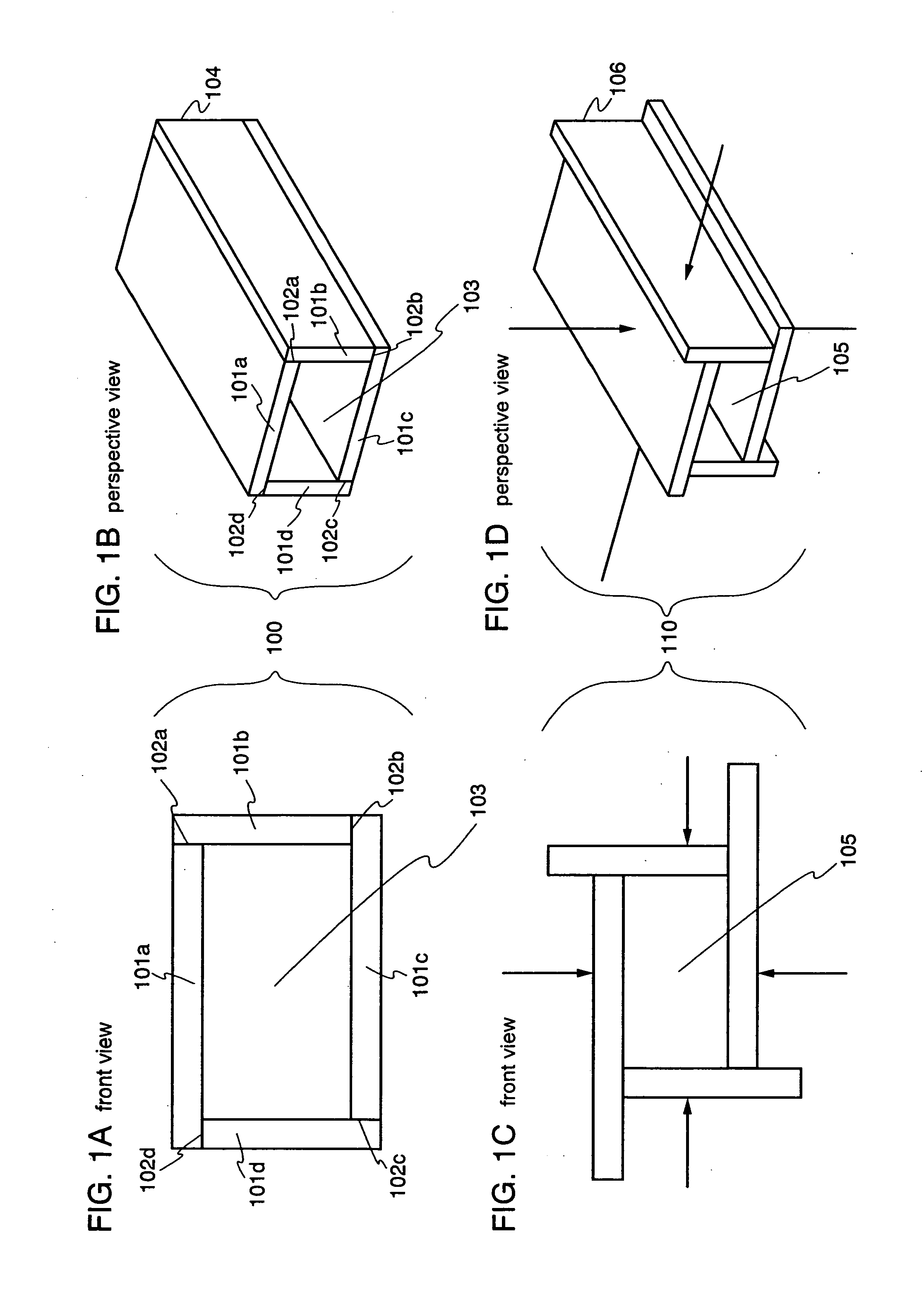

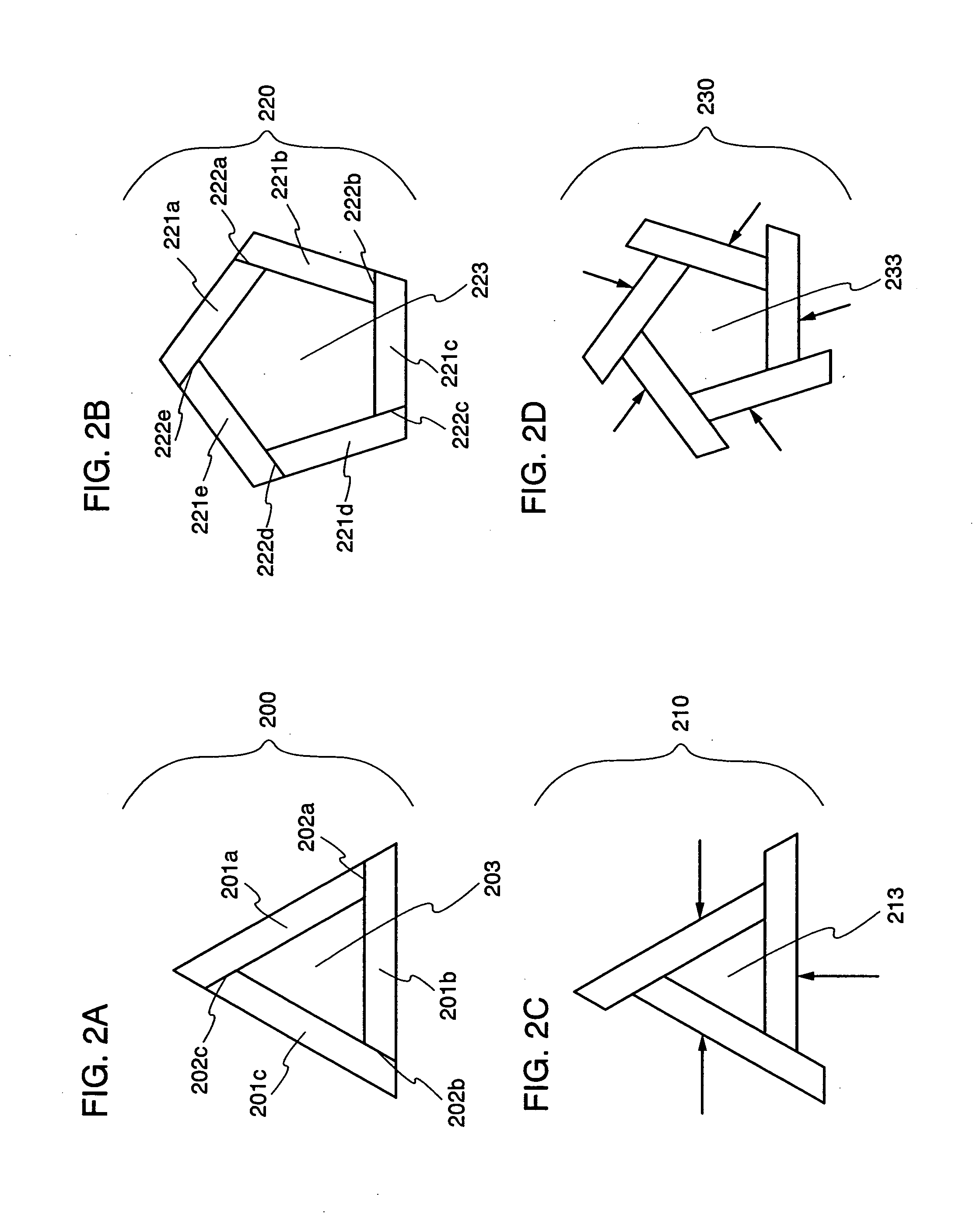

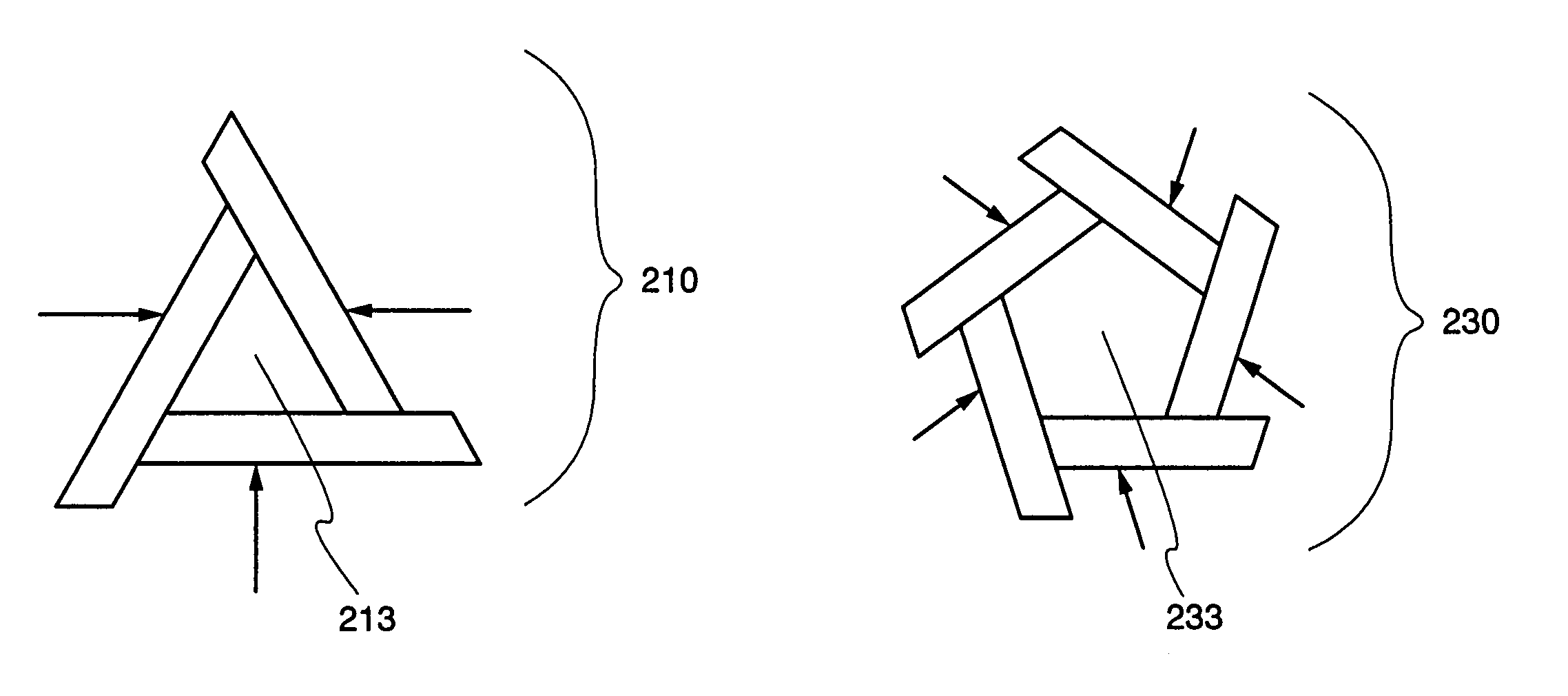

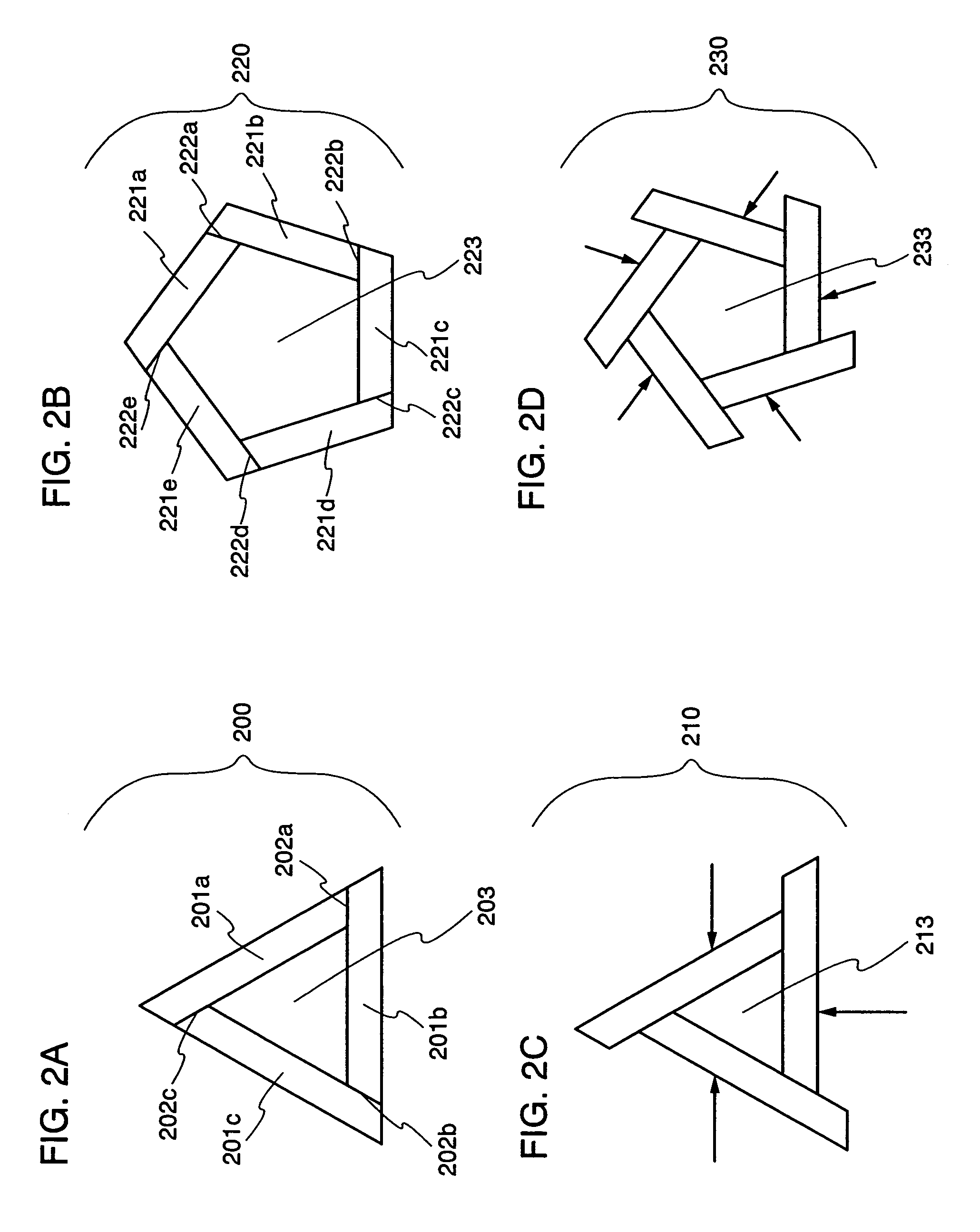

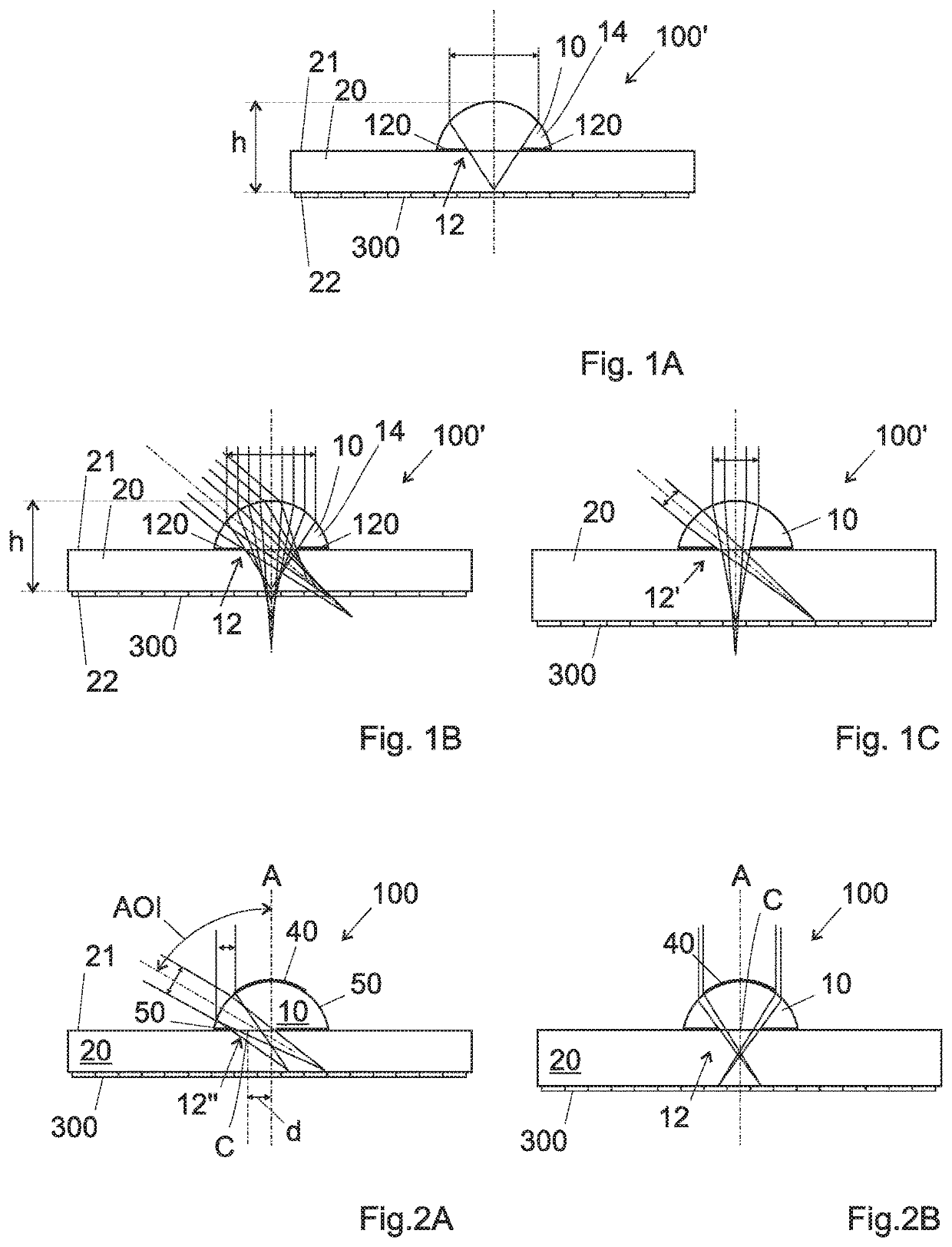

Optical element and light irradiation apparatus

InactiveUS20060227676A1Improves strength uniformityEven energy distributionPhotomechanical apparatusRecord information storageLight irradiationDevice material

It is an object of the present invention to provide an optical element which forms a beam spot with homogeneous energy distribution on an irradiated surface, and a light irradiation apparatus. It is another object of the invention to provide a manufacturing method of a semiconductor device using a beam spot with homogeneous energy distribution. One feature of the invention is to homogenize energy distribution of a beam spot on an irradiated surface by forming the optical element provided with a polygonal entrance and exit using a plurality of reflectors as side walls and introducing a beam to the optical element. Further, a beam spot with a desired size or shape can be obtained by making the reflectors movable. Furthermore, by using a light irradiation apparatus using the optical element, failure in manufacturing a semiconductor device can be reduced.

Owner:SEMICON ENERGY LAB CO LTD +1

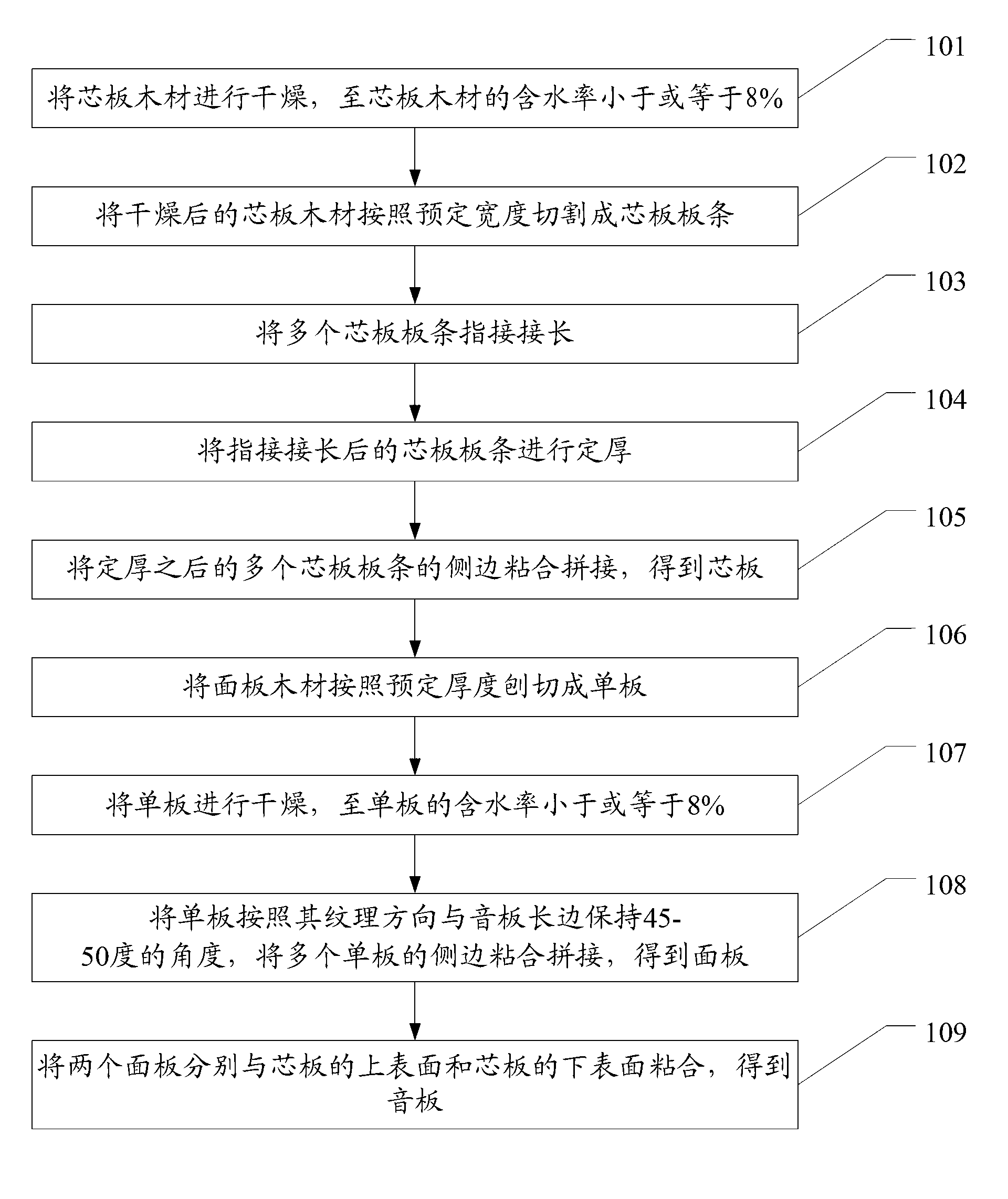

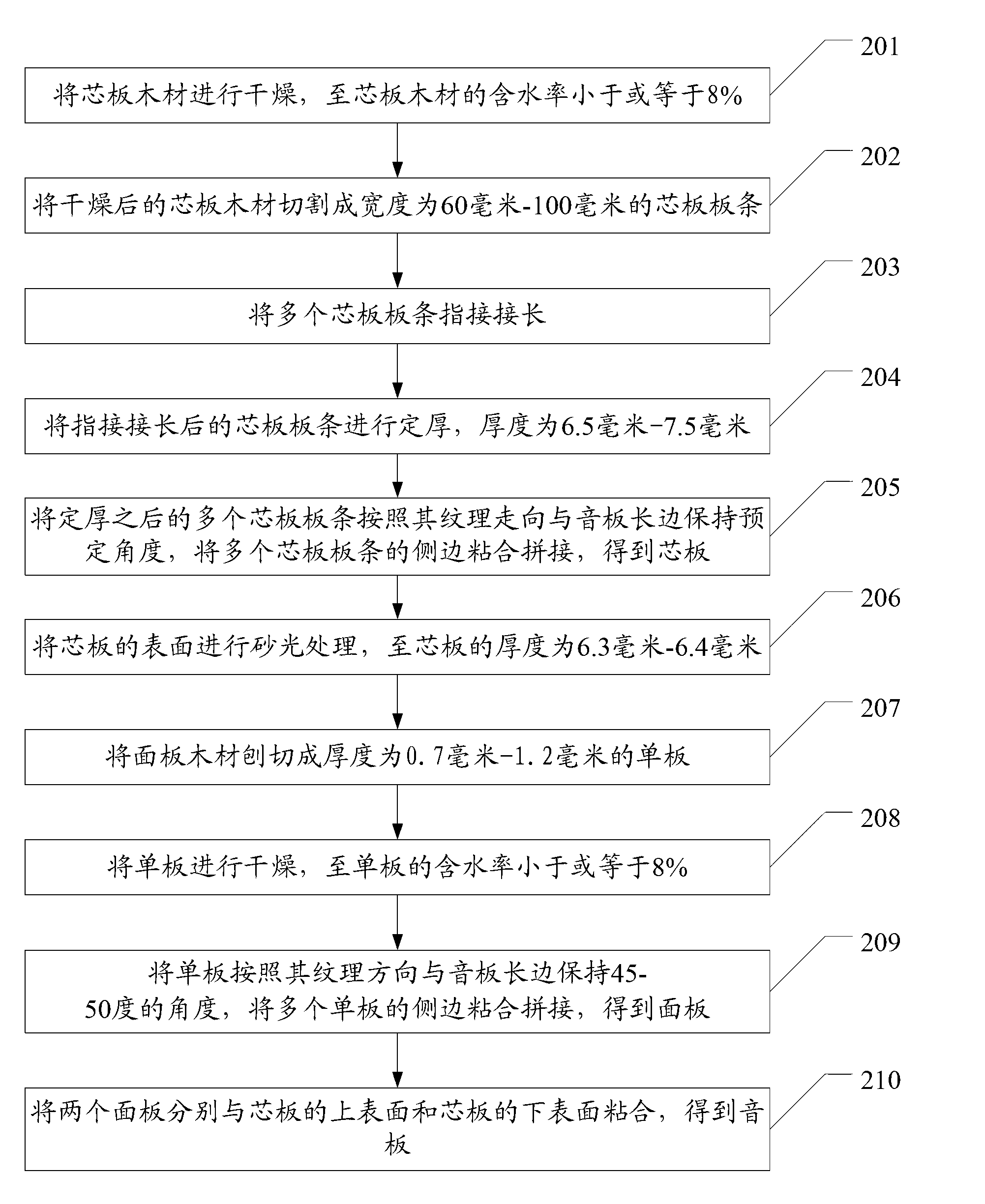

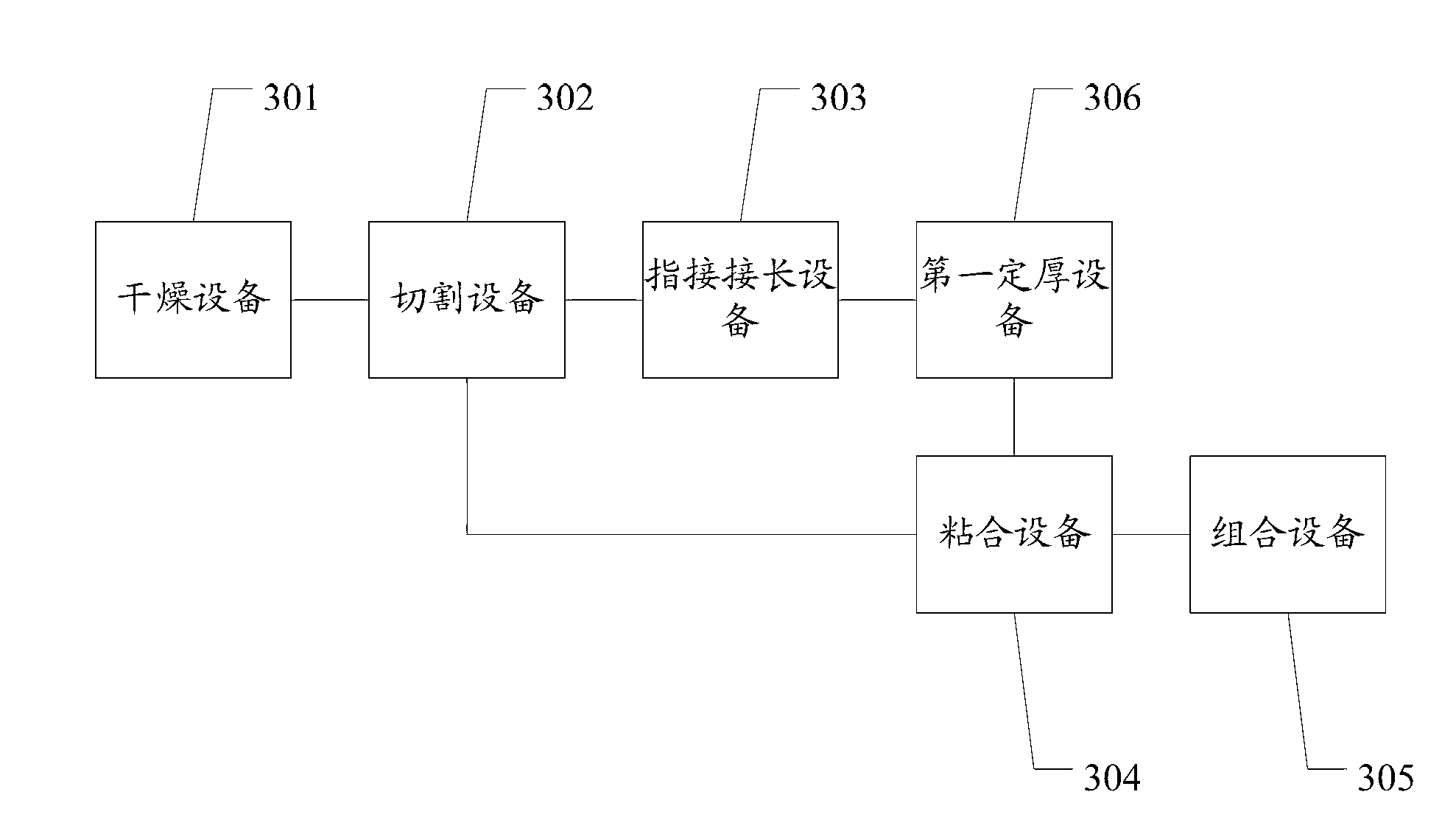

Manufacturing method and manufacturing system of piano soundboard

InactiveCN103218993AImproves strength uniformitySolve shrinkage and swellingStringed musical instrumentsPianoFinger joint

The invention relates to the manufacturing field of pianos, and specifically relates to a manufacturing method and a manufacturing system of a piano soundboard. The manufacturing method of the piano soundboard comprises the following steps of: manufacturing a core board, wherein the core board is rectangular, drying core board wood, cutting the core board wood into core board battens according to predetermined width, connecting a plurality of core board battens in by finger joint, thickening the connected core board battens, bonding and splicing the side edges of the plurality of thickened core board battens to obtain a core board manufacturing panel, chopping panel wood into veneers according to the predetermined thickness, drying the veneers, bonding and splicing the side edges of a plurality of veneers according to the condition that an angle between the texture direction and the long edges of the soundboard is 40-50 DEG to obtain panels, and respectively bonding two panels with the upper surface of the core board and the lower surface of the core board to obtain the soundboard. The manufacturing method and the manufacturing system of the piano soundboard, provided by the invention, are capable of solving the problem that the soundboard is capable of cracking since the external moisture change of the soundboard has the possibility of causing air shrinkage and wet expansion.

Owner:CHENGDU CANYA WOOD IND

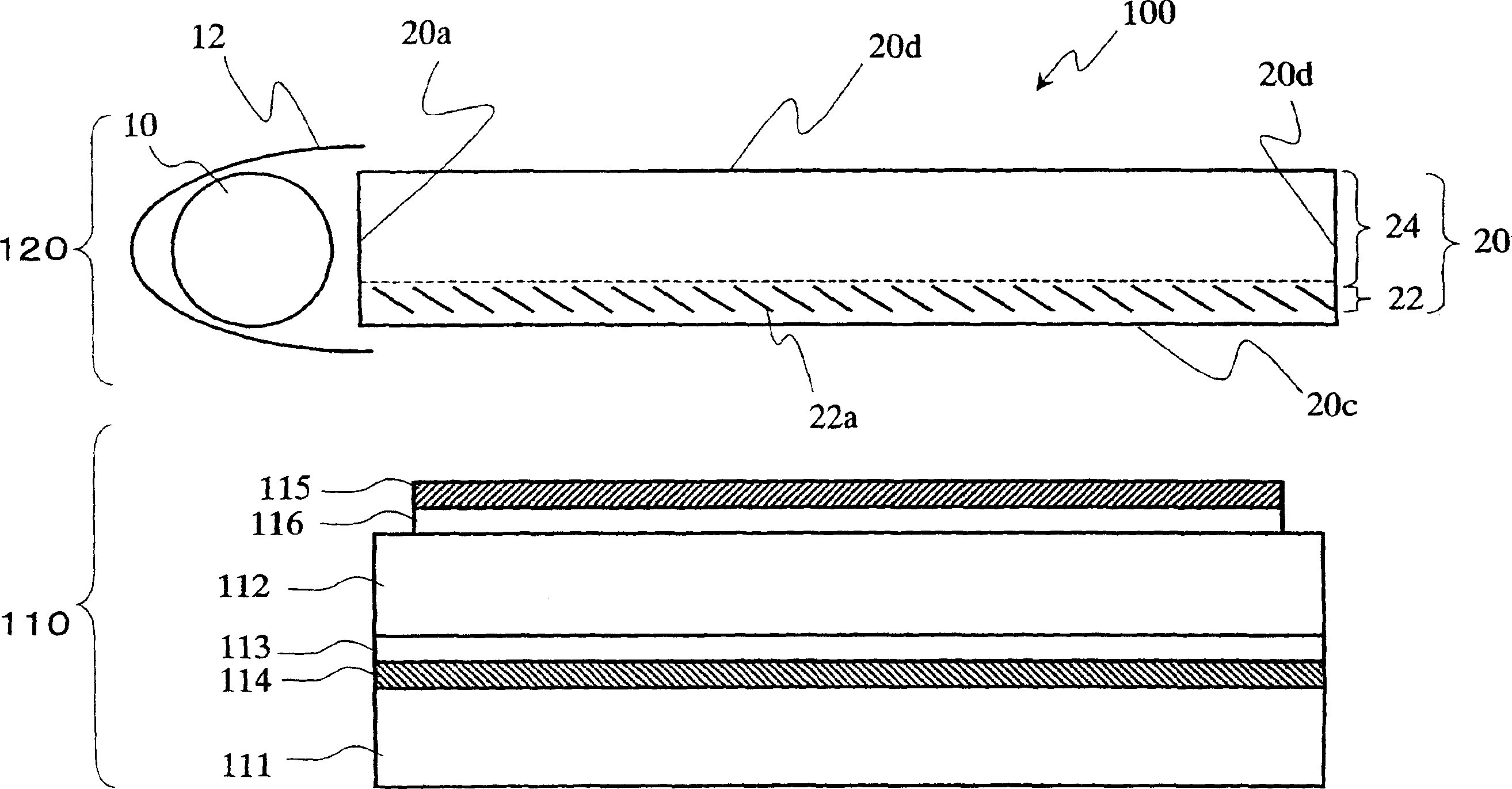

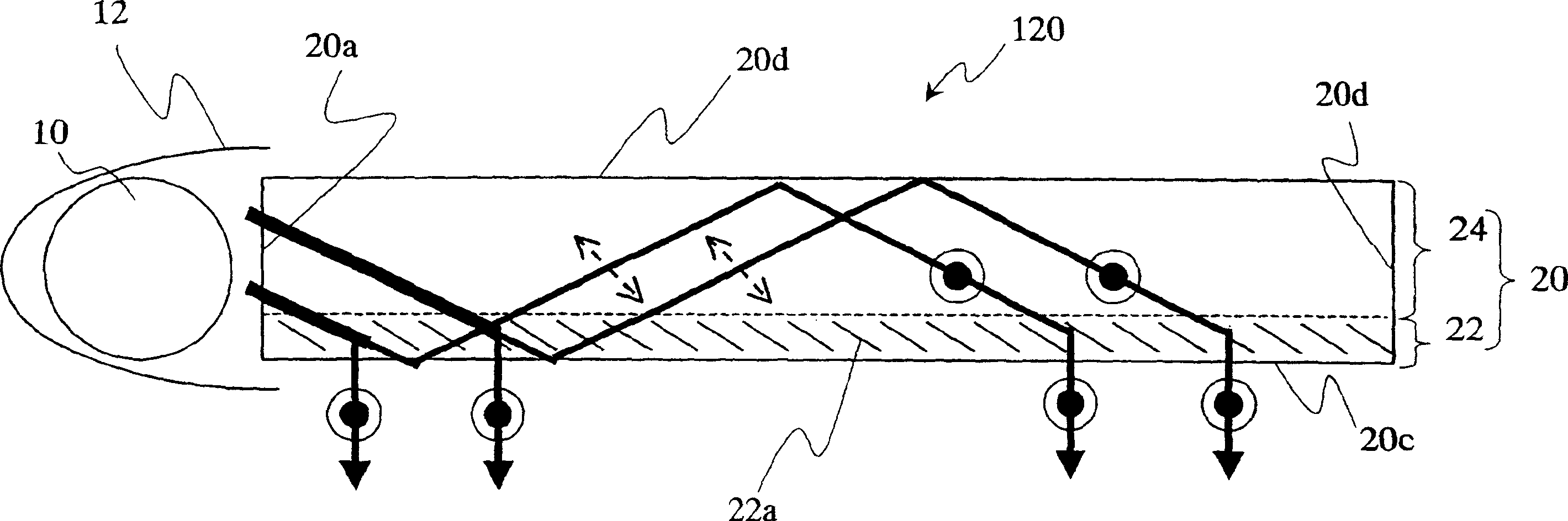

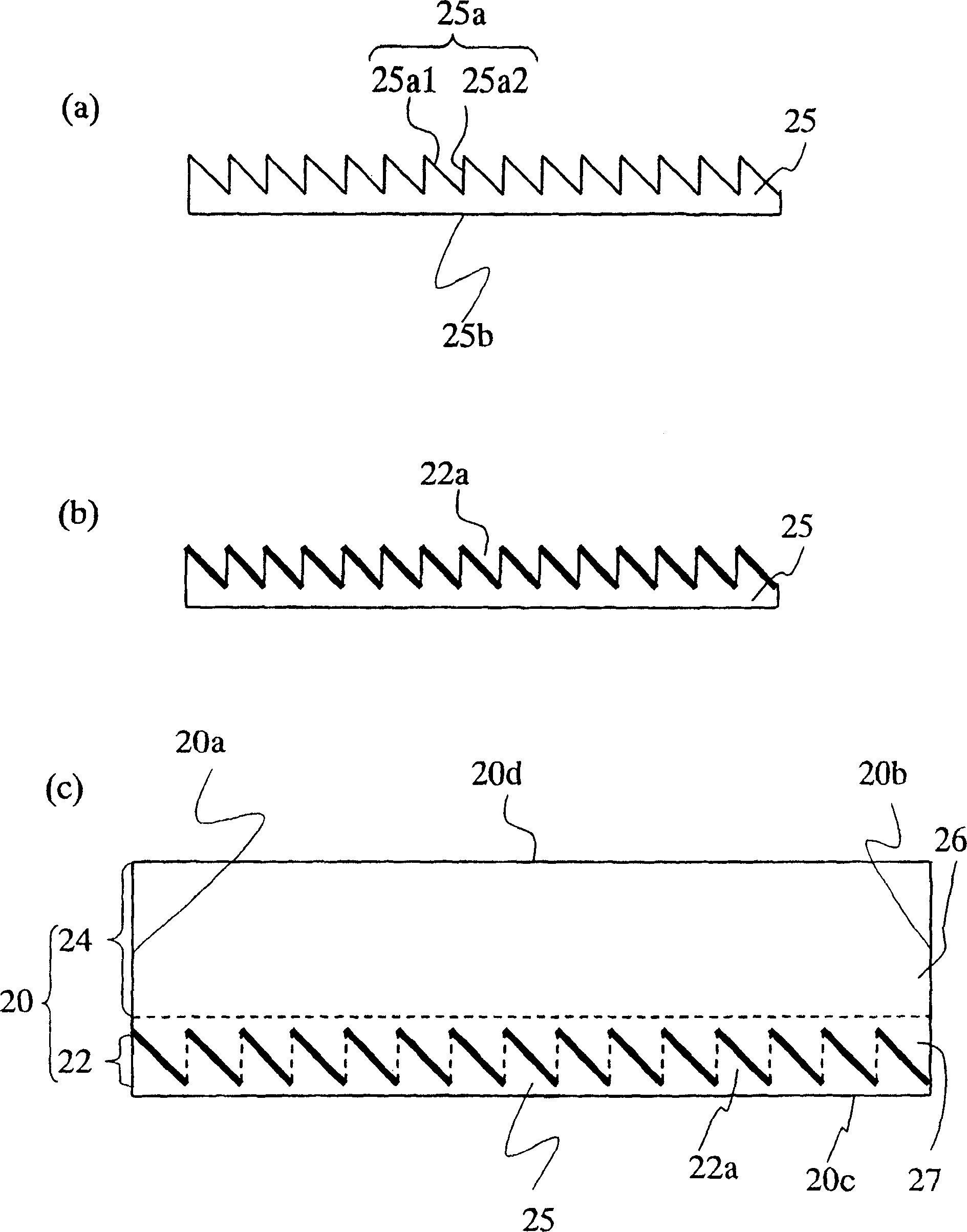

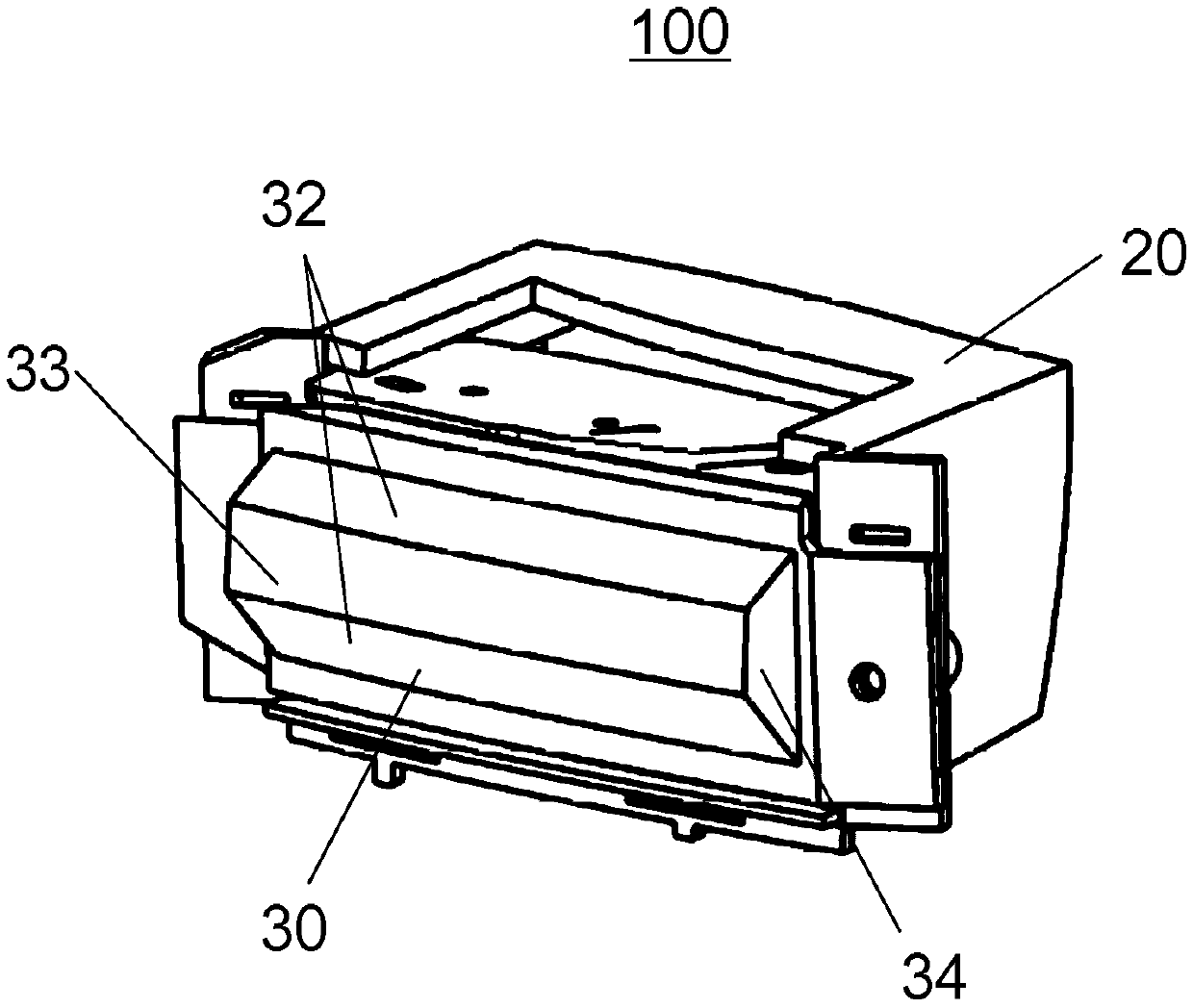

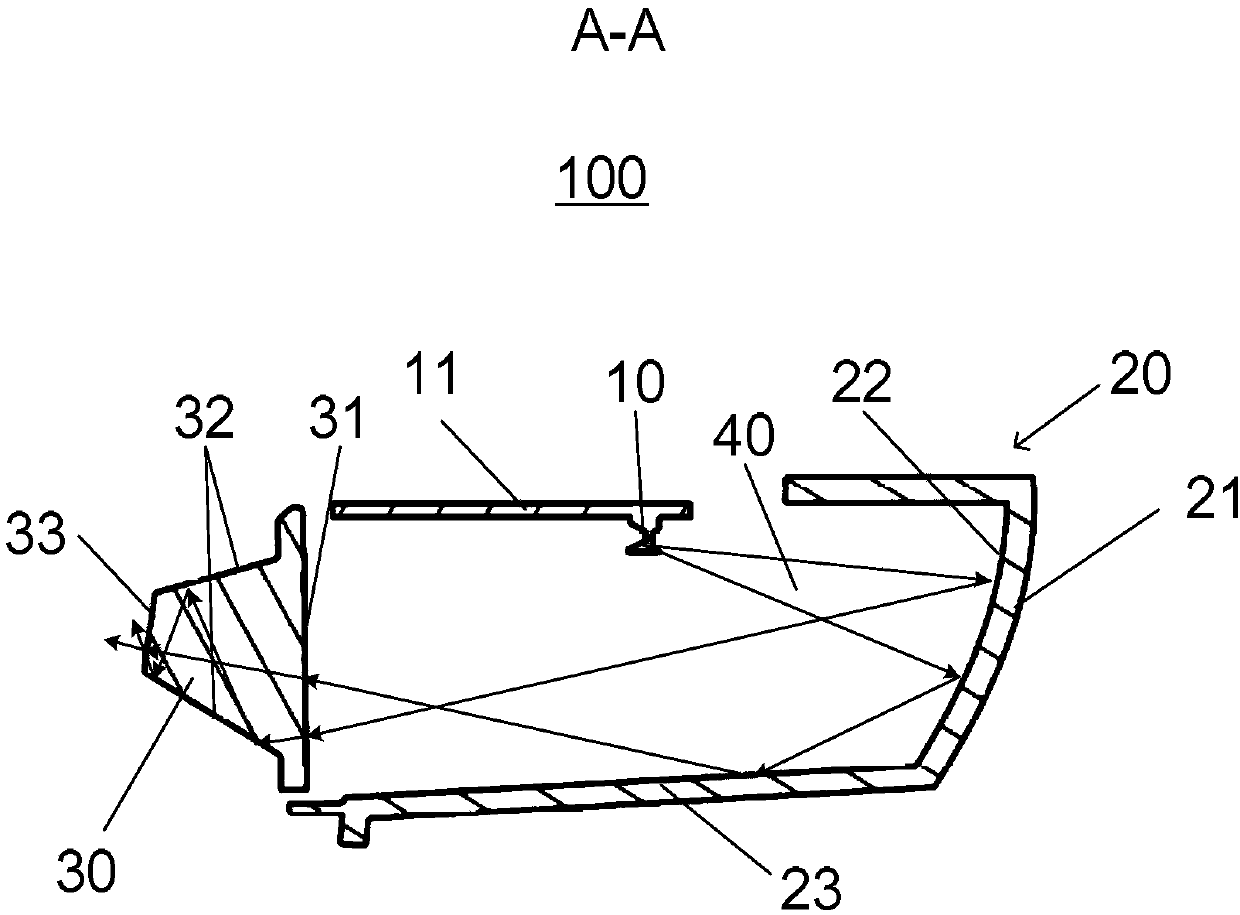

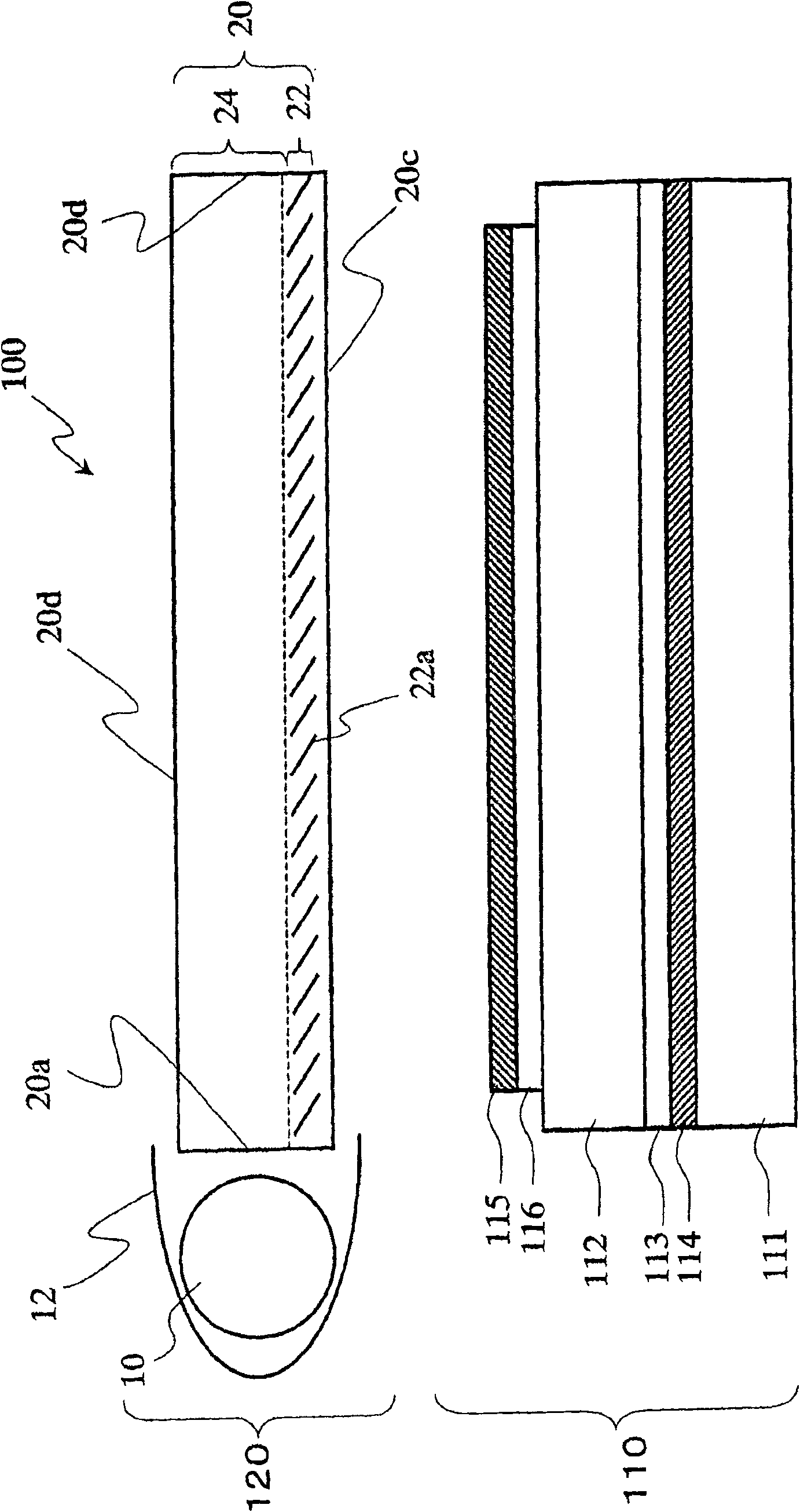

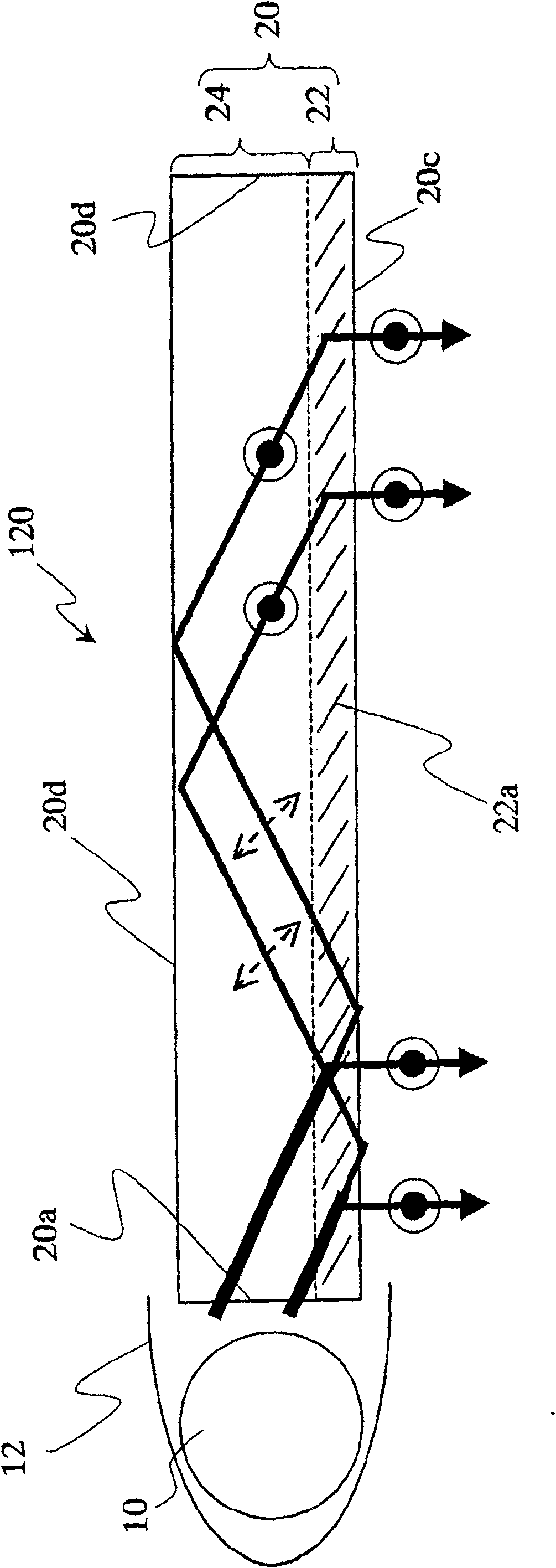

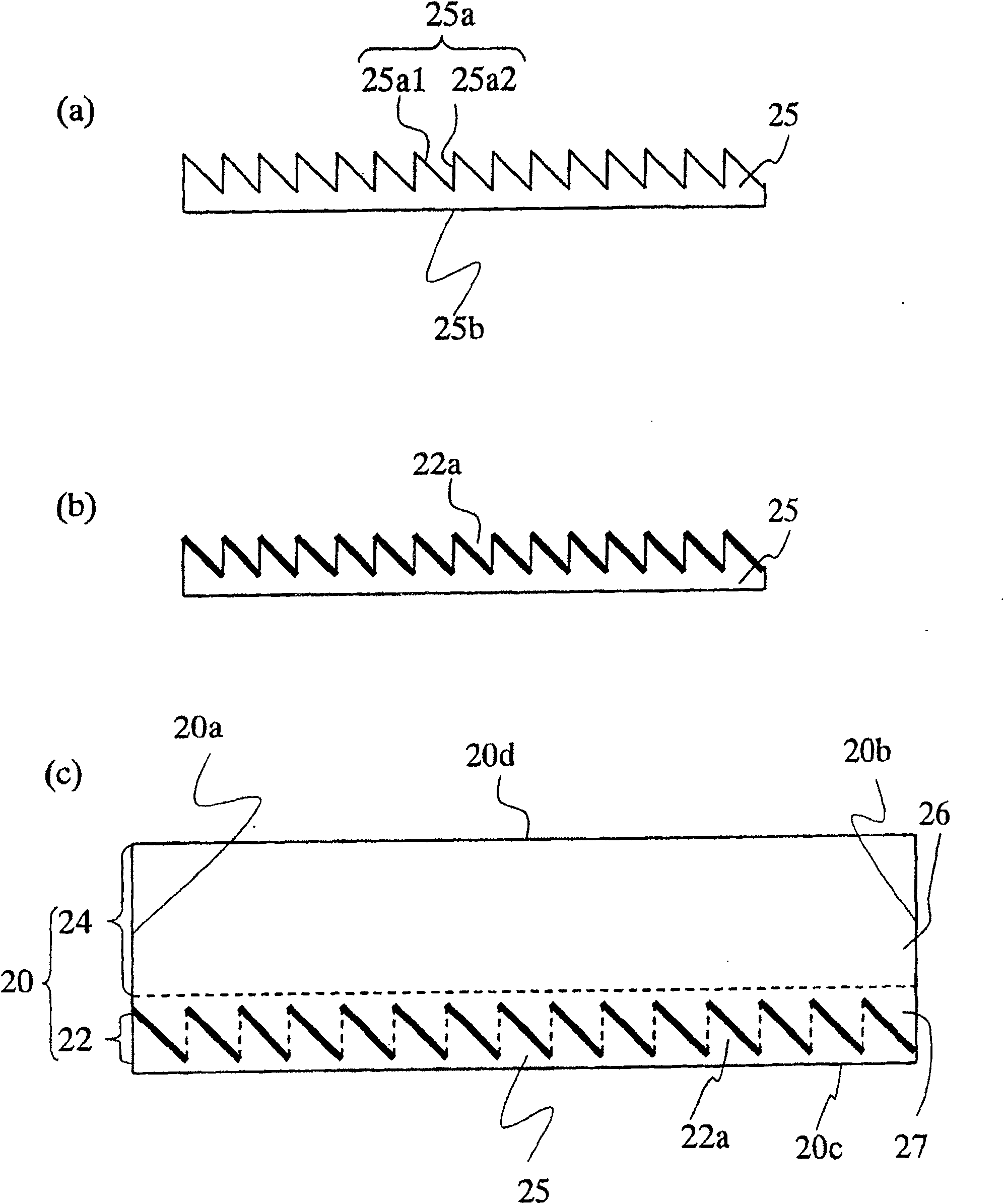

Lighting device and image display unit and light guide provided with it

InactiveCN1735768AImprove utilization efficiencyLow utilization efficiencyMechanical apparatusElongate light sourcesLight guideEffect light

A lighting device comprising a light source (10), and a light guide (20) having an incident surface (20a) for receiving a light emitted from the light source (10) and an output surface (20c) for outputting a light entered via the incident surface (20a). The light guide (20) has a polarization selection layer (22) for selectively outputting via the output surface (20c) a light in a specific polarization direction (first polarization) out of lights incident via the incident surface (20a), and a polarization conversion layer (24) for converting a second polarization different in polarization direction than the first polarization into the first polarization. The polarization selection layer (22) substantially reflects the first polarization toward the output surface (20c) side only.

Owner:SHARP KK

Optical element and light irradiation apparatus

InactiveUS7433568B2Improves strength uniformityEven energy distributionPhotomechanical apparatusRecord information storageLight irradiationDevice material

Owner:SEMICON ENERGY LAB CO LTD +1

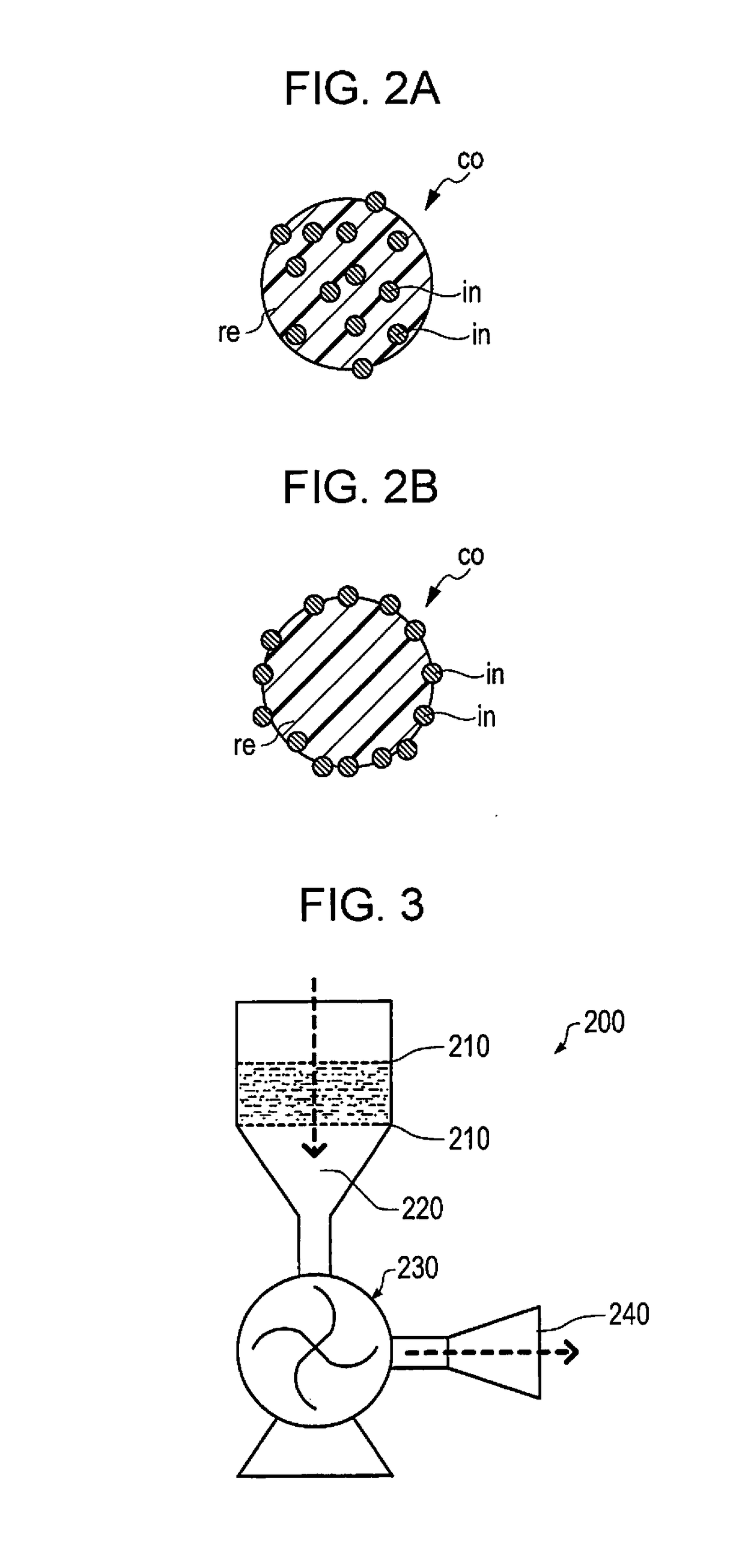

Cutting-resistant ultrahigh molecular weight polyethylene fiber and preparation method and use thereof

ActiveCN106555243AEvenly distributedImproves strength uniformityMonocomponent polyolefin artificial filamentArtifical filament manufactureSlagFiber

The invention provides a cutting-resistant ultrahigh molecular weight polyethylene fiber and a preparation method and use thereof. The cutting-resistant ultrahigh molecular weight polyethylene fibers comprise ultrahigh molecular weight polyethylene fibers, and hard fibers and hard fiber slag dispersed in the ultrahigh molecular weight polyethylene fibers, and a mass ratio of the ultrahigh molecular weight polyethylene fibers, the hard fibers to the hard fiber slag is 100: (3-6): (0.001-0.18). Compared with the existing polyethylene fiber, the cutting-resistant ultrahigh molecular weight polyethylene fiber satisfies the cutting performance EN388 five level standards. Through use of the hard fiber slag, the hard fibers are uniformly dispersed in the ultrahigh molecular weight polyethylene so that the finished product fiber has high strength uniformity and high friction resistance.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

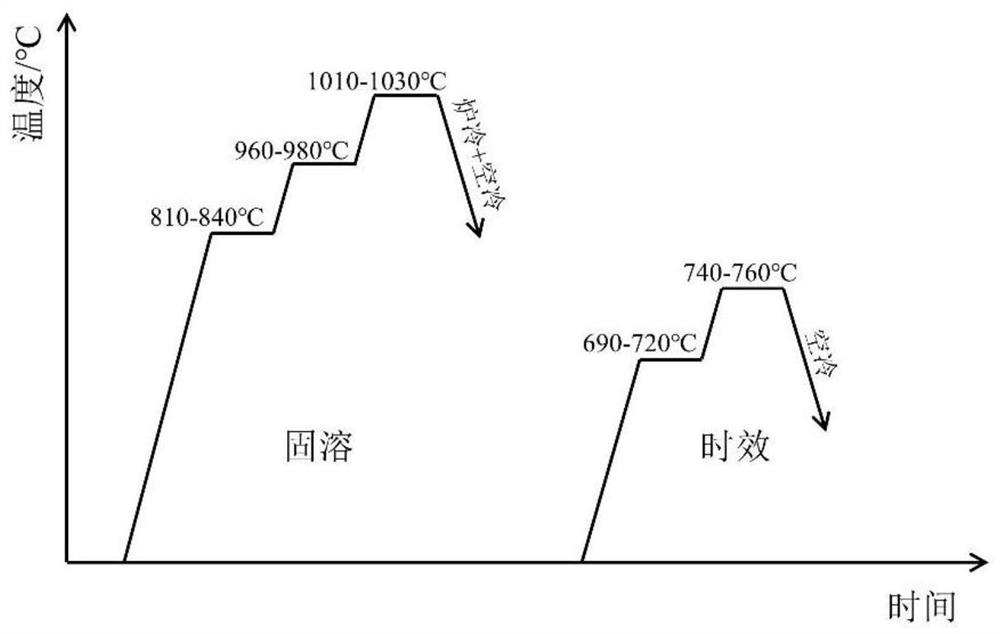

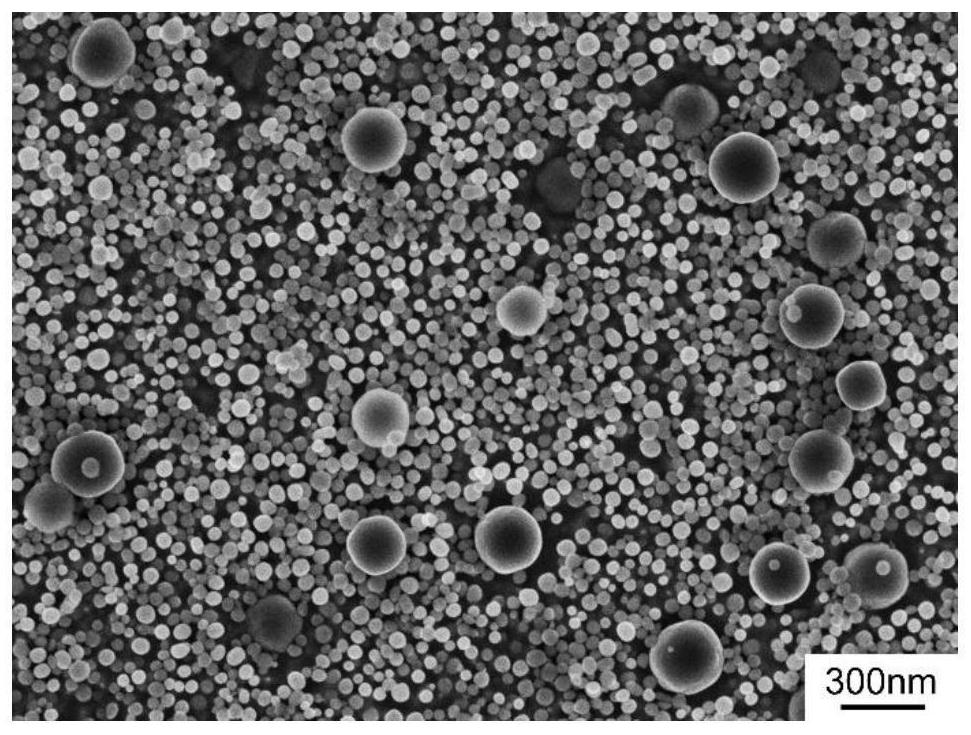

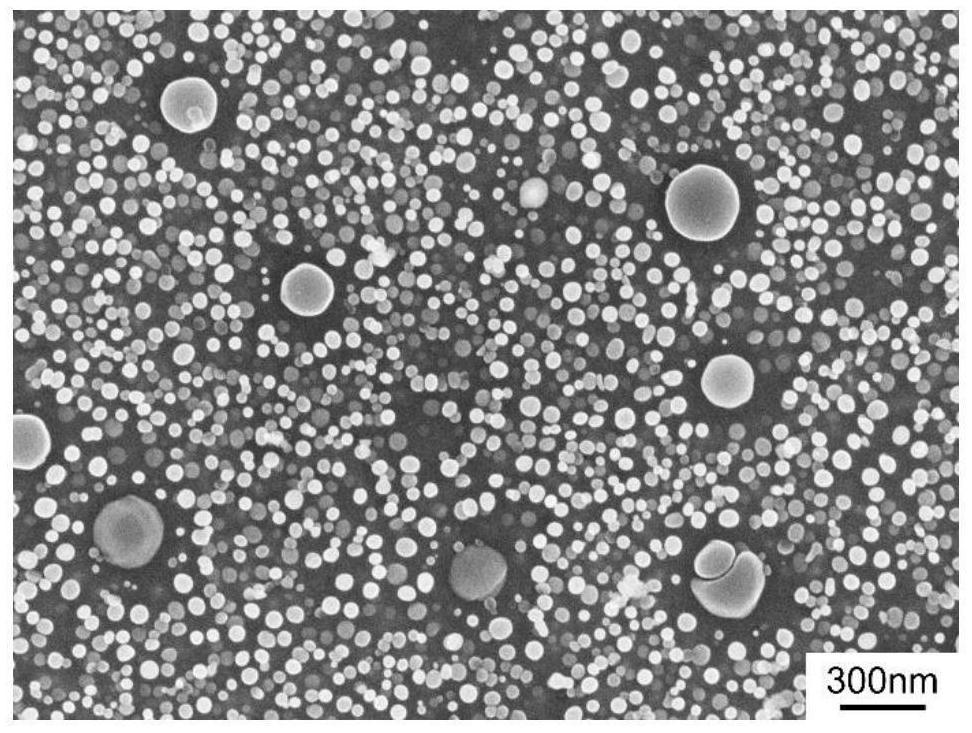

Heat treatment process for rapid aging of large-size GH4738 alloy forge piece

ActiveCN113564504AEvenly heatedReduce heating rateHeat treatment process controlProcess efficiency improvementSolution treatmentHeating furnace

The invention discloses a heat treatment process for rapid aging of a large-size GH4738 alloy forge piece, and belongs to the technical field of heat treatment of nickel-based high-temperature alloy. The process comprises the steps of firstly, carrying out solution treatment on the large-size GH4738 alloy forge piece, and carrying out cooling in a mode that the large-size GH4738 alloy forge piece is cooled in a furnace at first and then is cooled in air; and then carrying out aging treatment on the large-size GH4738 alloy forge piece in a heating furnace under the conditions that the aging treatment temperature ranges from 740 DEG C to 760 DEG C and the heat preservation time ranges from 4 h to 8 h, and cooling the large-size GH4738 alloy forge piece in air after the large-size GH4738 alloy forge piece is taken out. According to the heat treatment process, by optimizing the cooling speed of alloy obtained after solution treatment and cooperating with short-time aging treatment, a dispersed and evenly-distributed gamma' phase is promoted to be formed in a GH4738 alloy matrix. The treatment process has an unexpected effect on improving the strength uniformity of the alloy forge piece at the room temperature. The tensile strength difference corresponding to the edge and the core area of the forge piece at the room temperature is reduced to be within 15 MPa from about 40 MPa, and the yield strength difference is reduced to be within 15 MPa from about 50 MPa. Meanwhile, compared with traditional aging treatment, the heat treatment process has the advantages that the aging treatment time is greatly shortened, the production efficiency is improved, the production cost is reduced and important production and application value is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Sheet manufacturing apparatus and sheet manufacturing method

A sheet manufacturing apparatus includes a mixing unit that mixes fibers and a composite in the atmosphere, a forming unit that deposits and heats a mixture mixed by the mixing unit to form a sheet; in which the composite is resin particles with at least a portion of a surface coated by inorganic fine particles, and an absolute value of an average charging amount of the composite is 40 μC / g or higher.

Owner:SEIKO EPSON CORP

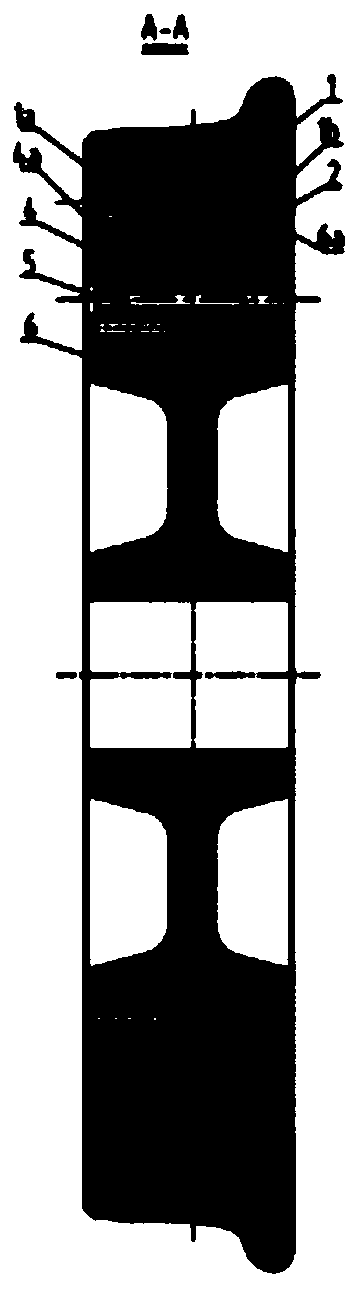

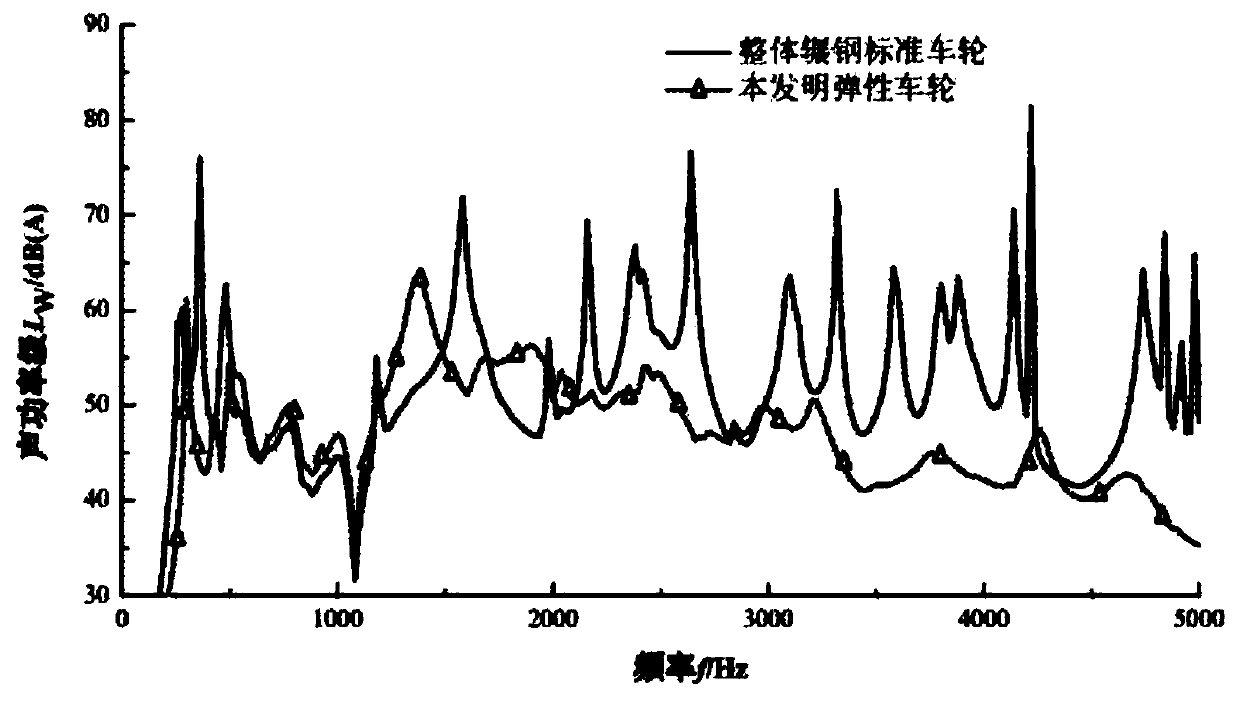

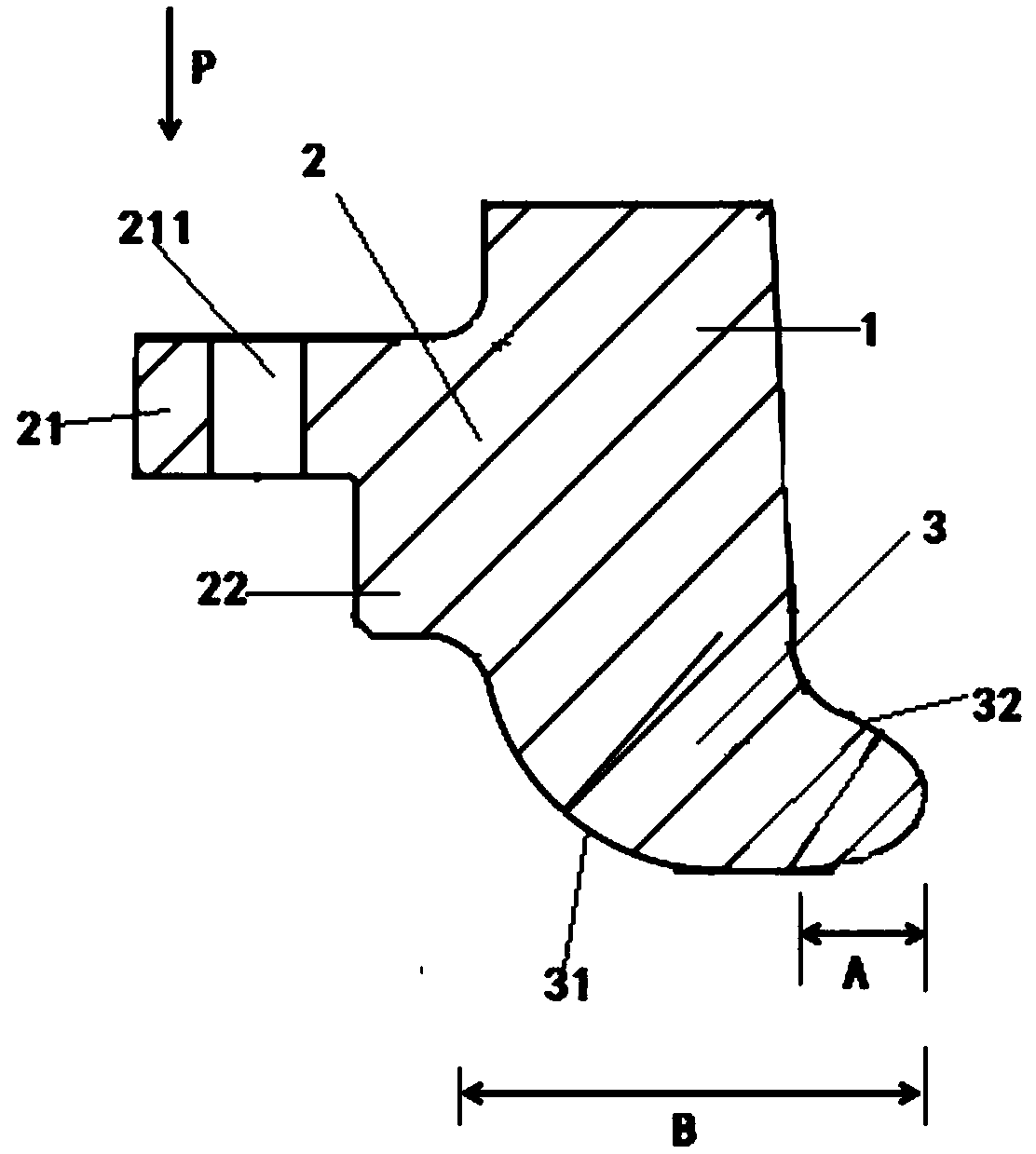

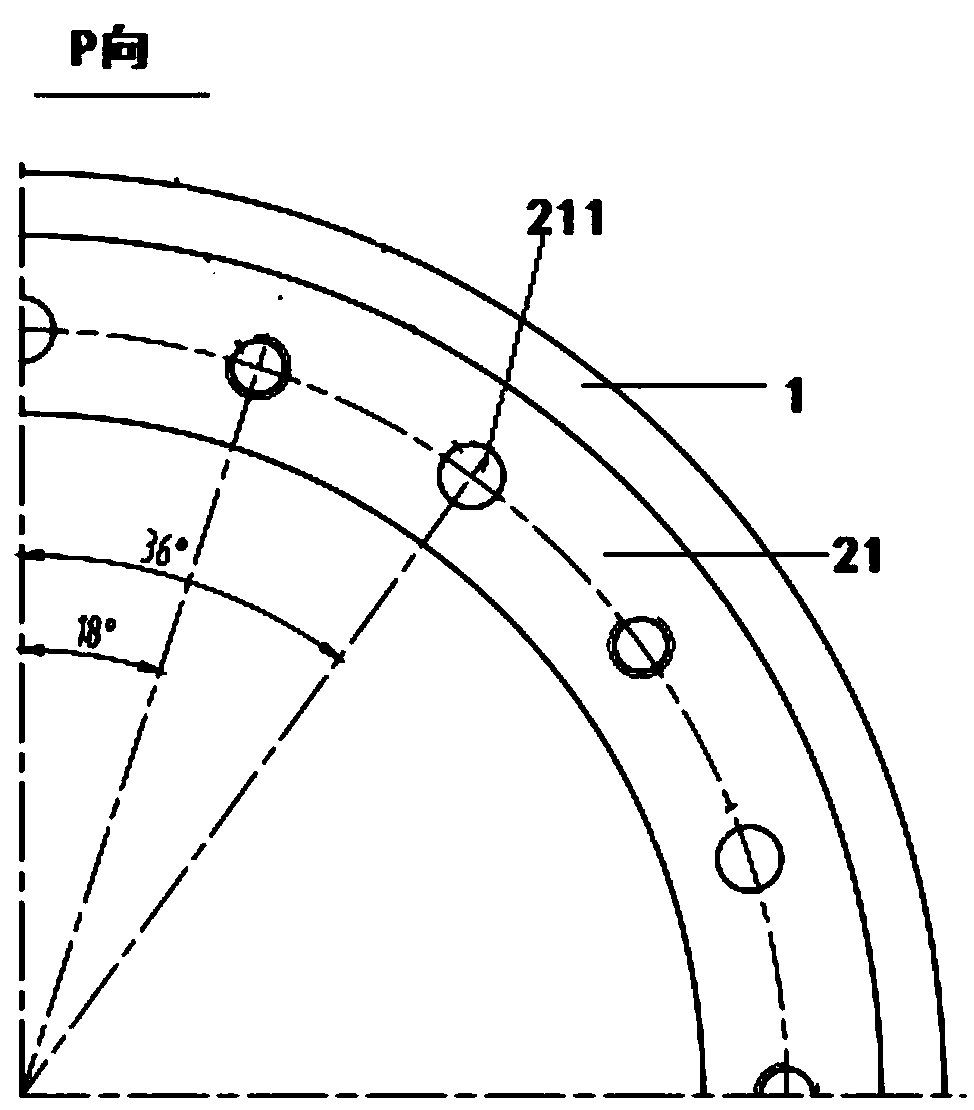

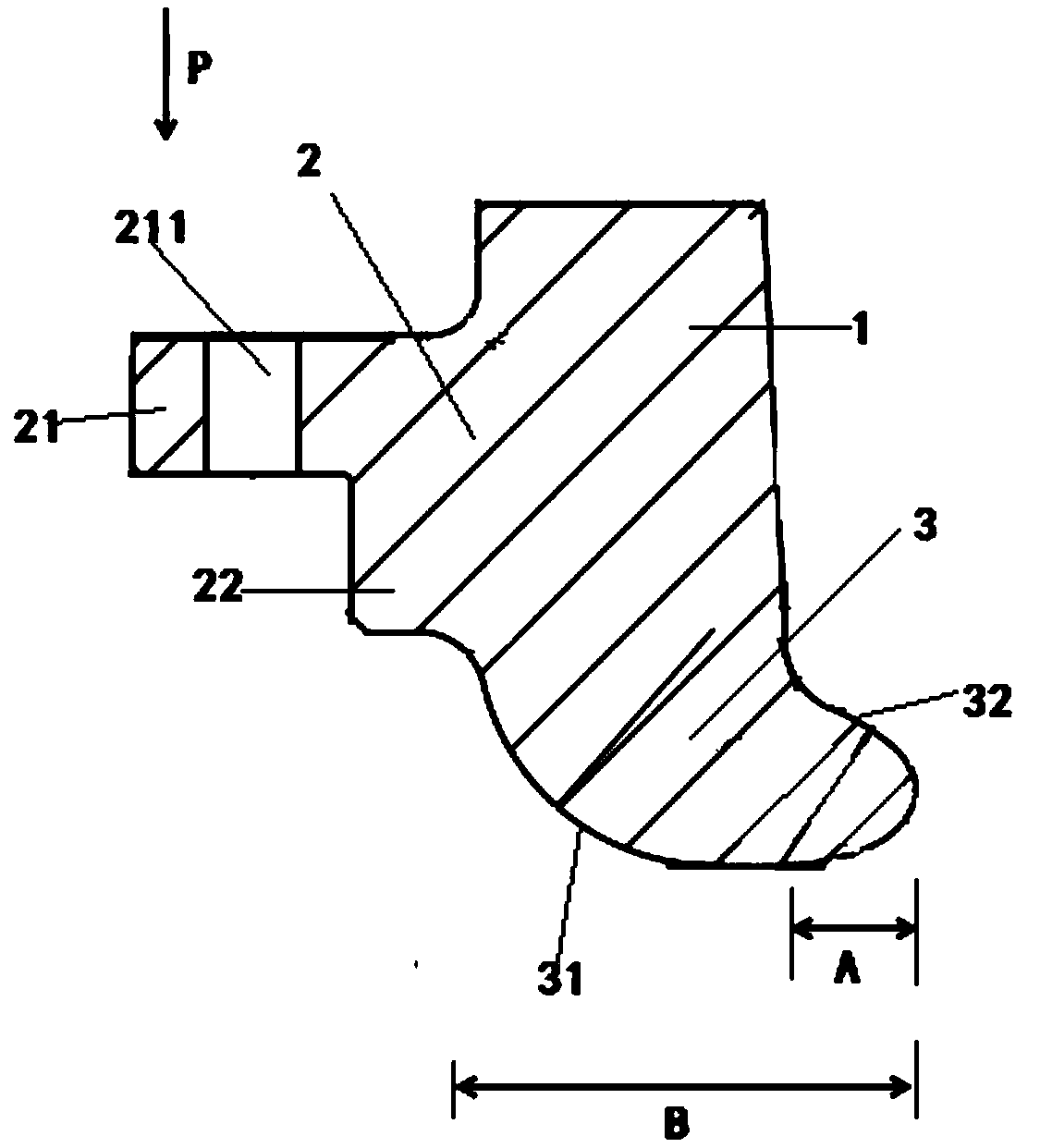

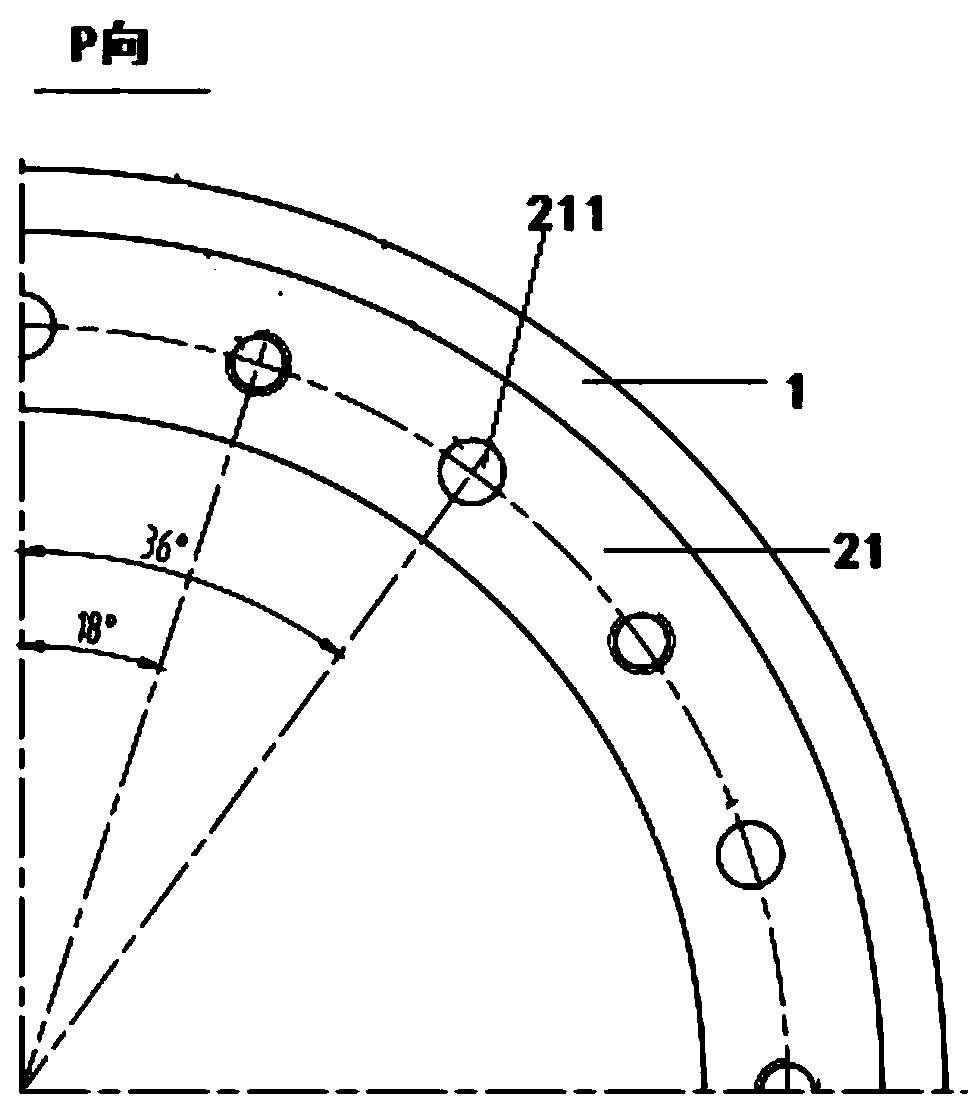

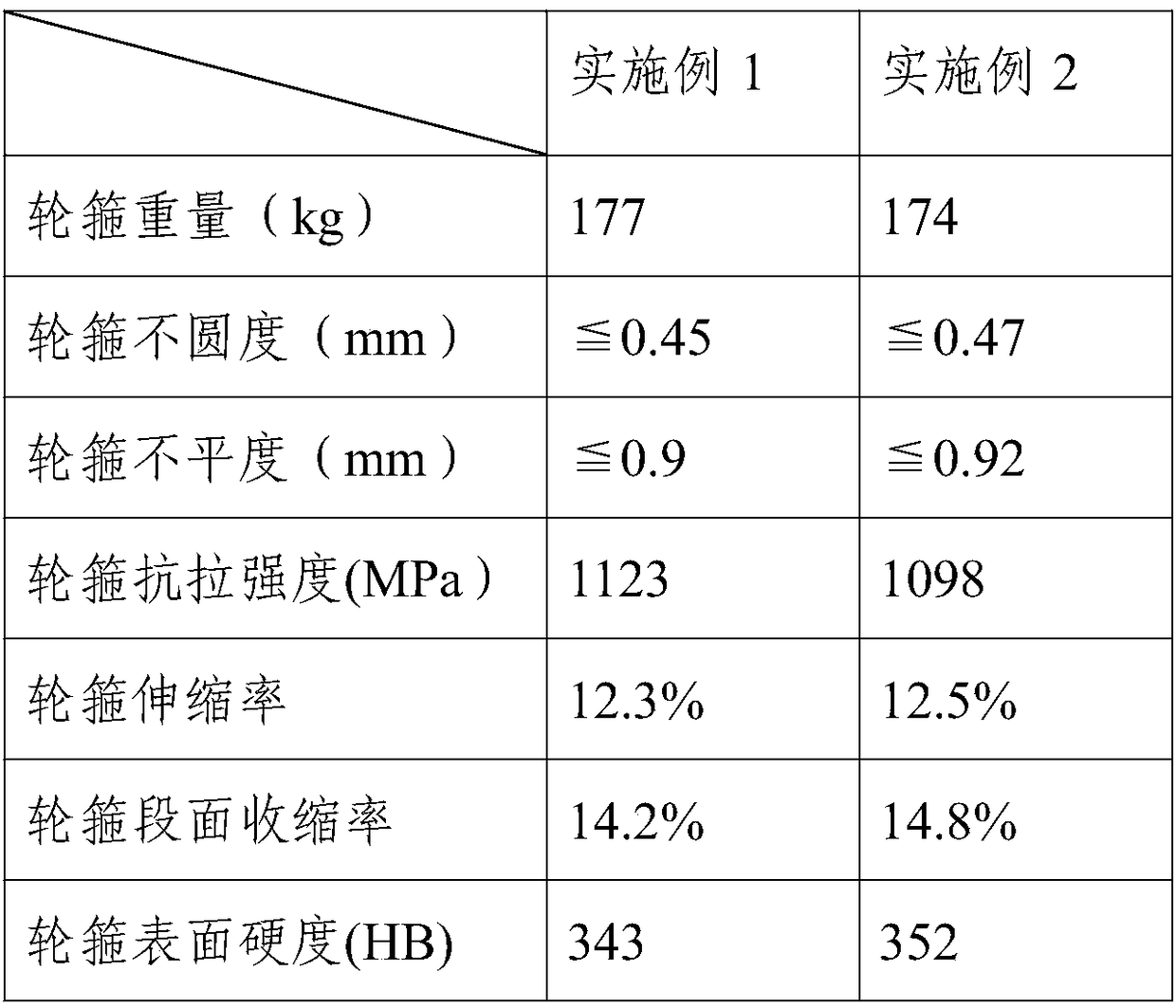

Shear-press composite type elastic wheel for low-floor tramcar and production process thereof

InactiveCN110539585AHigh tensile strengthImproves strength uniformityRail-engaging wheelsFurnace typesRare-earth elementNoise reduction

The invention provides a shear-press composite type elastic wheel for a low-floor tramcar and a production process thereof. The shear-press composite type elastic wheel for the low-floor tramcar comprises a wheel band, a press ring and a wheel core; the wheel band, the press ring and the wheel core are all made of high-purity iron alloy; the mass percentage of each component of the high-purity iron alloy is as follows: 0.015-0.5% of Si, 0.6-0.9% of Mn, 0.65-0.7% of C, 1.8-2.1% of Mg, 3.45-4.21% of Al, 0.005-0.04% of S, less than or equal to 0.3% of Cr, less than or equal to 0.30% of Cu, less than or equal to 0.25% of Ni, less than or equal to 0.04% of P, less than or equal to 0.08% of Mo, less than or equal to 0.05% of V, less than or equal to 0.02% of Sc, less than or equal to 0.03% of Tiand the balance of Fe. According to the shear-press composite type elastic wheel for the low-floor tramcar, by using a mode of adding a rare earth element and refining the rare earth element in steps, the tensile strength of the wheel band, the press ring and the wheel core is enhanced, the center of a material is close without a gap, and moreover, no metallic contamination is caused, and the strength uniformity of the surface is high; a rubber layer is embedded between the wheel band and the wheel core and has a vibration absorbing effect; the rubber layer possesses good radial stiffness andaxial stiffness; and meanwhile, the freedom of a wheel rim is limited; the problem that a tuned mass damper is additionally mounted on the external side of the wheel to suppress medium and low noisesis solved; the structure is simple; and the vibration absorbing and noise reduction effect is good.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High-strength light wheel rim for railcar and production process thereof

InactiveCN108705899AUniform wearEasy to passRail-engaging wheelsRolling resistance optimizationHigh intensityGravity center

The invention discloses a high-strength light wheel rim for a railcar. The high-strength light wheel rim comprises an outer wheel rim, a clamping seat is integrally and fixedly connected to the middleof the inner surface of the side wall of the outer wheel rim, and the clamping seat comprises a clamping table and a check ring, wherein the clamping table is coaxial with the outer wheel rim, the check ring is integrally and fixedly connected to the outer side of the bottom surface of the clamping table, and a plurality of threaded through holes are uniformly distributed in the end face of the clamping table; a pedal ring is integrally and fixedly connected to the bottom end face of the outer wheel rim, the surface of the pedal ring is an annular surface which is completely overlapped with the bottom surface of the outer wheel rim, the inner side edge of the annular surface is vertically and outwards bent to form an arc-shaped tread which extends downwards and outwards, and the outer side edge of the annular surface is vertically and outwards bent to form an outer arc surface with the bottom end overlapped with the outer edge of the arc-shaped tread. The tread of the wheel rim is aninclined face of 5 degrees, so that the wheelset weight is reduced, the wheel rim can pass a curve conveniently, and the tread wear can be more uniform. Due to the fact that the gravity center of a vehicle is lowered and the wheelset weight is reduced, the flexibility of rail wheels entering a rail is improved.

Owner:MAANSHAN TIANJUN MACHINERY MFG

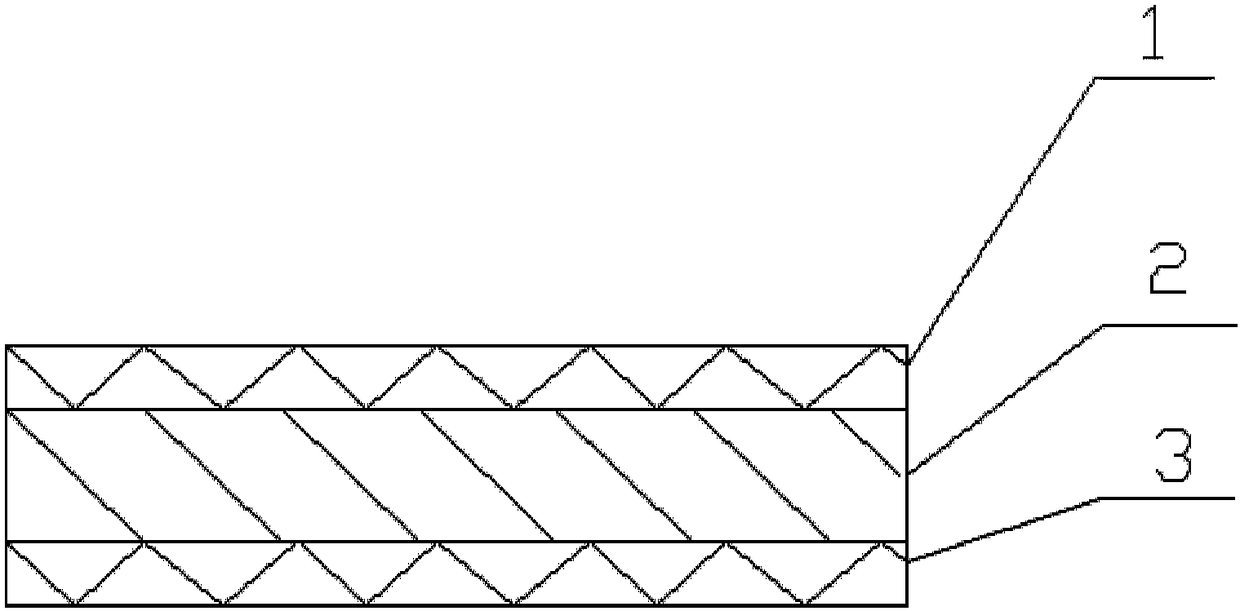

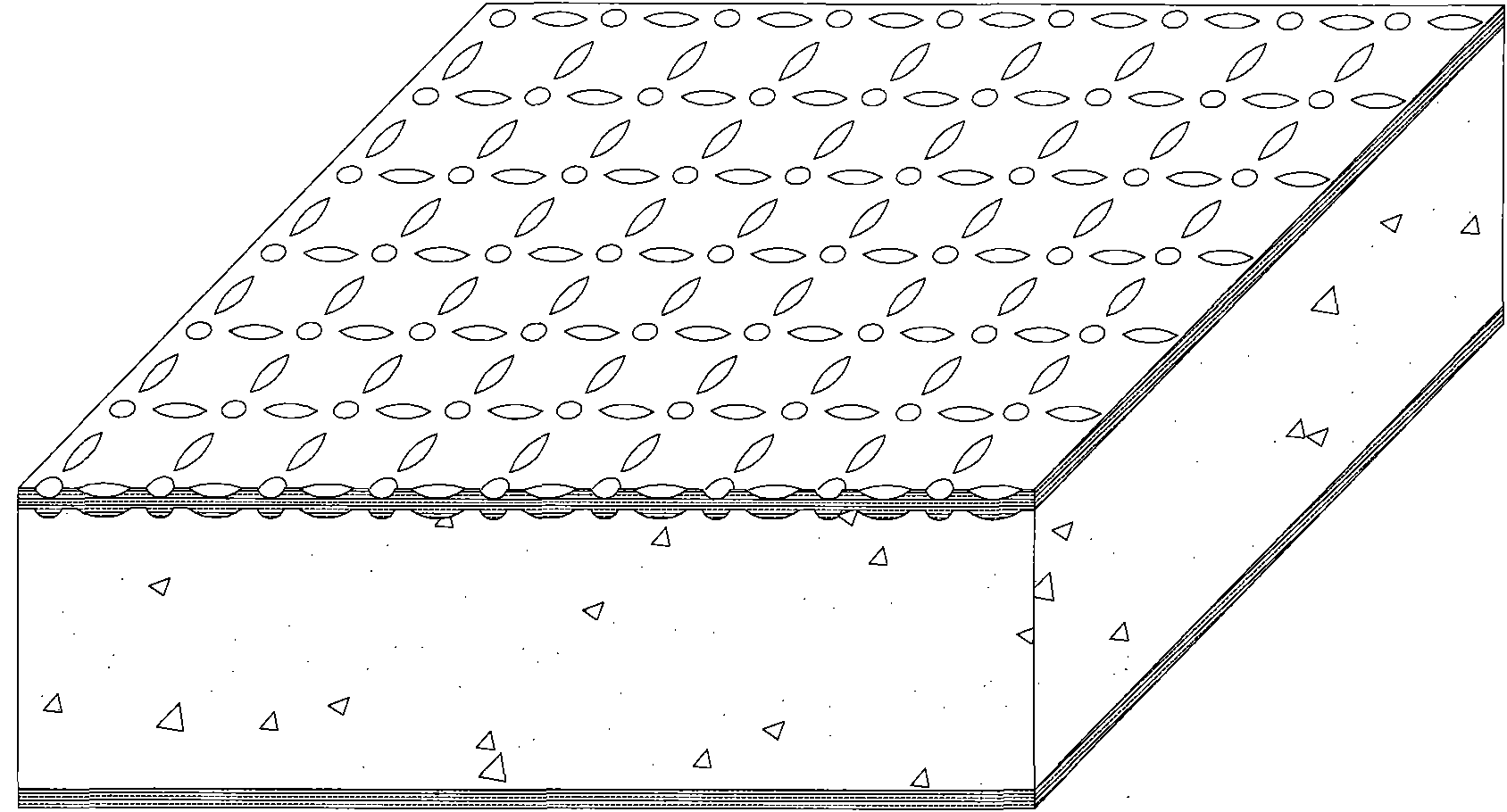

Waste fiber non-woven fabric

InactiveCN109402867AImproves strength uniformityNot easy to layerSynthetic resin layered productsNon-woven fabricsPulp and paper industryNonwoven fabric

The invention provides a waste fiber non-woven fabric. The waste fiber non-woven fabric sequentially includes an upper new fiber net layer, a middle waste fiber net layer and a lower new fiber net layer, wherein the three fiber net layers are reinforced through the stitching non-woven method. The waste fiber non-woven fabric is advantaged in that the waste fiber net layer is sandwiched through stitching and reinforcement through the stitching reinforcement method, is not easy to be layered and is not easy to shed in the middle, the strength of the nonwoven fabric is mainly borne by the upper and lower layers and stitching lines, so the overall strength uniformity of the nonwoven fabric is good.

Owner:HAIAN KEHAO TEXTILE CO LTD

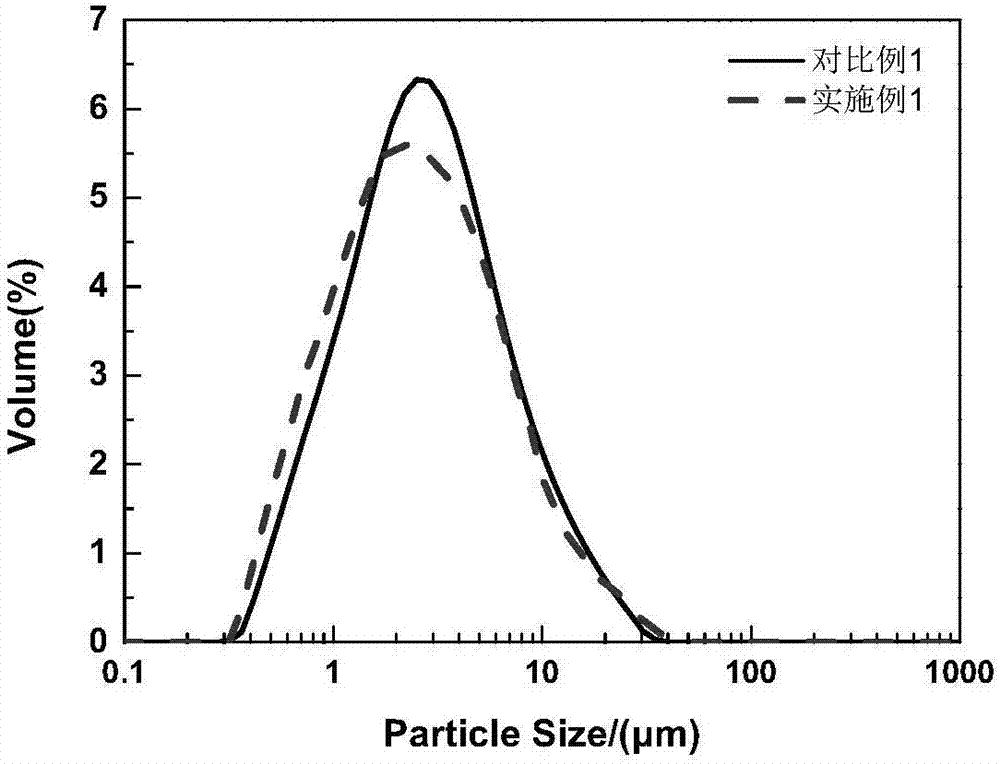

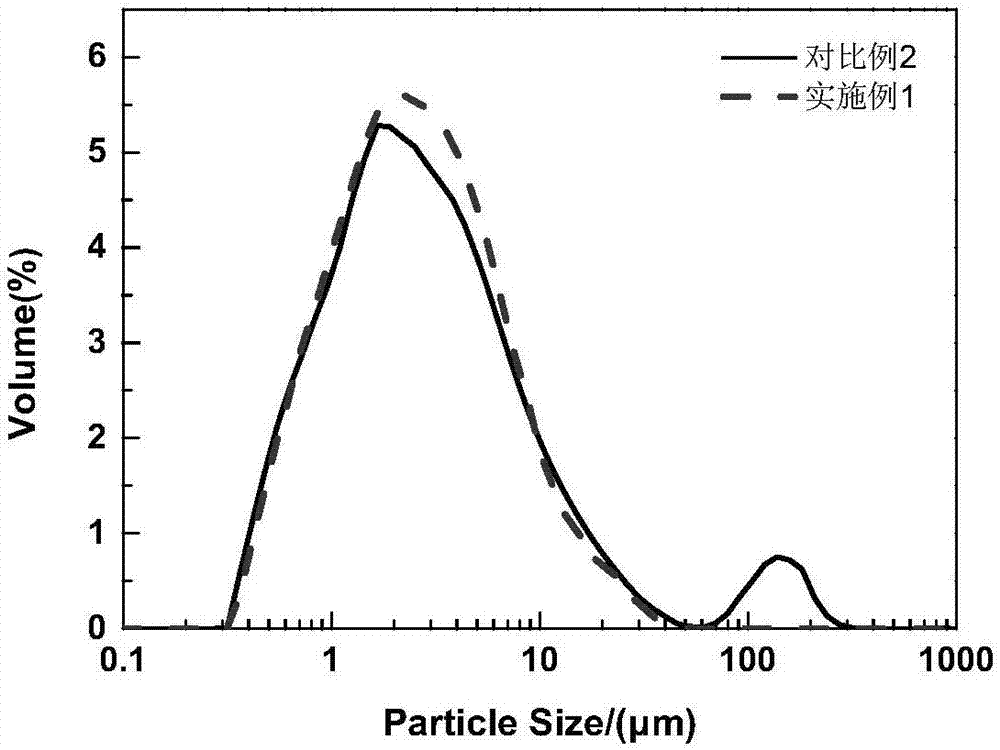

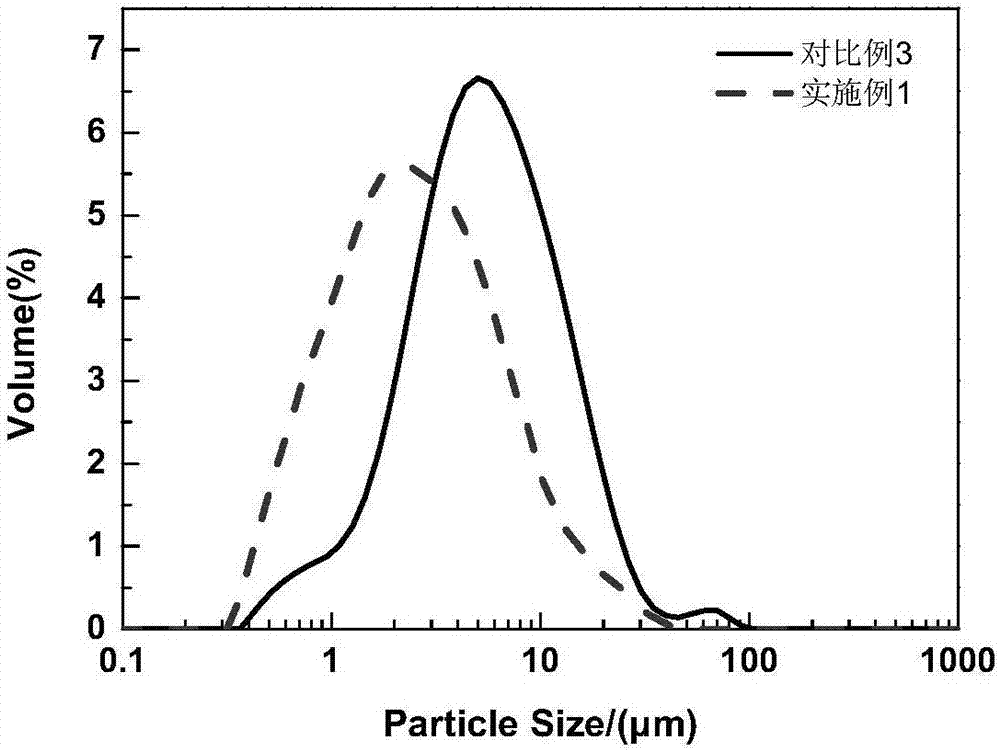

Pulpy metakaolin-base concrete admixture, and preparation method and application of admixture

The invention provides a pulpy metakaolin-base concrete admixture and a preparation method of the admixture. The admixture comprises a dry base, a composite dispersant and water, wherein the dry base consists of 30-90% by mass percentage of metakaolin and 10-70% by mass percentage of fly ash sinking beads; a mass ratio of the water to the dry base is (30-180):100; the composite dispersant consists of hydroxyethyl cellulose and a naphthalene water reducing agent; the hydroxyethyl cellulose accounts for 0.005-2.0% of the mass of the dry base; the naphthalene water reducing agent accounts for 0.001-1.0% of the mass of the dry base. The admixture reduces an adverse effect of the metakaolin on the working performance of concrete by utilizing combined action of the metakaolin, the fly ash sinking beads and the dispersant, and significantly improves the strength uniformity, the dispersity and the stability of a test block.

Owner:WUHAN UNIV OF TECH

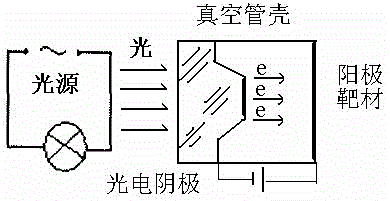

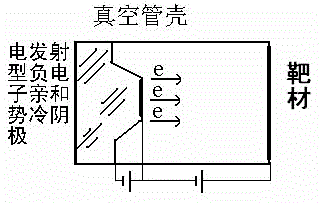

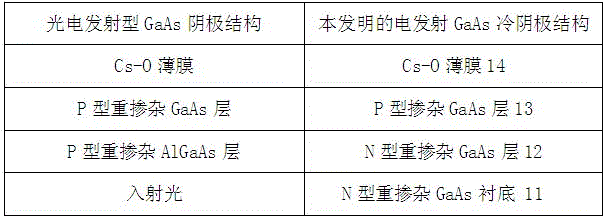

Negative electron affinity cold cathode X-ray tube

ActiveCN104599926ACompact structureImprove efficiencyX-ray tube electrodesX-ray tube vessels/containerSemiconductor materialsIndium

The invention discloses a negative electron affinity cold cathode X-ray tube. The negative electron affinity cold cathode X-ray tube is characterized in that the cold cathode consists of an electrical emission type negative electron affinity cold cathode, wherein the cold cathode material contains a P-N knot, and can be used for generating vacuum electron emission without additionally arranging a light source; an X-ray tube target material is positioned in a tube anode; the cold cathode and the anode target material are in sealed connection through cold indium, and the vacuum degree of the whole tube is E-8Pa. The negative electron affinity cold cathode X-ray tube has the advantages that the defect that a conventional photoelectric cathode X-ray source needs an external light source is solved, the X-ray tube is compact in structure, convenient to use and stable in beam. Compared with a field emission cathode X-ray tube, the X-ray tube cold cathode is a large-area semiconductor epitaxial wafer without a plurality of micro tips of the field cathode, and therefore, the X-ray is high in resolution and good in uniformity. The negative electron affinity cold cathode X-ray tube is suitable for all semiconductor materials, surfaces of which can form negative electrode affinity, suitable for GaAs, and also suitable for various photoelectric cathode materials of GaAsP, InGaAs, AlGaN and GaN.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Optical device, vehicle lamp and motor vehicle

PendingCN109990242AImproves strength uniformityIncrease flexibilityVehicle headlampsOptical signallingLight guideLight beam

The invention provides an optical device for a vehicle lamp, the vehicle lamp and a motor vehicle. The optical device comprises at least one light source, a light diffusion component and a light guiding component, wherein the light diffusion component is arranged to diffuse light beams emitted by the light source so as to form diffusion light beams; the light guiding component is provided with a light incident face, a reflection guiding face and a main light emitting face, the light incident face and the main light emitting face are located at the two opposite sides of the light guiding component, the reflection guiding face is located at the side face, between the light incident face and the main light emitting face, of the light guiding component, wherein the light incident face is configured to receive the diffused light beams, the reflection guiding face is configured to perform at least one-time reflection on the light beams incident from the light incident face so as to guide thereflected light beams to the main light emitting face, and the main light emitting face is configured to output the light beams reflected by the reflection guiding face to the exterior of the light guiding component.

Owner:沈阳法雷奥车灯有限公司

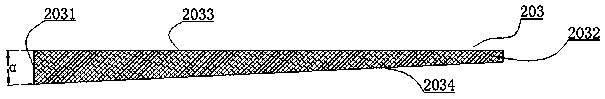

Backlight unit and LCD (liquid crystal display) device

InactiveCN105511158AGood optical performanceImprove installation stabilityPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a backlight unit and an LCD (liquid crystal display) device, relates to the technical field of LCD. The mounting reliability of a wedge-shaped light guide plate can be improved effectively, the thickness of the backlight unit can be further reduced, and lighting and thinning development of the LCD device can be realized. The backlight unit comprises the wedge-shaped light guide plate and a wedge-shaped back plate, wherein the wedge-shaped light guide plate comprises a light guide plate thick end, a light guide plate thin end as well as a light guide plate horizontal surface and a light guide plate inclined surface which are located between the light guide plate thick end and the light guide plate thin end; the wedge-shaped back plate comprises a back plate thick end, a back plate thin end as well as a back plate horizontal surface and a back plate inclined surface which are located between the back plate thick end and the back plate thin end; the light guide plate thick end is arranged at the back plate thin end, the light guide plate thin end is arranged at the back plate thick end, and the light guide plate inclined surface is attached to the back plate inclined surface. The backlight unit disclosed by the embodiment is applied to the LCD device.

Owner:HISENSE VISUAL TECH CO LTD

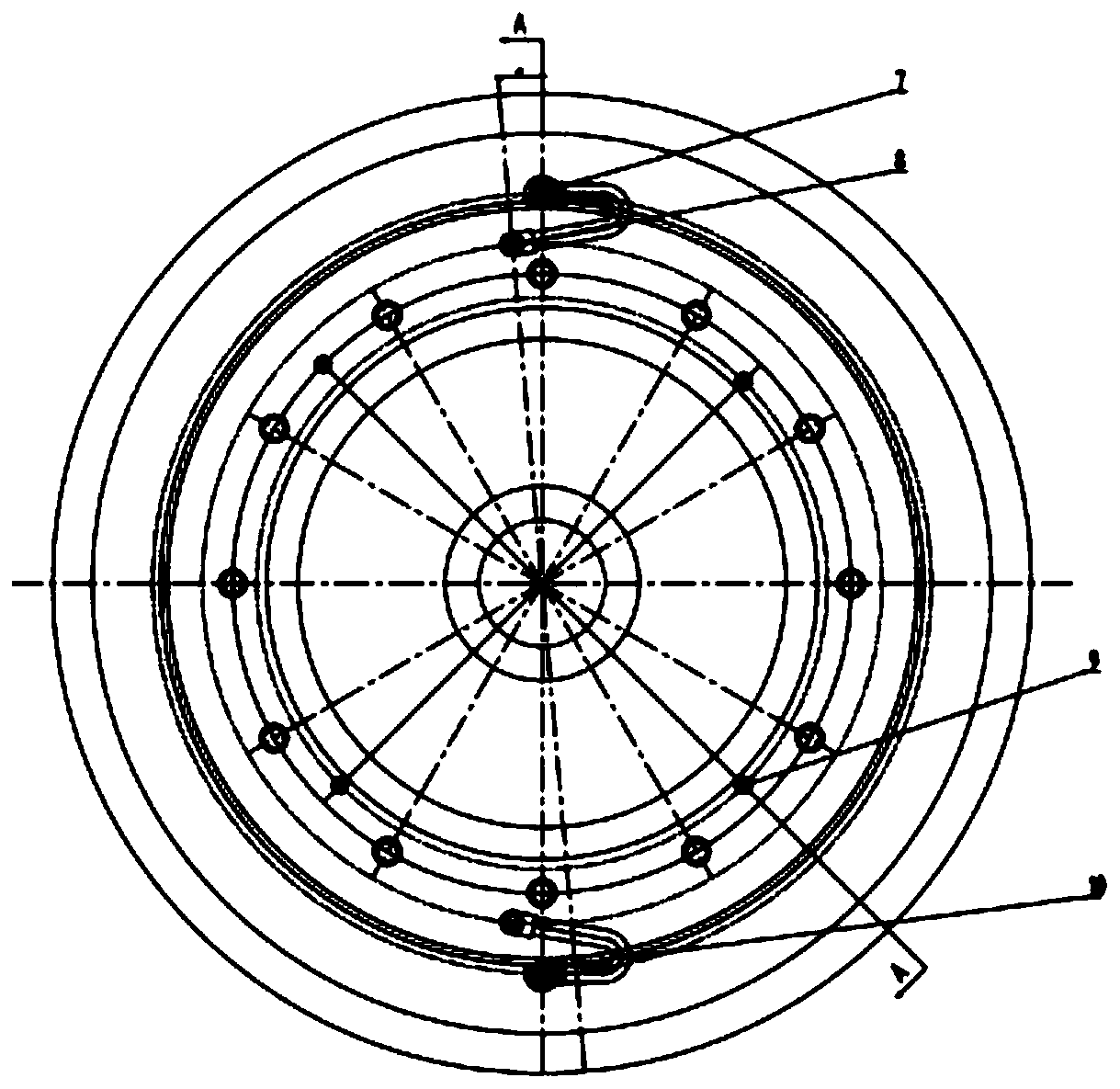

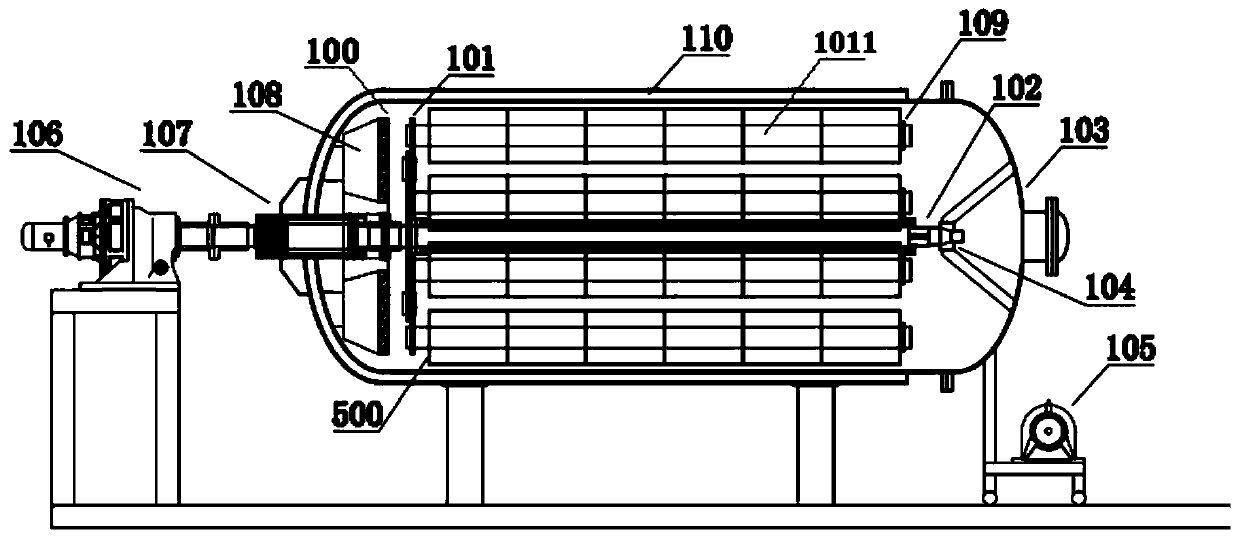

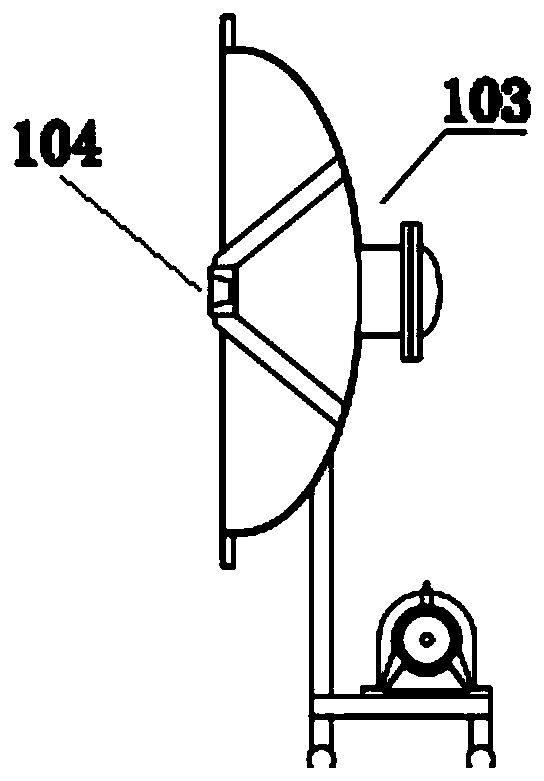

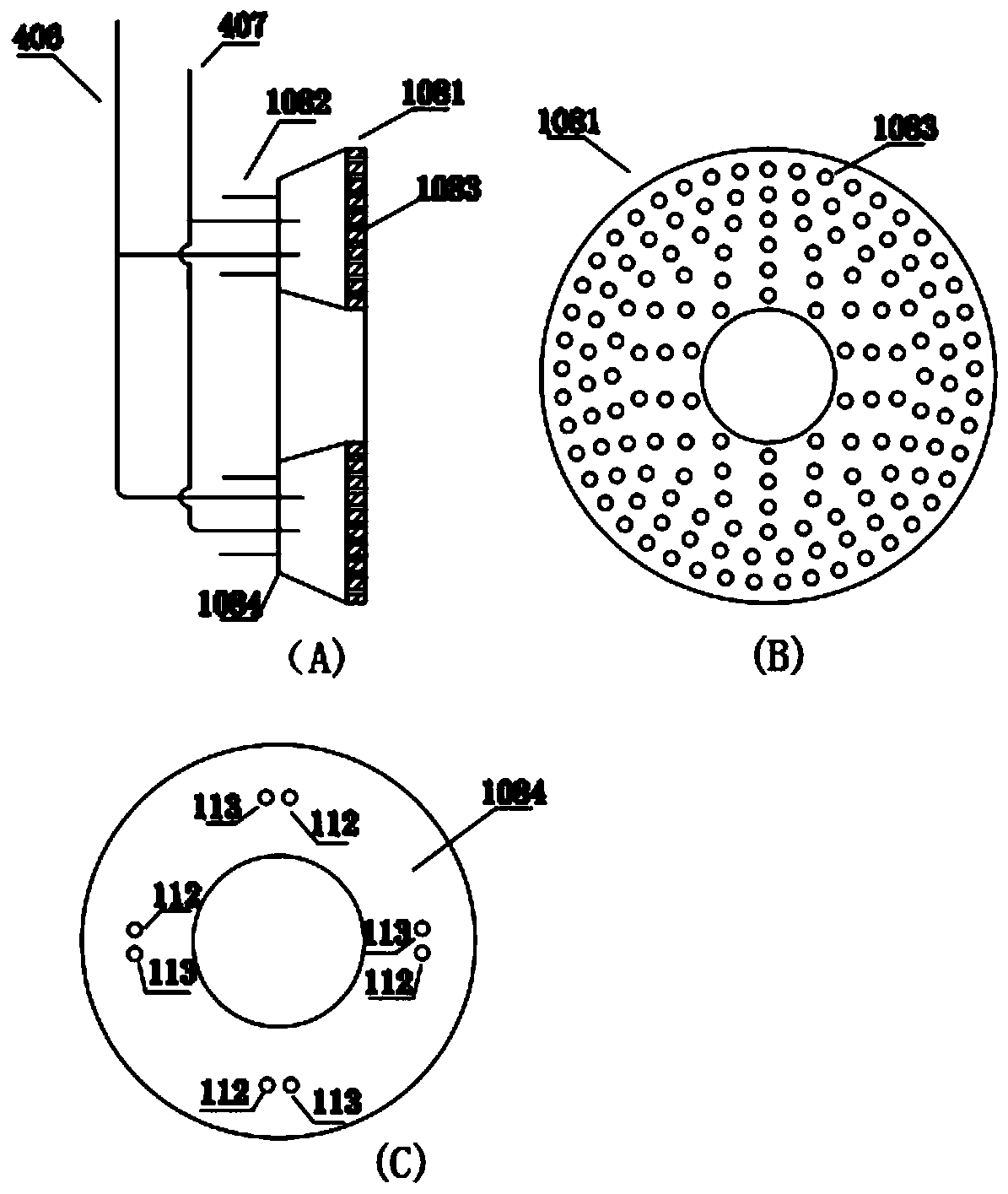

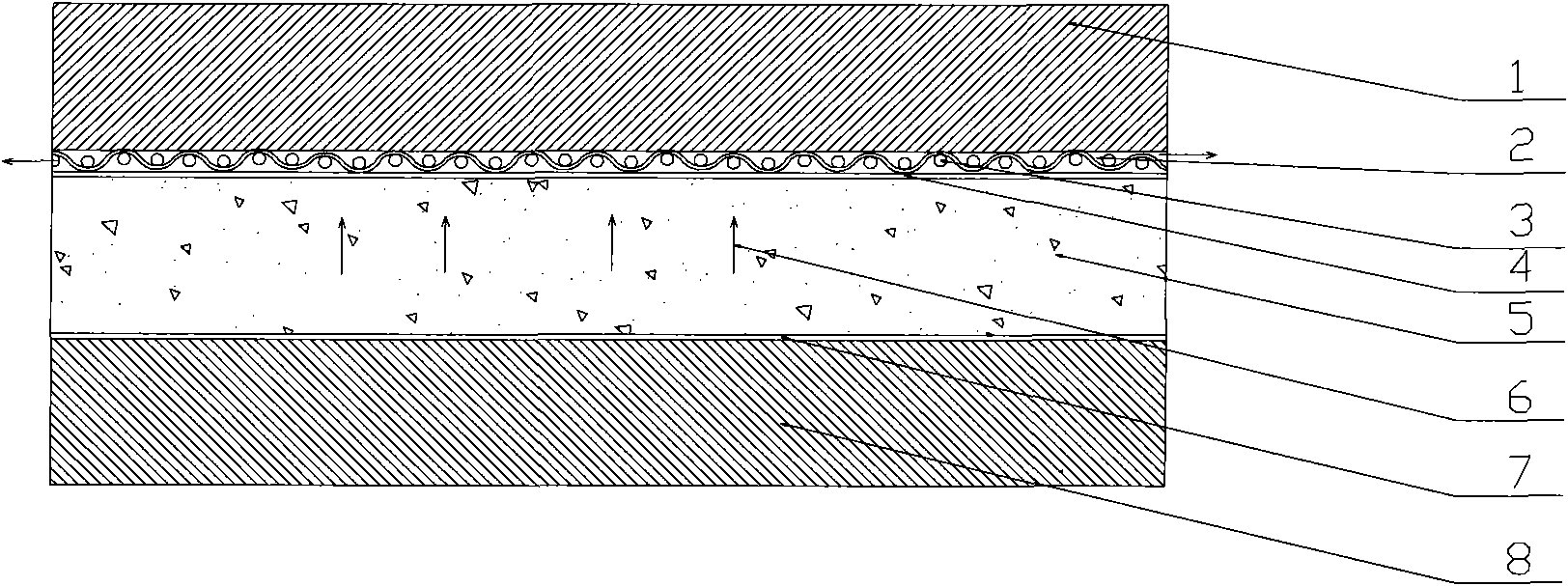

Fiber heat treatment reaction device, heat treatment system and heat treatment method

PendingCN111364109AEasy to realize industrializationPrevent oxidationArtificial thread manufacturing machinesFilament manufactureFiberThermodynamics

The invention discloses a fiber heat treatment device. The fiber heat treatment device comprises a reaction kettle body, a center shaft, a tow bearing device and a gas spraying device are arranged inthe reaction kettle body, wherein the tow bearing device is arranged on the center shaft and used for containing package fibers, and the central shaft is connected with an external driving mechanism.The invention further provides a fiber heat treatment system and a heat treatment method. According to the heat treatment reaction device, the whole roll of package fibers are placed on the tow bearing device, the space utilization rate of the heat treatment reaction device is increased, the heat treatment yield and the heat treatment efficiency are improved, and industrialization of fiber heat treatment is conveniently achieved; and meanwhile, the driving mechanism drives the center shaft to rotate so as to drive the whole roll of package fibers to rotate in the heat treatment process, the gas spraying device inputs inert gas into the heat treatment reaction device, the package fibers make full contact with the inert gas atmosphere, and small molecules separated out of the surfaces of thefibers due to the heat treatment reaction are blown away and brought away, so that heat treatment efficiency is improved.

Owner:宁波海格拉新材料科技有限公司

Tyre for high-strength light rail car and manufacturing technology thereof

The invention discloses a tyre for high-strength light rail car and a manufacturing technology thereof, and relates to the technical field of alloy preparation. The tyre comprises an outer tyre, a clamping seat is fixedly and integrally connected to the middle of the inner surface of the side wall of the outer tyre and comprises a clamping platform and a stop ring integrally and fixedly connectedto the outer side of the bottom surface of the clamping platform, wherein the clamping platform and the outer tyre are coaxially arranged, and several threaded through holes are formed in the end surface of the clamping platform; a tread ring is integrally and fixedly connected with the bottom end surface of the outer tyre, the surface of the tread ring is an annular surface completely coincidingwith the bottom surface of the outer tyre, the inner side of the annular surface vertically bends outward to form an arc tread surface extending downward and outward, and the outer side of the annularsurface vertically bends outward to form an outer arc surface with the bottom end coinciding with the outer side of the arc tread surface; the tread surface of the tyre is made into an oblique surface of 5 degrees, therefore the wheel set mass can be reduced, wheels can conveniently pass curve rails, the tread surface can be uniformly abraded, by lowering the gravity center of the car, the wheelset mass is reduced, and the flexibility of the rail entering of rail wheels is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Hot forming method for high-strength complex material particle board

InactiveCN101927519AGuarantee unimpededWon't clogWood working apparatusDomestic articlesWood shavingsAdhesive

The invention discloses a hot forming method for a high-strength complex material particle board. The method comprises the following steps of: placing a stainless steel plate and a complex material particle board assembly into a lower die frame sequentially; laying a steel mesh on the upper plane of the complex material particle board assembly, wherein the complex material particle board assembly comprises a shaving blank layer, and an upper complex material layer and a lower complex material layer which are arranged on the upper surface and the lower surface of the shaving blank layer respectively, and the shaving blank layer is formed by crushing plant particles, blending the crushed plant particles with adhesives and laying the mixture; and performing hot pressing on the complex material particle board assembly in the lower die frame by using an upper die, and unloading and cooling the die to obtain the complex material particle board. Effective steam diffusion channels can be formed in a hot pressing process, and steam in the shaving blank layer can be discharged in time, so that the increase of pressure is avoided after the steam aggregates, the probability of board explosion after the pressure is eliminated is greatly reduced, the strength uniformity of the complex material particle board is ensured and the strength of the complex material particle board prepared by the production process of the invention is improved.

Owner:NANJING HANQING BAMBOO PALLETAB

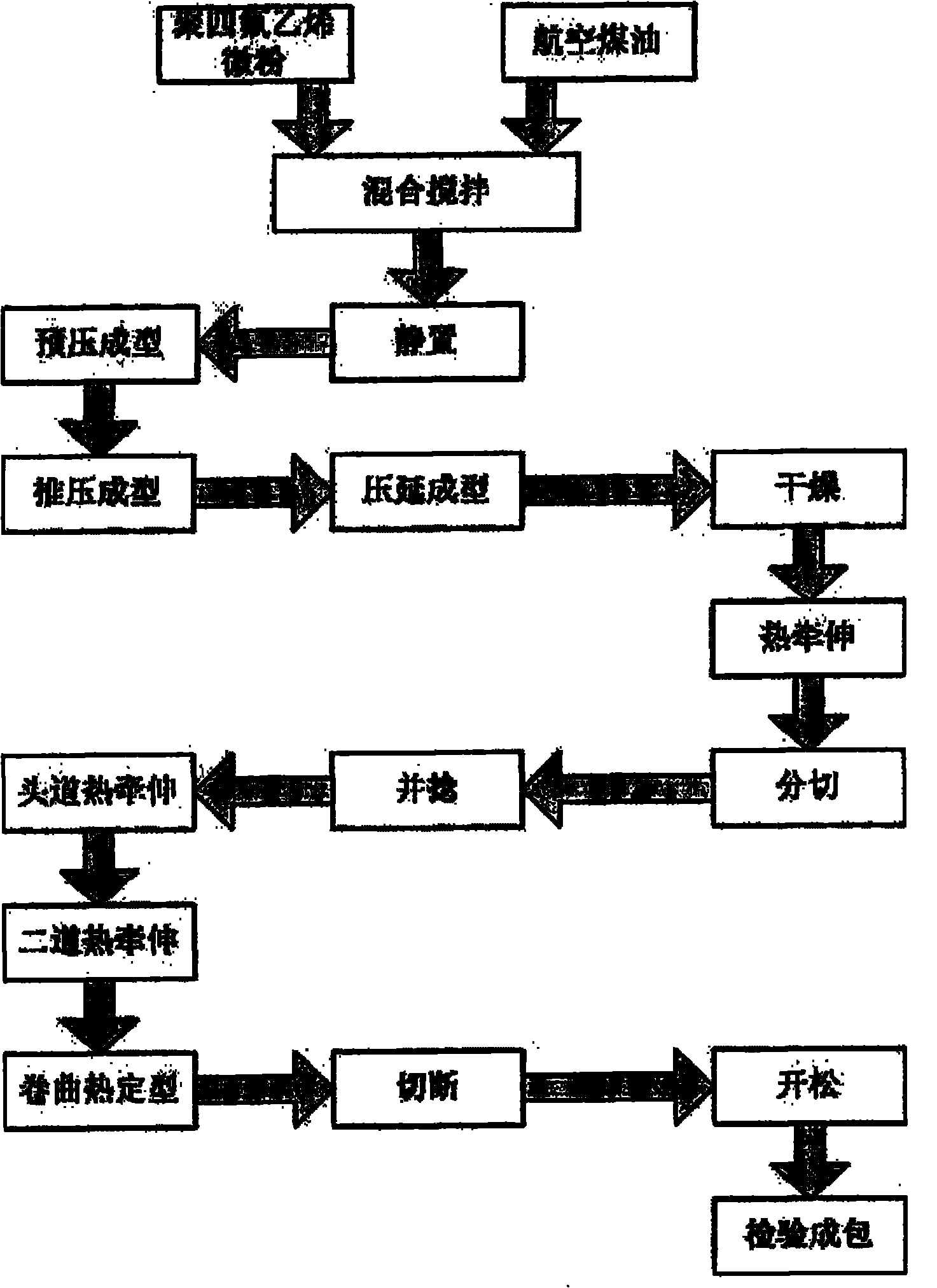

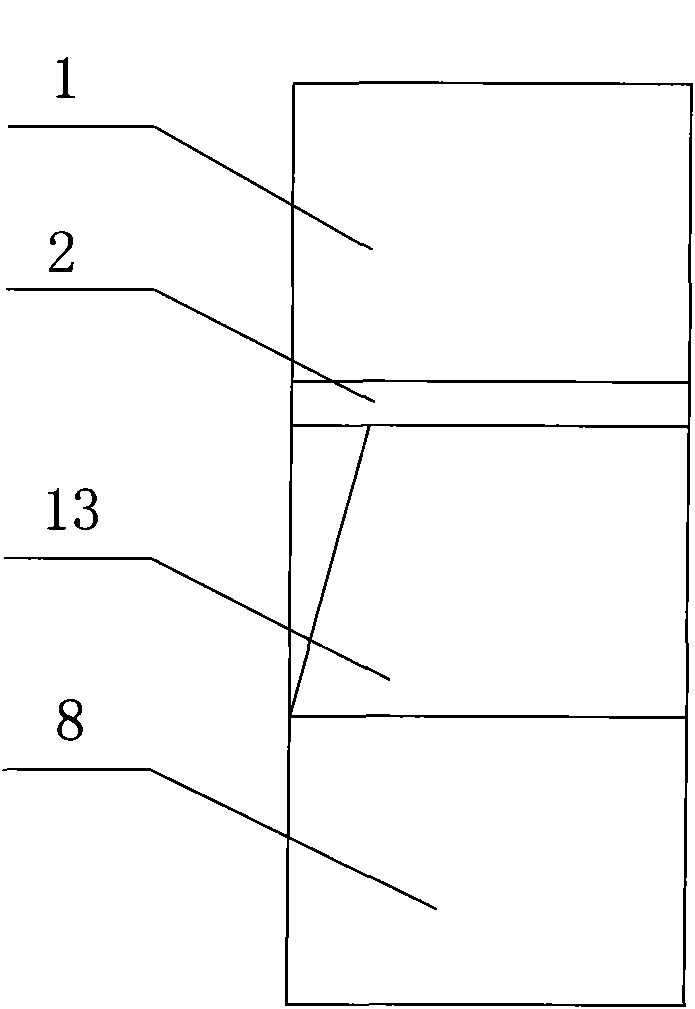

Manufacturing method of film split polytetrafluoroethylene fibers

ActiveCN102051703BWell mixedWeight optimizationFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentPre compressionHigh intensity

The invention aims to provide a manufacturing method of film split polytetrafluoroethylene fibers with high intensity, high uniformity and low production cost. A process comprises the following steps of: mixing polytetrafluoroethylene micro-powder and a lubricant; stirring; standing; performing pre-compression molding; performing press molding; performing calendaring molding; drying; cutting; performing primary hot stretching; performing secondary hot stretching; performing heat shaping; and winding so as to obtain high-intensity polytetrafluoroethylene fibers. In the manufacturing process, temperatures during drying, cutting, primary hot stretching, secondary hot stretching and heat shaping rise in turn.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

Micro-optical component for generating an image

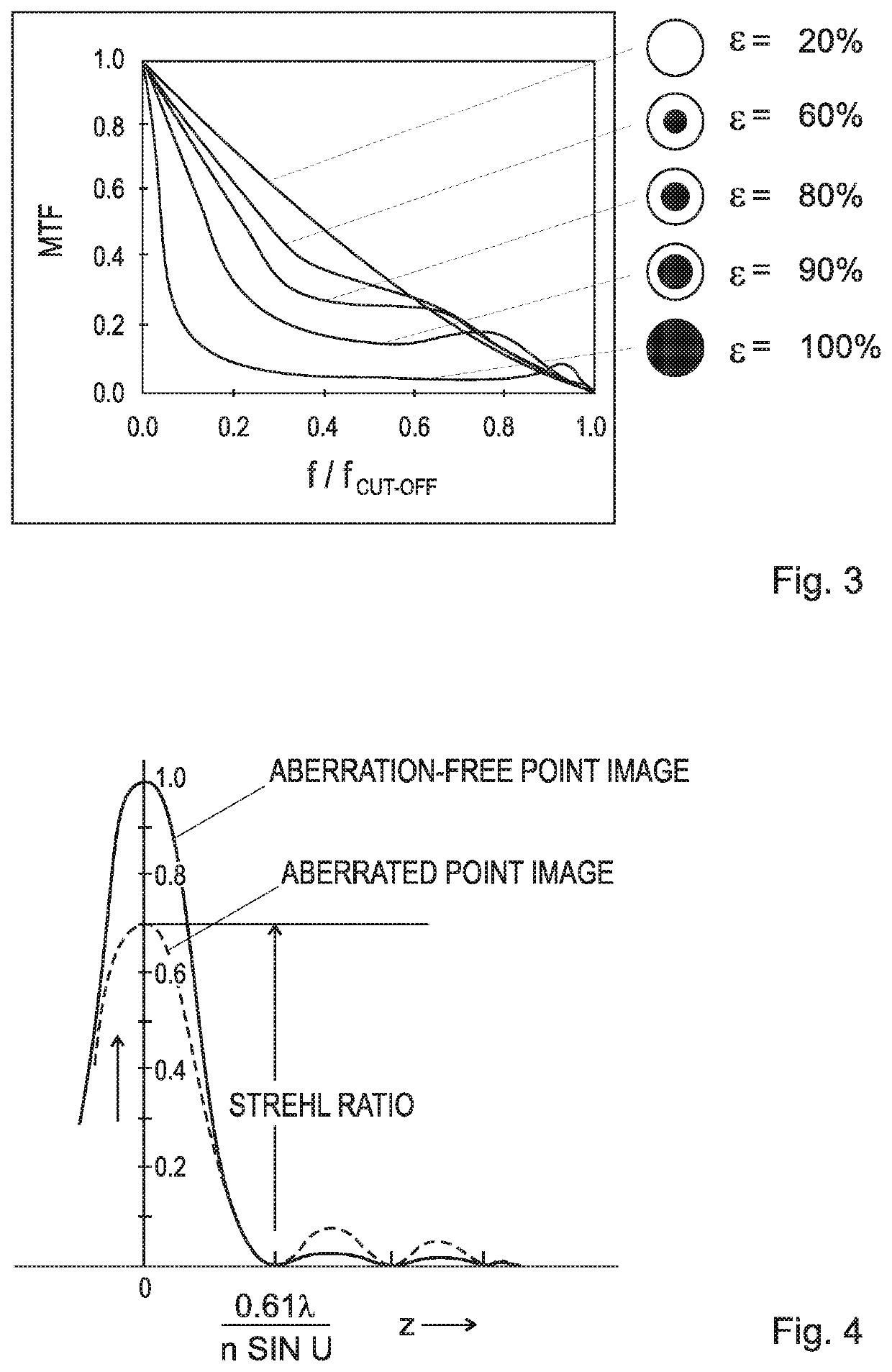

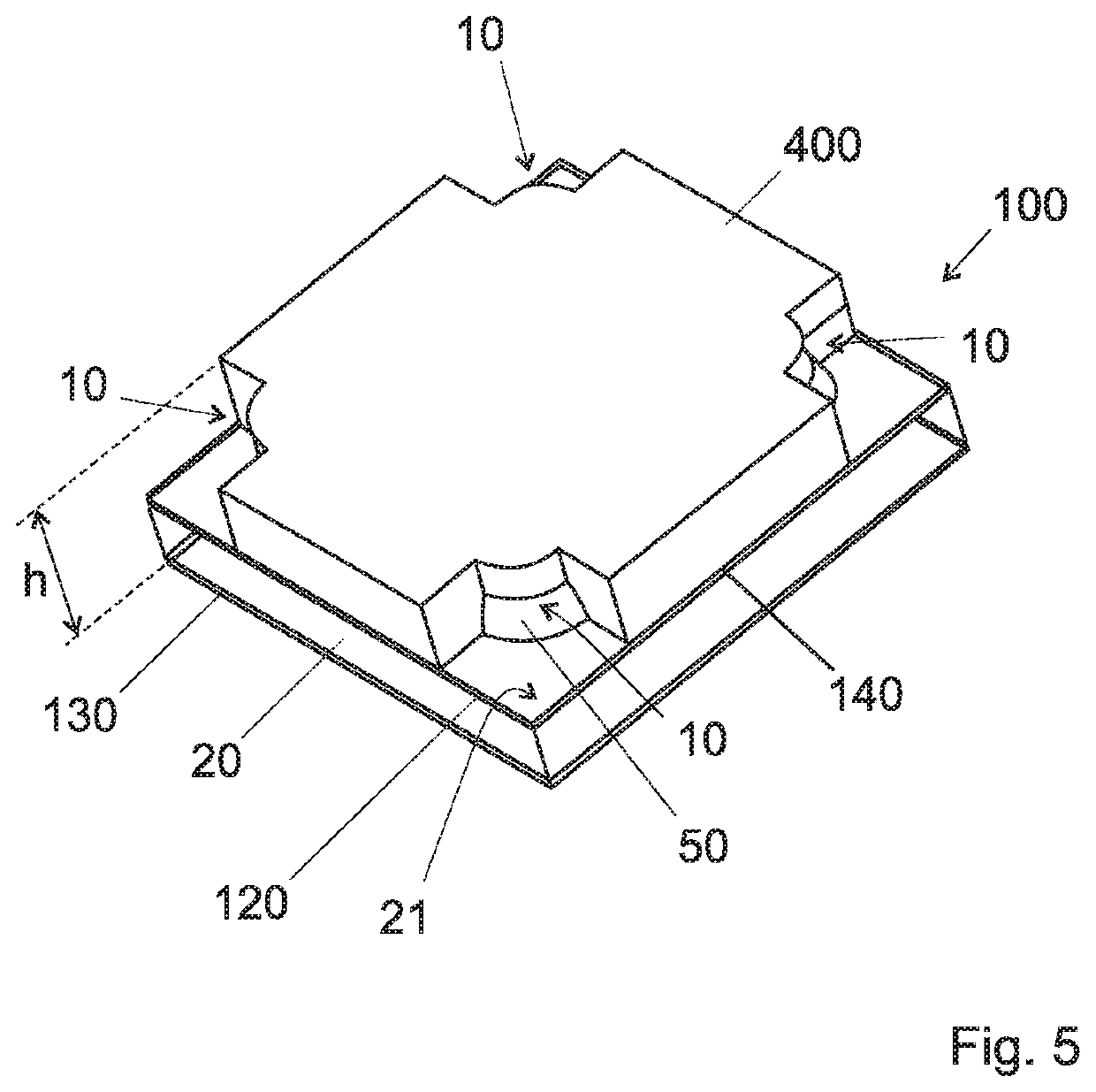

InactiveUS20200021723A1Improves strength uniformityReduce image blurTelevision system detailsSolid-state devicesImage resolutionTransmittance

A micro-optical component for generating an image, including a substrate and a lens. The substrate, includes a first surface and a second surface, wherein the first surface includes an aperture, and the second surface is arranged to be connected to a pixel array. The lens is placed on the first surface so as to cover the aperture. The focal point of the lens belongs to the second surface. The lens includes an obscuration element generating at the lens an obscured area and an unobscured area. The obscuration element is dimensioned to reduce the light transmittance towards the pixels for a fraction of the viewing angles only and at the same time. The obscured area is dimensioned so that the optical resolution of the lines is not smaller than the image resolution given by the size of the pixels.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

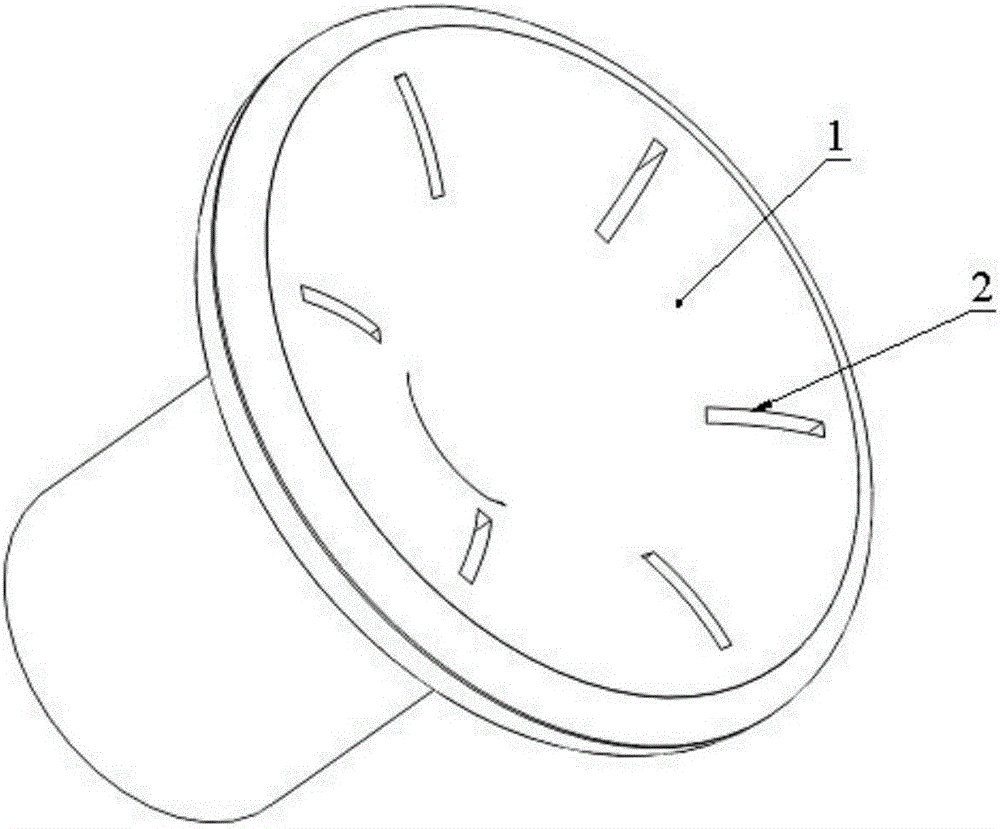

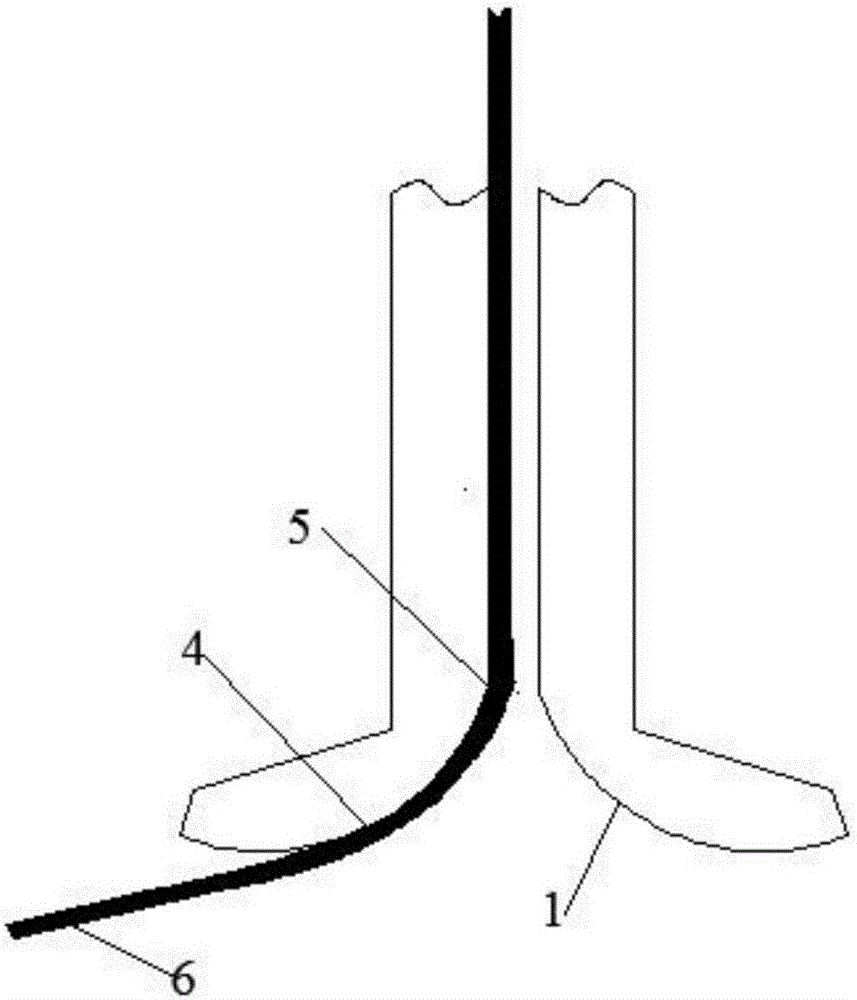

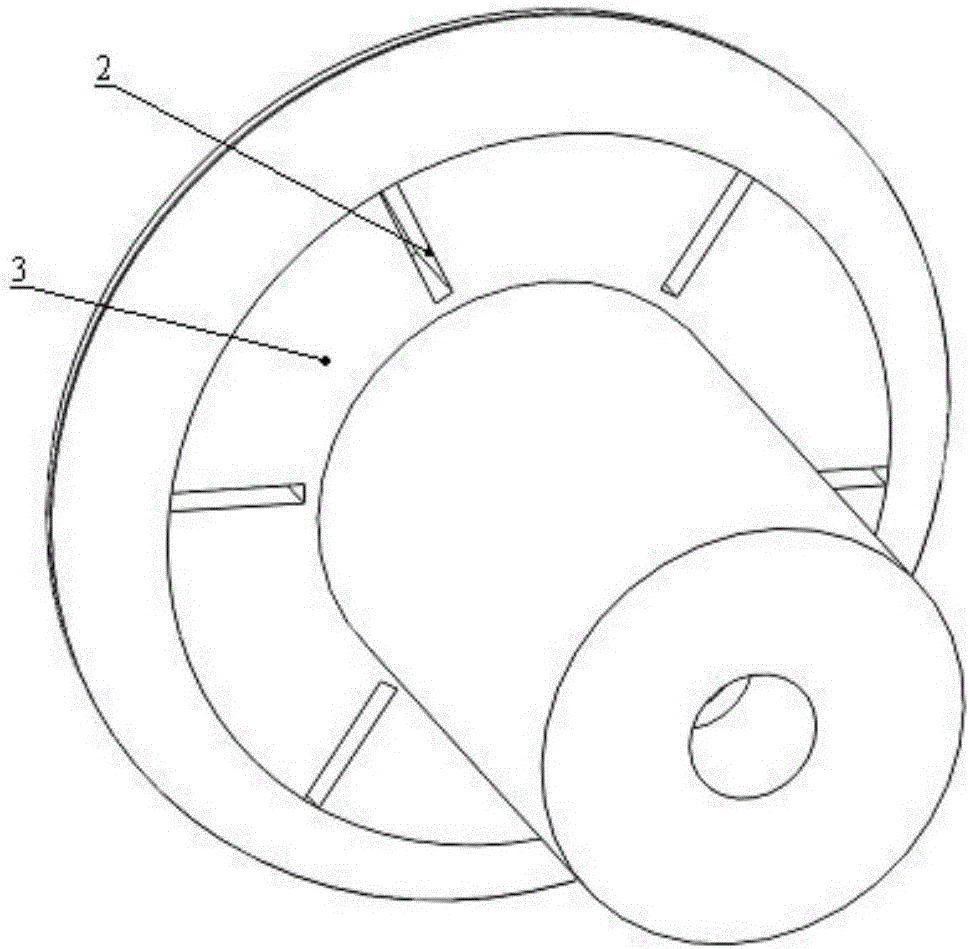

Rotor spinning false twister

InactiveCN106319696AReduce broken endsGood industry upgradeContinuous wound-up machinesOpen-end spinning machinesCombingYarn

The invention discloses a rotor spinning false twister. Narrow slits penetrating a cambered surface are formed in the cambered surface of a false twister body and connected with external fans, and air exhaust functions are achieved. When yarns are spun in a rotor spinning manner, the yarns can be adsorbed on the narrow slits by external negative pressure, friction action among the spun yarns and the cambered surface of the false twister body can be increased, so that false twisting action of the false twister is enhanced, and end breakage is decreased when the yarns are spun in the rotor spinning manner. The rotor spinning false twister can effectively solve the problem of end breakage in rotor spinning of combed noil yarns below 14.7tex, and can help enterprises to effectively upgrade industries and save production cost.

Owner:JIANGSU PUMEI TEXTILE CO LTD

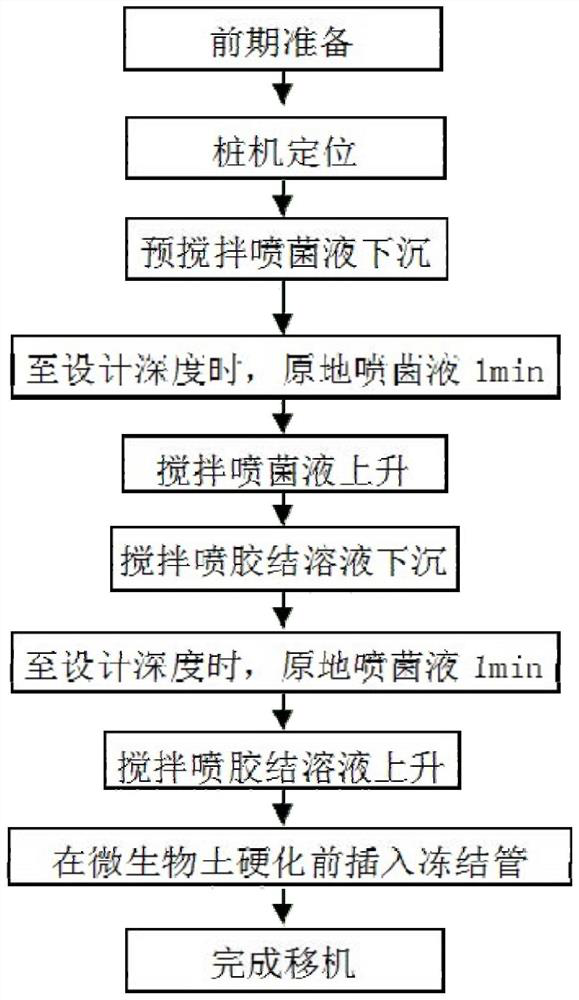

Frozen microorganism soil mixing pile

ActiveCN113235579AImprove bearing capacityIncreased shear strengthBacteriaMicroorganism based processesMicroorganismSoil science

The invention provides a frozen microorganism soil mixing pile. Soft soil is forcibly mixed with a water reducing agent, a bacterial liquid and a cementing solution on site in a foundation, so that the soft soil is hardened into foundation soil; and then a freezing method is implemented, so that the phenomena of frost heaving and thaw collapse of surrounding stratums can be effectively inhibited, and the bearing capacity, the shear strength, the pile body strength and the impermeability of the microorganism soil mixing pile are enhanced. According to the frozen microorganism soil mixing pile, soft soil gaps are filled with the cementing solution, and the bacterial liquid containing bacillus pasteurii and pseudomonas oryzihabitans is added, so that cracks generated when the mixing pile is frozen are repaired, and the bearing capacity of the mixing pile is improved; and by adding the water reducing agent, the impermeability of the microorganism soil mixing pile is improved, and the influence of water on the freezing effect is reduced.

Owner:HAINAN UNIVERSITY

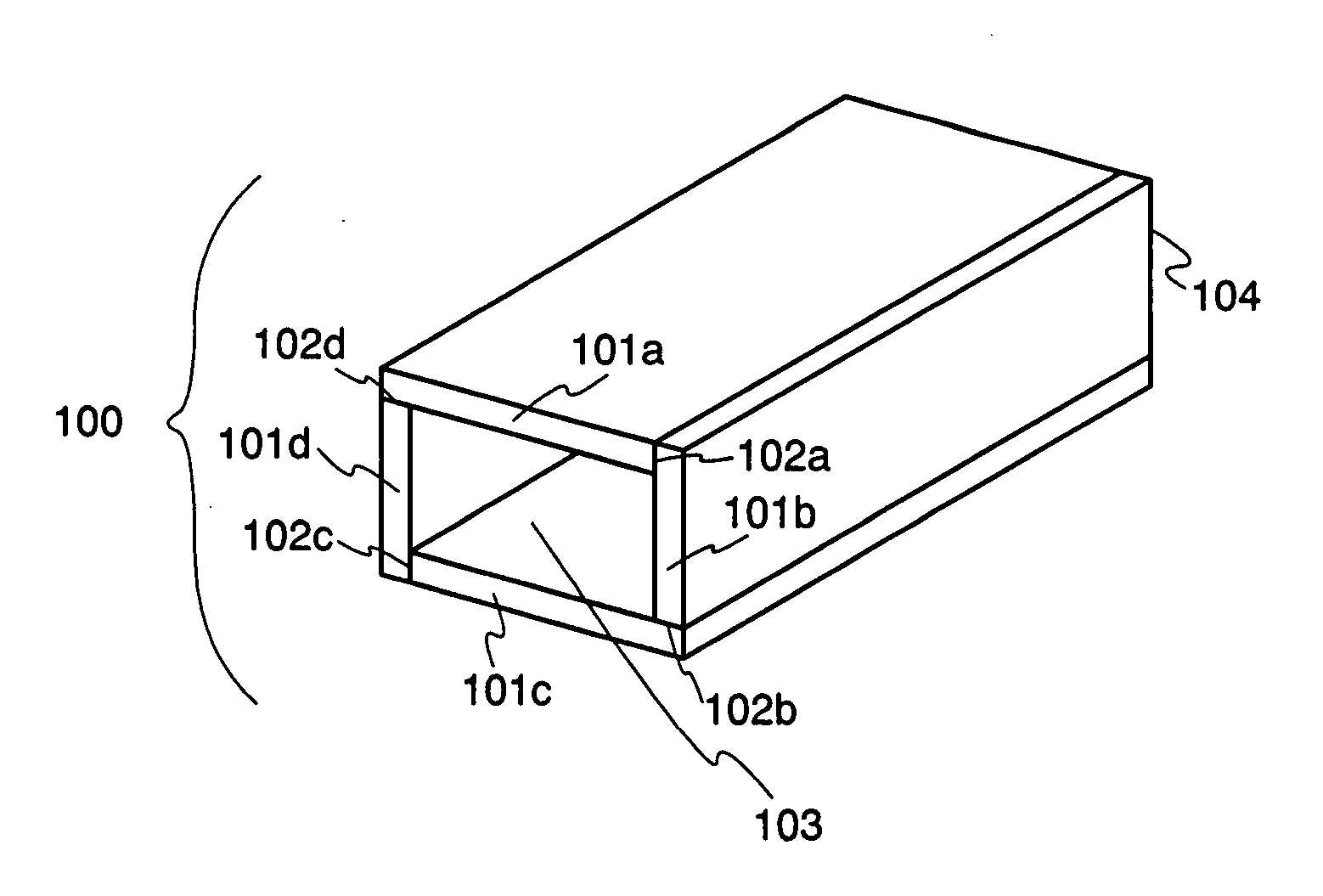

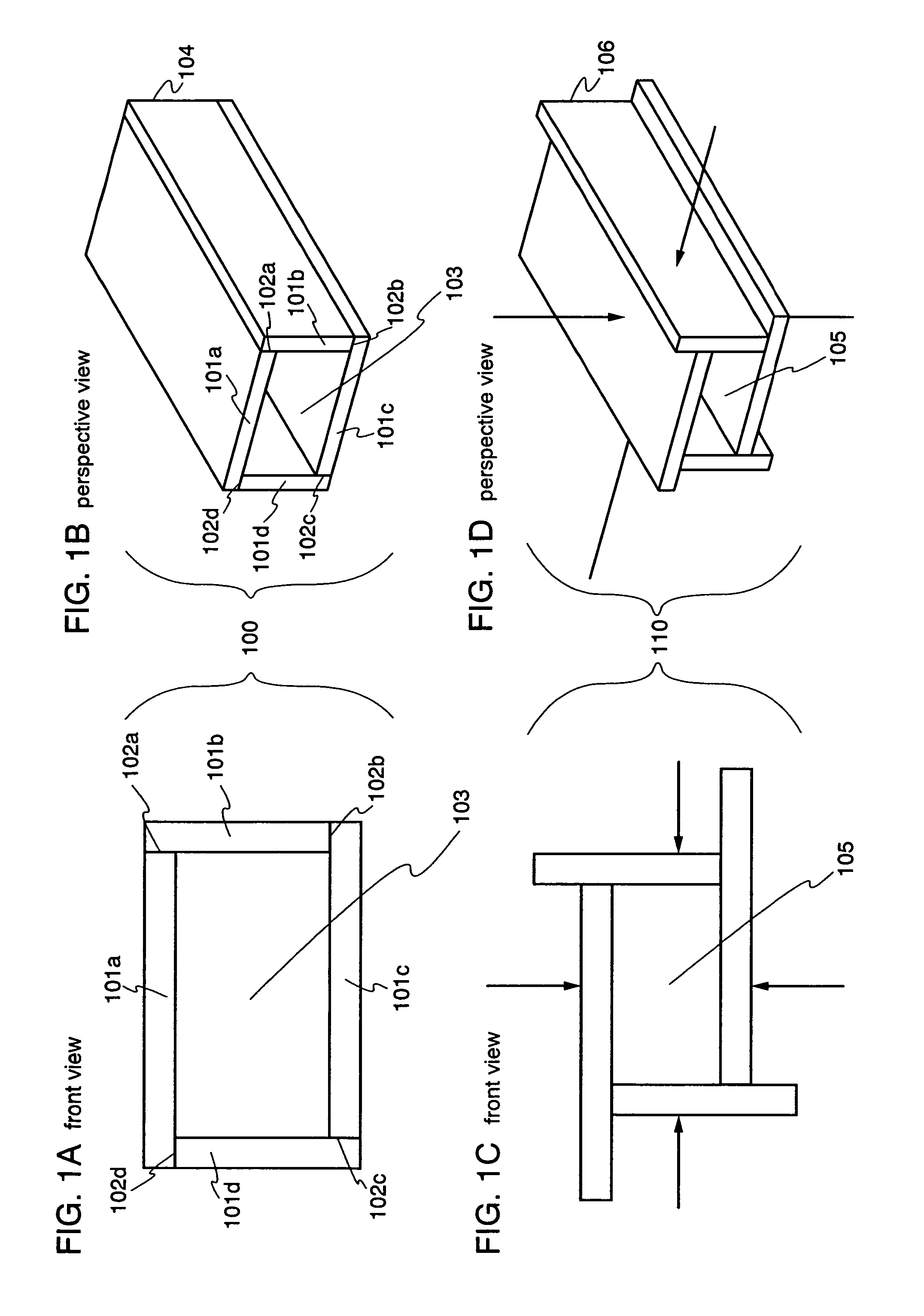

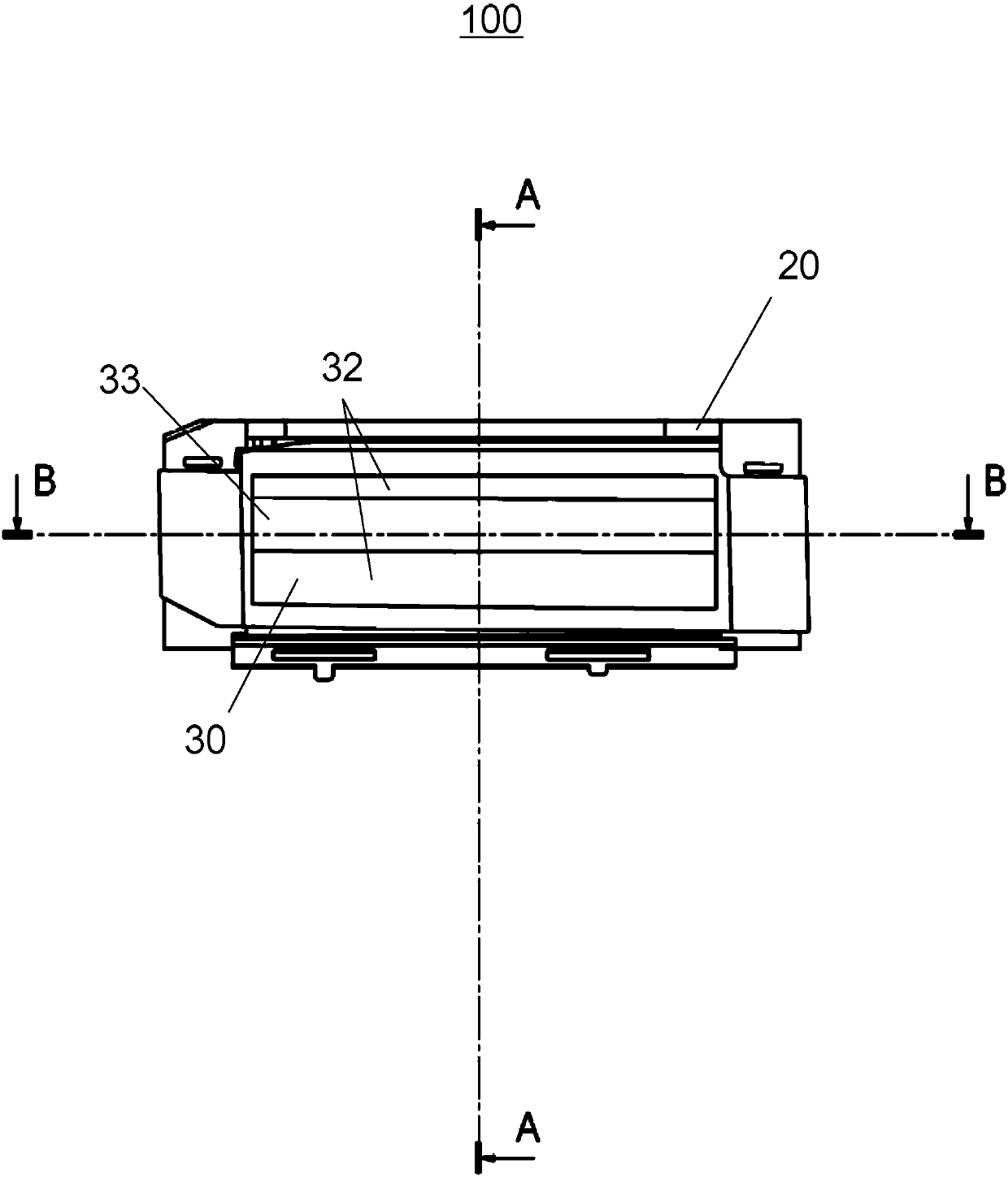

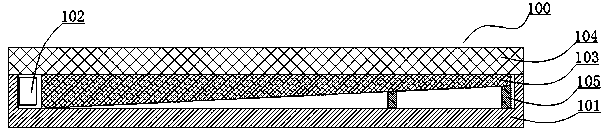

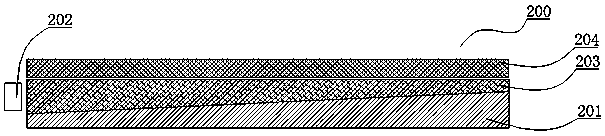

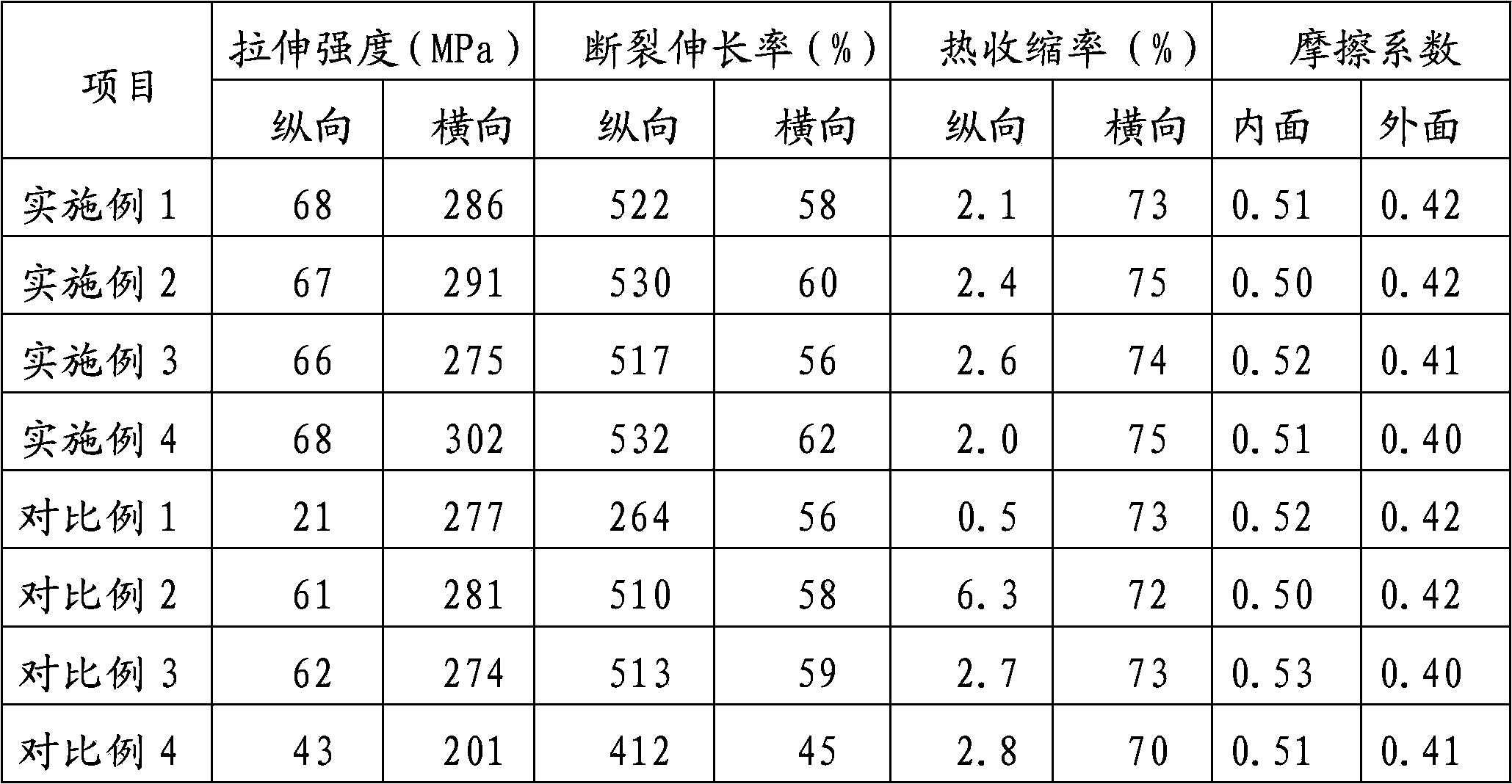

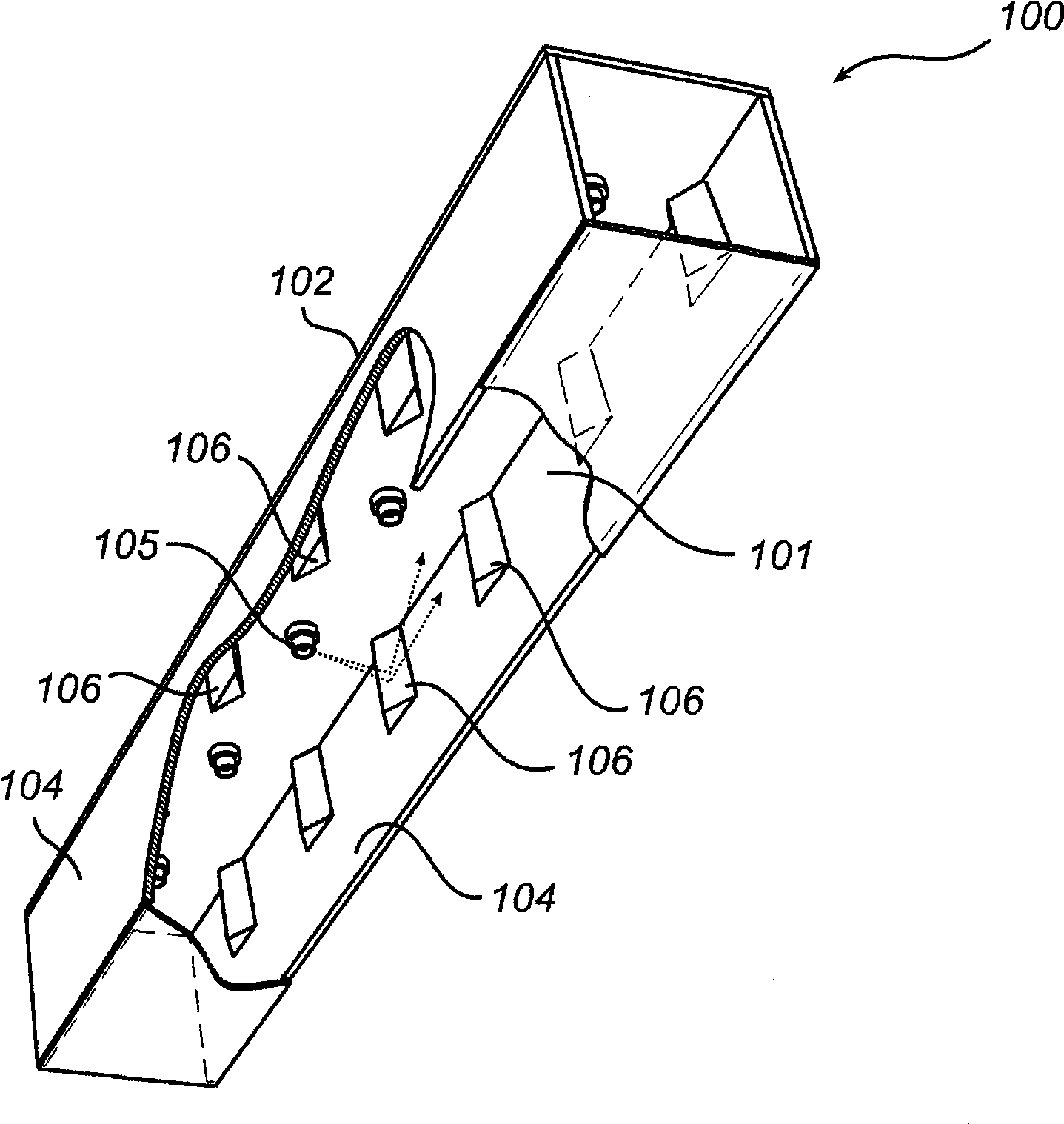

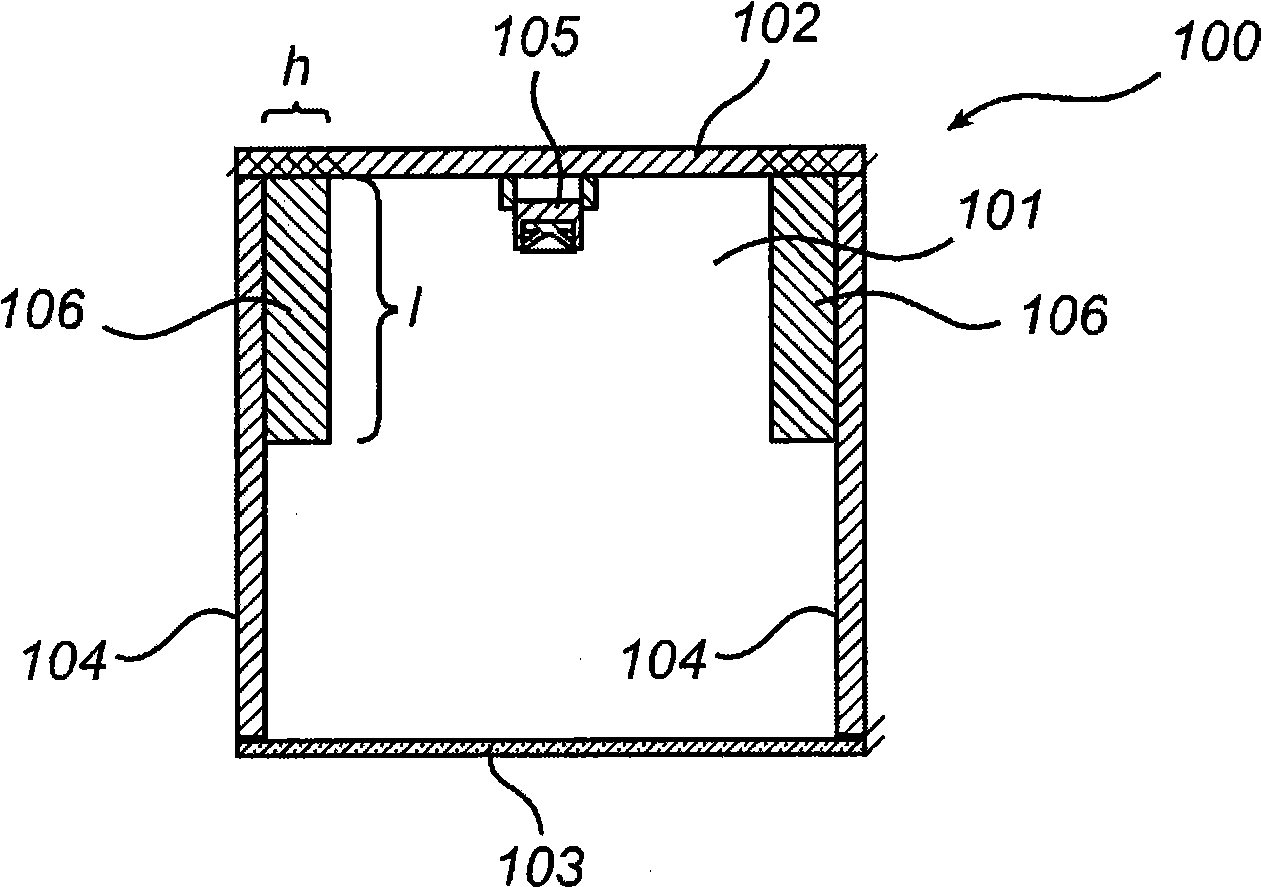

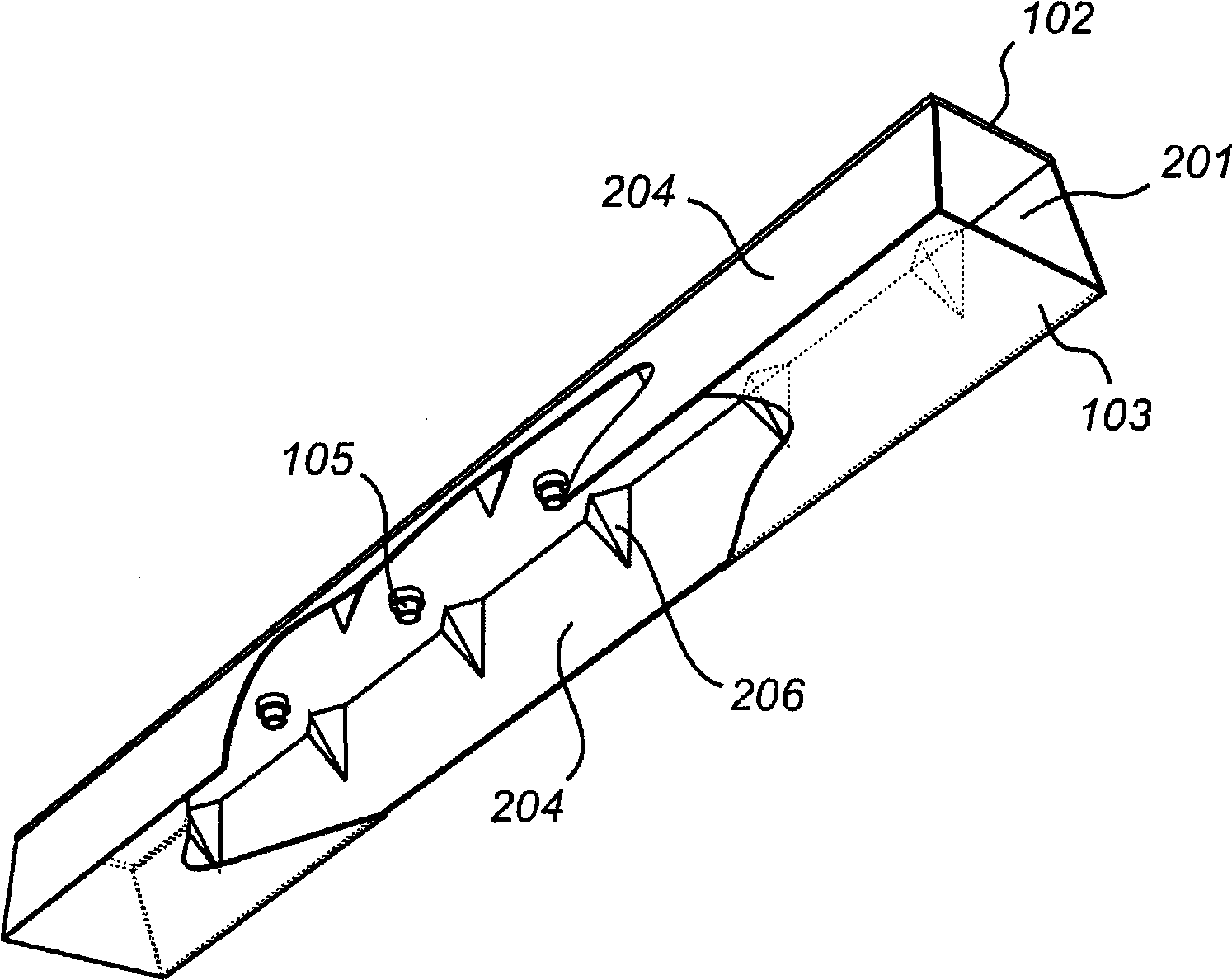

Device for mixing light of side emitting leds

InactiveCN101535712AGood color mixing propertiesImproves strength uniformityPoint-like light sourceElongate light sourcesEngineeringLight emitting device

A light emitting device (100) is provided that comprises a longitudinally elongated housing (101) comprising a top wall (102) and opposing diffusing surface (103), and two mutually opposing reflective longitudinally elongated sidewalls (104) connecting said top wall (102) with said diffusing surface (103). An array of mutually spaced apart light emitting diodes (105) arranged is in said housing along the longitudinal extension thereof, and at least one of said sidewalls (104) is provided with an array of mutually spaced apart light redirecting means (106). The light redirecting means reflect light away from the LED that emitted the light, leading to a good mixing of light from the LEDs in the array.

Owner:KONINK PHILIPS ELECTRONICS NV

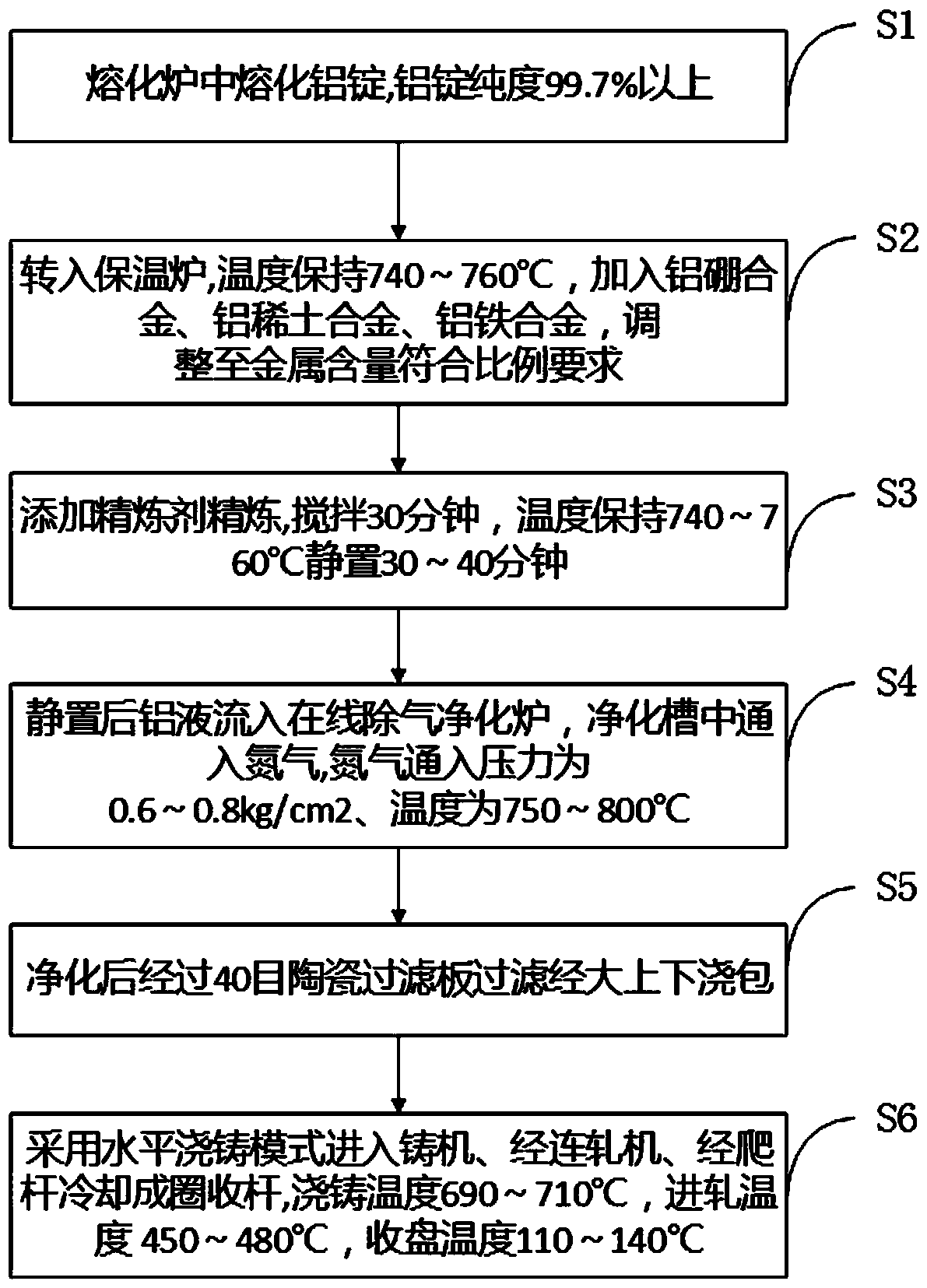

High-strength and high-conductivity aluminum rod material and production method

The invention discloses a high-strength and high-conductivity aluminum rod material and a production method. The aluminum rod material comprises the following alloy components in percentage by weight:0.16-0.19% of iron, 0.03-0.45% of silicon, 0.02-0.05% of boron, 0.02-0.2% of lanthanum, less than 0.01% of manganese chrome vanadium titanium, and the balance of aluminum, wherein the ratio of iron to silicon is controlled to 3.5-6. According to the produced high-strength and high-conductivity aluminum rod material, the main performance indexes meet the requirements of GB / T3954, namely, the tensile strength is 140 MPa or higher, the conductivity is 62.5% IACS, and the single-coil aluminum bar strength deviation is 4 MPa; the tensile strength of a large-section conductor aluminum wire producedthrough the aluminum bar is not less than 180 MPa, and the tensile strength difference is not greater than 20 MPa, the conductivity is 62.5% IACS; unnecessary energy consumption in an ultrahigh voltage power transmission process is eliminated.

Owner:特变电工山东鲁能泰山电缆有限公司

Lighting device and image display unit and light guide provided with it

InactiveCN100591989CImprove utilization efficiencyLow utilization efficiencyMechanical apparatusElongate light sourcesLight guideEffect light

Owner:SHARP KK

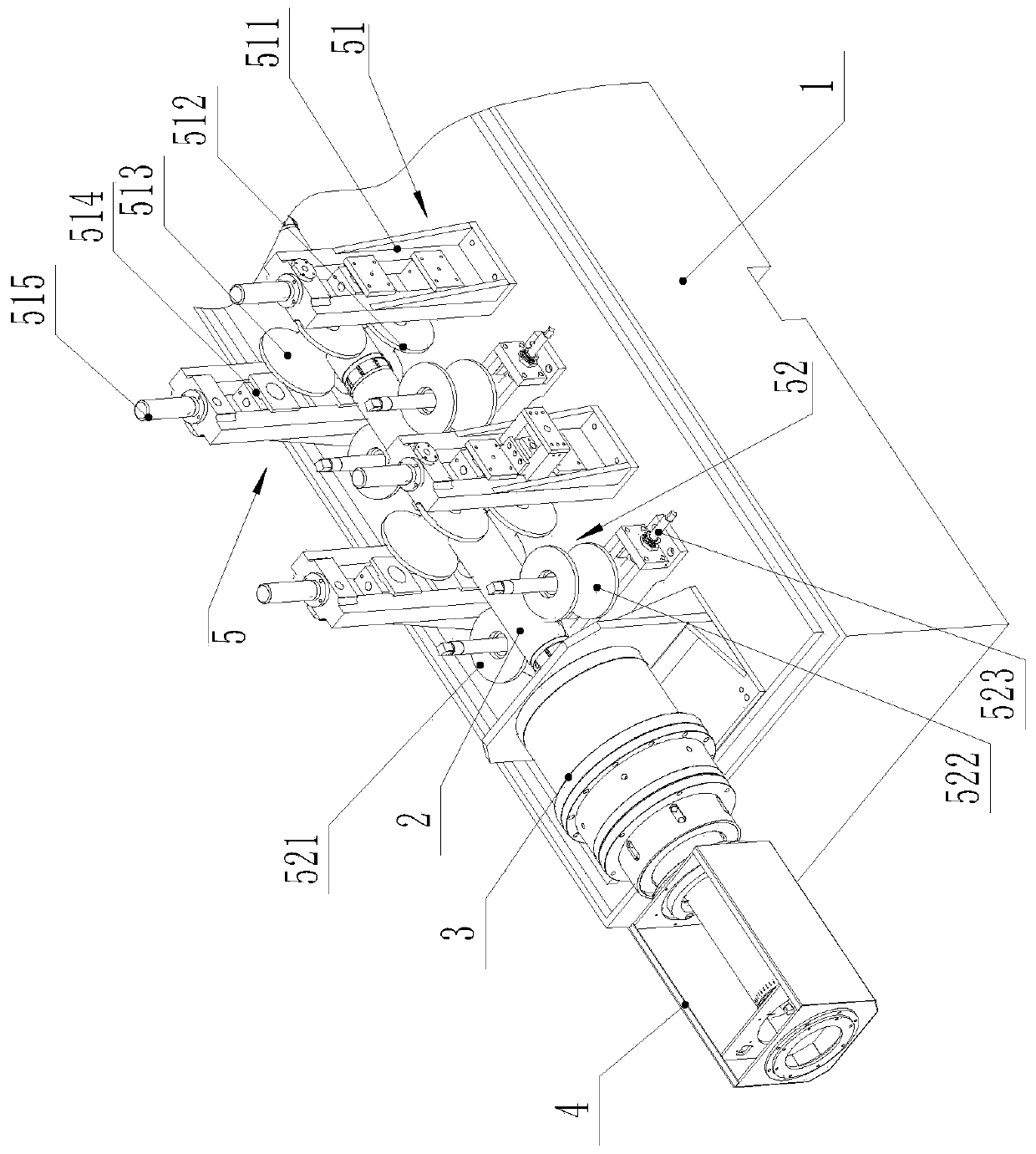

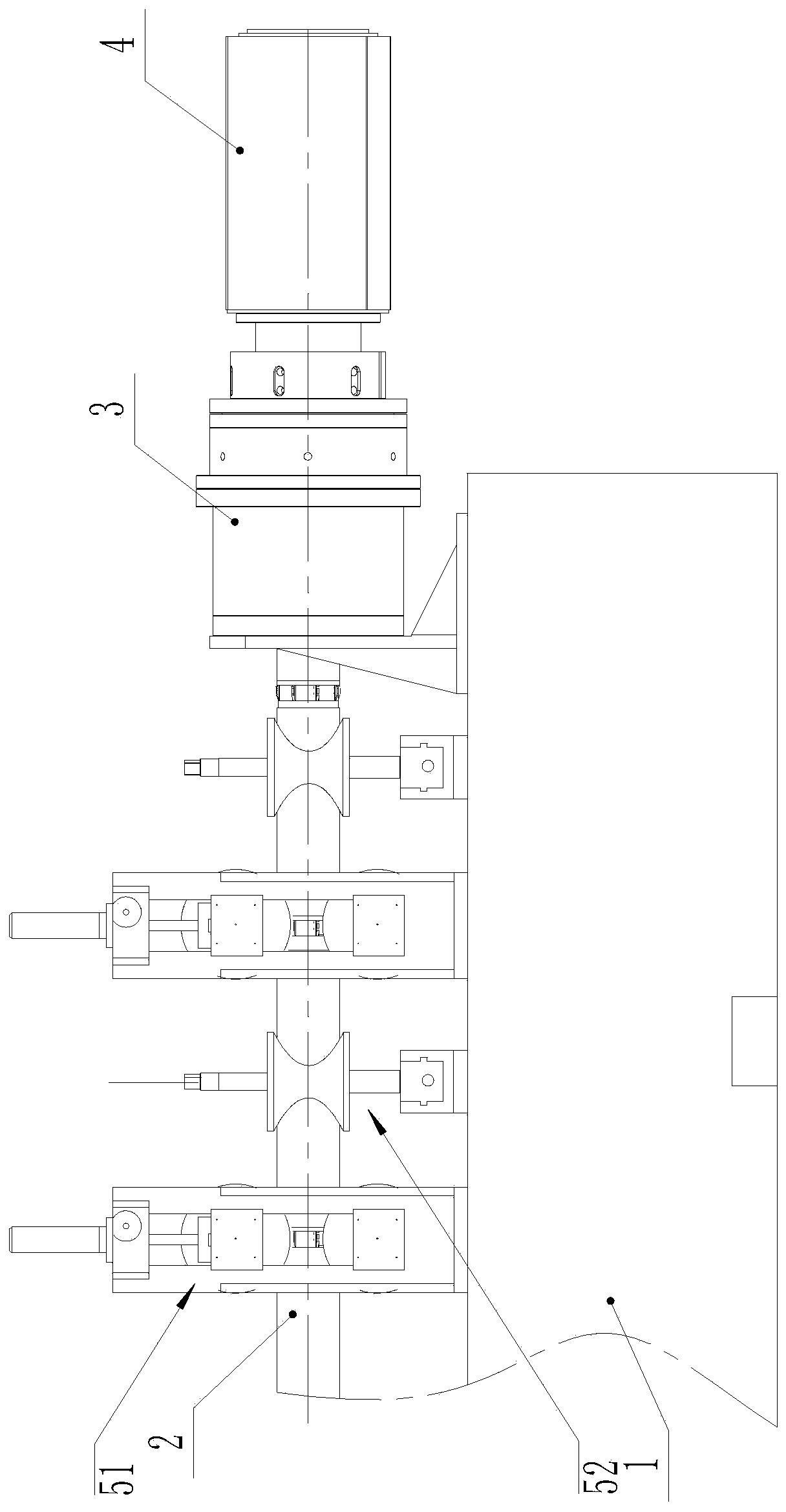

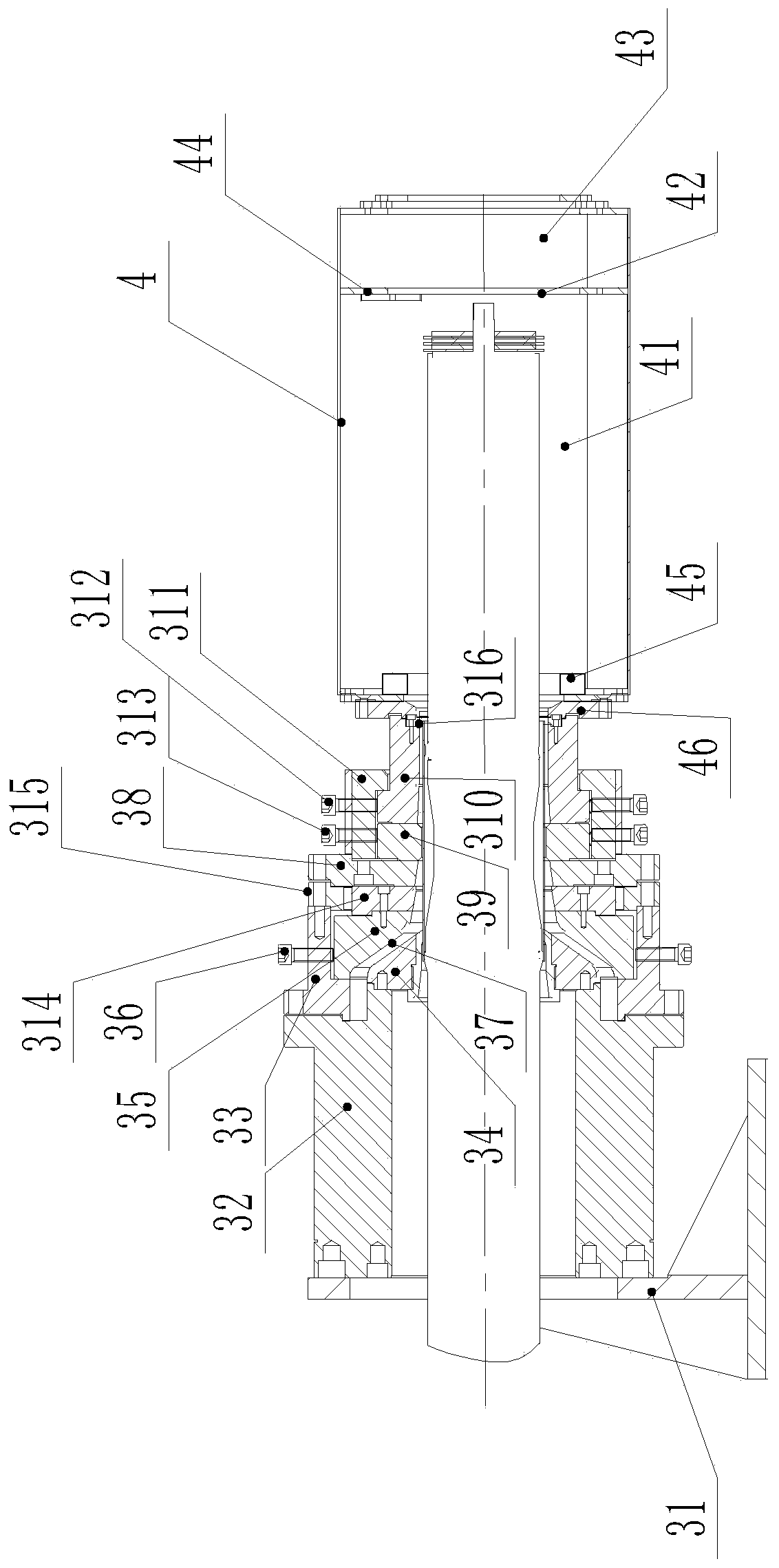

Forming device of hole net steel skeleton reinforced composite pipe

The invention discloses a forming device of a hole net steel skeleton reinforced composite pipe. The forming device comprises a machine base, a forming inner mold and a forming outer mold, wherein theforming inner mold and the forming outer mold are arranged on the machine base; the forming outer mold is arranged on the periphery of the forming inner mold in a concentrically sleeving manner, a forming channel allowing a hole net steel skeleton to penetrate through and plastic fluid to penetrate through is formed between the forming inner mold and the forming outer mold, the forming inner moldis provided with a shaping segment, and correspondingly, a positioning and shaping mechanism used for positioning and shaping the hole net steel skeleton is arranged at the position, corresponding tothe shaping segment, of the machine base. According to the forming device, in the forming process, the hole net steel skeleton is shaped, and the forming quality of the composite pipe is improved.

Owner:ZHANGJIAGANG XIEXIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com