A kind of super-feeding film stretching process

An over-feeding and thin-film technology, applied in the field of stretching technology, can solve the problems that the diaphragm cannot be relaxed and fully retracted, the film slips and scratches, the film adheres to the roller and burns scars, etc., and achieves stepless adjustment of longitudinal shrinkage rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description of the embodiments will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention. Changes in the definition of the present invention and / or formal but not substantial changes to the overall structure shall be regarded as the protection scope limited by the technical solutions of the present invention.

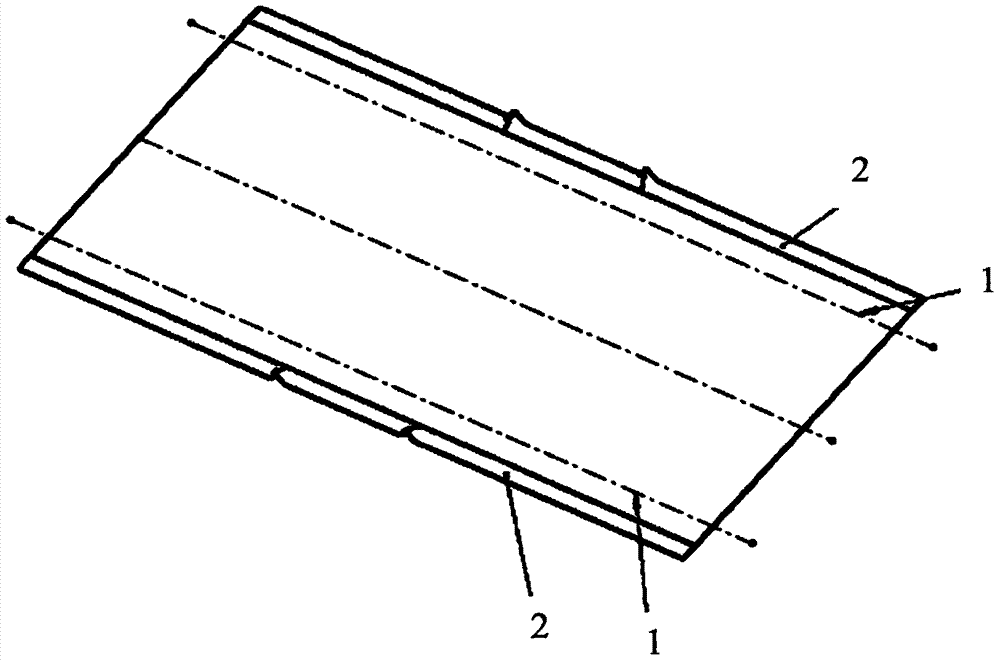

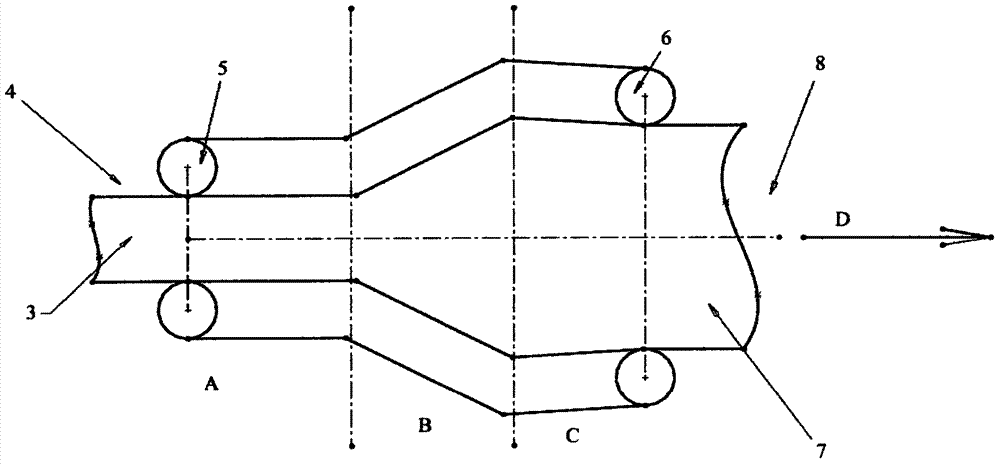

[0022] Description of reference numerals in the description: trimming line 1, thick edge 2, thick sheet 3, cross-drawing inlet 4, inlet sprocket 5, outlet sprocket 6, film 7, cross-drawing outlet 8, active pair of rollers 9, clamp 10, active Overfeeding roller 11, driving roller 12, pressing roller 13, driving roller 14, pressing roller 15, film 16, protrusion 17, active film feeding crawler 18, preheating section A, stretching section B, cooling and setting section C, Traction windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com