Pulpy metakaolin-base concrete admixture, and preparation method and application of admixture

A metakaolin and admixture technology, which is applied in the field of slurry metakaolin-based concrete admixture and its preparation, can solve the problems that metakaolin cannot be uniformly dispersed, the fluidity and slump are reduced, and the surface energy is high, so as to improve the Volume stability and durability, improved interfacial transition zone, improved effect of improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

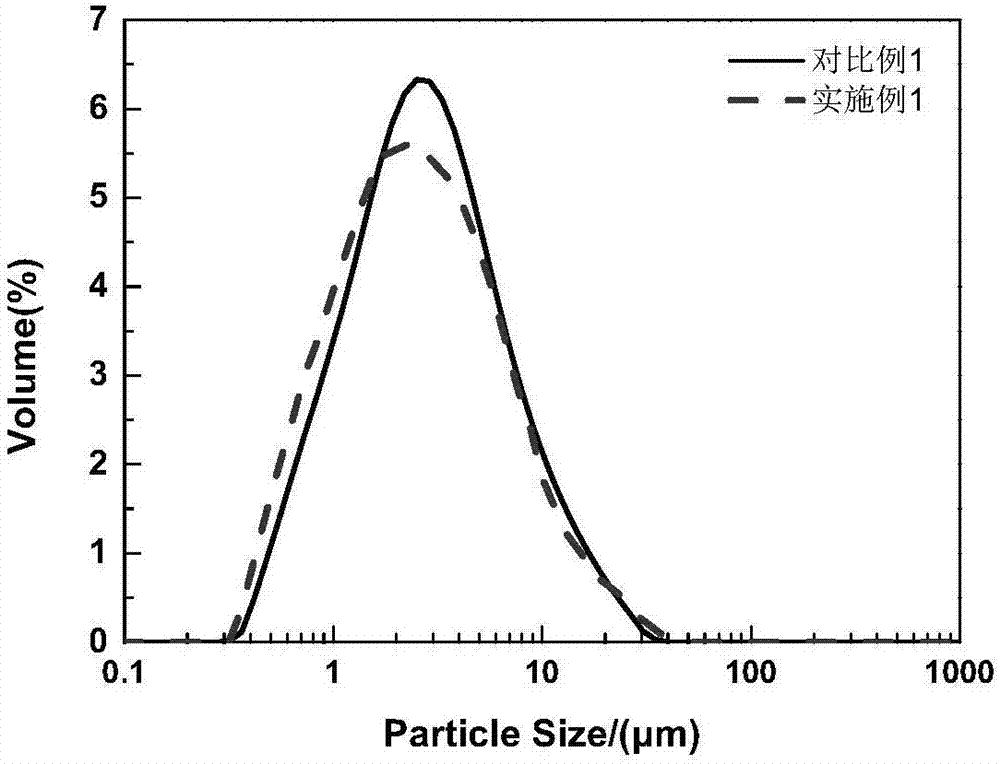

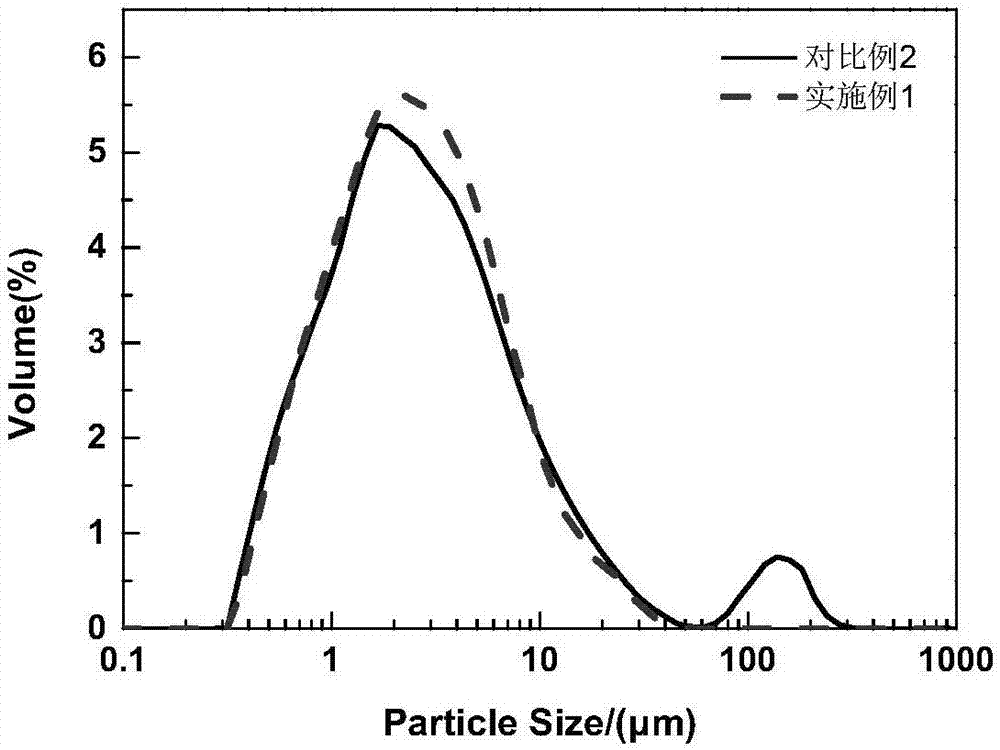

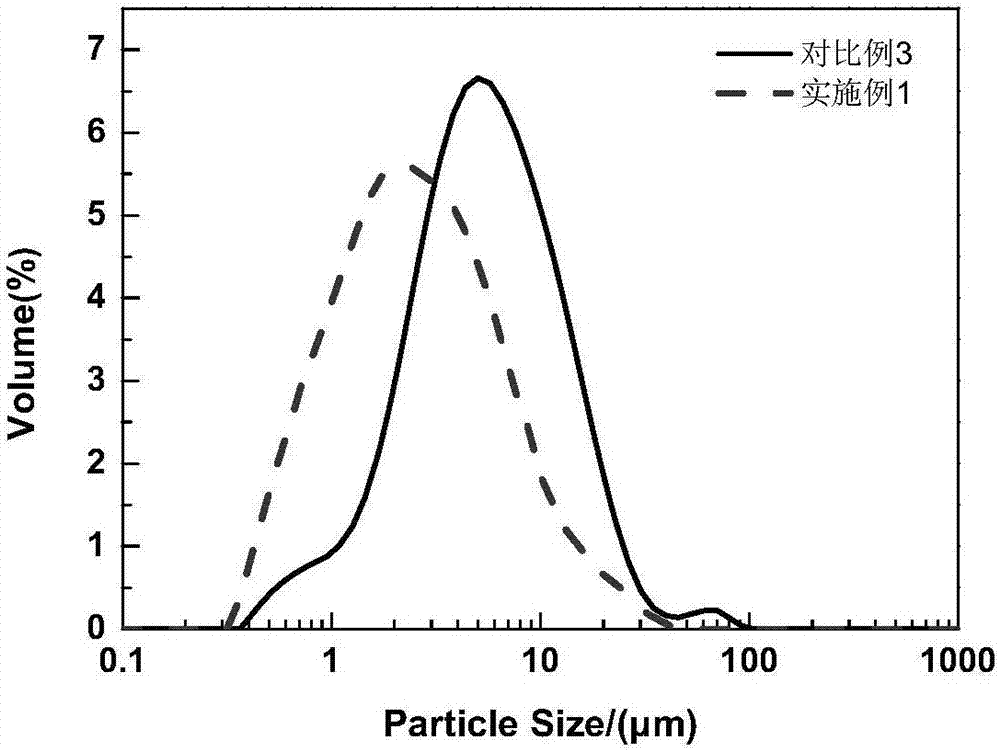

[0027] The admixture that this embodiment provides comprises dry basis, composite dispersant and water; Dry basis is made up of metakaolin and fly ash sedimentation beads, and its quality is respectively 60g and 40g, and the quality of water is 100g, hydroxyethyl cellulose The mass is 0.05g, and the naphthalene-based water reducer is 0.01g. The specific ratio is shown in Table 1. In this embodiment, the naphthalene-based water reducer is powdered sodium dinaphthylmethane disulfonate.

[0028] The preparation method of the admixture provided in this example is as follows: mix 60 g of metakaolin and 40 g of fly ash pellets and stir for 5 to 10 minutes, then dissolve the composite dispersant hydroxyethyl cellulose dissolved in 100 g of water and naphthalene-based reducing The water agent is added to the powder, and the stirring is continued for 25 to 35 minutes to obtain the slurry-like metakaolin-based concrete admixture.

Embodiment 2

[0052] Put the selected two groups of powder metakaolin and fly ash pellets into the mixer according to the mass of 100g each time, and carry out premixing for 5-10 minutes each time; put the selected dispersant into the weighed water completely Dissolve, then pour into one of the mixtures of one group, and continue to stir for 25-35 minutes to obtain the dispersed slurry-like metakaolin-based concrete admixture slurry B, and the other group of mixtures Add weighed water and stir for 25-35 minutes to obtain undispersed slurry metakaolin-based concrete admixture slurry A (as comparative example 4). For details, see Table 5.

[0053] Table 5 Mixing ratio of different slurry metakaolin-based concrete admixtures (g)

[0054] Numbering

fly ash beads

water

Slurry A

60

40

/

/

100

slurry B

60

40

0.05

0.01

100

[0055] Taking the mortar specimen...

Embodiment 3-5

[0063] Taking the mortar specimen as the object of investigation, according to the total mass (dry basis) of metakaolin and fly ash sinking beads, 5%, 10%, 15% and other masses were used to replace the cementitious material to prepare mortar. Select standard sand with a water-cement ratio of 0.5. The mortar mix ratio is shown in Table 8.

[0064] Table 8 Mortar mix ratio

[0065]

[0066] According to GB / T 2429-2005 " cement mortar fluidity test method " test the fluidity of reference sample, the mixture of embodiment 3-5; According to GB / T 17671-1999 " cement mortar strength test method ", use The universal compression testing machine tests the 3-day, 7-day and 28-day compressive strength of the benchmark sample and Examples 3-5.

[0067] Table 9 Fluidity of mortar and compressive strength of test block

[0068]

[0069] Table 9 illustrates: embodiment 3-5 pulpy metakaolin-based concrete admixture dosage is that metakaolin and fly ash sinking pearls account for 5%, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com