Equipment and technique for puffing foodstuff

The technology of puffing equipment and puffing process is applied in the directions of food forming, food science, application, etc., which can solve the problems of unsatisfactory powder puffing and complicated production process, and achieve better puffing effect, simple production process and high puffing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

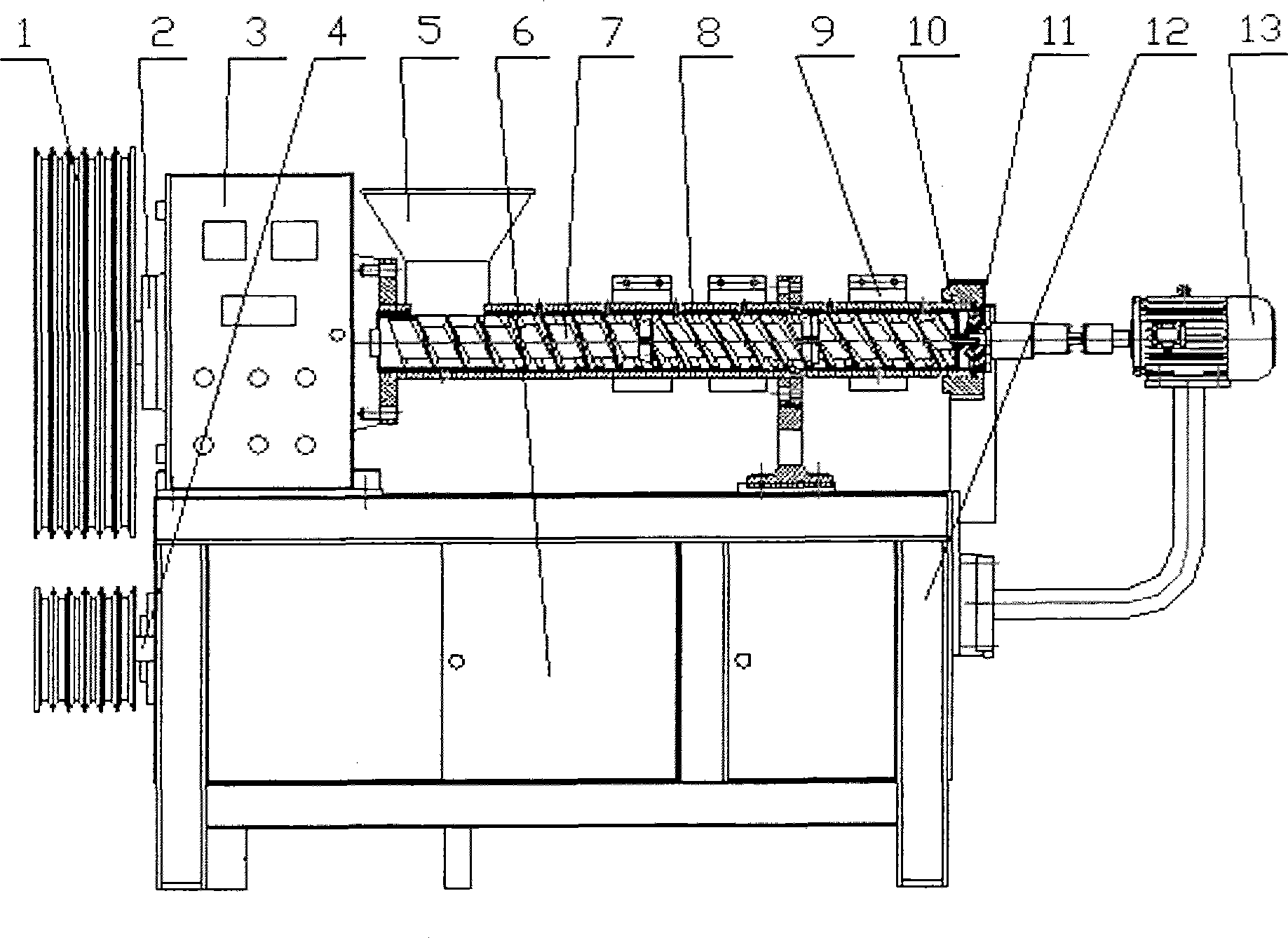

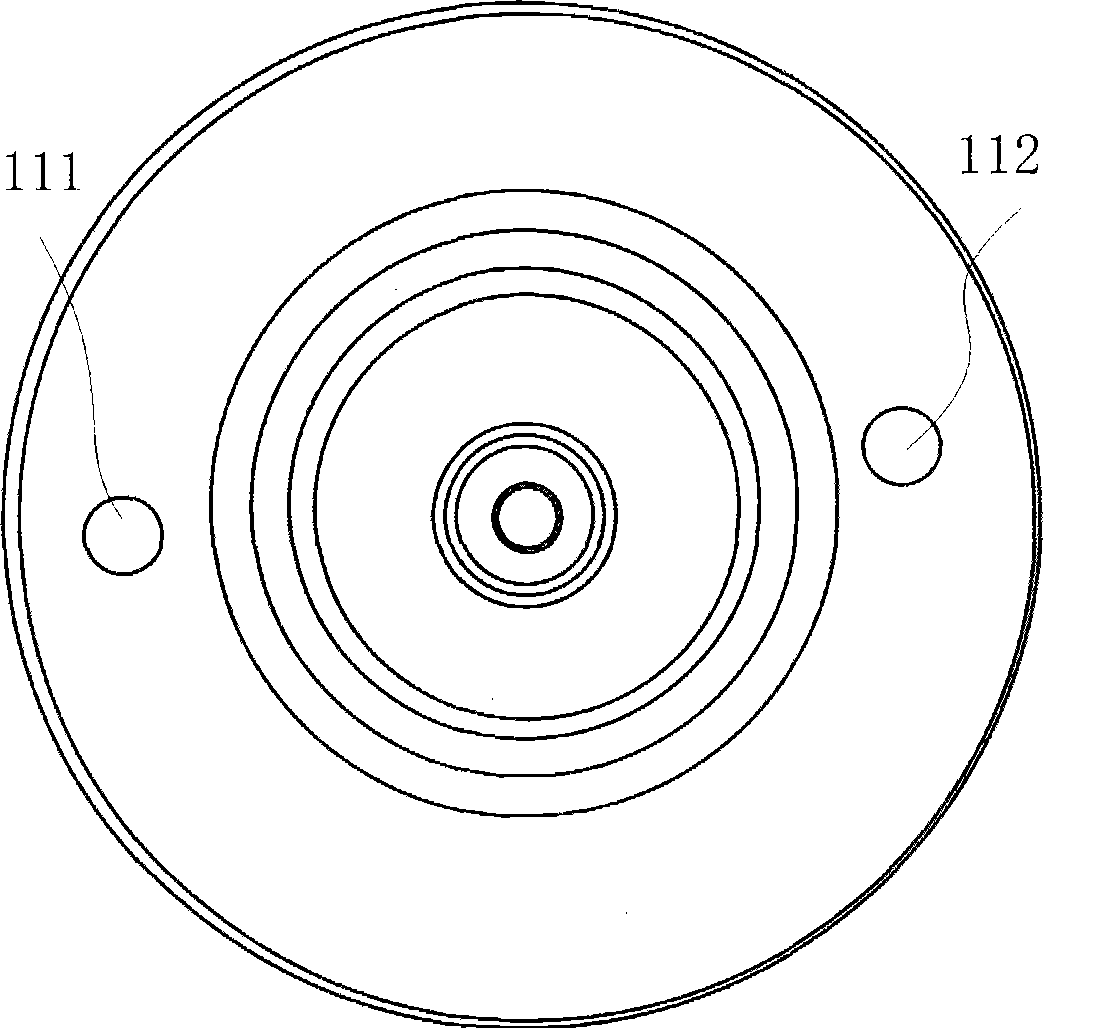

[0024] The main machine of the extruder in this example consists of a frame, a motor, an extruding cavity, a pelletizing mechanism, and a feed control device. Please refer to figure 1 As shown, it mainly includes pulley 1, bearing 2, electric control cabinet 3, main motor 4, feed control device 5, cabinet 6, screw rod 7, sleeve 8, far-infrared heating ring 9, resistance template 10, die head 11, Frame 12 and pelletizing motor 13.

[0025] The main motor 4 drives the main shaft to rotate, and the screw rod 7 is connected with the main shaft and rotates in the sleeve. The far-infrared electric heating ring 9 outside the sleeve can automatically adjust and control heating by a predetermined temperature through an automatic temperature controller and a temperature sensor, and the heating temperature is selected at 160 degrees. The pelletizing motor rotates the pelletizing knife through the coupling. The size and shape of the finished particles can be changed by combining differ...

Embodiment 2

[0028] Embodiment 2: The main difference from Embodiment 1 is that in this example, the driving power of the screw is 55kw, and the specification of the dual-mode holes is Φ5mm. The heating temperature is selected at 170 degrees.

Embodiment 3

[0030] The difference from Example 1 is that, in this example, the driving power of the screw is 60kw, the size of the double-die hole is Φ6mm; the heating temperature is selected at 180 degrees; the feeding control device 5 controls the raw material to be fed uniformly at a speed of 7Kg per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com