Heat treatment process for rapid aging of large-size GH4738 alloy forge piece

An aging treatment, large-scale technology, applied in the field of heat treatment technology, can solve the problems of inability to eliminate tissue differences, long production cycles, and large differences in γ' phase content, so as to shorten the aging treatment time, improve strength uniformity, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

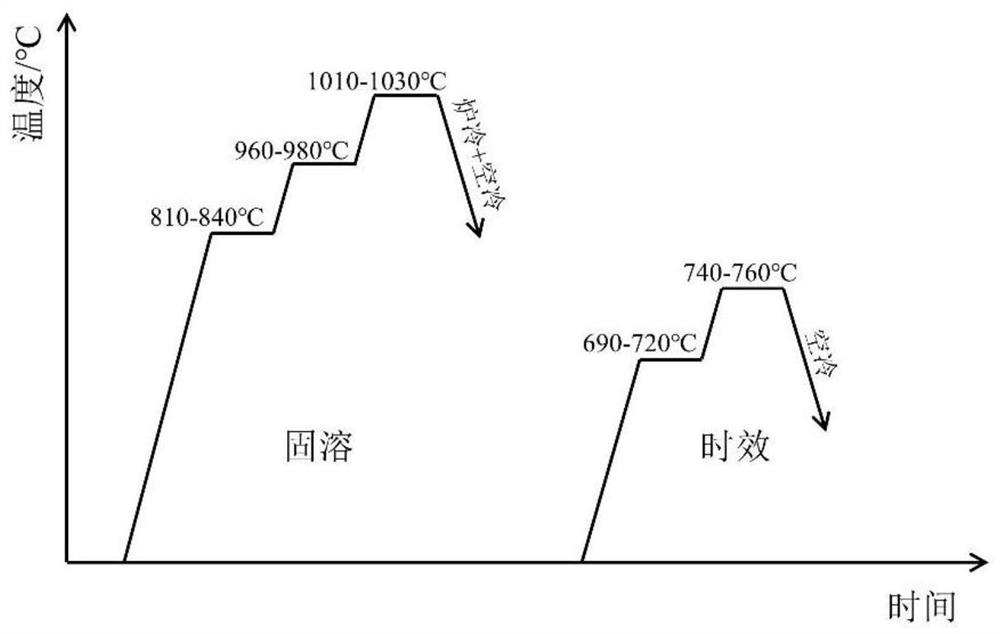

[0025] 1) Put the large-sized GH4738 alloy forging into the heating furnace for solution treatment: the heating furnace first raises the temperature to 830°C at a heating rate of 5°C / min, and keeps it for 40 minutes; then raises the temperature to 960°C at a heating rate of 8°C / min , keep warm for 50min; then raise the temperature to 1020℃ at a heating rate of 5℃ / min, and keep warm for 60min; after that, air is introduced into the heating furnace, and after cooling to below 500℃ at a rate of 110-130℃ / min, the alloy forging is taken out and air-cooled to room temperature.

[0026] 2) Put the GH4738 alloy forging after the solution treatment in step 1) into the heating furnace for aging treatment: the heating furnace first raises the temperature to 700°C at a heating rate of 5°C / min, and keeps it for 40min; The heating rate was raised to 750°C, kept for 6 hours, and then taken out and air-cooled to room temperature.

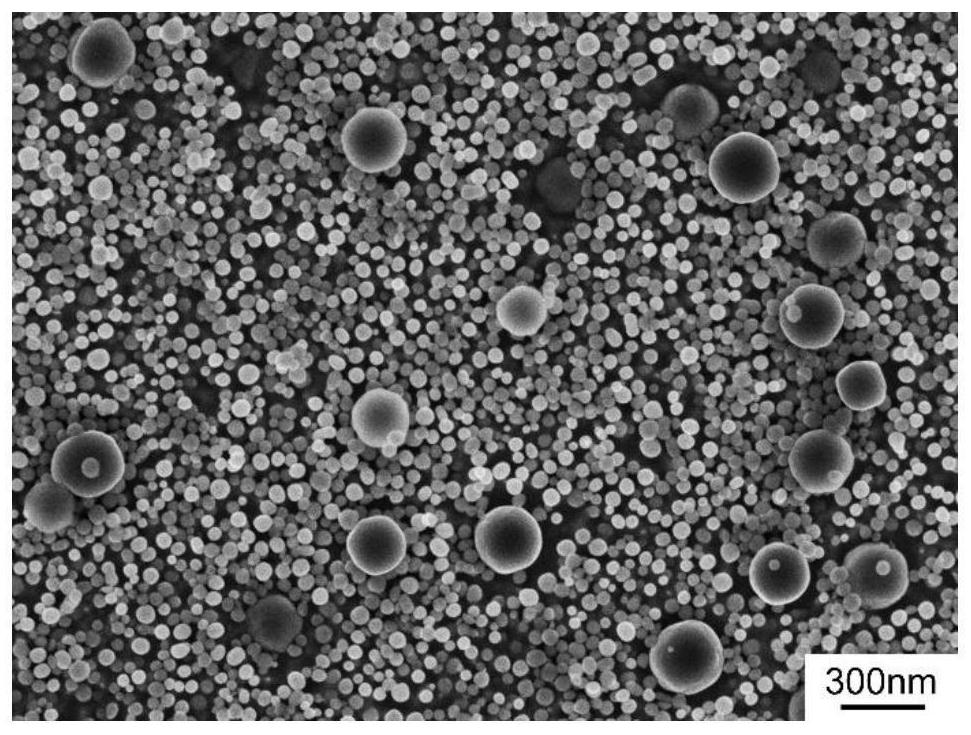

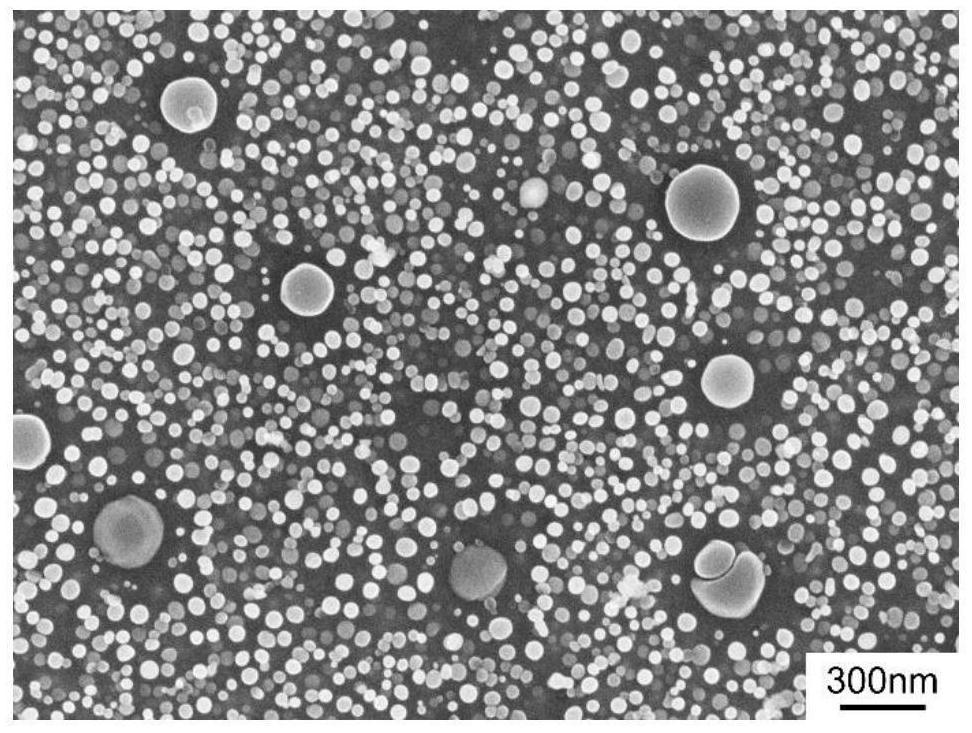

[0027] figure 2 , image 3 They are the γ′ phase distribu...

Embodiment 2

[0032] 1) Put the large-sized GH4738 alloy forging into the heating furnace for solution treatment: the heating furnace first raises the temperature to 820°C at a heating rate of 6°C / min, and keeps it for 50 minutes; then raises the temperature to 970°C at a heating rate of 5°C / min , hold for 40 minutes; then raise the temperature to 1030°C at a heating rate of 3°C / min, and hold for 40 minutes; after that, air is introduced into the heating furnace, and after cooling to below 500°C at a rate of 130-150°C / min, the alloy forging is taken out and air-cooled to room temperature.

[0033] 2) Put the GH4738 alloy forging after solution treatment in step 1) into a heating furnace for aging treatment: the heating furnace first raises the temperature to 710°C at a heating rate of 6°C / min, and keeps it for 30min; then heats it at a heating rate of 5°C / min The heating rate was raised to 760°C, kept for 8 hours, and then taken out and air-cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com