Iron powder cold-pressed pellets non-drying adhesive

A technology of cold-pressed pelletizing and polymer binder, which is applied in the field of iron ore powder and iron-containing dust cold-pressed pelletizing and drying-free binder, which can solve the problems of easily broken pulverization, energy consumption and slag production. Increase, low mechanical strength of cold-pressed pellets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

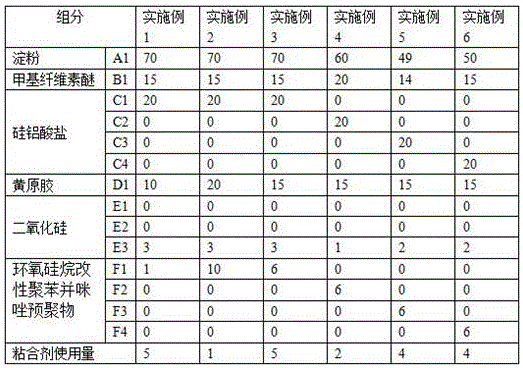

Embodiment 1~6

[0149] (1) Configure the adhesive according to the formula in Table 1 below (the amounts of the following components are all parts by weight);

[0150] (2) Add the prepared adhesive to the wet iron powder with a water content of 5%;

[0151] (3) The amount of adhesive added is in accordance with Table 1 (the amount added is parts by weight);

Embodiment 7~9

[0153] (1) Configure the adhesive according to the formula in Table 2 below (the amounts of the following components are all parts by weight);

[0154] (2) Add the prepared adhesive to the wet iron powder with a water content of 9%;

[0155] (3) The amount of adhesive added is in accordance with Table 2 (the amount added is parts by weight);

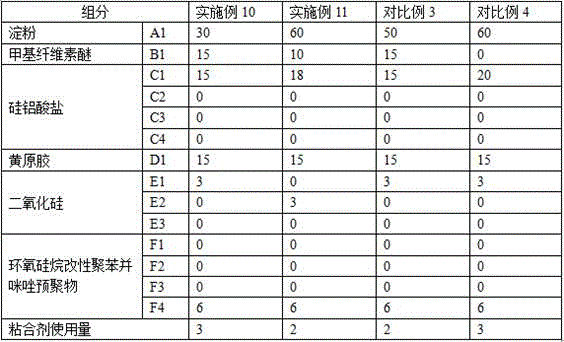

Embodiment 10~11

[0157] (1) Configure the adhesive according to the formula in Table 3 below (the amounts of the following components are all parts by weight);

[0158] (2) Add the prepared adhesive to the wet iron powder with a water content of 7%;

[0159] (3) The amount of adhesive added is in accordance with Table 3 (the amount added is parts by weight);

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com