Thermoplastic composite building material and method of making same

a technology of thermoplastic composites and building materials, applied in the field of thermoplastic composite building materials and making same, can solve the problems of affecting the quality of thermoplastic composites, etc., and achieves the effects of reducing the number of raw materials, and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

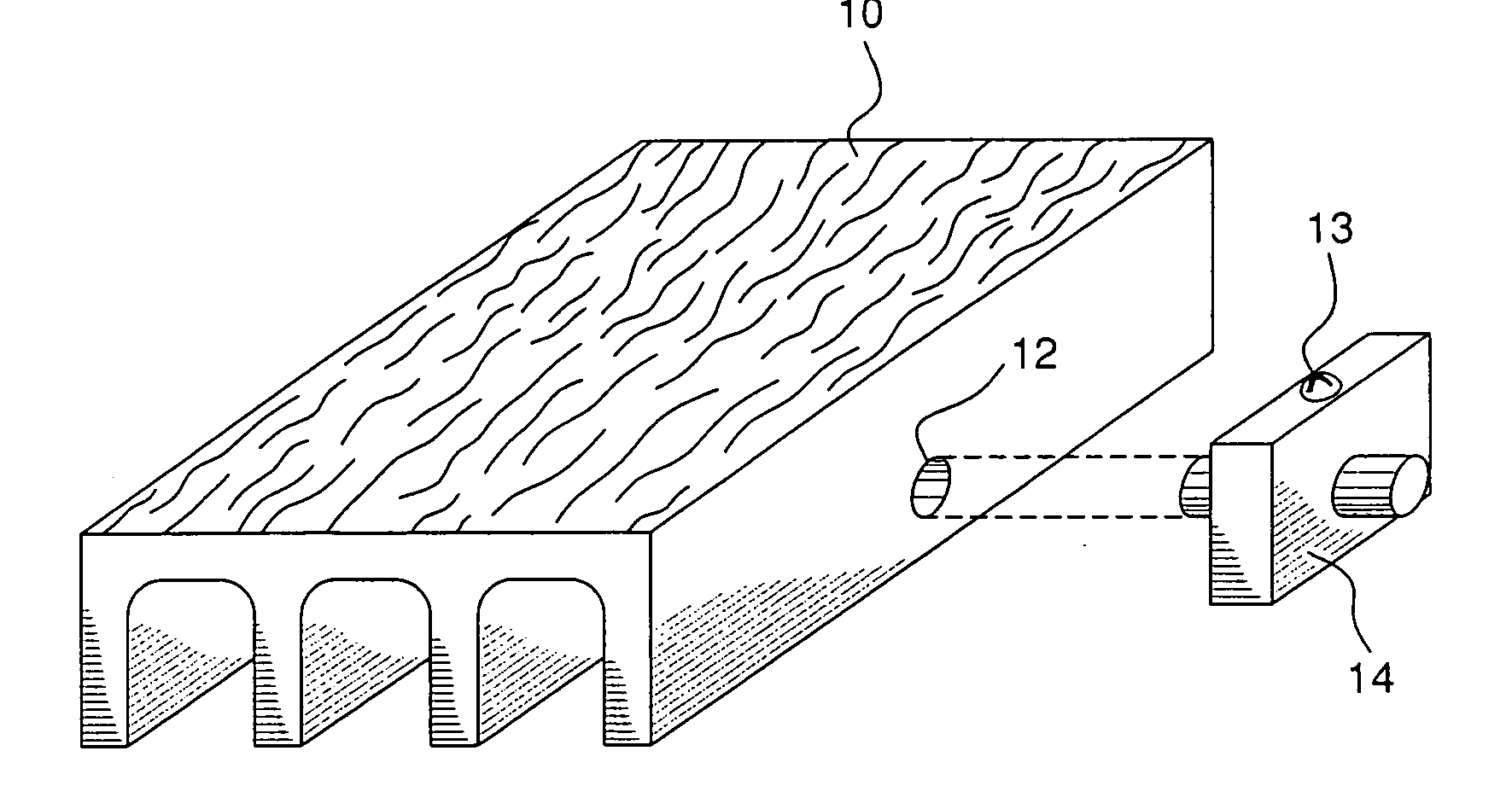

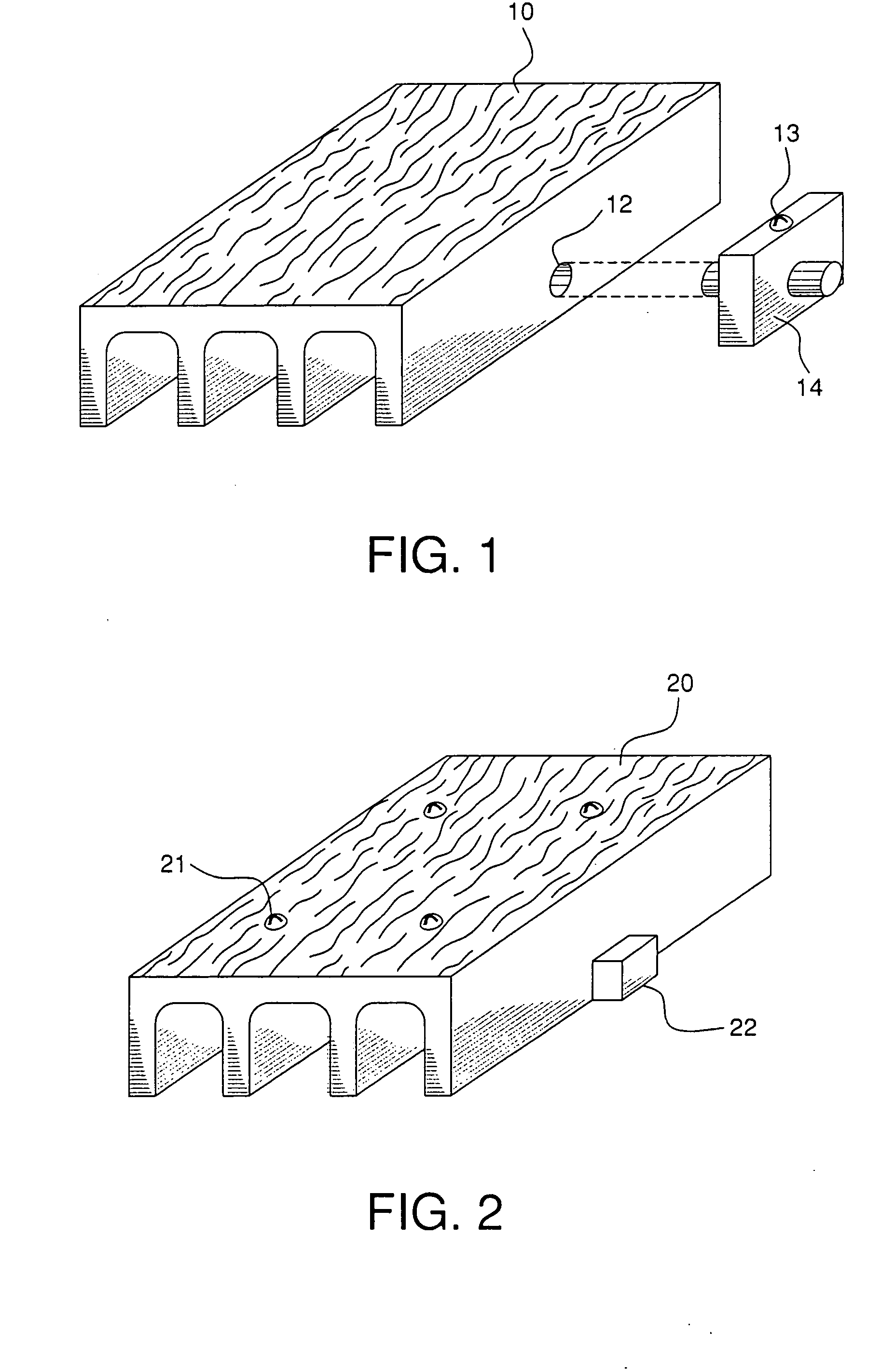

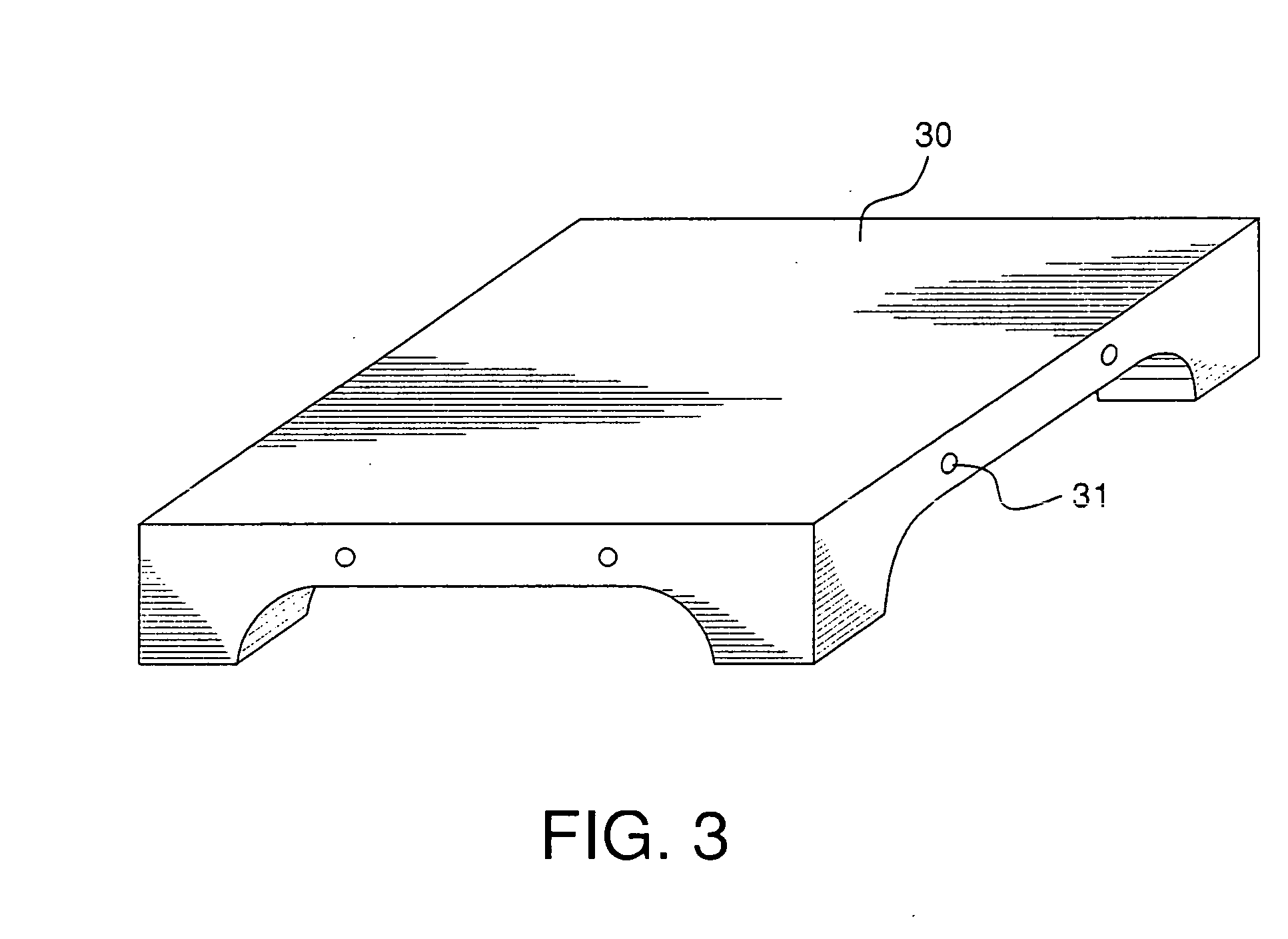

[0026] The present invention relates to a consolidated form of the commingled continuous filaments of glass fibers and polymeric fibers as reinforcement. The consolidation of the commingled fibers into composite reinforcement may be made in-situ during in-line extrusion of the final end product extrudate, or, alternatively, prepared as a tape or rod and incorporated into an off-line extrusion of final product. In either case, the materials of the present invention are incorporated through a cross-head die into the polymer extrudate. In this way, the matrix polymer encapsulates the inside and outside surface of the hollow profile product.

[0027] Another production process is to subject these commingled fibers through pultrusion and its die, followed by overlay extrusion of a cap stock polymer using a separate extruder, all in-line. In this case, the capstock polymer covers only the outside surface. The commingled fibers are heated prior to entering into the series of forming dies whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com