High-strength and high-conductivity aluminum rod material and production method

A production method and conductivity technology, which is applied to high-strength conductivity aluminum rod materials and production fields, can solve the problems of mutual constraints between aluminum resistivity and strength, reduced safety and reliability of wires, and increased raw material costs, so as to avoid annealing Effect, low cost, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

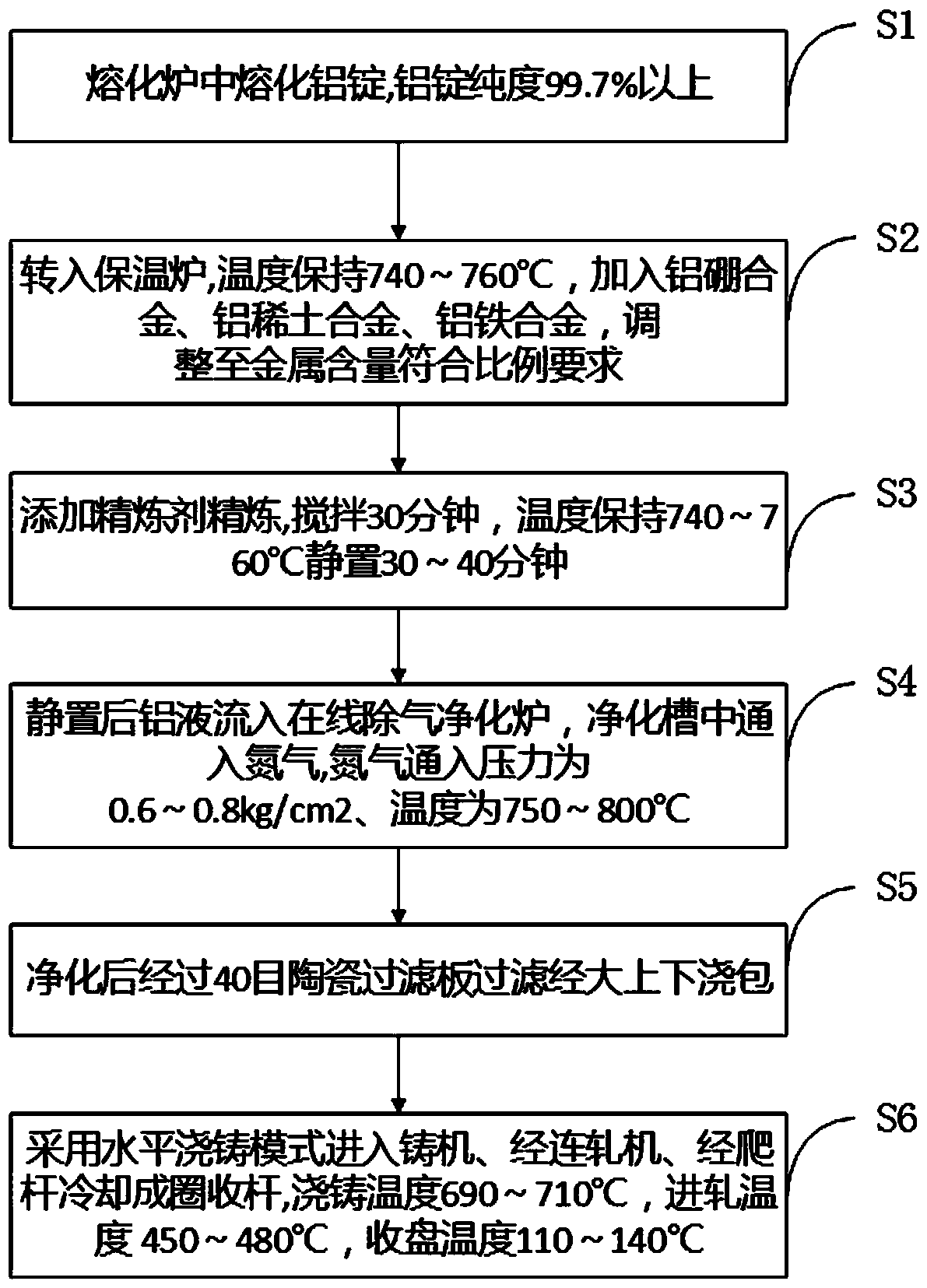

[0030] refer to figure 1 as shown,

[0031] Follow the steps below to produce aluminum rods

[0032] Put 99.70% aluminum ingots into the melting furnace, transfer to the holding furnace, adjust the temperature to maintain 740 °C, add aluminum-boron alloy, aluminum rare earth alloy, aluminum-iron alloy; adjust the mass ratio of elements to iron 0.17%, silicon 0.035%, boron 0.03%, lanthanum 0.08%, manganese, titanium, chromium and vanadium are controlled below 0.01%, adding refining agent for refining; stirring for 30 minutes, keeping the temperature at 740°C for 30 minutes; 0.6kg / cm2, the temperature is 750°C; after purification, it is filtered through a 40-mesh ceramic filter plate, passed through a large upper and lower ladle, and enters the casting machine in a horizontal casting mode, passes through a continuous rolling mill, and is cooled by a climbing rod to form a circle and close the rod; the casting temperature is 690 °C, the rolling temperature is 460 °C, and the cl...

Embodiment 2

[0034] Follow the steps below to produce aluminum rods

[0035] Put 99.70% aluminum ingots into the melting furnace, transfer to the holding furnace, adjust the temperature to maintain 750 ℃, add aluminum-boron alloy, lanthanide aluminum rare earth alloy, aluminum-iron alloy; adjust iron 0.19%, silicon 0.04%, boron 0.05%, lanthanum 0.1% Manganese, titanium, chromium and vanadium are controlled below 0.01%, adding refining agent for refining; stirring for 35 minutes, keeping the temperature at 750°C and standing for 40 minutes; after standing, the molten aluminum flows into the online degassing purification furnace, and the pressure of nitrogen in the purification tank is 0.7kg / cm2, the temperature is 760°C; after purification, it is filtered through a 40-mesh ceramic filter plate, passed through a large upper and lower ladle, and enters the casting machine in a horizontal casting mode, passes through a continuous rolling mill, and is cooled by climbing rods to form a circle an...

Embodiment 1

[0036] The aluminum rod material produced in embodiment 1 and embodiment 2 is through inspection, and the results are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com