Epoxy resin concrete for grouting of bridge expansion joints and road-bridge joints

An epoxy resin and concrete technology, applied in the field of concrete, can solve the problems of volatile environment of toxic volatile substances, unqualified construction product quality, waste of environmental energy of generators, etc., so as to improve construction efficiency and project quality, and improve construction efficiency. The effect of shortening the quality of the project and the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

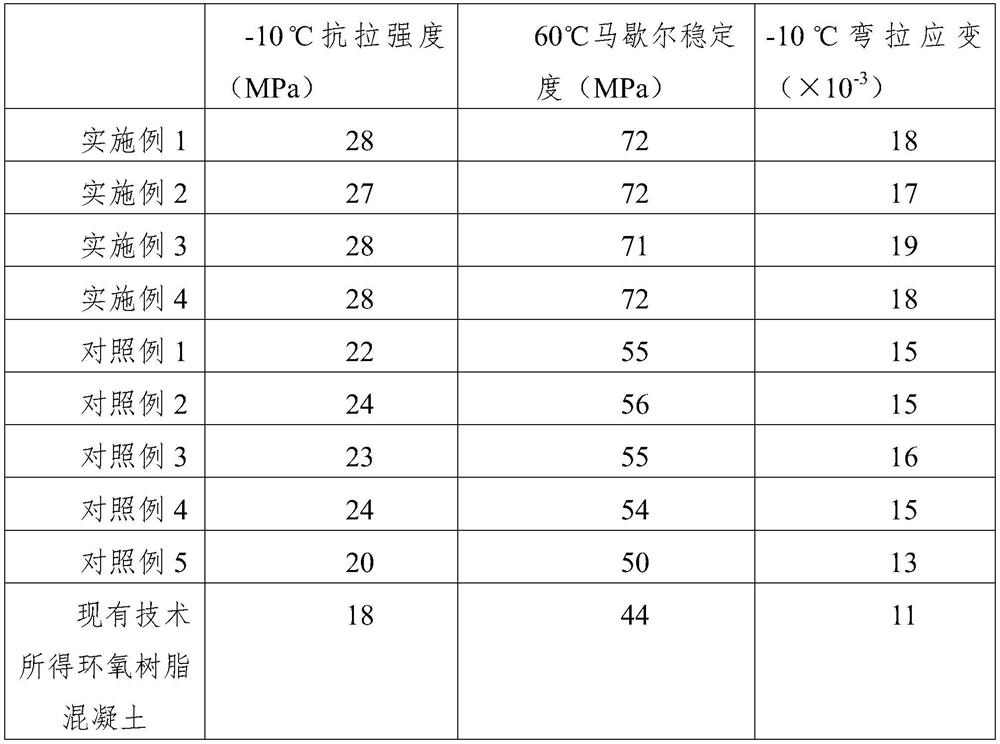

Examples

Embodiment 1

[0031] An epoxy resin concrete for grouting bridge expansion joints and road-bridge joints, the composition of the epoxy resin concrete includes the following raw materials in parts by weight: 70 parts of bisphenol A epoxy resin E51, epoxy active toughening agent D- 10 parts of 411, 5 parts of glycidyl ether, 0.3 parts of defoamer, 0.1 part of leveling agent, 0.3 parts of silane coupling agent kh550, 20 parts of Mannisamine, 60 parts of modified aromatic amine, 40 parts of polyamide, 425# 20 parts of cement, 20 parts of 10-20 mesh quartz sand, 40 parts of 8-10 mesh quartz sand, 40 parts of 5-8 mesh quartz sand, 20 parts of polyarylether nitrile, 5 parts of sorbitol ester, polyoxyethylene sorbitol ester 10 parts, 5 parts of 10-20 mesh glass bead powder.

[0032] The preparation method of this epoxy resin concrete comprises the following steps:

[0033](1) Weigh component A raw materials by mass parts: bisphenol A epoxy resin E51, epoxy active toughening agent D-411, glycidyl e...

Embodiment 2

[0039] An epoxy resin concrete for grouting bridge expansion joints and road-bridge joints, the composition of the epoxy resin concrete includes the following raw materials in parts by weight: 80 parts of bisphenol A epoxy resin E51, epoxy active toughening agent D- 5 parts of 411, 10 parts of glycidyl ether, 0.1 parts of defoamer, 0.3 parts of leveling agent, 0.1 part of silane coupling agent kh550, 30 parts of Mannisamine, 50 parts of modified aromatic amine, 50 parts of polyamide, 425# 10 parts of cement, 20 parts of 10-20 mesh quartz sand, 40 parts of 8-10 mesh quartz sand, 40 parts of 5-8 mesh quartz sand, 10 parts of polyarylether nitrile, 10 parts of sorbitol ester, polyoxyethylene sorbitol ester 5 parts, 10 parts of 10-20 mesh glass bead powder.

[0040] The preparation method of this epoxy resin concrete comprises the following steps:

[0041] (1) Weigh component A raw materials by mass parts: bisphenol A epoxy resin E51, epoxy active toughening agent D-411, glycidyl...

Embodiment 3

[0047] An epoxy resin concrete for grouting bridge expansion joints and road-bridge joints, the composition of the epoxy resin concrete includes the following raw materials in parts by weight: 75 parts of bisphenol A epoxy resin E51, epoxy active toughening agent D- 10 parts of 411, 7 parts of glycidyl ether, 0.2 parts of defoamer, 0.1 part of leveling agent, 0.2 parts of coupling agent, 25 parts of Mannisamine, 60 parts of modified aromatic amine, 50 parts of polyamide, 15 parts of 425# cement Parts, 15 parts of 10-20 mesh quartz sand, 50 parts of 8-10 mesh quartz sand, 35 parts of 5-8 mesh quartz sand, 20 parts of polyarylether nitrile, 7 parts of sorbitol ester, 10 parts of polyoxyethylene sorbitol ester , 7 parts of 10-20 order glass bead powder.

[0048] The preparation method of this epoxy resin concrete comprises the following steps:

[0049] (1) Weigh component A raw materials by mass parts: bisphenol A epoxy resin E51, epoxy active toughening agent D-411, glycidyl et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com