Method for producing thick low hot shrinkage rate polyester film

A technology of polyester film and production method, which is applied in the field of film manufacturing, can solve problems such as impact on the use of end products, no significant reduction in shrinkage rate, inconvenience in product production and processing, etc., and achieve the effect of reducing longitudinal shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

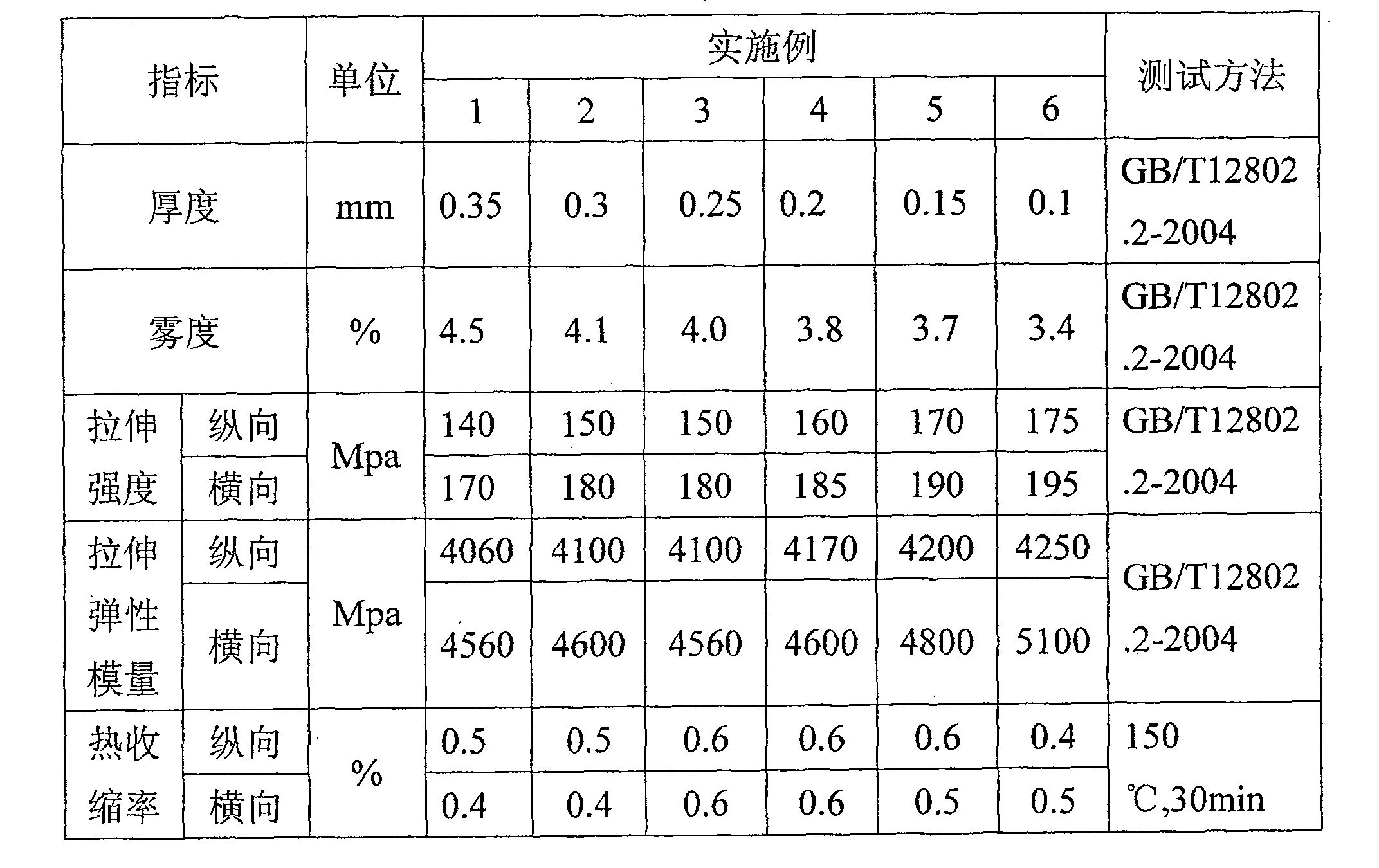

Examples

Embodiment 1

[0015] The present invention produces thick type low thermal shrinkage polyester film, carries out according to the following steps.

[0016] (1), adopt direct esterification process to prepare pure polyester chips and those containing anti-blocking agent as polyester masterbatch. Mix TPA and EG in a molar ratio of 1:1.1-1:2.0, and then add SiO 2 Ethylene glycol suspension and catalyst, stabilizer for esterification, wherein SiO 2 The mass fraction is 0.01%-0.8%, and then the polycondensation reaction is carried out at 260°C-290°C, the vacuum degree is 10pa-70pa, and the reaction time is 2-3h, and the polyester chip raw material is obtained. After the polyester raw material is dried, the polyester raw material with a moisture content of less than 30ppm is sent into the extruder to be melted, and the thick sheet is extruded through the melt pipe, the coarse filter, the fine filter and the die head. The temperature of the head is controlled at 280°C-285°C, the line speed of th...

Embodiment 2

[0023] The present invention produces thick type low thermal shrinkage polyester film, carries out according to the following steps.

[0024] (1) After the polyester raw material is dried, feed the polyester raw material with a moisture content of less than 40ppm into the extruder to melt, and extrude a thick sheet through a melt pipe, a coarse filter, a fine filter and a die head, and extrude a thick The temperature of the die head is controlled at 285°C-290°C during sheeting, the line speed of the thick sheet is controlled at 0.15m / s-0.2m / s during extrusion, and the thick sheet is cooled with a casting roller at a temperature of 30°C and cold air .

[0025] (2) Longitudinal stretching, relaxation, and setting: the thick sheet is peeled off by the peeling roller, preheated by the roller at a temperature of 75°C-80°C, and the thick sheet is heated in an infrared heating zone of 120°C-140°C. The line speed of m / s-0.56m / s and the longitudinal stretching ratio of 2.5-2.8:1 are u...

Embodiment 3

[0031] The present invention produces thick type low thermal shrinkage polyester film, carries out according to the following steps.

[0032](1) After the polyester raw material is dried, the polyester raw material with a moisture content of less than 40ppm is sent into the extruder to melt, and the thick sheet is extruded through the melt pipe, the coarse filter, the fine filter and the die head, and the extruded The temperature of the die head is controlled at 290°C-295°C for thick sheets, and the line speed of thick sheets is controlled at 0.15m / s-0.2m / s during extrusion. cool down.

[0033] (2) Longitudinal stretching, relaxation, and setting: the thick sheet is peeled off by the peeling roller, preheated by a roller at a temperature of 75°C-80°C, and the thick sheet is heated in an infrared heating zone of 120°C-140°C. M / s-0.56m / s line speed, 2.5-2.8:1 longitudinal stretching ratio for longitudinal stretching, time control within 0.3s for longitudinal stretching, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com