Thermal-shrinkage tube expanding mould

A heat-shrinkable tube and mold technology, which is applied in the field of heat-shrinkable tube expansion molds, can solve problems such as high manufacturing costs, limited expansion speed, and poor mold cooling effect, and achieve good cooling effect and stable expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

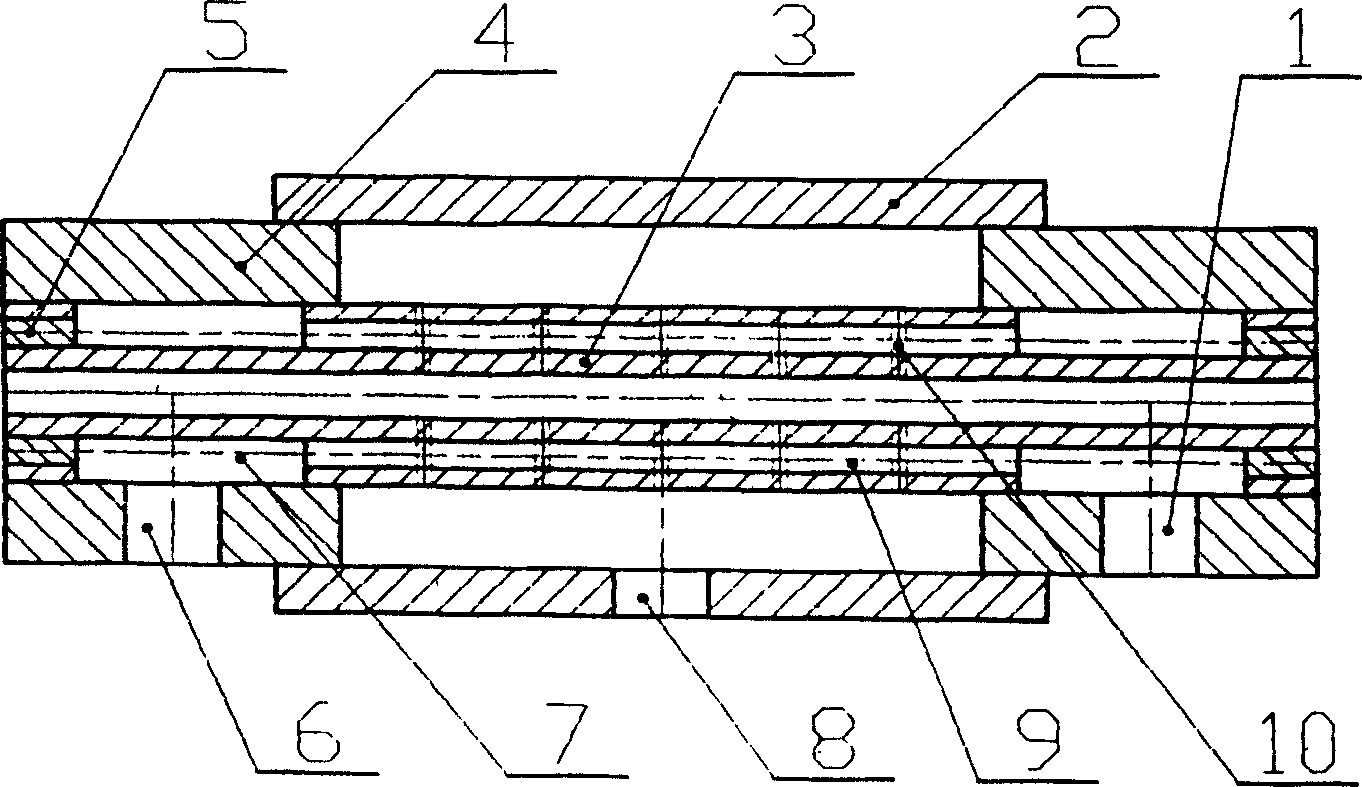

[0012] In Fig. 1, there are two long cooling holes (9) parallel to the axis of the sizing pipe (3), both ends of the long cooling holes (9) are blocked with plugs (5), and the sizing pipe (3) There are cooling water rings (7) on both sides of the cooling water ring (7), a cooling water jacket (4) on the outside of the cooling water ring (7), a vacuum jacket (2) on the outside of the cooling water jacket (4), and two There are 5 rows of vacuum holes (10) between the two cooling water rings, cooling water outlet (6) on the left cooling water jacket (4), cooling water inlet (1) on the right cooling water jacket (4), vacuum Vacuum suction port (8) is arranged on cover (2).

[0013] The cooling water enters the right cooling water ring (7) from the cooling water inlet (1), reaches the left cooling water ring (7) through the cooling long hole (9), and flows out through the cooling water outlet (6). tube to cool. A closed space is formed between the vacuum jacket (2), the cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com