Diameter-expanding device for shape memory alloy reducing tube joint

A memory alloy and reducing pipe technology, which is applied in the field of shape memory alloy reducing pipe joint diameter expansion devices, can solve the problems of design and diameter expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

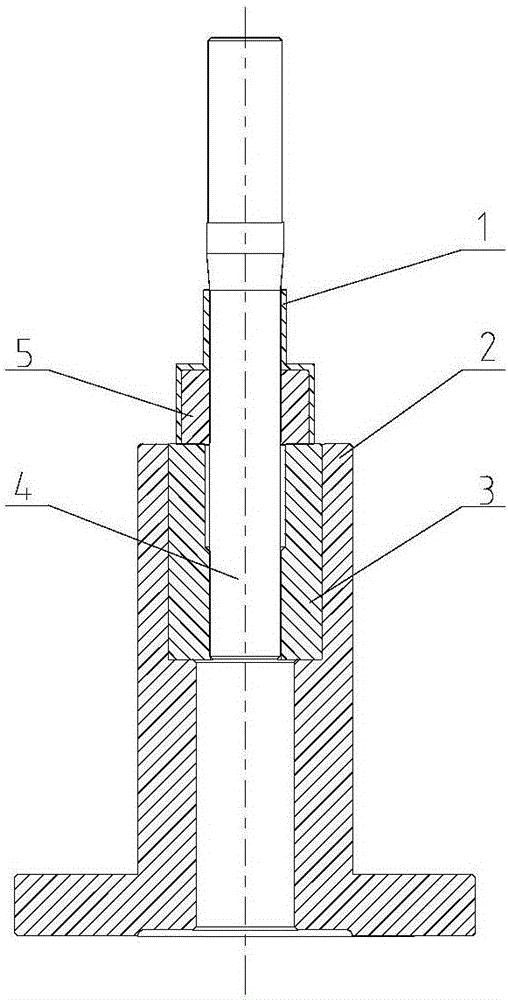

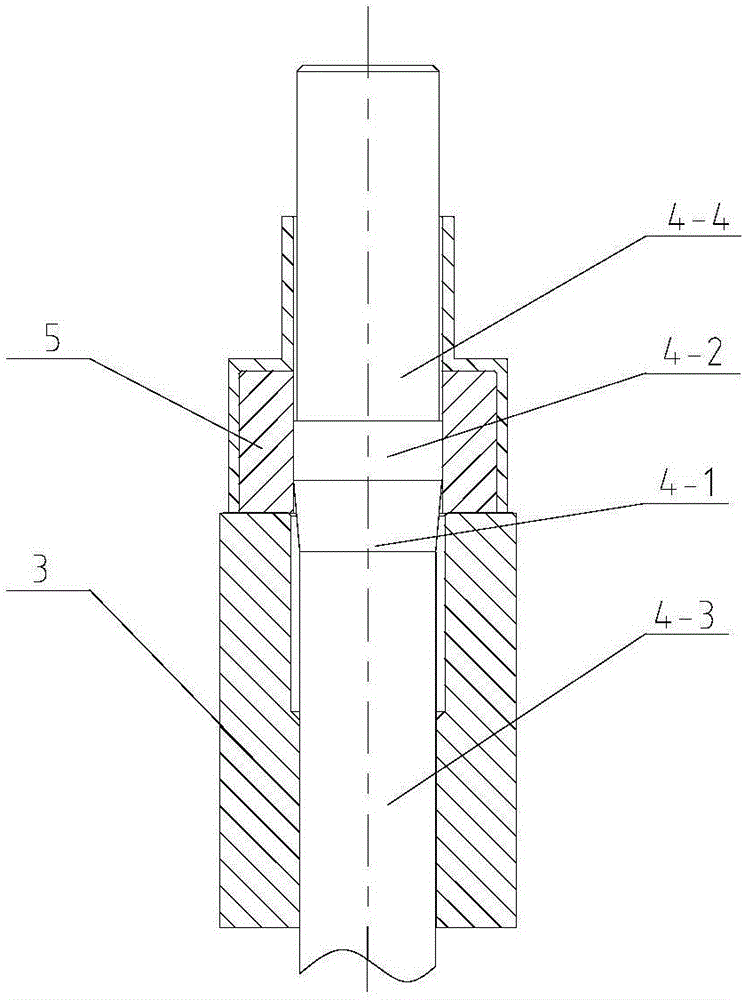

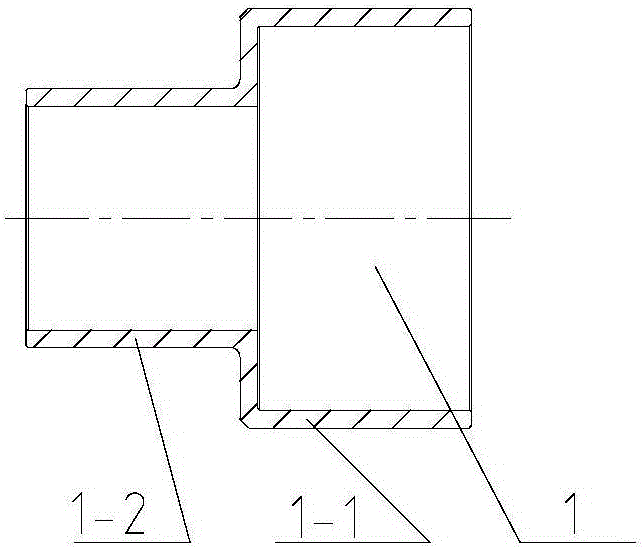

[0027] Such as Figure 1 to Figure 6 The diameter expansion device of a shape memory alloy variable diameter pipe joint shown includes: a base 2, a guide bush 3, a diameter expansion pressure rod 4 and a split expansion block 5;

[0028] The upper end of the base 2 is preset with a longitudinally extending sleeve guide hole 2-1;

[0029] The guide bush 3 is assembled in the bush guide hole 2-1, and the height of the guide bush 3 is equal to the depth of the bush guide hole 2-1;

[0030] Expanding pressure rod 4 is a variable-diameter cylindrical rod body, the lower part of which is processed into a guide section 4-3 with a smaller diameter, the middle transition part is processed into a conical reaming section 4-1, and the upper part of the conical reaming section 4-1 is processed into The retaining section 4-2 with a larger diameter, the upper part of the retaining section 4-2 is processed into an unloading section 4-4 whose diameter is smaller than that of the retaining sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com