Patents

Literature

42results about How to "Longitudinal shrinkage is low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

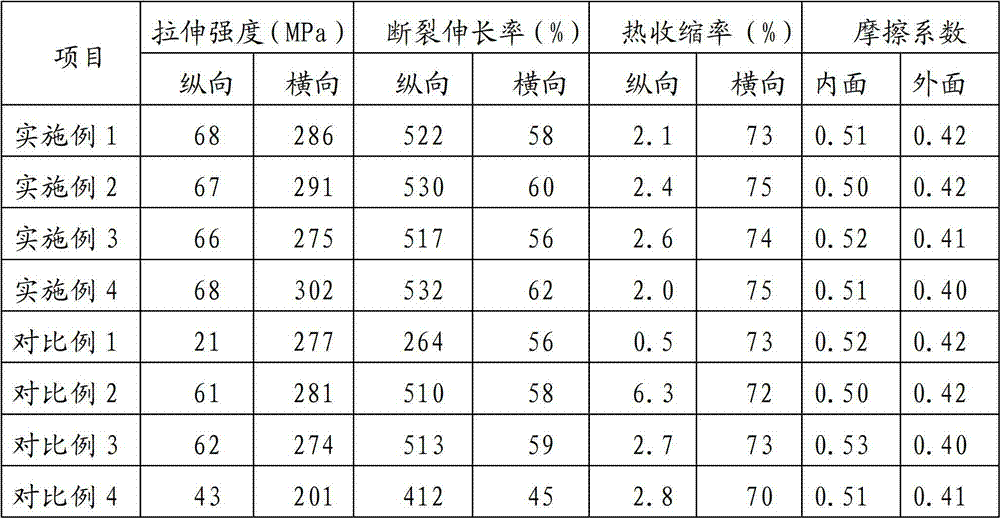

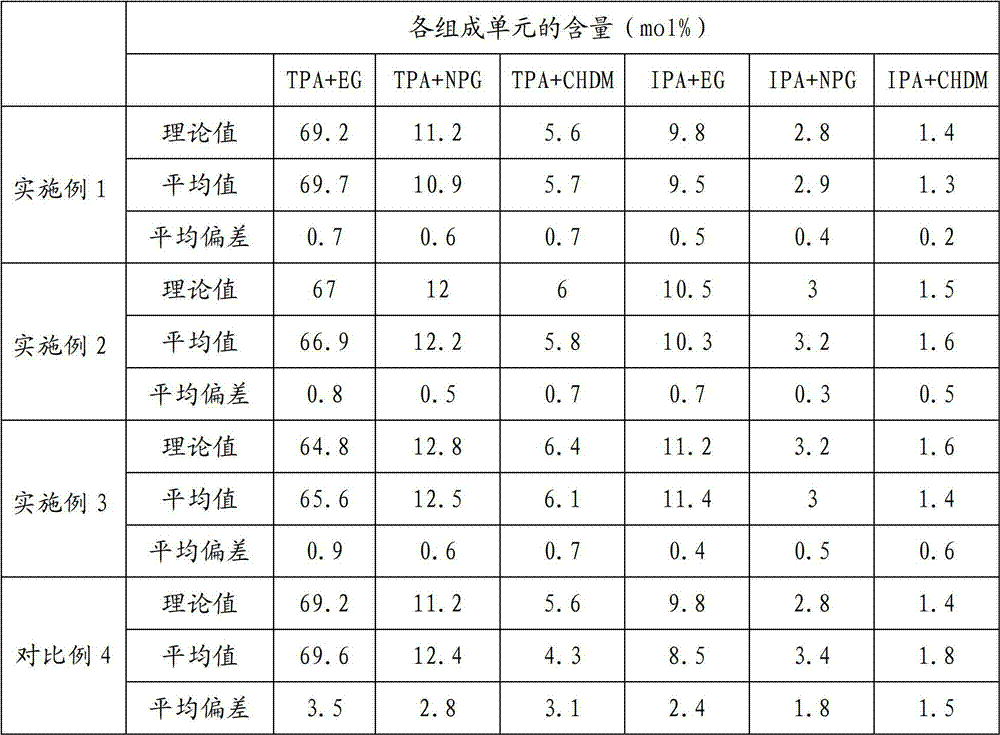

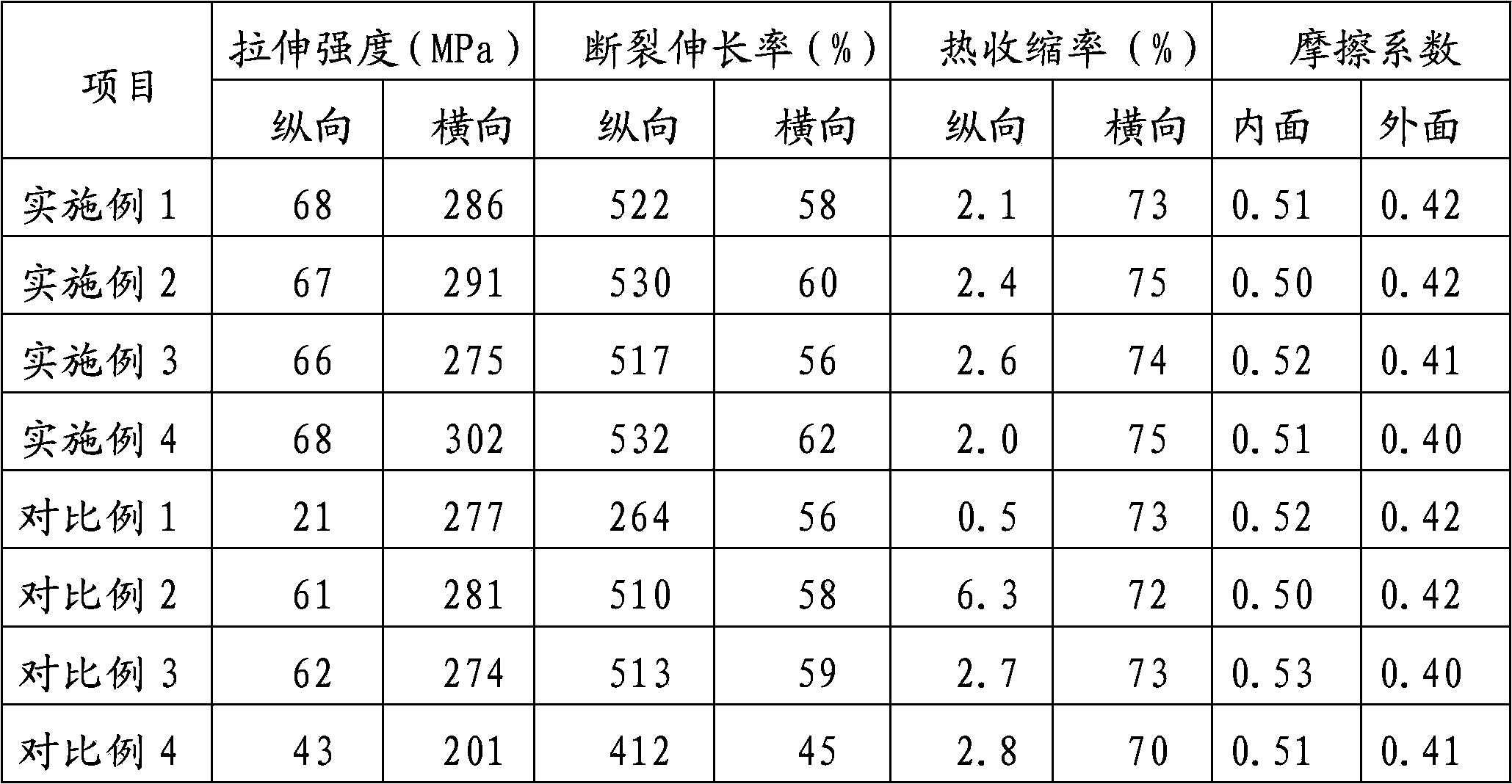

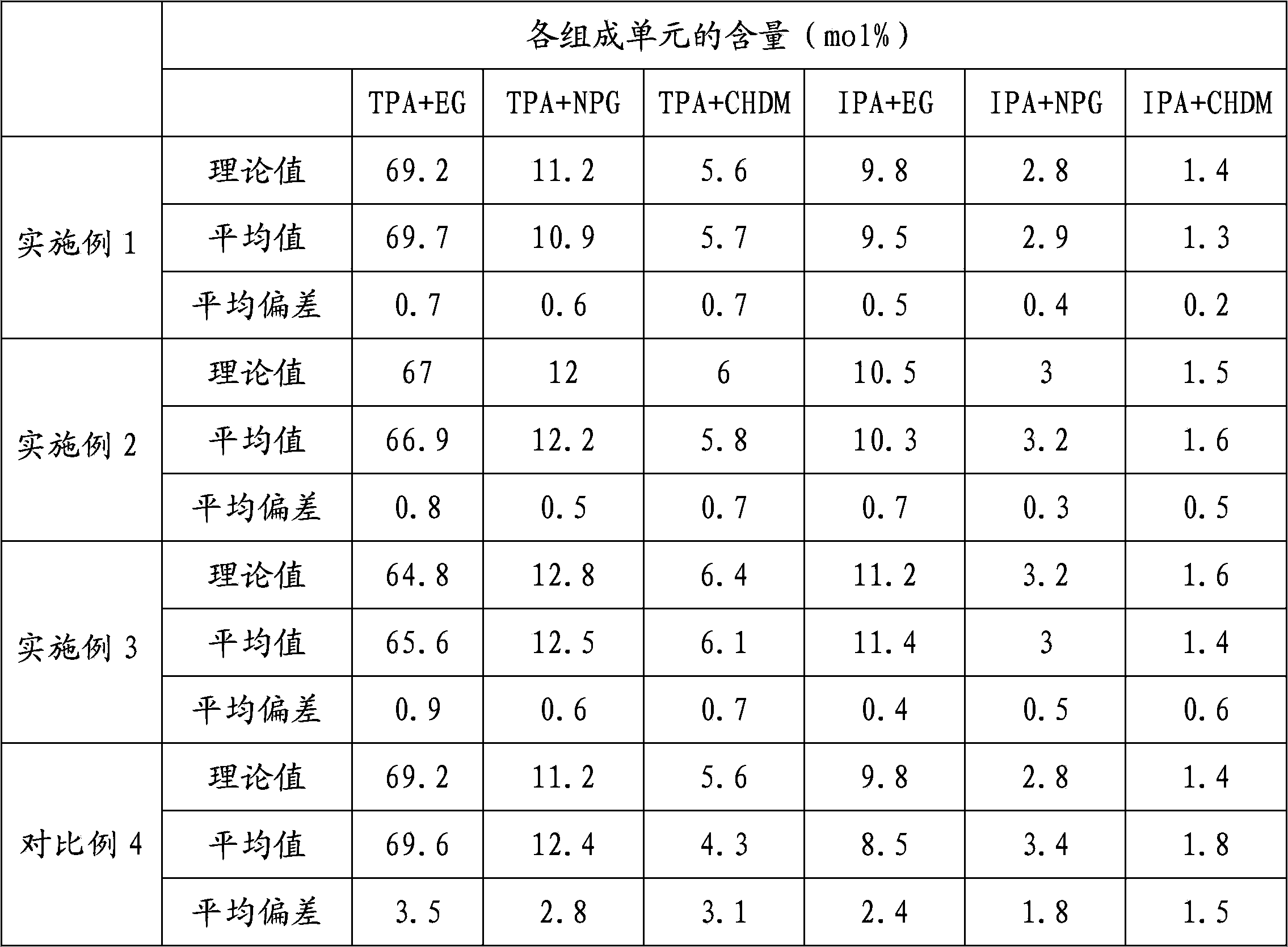

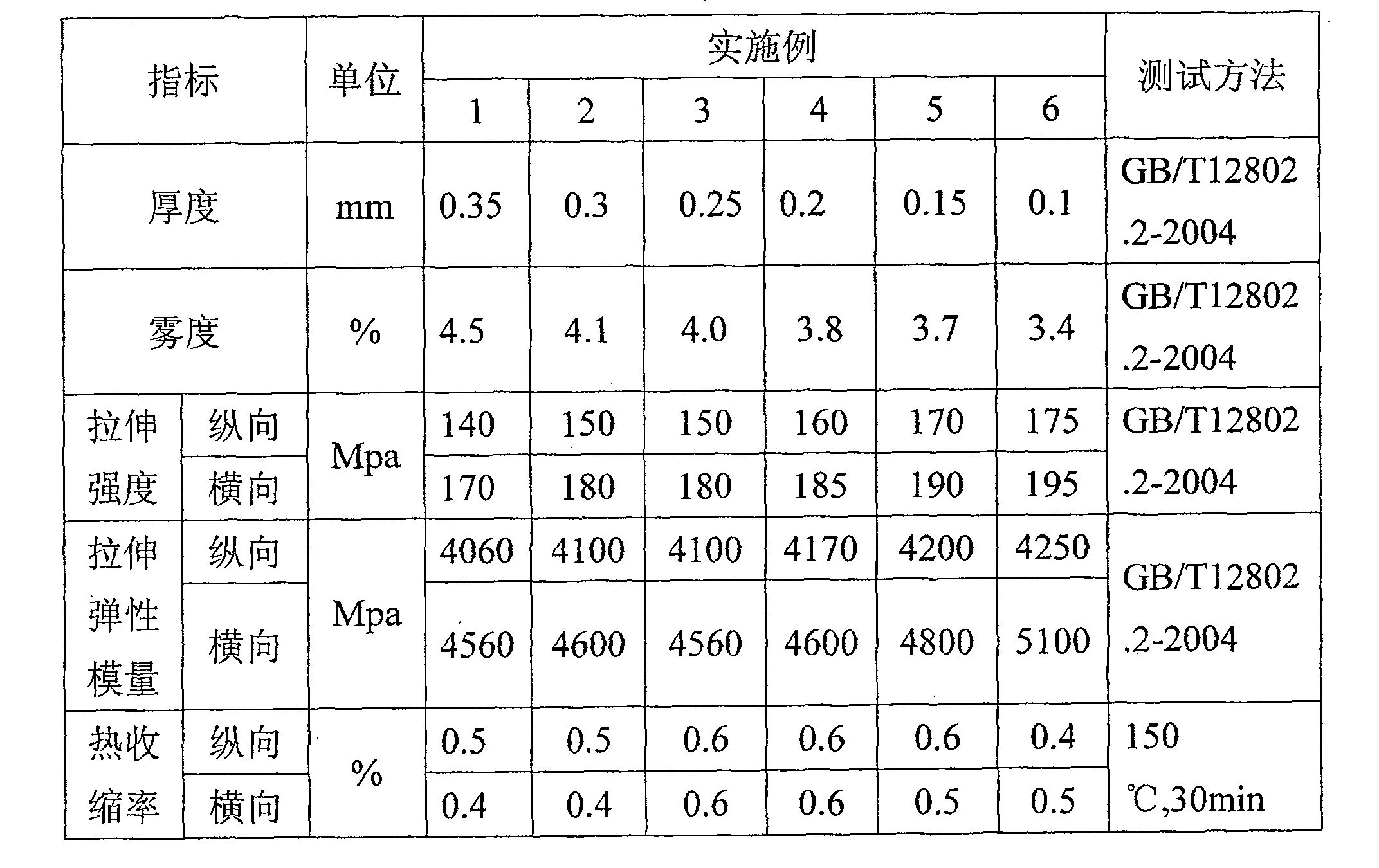

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

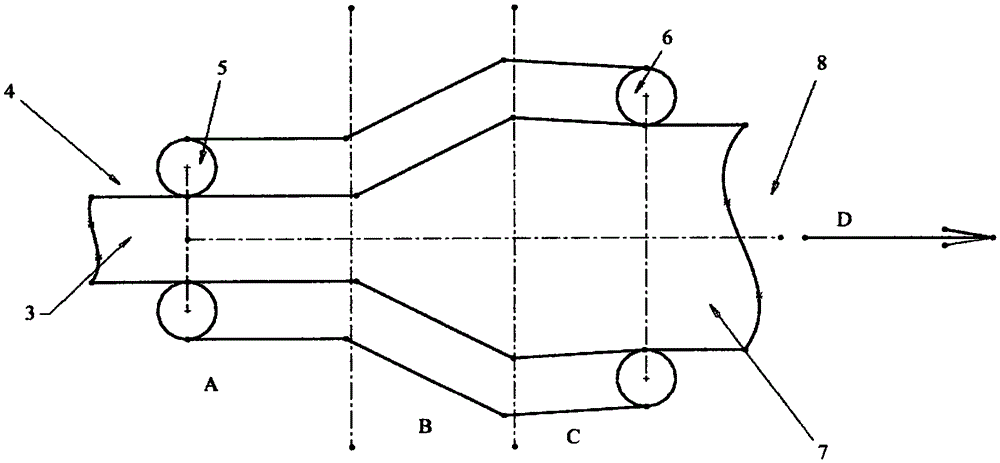

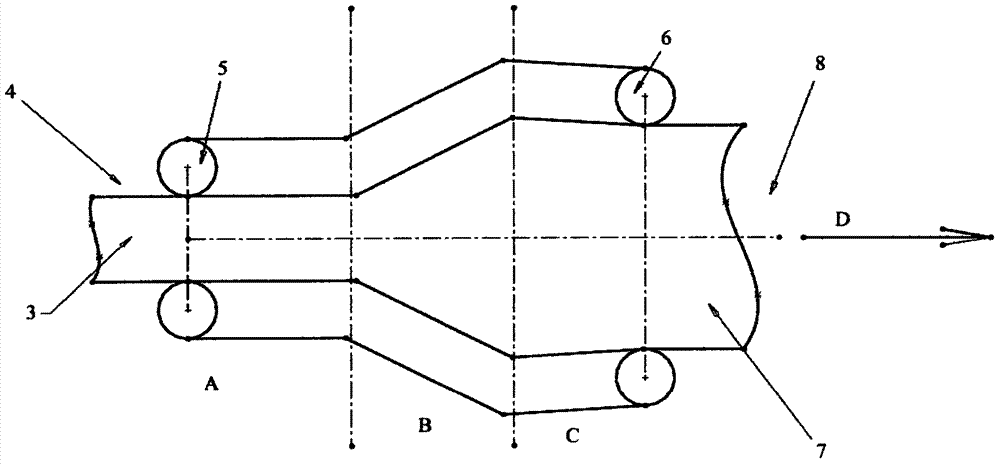

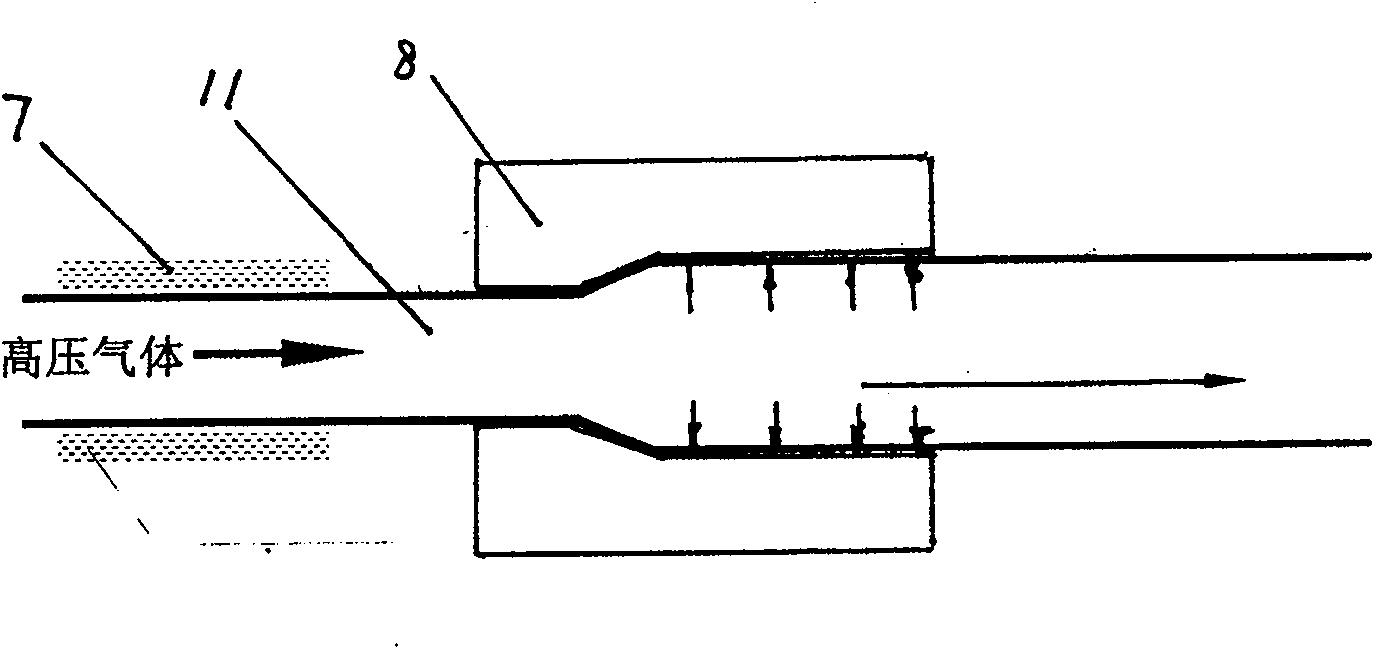

Overfeeding type thin film drawing process

ActiveCN105252752ALongitudinal shrinkage is lowLongitudinal shrinkage stepless adjustmentLongitudinal contractionMechanical engineering

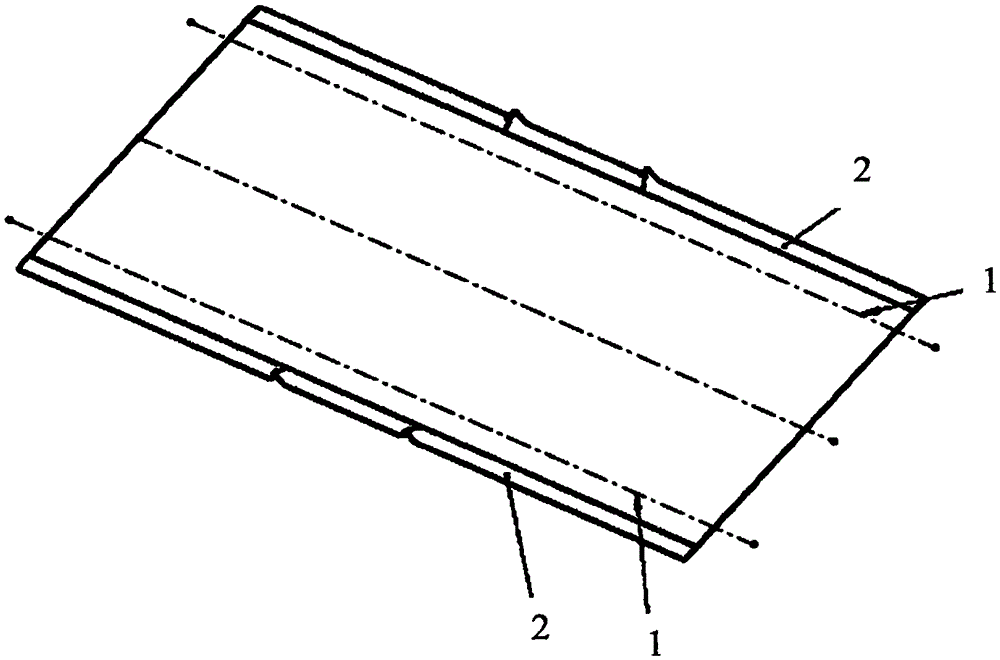

The invention discloses an overfeeding type thin film drawing process. In the thin film drawing process, the length of a thin film clamped by clamps is larger than the length of chain clamps of a drawing machine, redundant parts are formed between the length of the thin film and the length of the chain clamps in the film clamping, feeding and drawing process, and the redundant parts are accumulated in gaps between the clamps to form wrinkles. By the adoption of the overfeeding type thin film drawing process, the thin film is not accumulated in clamping sections of the clamps and only accumulated in the gaps between the front and back clamps, and when the transversely-drawn thin film shrinks longitudinally, the edges of the film do not shrink longitudinally at the clamping portions of the clamps, the portions, close to the inner side, of the thin film shrink longitudinally, and the longitudinal shrinkage ratio is reduced. The redundant parts, namely the wrinkles are reserved in clamping seams and cut off at the rear edge portion of a transversely-drawing outlet and are not components of products. By the adoption of the overfeeding type thin film drawing process, the stepless adjustment longitudinal shrinkage ratio can be acquired, so that the longitudinal shrinkage ratio of the transversely-drawn thin film is controlled within a controllable range.

Owner:北京华腾佳和科技有限公司 +1

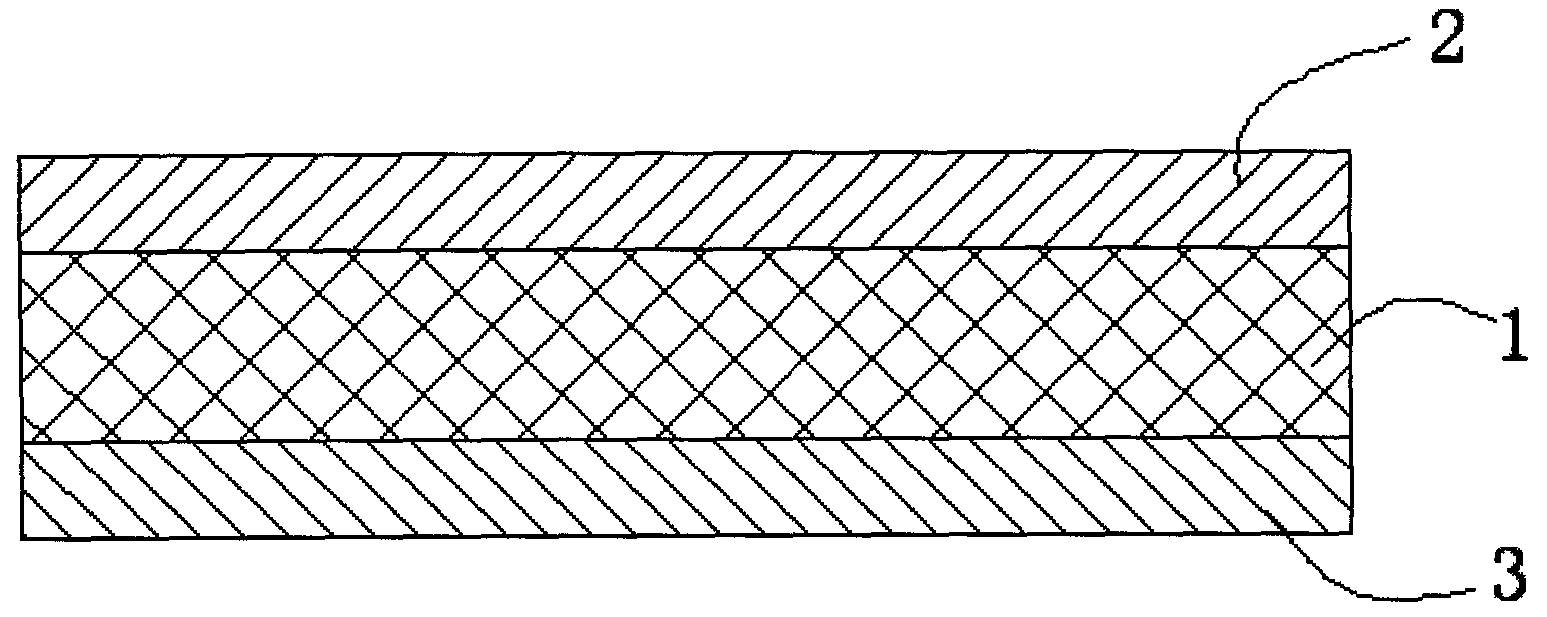

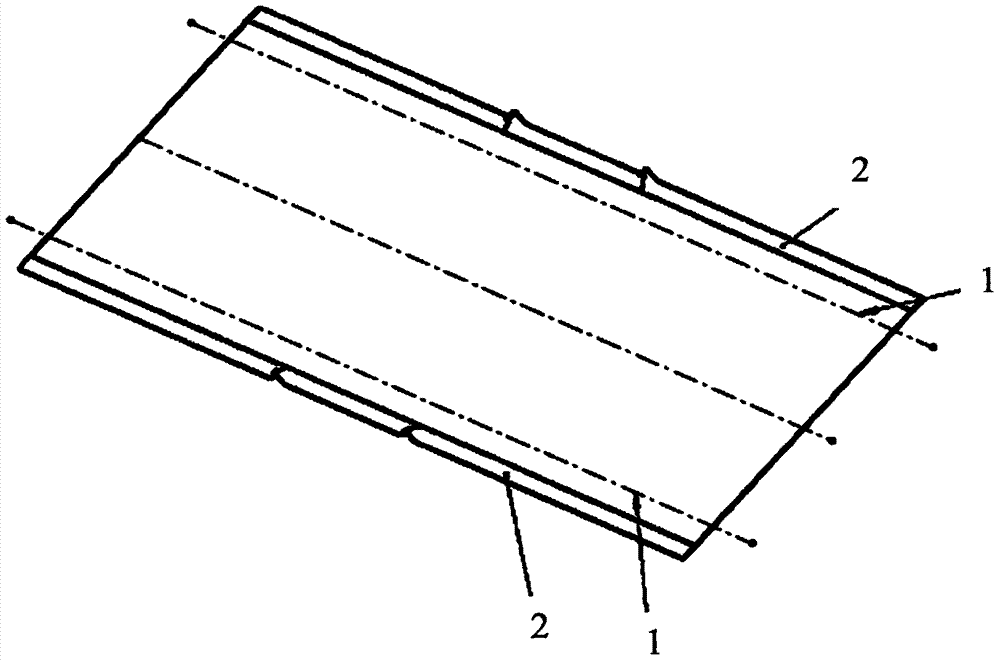

Low-shrinkage rate bidirectional stretching plastic thin film and preparation method thereof

InactiveCN103522713ALongitudinal shrinkage is lowLongitudinal shrinkage controlSynthetic resin layered productsWinding machineSurface layer

The invention discloses a low-shrinkage rate bidirectional stretching plastic thin film which comprises a core layer and also comprises an upper surface layer and a lower surface layer, wherein the upper surface layer and the lower surface layer are made of the following materials in parts by weight: 60 parts of polyethylene glycol terephthalate with the SiO2 content of 3,000 ppm and 40 parts of polyethylene glycol terephthalate. The preparation method for the low-shrinkage rate bidirectional stretching plastic thin film comprises the following steps of A. coextruding an upper surface layer material, a core layer material and a lower surface layer material after material mixing is executed; B. longitudinally stretching; C. transversely stretching, and cutting off two longitudinal edges of the film before the film is completely cooled; D. performing corona treatment on the film from a widening machine in a dragger, and winding the film from the dragger in a winding machine. The two longitudinal edges of the film are cut off before the film is completely cooled, so that the film can be shrunk to a certain extent in the longitudinal direction, and the longitudinal shrinkage rate can be reduced; furthermore, the film can be shrunk to a certain extent in the transverse direction during the longitudinal shrinkage of the film, and therefore, according to the method, the transverse shrinkage rate of the film can be controlled at the same time.

Owner:NINGBO DXC NEW MATERIAL TECH

Halogen-free double-wall heat shrinkable tube of flame-retardant properties and preparing method thereof

InactiveCN101759907ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinCombustion

The present invention relates to a heat shrinkable tube, particularly to a halogen-free double-wall heat shrinkable tube of flame-retardant properties and a preparing method thereof. The tube is prepared from an outer wall material and an inner wall material based on shares by weight. The outer wall material consists of 53 shares of first polyolefin mixed resin, 10 shares of first auxiliaries and 37 shares of flame retardant. The inner wall material consists of 53 shares of second polyolefin mixed resin, 10 shares of second auxiliaries and 37 shares of flame retardant. The preparing method comprises: preparing the inner and the outer wall materials of the double-wall heat shrinkable tube, extruding, irradiating, expanding and molding. Compared with traditional shrinkable tubes, the present invention has the technical characteristics of adoption of special halogen-free flame retardant in raw materials, good product flame-retardant effect, heat resistance, good properties, no pollution during combustion and low cost. The present invention has obvious economic benefit and environmental protection benefit, and is suitable for large-scale popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

High-voltage halogen-free flame-retardant double-wall heat shrinkage tube and preparation method thereof

ActiveCN101696298ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinEconomic benefits

The invention relates to a heat shrinkage tube, in particular to a high-voltage halogen-free flame-retardant heat-shrinkage tube and a preparation method thereof. The high-voltage halogen-free flame-retardant double-wall heat shrinkage tube comprises an outer-wall material and an inner-wall material; wherein the outer-wall material comprises the following ingredients in parts by weight: 80 parts of first polyolefin mixed resin, 10 parts of first auxiliary agent, 5 parts of flame retardant and 5 parts of auxiliary flame retardant; the inner-wall material comprises the following ingredients in parts by weight: 80 parts of second polyolefin mixed resin, 10 parts of second auxiliary agent, 5 parts of flame retardant and 5 parts of auxiliary flame retardant; and the preparation method comprises the following steps of: preparing the inner-wall material and the outer-wall material of the double-wall heat shrinkage tube, extruding, irradiating, expanding and molding. Compared with the traditional heat-shrinkage tube, the high-voltage halogen-free flame-retardant double-wall heat shrinkage tube has the technical characteristics that: as the flame retardant and the auxiliary flame retardant are adopted in the raw materials, the product has good flame retarding effect, high-temperature resistance, favorable performance, no pollution even in the combustion process, reduced cost, remarkable economic benefit and environment-friendly benefit and is suitable for large-scale popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Semiconduction medium and low voltage halogen-free flame retardant single-wall heat-shrinkable tube and preparation method thereof

InactiveCN101759901ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinLow voltage

The invention relates to a heat-shrinkable tube, in particular to a semiconduction medium and low voltage halogen-free flame retardant single-wall heat-shrinkable tube and a preparation method thereof. The heat-shrinkable tube consists of a wall, and materials of the wall comprise the following raw materials in parts by weight: 70 parts of polyolefin mixed resin, 10 parts of conductive carbon black, 10 parts of auxiliary agent, 20 parts of flame retardant and 10 parts of auxiliary flame retardant. The preparation method comprises the following steps of: preparing an inner wall material of the single-wall heat-shrinkable tube; extruding; irradiating; expanding; and molding. Compared with the traditional shrinkable tubes, the single-wall heat-shrinkable tube has the technical characteristics that the halogen-free flame retardant is adopted in the raw materials, and the product has good flame retardant effect, high temperature resistance, no pollution during combustion and reduced cost, is suitable for working under a high-voltage condition of 10kV, has obvious economic benefits and environmental protection benefits and is suitable for large-scale popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Low-voltage halogen-free retarding two-wall heat-shrinkage tube and preparation method thereof

ActiveCN101696301ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinCombustion

The invention relates to a heat-shrinkage tube, in particular to a low-voltage halogen-free retarding two-wall heat-shrinkage tube and a preparation method thereof. The low-voltage halogen-free retarding two-wall heat-shrinkage tube comprises an outer wall material and an inner wall material, wherein the outer wall material comprises 60 parts by mass of first polyolefin mixed resin, 10 parts by mass of first assistant, 20 parts by mass of fire retardant and 10 parts by mass of auxiliary fire retardant; and the inner wall material comprises 60 parts by mass of second polyolefin mixed resin, 10 parts by mass of second assistant, 20 parts by mass of fire retardant and 10 parts by mass of auxiliary fire retardant. The preparation method comprises the following steps of preparing, extruding, radiating and expanding to form the inner wall material and the outer wall material of the two-wall heat-shrinkage tube. Compared with the traditional heat-shrinkage tube, the invention has the technical characteristics that because the fire retardant and the auxiliary fire retardant are adopted in the raw materials, the low-voltage halogen-free retarding two-wall heat-shrinkage tube has good retarding property, high temperature resistance, better property, no pollution in combustion, cost reduction and remarkable economic and environmental-friendly benefits, and is suitable for massive popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Semiconducting halogen-free flame retardant double-wall heat-shrinkable tube and preparation method thereof

InactiveCN101701089ANo pollution in the processImprove flame retardant performanceCable junctionsPolyolefinEconomic benefits

The invention relates to a heat-shrinkable tube, in particular to a semiconducting halogen-free flame retardant double-wall heat-shrinkable tube and a preparation method thereof. The tube consists of an outer wall material and an inner wall material. In parts by weight, the outer wall material contains 43 parts of first polyolefin mixed resin, 10 parts of graphitized carbon black, 10 parts of first assistant and 37 parts of flame retardant, and the inner wall material contains 53 parts of second polyolefin mixed resin, 10 parts of second assistant and 37 parts of flame retardant. The preparation method comprises the following steps of: preparing the inner and the outer wall materials of the double-wall heat-shrinkable tube, extruding, irradiating and expanding molding. Compared with traditional shrinkable tubes, the double-wall heat-shrinkable tube has the technical characteristics that the special halogen-free flame retardant is employed in the raw material, and therefore, products have good flame retardant effect, high temperature resistance and good performance, and the pollution can not be generated even if the products are burnt; the cost is lowered, obvious economic benefits and environmental protection effects are obtained, thereby being suitable for large-scale popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Semiconductor high-pressure single-wall heat-shrinkable tube and preparation method thereof

ActiveCN101701092ALongitudinal shrinkage is lowStable expansionCable junctionsPolyolefinHigh pressure

The invention relates to a heat-shrinkable tube, in particular to a semiconductor high-pressure single-wall heat-shrinkable tube and a preparation method thereof. The Semiconductor high-pressure single-wall heat-shrinkable tube is prepared from a wall material which comprises the following components in parts by weight: 90 parts of mixed polyolefin resin, 10 parts of conductive carbon black and 10 parts of auxiliary agent. The preparation method comprises the following steps of: the preparation of the wall material of the semiconductor high-pressure single-wall heat-shrinkable tube; extrusion; irradiation; and extending and molding. Compared with conventional shrinkable tubes, the semiconductor high-pressure single-wall heat-shrinkable tube keeps the characteristics of good electrical property, chemical property, and the like of ordinary heat-shrinkable tubes, and has all use properties of the ordinary heat-shrinkable tubes and the properties of water proofing, sealing, damp proofing, and the like.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Semiconductor low-pressure halogen free flame retardant single-wall heat-shrinkable tube and preparation method thereof

ActiveCN101701087ANo pollution in the processImprove flame retardant performanceCable junctionsPolyolefinEconomic benefits

The invention relates to a heat-shrinkable tube, in particular to a semiconductor low-pressure halogen free flame retardant single-wall heat-shrinkable tube and a preparation method thereof. The heat-shrinkable tube consists of a wall which is prepared from the following components in parts by weight: 60 parts of mixed polyolefin resin, 10 parts of conductive carbon black, 10 parts of auxiliary agent, 20 parts of flame retardant and 10 parts of auxiliary flame retardant. The preparation method comprises the following steps of: preparation of an inner wall material of the single-wall heat-shrinkable tube; extrusion; irradiation; and extending and molding. Compared with conventional shrinkable tubes, due to the adoption of the halogen free flame retardant in the raw materials, the heat-shrinkable tube has the characteristics of good flame retardant effect, high temperature resistance, good performance, no pollution even when burnt, cost reduction, obvious economic benefit and environment protection benefit and is suitable for being popularized and applied in a large scale.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

Semiconducting flame retardant single-wall heat-shrinkable tube and preparation method thereof

InactiveCN101701086AImprove flame retardant performanceLongitudinal shrinkage is lowCable junctionsPolyolefinCompound (substance)

The invention relates to a heat-shrinkable tube, in particular to a semiconducting flame retardant single-wall heat-shrinkable tube and a preparation method thereof. The semiconducting flame retardant single-wall heat-shrinkable tube consists of a wall material. In parts by weight, the wall material contains 50 parts of polyolefin mixed resin, 10 parts of graphitized carbon black, 20 parts of assistant and 30 parts of flame retardant. The preparation method comprises the following steps of: preparing the inner and the outer wall materials of the flame retardant single-wall heat-shrinkable tube, extruding, irradiating and expanding molding. Compared with traditional shrinkable tubes, the single-wall heat-shrinkable tube has the technical characteristics that the wall material has the flame retardant performance, the outer layer keeps the characteristics of good electrical properties, chemical properties and the like of common heat-shrinkable tubes; and the single-wall heat-shrinkable tube has all use characteristics of the common heat-shrinkable tubes and also has the performances of water proofing, sealing, moisture proofing, corrosion prevention and the like.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Flame-retarding single-wall heat-shrinkable tube and preparation method thereof

InactiveCN101696300BImprove flame retardant performanceHigh strengthCable junctionsPolyolefinFire retardant

Owner:江苏达胜热缩防护用品有限公司

Semi-conducting halogen-free fire retardant single-wall heat-shrinkable tube and preparation method thereof

ActiveCN101696295ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinEconomic benefits

The invention relates to a heat-shrinkable tube, in particular to a semi-conducting halogen-free fire retardant single-wall heat-shrinkable tube and a preparation method thereof. The semi-conducting fire retardant single-wall heat-shrinkable tube comprises wall materials which contain the following raw materials in parts by mass: 53 parts of polyolefin mixed resin, 10 parts of conductive black, 10 parts of assistants and 37 parts of fire retardant. The preparation method of the heat-shrinkable tube comprises the following steps of wall material preparation, extrusion, irradiation and expansion-moulding. Compared with a traditional heat-shrinkable tube, the invention has the technical characteristics that since special halogen-free fire retardant is adopted in the raw materials, the semi-conducting halogen-free fire retardant single-wall heat-shrinkable tube has better fire retardant effect, high-temperature resistant character and good performances, no pollution after burnt, cost reduction, remarkable economic benefits and environmental protection benefits; therefore, the invention is suitable for mass promotion and application.

Owner:江苏达胜热缩防护用品有限公司

Medium and low pressure flame retardant single wall thermal shrinkage pipe and preparation method thereof

ActiveCN101698719AMake up for the shortcomings of not being able to waterproof and sealHave all the performanceCable junctionsPolyolefinShrinkage rate

The invention relates to a thermal shrinkage pipe, in particular to a medium and low pressure flame retardant single wall thermal shrinkage pipe and a preparation method thereof. The medium and low pressure flame retardant single wall thermal shrinkage pipe is made from a wall material which comprises 70 parts of polyolefin mixed resin, 10 parts of auxiliary agent and 30 parts of flame retardant by weight. The preparation method comprises the following steps: preparing the inner wall material of the flame retardant single wall thermal shrinkage pipe, extruding, irradiating and expanding for molding. Compared with the traditional shrinkage pipe, the invention has the technical characteristics that the wall material has flame resistance and can be applied under 10kV high voltage, and the medium and low pressure flame retardant single wall thermal shrinkage pipe not only has all operational properties of the common thermal shrinkage pipe, but also has the properties of water prevention, sealing, moisture prevention, corrosion prevention and the like; and the shrinkage pipe fully meets the environmental requirements of the ROHS instructions of European Union and other countries, and has the advantages of low temperature shrinkage, 3-4 times stable expansion, low longitudinal shrinkage rate, and the like.

Owner:江苏达胜热缩防护用品有限公司

Semi-conducting high-voltage fire retardant single-wall heat-shrinkable tube and preparation method thereof

ActiveCN101696294AMake up for the shortcomings of not being able to waterproof and sealHave all the performanceCable junctionsPolyolefinEngineering

The invention relates to a heat-shrinkable tube, in particular to a semi-conducting high-voltage fire retardant single-wall heat-shrinkable tube and a preparation method thereof. The semi-conducting high-voltage fire retardant single-wall heat-shrinkable tube is made of wall materials, wherein an external wall material contains the following raw materials in parts by mass: 90 parts of polyolefin mixed resin, 10 parts of conductive black, 10 parts of assistants and 30 parts of fire retardant. The preparation method of the heat-shrinkable tube comprises the following steps of preparation of internal and external wall materials, extrusion, irradiation and expansion-moulding. Compared with a traditional heat-shrinkable tube, the invention has the technical characteristics that the wall materials are fire retardant, and the heat-shrinkable tube is applied to a 35 kV high voltage, has all the service performances of the traditional heat-shrinkable tube and also has watertightness, leakproofness, corrosion-resistance and dampproof performance; in addition, the heat-shrinkable tube completely meets the environmental protection requirement of ROHS of countries of European Union and has the advantages of low-temperature shrinkage, three-time to four-time stable expansion, low longitudinal shrinking rate and the like.

Owner:江苏达胜热缩防护用品有限公司

Medium and low pressure flame retardant single wall thermal shrinkage pipe and preparation method thereof

InactiveCN101698719BMake up for the shortcomings of not being able to waterproof and sealHave all the performanceCable junctionsPolyolefinShrinkage rate

The invention relates to a thermal shrinkage pipe, in particular to a medium and low pressure flame retardant single wall thermal shrinkage pipe and a preparation method thereof. The medium and low pressure flame retardant single wall thermal shrinkage pipe is made from a wall material which comprises 70 parts of polyolefin mixed resin, 10 parts of auxiliary agent and 30 parts of flame retardant by weight. The preparation method comprises the following steps: preparing the inner wall material of the flame retardant single wall thermal shrinkage pipe, extruding, irradiating and expanding for molding. Compared with the traditional shrinkage pipe, the invention has the technical characteristics that the wall material has flame resistance and can be applied under 10kV high voltage, and the medium and low pressure flame retardant single wall thermal shrinkage pipe not only has all operational properties of the common thermal shrinkage pipe, but also has the properties of water prevention, sealing, moisture prevention, corrosion prevention and the like; and the shrinkage pipe fully meets the environmental requirements of the ROHS instructions of European Union and other countries, and has the advantages of low temperature shrinkage, 3-4 times stable expansion, low longitudinal shrinkage rate, and the like.

Owner:江苏达胜热缩防护用品有限公司

Semiconduction high-voltage halogen-free flame retardant single-wall heat-shrinkable tube and preparation method thereof

InactiveCN101759908BNo pollution in the processImprove flame retardant performanceCable junctionsPolyolefinTemperature resistance

The invention relates to a heat-shrinkable tube, in particular to a semiconduction high-voltage halogen-free flame retardant single-wall heat-shrinkable tube and a preparation method thereof. The heat-shrinkable tube consists of a wall, and materials of the wall comprise the following raw materials in parts by weight: 80 parts of polyolefin mixed resin, 10 parts of conductive carbon black, 10 parts of auxiliary agent, 20 parts of flame retardant and 10 parts of auxiliary flame retardant. The preparation method comprises the following steps of: preparing the material of the inner wall of the single-wall heat-shrinkable tube; extruding; irradiating; expanding; and molding. Compared with the traditional shrinkable tubes, the single-wall heat-shrinkable tube has the technical characteristics that the halogen-free flame retardant is adopted in the raw materials, and the product has good flame retardant effect, high temperature resistance, no pollution during combustion and reduced cost, issuitable for working under a high-voltage condition of 35kV, has obvious economic benefits and environment protection benefits and is suitable for large-scale popularization and application.

Owner:江苏达胜热缩防护用品有限公司

Strong halogen-free flame-retardant single-wall heat-shrinkable tube and preparation method thereof

InactiveCN104059280ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinCombustion

The invention relates to a heat-shrinkable tube, and particularly relates to a strong halogen-free flame-retardant single-wall heat-shrinkable tube and a preparation method thereof. The heat-shrinkable tube comprises wall materials which is composed of, by mass, 50 parts of polyolefin mixed resin, 10 parts of an auxiliary agent, 30 parts of a flame retardant, and 10 parts of an auxiliary flame retardant; the preparation method comprises the steps of preparation of the inner wall material of the single-wall heat-shrinkable tube, extrusion, irradiation, and expansion moulding. When compared with technical characteristics of conventional shrinkable tubes, the heat-shrinkable tube of the invention adopts the flame retardant and the auxiliary flame retardant in the raw materials, is good in flame retardance, resistant to high temperature, and good in performance, causes no pollution even during combustion, is low in cost, has significant economic benefit and environment protection benefit, and is suitable for large-scale popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Middle and low-pressure halogen-free flame retarding single-wall heat-shrinkable tube and manufacturing method thereof

ActiveCN101759904ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsCombustionPulp and paper industry

The invention relates to a heat-shrinkable tube, in particular to a middle and low-pressure halogen-free flame-retarding single-wall heat-shrinkable tube and a manufacturing method thereof. The tube is composed of a wall. The material of the comprises the following components by mass: 70 portions of polyolefine mixed resin, 10 portions of auxiliary agent, 20 portions of flame retardant and 10 portions of auxiliary flame retardant. The manufacturing method comprises the step of preparing the inner wall material of the single-wall heat-shrinkable tube, extruding, radiating, expanding and forming. Compared with the traditional technology for manufacturing heat-shrinkable tube, the invention has the characteristics that the halogen-free flame retardant is adopted, the product has good flame retardant effectiveness, high temperature resistance, no pollution even in combustion and low cost; the product is applicable to operating under the conditions of 10 kV, has significant economical benefits and environment protection benefits, and is suitable for large-scale popularization and application.

Owner:江苏达胜热缩防护用品有限公司

Semiconductor single-wall thermal shrinkage pipe and preparation method thereof

InactiveCN101696297BHigh strengthLongitudinal shrinkage is lowCable junctionsPolyolefinSemiconductor

The invention relates to a thermal shrinkage pipe, in particular to a semiconductor single-wall thermal shrinkage pipe and a preparation method thereof. The semiconductor single-wall thermal shrinkage pipe is made of a wall material which comprises the following components in parts by mass: 80 parts of polyolefin mixed resin, 10 parts of graphitized carbon black and 20 parts of addition agent. The preparation method comprises the following steps of: preparing the wall material of the semiconductor single-wall thermal shrinkage pipe, extruding, irradiating, expanding and forming. Compared witha traditional shrinkage pipe, the invention has the technical characteristics that the outer layer of the thermal shrinkage pipe remains favorable electrical property, chemical property and other characters of a common thermal shrinkage pipe; in addition, the semiconductor single-wall thermal shrinkage pipe not only has all service performances of the common thermal shrinkage pipe, but also has the performance such as waterproofness, sealability, dampproofness, corrosion prevention, and the like.

Owner:江苏达胜热缩防护用品有限公司

A kind of super-feeding film stretching process

ActiveCN105252752BLongitudinal shrinkage is lowLongitudinal shrinkage stepless adjustmentEngineeringMechanical engineering

The invention discloses an overfeeding type thin film drawing process. In the thin film drawing process, the length of a thin film clamped by clamps is larger than the length of chain clamps of a drawing machine, redundant parts are formed between the length of the thin film and the length of the chain clamps in the film clamping, feeding and drawing process, and the redundant parts are accumulated in gaps between the clamps to form wrinkles. By the adoption of the overfeeding type thin film drawing process, the thin film is not accumulated in clamping sections of the clamps and only accumulated in the gaps between the front and back clamps, and when the transversely-drawn thin film shrinks longitudinally, the edges of the film do not shrink longitudinally at the clamping portions of the clamps, the portions, close to the inner side, of the thin film shrink longitudinally, and the longitudinal shrinkage ratio is reduced. The redundant parts, namely the wrinkles are reserved in clamping seams and cut off at the rear edge portion of a transversely-drawing outlet and are not components of products. By the adoption of the overfeeding type thin film drawing process, the stepless adjustment longitudinal shrinkage ratio can be acquired, so that the longitudinal shrinkage ratio of the transversely-drawn thin film is controlled within a controllable range.

Owner:北京华腾佳和科技有限公司 +1

Middle and low-pressure halogen-free flame retarding single-wall heat-shrinkable tube and manufacturing method thereof

InactiveCN101759904BNo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsCombustionPulp and paper industry

The invention relates to a heat-shrinkable tube, in particular to a middle and low-pressure halogen-free flame-retarding single-wall heat-shrinkable tube and a manufacturing method thereof. The tube is composed of a wall. The material of the comprises the following components by mass: 70 portions of polyolefine mixed resin, 10 portions of auxiliary agent, 20 portions of flame retardant and 10 portions of auxiliary flame retardant. The manufacturing method comprises the step of preparing the inner wall material of the single-wall heat-shrinkable tube, extruding, radiating, expanding and forming. Compared with the traditional technology for manufacturing heat-shrinkable tube, the invention has the characteristics that the halogen-free flame retardant is adopted, the product has good flame retardant effectiveness, high temperature resistance, no pollution even in combustion and low cost; the product is applicable to operating under the conditions of 10 kV, has significant economical benefits and environment protection benefits, and is suitable for large-scale popularization and application.

Owner:江苏达胜热缩防护用品有限公司

Method for producing thick low hot shrinkage rate polyester film

ActiveCN100496948CLongitudinal shrinkage is lowIncrease relaxation processFlat articlesPolyesterShrinkage rate

The process of producing thick polyester film with low thermal shrinkage rate includes the following steps: 1. melting material, extruding thick sheet and cooling; 2. stripping thick sheet, heating, longitudinally stretching in the line speed of 0.2-1.1 m / s and stretching power of 2.0-3.5 to 1, longitudinally relaxing and fixing; 3. preheating, transversely stretching at 110-160 deg.c and in stretching power of 3.0-5.0 to 1, longitudinally and transversely relaxing, and fixing; 4. cooling in the line speed lower than line speed in transverse stretching, heating, longitudinally post-relaxing, cooling and fixing; 5. high voltage corona treatment; and 6. winding the film in the line speed lower than the longitudinally relaxing line speed and in the tension controlled in 100-250 N. The process can reduce the longitudinal thermal shrinkage rate to near to or equal to the transverse thermal shrinkage rate.

Owner:JIANGSU YUXING FILM TECH

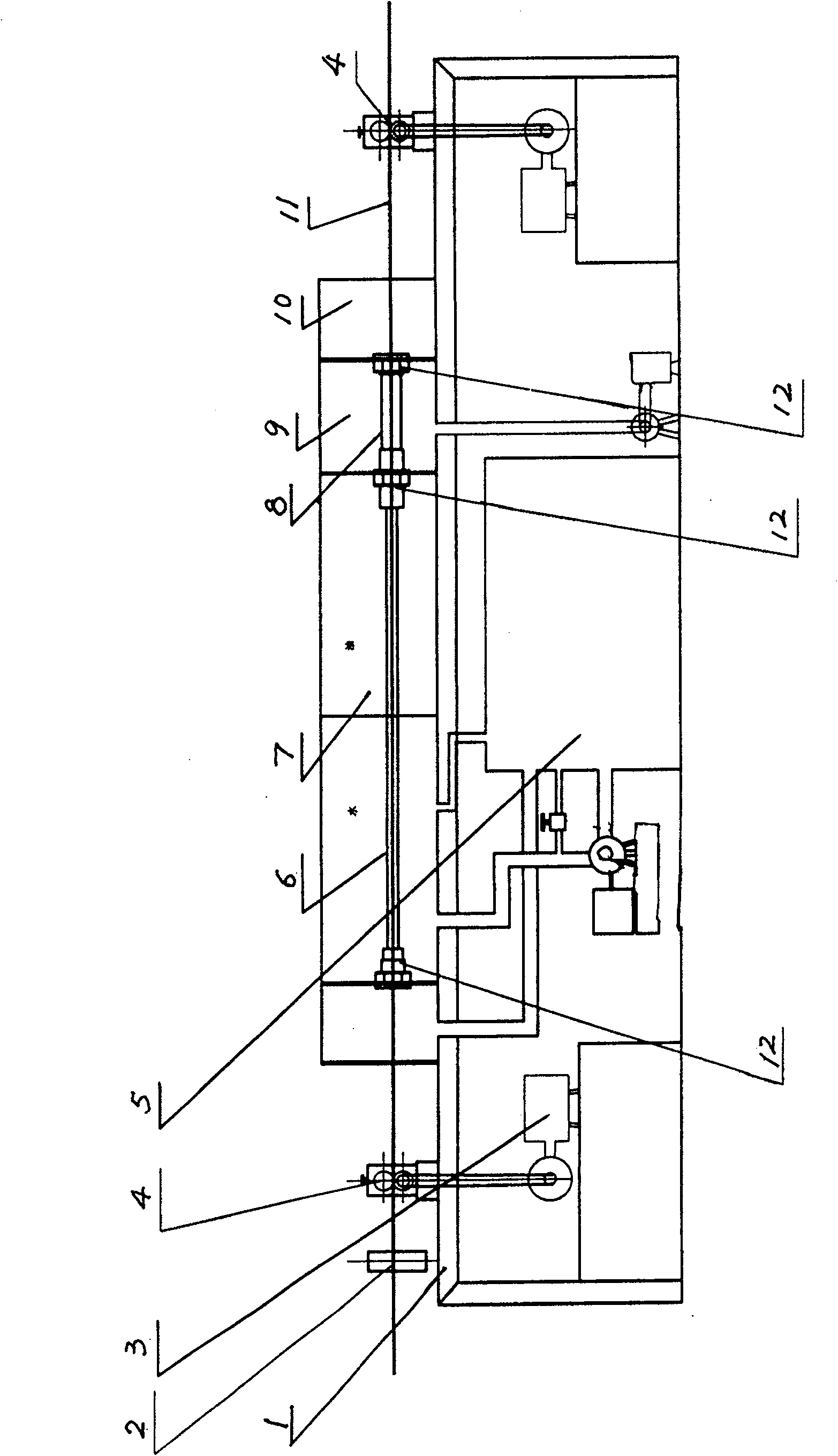

Thermal contraction inflation continuous expanding device

The invention provides a method and device for inflating and continuously expanding a heat-shrinkable tube. A heat-shrinkable tube guide roller is arranged on the expansion machine platform, and a traction mechanism, a water bath box, an oil bath box, an expansion mold box, and a cooling and setting room are sequentially arranged between them. , the control mechanism is connected with the water bath box, the oil bath box and the control end of the traction mechanism through the corresponding lines. The expansion mold box is equipped with a heat shrinkable tube expansion mold, and the two ends are connected with the oil bath box and the cooling and shaping through the sizing outlet connector. chamber sealed connection. Using the principle of high-pressure gas-assisted forming, adopting the positive pressure inflation expansion method, the heat-shrinkable tube is heated and softened, and the high-pressure gas is introduced into the expansion mold to be inflated and formed by high-pressure gas, and then cooled and shaped, through heating, expansion and cooling. , traction, and complete the expansion production process of the heat shrinkable tube. The invention reduces the friction between the pipe material and the expanded sizing, and the longitudinal shrinkage rate of the product is less than 10%. The production efficiency is improved, and the expansion speed can reach more than 2-10 m / min.

Owner:CHINA KINWA HIGH TECH

Semiconductor high-pressure single-wall heat-shrinkable tube and preparation method thereof

The invention relates to a heat-shrinkable tube, in particular to a semiconductor high-pressure single-wall heat-shrinkable tube and a preparation method thereof. The Semiconductor high-pressure single-wall heat-shrinkable tube is prepared from a wall material which comprises the following components in parts by weight: 90 parts of mixed polyolefin resin, 10 parts of conductive carbon black and 10 parts of auxiliary agent. The preparation method comprises the following steps of: the preparation of the wall material of the semiconductor high-pressure single-wall heat-shrinkable tube; extrusion; irradiation; and extending and molding. Compared with conventional shrinkable tubes, the semiconductor high-pressure single-wall heat-shrinkable tube keeps the characteristics of good electrical property, chemical property, and the like of ordinary heat-shrinkable tubes, and has all use properties of the ordinary heat-shrinkable tubes and the properties of water proofing, sealing, damp proofing,and the like.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Semi-conducting low-medium voltage fire retardant single-wall heat-shrinkable tube and preparation method thereof

InactiveCN101696293BMake up for the shortcomings of not being able to waterproof and sealHave all the performanceCable junctionsPolyolefinEngineering

The invention relates to a heat-shrinkable tube, in particular to a semi-conducting low-medium voltage fire retardant single-wall heat-shrinkable tube and a preparation method thereof. The semi-conducting low-medium voltage fire retardant single-wall heat-shrinkable tube comprises wall materials which contain the following raw materials in parts by mass: 70 parts of polyolefin mixed resin, 10 parts of conductive black, 10 parts of assistants and 30 parts of fire retardant. The preparation method of the heat-shrinkable tube comprises the following steps of preparation of internal wall materials, extrusion, irradiation, and expansion-moulding. Compared with a traditional heat-shrinkable tube, the invention has the technical characteristics that the wall materials are fire retardant, and theheat-shrinkable tube is applied to a 10 kV high voltage, has all the service performances of the traditional heat-shrinkable tube and also has watertightness, leakproofness, corrosion-resistance and dampproof performance; in addition, the heat-shrinkable tube completely meets the environmental protection requirement of ROHS of countries of European Union and has the advantages of low-temperature shrinkage, three-time to four-time stable expansion, low longitudinal shrinking rate and the like.

Owner:江苏达胜热缩防护用品有限公司

Low-voltage halogen-free retarding two-wall heat-shrinkage tube and preparation method thereof

ActiveCN101696301BNo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinCombustion

The invention relates to a heat-shrinkage tube, in particular to a low-voltage halogen-free retarding two-wall heat-shrinkage tube and a preparation method thereof. The low-voltage halogen-free retarding two-wall heat-shrinkage tube comprises an outer wall material and an inner wall material, wherein the outer wall material comprises 60 parts by mass of first polyolefin mixed resin, 10 parts by mass of first assistant, 20 parts by mass of fire retardant and 10 parts by mass of auxiliary fire retardant; and the inner wall material comprises 60 parts by mass of second polyolefin mixed resin, 10parts by mass of second assistant, 20 parts by mass of fire retardant and 10 parts by mass of auxiliary fire retardant. The preparation method comprises the following steps of preparing, extruding, radiating and expanding to form the inner wall material and the outer wall material of the two-wall heat-shrinkage tube. Compared with the traditional heat-shrinkage tube, the invention has the technical characteristics that because the fire retardant and the auxiliary fire retardant are adopted in the raw materials, the low-voltage halogen-free retarding two-wall heat-shrinkage tube has good retarding property, high temperature resistance, better property, no pollution in combustion, cost reduction and remarkable economic and environmental-friendly benefits, and is suitable for massive popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Single-wall heat-shrinkable tube and preparation method thereof

The invention relates to a heat-shrinkable tube, in particular to a single-wall heat-shrinkable tube and a preparation method thereof. The single-wall heat-shrinkable tube is made from wall materials which comprise 80 parts by weight of polyolefin mixed resin and 20 parts by weight of addition agents. The preparation method comprises the following steps of: preparing the wall materials of the single-wall heat-shrinkable tube; extruding; irradiating; and expanding for forming. Compared with the traditional heat-shrinkable tube, the invention has the technical advantages of keeping the characteristics, i.e. good electrical property, chemical property, and the like of a common heat-shrinkable tube at an outer layer and having all the service properties of the common heat-shrinkable tube and waterproof property, sealing property, dampproof property, anticorrosion property, and the like.

Owner:江苏达胜热缩防护用品有限公司

Medium and low pressure single wall thermal shrinkage pipe and preparation method thereof

The invention relates to a thermal shrinkage pipe, in particular to a medium and low pressure single wall thermal shrinkage pipe and a preparation method thereof. The medium and low pressure single wall thermal shrinkage pipe is made from a wall material which comprises 85 parts of polyolefin mixed resin and 10 parts of auxiliary agent by weight. The preparation method comprises the following steps: preparing the wall material of the medium and low-pressure single wall thermal shrinkage pipe, extruding, irradiating and expanding for molding. Compared with the traditional shrinkage pipe, the invention has the technical characteristics that an outer layer keeps the good electrical properties, chemical properties and other characteristics of a common thermal shrinkage pipe, has all operational properties of the common thermal shrinkage pipe, and also has the properties of water prevention, sealing, moisture prevention, corrosion prevention and the like.

Owner:江苏达胜热缩防护用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com