Patents

Literature

113results about How to "Stable expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

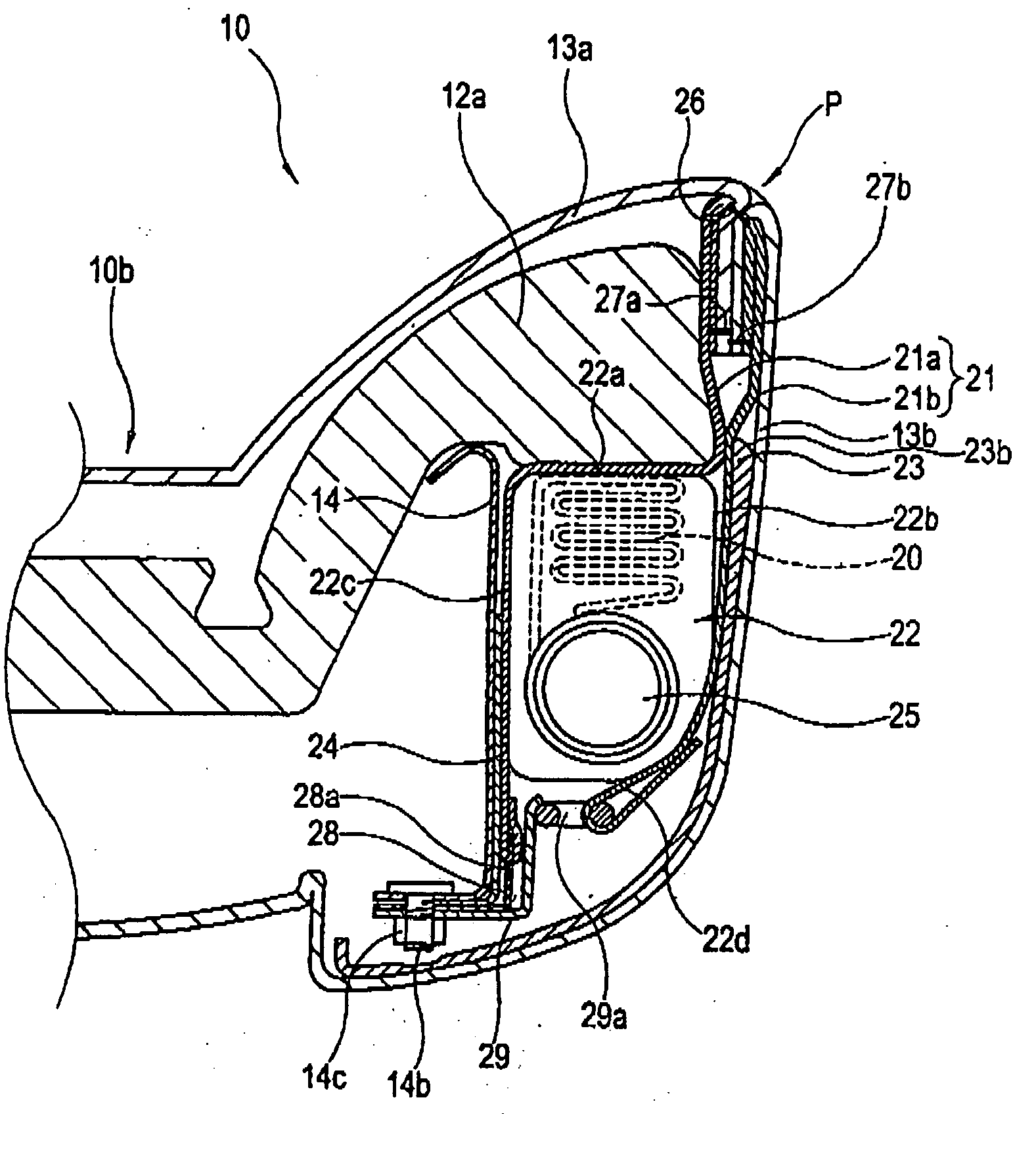

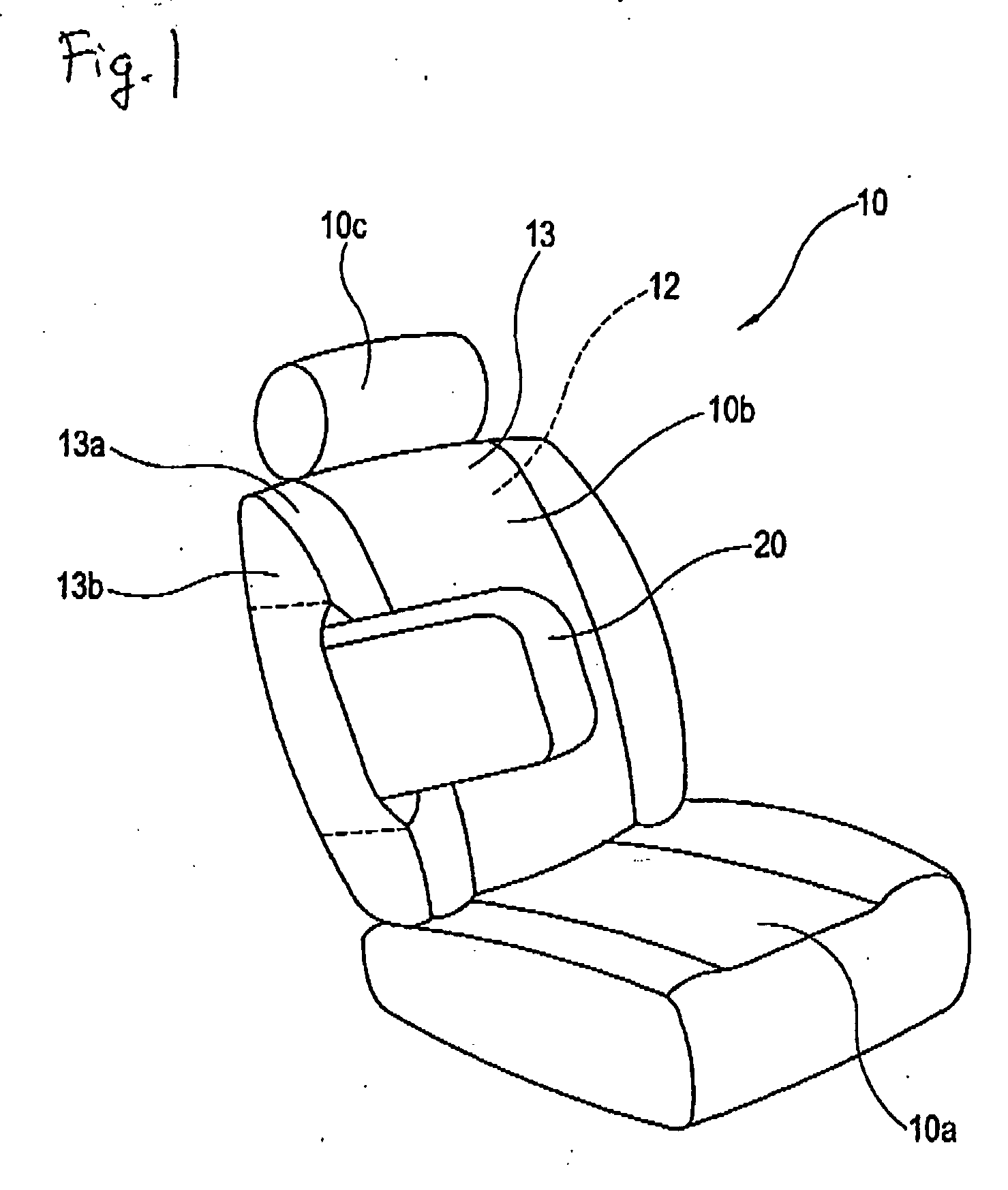

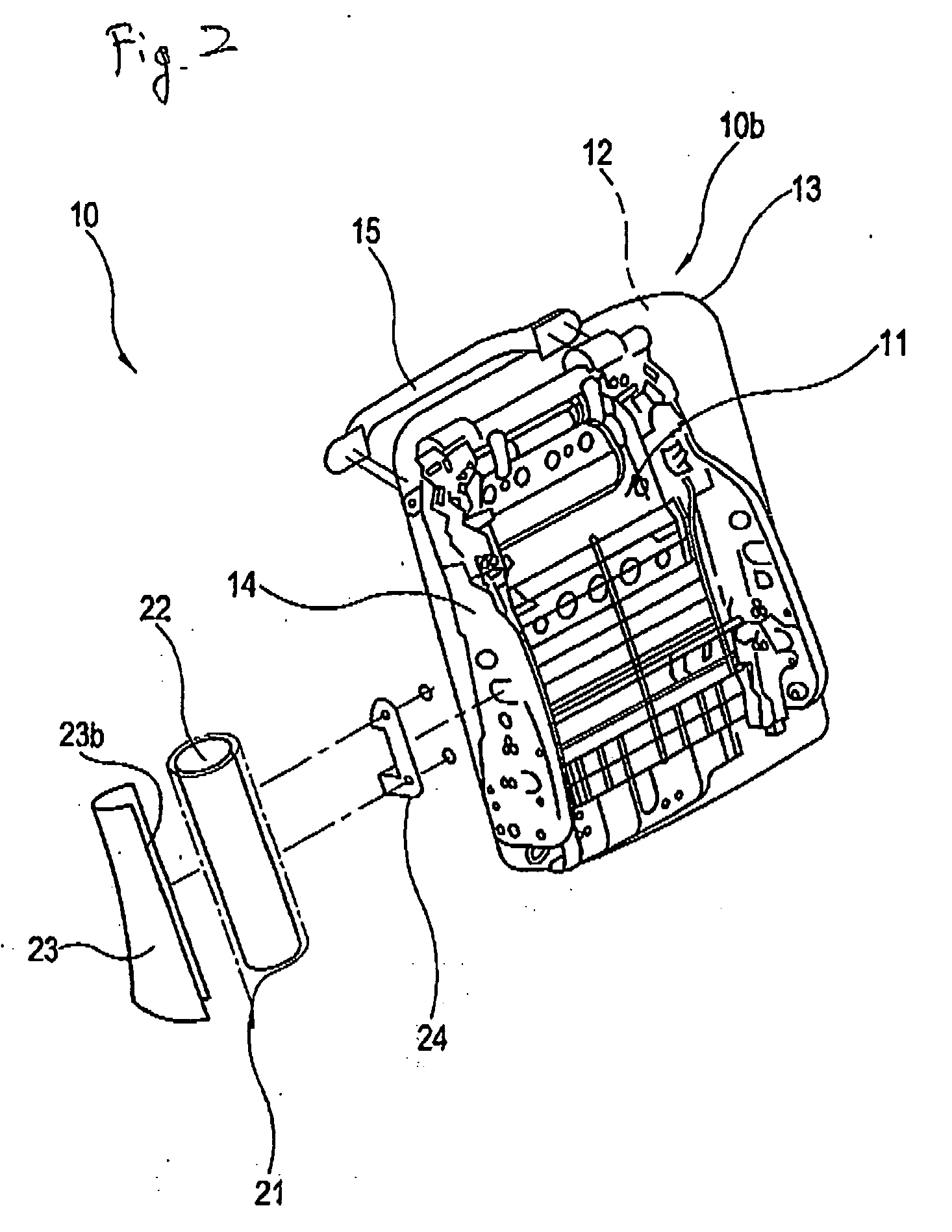

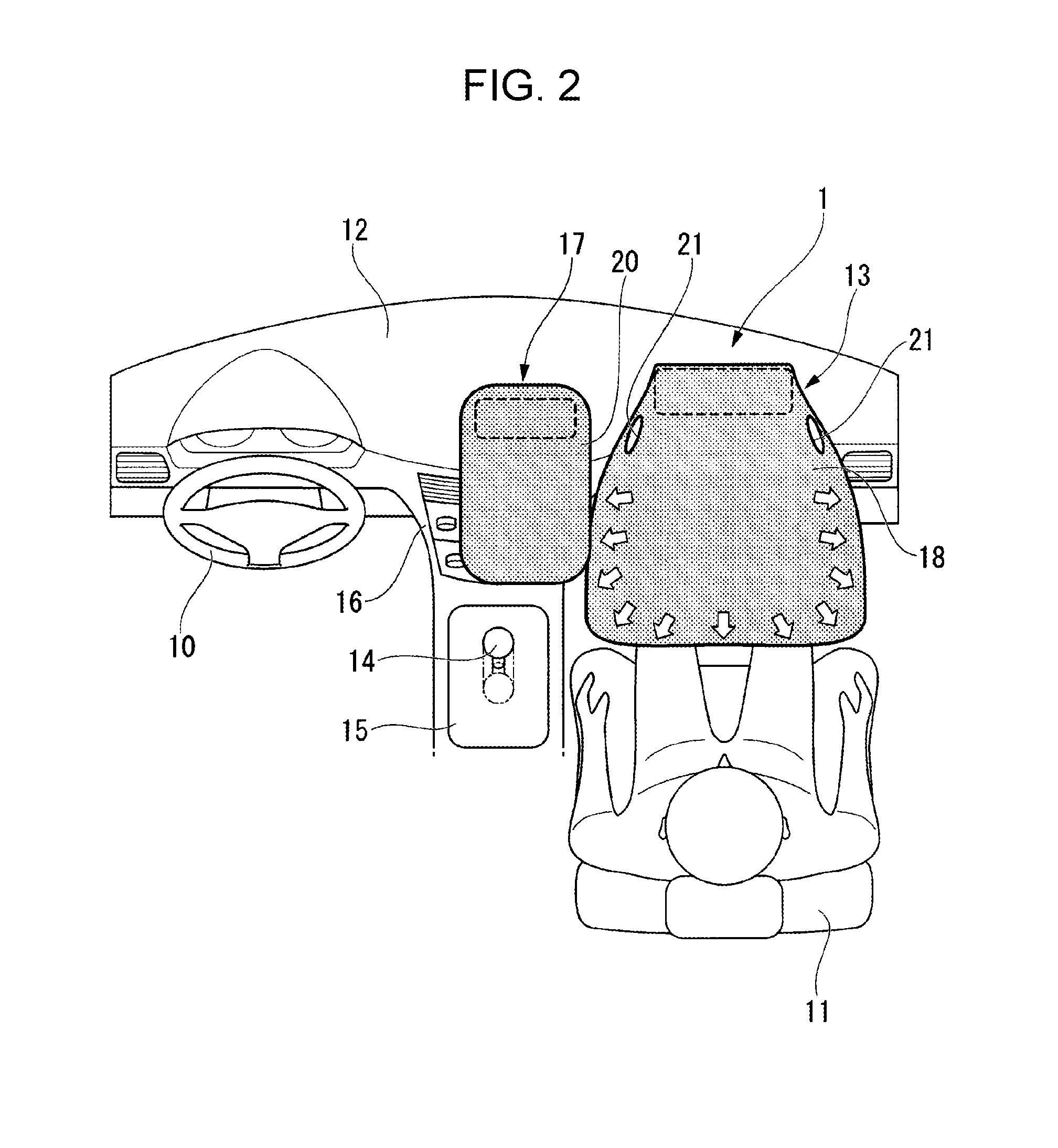

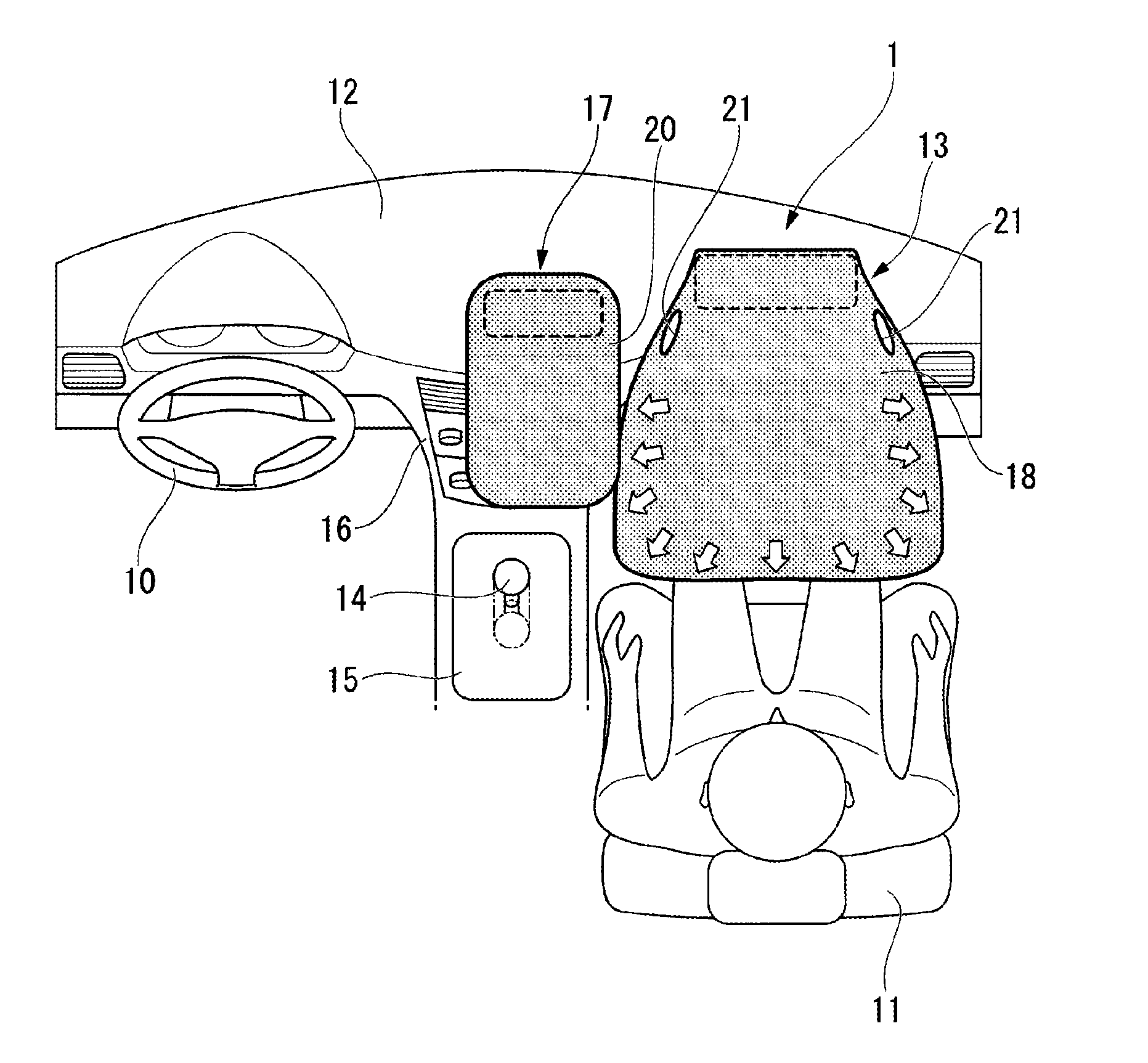

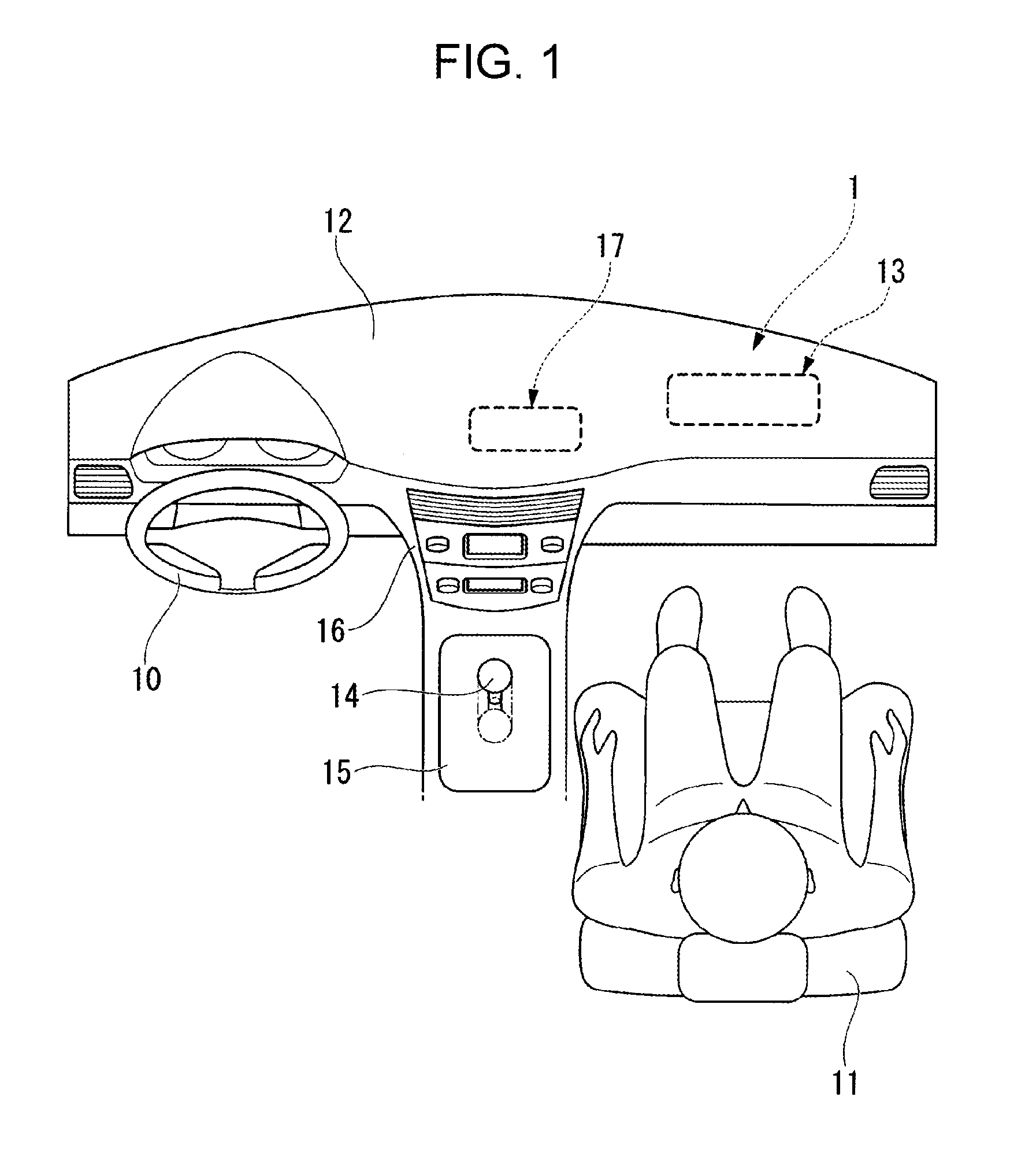

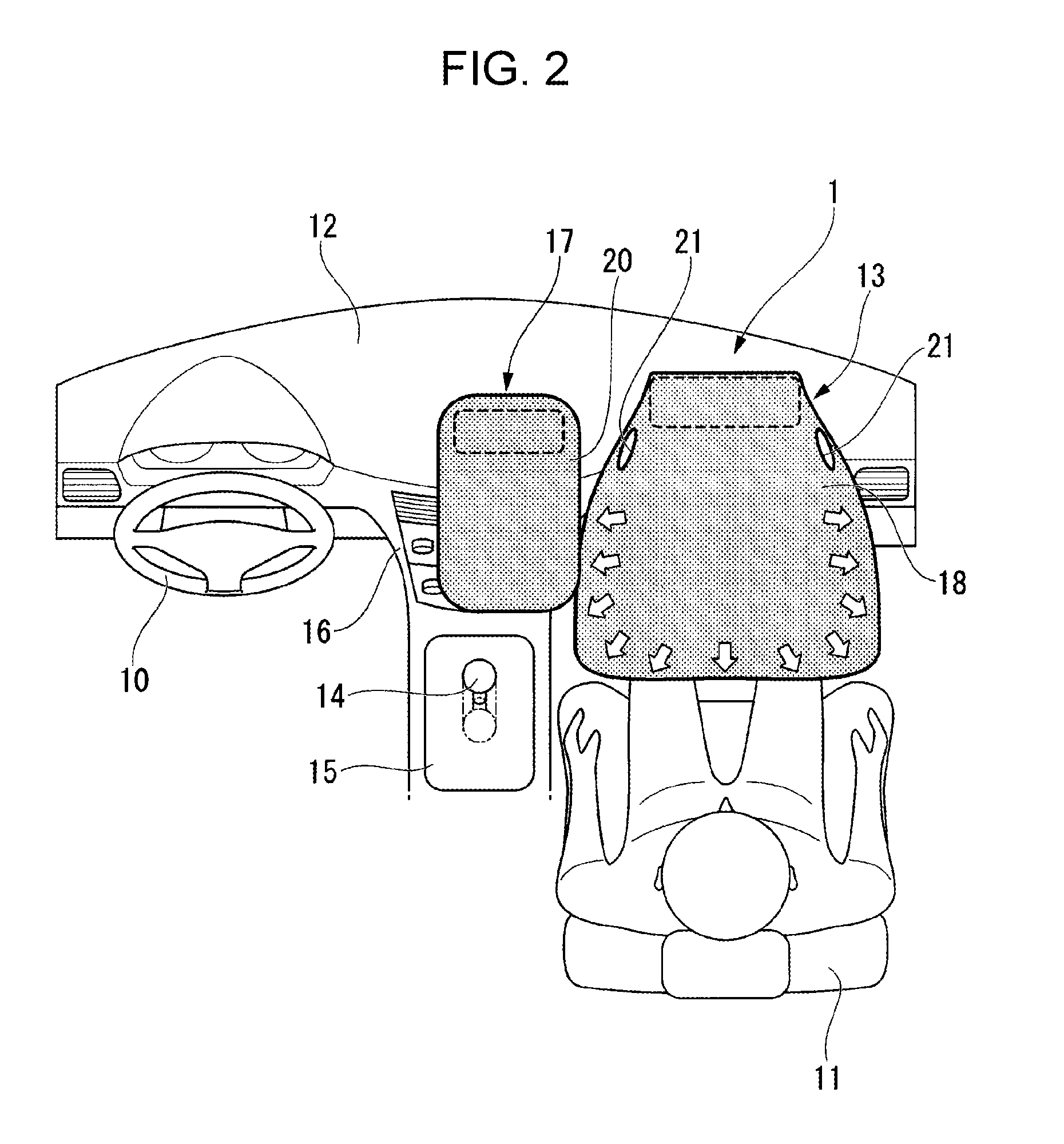

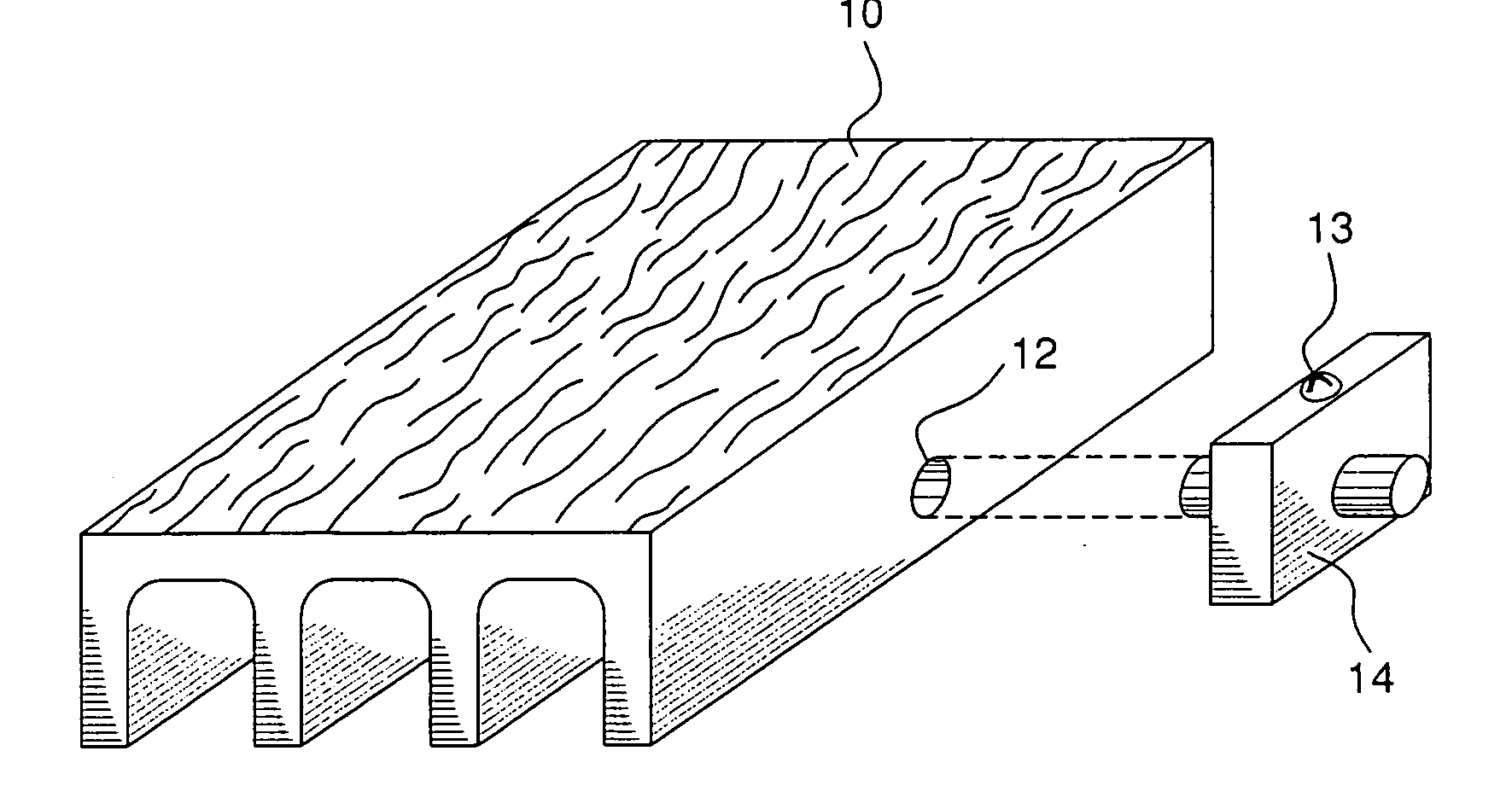

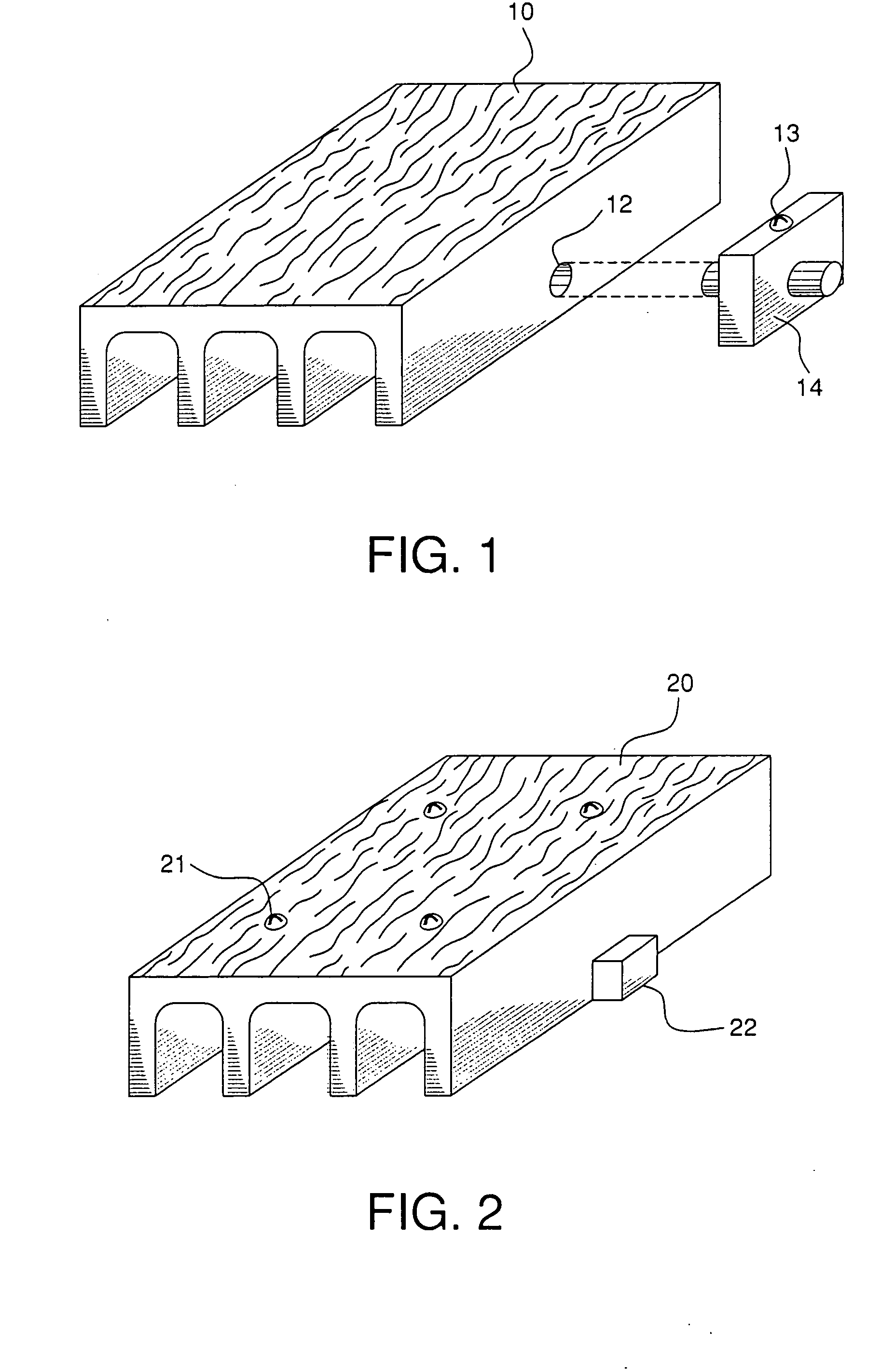

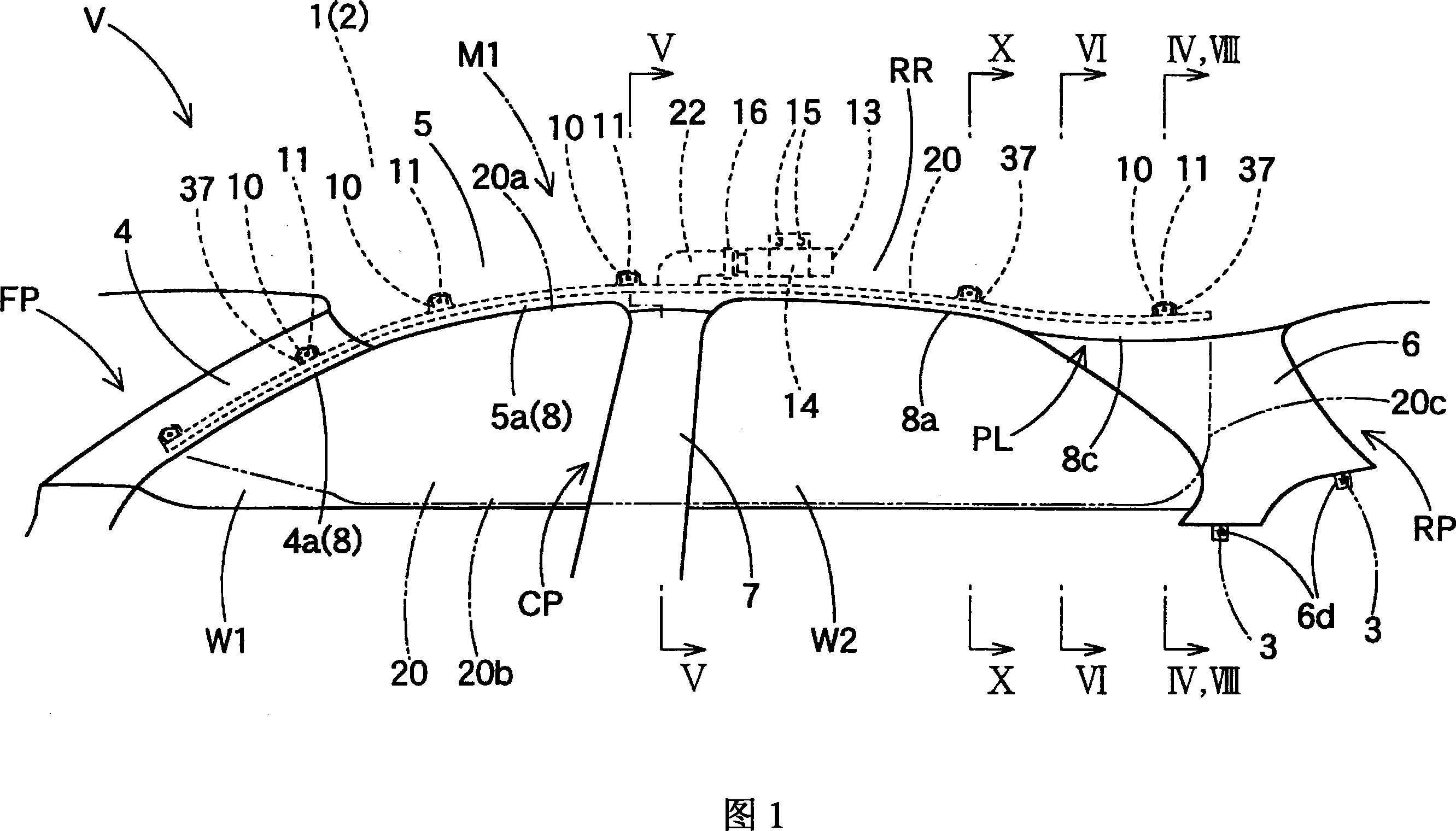

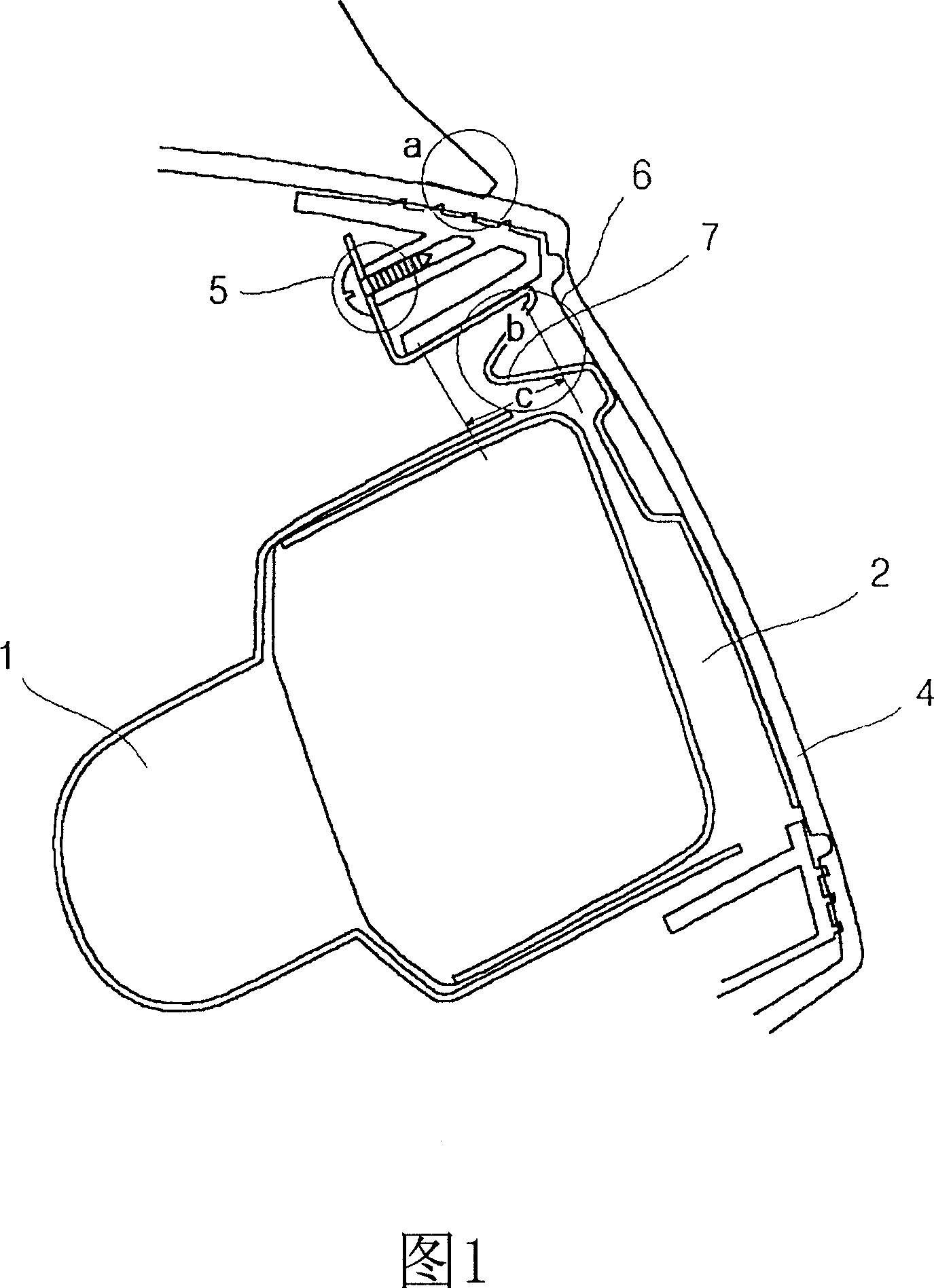

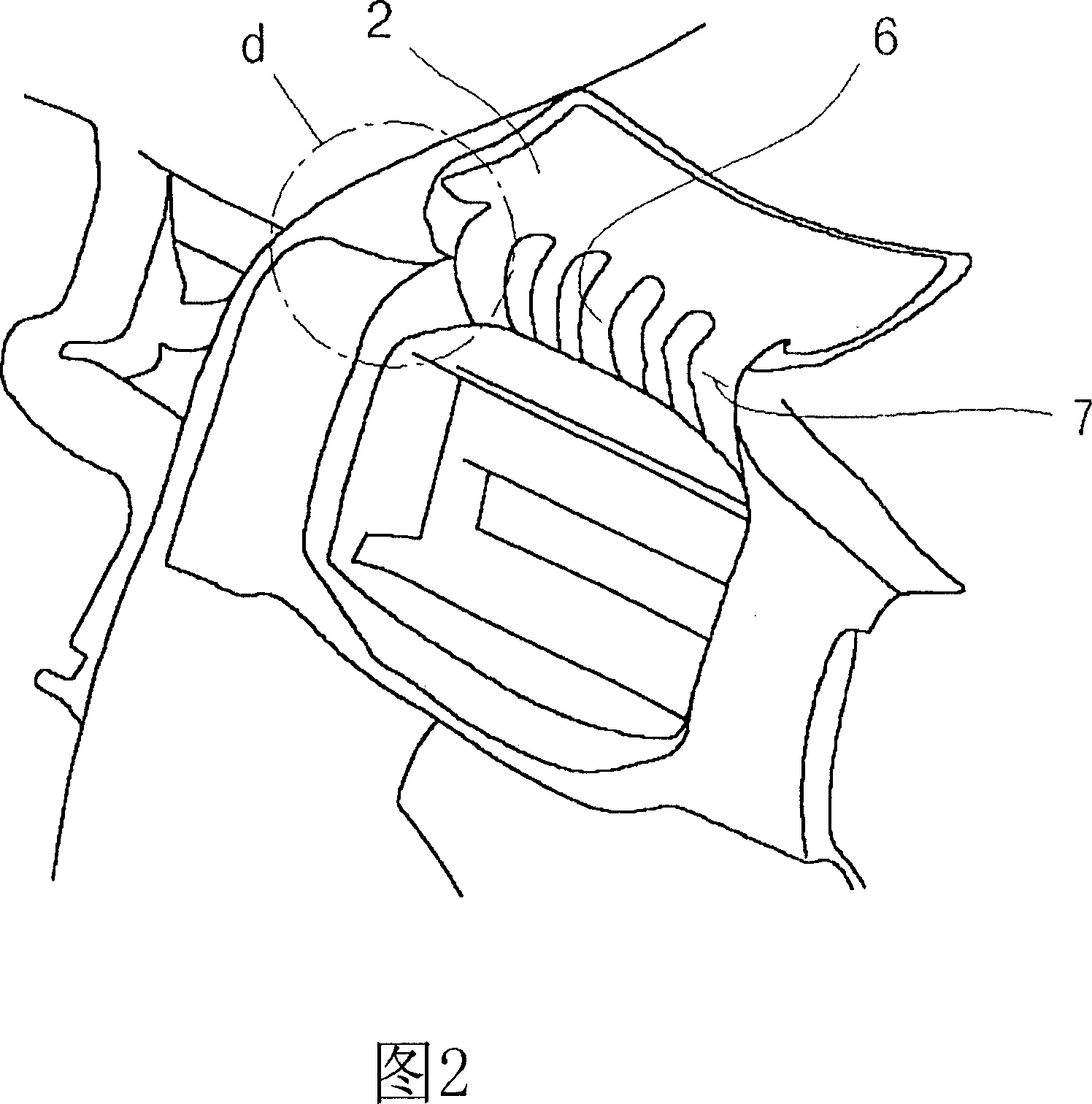

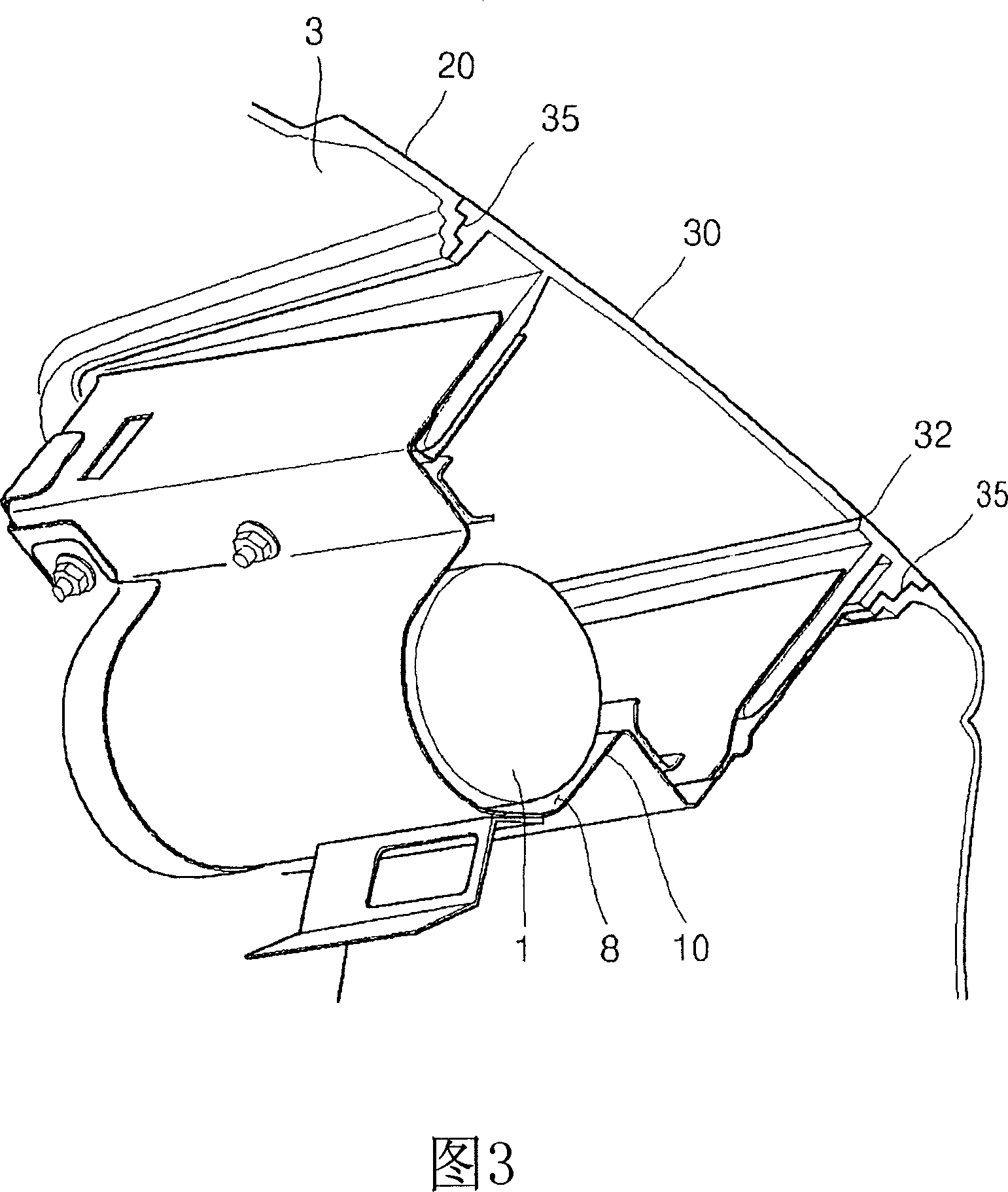

Seat with a side airbag

InactiveUS20060131848A1Improve responseStable expansionUpholstery manufactureVehicle seatsLateral airbagEngineering

A seat 10 with a side airbag has front and side reinforcement fabrics 21a and 21b covering a front and a side of an airbag unit 22, respectively. These reinforcement fabrics are joined to each other so as to be deployed at an inflating position of an airbag 20 by virtue of an inflating force. The front reinforcement fabric 21a and a front skin 13a are joined to each other so as not to be broken at the inflating position P by virtue of the inflating force. A side skin 13b is provided on an outside of a shape retaining member 23 that is provided on an outside of the side reinforcement fabric 21b, and the side reinforcement fabric 21a and the side skin 13b are joined to each other so as not to be broken at the inflating position P by virtue of the inflating force.

Owner:NHK SPRING CO LTD

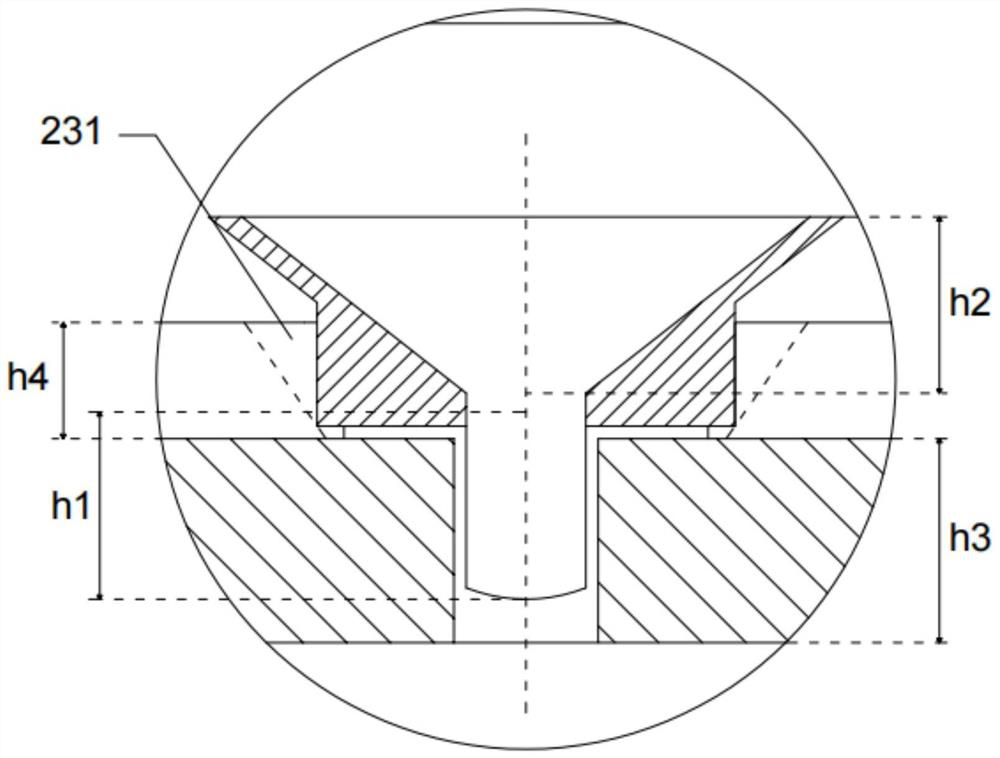

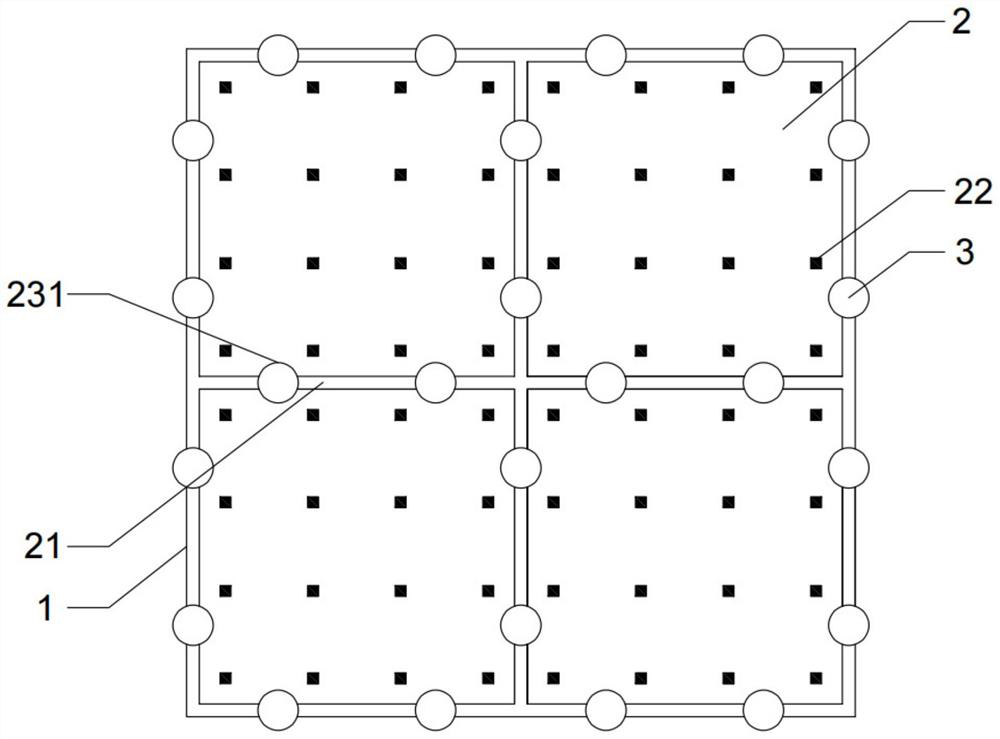

Ultrahigh-strength concrete and preparation method thereof

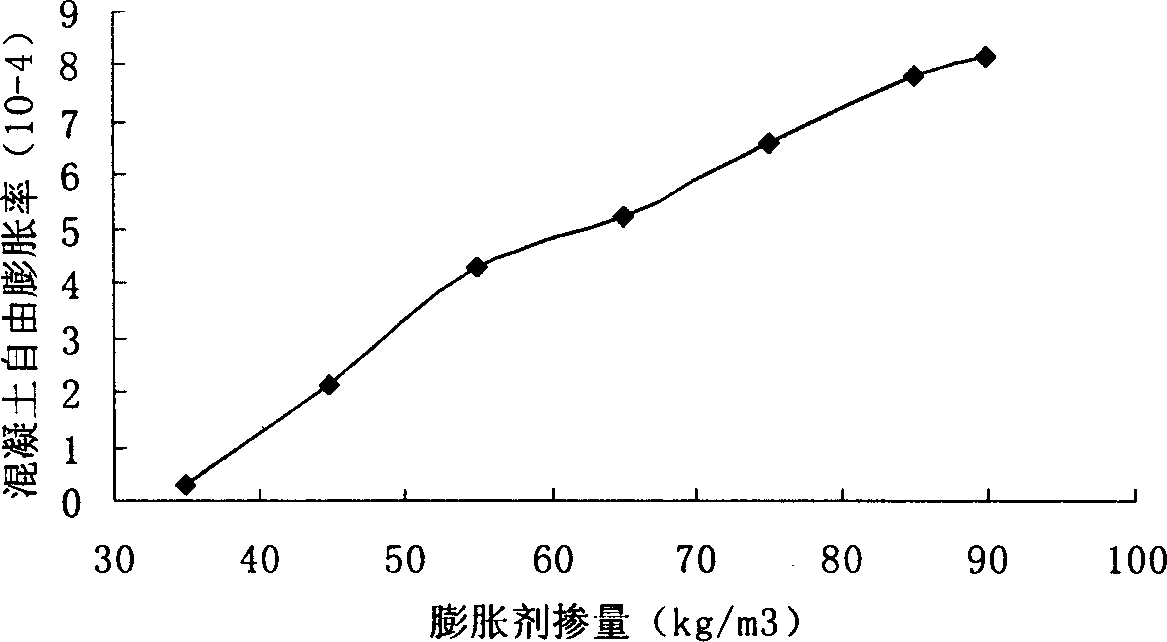

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

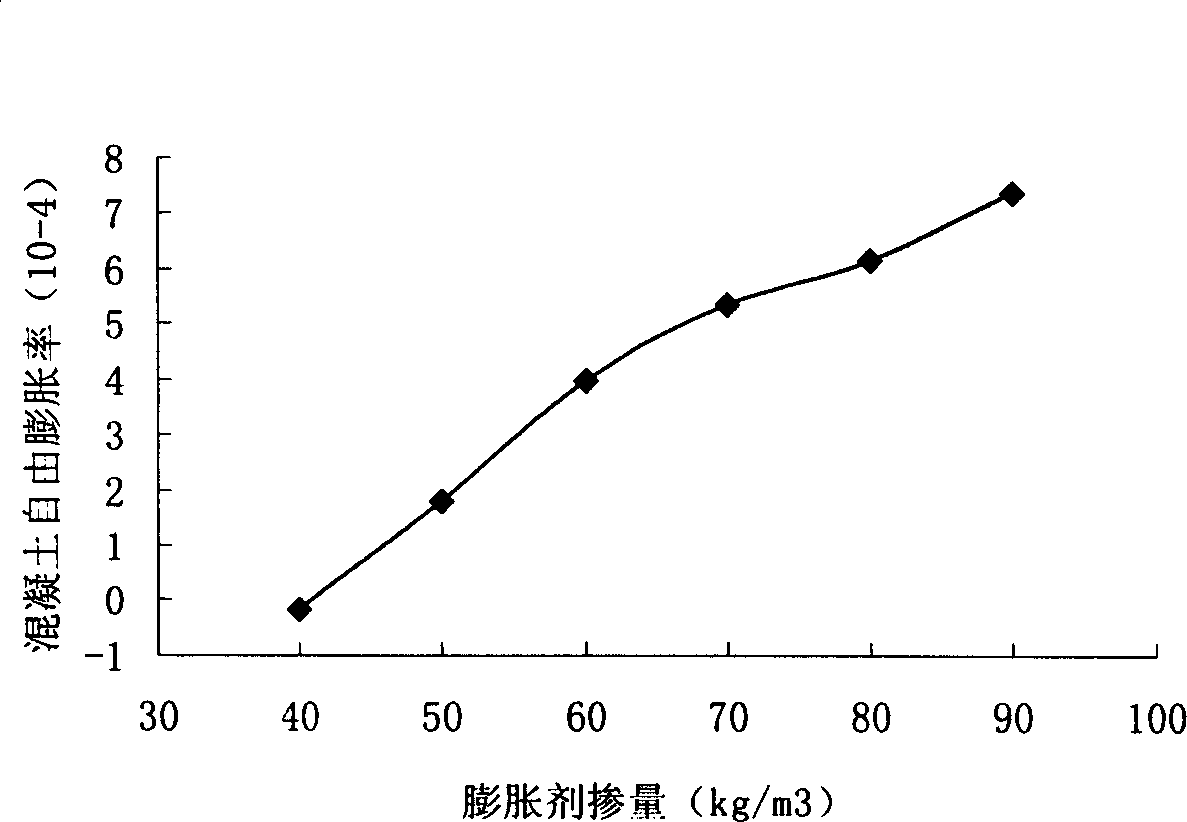

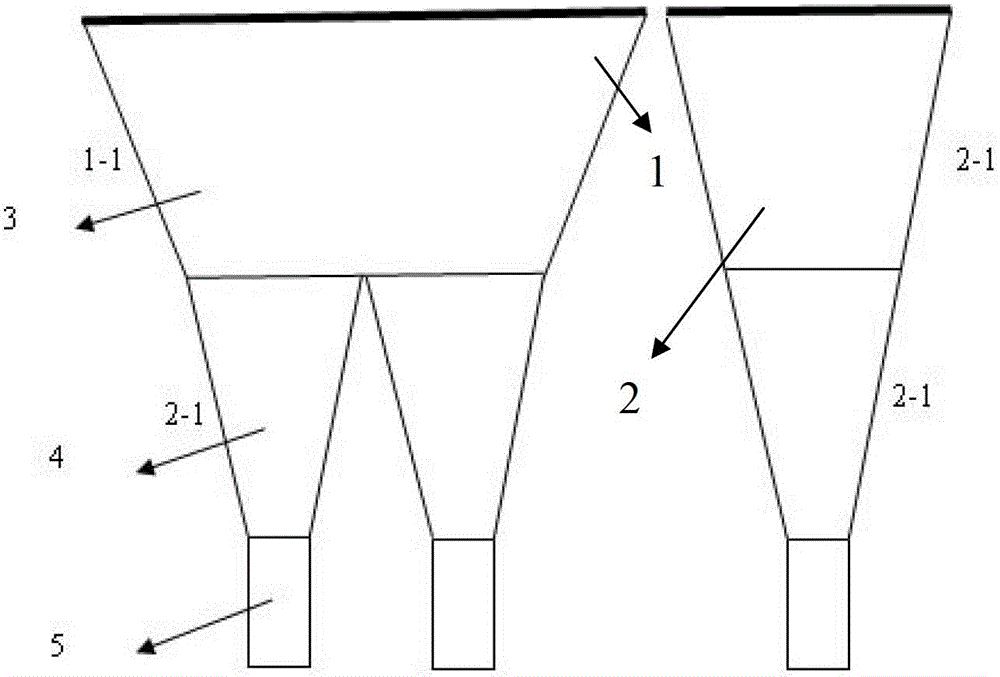

Expansion designable high strength steel pipe concrete and its prepn

InactiveCN1772690AReach the function of sustainable expansionGood expansion performanceSolid waste managementCeramicwarePortland cementHigh energy

The present invention is expansion designable C50 and C60 high strength steel pipe concrete and its preparation process, and features that the expansion designable high strength steel pipe concrete is prepared with P.O42.5 or P.O52.5 Portland cement, water, sand, crushed stone, flyash, efficient set retarding water reducing and plasticity keeping agent WUT-G and closed concrete high-energy delayed expanding agent in certain weight proportion. The present invention has lowered concrete air content not higher than 1.5 %, reduced abhesion between steel pipe and concrete caused by air adhesion and sustained stable expansion of kernel concrete.

Owner:WUHAN UNIV OF TECH

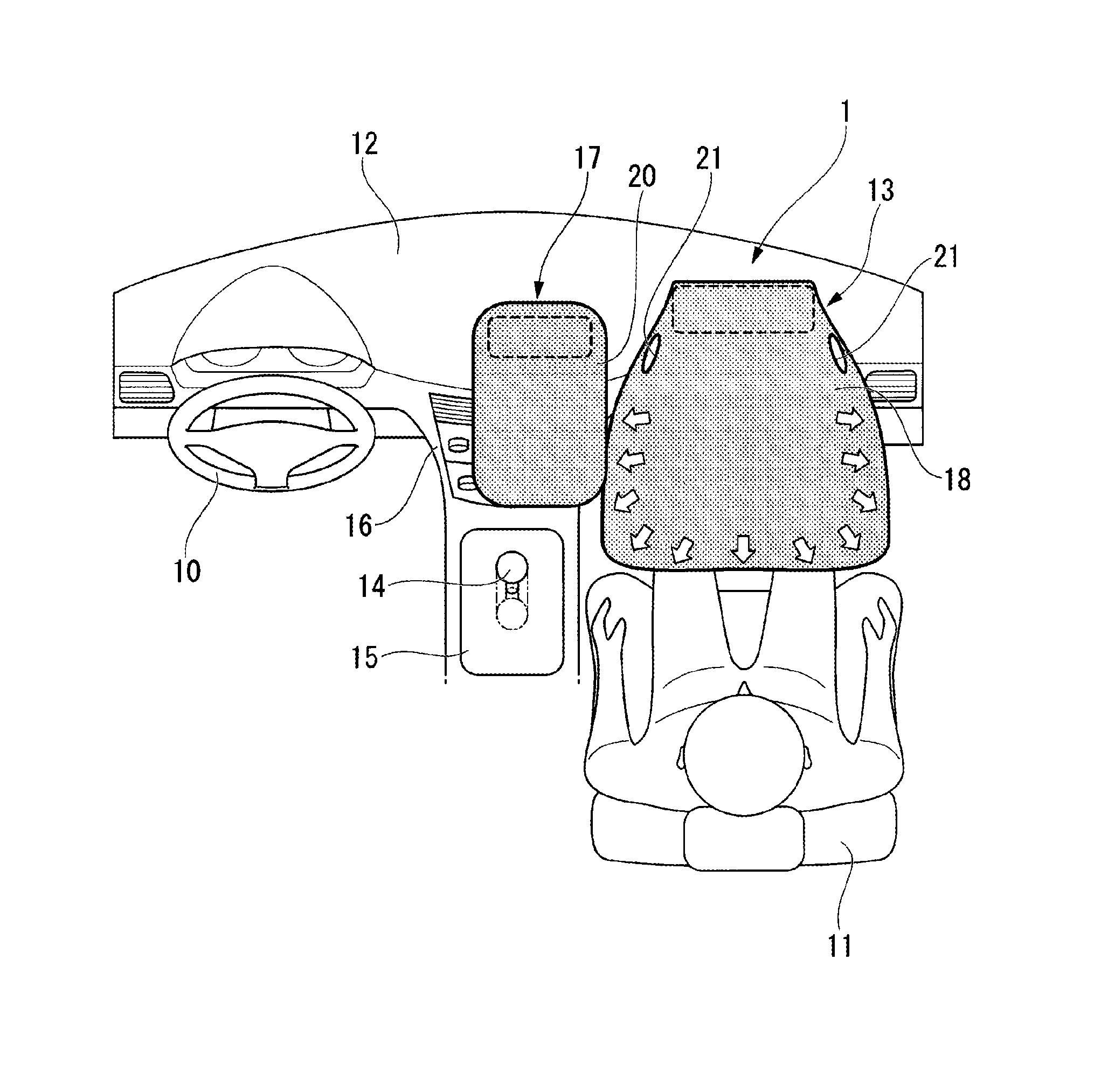

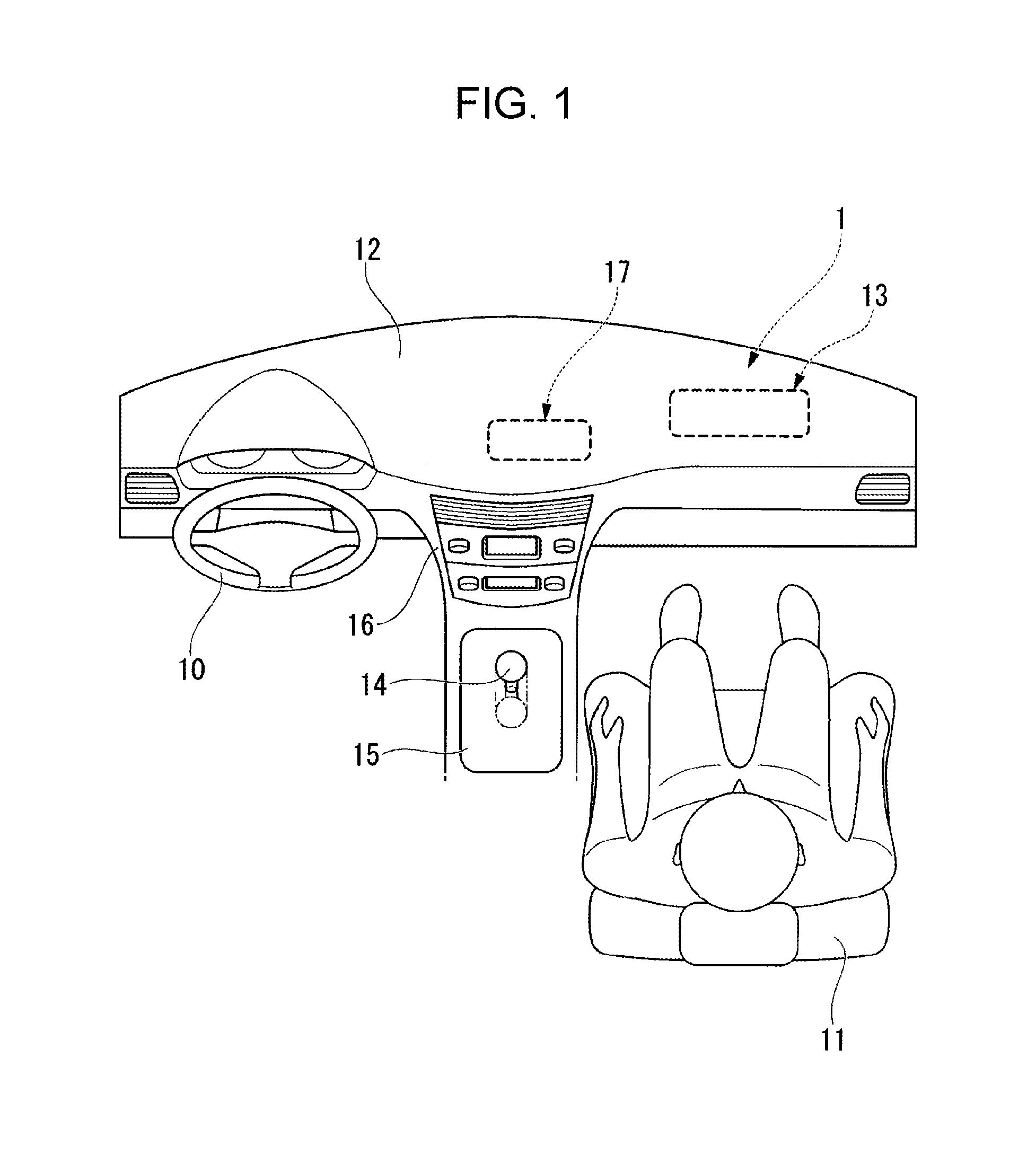

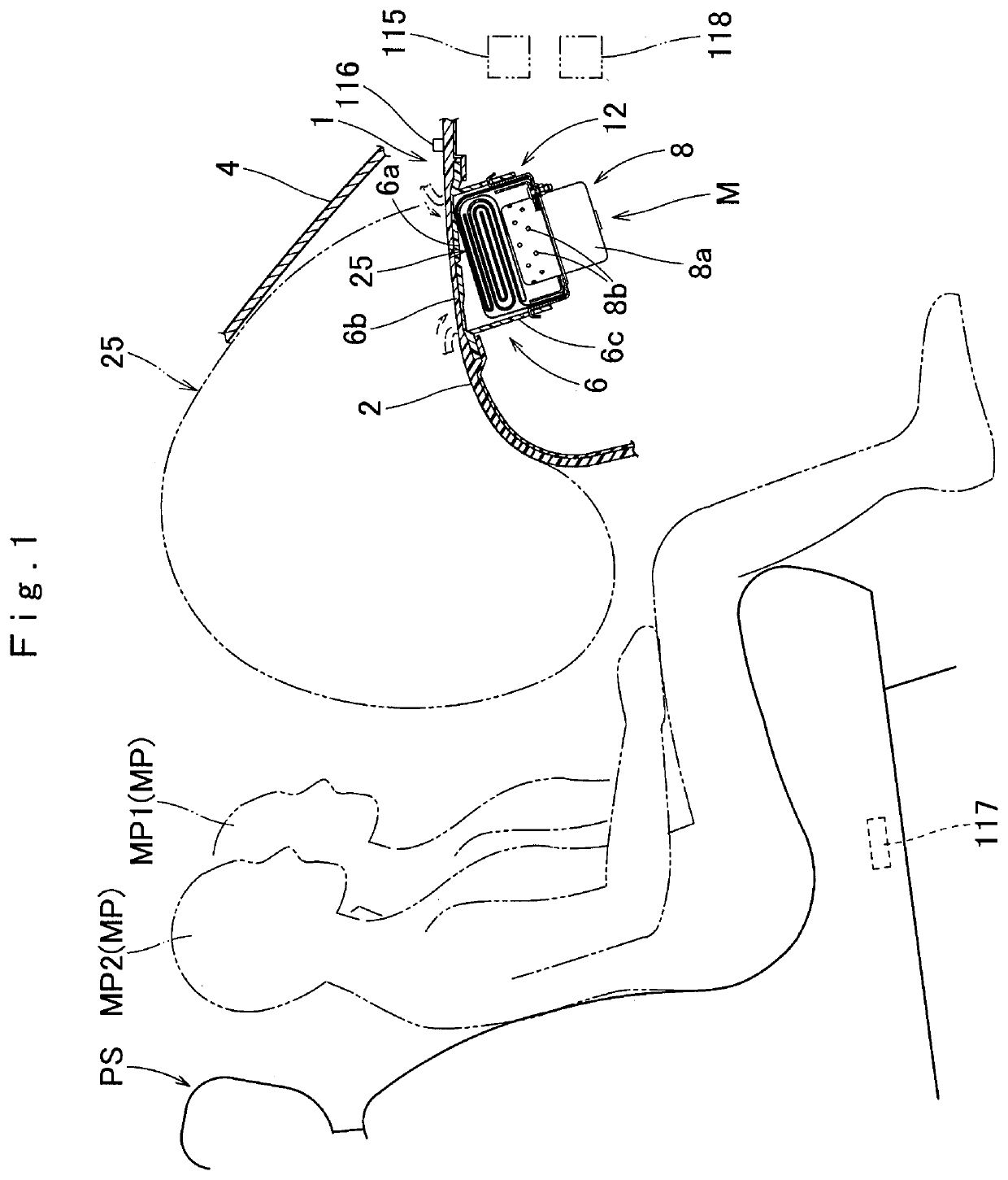

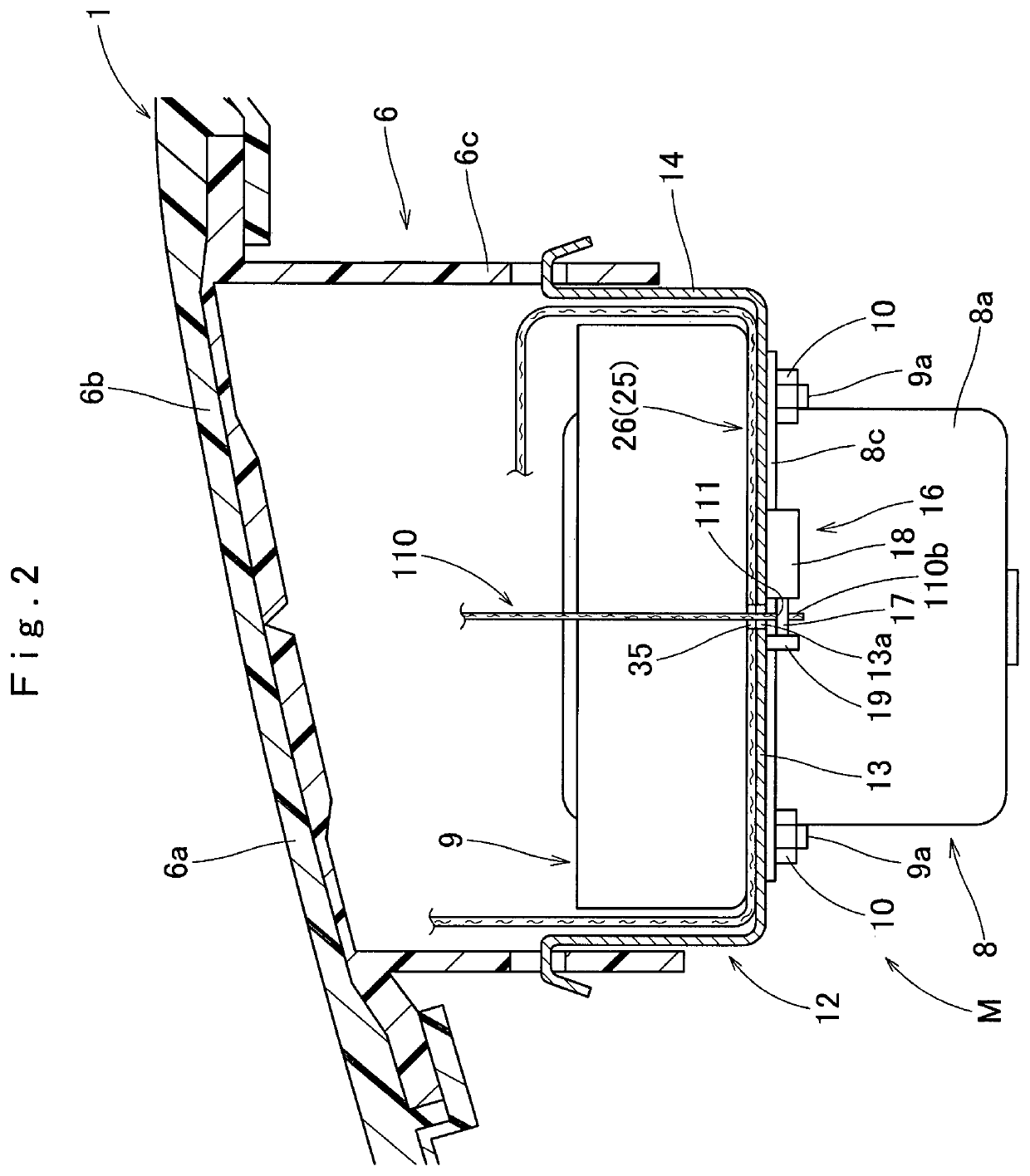

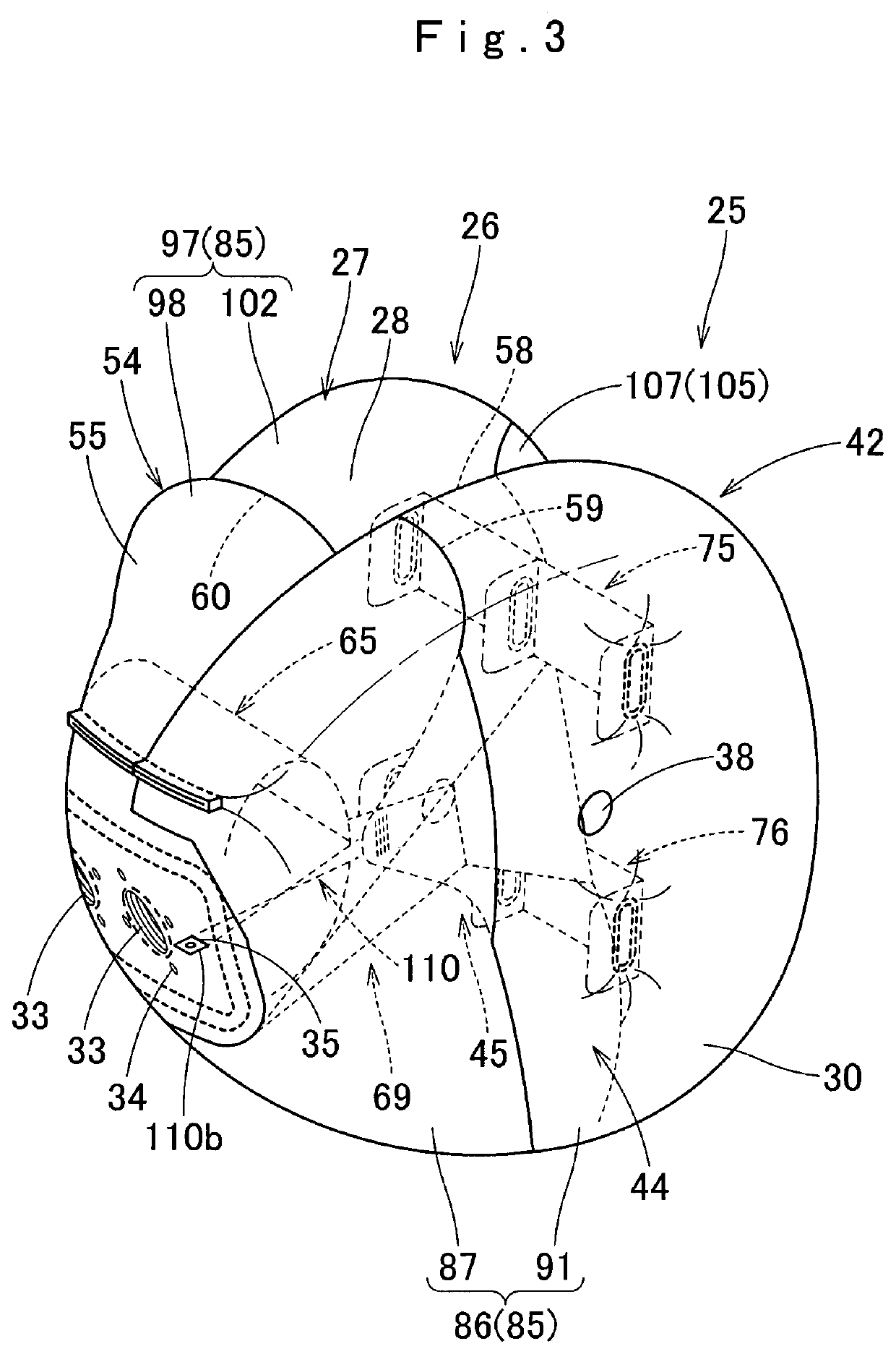

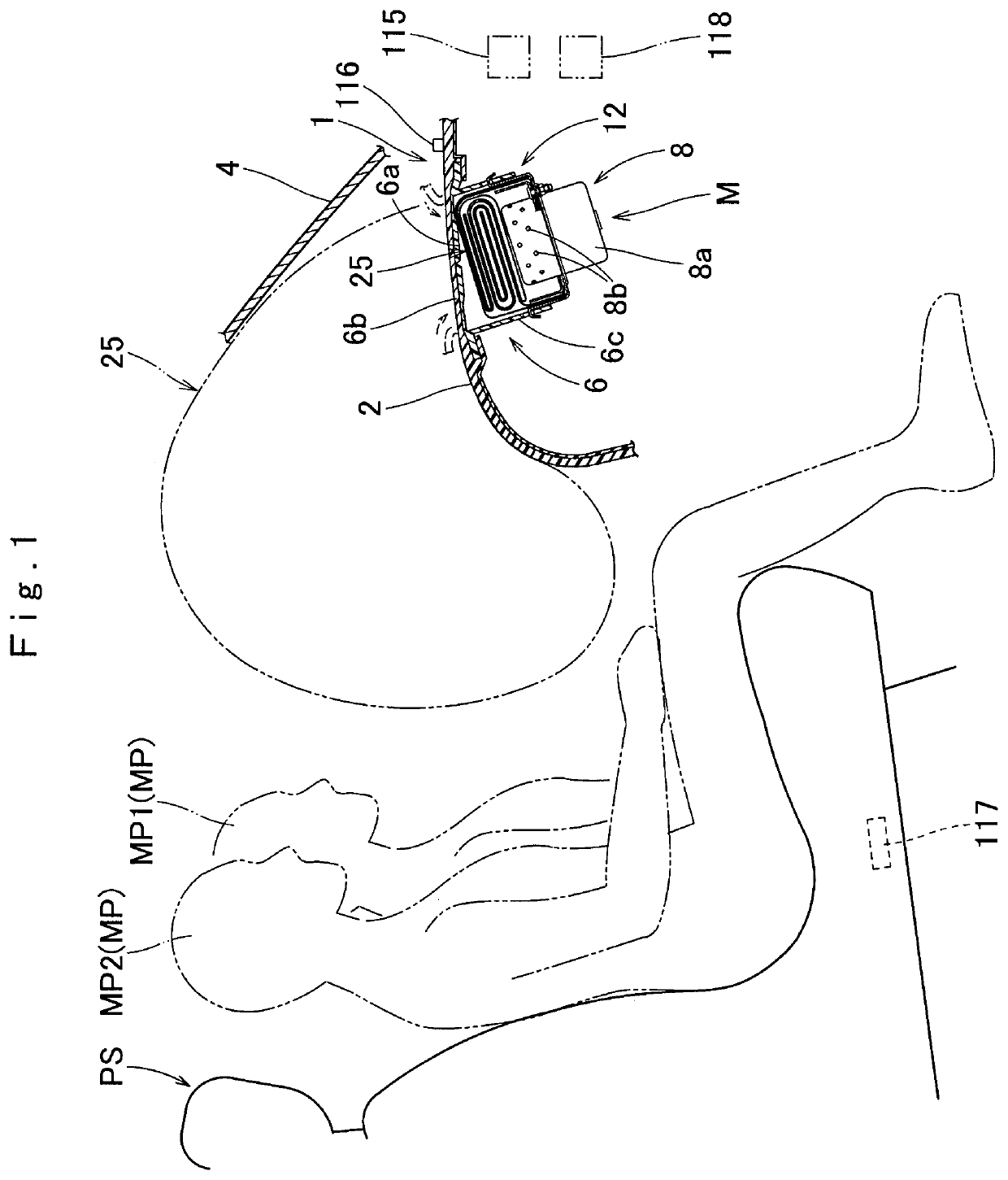

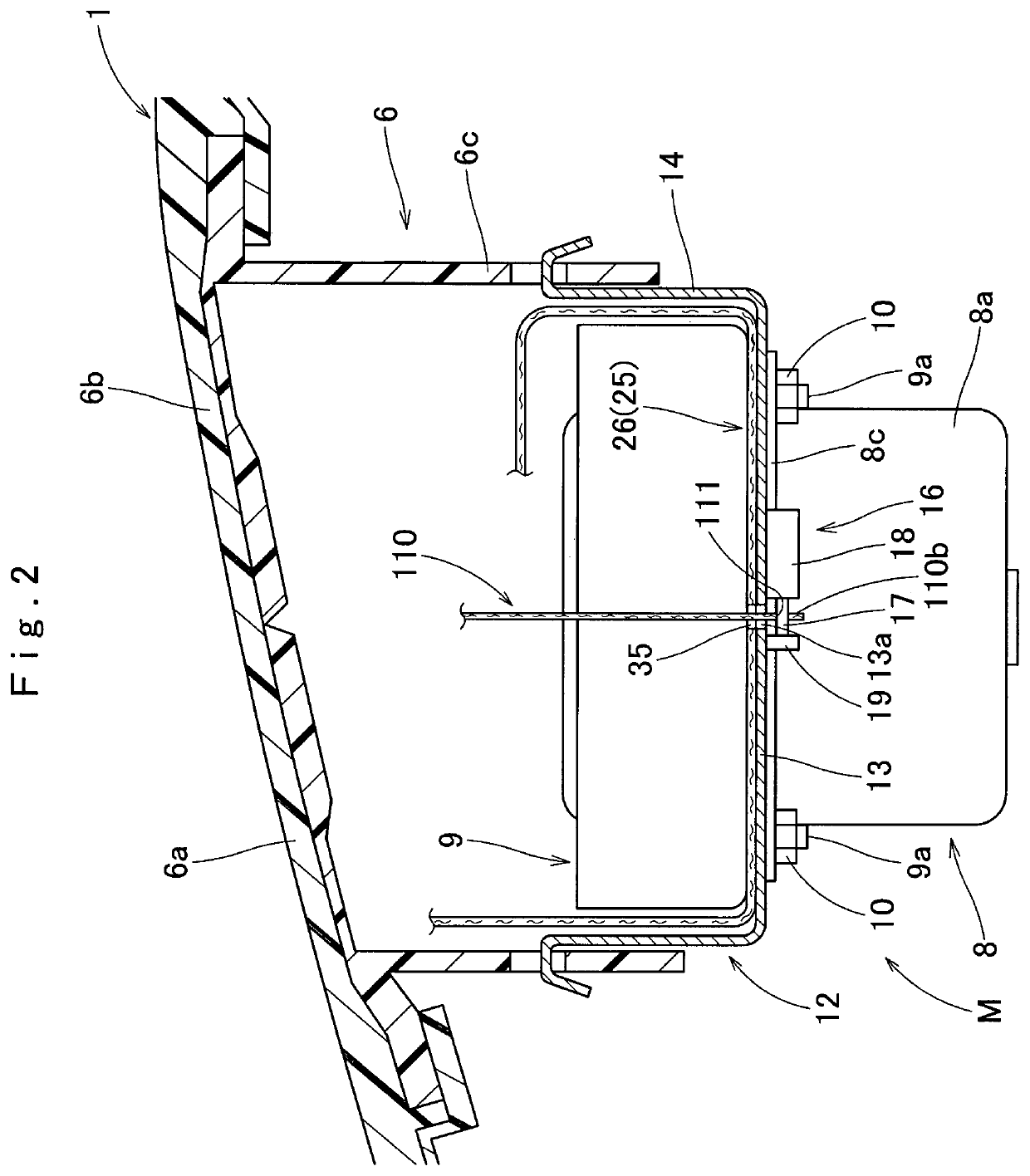

Airbag device

ActiveUS9550469B2Stable expansionFirm supportPedestrian/occupant safety arrangementEngineeringAirbag

An airbag device includes a main airbag unit with a main bag body that is inflated and deployed from a front side of a front seat when impact is input, and a supplemental airbag unit with a supplemental bag body that is inflated and deployed from a side portion of the main airbag unit when impact is input. The supplemental bag body comes into contact with the main bag body when inflated and deployed and restricts inflation and deployment of the main bag body.

Owner:HONDA MOTOR CO LTD

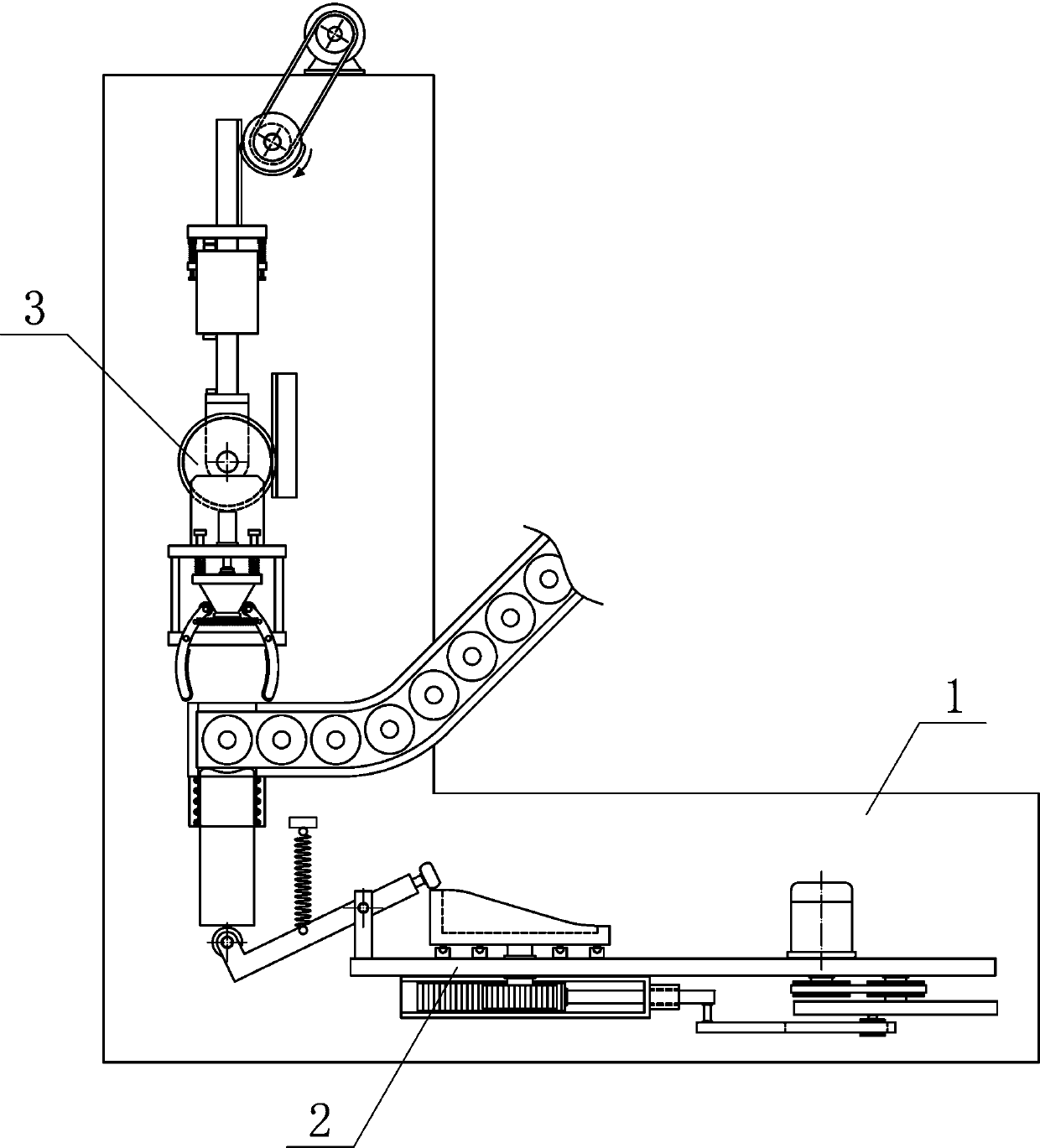

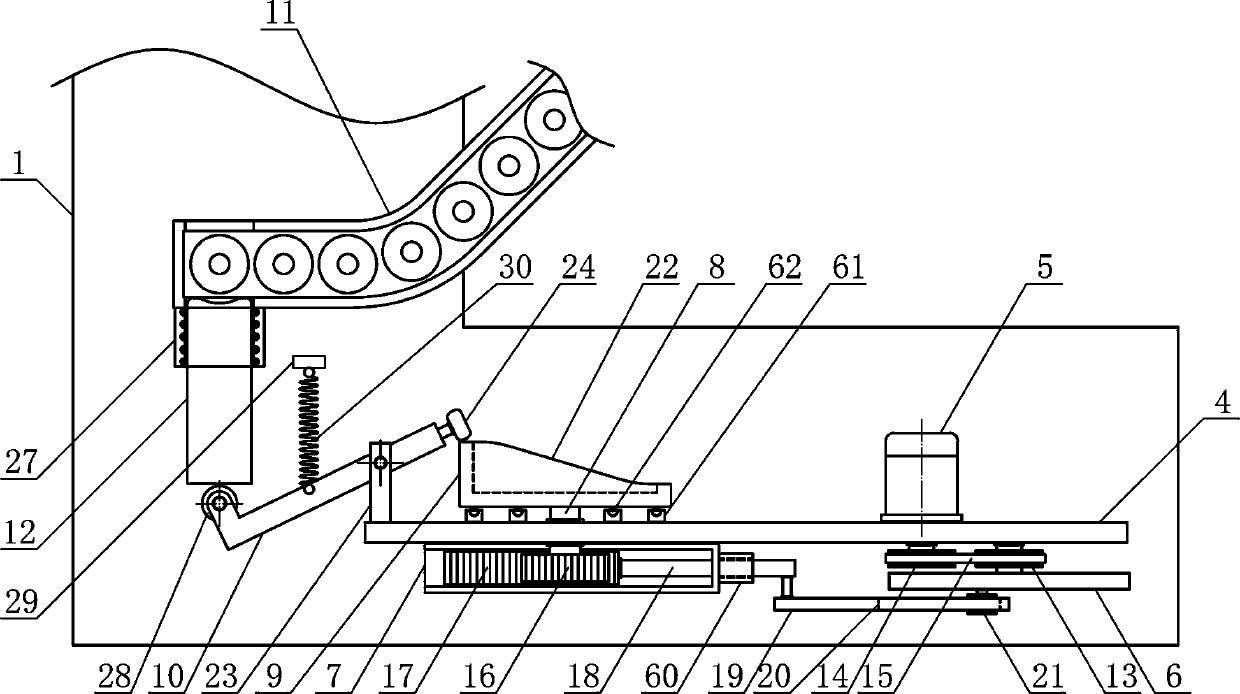

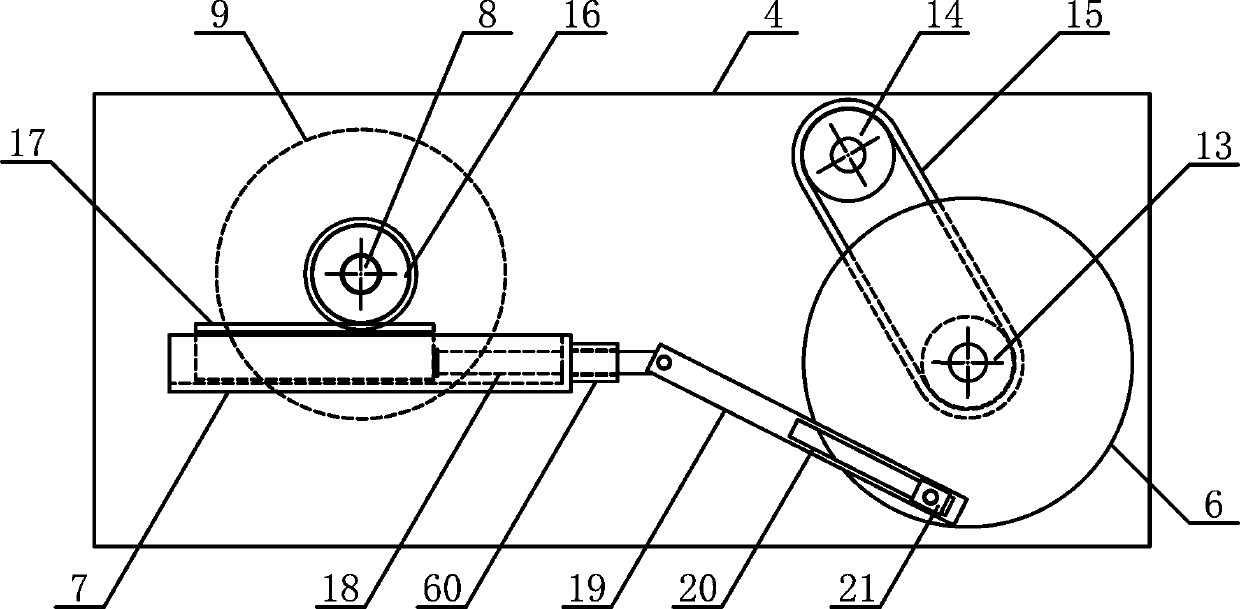

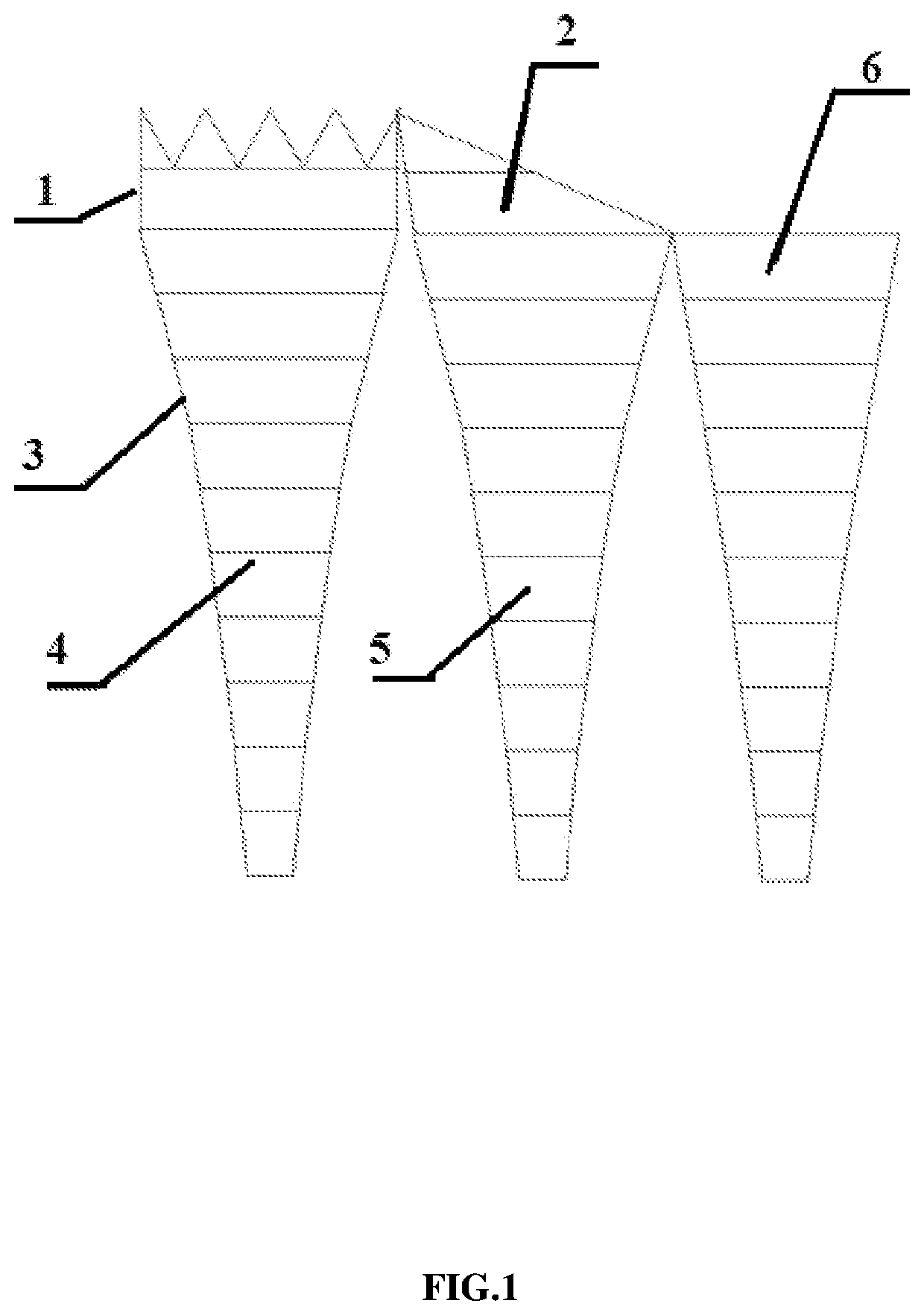

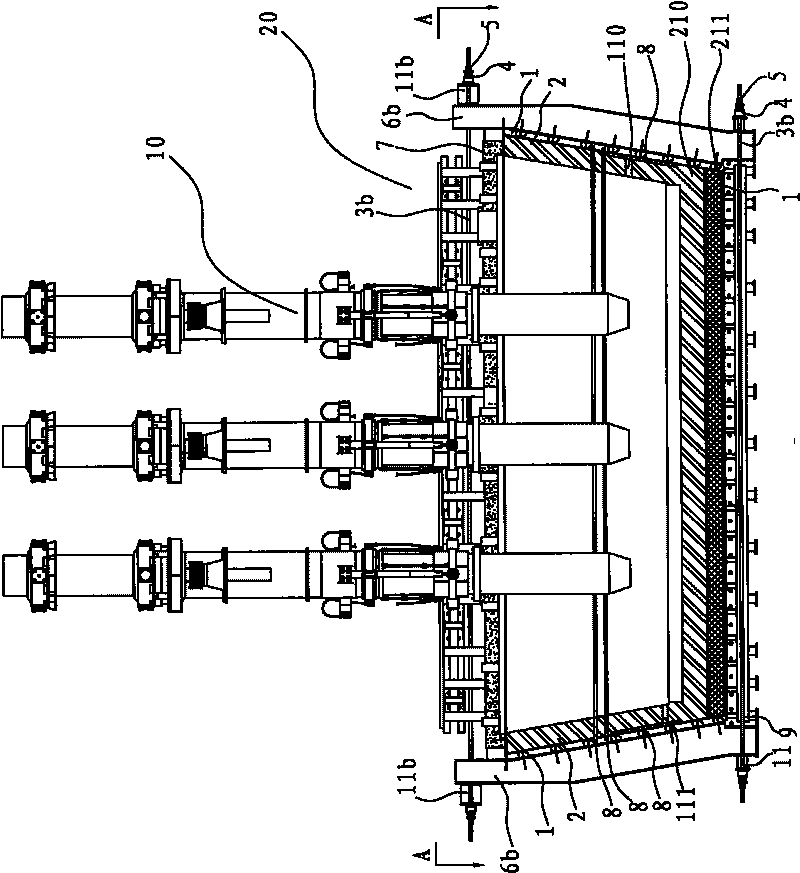

Chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing

ActiveCN111039094AHigh degree of automationSmooth and accurate reciprocating translational movementFilament handlingFiberGear wheel

The invention discloses a chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing and belongs to the field of textile processing mechanical equipment. Accordingto the chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing of the invention, a bobbin feeding mechanism is horizontally and fixedly arranged at the lower side of a bobbin guiding support; a bobbin transferring mechanism above one side of the bobbin feeding mechanism is vertically arranged on the bobbin guiding support; a push rod rotating slope is arranged on the upper side of a reciprocating rotating cam; the middle of a reciprocating rotating rod is hinged to the upper side of a rotating rod supporting seat; a bobbin guiding and feeding pipe locatedabove the reciprocating rotating rod is fixedly arranged on the bobbin guiding support; a lifting transferring guide plate is slidably arranged on a lifting fixing sleeve in a vertical direction; a gear rotating support at the lower end of the lifting transferring guide plate is vertically and rotationally connected with a lifting rotating gear; and a bobbin clamping mechanism is fixedly arrangedon one side of the lifting rotating gear in the radial direction of the lifting rotating gear. The chemical fiber bobbin continuous transferring and feeding device is reasonable in structural design,can efficiently, stably and sequentially feed and machine chemical fiber bobbins one by one, is high in automation degree, and meets processing and using requirements.

Owner:桐乡市富昌化纤股份有限公司

Airbag device

ActiveUS20160159312A1Stable expansionFirm supportPedestrian/occupant safety arrangementEngineeringAirbag

An airbag device includes a main airbag unit with a main bag body that is inflated and deployed from a front side of a front seat when impact is input, and a supplemental airbag unit with a supplemental bag body that is inflated and deployed from a side portion of the main airbag unit when impact is input. The supplemental bag body comes into contact with the main bag body when inflated and deployed and restricts inflation and deployment of the main bag body.

Owner:HONDA MOTOR CO LTD

Thermoplastic composite building material and method of making same

InactiveUS20050029709A1Improve the immunityWell-defined wood grain surfaceWood working apparatusCeramic shaping apparatusMohs scale of mineral hardnessHardness

Polymer composite building materials are provided which contain about 30-80 weight percent resin, 20-70 weight percent fillers and additives, in which the fillers contain at least one bulk filler for reducing the amount of resin needed to make the building material, and at least one aesthetically functional filler for providing the building material with an aesthetic appearance. The bulk filler and the aesthetically functional filler are non toxic, resistant to bacterial attack, and have a Mohs hardness of less than about 5.

Owner:CERTAINTEED CORP

On-load washing method for thermodynamic system

InactiveCN1667344ASolution can not be cleanedHigh strengthAmpholytes/electroneutral surface-active compoundsFlush cleaningActive agentDesalination

The invention relates to a heating power system bearing load cleaning method. The feature is adding agent that has cleaning and maintaining function into agent melding trunk and diluted by desalination water. The compounding of the agent is: interface active agent 5-20%, penetrating agent 5-8%, removing agent 5-15%, dispersing agent 5-20%, surface passivator 5-10%, and the other is water. Adding the agent into system while the boiler or the steam turbine is running, the pH value is maintained between 6 and 10 while cleaning.

Owner:武汉天龙鑫商贸有限公司

High-strength concrete composite expanding agent for steel tube and preparation method thereof

ActiveCN103011655AControllable hydration timeHigh development valueHigh strength concreteWork performance

The invention relates to a high-strength concrete composite expanding agent for a steel tube and a preparation method thereof. The high-strength concrete composite expanding agent comprises the raw material by weight percentage as follows: 30-50% of light calcined magnesium oxide, 8-30% of calcium oxide, 30-60% of zeolitized crushed crude pearlite, and 0.1-0.3% of industrial stearic acid. The water demand for hydration of light calcined magnesium oxide is small in use level, and the light calcined magnesia has the delayed expansion performance and can compensate volume shrinkage of concrete at an older age. The calcium oxide is fast to hydrate and can compensate self-shrinkage and cooling shrinkage of concrete in an earlier stage. The zeolitized crushed crude pearlite can improve the working performance of concrete, so that concrete has good peaceability, and calcium oxide and magnesium oxide expanding components are distributed uniformly in the concrete, so that the problem of nonuniform expansion of concrete is solved. The high-strength concrete composite expanding agent is stable in long-term expansion performance, and expansion and shrinkage as well as strength are in synergetic development. The water required for expansion is little, concrete in a sealed state expands continuously and stably, and the working performance of concrete can be improved. The high-strength concrete composite expanding agent is particularly suitable for preparing steel tube concrete.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

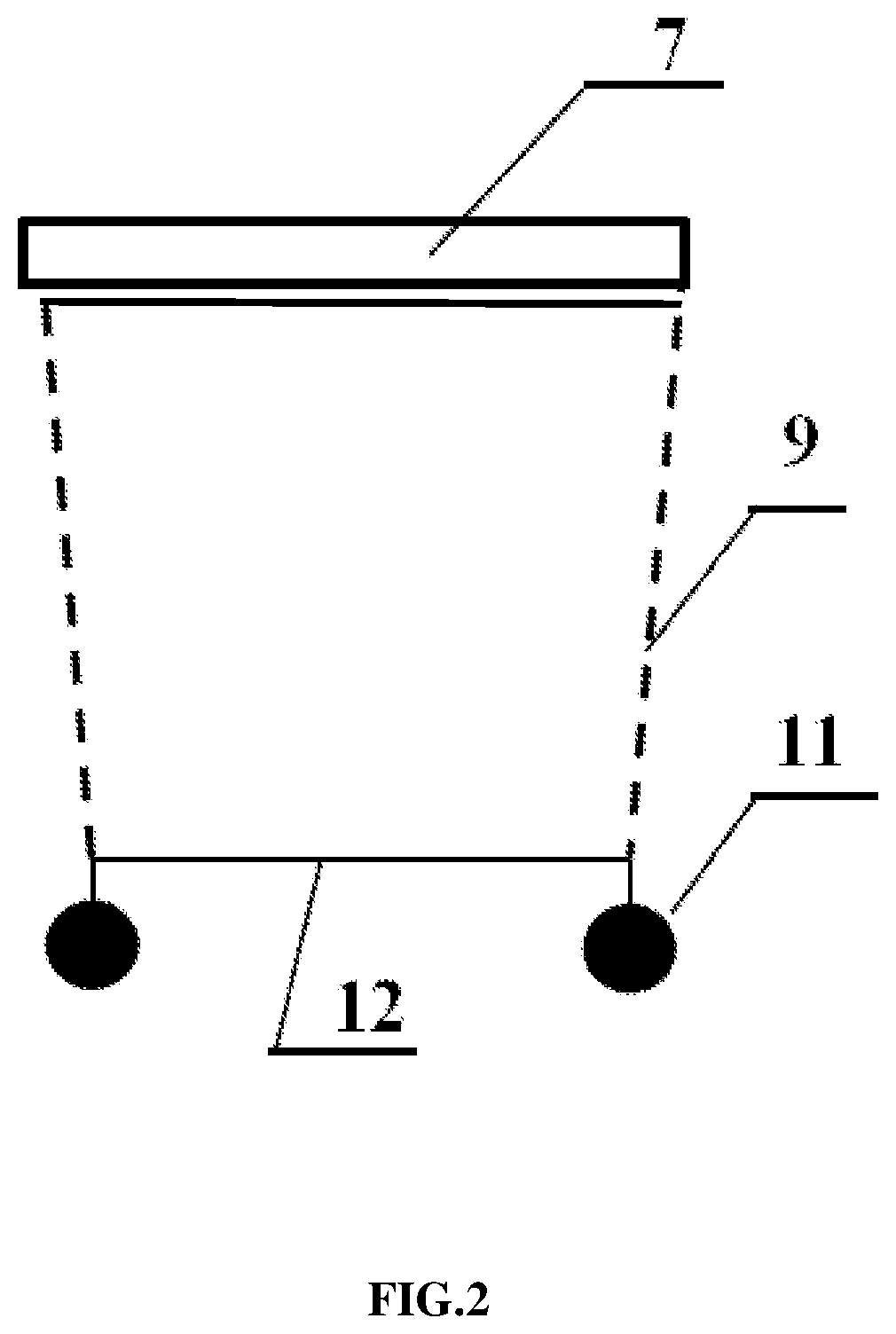

Frame type double-bag drag net for assessing euphausiasuperba resource

The invention discloses a frame type double-bag drag net for assessing euphausiasuperba resource, wherein a polyethylene diamond-mesh netting is adopted; the drag net is characterized in that a single-layer small-mesh four-piece frame structure is adopted; the mesh of the netting at the opening of the net is 50 mm, the perimeter of the opening of the net is 30 meters, and the height of the netting is 2 meters; the opening of the net is sewed on a border rope; the border rope is connected with upper, lower and lateral frames; the length of back and abdominal frames is 4 meters, and the height of the lateral frame is 2 meters; the mesh of the netting on the rear part of the net body is 25 mm, the height of the netting is 2.25 m, the back and abdominal single-piece nettings on the front part are sewed with the two nettings at the rear part respectively, and the lateral net netting on the front part is sewed with the single-piece netting at the rear part; the mesh of the netting of a net bag is 15 mm, the height of the netting of the net bag is 1.2 m, the rear part of the net body is sewed with the front part of the net bag to form two net bags; one floater with buoyancy of 5 kg is arranged on the two sides of the upper frame of the net respectively; an iron chain with gravity force of 10 kg is additionally arranged on the two sides of the lower frame respectively; three cross ropes are adopted by the upper frame; two cross ropes are adopted by the lower frame; and the four cross ropes are crossed and then are connected with one drag rope by using a shackle.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

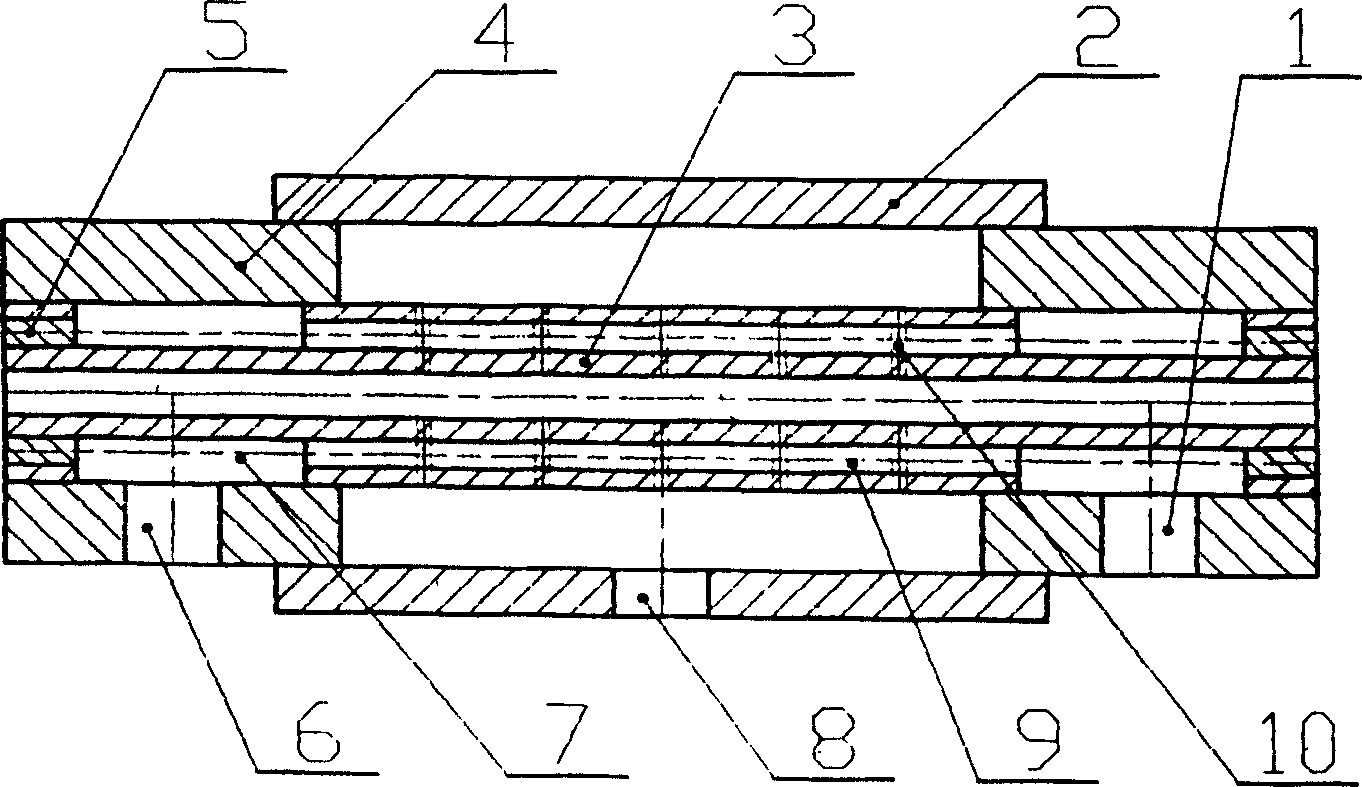

Thermal-shrinkage tube expanding mould

An expanding die for the thermally contracted pipe is composed of a sizing pipe with a longitudinal cooling hole through which the cooling water flows, a cooling water jacket, and a vacuum jacket. It has high expanding speed (10 m / min) and cooling effect.

Owner:CHANGYUAN GRP

Halogen-free flame-retardant PBT/PP (polybutylece terephthalate/propylene)-based wood plastic composite material and preparation method thereof

InactiveCN104312093AReduce hydrolytic degradationHigh tensile strengthPolytetramethylene terephthalatePolymer science

The invention relates to the technical field of wood plastic composite materials and particularly relates to a halogen-free flame-retardant PBT / PP (polybutylece terephthalate / propylene)-based wood plastic composite material and a preparation method thereof. The wood plastic composite material is prepared from the following raw materials in parts by weight: 20-30 parts of polybutylene terephthalate, 10-20 parts of propylene, 28-35 parts of melamino-formaldehyde modified plant fibers, 18-23 parts of coated ammonium polyphosphate, 1-3 parts of a 4A molecular sieve, 4-8 parts of maleic anhydride grafted polyolefin, 2-3 parts of a lubricant, 0.2-0.5 part of an antioxidant and 0.2-0.5 part of a light stabilizer. The wood plastic composite material provided by the invention is high in mechanical strength, and vertical combustion of a sample bar which is 1.6mm thick passes UL-94V-0 grade, the tensile strength reaches 36.3MPa, the bending strength reaches 48.8MPa, the thermal deformation temperature is 144.8 DEG C, and the long-term using temperature reaches up to 120 DEG C.

Owner:东莞市若钻新材料科技有限公司

Production process of autoclaved aerated concrete

InactiveCN101585206AUniform rate of riseUniform bubble sizeCeramic shaping apparatusBuilding materialWork in process

The invention relates to production process of building materials, particularly relates to production process of autoclaved aerated concrete, includes regular steps of preparing materials, pouring, cutting and autoclave, and also includes step of heat insulation and convalesce, and the covalesce is indoors with a room temperature between 40 to 60 DEG, after heat insulation and convalesce, clay body is proceeded with autoclave; the convalesce room is imported with waste steam discharged by covalesce workshop to maintain room temperature. The invention is added with a step of heat insulation and convalesce, such that clay body can proceed gas generation and thicking at a proper temperature basically, which solves a series of problems of clay body bubble, clay body boiling, ununiform gas generation, submerged shrink, model collapse, which affects quality of clay body, and at the same time, the waste stream is provided with comprehensive and effective use, energy-saving and environment-protective, fermentation time of covalesce is reduced for 1 to 2 hours than regular operation, and production efficiency is improved, and percent of pass of clay body (semi-manufactured goods) can be improved from original 87.3% to 99.8%, and then cost is saved.

Owner:东莞市盛丰建材有限公司

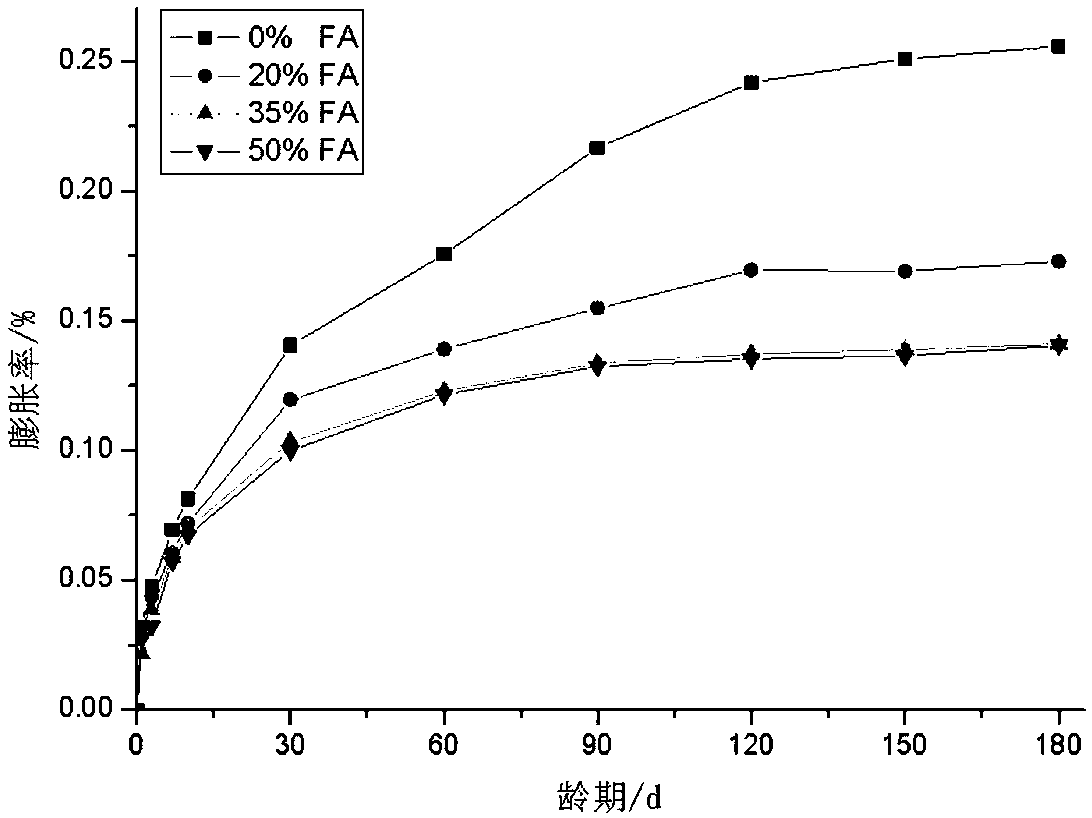

Cement expansive material with harmonious coordinated development of expansion rate and concrete strength

ActiveCN104193266AIncreased durabilityStable expansionSolid waste managementUltimate tensile strengthFly ash

The invention relates to a cement expansive material with harmonious coordinated development of expansion rate and concrete strength, which is prepared from the following raw materials in parts by weight: 40-50 parts of gypsum powder, 16-25 parts of sulfoaluminate clinker, 5-15 parts of quicklime powder, 10-30 parts of fly ash, 2-8 parts of inorganic additive and 1-5 parts of inorganic retarder. The product has the advantages of simple preparation technique, no need of calcining or stirring and lower production cost, and can save abundant energies; and the early expansion character development is quick, and the medium-later expansion development is stable, so the expansion rate can be coordinated with the development of the concrete strength.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

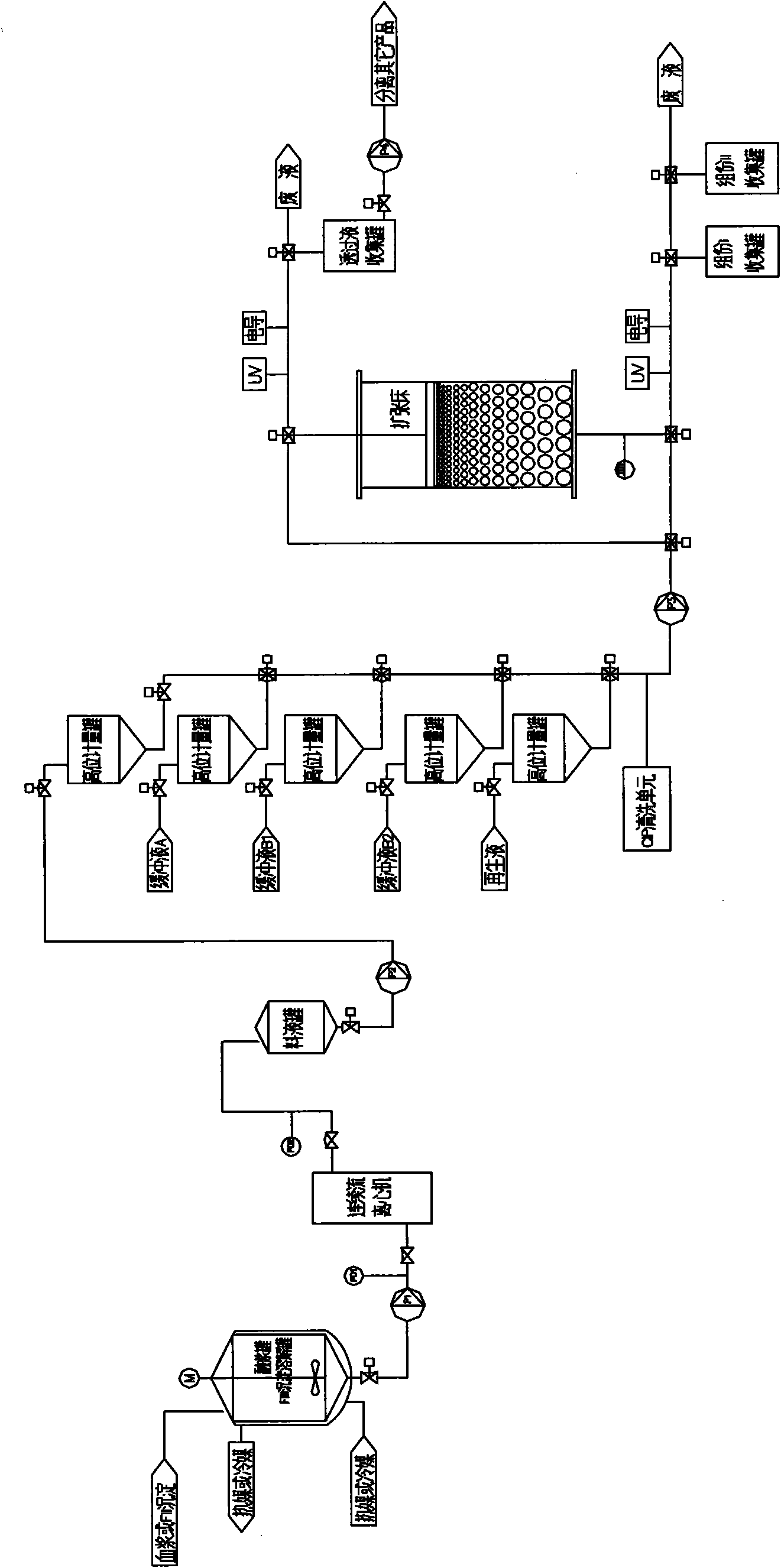

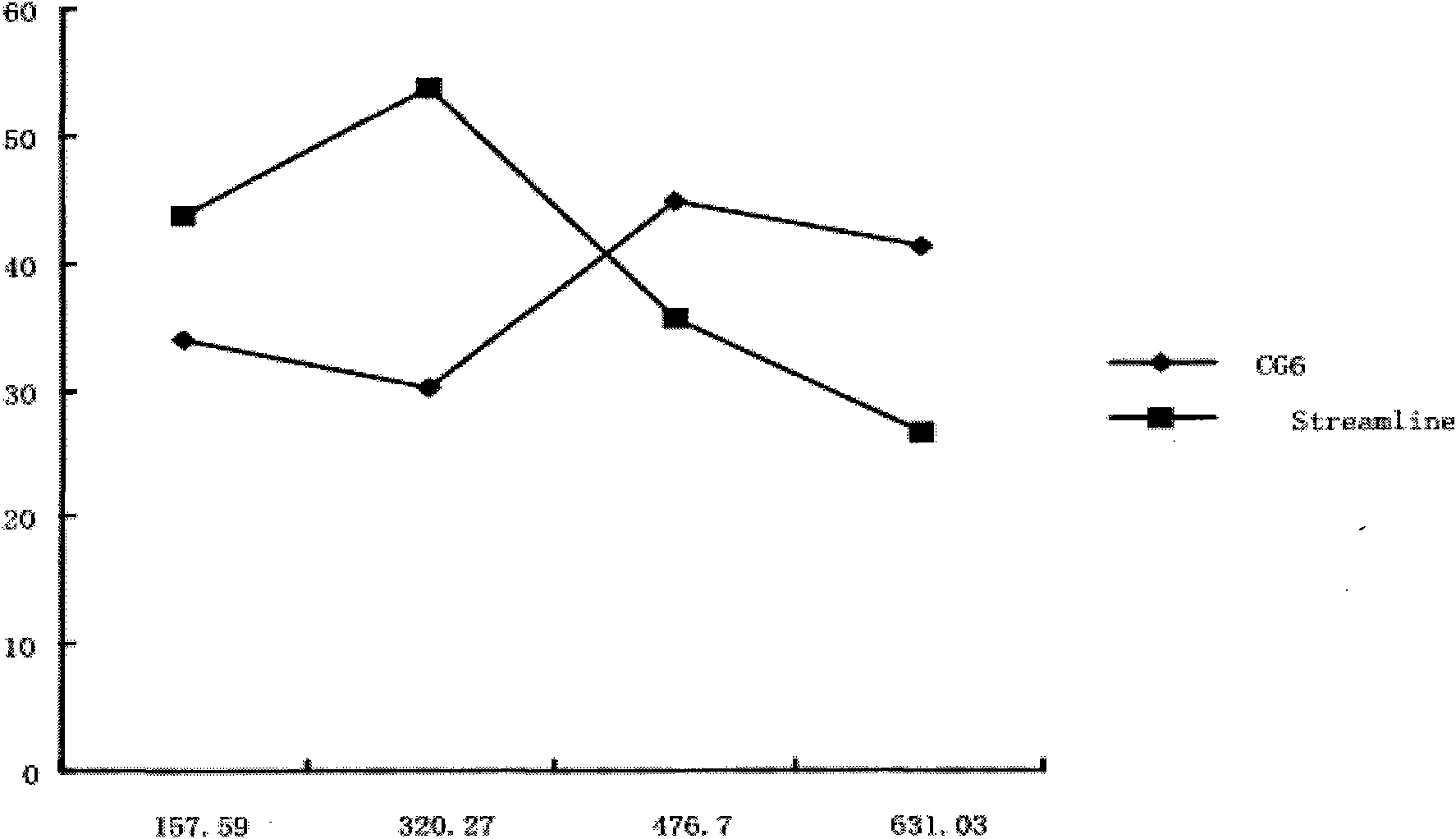

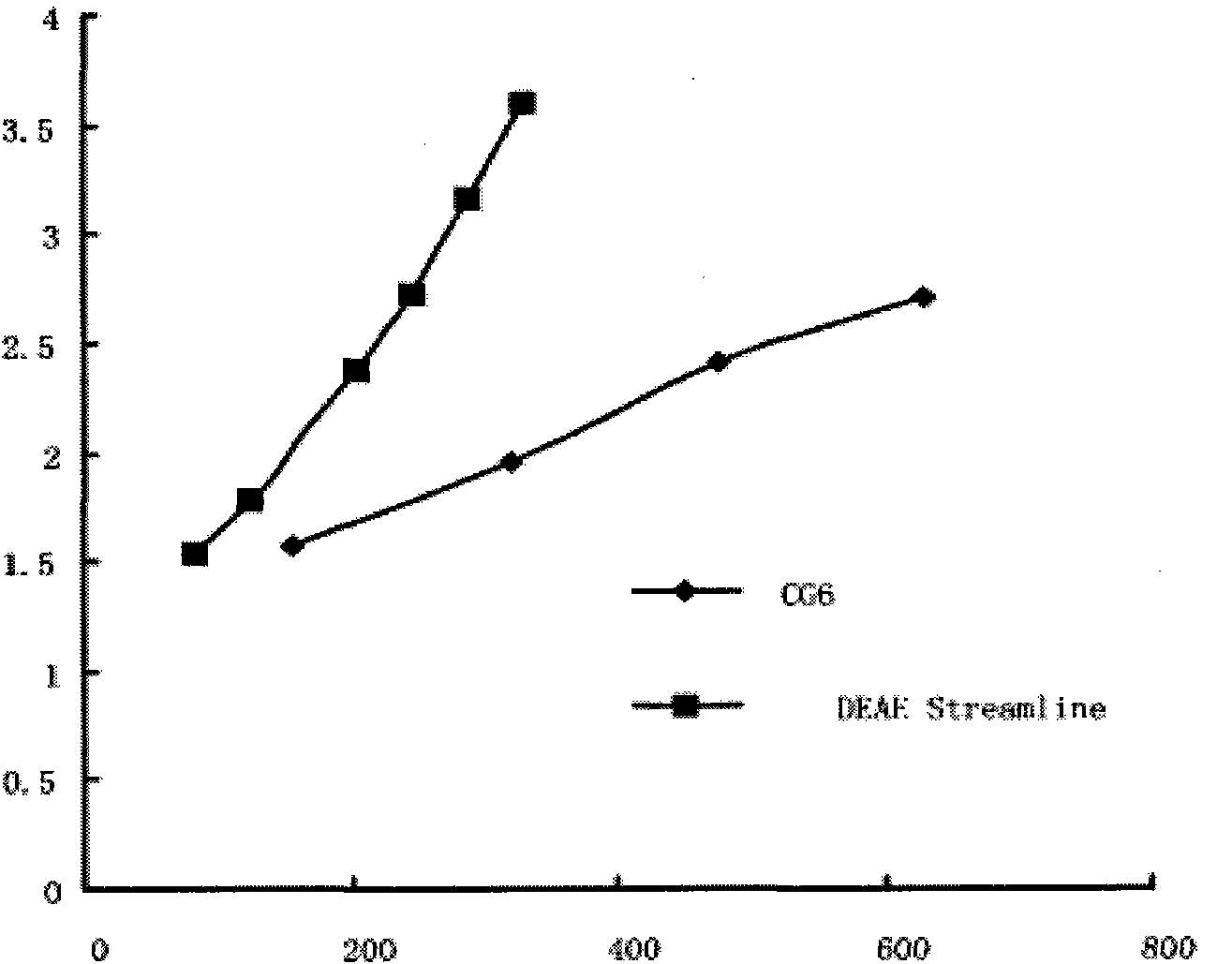

Method for absorbing and separating human prothrombin complex by utilizing expansion bed

InactiveCN101838304AAdsorption separation stabilityEfficient Adsorption SeparationPeptide preparation methodsContinuous flow centrifugationPROTHROMBIN COMPLEX

The invention relates to a method for absorbing and separating a human prothrombin complex by utilizing an expansion bed, comprising the following steps: (a) separating cryoprecitation from melted refrigerated plasma by using a refrigeration type continuous flow centrifuge, and collecting supernate as a raw material; (b) carrying out stable expansion on an expansion bed by using a buffer solution A, wherein the buffer solution A is 0.05mol / L1tris-citric acid with the PH value of 7.0; (c) rapidly switching into a feed solution after the expansion bed is in stable balance, stopping feeding and rapidly switching into the buffer solution A when breakthrough points reaches 5-10%, and washing in an expanded mode; and (d) switching into buffer solutions of 0.4mol / L NaCl and 1.6mol / L NaCl after washing, carrying out gradient elution in a stationary bed mode, and collecting the protein elution peak of the buffer solution of 1.6mol / L NaCl to obtain a prothrombin complex crude product.

Owner:成都英德生物工程有限公司

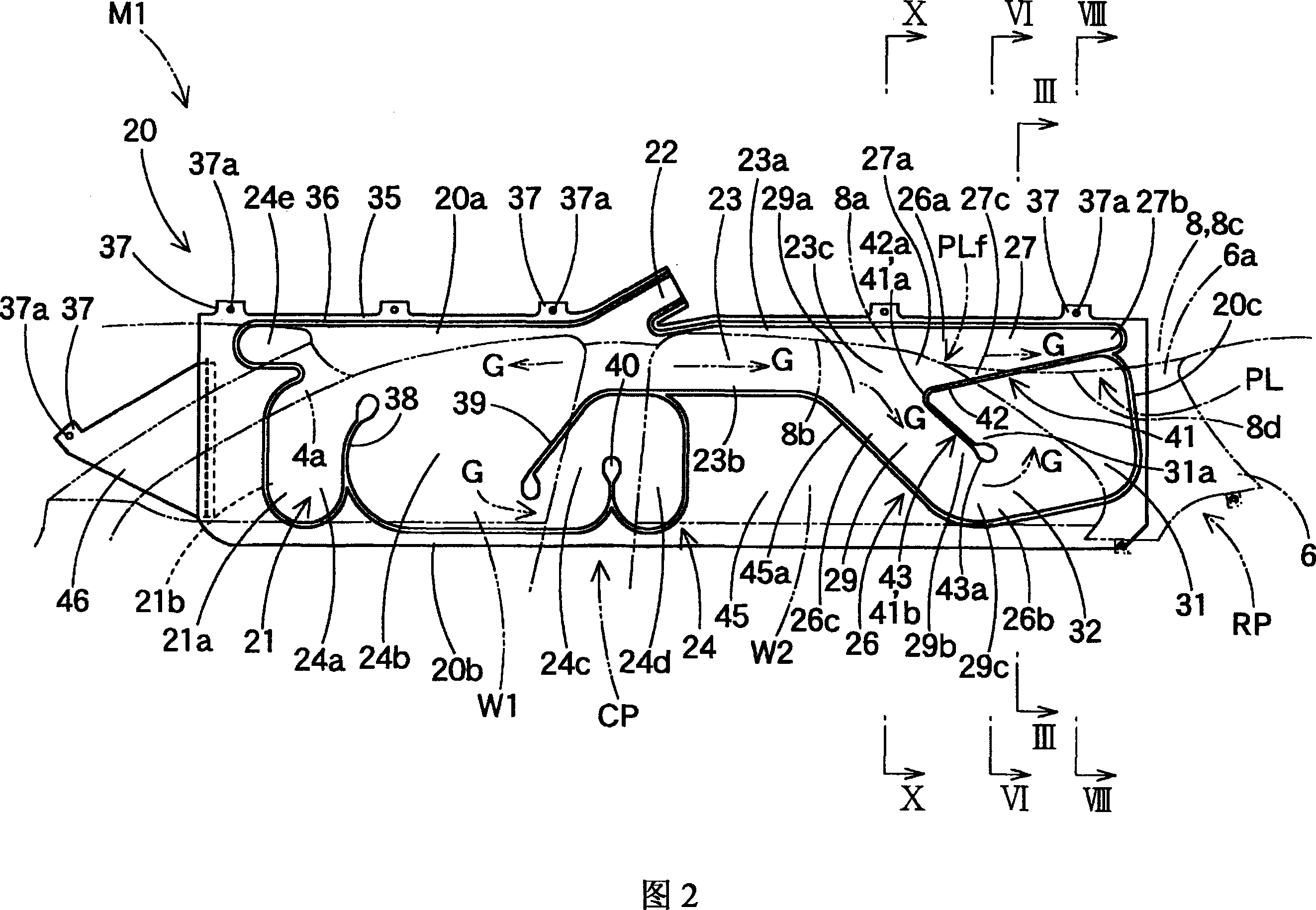

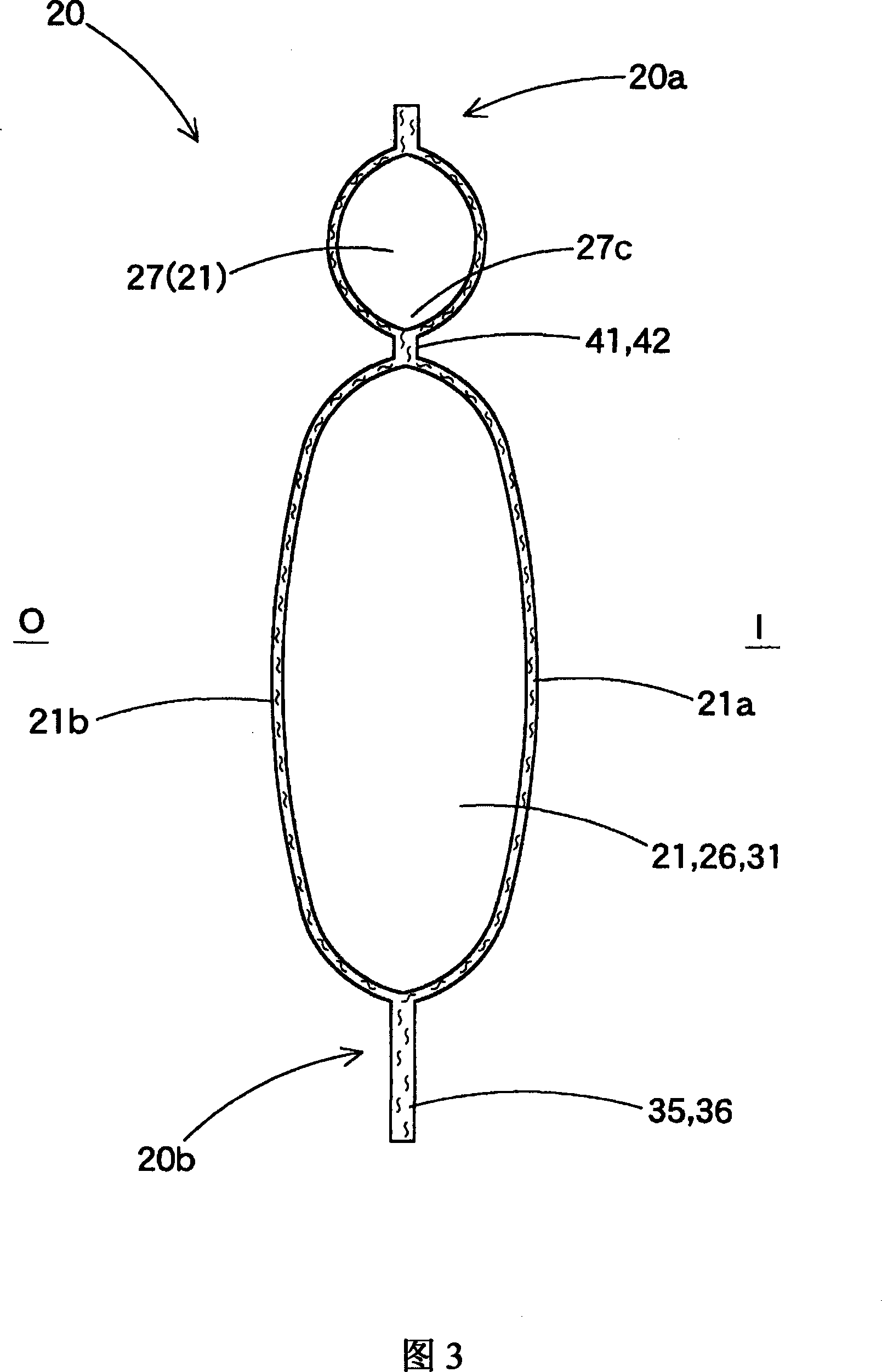

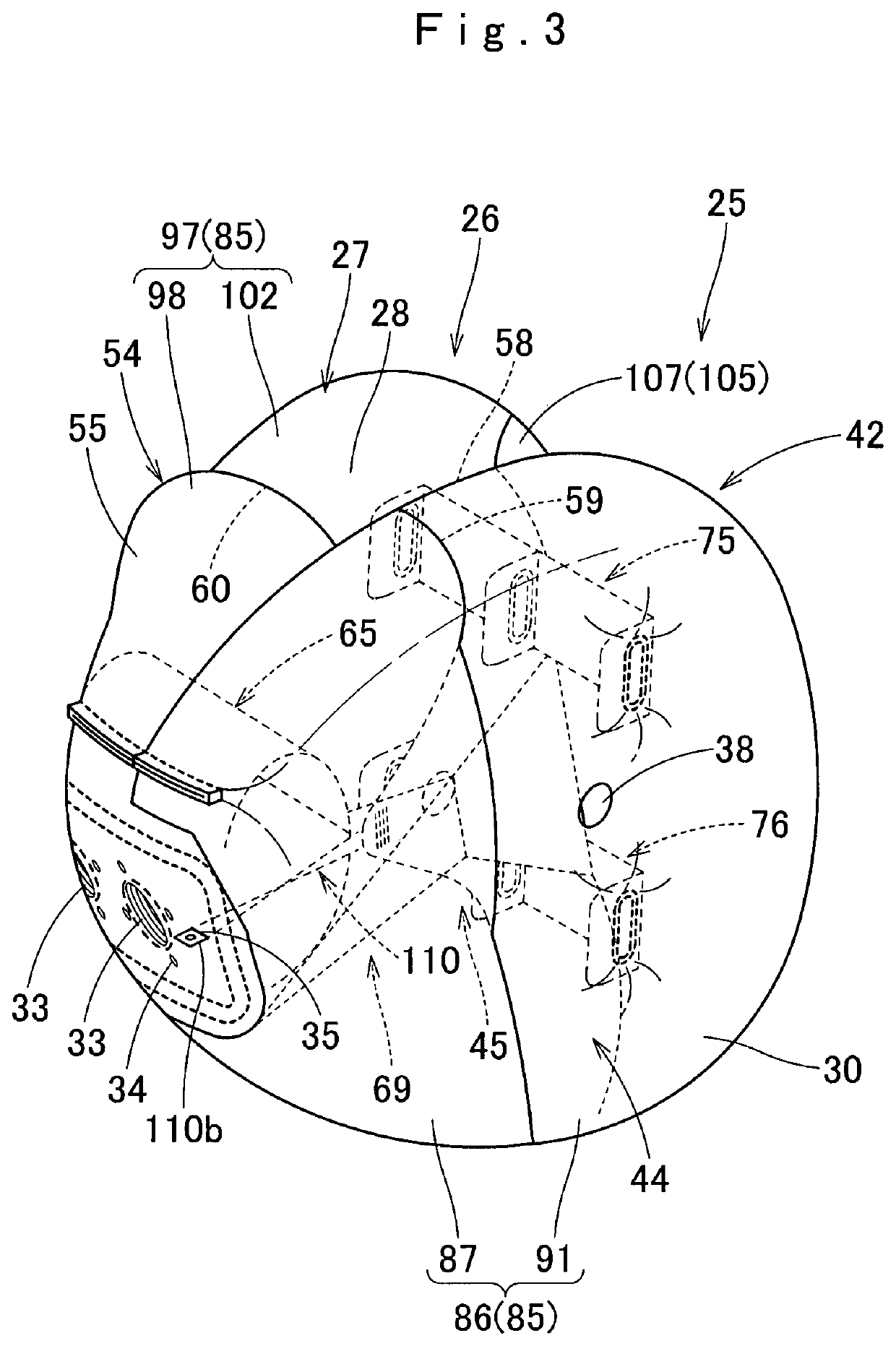

Head-protecting airbag apparatus

ActiveCN101100181AStable expansionSmooth expansionPedestrian/occupant safety arrangementEngineeringAirbag

The airbag of the head-protecting airbag apparatus includes a rear inflatable portion deployed at the interior side of the rear pillar. The rear inflatable portion includes an upper side portion extending rearward from a gas feed passage disposed at the upper periphery of the airbag, a main body disposed below the upper side portion and partitioned from the upper side portion by a partitioning portion, and a branched portion extending downward from the gas feed passage. The main body inflates with inflation gas fed from an inlet opening disposed at the lower end of the branched portion. At least a front lower area of the upper side portion is located below a parting line between a rear pillar garnish and an airbag cover at full inflation of the airbag. The upper side portion and the gas feed passage are folded and housed at exterior side of the folded-up main body and branched portion such that the main body is pushed out toward an interior of the vehicle getting over the upper end of the rear pillar garnish by the upper side portion and the gas feed passage.

Owner:TOYODA GOSEI CO LTD

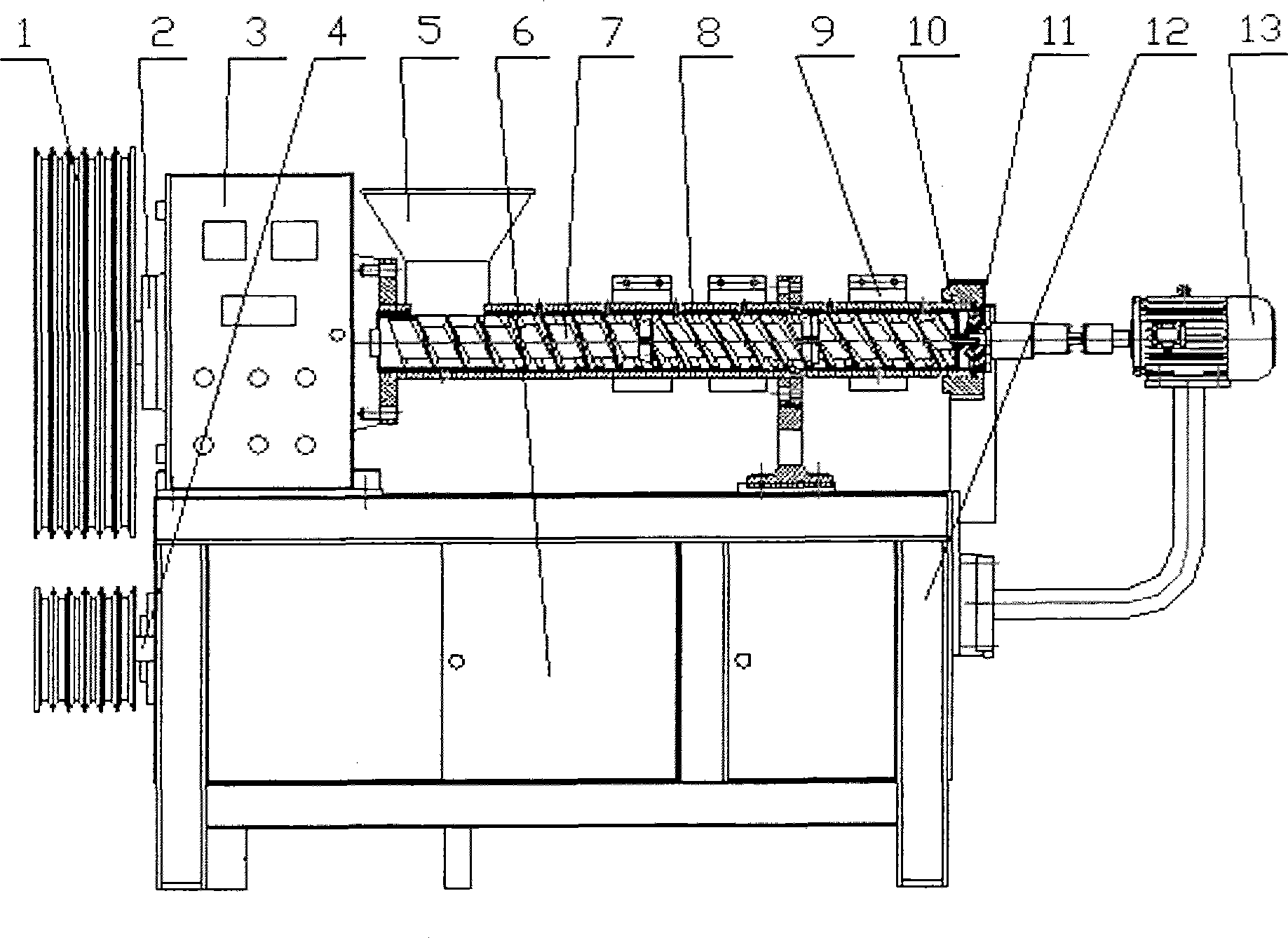

Equipment and technique for puffing foodstuff

InactiveCN101375734AAchieve food grade puffingLow moisture content requirementFood shapingFood gradeAdditive ingredient

The invention discloses equipment and a technology for food puffing. The equipment comprises a main electric motor and a puffing formation cavity, wherein, the puffing formation cavity is composed of a screw, a sleeve and a die head, the screw is arranged inside the sleeve, the die head is fixedly connected with one end of the sleeve, and double die holes are formed on the die head. The invention can achieve the purpose of puffing rice at food grade. According to the invention, the requirement for moisture content of rice is relatively low, and ingredients are not crushed in advance unnecessarily, so that the production efficiency is greatly improved. As the invention improves the adaptability of the prior art, the puffing rate increases, and a better puffing effect is achieved. Puffed rice produced by adopting the technology has the advantage that a heavy decline in the volume weight of powder made from the puffed rice is brought about. Therefore, according to the fact that the smaller volume weight can enable the rice powder to be more soluble and also can enable the taste to be better, the powder made from the puffed rice is taken as the main ingredient for rice powder for babies to ensure that the rice powder can be easily digested by babies and is good in taste.

Owner:杨小静 +1

Nitrogen-phosphorus compounded expansive type halogen-free flame retardant as well as application thereof in wood-plastic composite material

The invention relates to the technical field of wood-plastic composite materials, and in particular relates to a nitrogen-phosphorus compounded expansive type halogen-free flame retardant as well as application thereof in a wood-plastic composite material. The nitrogen-phosphorus compounded expansive type halogen-free flame retardant comprises the following raw materials in parts by weight: 28-35 parts of melamine-formaldehyde resin modified plant fiber and 18-23 parts of coated ammonium polyphosphate, wherein the melamine-formaldehyde resin modified plant fiber is melamine-formaldehyde resin modified wood dust or melamine-formaldehyde resin modified bamboo powder; the coated ammonium polyphosphate is epoxy resin coated ammonium polyphosphate; the particle size of the coated ammonium polyphosphate is 10-20mu m; the polymerization degree of the coated ammonium polyphosphate is 1000-5000; the phosphorus content of the coated ammonium polyphosphate is greater than or equal to 28%; the nitrogen content of the coated ammonium polyphosphate is greater than or equal to 14%. The nitrogen-phosphorus compounded expansive type halogen-free flame retardant is good in flame retardancy effect, free of halogen and particularly applicable to preparation of wood-plastic composite materials.

Owner:东莞市若钻新材料科技有限公司

Phase-change energy-storage three-dimensional fabric concrete canvas and preparation method thereof

The invention discloses phase-change energy-storage three-dimensional fabric concrete canvas which has properties of heat preservation, rapid curing and hardening, flame retardancy, water resistance,wind resistance and the like, and is capable of meeting requirements that a temporary tent is rapidly constructed as a refuge. The phase-change energy-storage three-dimensional fabric concrete canvasdisclosed by the invention is composed of a three-dimensional partitioned fabric and a cement grouting sizing agent, wherein the three-dimensional partitioned fabric is a glass fiber knitted three-dimensional partitioned fabric of which the thickness is 20-30mm; the cement grouting sizing agent is composed of rapidly hardened cement, quartz sand and a phase-change material; by 100 parts of the cement grouting sizing agent, the amount of the rapidly hardened cement in the cement grouting sizing agent is 35-45 parts, the amount of the quartz sand is 45-60 parts, and the amount of the phase-change material is 2-10 parts; the rapidly hardened cement, the quartz sand and the phase-change material can be uniformly mixed and used later when the canvas is used.

Owner:ARMY ENG UNIV OF PLA

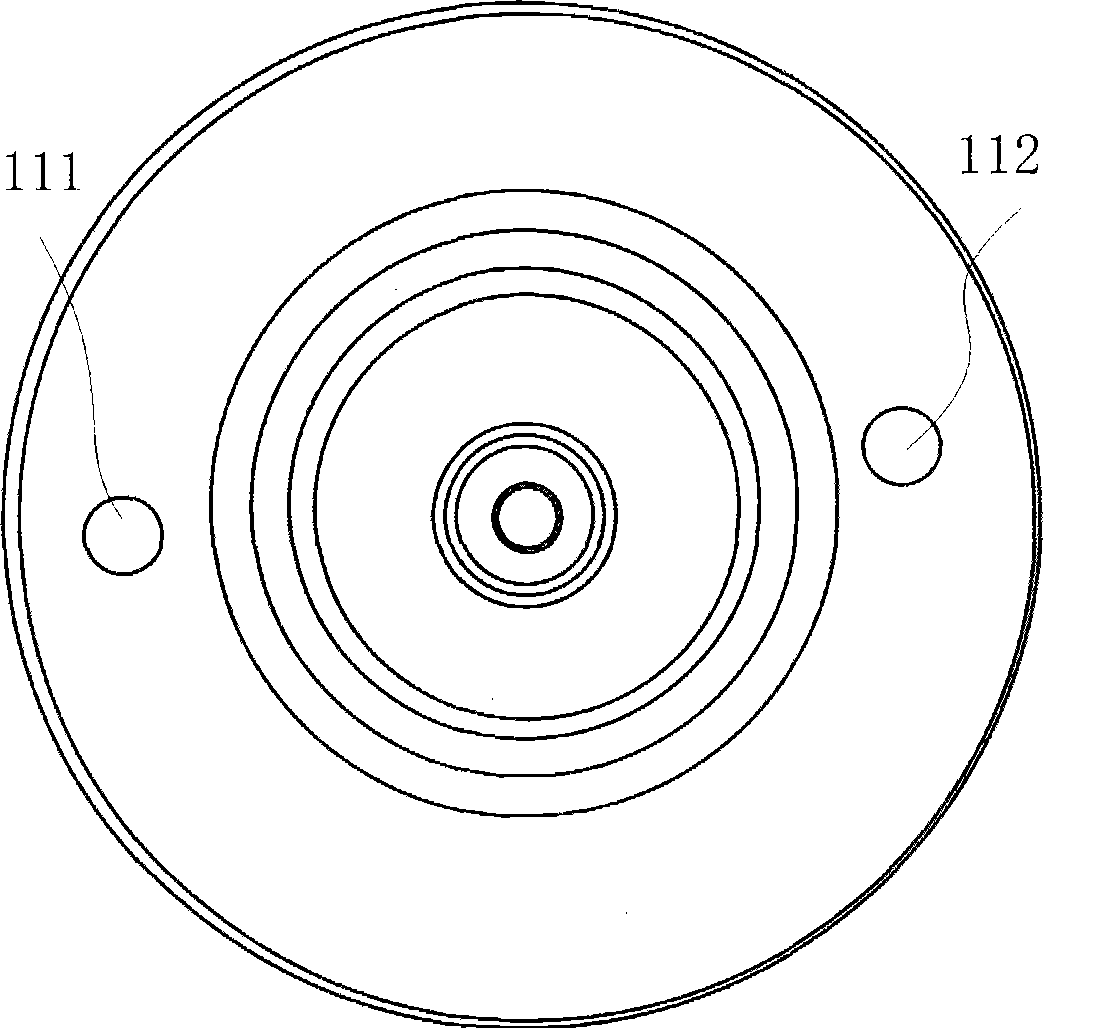

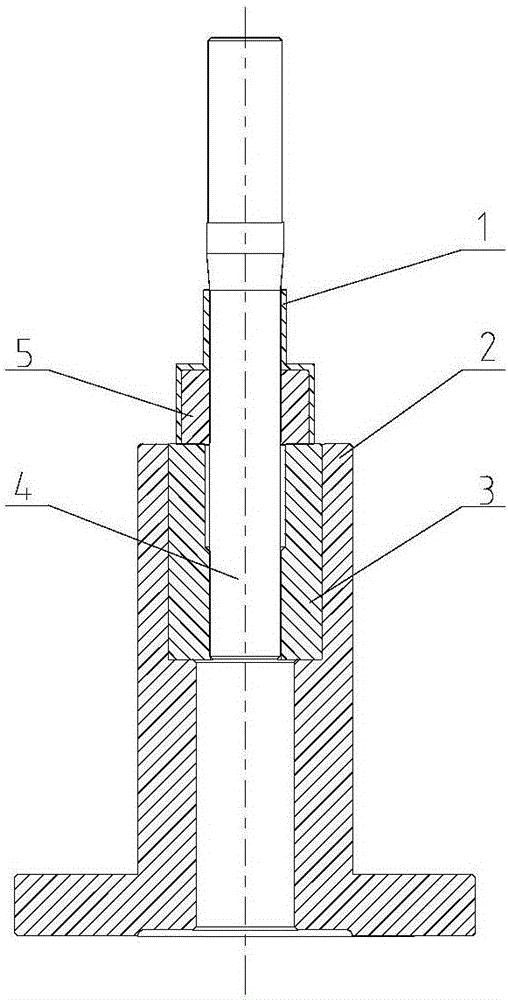

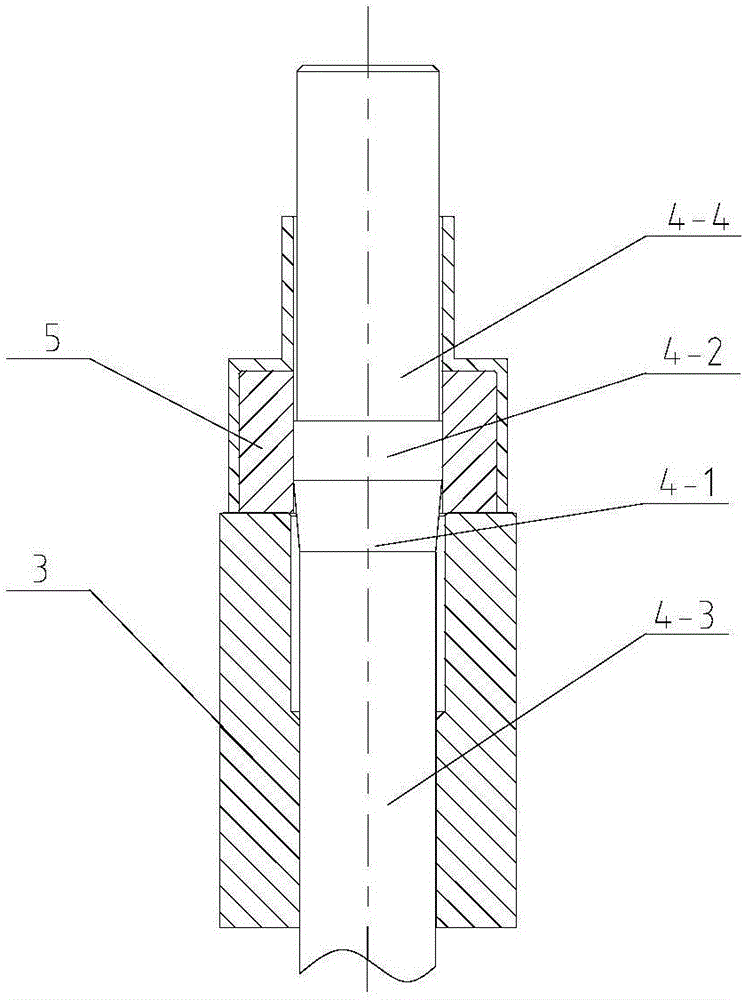

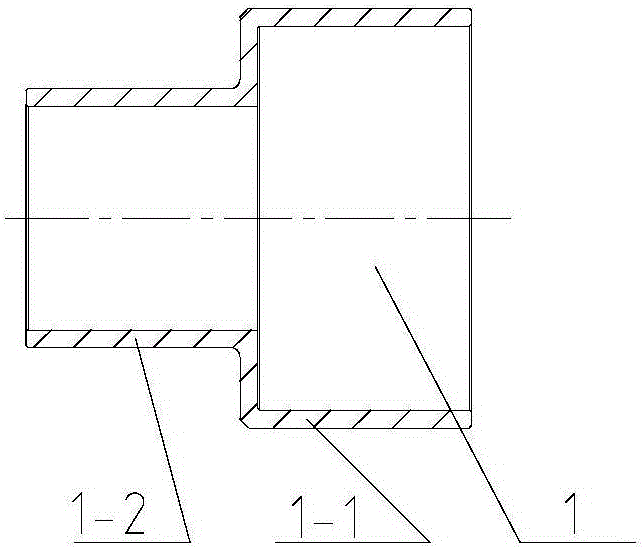

Diameter-expanding device for shape memory alloy reducing tube joint

The invention discloses a diameter-expanding device for a shape memory alloy reducing tube joint. The device comprises a base, a guide shaft sleeve, a reducing compression bar and split diameter-expanding blocks, wherein a shaft sleeve guide hole which extends longitudinally is pre-formed in the upper part of the base; the guide shaft sleeve is assembled in the shaft sleeve guide hole; a push rod guide hole which extends longitudinally is machined at the center of the guide shaft sleeve; the diameter-expanding compression bar is a reducing cylindrical bar body, the lower part is machined to a guide section with a relatively small diameter and the middle transitional part is machined to a cone-shaped hole-expanding section, the upper part of the cone-shaped hole-expanding section is machined to a retaining section which is relatively greater in diameter, and the upper part of the retaining part is machined to a sleeve removing section which is smaller than the retaining section in diameter; the split diameter-expanding blocks are fan-shaped blocks which averagely cut a ring, and the cutting quantity is greater than or equal to 2; the split diameter-expanding blocks are embedded into the large-diameter part of the shape memory alloy reducing tube joint. According to the device disclosed by the invention, the diameter-expanding compression bar presses downward gradually, so that the cone-shaped hole-expanding section and the retaining section successively act on the split diameter-expanding blocks inside the small-diameter part and the large-diameter part of the shape memory alloy reducing tube joint so as to integrally expand the diameter.

Owner:DALIAN MARITIME UNIVERSITY

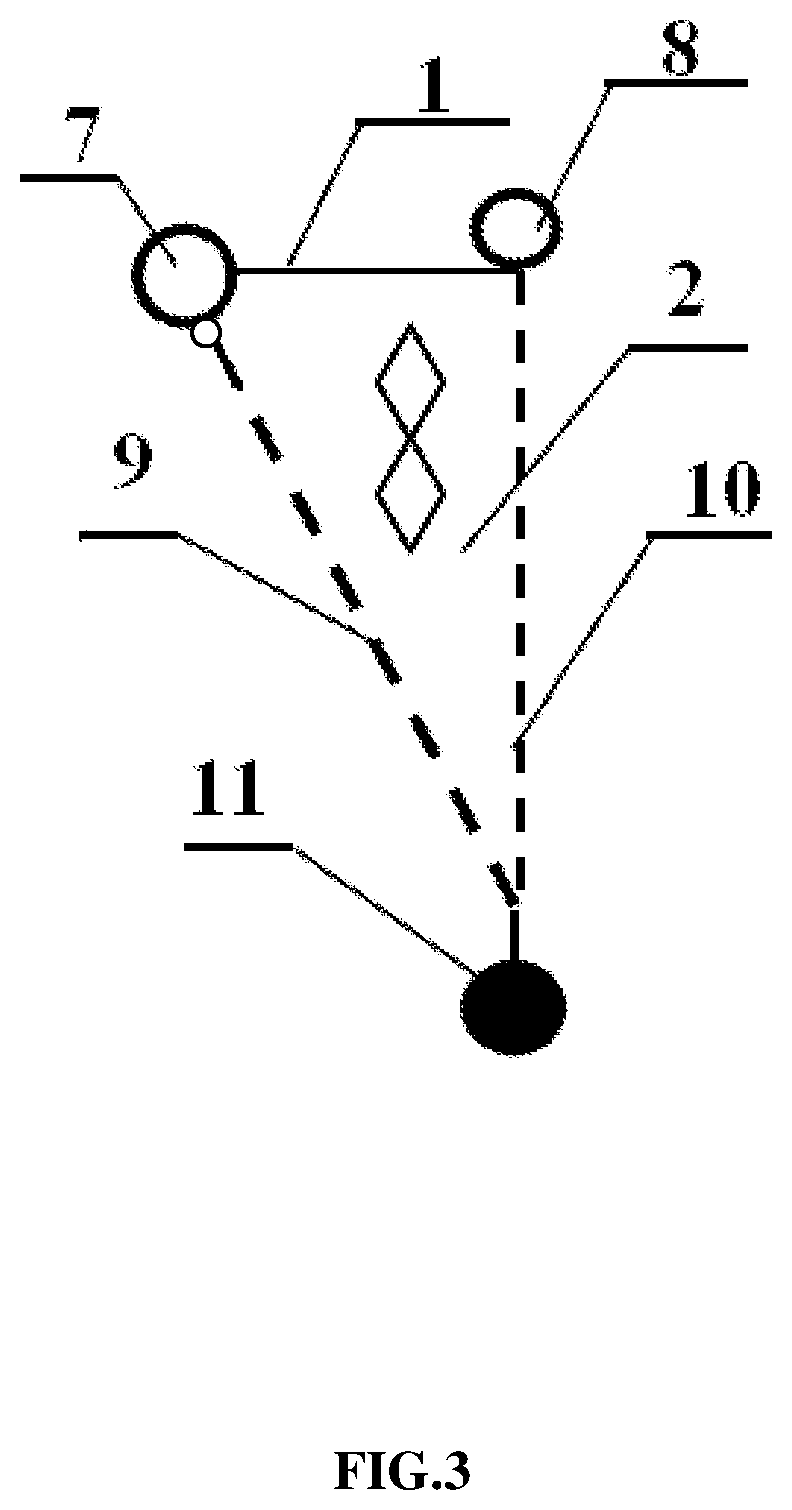

Antarctic krill trawl with centralized sinker and self-expandable mouth structure

InactiveUS20210378219A1Reduce labor costsImprove processing efficiencyFishing netsOther angling devicesLower borderFishery

It is provided an Antarctic Krill trawl with a centralized sinker and a self-expandable mouth structure, including a beam, an upper border rope, a lower border rope, a lateral line, a cover net, a flank net and a body net. A length of the beam is 18 to 20 meters. The beam enables the mouth to be expanded horizontally, a sinker is provided at each of two sides of a belly net at a front end of a first mouth of the body net. A component force of a sinking force by the sinker is transmitted through the lateral line and a sewing edge so as to cause the lower border rope in a tensioning state due to the transmitted force. The body net comprises a back net, a lateral net and a belly net. Taper ratios of the back net and the lateral net are 2-1.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Airbag device

ActiveUS20200094768A1Damage suppressionAccurate protectionPedestrian/occupant safety arrangementEngineeringAirbag deployment

An airbag having an exhaust hole and an opening / closing control device configured to control opening and closing of the exhaust hole are provided. The airbag includes a bag body, and a discharge portion having the exhaust hole, the discharge portion is configured to maintain a blocked state of the exhaust hole by being drawn into the bag body at the time of inflation of the bag body in a state where connection between a connection member and the opening / closing control device is maintained, and to be inflated by protruding from the bag body at the time of inflation of the bag body in a state where the connection between the connection member and the opening / closing control device is released to open the exhaust hole. A dummy inflation portion inflated to partially protrude from the bag body is formed at a position approximately symmetrical to the discharge portion. A volume of the dummy inflation portion at the time of inflating completion is set to be smaller than a volume of the discharge portion in a state where the exhaust hole is open at the time of inflation.

Owner:TOYODA GOSEI CO LTD

Airbag door structure for vehicular passenger seat

InactiveCN1962321AEasy to tearStable expansionPedestrian/occupant safety arrangementDomestic articlesDual injectionDecrease weight

Disclosed is an airbag door structure for vehicular passenger seats having an airbag door and a crash pad integrally formed, preferably in a dual injection molding process using different materials to hide tear lines of the airbag door and crash pad for aesthetic appearance. The airbag door structure can have a reduced number of components to decrease weight and save cost and uses a material undergoing sever change in physical properties as temperature varies for the crash pad and a ductile material undergoing little change as temperature varies for the airbag door so that the airbag can expand stably at various external temperatures without being easily tom off by impact from outside the door.

Owner:HYUNDAI MOTOR CO LTD

Halogen-free double-wall heat shrinkable tube of flame-retardant properties and preparing method thereof

InactiveCN101759907ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinCombustion

The present invention relates to a heat shrinkable tube, particularly to a halogen-free double-wall heat shrinkable tube of flame-retardant properties and a preparing method thereof. The tube is prepared from an outer wall material and an inner wall material based on shares by weight. The outer wall material consists of 53 shares of first polyolefin mixed resin, 10 shares of first auxiliaries and 37 shares of flame retardant. The inner wall material consists of 53 shares of second polyolefin mixed resin, 10 shares of second auxiliaries and 37 shares of flame retardant. The preparing method comprises: preparing the inner and the outer wall materials of the double-wall heat shrinkable tube, extruding, irradiating, expanding and molding. Compared with traditional shrinkable tubes, the present invention has the technical characteristics of adoption of special halogen-free flame retardant in raw materials, good product flame-retardant effect, heat resistance, good properties, no pollution during combustion and low cost. The present invention has obvious economic benefit and environmental protection benefit, and is suitable for large-scale popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

High-voltage halogen-free flame-retardant double-wall heat shrinkage tube and preparation method thereof

ActiveCN101696298ANo pollution in the processImprove flame retardant performanceCable junctionsPigment treatment with organosilicon compoundsPolyolefinEconomic benefits

The invention relates to a heat shrinkage tube, in particular to a high-voltage halogen-free flame-retardant heat-shrinkage tube and a preparation method thereof. The high-voltage halogen-free flame-retardant double-wall heat shrinkage tube comprises an outer-wall material and an inner-wall material; wherein the outer-wall material comprises the following ingredients in parts by weight: 80 parts of first polyolefin mixed resin, 10 parts of first auxiliary agent, 5 parts of flame retardant and 5 parts of auxiliary flame retardant; the inner-wall material comprises the following ingredients in parts by weight: 80 parts of second polyolefin mixed resin, 10 parts of second auxiliary agent, 5 parts of flame retardant and 5 parts of auxiliary flame retardant; and the preparation method comprises the following steps of: preparing the inner-wall material and the outer-wall material of the double-wall heat shrinkage tube, extruding, irradiating, expanding and molding. Compared with the traditional heat-shrinkage tube, the high-voltage halogen-free flame-retardant double-wall heat shrinkage tube has the technical characteristics that: as the flame retardant and the auxiliary flame retardant are adopted in the raw materials, the product has good flame retarding effect, high-temperature resistance, favorable performance, no pollution even in the combustion process, reduced cost, remarkable economic benefit and environment-friendly benefit and is suitable for large-scale popularization and application.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

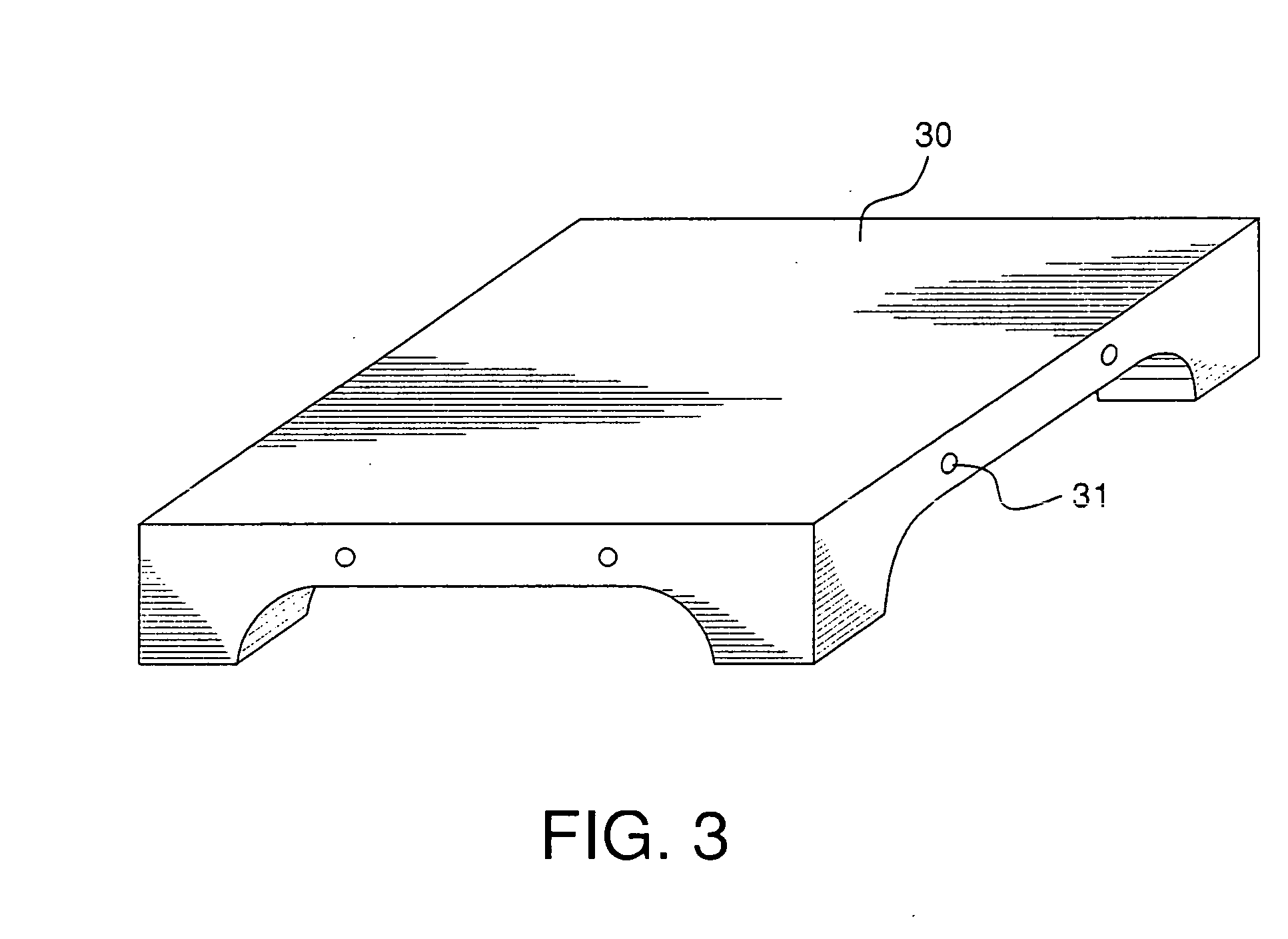

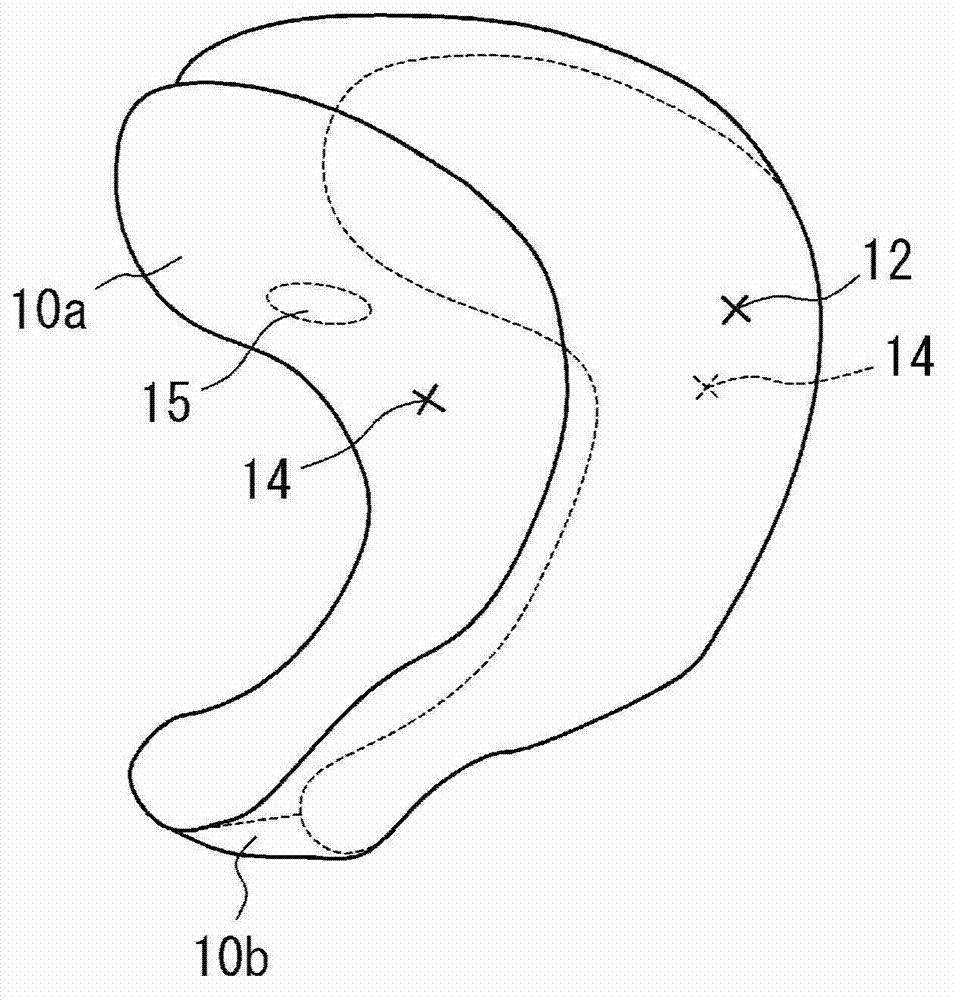

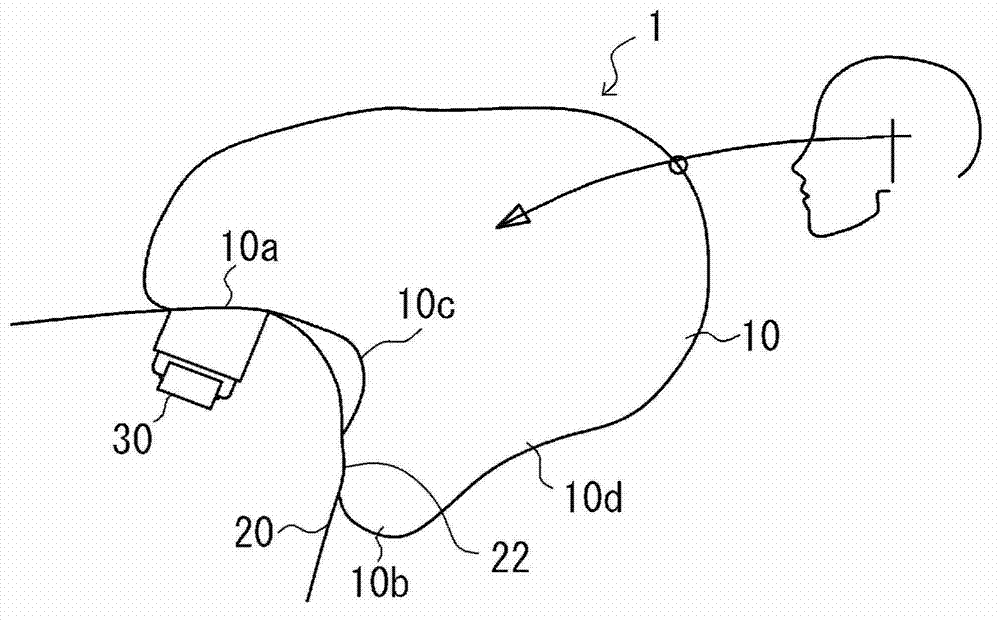

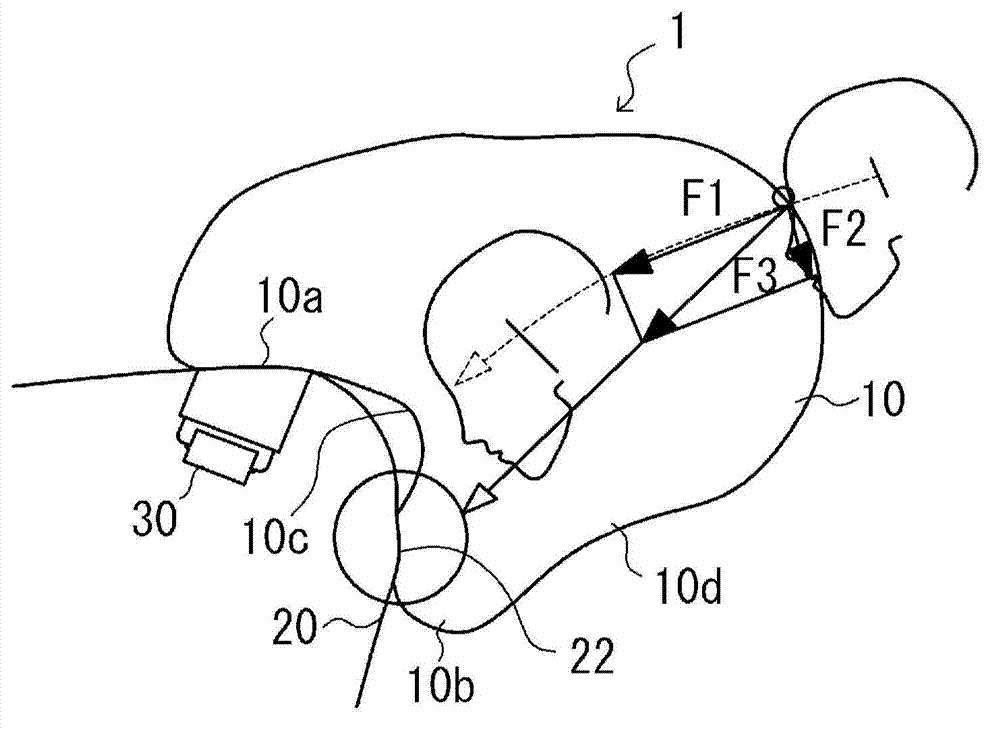

Method of manufacturing cushion for front passenger seat air bag device

InactiveCN102858600AReduce capacityStable expansionPedestrian/occupant safety arrangementEngineeringAirbag

Achieved is a cushion for a front passenger seat air bag device such that the capacity is reduced, and that moreover, coaction during inflation and deployment is stabilized. Disclosed is a method of manufacturing the cushion (10) for the front passenger seat air bag device (1) such that base fabrics constitute a main panel (12) and left and right side panels (14), and that the side edges of the main panel (12) and those of the left and right side panels (14) are sewn together, with the result that the cushion (10) is provided with a shape portion having an arbitrary radius of curvature. The main panel (12) and the side panels (14) are sewn together in such way that a rectangular opening is formed in the portion where the main panel (12) and the side panels (14) start to be sewn together and where this sewing operation is completed, the length of the short sides of the rectangular opening being equal to the width of the ends of the side panels (14), and the length of the long sides of the rectangular opening being equal to the width of the ends of the main panel (12). Subsequently, the short sides are tucked into the opening. Thereafter, the short sides and the long side are sewn together, and thereby the shape portion having the arbitrary radius of curvature is formed.

Owner:ASHIMORI INDS

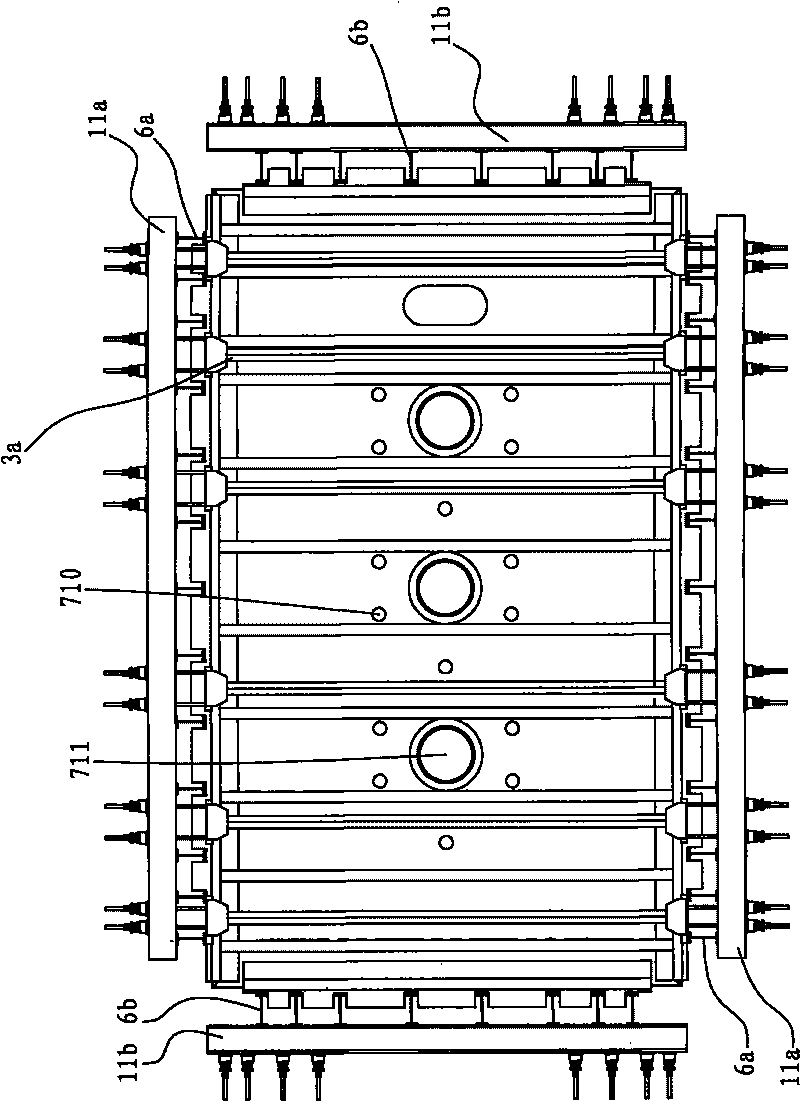

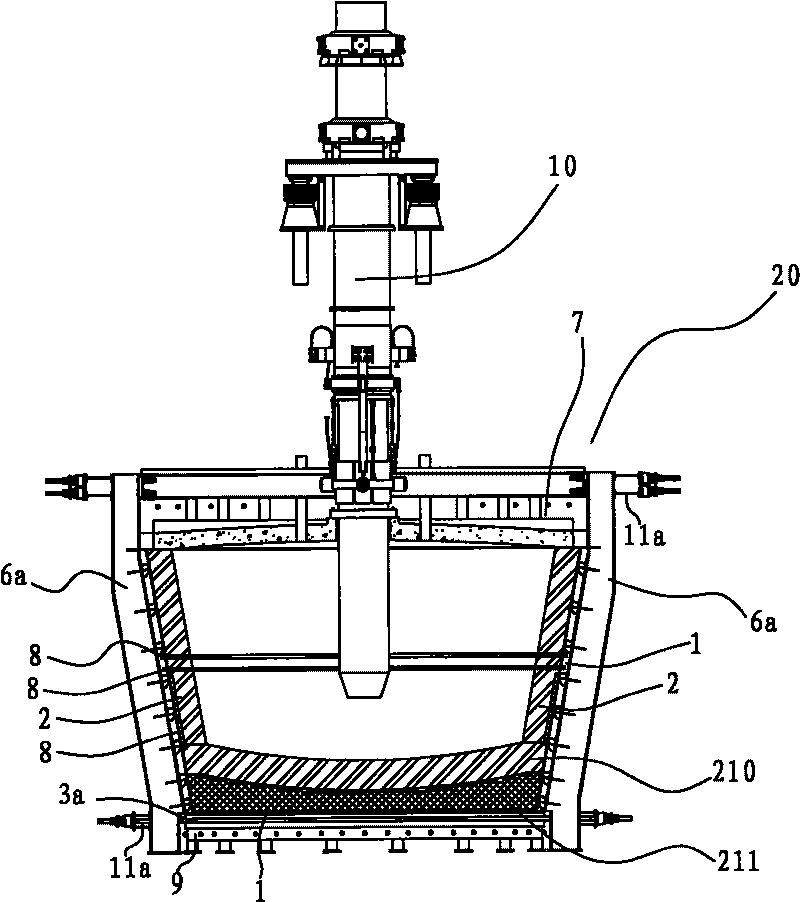

Electric furnace

ActiveCN101762152APromote expansionStable expansionLighting and heating apparatusElectric arc furnaceSlag

The invention relates to an electric furnace which comprises a furnace body, an elastic frame and an electrode, wherein the furnace body, of which the side walls incline inwards from top to bottom, comprises a furnace shell and a furnace cover; the furnace shell is provided with a product discharge port and a slag discharge port; the top end of the furnace shell is opened, and the side walls and the bottom wall of the furnace shell are provided with a refractory material layer; the furnace cover is arranged on the top end of the furnace shell to cover the opened top end of the furnace shell; the elastic frame is arranged outside the furnace shell to hoop the furnace shell; the electrode extends into the furnace body after penetrating the furnace cover from the top of the furnace body, and can move from top to bottom. The electric furnace of the invention has good integrated expansibility of the furnace body, i.e. the furnace body is expanded stably, uniformly and synchronously so that the service life of the furnace body is prolonged, the maintenance operation is reduced, and the cost is decreased.

Owner:CHINA ENFI ENGINEERING CORPORATION

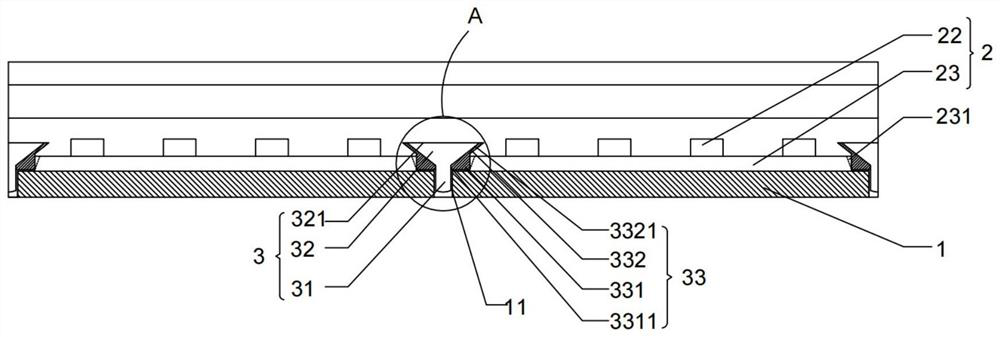

Backlight module and display device

ActiveCN114545685ASimple structureEasy to operatePlanar light sourcesCoatingsDisplay deviceEngineering

The invention provides a backlight module. The backlight module comprises a back plate and a backlight part installed on the back plate. The plurality of backlight parts are arranged on the back plate; an abutted seam is arranged between every two adjacent backlight parts at intervals; an adjusting piece is mounted at each abutted seam; the adjusting piece comprises a connecting part and a connecting part, wherein one end of the connecting part penetrates through the abutted seam to be installed on the back plate; the depth of the connecting part mounted in the back plate is adjustable; the adjusting part is arranged at the end, away from the back plate, of the connecting part, and the outer diameter of the adjusting part is gradually reduced in the direction towards the back plate; one end of the adjusting part enters the abutted seam; the width of the abutted seam is adjusted by adjusting the degree of the adjusting part entering the abutted seam; compared with the prior art, the backlight module is provided with the adjusting part, an operator can finely adjust the width of the abutted seam between the backlight parts through the adjusting part, and all the abutted seams of the backlight module meet the standard requirement.

Owner:CHANGSHA HKC OPTOELECTRONICS CO LTD +1

Airbag device with exhaust hole

ActiveUS11124149B2Accurate protectionSimple configurationPedestrian/occupant safety arrangementControl theoryAirbag deployment

An airbag having an exhaust hole and an opening / closing control device configured to control opening and closing of the exhaust hole are provided. The airbag includes a bag body, and a discharge portion having the exhaust hole, the discharge portion is configured to maintain a blocked state of the exhaust hole by being drawn into the bag body at the time of inflation of the bag body in a state where connection between a connection member and the opening / closing control device is maintained, and to be inflated by protruding from the bag body at the time of inflation of the bag body in a state where the connection between the connection member and the opening / closing control device is released to open the exhaust hole. A dummy inflation portion inflated to partially protrude from the bag body is formed at a position approximately symmetrical to the discharge portion. A volume of the dummy inflation portion at the time of inflating completion is set to be smaller than a volume of the discharge portion in a state where the exhaust hole is open at the time of inflation.

Owner:TOYODA GOSEI CO LTD

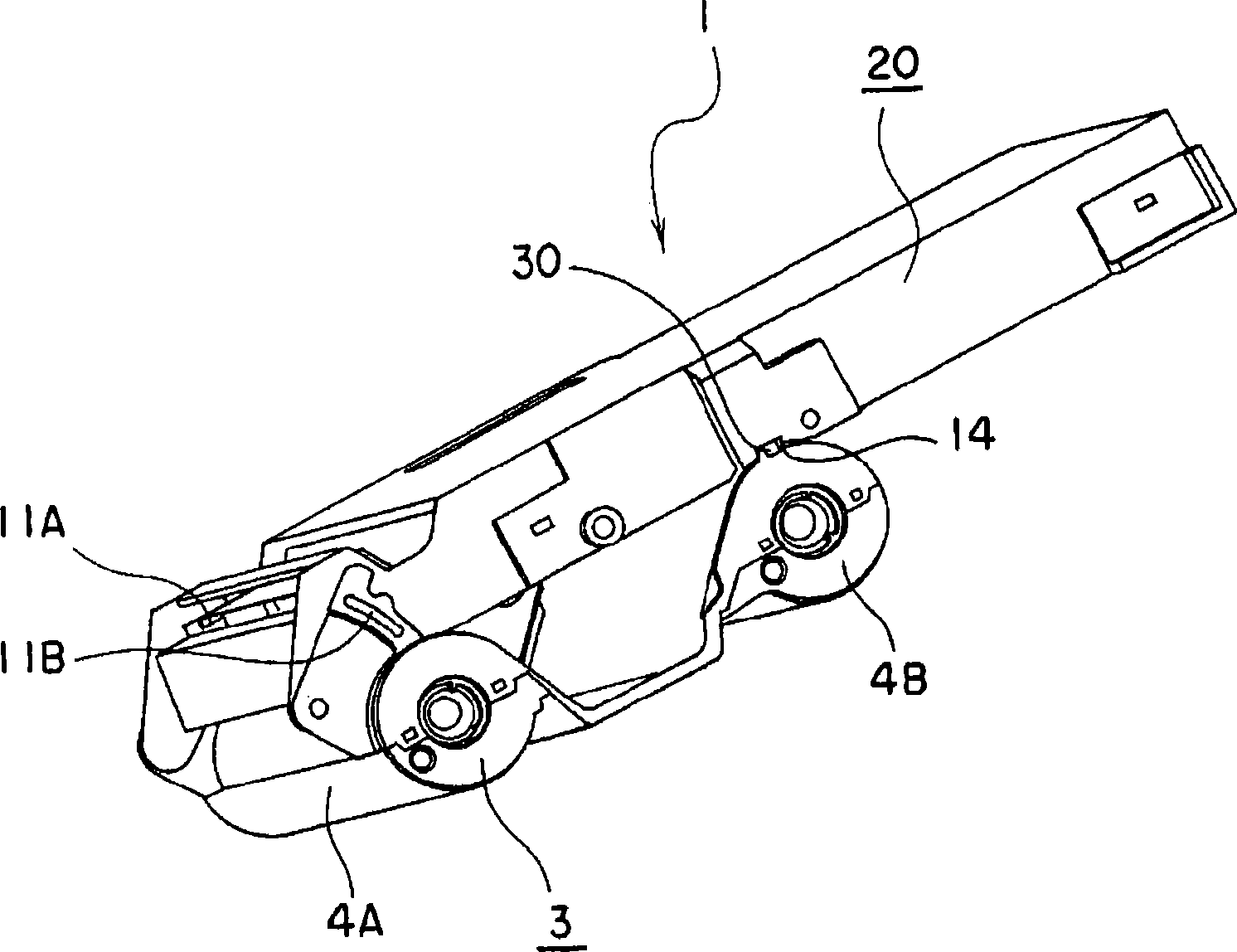

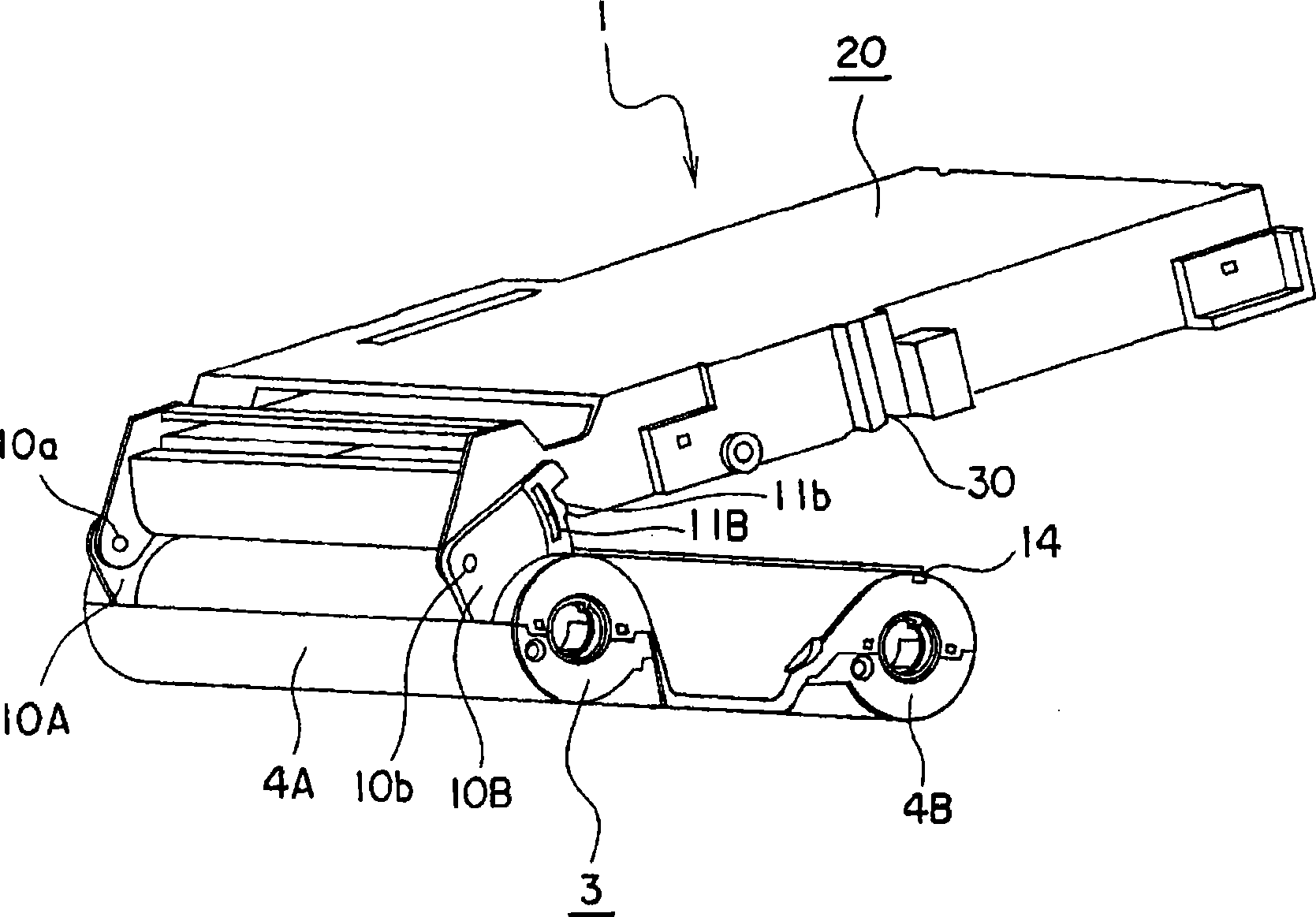

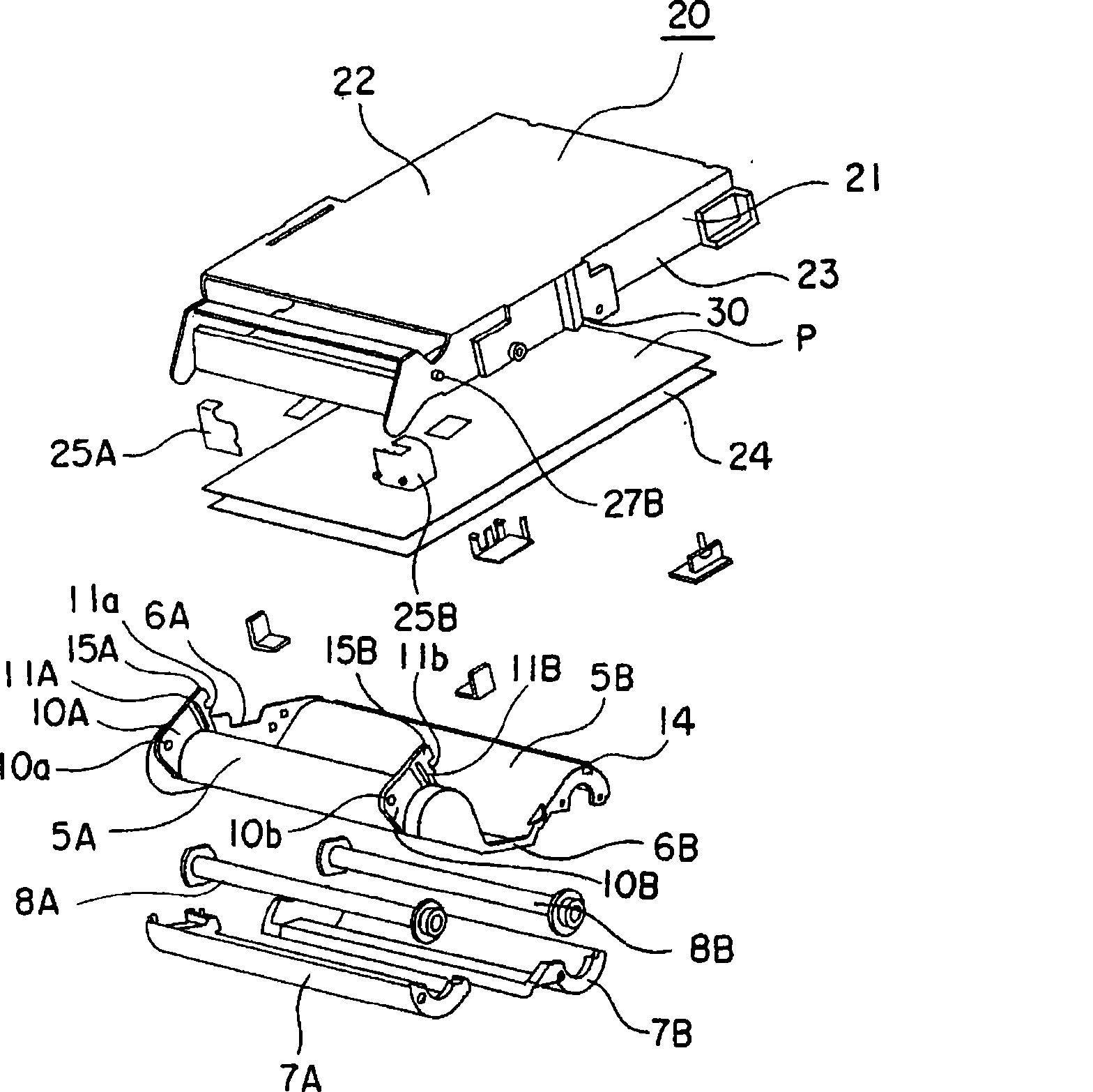

Ribbon cassette structure integrated with paper feed tray and printer using the ribbon cassette structure integrated with paper feed tray

InactiveCN101450551ACompact structureShipping compactInk ribbon cartridgesPrinting mechanismsBobbinEngineering

The invention provides a ribbon cassette structure integrated with a paper feed tray capable of changing into compact structure when conveying the circulation path and changing into better state suitable for using when used by the printer. The structure is characterized that: a pair of bobbin receiving units (4A, 4B) that are connected to each other, and the paper feed tray (20) are pivotally connected to each other so as to be opened or closed between an open state when they both are mostly separated from each other, and a closed state when they are conencted.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com