Stitch knitting non-weaving cloth for electrical tape base cloth and production method thereof

A non-woven fabric and stitch-bonded technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problems of vertical and horizontal tearing strength without a clear solution, and achieve convenient hand-tearing, low grammage, and uneven grammage low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

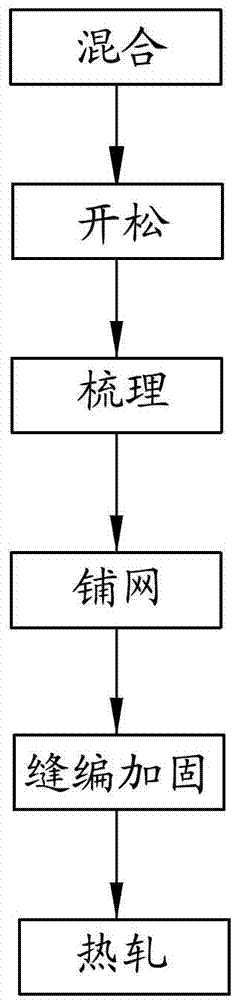

Method used

Image

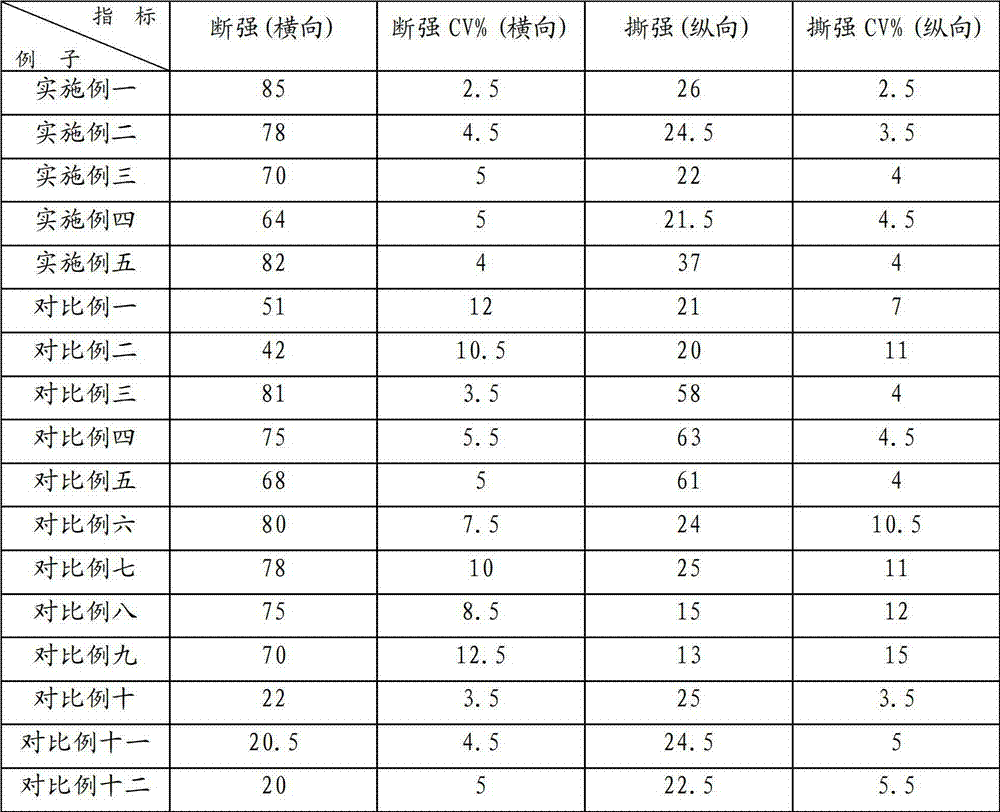

Examples

Embodiment 1

[0029] The present invention relates to a seam-bonded nonwoven fabric for electrical tape base fabric, which comprises 50 wt% of polyester staple fibers with a fiber fineness of 1.4D and a length of 51 mm and 50 wt% of polyester staple fibers with a fiber fineness of 2D and a length of 51 mm After the mixed fiber is used as the raw material to make the fiber web, the active warping method is used to reinforce the sutures with 75D / 72F fine denier polyester DTY filaments that have undergone a specific warping method. Then it is made by hot rolling process.

[0030] It should be noted that the polyester staple fiber with a specific fineness involved in the present invention is a polyester staple fiber with a fineness of 1.4D-15D, wherein the polyester staple fiber with a fineness of 1.4-2D and a length of 32-51mm and a fineness of 2D-2.5D and a length of The total content of polyester staple fibers with a size of 51-102mm is not less than 70%, and the content of polyester staple ...

Embodiment 2

[0039] The present invention relates to a seam-bonded nonwoven fabric for electrical tape base fabric, comprising 50wt% polyester staple fibers with a fiber fineness of 1.4D and a length of 51mm and 30wt% polyester staple fibers with a fiber fineness of 2D and a length of 51mm And 20wt% fiber fineness of 6D, length of 51mm polyester staple fiber mixed fiber as raw material to make fiber web, adopt the way of active warping, with 75D / 72F fine denier polyester DTY filament through specific warping method Reinforced sutures are stitched and reinforced on a stitch-bonding machine with adjusted technology and then made by hot rolling.

[0040] This embodiment also provides a method for preparing a seam-bonded nonwoven fabric for electrical tape base fabrics. After opening and carding polyester staple fibers of a specific denier, they are laminated to form a fiber web with a specific single-layer grammage. The warp let-off method uses fine-denier polyester filaments that have underg...

Embodiment 3

[0048] The present invention relates to a seam-bonded nonwoven fabric for electrical tape base cloth, with 40wt% polyester staple fibers with a fiber fineness of 2D and a length of 51mm and 40wt% fiber fineness of 2.5D, a length of 51mm and 20wt% fibers The mixed fiber of polyester staple fiber with a fineness of 15D and a length of 102mm is used as a raw material to make a fiber web, and the warp is actively let off, and the suture is reinforced with 75D / 72F fine denier polyester DTY filament after a specific warping method. It is stitched and strengthened on a stitch-bonding machine adjusted by the process, and then made by a hot-rolling process.

[0049] This embodiment also provides a method for preparing a seam-bonded nonwoven fabric for electrical tape base fabrics. After opening and carding polyester staple fibers of a specific denier, they are laminated to form a fiber web with a specific single-layer grammage. The warp let-off method uses fine-denier polyester filamen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com