A method for preventing sticking of tobacco sheets

A tobacco sheet and protective agent technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve the problems of thin sheets and thin sheets without a good diaphragm, molecular motion adhesion, and large contact area, so as to achieve long retention time, reduce adhesion, The effect of enhancing the stability of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

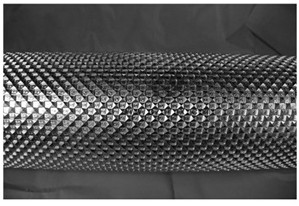

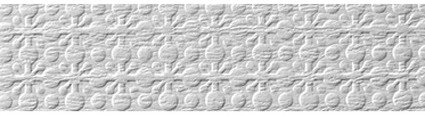

Image

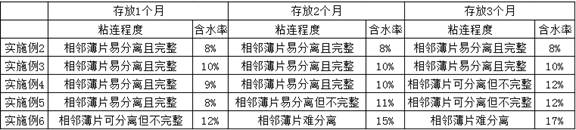

Examples

Embodiment 1

[0026] Preparation of water-soluble rosin pentaerythritol ester:

[0027] Weigh 300 g of refined rosin, grind it into a 500 mL four-neck flask, heat and melt it, when the temperature rises to about 160-170°C, stir, slowly add a certain amount of maleic anhydride, and keep it at about 185-190°C , react for 2 hours, add a certain amount of pentaerythritol and 0.3g of a common esterification catalyst, heat up to 210-250°C, react for 2-5h, remove moisture and low boiling point substances, cool down to about 200°C, and discharge to obtain water-soluble rosin pentaerythritol esters.

Embodiment 2

[0029] Preparation of anti-adhesive tobacco sheets:

[0030] Tobacco waste is manually cleaned, pretreated by washing stems, and dried;

[0031] Weigh 500g of the raw material after removal of impurities and put it into 2.5L extract solution, the extract solution is 2% urine solution aqueous solution, ultrasonic extraction at 40-60°C, the ultrasonic extraction frequency is 3KHz-5KHz, the extraction time is 4-6h, solid-liquid Extraction obtained after separation and treatment;

[0032] Centrifuge the extract with a butterfly centrifuge at 12000r / min, centrifuge for 3-5min, reduce the slag content, and take the supernatant;

[0033] Concentrate the purified extract to 40% using a double-effect rising film evaporator to obtain a concentrate;

[0034] Filter the concentrated solution through a 200-mesh rectangular sieve to obtain a filtered concentrated solution; according to the "Technical Specifications for Reconstituted Tobacco Leaf by Papermaking Method", add flavors and fra...

Embodiment 3

[0041] Preparation of anti-adhesive tobacco sheets:

[0042] Tobacco waste is manually cleaned, pretreated by washing stems, and dried;

[0043] Weigh 500g of the raw material after removal of impurities and put it into 2.5L extract solution, the extract solution is 2% urine solution aqueous solution, ultrasonic extraction at 40-60°C, the ultrasonic extraction frequency is 3KHz-5KHz, the extraction time is 4-6h, solid-liquid Extraction obtained after separation and treatment;

[0044] Centrifuge the extract with a butterfly centrifuge at 12000r / min, centrifuge for 3-5min, reduce the slag content, and take the supernatant;

[0045] Concentrate the purified extract to 40% using a double-effect rising film evaporator to obtain a concentrate;

[0046] Filter the concentrated solution through a 200-mesh rectangular sieve to obtain a filtered concentrated solution; according to the "Technical Specifications for Reconstituted Tobacco Leaf by Papermaking Method", add flavors and fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com