Thermoshrinkable polyester film and preparation method thereof

A technology of polyester film and heat shrinkage, which is applied in the field of preparation of heat shrinkable polyester film, can solve the problems of uniformity decrease, low speed of production line, separation of raw materials, etc., and achieve the improvement of ductility and uniformity of heat shrinkage and uniformity of strength Improvement, intermolecular stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

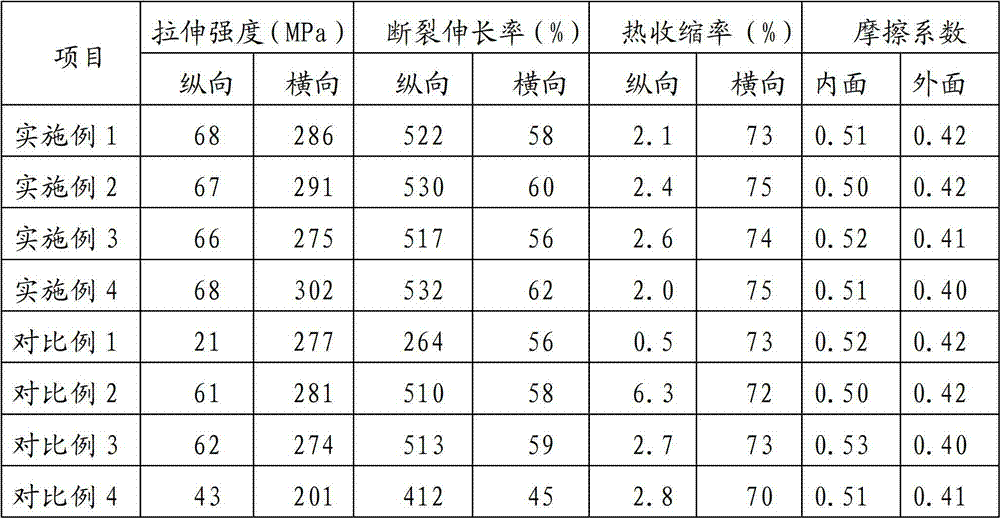

Examples

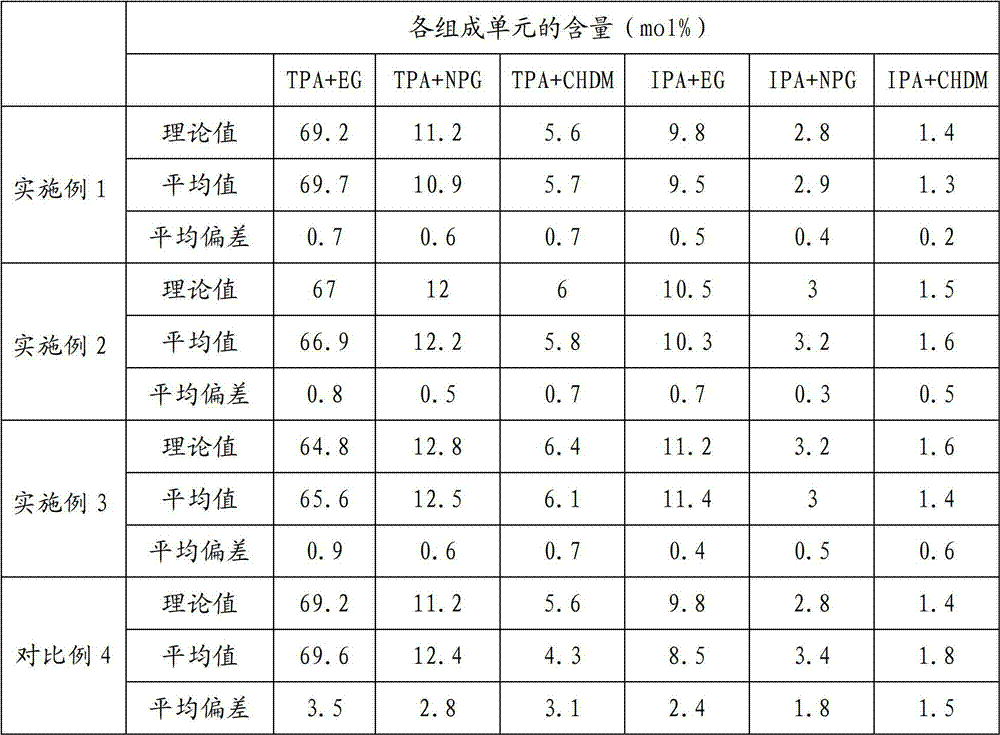

Embodiment 1

[0035] (1) Ingredients: The intrinsic viscosity is 0.8dl / g, 20% IPA, 80% TPA and 20% NPG, 10% CHDM, 70 %EG copolymerized PET copolyester and PET polyester are mixed according to the content ratio of 70wt% and 30wt% as the core layer raw material. PET copolyester and PET polyester containing 3000ppm anti-blocking agent silica with a particle size of 1.2μm are mixed according to the content ratio of 70wt% and 30wt% as the surface layer raw material. After the various polyester raw materials are dedusted, they enter their respective silos, and then pass through a buffer silo for buffering, and then are measured by the loss-in-weight scale according to the ratio of raw materials, and then enter the entrance of the twin-screw extruder through an accumulator at the same time. , The error range of the added amount of the material-to-feed ratio is ≤1%.

[0036] (2) Extrusion casting: Under the conditions of vacuum degree of 5mbar and extrusion temperature of 265°C, the homogeneously ...

Embodiment 2

[0040] (1) Ingredients: With an intrinsic viscosity of 0.85dl / g, 20% IPA, 80% TPA and 20% NPG, 10% CHDM, 70% EG copolymerized PET copolyester and PET polyester are mixed according to the content ratio of 75wt% and 25wt% as the core material. Mix PET copolyester with PET polyester containing 3300ppm anti-blocking agent calcium carbonate with a particle size of 2.8μm at a content ratio of 75wt% and 25wt%, as the surface layer raw material, and send it to the cyclone separator by vacuum suction. Dust removal, after dust removal, enters the respective silos respectively, and then after being buffered by a hose, after being measured by the weight loss scale according to the ratio of raw materials, at the same time, it enters the entrance of the twin-screw extruder through a funnel-shaped collector, and the materials The error range of the added amount of the feed ratio is ≤1%.

[0041] (2) Extruded cast sheet: Under the condition of vacuum degree of 4mbar and extrusion temperature...

Embodiment 3

[0045] (1) Ingredients: The intrinsic viscosity is 0.75dl / g, 20% IPA, 80% TPA and 20% NPG, 10% CHDM, 70 %EG copolymerized PET copolyester and PET polyester are mixed according to the content ratio of 80wt% and 20wt% as the core material. Mix PET copolyester and PET polyester containing 3000ppm anti-blocking agent silica with a particle size of 0.9μm at a content ratio of 80wt% and 20wt% as the surface layer raw materials, and send various raw materials by compressed air feeding To the cyclone separator for dust removal, after dust removal, they enter their respective silos, and then after being buffered by a buffer device, they are measured by their respective loss-in-weight scales according to the ratio of raw materials, and at the same time enter the twin-screw through a funnel-shaped collector. At the entrance of the extruder, the error range of the added amount of the material-to-feed ratio is ≤1%.

[0046] (2) Extrusion casting: Under the conditions of vacuum degree of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com