Expansion designable high strength steel pipe concrete and its prepn

A technology for concrete filled steel tubes and concrete, which is applied in ceramic products, solid waste management, climate sustainability, etc., can solve the problems of inability to obtain water supplementation, and achieve the effects of high water reduction rate, long expansion time and high expansion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

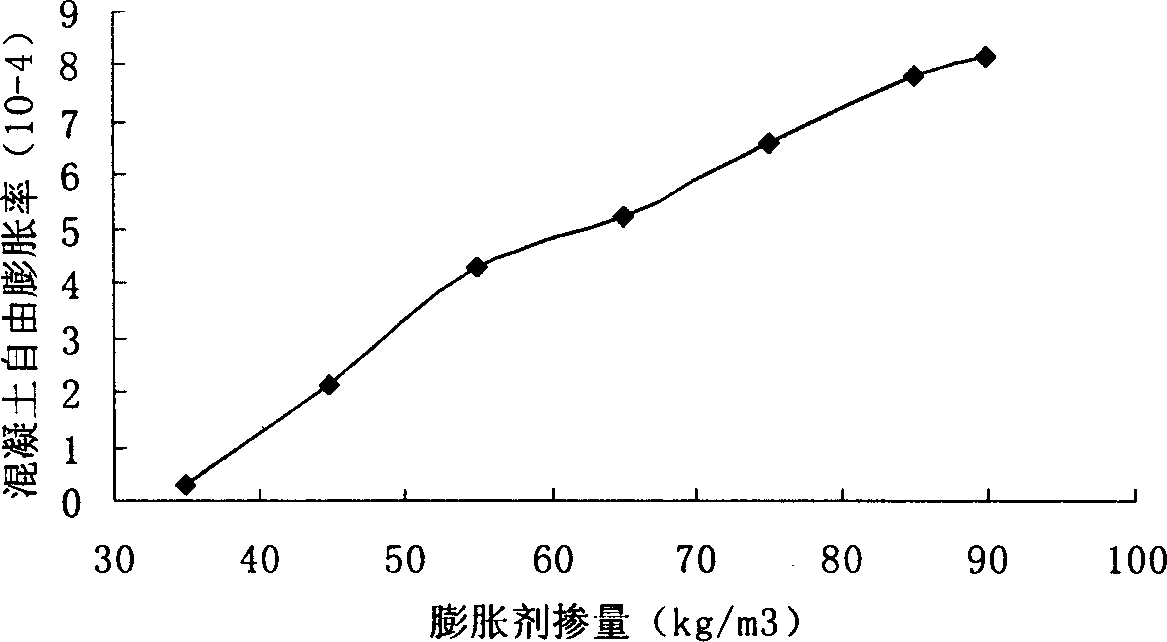

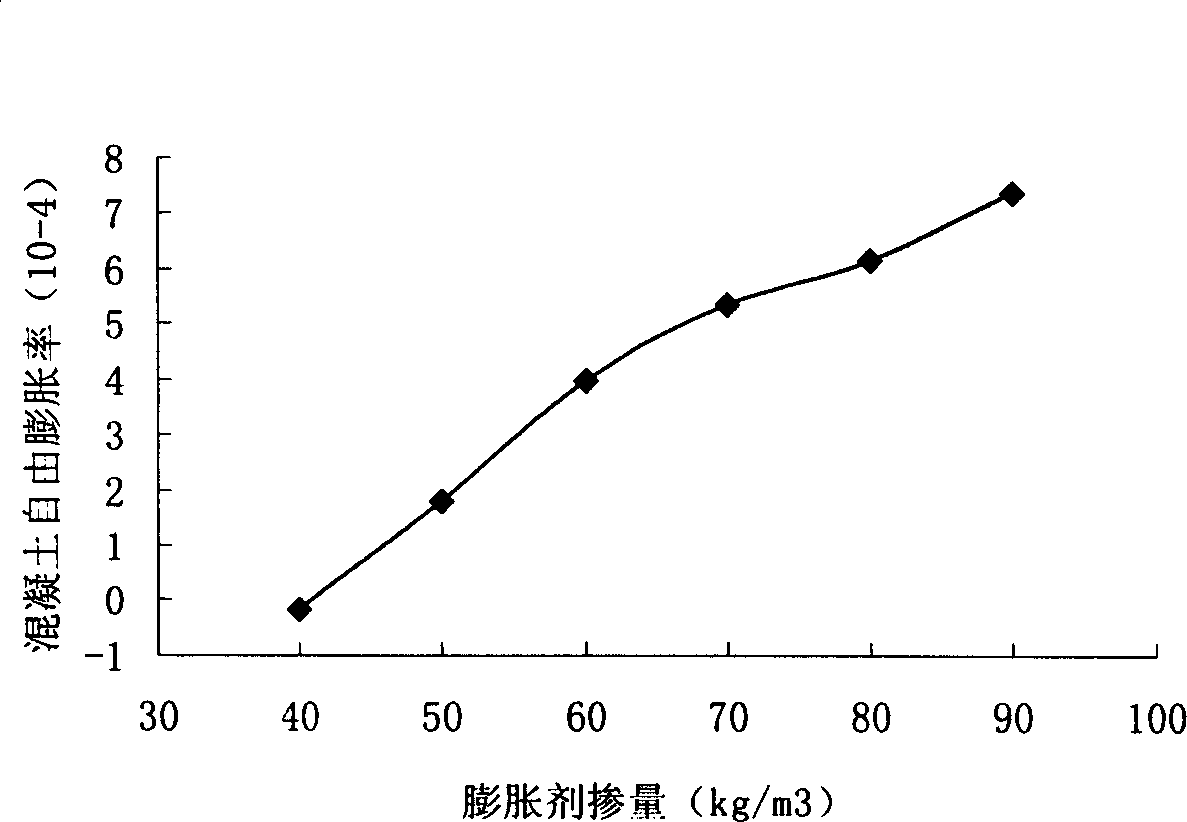

[0045] Example 1: Designable expansion of high-strength steel pipe concrete and its preparation method, using a special admixture for steel pipe concrete (retarding and high-efficiency water-reducing and plastic-retaining agent), reducing the gap caused by gas adhesion on the steel pipe wall; using closed concrete The high-energy retarded expansion agent and the special admixture for concrete filled steel pipe concrete can realize the continuous and stable expansion of high-strength steel tube concrete; the above two technologies are combined and applied to C50 and C60 concrete filled steel tubes, and the specific retarding high-efficiency water-reducing and plastic-retaining agent WUT-G for steel tube concrete The percentage of the total mass is 0.9-1.5%, and the dosage of the closed concrete high-energy delayed expansion agent is 45-90kg / m3; according to the concrete water-binder ratio and sand ratio, by adjusting the dosage of the closed concrete high-energy delayed expansion...

example 2

[0061] Example 2: For high-strength concrete-filled steel tubes with designable expansion, special admixtures for concrete-filled steel tubes (retarding and high-efficiency water-reducing and plastic-retaining agents) are used to reduce the gaps caused by gas adhering to the steel tube walls; high-energy delaying expansion agents for closed concrete are used and special admixtures for concrete filled steel tube concrete to achieve continuous and stable expansion of high-strength steel tube concrete; the above two technologies are combined and applied to C50 and C60 steel tube concrete. The percentage of the closed concrete high-energy delayed expansion agent is 0.9-1.5%, and the dosage of the closed concrete high-energy delayed expansion agent is 45-90kg / m3; according to the concrete water-binder ratio and sand ratio, by adjusting the dosage of the closed concrete high-energy delayed expansion agent, the expansion of the concrete can be adjusted. design.

[0062] Specific appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com