Ribbon cassette structure integrated with paper feed tray and printer using the ribbon cassette structure integrated with paper feed tray

An all-in-one printer technology, applied in ink ribbon boxes, printing devices, printing, etc., can solve the problems of large volume, waste of space, and inability to support thermal heads, etc., and achieve the effect of stable operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

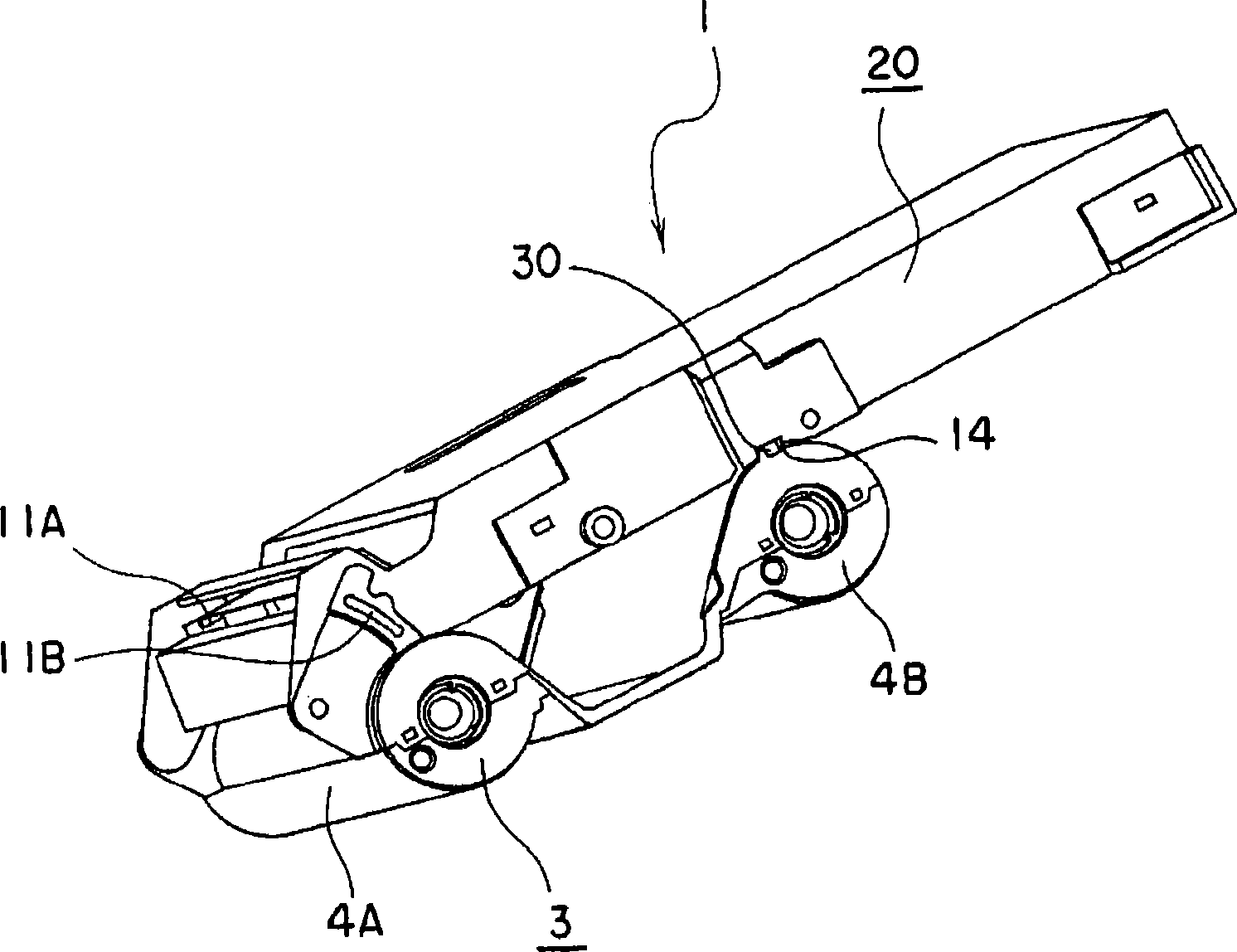

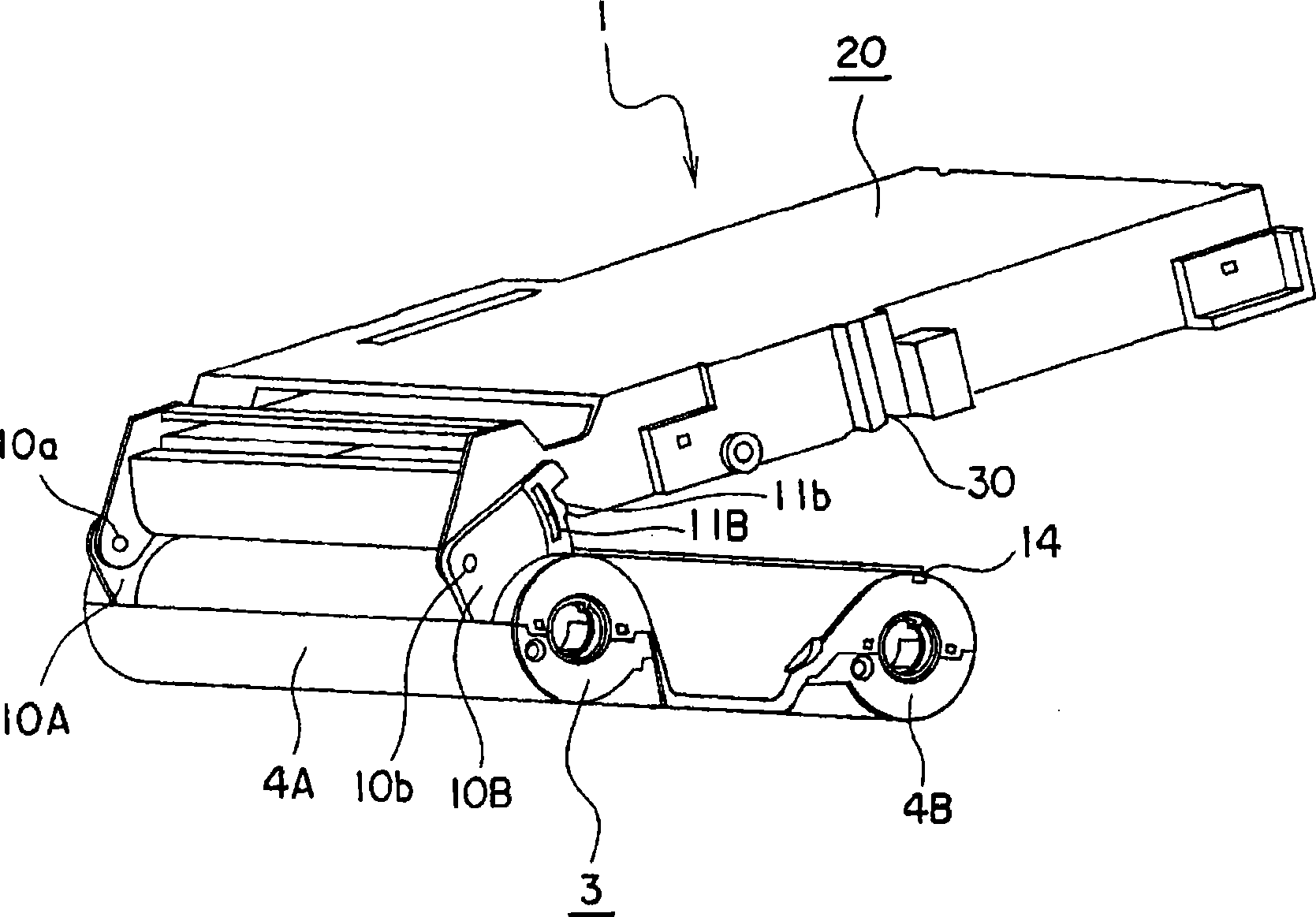

[0067] Figure 1 to Figure 3 It is a figure showing an embodiment of the tape cassette structure integrated with the paper feeding tray of the present invention. The tape cassette structure 1 of the integrated paper feeding tray of this embodiment is constituted by integrally forming the tape cassette 3 and the paper feeding tray 20, wherein The tape cassette 3 has a pair of roller housings 4A, 4B each having a cylindrical shape.

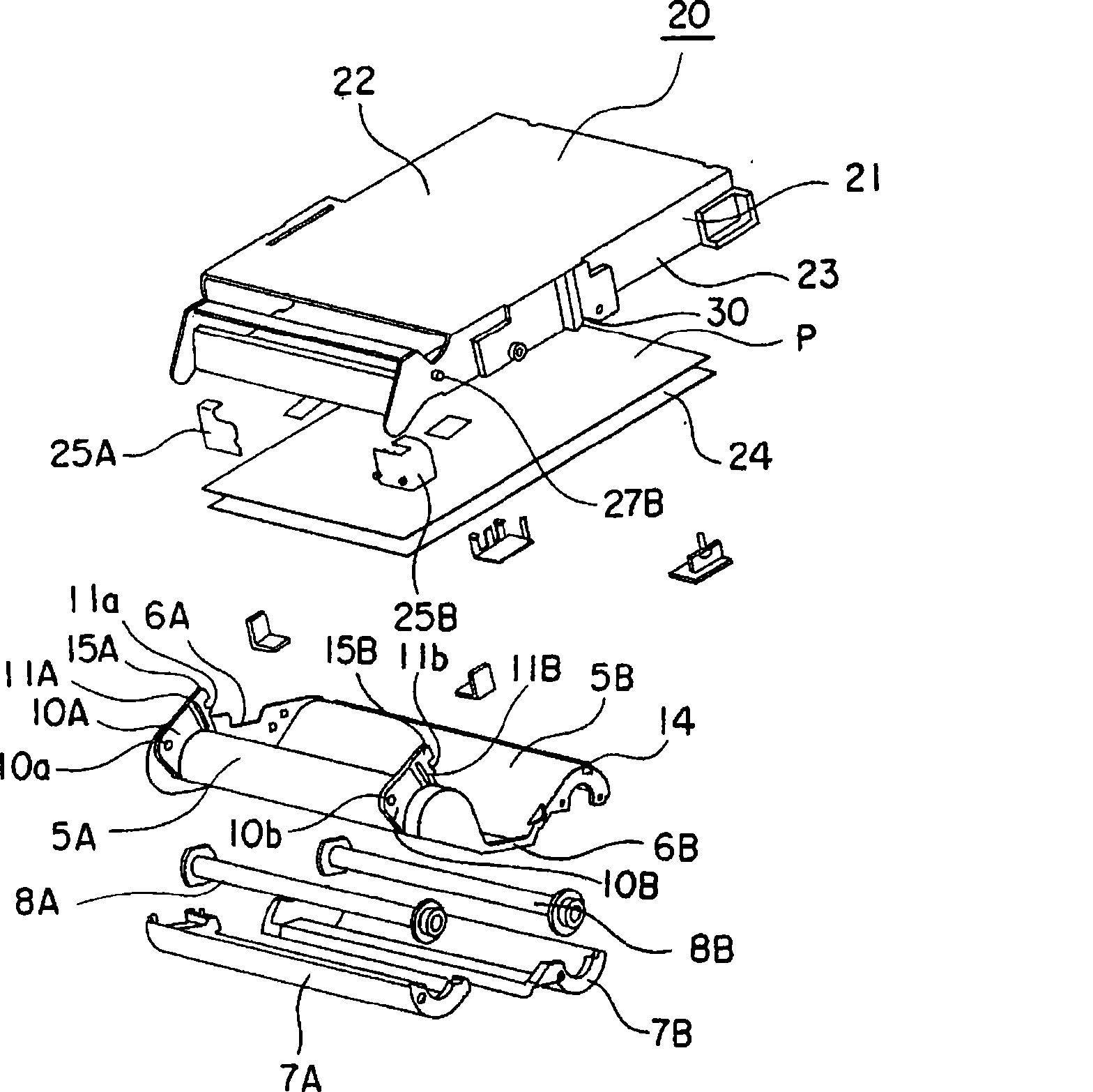

[0068] The above cassette 3 as in image 3 As shown in the exploded view in detail, the upper half parts 5A, 5B of the two roller storage parts 4A, 4B are connected at both ends by the plate part 6A integrated with the two and the arm part 6B bent into a deep disc shape in cross section. , and constituted by the lower half 7A, 7B that can be clutched and fitted on each upper half 5A, 5B, and the rollers 8A, 8B that can rotate freely are accommodated in each roller accommodation portion 4A, 4B, and they are installed in the drawing Ink ribbon not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com